Craftsman 143991200 Owner’s Manual

SEARS

operator's

manual

MODEL NO. 143.99120(

SOLID STATE IGNITION

ENGINE

CAUTION:

Read RULES for

Safe OPERATI()N

and INSTRUCTIONS

Carefully

] a_k california Proposition 65 WARNING: The anglne exhaust from this productcontains chemicals I

Printed in U.S.A. 2-1-99 181-1197-11

known to the State of California to cause cancer,birthdefects or otherreproductive harm.

Sold by SEARS, ROEi]UCK AND CO., CHICAGO,IL 60684 U.S.A.

and SEARS CANADA, INC., T_RONTO, ONTARIO, CANADA

• Operating

• Maintenance

• Repair Parts

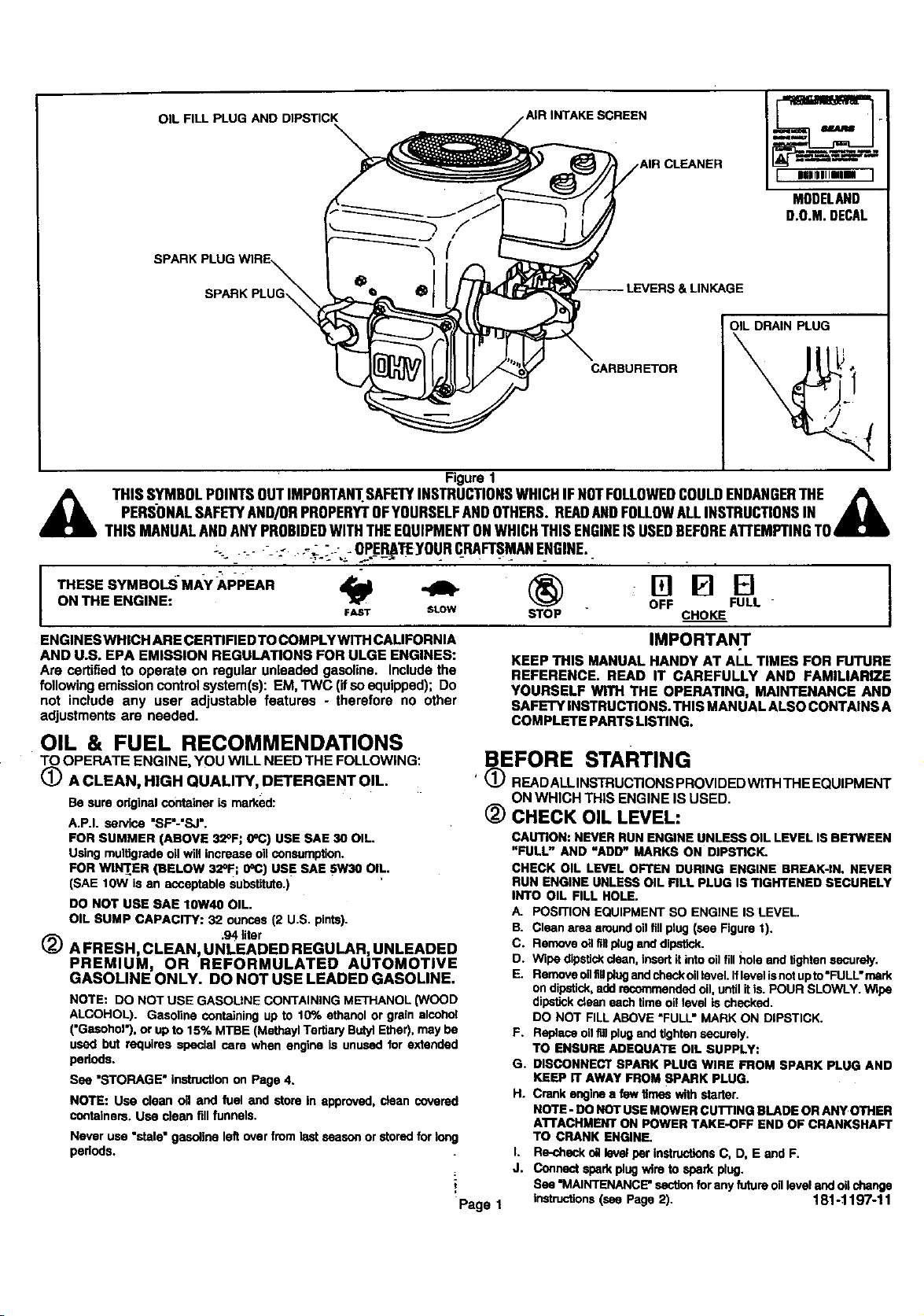

OIL FILL PLUG AND DIPSTICK

\

THISSYMBOLPOINTSOUTIMPORTANTSAFETYINSTRUCTIONSWHICHIFNOTFOLLOWEDCOULDENDANGERTHE A

PERSONALSAFETYAND/0RPROPERYTOFYOURSELFANDOTHERS.READANDFOLLOWALLINSTRUCTIONSIN

THISMANUALANDANYPROBIDEDWITHTHEEQUIPMENTONWHICHTHISENGINEIS USEDBEFOREATrEMPTINGTO0

o-_ -_- - : _.£".- -OPE_RATEyOURCRAFTSMANENGINE.

THESE SYMBOLS MAY APPEAR

ON THE ENGINE:

ENGINES WHICH ARE CERTIFIED TO COMPLY WITH CALIFORNIA

AND U.S. EPA EMISSION REGULATIONS FOR ULGE ENGINES:

Are certified to operate on regular unleaded gasoline. Include the

following emission control system(s): EM, TWC (if so equipped); Do

not include any user adjustable features - therefore no other

adjustments are needed.

OIL & FUEL RECOMMENDATIONS

TO OPERATE ENGINE, YOU WILL NEED THE FOLLOWING:

(_ A CLEAN, HIGH QUALITY, DETERGENT OIL.

