Craftsman 143993503 Owner’s Manual

operator's

manual

MODEL NO. 143.993503

SOLID STATE IGNITION

ENGIN

CAUTION:

Read RULES for

Safe OPERATION

and INSTRUCTIONS

Carefully

,&

Printed in U.S.A. 3-1-99 181-1200-11

California Proposition 65 WARNING: a'he engine exhaust from this product contains chemicals I

known to the State of California to cause cancer, birth defects or other reproductive harm.

Sold by SEARS, ROEBUCK AND CO., CHICAGO, IL 60684 U.S.A.

and SEARS CANADA, INC., TORONTO, ONTARIO, CANADA

• Operating

• Maintenance

• Repair Parts

I

I IIIIIIIIH lllinlt I

MODEL AND

D.O.M. DECAL

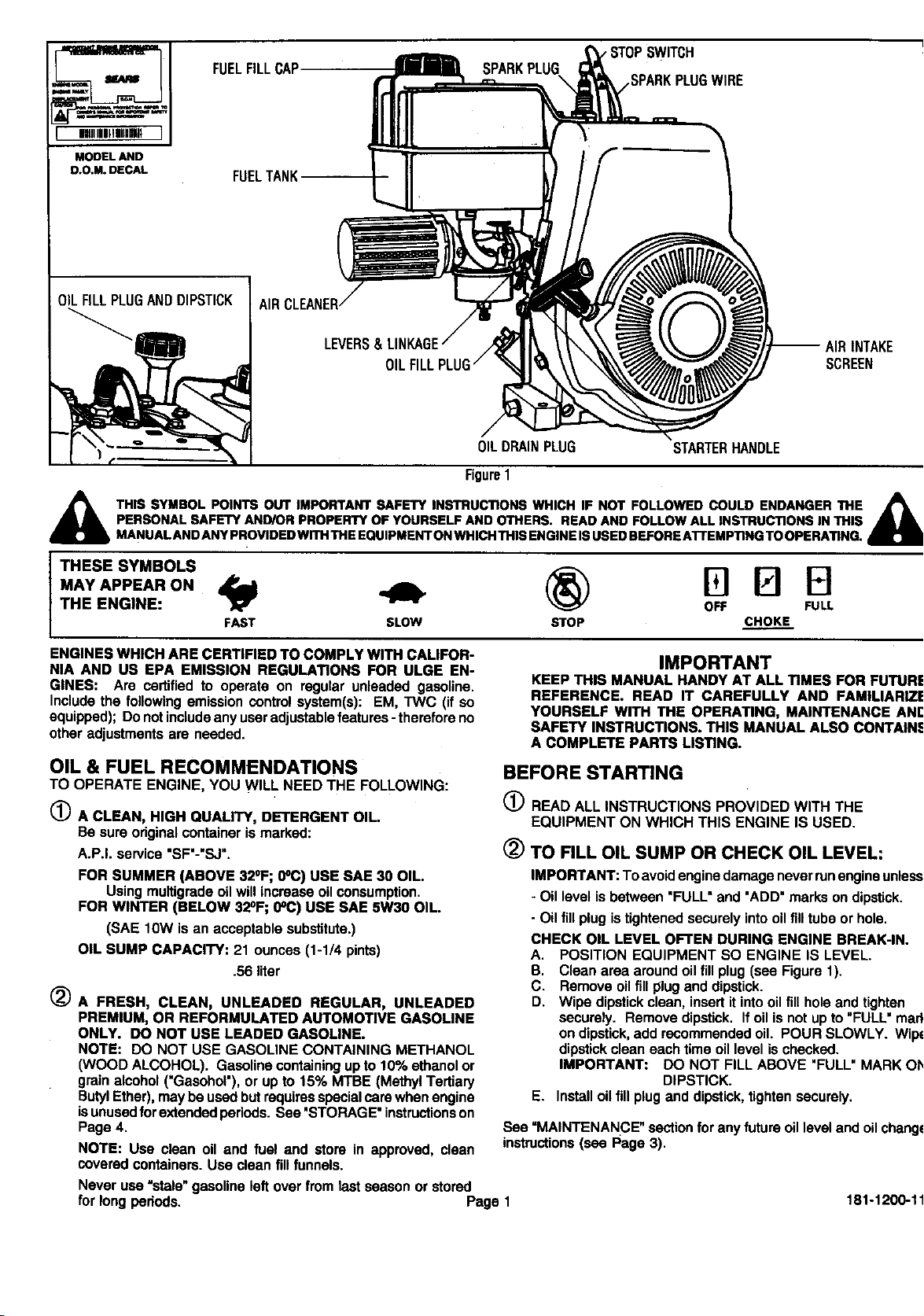

FUELFILLCAP SPARKPLUG

FUELTANK

,"STOPSWITCH

SPARKPLUGWIRE

FILLPLUGANDDIPSTICK

AIR C

LEVER INTAKE

SCREEN

01LDRAINPLUG STARTERHANDLE

Figure1

_k THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH IF NOT FOLLOWED COULD ENDANGER THE

MAY APPEAR ON El

THE ENGINE: OFF FULL

J THESE SYMBOLS (_ i._1 _1

ENGINES WHICH ARE CERTIFIED TO COMPLY WITH CALIFOR-

NIA AND US EPA EMISSION REGULATIONS FOR ULGE EN-

GINES: Are certified to operate on regular unleaded gasoline.

Include the following emission control system(s): EM, TWC (if so

equipped); Do notinclude any user adjustable features - therefore no

other adjustments are needed.

OIL & FUEL RECOMMENDATIONS

TO OPERATE ENGINE, YOU WILL NEED THE FOLLOWING:

(_A CLEAN, HIGH QUALITY, DETERGENT OIL.

(_A FRESH, CLEAN, UNLEADED REGULAR, UNLEADED

PERSONAL SAFETY AND/OR PROPERTY OF YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS

MANUALAND ANYPROVIDEDWITHTHEEQUIPMENTONWHICHTHIS ENGINE ISUSED BEFOREAI-rEMPTING TOOPERATING.

FAST SLOW STOP CHOKE

IMPORTANT

KEEP THIS MANUAL HANDY AT ALL TIMES FOR FUTURE

