Craftsman 143993506 Owner’s Manual

.AR$

operator's

manual

MODEL NO. 143.99350E

3.5 RESERVE POWER

10 INCH CUBIC (163 cc)

DISPLACEMENT

SOLID STATE IGNITION

ENGIN

CAUTION:

Read RULES for

Safe OPERATION

and INSTRUCTIONS

Carefully

_ alifornia Proposition 65 WARNING: The engine exhaust from this product contains chemicals I

known to the State of California to cause cancer, birth defects or other reproductive harm.

Sold by SEARS, ROEBUCK AND CO., CHICAGO, IL 60684 U.S.A.

and SEARS CANADA, INC., TORONTO, ONTARIO, CANADA

• Operating

• Maintenance

• Repair Parts

I

Pdntedin U.S.A. 4-1-99 181-1190-11

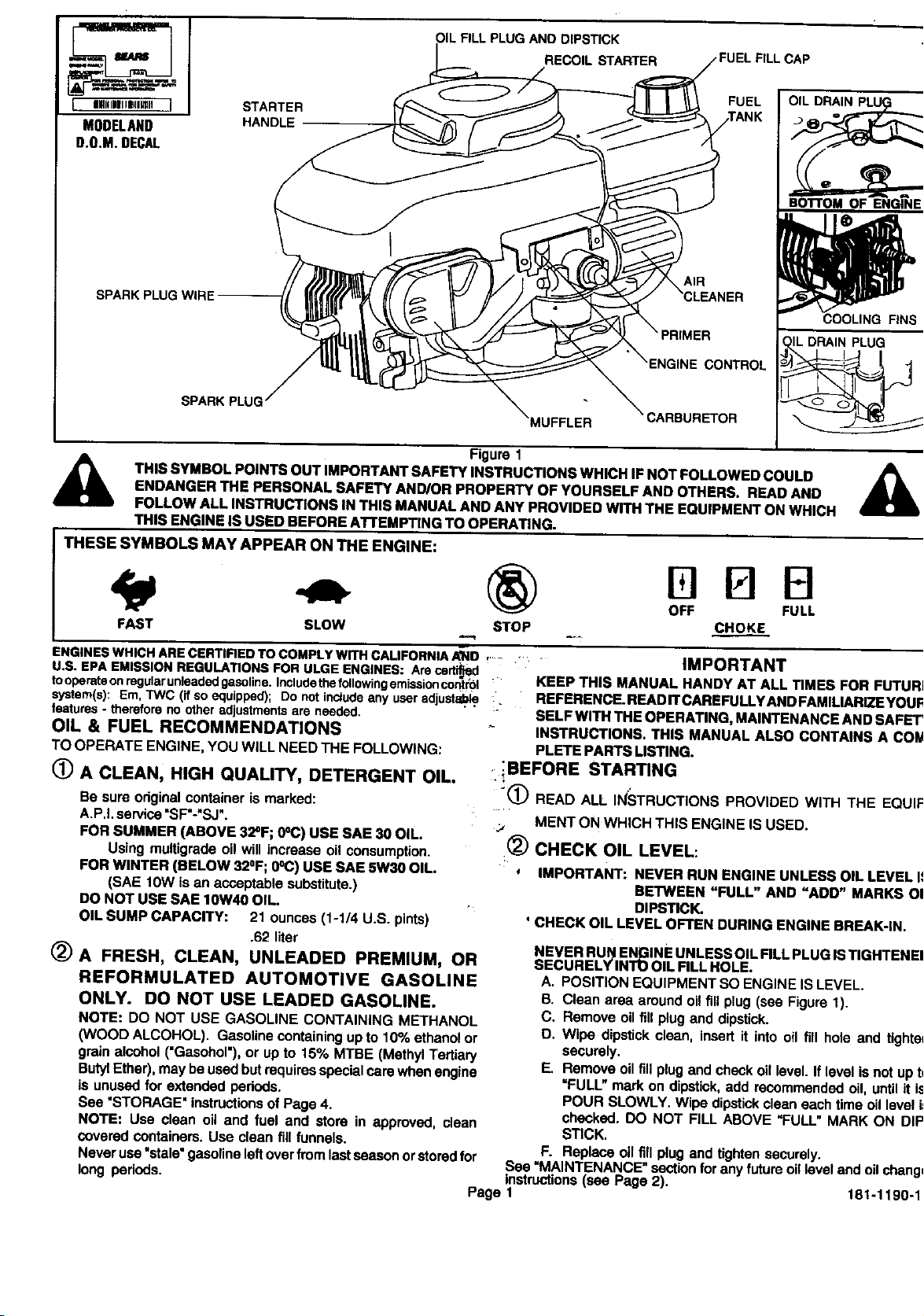

OIL FILL PLUG AND DIPSTICK

RECOIL STARTER

CAP

I ilmlll|lll|bllml ]