Be sum original container is marked:

A.P.I. service "SF'-'SJ".

FOR SUMMER (ABOVE 32°F; 0°C) USE SAE 30 OIL,

Using mulitgrade oil will increase oil consumption.

FOR WIN'[ER (BELOW 32°F; (PC) USE SAE 5W30 OIL.

(SAE 10W is an acceptable Substitute.)

DO NOT USE SAE 10W40 OIL.

OIL SUMP CAPACITY: 32 ounces 12 U.S. pints).

(_) .94 Iitar

A FRESH, CLEAN, UNLEADED REGULAR, UNLEADED

PREMIUM, OR REFORMULATED AUTOMOTIVE

GASOLINE ONLY. DO NOT USE LEADED GASOLINE.

NOTE: DO NOT USE GASOLINE CONTAINING METHANOL (WDOD

ALCOHOL). Gasoline containing up to 10% ethanol or grain alcohol

('Gasohol'), or up to 15% MTBE (Msthayl Tertiary ButylEther), may be

used but requires special cam when engine is unused for extended

periods.

See "STORAGE" instruction on Page 4.

NOTE: Usa dean oil and fuel and store in approved, dean covered

containers. Use clean fill funnels.

Neveruse"stale"gasolineleftover fromlastseason orstoredfor long

periods.

._ . .-. -

FAST SLOW

AIR CLEANER II I|llBiinlit ill I

OIL DRAIN PLUG

CARBURETOR

Figure 1

,

PIE]El

STOP CHOKE

OFF FULL

IMPORTANT

KEEP THIS MANUAL HANDY AT ALL TIMES FOR FUTURE

REFERENCE. READ IT CAREFULLY AND FAMILIARIZE

YOURSELF WITH THE OPERATING, MAINTENANCE AND

SAFETY INSTRUCTIONS. THIS MAN UAL ALSO CONTAINS A

COMPLETE PARTS LISTING.

BEFORE STARTING

' (_ READALLINSTRUCTIONSPROVIDEDWITHTHEEQUIPMENT

ON WHICH THIS ENGINE IS USED.