REFERENCE. READ IT CAREFULLY AND FAMILIARIZE

YOURSELF WITH THE OPERATING, MAINTENANCE AND

SAFETY INSTRUCTIONS. THIS MANUAL ALSO CONTAINS

A COMPLETE PARTS LISTING.

BEFORE STARTING

_) READ ALL INSTRUCTIONS PROVIDED WITH THE

Be sure odginal container is marked:

A.P.I. service "SF'-"SJ".

FOR SUMMER (ABOVE 32°F; 0°C) USE SAE 30 OIL.

Using multigrade oil will increase oil consumption.

FOR WINTER (BELOW 320F; 0°C) USE SAE 5W30 OIL.

(SAE 10W is an acceptable substitute.)

OIL SUMP CAPACITY: 21 ounces (1-1/4 pints)

.56 liter

PREMIUM, OR REFORMULATED AUTOMOTIVE GASOLINE

ONLY. DO NOT USE LEADED GASOLINE.

NOTE: DO NOT USE GASOLINE CONTAINING METHANOL

(WOOD ALCOHOL). Gasoline containing up to 10% ethanol or

grain alcohol ("Gasohol'), or up to 15% MTBE (Methyl Tertiary

Butyl Ether), may be used but requiresspecial care when engine

isunused for extended periods. Sea "STORAGE" instructionson

Page 4.

NOTE: Usa clean oil and fuel and store in approved, clean

covered containers. Use clean fill funnels.

EQUIPMENT ON WHICH THIS ENGINE IS USED.

(_ TO FILL OIL SUMP OR CHECK OIL LEVEL:

IMPORTANT: To avoid engine damage never run engine unless:

- Oil level is between "FULL" and "ADD" marks on dipstick.

- Oil fillplug is tightened securely into oil fill tube or hole,

CHECK OIL LEVEL OFTEN DURING ENGINE BREAK-IN.

A, POSITION EQUIPMENT SO ENGINE IS LEVEL.

B, Clean area around oil fill plug (see Figure 1).

C. Remove oil fill plug and dipstick.

D. Wipe dipstick clean, insert it into oil fill hole and tighten

securely. Remove dipstick. If oil is not up to "FULL" mark

on dipstick, add recommended oil. POUR SLOWLY. Wipe

dipstick clean each time oil level is checked.

IMPORTANT: DO NOT FILL ABOVE "FULL" MARK ON

DIPSTICK.