MODELAND

O.Q.M. DECAL

SPARK PLUG WIRE

SPARK PLUG

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH IF NOT FOLLOWED COULD _'_

ENDANGER THE PERSONAL SAFE'P( ANDIOR PROPERTY OF YOURSELF AND OTHERS, READ AND

FOLLOW ALL INSTRUCTIONS IN THIS MANUAL AND ANY PROVIDED WITH THE EQUIPMENT ON WHICH

THIS ENGINE IS USED BEFORE ATFEMPTING TO OPERATING.

STARTER

HANDLE

THESE SYMBOLS MAY APPEAR ON THE ENGINE:

Figure 1

MUFFLER

AIR

GINE CONTROL

CARBURETOR

FUEL

BOTTOM OF ENGINE

DRAIN PLUG

/

FAST SLOW STOP

ENGINESWHICH ARE CERTIRED TO COMPLY WITHCALIFORNIA A'_ID ...... 4

U.S. EPA EMISSION REGULATIONS FOR ULGE ENGINES: Are cert'd_l

tooperateonregutarunleadedgasettne,tnctudethefottowingemissionco_t

system(s): Era,TWC (if so equipped); Do notinctudeany useredjustal_e :.

features - therefore noother adjustments are needed.

OIL & FUEL RECOMMENDATIONS

TO OPERATE ENGINE, YOU WILL NEED THE FOLLOWING:

(_ A CLEAN, HIGH QUALITY, DETERGENT OIL.

Be sure odginal container Is marked:

A.P,I. service =SF'-"SJ".

FOR SUMMER (ABOVE 32°F; (PC) USE SAE 30 OIL.

Using multigrade oil will increase oil consumption.

FOR WINTER (BELOW 32°F; 0°C) USE SAE 5W30 OIL.

(SAE 10W is an acceptable substitute.)

DO NOT USE SAE 10W40 OIL.

OIL SUMP CAPACITY: 21 ounces (1-1/4 U.S. pints)

.62 liter

(_ A FRESH, CLEAN, UNLEADED PREMIUM, OR

REFORMULATED AUTOMOTIVE GASOLINE

ONLY. DO NOT USE LEADED GASOLINE.

NOTE: DO NOT USE GASOLINE CONTAINING METHANOL

(WOOD ALCOHOL). Gasoline containing up to 10% ethanol or

grain alcohol ('Gasohol"), or up to 15% MTBE (Methyl Tertiary

Butyl Ether), may be used but requires speciat care when engine

is unused for extended periods.

See "STORAGE" instructions of Page 4.

NOTE: Use clean oil and fuel and store in approved, clean

covered containers. Use clean fill funnels.

Never use "stale"gasoline left over from last season orstored for

long periods.

• _BEFORE STARTING

"_) READ ALL II_STRUCTIONS PROVIDED WITH THE EQUIP-

_, MENT ON WHICH THIS ENGINE IS USED.

(_ CHECK OIL LEVEL:

, IMPORTANT: NEVER RUN ENGINE UNLESS OIL LEVEL IS

See "MAINTENANCE" sec_zonfor any future oi_lever and oil change

instructions (see Page 2).

Page 1

MRB

OFF FULL

CHOKE

IMPORTANT

KEEP THIS MANUAL HANDY AT ALL TIMES FOR FUTURE

REFERENCE.READrrCAREFULLYANDFAMILIARIZEYOUR,

SELF WITH THE OPERATING, MAINTENANCE AND SAFETY

INSTRUCTIONS. THIS MANUAL ALSO CONTAINS A COM.

PLETE PARTS LISTING.

BETWEEN "FULL" AND "ADD" MARKS ON

DIPSTICK.