(_) CHECK OIL LEVEL:

CAUTION: NEVER RUN ENGINE UNLESS OIL LEVEL IS BETWEEN

"FULL" AND "ADD" MARKS ON DIPSTICK.

CHECK OIL LEVEL OFTEN DURING ENGINE BREAK-IN. NEVER

RUN ENGINE UNLESS OIL RLL PLUG IS TIGHTENED SECURELY

INTO OIL FILL HOLE.

A. POSITION EQUIPMENT SO ENGINE IS LEVEL.

B. Clean area aroundoil fillplug (see Figure I).

C. Remove oil finplug and dipstick.

D. Wipe dipstickclean, Insert it into oil fill hole and tighten securely.

E. Remove oilfibplug and checkoil level. If level isnot up to"FULL" mark

on dipstick, add recommended oil, until it is. POUR SLOWLY. W'lpe

dipstick clean each time oHlevel is checked.

DO NOT FILL ABOVE "FULL" MARK ON DIPSTICK.

F. Replace oilfill plug and Ughtan securely.

TO ENSURE ADEQUATE OIL SUPPLY:

G. DISCONNECT SPARK PLUG WIRE FROM SPARK PLUG AND

KEEP IT AWAY FROM SPARK PLUG.

H. Crank engine a few times with starter.

NOTE - DO NOT USE MOWER Cut-rING BLADE OR ANY OTHER

A'rrACHMEHT ON POWER TAKE-OFF END OF CRANKSHAFT

TO CRANK ENGINE.

I. Re-check oil level per instructions C, D, E and F.

J. Connect spark plug wire to spark plug.

!

Page 1

See "MAINTENANCE" section forany future offlevel and oil change

Instructions (see Page 2). 181-1197-11

MODELAND

D.O.M. DECAL

BEFORE STARTING (Continued)

(_ FILL FUEL TAN K wifh gasoline as specitled inthe preceding'oiL

& FUEL RECOMMENDATIONS," item 2.

NEVER MIX OIL WITH GASOUNE

Never use "stale" gasoline left over from last season or stored for long

pedods,

_NEVER FILL FUEL TANK INDOORS. NEVER FILL FUEL TANK I

WHEN ENG NE S RUNN NG OR HOT DO NOT SMOKE WHEN

I FILLING FUEL TANK. I

_NEVER FILL FUEL TANK COMPLETELY. FILL TANK TO 1/2"

BELOW BO'I-FOM OF FILLER NECK TO PROVIDE SPACE FOR

FUEL EXPANSION. WIPE ANY FUEL SPILLAGE FROM ENGINE

AND EQUIPMENT BEFORE STARTING ENGINE.

_kANY LIQUEFIED pETROLEUM (LPG) OR NATURAL GAS FUEL

SYSTEM MUST BE LEAKPROOF AND MEET ALL APPLICABLE

I CODES AND REGULATIONS.

(_) CHECK THE FOLLOWING:

_IA. BE SURE EQUIPMENT IS IN NEUTRAL GEAR WITH CLUTCHES,

BELTS, CHAINS AND SAFETY SWITCHES DISENGAGED.

(FOLLOW EQUIPMENT MANUFACTURER'S INSTRUCTIONS).

THIS SHOULD PLACE ANY SAFETY SWITCHES IN SAFE

STARTING PosmoN.

B. Be sure spark plug wire Is attached to spark plug (see Rgure 1).

C. Be sure any ignition switch on engine or equipment is in ON, RUN

or START position.

STARTING

_kNEVER RUN ENGINE INDOORS OR IN ENCLOSED, POORLY

VENTILATED AREAS. ENGINE EXHAUST CONTAINS CARBON

MONOXIDE, AN ODORLESS AND DEADLY GAS (CARBON

MONOXIDE IS ALSO PRESENT IN ENGINE EXHAUST FROM LIQUID

PETROLEUM (LPG) AND NATURAL GAS FUEL SYSTEMS).