E. Install oil fill plug and dipstick, tighten securely.

See =MAINTENANCE" section for any future oil level and oil change

instructions (see Page 3).

Never use=stale" gasolineleftover fromlastseasonor stored

for longpedods. Page 1

181-1200-11

BEFORE STARTING (Continued)

STOPPING

(_) FILL FUELTANKwithgasolineasspecifiedinthepreceding

=OIL& FUEL RECOMMENDATIONS," item 2.

NEVER MIX OIL WITH GASOLINE

Never use "stale"gasoline left over from last season orstored for

long periods.

_IL NEVER FILL FUEL TANK INDOORS, NEVER FILL FUEL I

TANK WHEN ENGINE IS RUNNING OR HOT. DO NOT SMOKE

I WHEN FILLING FUEL TANK.

_IL NEVER FILL FUEL TANK COMPLETELY. FILL TANK TO 1/2"

BELOW BO'I'rOM OF FILLER NECK TO PROVIDE SPACE

I FOR FUEL EXPANSION. WIPE ANY FUEL SPILLAGE FROM

ENGINE AND EQUIPMENT BEFORE STARTING ENGINE.

_bANY LIQUEFIED PETROLEUM (LPG) OR NATURAL GAS I

FUEL SYSTEM MUST BE LEAKPROOF AND MEET ALL

APPLICABLE CODES AND REGULATIONS.

(_ CHECK THE FOLLOWING:

A. BE SURE EQUIPMENT IS IN NEUTRAL GEAR WITHI

_lL CLUTCHES, BELTS, CHAINS AND SAFETY SWITCHES I

DISENGAGED. (FOLLOW EQUIPMENT MANUFAC- I

l URER'S INSTRUCTIONS). THIS SHOULD PLACE ANY

SAFETY SWITCHES IN SAFE STARTING PosmoN.

B. Be sure spark plugwire is attached to spark plug (see Figure

1).

C. Be sure stop switch nextto spark plug is notcontacting spark

plug (see Figure 1).

D, Be sure any ignitionswitch on engine or equipment is in ON,

RUN or START position.

STARTING

_k NEVER RUN ENGINE INDOORS OR IN ENCLOSED, POORLY

VENTILATED AREAS. ENGINE EXHAUST CONTAINS CAR-

BON MONOXIDE, AN ODORLESS AND DEADLY GAS (CAR-

BON MONOXIDE IS ALSO PRESENT IN ENGINE EXHAUST

FROM LIQUID PETROLEUM (LPG) AND NATURAL GAS

FUEL SYSTEMS).

_KEEP HANDS, FEET, HAIR AND LOOSE CLOTHING AWAYFROM ANY MOVING PARTS ON ENGINE AND EQUIPMENT.