' CHECK OIL LEVEL OFTEN DURING ENGINE BREAK-IN.

NEVER RUN ENGINE UNLESS OIL FILL PLUG ISTIGHTENED

SECURELYINTO OIL FILL HOLE.

A, POSITION EQUIPMENT SO ENGINE IS LEVEL.

B. Clean area around oil fill plug (see Figure 1).

C. Remove oil fillplug and dipstick.

O. Wipe dipstick clean, insert it into oil fill hole and tighten

securely.

E. Remove oil flU plug and check oil Level. If Levoiis not up to

=FULL" mark on dipstick, add recommended oil, until it is.

POUR SLOWLY. Wipe dipstick clean each time oil level is

checked. DO NOT FILL ABOVE "FULL" MARK ON DIP-

STICK•

F. Replace oil fill plug and tighten securely.

181-1190-11

BEFORE STARTING (Continued)

STOPPING

(_) FILL FUEL TAN K with gasoline as specified in the preceding

"OIL & FUEL RECOMMENDATIONS item 2.

NEVER MIX OIL WITH GASOLINE

Never use =stale* gasoline left overfrom last season or stored for

long pedods.

,_ NEVER FILL FUEL TANK INDOORS. NEVER FILL FUELTANK

WHEN ENG NE S RUNN NG OR HOT. DO NOT SMOKE WHEN

FILLING FUEL TANK.

_k NEVER FILL FUEL TANK COMPLETELY. FILL TANK TO 1/2"

BELOW BOTTOM OF FILLER NECK TO PROVIDE SPACE FOR

FUEL EXPANSION. WIPE ANY FUEL SPILLAGE FROM EN-

GINE AND EQUIPMENT BEFORE STARTING ENGINE.

,_ANY LIQUERED PETROLEUM (LPG) OR NATURAL GAS FUEL

SYSTEM MUST BE LEAKPROOF AND MEET ALL APPLICA-

I BLE CODES AND REGULATIONS.

(_ CHECK THE FOLLOWING:

_k/_ BE SURE EQUIPMENT IS IN NEUTRAL GEAR WITH

CLUTCHES, BELTS, CHAINS AND SAFETY SWITCHES

DISENGAGED. (FOLLOW EQUIPMENT MANU-

FACTURER'S INSTRUCTIONS.) THIS SHOULD PLACE

ANY SAFETY SWITCHES IN SAFE STARTING POSITION.

B. Be suresparkplugwireisattachedtosparkplug(see Figure

1).

(_) Move ENGINE CONTROL (see Figure 1) to STOP.

(_) AFTER ENGINE IS STOPPED:

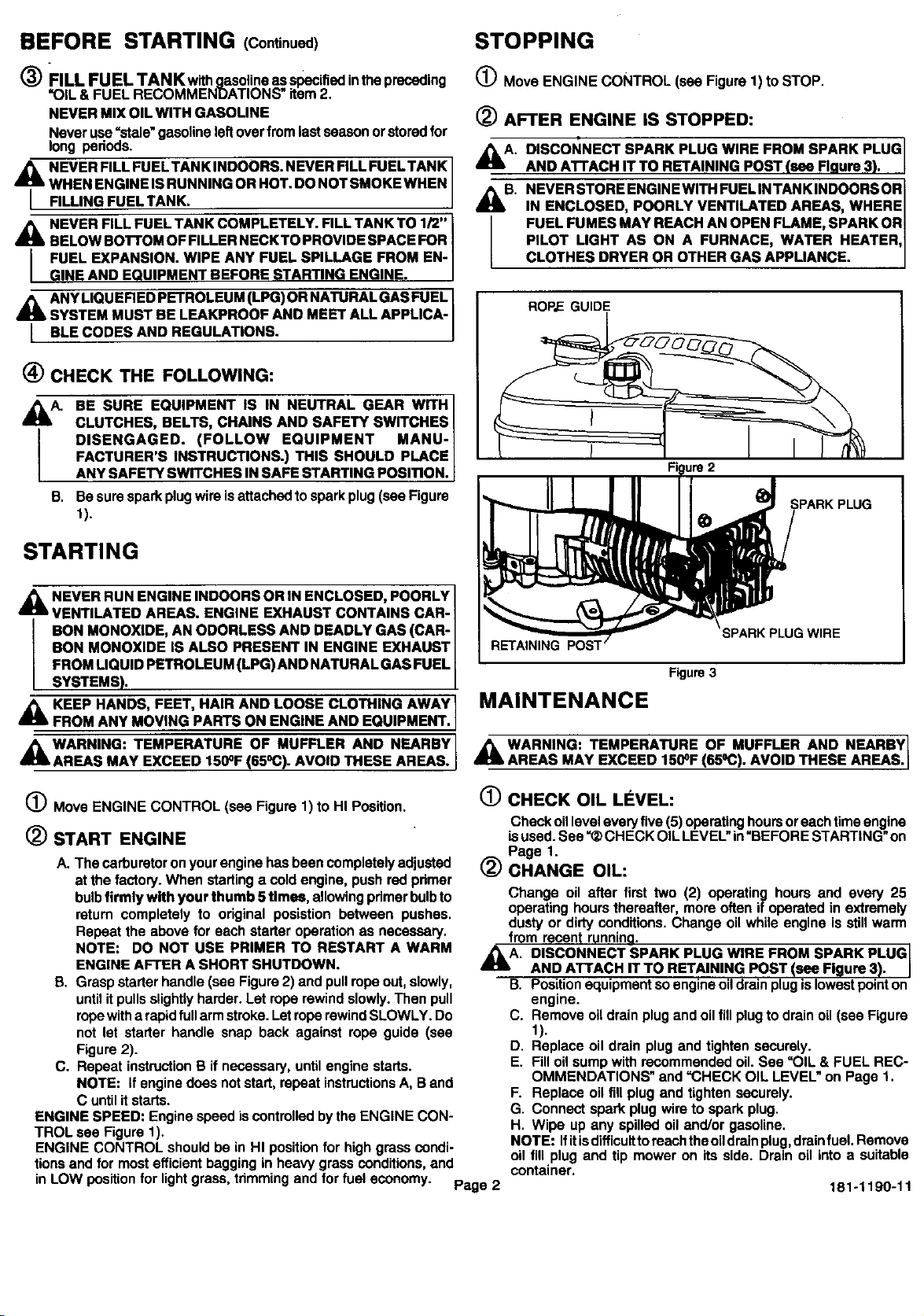

_A. DISCONNECT SPARK PLUG WIRE FROM SPARK PLUG

_B. NEVER STORE ENGINE WITHFUELIN T_iKINI_ORS OR

AND AI-rACH IT TO RETAINING POST (see FIgure 3).

IN ENCLOSED, POORLY VENTILATED AREAS, WHERE

FUEL FUMES MAY REACH AN OPEN FLAME, SPARK OR

PILOT LIGHT AS ON A FURNACE, WATER HEATER,

CLOTHES DRYER OR OTHER GAS APPLIANCE.

ROPE GUIDE

Fi, lm 2

STARTING

,_ NEVER RUN ENGINEINDOORS OR IN ENCLOSED,POORLY ]

VENTILATED AREAS ENGINE EXHAUST CONTAINS CAR-

BON MONOXIDE, ANODORLESS AND DEADLY GAS (CAR-

BON MONOXIDE IS ALSO PRESENT IN ENGINE EXHAUST/

FROMLIQUID PETROLEUM(LPG) AND NATURALGAS FUEL

SYSTEMS). I

_ KEEP HANDS, FEET, HAIR AND LOOSE CLOTHING AWAY

FROM ANY MOVING PARTS ON ENGINE AND EQUIPMENT.

_ WARNING: TEMPERATURE OF MUFFLER AND NEARBY

AREAS MAY EXCEED 15(PF (65°C). AVOID THESE AREAS.

(_]) Move ENGINE CONTROL (see Figure 1) to HI Position.

(_) START ENGINE

A. The carburetor on your engine has been completely adjusted

at the factory. When starting a cold engine, push red pdmer

bulb firmly with your thumb 5 times, allowing primer bulbto

return completely to original posistion between pushes,

Repeat the above for each starter operation as necessary,

NOTE: DO NOT USE PRIMER TO RESTART A WARM

ENGINE AFTER A SHORT SHUTDOWN.

B. Grasp starter handle (see Figure 2) and pull rope out, slowly,

until it pulls slightly harder. Let rope rewind slowly. Then pull

rope witha rapidfull arm stroke. Let rope rewind SLOWLY. Do

not let starter handle snap back against rope guide (see

Figure 2).