_b= KEEP HANDS, FEET, HAIR AND LOOSE CLOTHING AWAY FROM

ANY MOVING PARTS ON ENGINE AND EQUIPMENT.

_BE SURE AIR INTAKE SCREEN (see Fig. 1) IS SECURELY IN PLACE

TO AVOID CONTACT WITH MOVING PARTS.

_ILWARNING TEMPERATURE OF MUFFLER AND NEARBY AREAS

MAY EXCEED 150°F (65=C). AVOID THESE AREAS.

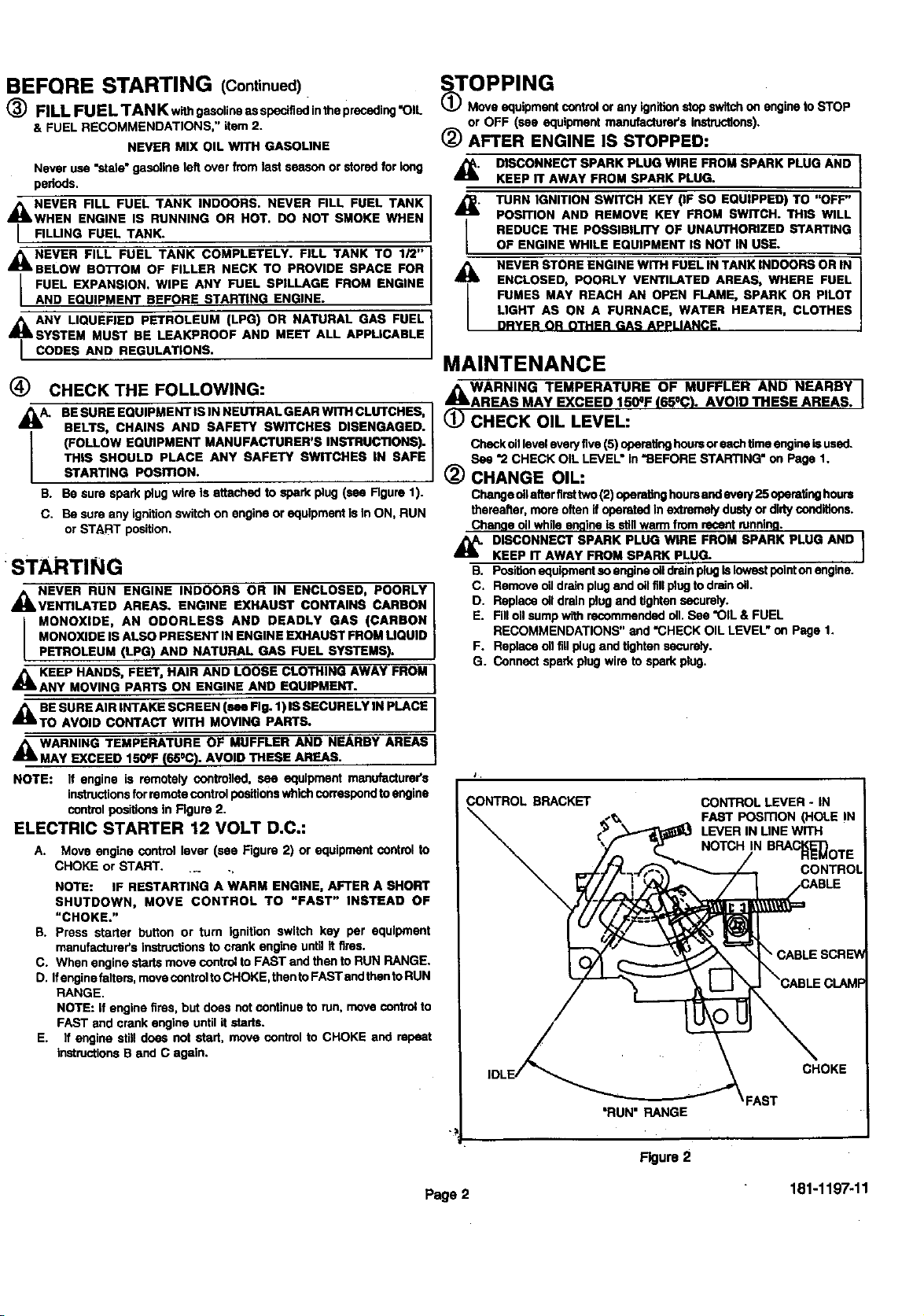

NOTE: If engine is remotely controlled, see equipment manufacturer's

instructionsfor remote control positions which correspond to engine

control positions In Figure 2.

ELECTRIC STARTER 12 VOLT D.C.:

A. Move engine control lever (see Ftgure 2) or equipment control to

CHOKE or START.

NOTE: IF RESTARTING A WARM ENGINE, AFTER A SHORT

SHUTDOWN, MOVE CONTROL TO "FAST" INSTEAD OF

"CHOKE."

B. Press starter button or turn ignition switch key par equipment

manufacturer's instructions to crank engine until it fires.

C. When engine starts move control to FAST and then to RUN RANGE.

D. Ifengine falters, move control toCHOKE, than to FAST and then to RUN

RANGE.

NOTE: If engine fires, but does not continue to run, move control to

FAST and crank engine until it starts.

E. If engine still does not start, move control to CHOKE and repeat

instructions B and C again.

)TOPPING

Move equipment control or any ignition stop switch on engine to STOP

or OFF (see equipment manufacturer's instructions).

(,_ AFTER ENGINE IS STOPPED:

DISCONNECT SPARK PLUG WIRE FROM SPARK PLUG AND

KEEP rr AWAY FROM SPARK PLUG.

,_ TURN IGNITION SWITCH KEY (IF SO EQUIPPED) TO "OFF"

POSITION AND REMOVE KEY FROM SWITCH. THIS WILL

I REDUCE THE POSSIBILITY OF UNAUTHORIZED STARTING

OF ENGINE WHILE EQUIPMENT IS NOT IN USE.

_k NEVER STORE ENGINE WITH FUEL IN TANK INDOORS OR IN

ENCLOSED, POORLY VENTILATED AREAS, WHERE FUEL

FUMES MAY REACH AN OPEN FLAME, SPARK OR PILOT

LIGHT AS ON A FURNACE, WATER HEATER, CLOTHES

DRYER OR OTHt=R GAS APPLIANCE.

MAINTENANCE

,_WARNING TEMPERATURE OF MUFFLER AND NEARBY

AREAS MAY EXCEED 150=F (65°C). AVOID THESE AREAS. I

1_ CHECK OIL LEVEL:

Check oil level every rive (5) operating hours or each rime engineis used.

See "2 CHECK OIL LEVEL" in "BEFORE STARTING" on Page 1.

(_) CHANGE OIL:

Change oilafterrirst two (2) operatinghours andeveP/25 operatinghours

thereafter, more often if operated In extremely dusty or dirty conditions.

Change oil while engine Is stillwarm from recent running.

_. DISCONNECT SPARK PLUG WIRE FROM SPARK PLUG AND

KEEP IT AWAY FROM SPARK PLUG.

B. Posirionequipment so engine oil drain plug is lowest pointon angine.

C. Remove oil drain plug and oll rillplug to droin oil.

D. Replace oil drain plug and _ghten securely.

E. Fill oil sump with recommended oil. See "OIL & FUEL

RECOMMENDATIONS" and "CHECK OIL LEVEL" on Page 1.