,_k WARNING: TEMPERATURE OF MUFFLER AND NEARBY I

AREAS MAY EXCEED 150°F (65°C). AVOID THESE AREAS. J

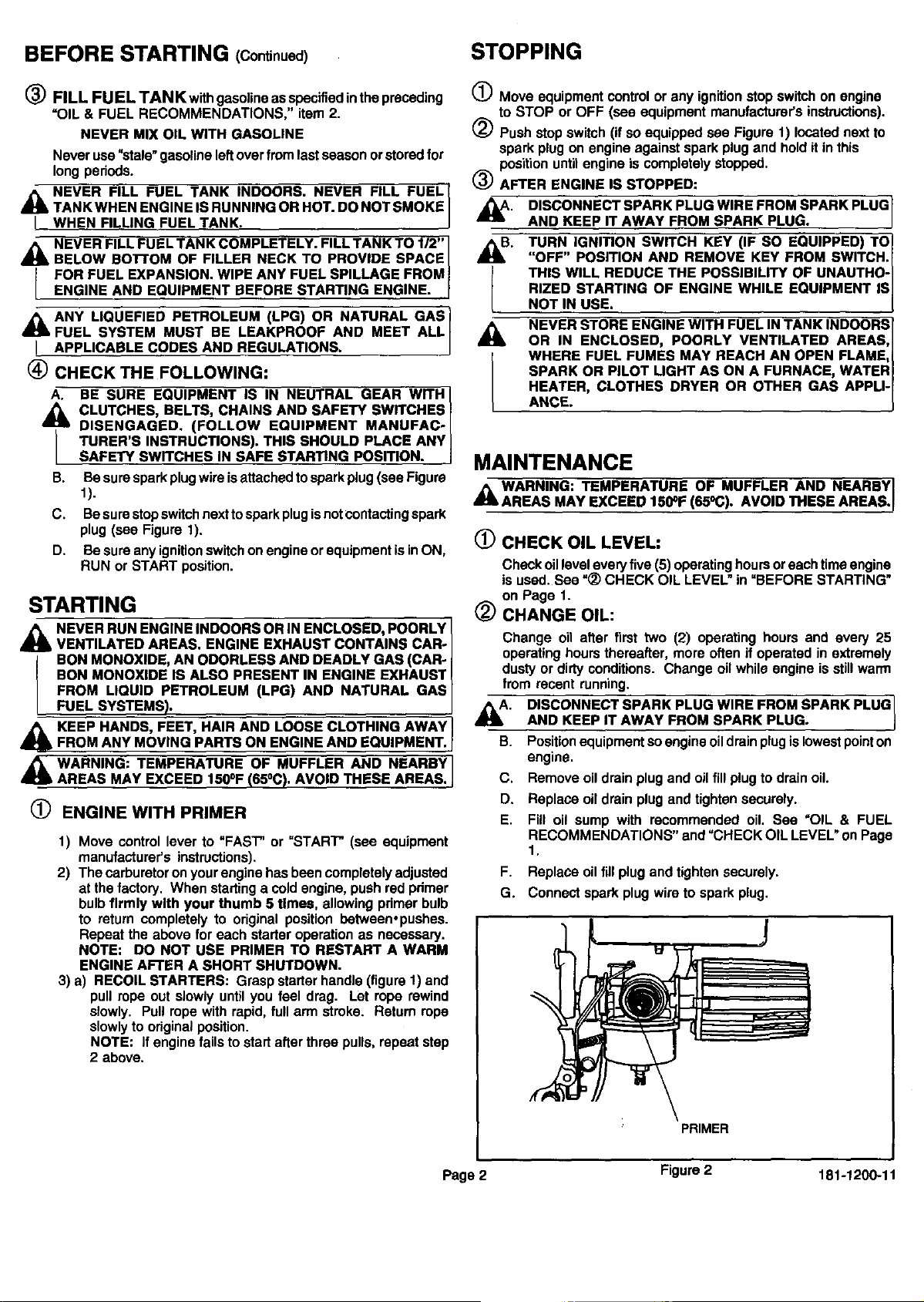

ENGINE WITH PRIMER

1) Move controllever to "FAST"or "START"(see equipment

manufacturer's instructions).

2) The carburetoronyourenginehasbsencompletelyadjusted

at thefactory. When startinga coldengine,pushredpdmer

bulbflrrnly with your thumb 5 times, allowingprimerbulb

to return completelyto originalpositionbetween,pushes.

Repeat the abovefor each starteroperationas necessary.

NOTE: DO NOT USE PRIMER TO RESTART A WARM

ENGINE AFTER A SHORT SHUTDOWN.

3) a) RECOIL STARTERS: Graspstarterhandle(figure1)and

pull ropeout slowly untilyoufeel drag. Let roperewind

slowly. Pullropewithrapid, full arm stroke. Returnrope

slowlyto odginalposition.

NOTE: If enginefails to startafterthroepulls,repeatstep

2 above.

(_ Move equipment control or any ignition stop switch on engine

to STOP or OFF (see equipment manufacturer's instructions).

(_ Push stop switch (if so equipped see Figure 1) located next to

spark plug on engine against spark plug and hold it in this

position until engine is completely stopped.

I_) AFTER ENGINE IS STOPPED:

_. DISCONNECT SPARK PLUG WIRE FROM SPARK PLUGI

_liB. TURN, IGNITION SWITCH KEY (IF SO EQUIPPED) TO I

,&

AND KEEP IT AWAY FROM SPARK PLUG. .J

OFF POSITION AND REMOVE KEY FROM SWITCH, I

THIS WILL REDUCE THE POSSIBILITY OF UNAUTHO-

RIZED STARTING OF ENGINE WHILE EQUIPMENT IS

NOT IN USE.

NEVER STORE ENGINE WITH FUEL IN TANK INDOORS I

OR IN ENCLOSED, POORLY VENTILATED AREAS, I

WHERE FUEL FUMES MAY REACH AN OPEN FLAME, I

SPARK OR PILOT LIGHT AS ON A FURNACE, WATER I

HEATER, CLOTHES DRYER OR OTHER GAS APPLI-

I

ANCE.