C. Repeat instruction E if necessary, until engine starts.

NOTE: if engine does not start, repeat instructions A, B and

C until itstarts.

ENGINE SPEED: Engine speed is controlled bythe ENGINE CON-

TROL see Figure 1).

ENGINE CONTROL should be in HI position for high grass condi-

tions and for most efficient bagging in heavy grass conditions, and

in LOW position for light grass, trimming and for fuel economy. Page 2

SPARK PLUG WIRE

Figure3

MAINTENANCE

_ WARNING: TEMPERATURE OF MUFFLER AND NEARBY]

AREAS MAY EXCEED 150°F (65°C). AVOID THESE AREAS.J

(_) CHECK OIL LEVEL:

Check oillevel every five (5) operating hours or each time engine

isused. See =_ CHECK OIL LEVEL" in"BEFORE STARTING" on

Page 1.

(_) CHANGE OIL:

Change oil after first two (2) operating hours and every 25

operating hours thereafter, more often if operated in extremely

dusty or dirty conditions. Change oil while engine is still warm

from recent r_Jnnin_l.

,_A, DISCONNECT SPARK PLUG WIRE FROM SPARK PLUG

AND ATTACH IT TO RETAINING POST (see Figure 3).

B. Position equipment so engioe oildrain plugis lowest point on

engine.

C. Remove oil drain plug and oil fill plug to drain oil (see Figure

1).

D. Replace oil drain plug and tighten securely.

E. Fill oil sump with recommended oil. See "OIL & FUEL REC-

OMMENDATIONS" and "CHECK OIL LEVEL" on Page 1.

F. Replace oil fill plug and tighten securely.

G. Connect spark plug wire to spark plug.

H, Wipe up any spilled oil and/or gasoline.

NOTE: Ifitis difficultto reach the oildrain plug,drain fuel. Remove

oil fill plug and tip mower on its side. Drain oil into a suitable

container.

181-1190-11

MAINTENANCE (Continued) MAINTENANCE (Continued)