F. Replace oil fill plug and tighten securely.

G. Connect spark plug wire to spark plug.

CONTROL BRACKET

CONTROL LEVER - IN

FAST POSITION (HOLE IN

LEVER IN LINE WITH

NOTCH IN BRAC_NoT E

CONTROt

l

"RUN" RANGE

Figure 2

Page2 181-1197-11

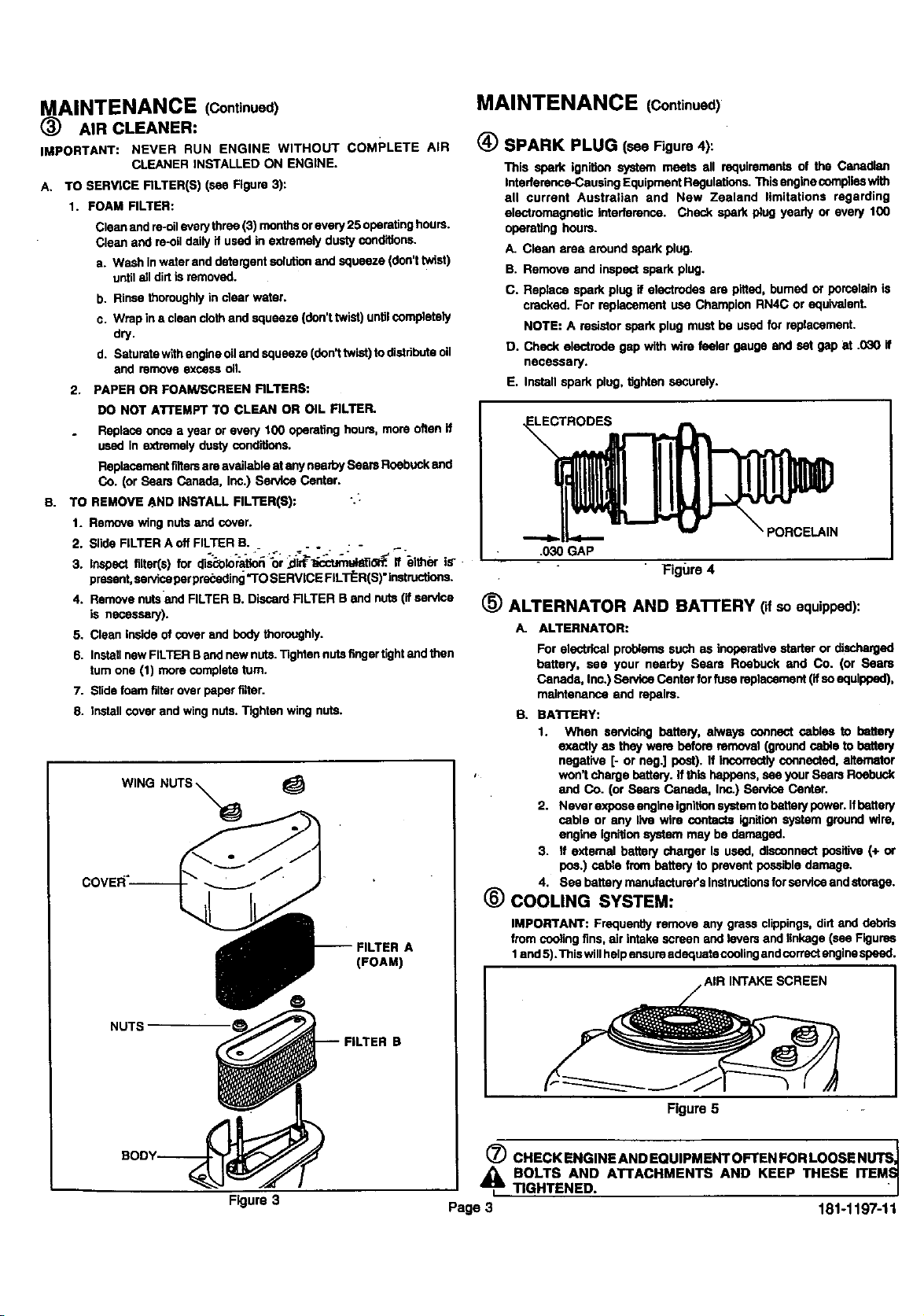

MAINTENANCE (Continued)

(_) AIR CLEANER:

IMPORTANT: NEVER RUN ENGINE WITHOUT coMPLETE AIR

CLEANER INSTALLED ON ENGINE.