MAINTENANCE

_kWARNING: TEMPERATURE OF MUFFLER AND NEARBY I

AREAS MAY EXCEED 150°F (65eC), AVOID THESE AREAS,!

CHECK OIL LEVEL:

Checkoilleveleveryfive(5) operatinghoursoreachtimeengine

is used.See "_)CHECK OIL LEVEL"in =BEFORESTARTING"

on Page 1.

CHANGE OIL:

Change oil after first two (2) operating hours and every 25

operating hours thereafter, more often if operated in extremely

dusty or dirty conditions. Change oil while engine is still warm

from recent running.

,_A. DISCONNECT SPARK PLUG WIRE FROMSPARK PLUG

AND KEEP T AWAY FROM SPARK PLUG.

B. Positionequipment so engine oil drain plugis lowest pointon

engine.

C. Remove oil drain plug and oil fill plug to drain oil.

D. Replace oil drain plug and tighten securely.

E. Fill oil sump with recommended oil. See "OIL & FUEL

RECOMMENDATIONS" and =CHECK OIL LEVEL" on Page

1.

F. Replaceoilfill plugandtightensecurely.

G. Connectsparkplugwiretospark plug.

i PRIMER

Page 2 Figure 2 181-1200-11

MAINTENANCE (Continued)

MAINTENANCE (Continued)