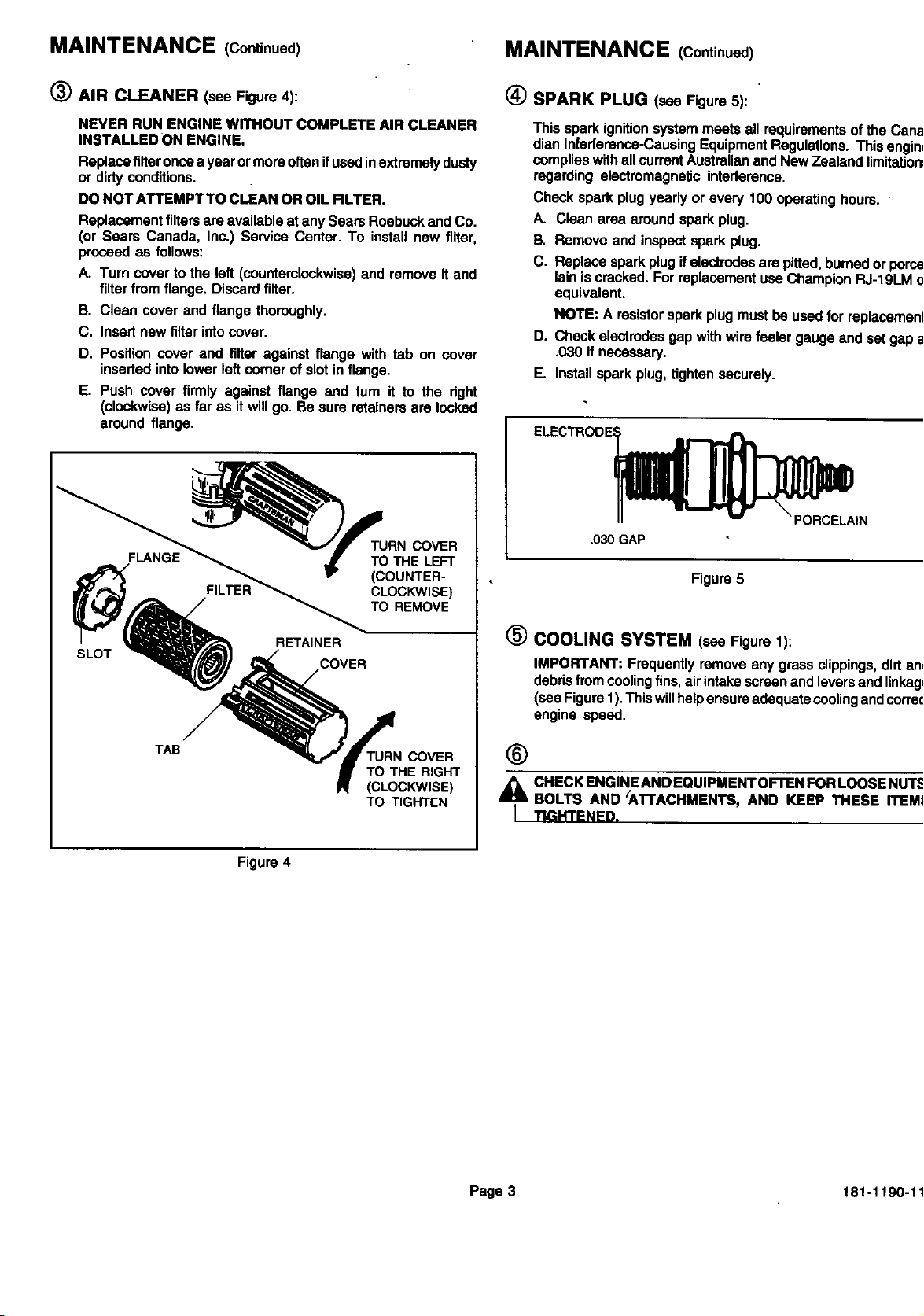

(_ AIR CLEANER (seeFigure4):

NEVER RUN ENGINE WITHOUT COMPLETE AIR CLEANER

INSTALLED ON ENGINE.

Replacefilteroncea yearormoreoftenif usedinextremelydusty

or dirtyconditions.

OO NOT ATTEMPTTO CLEAN OR OIL FILTER.

Replacementfilters are availableatany SearsRoebuckandCo.

(or Sears Canada, Inc.) Service Center. To installnew filter,

proceedas follows:

A. Turn coverto the left(countemlockwise)and removeitand

filterfrom flange. Discardfilter.

B. Clean cover andflange thoroughly.

C. Insertnew filter intocover.

D. Positioncover and filter against flange withtab on cover

insertedintolowerleftcomer of slotin flange.

E. Push cover firmly against flange and turn it to the fight

(clockwise)as far as it willgo. Be sure retainemare locked

around flange.

FLANGE

i_ TO THE LEFT

w (COUNTER-

FILTER CLOCKWISE)

RN COVER

TO REMOVE

(_ SPARK PLUG (seeFigure5):

Thissparkignitionsystemmeetsall requirementsof theCans.

dianInferferenoe-CausingEquipmentRegulations.Thisengine

complieswithall currentAustralianand New Zealandlimitations

regardingelectromagneticinterference.

Checksparkplugyearlyor evew 100 operatinghours.

A. Clean area aroundsparkplug.

B. Removeand inspectsparkplug.

C. Replacesparkplug if eLectrodesare pitted,burned orporce,

lainis cracked.For replacementuseChampionRJ-19LMo=

equivalent.

NOTE: A resistorsparkplugmustbe usedfor replacement

D. Check electrodesgapwithwirefeeler gauge and setgap a

.030 if necessary.

E. Installsparkplug,tightensecurely.

ELECTRODES

.030 GAP

Figure5

SLOT

TAB

RETAINER

Figure 4

COVER

COVER

TO THE RIGHT

(CLOCKWISE)

TO TIGHTEN

(_) COOLING SYSTEM (seeFigure1):

IMPORTANT: Frequentlyremoveany grass clippings,dirtant

debrisfromcoolingfins,airintakescreenandleversandlinkag_

(seeFigure1),Thiswillhelpensureadequatecoolingandcorrecl

engine speed.

®

_ CHECK ENGINE AND ECIUIPMENI" OFTEN FOR LOOSE NUTS

BOLTS AND/A'I-rACHMENTS, AND KEEP THESE ITEM.=

] TIGHTENED.

Page 3 181-1190-11

Loading...

Loading...