A. TO SERVICE RLTER(S) (see Figure 3):

1. FOAM RLTER:

Clean and re-oilevery throe (3) monthsor every 25 operating hours.

Clean and re-oil daily if used in extremely dusty conditions.

a. Wash in water and detergent solution and squeeze (don't twist)

untilail dirt is removed.

b. Rinse thoroughly in clear water.

c. Wrap in a clean cloth and squeeze (don't twist) until completely

dry.

d. Saturate w_h engineoiland squeeze (don't twist) to dlatdbuts oil

and remove excess oil.

2. PAPER OR FOAM/SCREEN FILTERS:

DO NOT ATrlEMPT TO CLEAN OR OIL FILTER

Replace once a year or every 100 operating hours, more often if

used In exlmmely dusty condiflans.

Replacement filtersere available at any naerby Sears Roebuck and

Co. (or Sears Canada, Ins.) Service Center.

B. TO

REMOVE AND INSTALL RLTER(S): ".:

1. Remove wing nuts and cover.

2. Slide FILTER A off FILTER B.

3. I_ tiiter(s)for_i_o=o_ or_u_n_. e _lther

present, service perpreceding"TO SERVICE FILTl_R(S)'lnstructions.

4. Remove nutsand FILTER B. Discard FILTER B and nuts (ifservice

is necessary).

5. Clean inside of cover and body thoroughly.

6. Instatl new FILTER B and naw nuts.Tightan nutstinger tightand than

turn one (t) more complete turn.

7. Stide foam tilterover paper tilter.

8. Install cover and wing nuts.Tighten wing nuts.

A

(FOAM)

MAINTENANCE (Continued)

®

SPARK PLUG (see Figure4):

"l_is spark ignition system meets all requirements of the Canadian

Interference-Causing Equipment Regulations. This engine complieswith

all current Australian and New Zealand limitations regarding

electromagnetic interference. Check spark plug yearly or every 100

operating hours.

A. Clean area around spark plug.

B. Remove and inspect spark plug.

C. Replace spark plug if electrodes are pitted, bumed or porcelain is

cracked. For replacement use Champion RN4C or equivalent.

NOTE: A resistor spark plug must be used for replacement.

O. Check electrode gap with wire feeler gauge and set gap at .030 if

necessary.

E. Install spark plug, I_htan securely.

.030 GAP

FigtJre 4

(_) ALTERNATOR AND BA'I-FERY (if so equipped):

A. ALTERNATOR:

Forelectricalproblemssuchas inoperativestarteror discharged

battery, see your nearby Sears Roebuckand Co. (or Sears

Canada,Inc.)ServiceCenterforfusereplacement(ifsoequipped),

maintenanceand repairs.

B. SATrERY:

1. When servicing battery, always connect cables to battely

exactly as they were before removal (ground cable to battery

negative [- or nng.] post). If incorrectly connected, alternator

won't charge battery. If this happens, see your Sears Roebuck

and Co. (or Sears Canada, Ins.) San/ice Center.

2. Never expose engine Ignltlensyatem to battery power, if battery

cable or any live wire contacts ignition system ground wire,

engine ignition system may be damaged.

3. If extemoi battery charger is used, disconnect positive (+ or

po6.) cable from bettery to prevent possible damage.

4. See battery manufacturer's Instructionsfor service and sforsga.

_) COOLING SYSTEM:

IMPORTANT: Frequently remove any grass clippings, dirt and dobds

from cooling tins, air intake screen and levers and linkage (see Figures

I and 5).This will helpensurs edequate cooling andcorrectengine speed.

NUTS

Figure 3

FILTER B

F_um 5

BOLTS AND ATTACHMENTS AND KEEP THESE ITEMS_

_k=_ CHECK ENGINE AND EQUIPMENT OFTEN FOR LOOSE NUTSI

TIGHTENED. I

Page3 181-1197-11

Loading...

Loading...