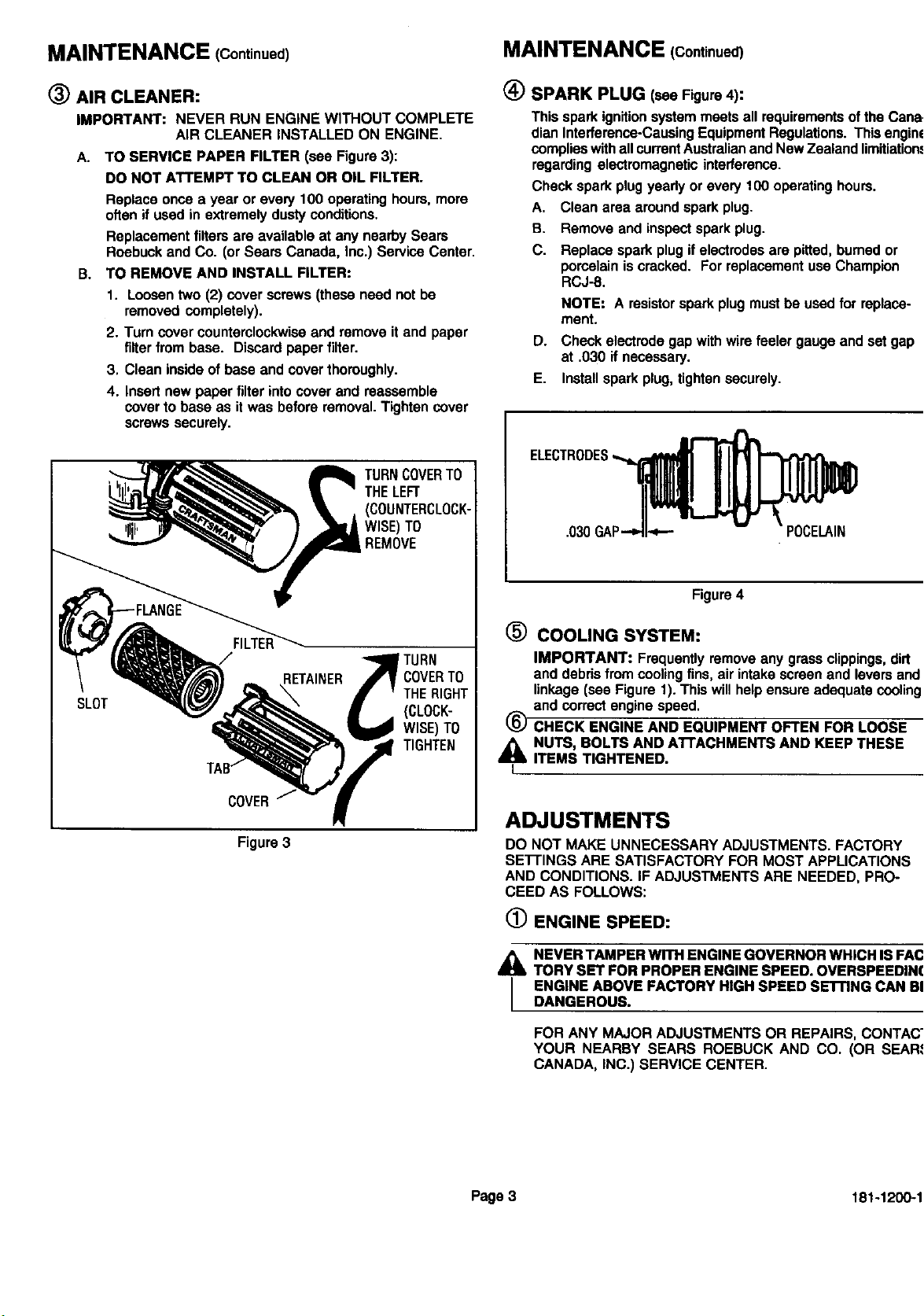

(_ AIR CLEANER:

IMPORTANT: NEVER RUN ENGINE WITHOUT COMPLETE

AIR CLEANER INSTALLEDON ENGINE.

A. TO SERVICE PAPER FILTER (see Figure3):

DO NOT ATTEMPT TO CLEAN OR OIL FILTER.

Replaceonce a year or every 100 operatinghours,more

oftenifused in extremelydustyconditions.

Replacementfilters are availableatany nearbySears

Roebuckand Co. (or Sears Canada, Inc.) ServiceCenter.

B. TO REMOVE AND INSTALL FILTER:

1. Loosentwo (2) cover screws(these need notbe

removedcompletely).

2. Turn cover counterclockwiseand removeitand paper

filterfrom base. Discardpaperfilter.

3. Clean insideofbase andcover thoroughly.

4. Insert newpaper filter intocover and reassemble

cover tobase as itwas beforeremoval.Tightencover

screwssecurely.

TURNCOVERTO

THELEFT

(COUNTERCLOCK-

WISE)TO

REMOVE

®

SPARK PLUG (see Figure4):

Thissparkignitionsystemmeets allrequirementsofthe Cana-

dianInterference-CausingEquipmentRegulations.Thisengine

complieswithall currentAustralianandNewZealandlimitiations

regardingelectromagneticinterference.

Checkspark plugyeedyor every100 operatinghours.

A. Clean area aroundspark plug.

B. Removeand inspectsparkplug.

C. Replacesparkplugifelectrodesare pitted,bumedor

porcelainis crackad. For replacementuse Champion

RCJ-8.

NOTE: A resistorsparkplugmustbe usedfor replace-

ment.

D. Checkelectrodegap withwirefeeler gaugeandset gap

at .030 if necessary.

E. Installsparkplug, tightensecurely.

POCELAIN

SLOT

COVERJ

Figure3

RETAINER

'TURN

COVERTO

THERIGHT

(CLOCK-

WISE)TO

TIGHTEN

Figure 4

(_) COOLING SYSTEM:

IMPORTANT: Frequently remove any grass clippings, dirt

and debds from cooling fins, air intake screen and levers and

linkage (see Figure 1). This will help ensure adequate cooling

and correct engine speed.

CHECK ENGINE AND EQUIPMENT OFTEN FOR LOOSE

_ NUTS, BOLTS AND A'I-I'ACHMENTS AND KEEP THESE

ITEMS TIGHTENED.

ADJUSTMENTS

DO NOT MAKE UNNECESSARY ADJUSTMENTS. FACTORY

SE'I-rlNGS ARE SATISFACTORY FOR MOST APPLICATIONS

AND CONDITIONS. IF ADJUSTMENTS ARE NEEDED, PRO-

CEED AS FOLLOWS:

(_ ENGINE SPEED:

_ NEVER TAMPER WITH ENGINE GOVERNOR WHICH IS FAC-

TORY SET FOR PROPER ENGINE SPEED. OVERSPEEDING

ENGINE ABOVE FACTORY HIGH SPEED SE'I'RNG CAN BE

DANGEROUS.

FOR ANY MAJOR ADJUSTMENTS OR REPAIRS, CONTACT

YOUR NEARBY SEARS ROEBUCK AND CO. (OR SEAR,_

CANADA, INC.) SERVICE CENTER.

Page 3 181-1200-1"

Loading...

Loading...