Craftsman 143991004 Owner’s Manual

SEARS

operator's

manual

MODE_L NO. 143.991004

SOLID STATE IGNITION

ENGINE

CAUTION:

Read RULES for

Safe OPERA:IION

and INSTRUCTIONS

Carefully

A California Proposition65 WARNING: Thoo._neexhaust fromthis product contains chemicals

Printed in U.S.A. 3-1-9p 181-1192-11

known to the State of California tocause cancer, birth defects or otherreproductiveharm.

Sold by SEARS, ROEBUCK AND _O., CHICAGO, IL 60684 U.S.A.

and SEARS CANADA, INC., TORONTO, ONTARIO, CANAD A

• Operating

• Maintenance

• Repair Parts

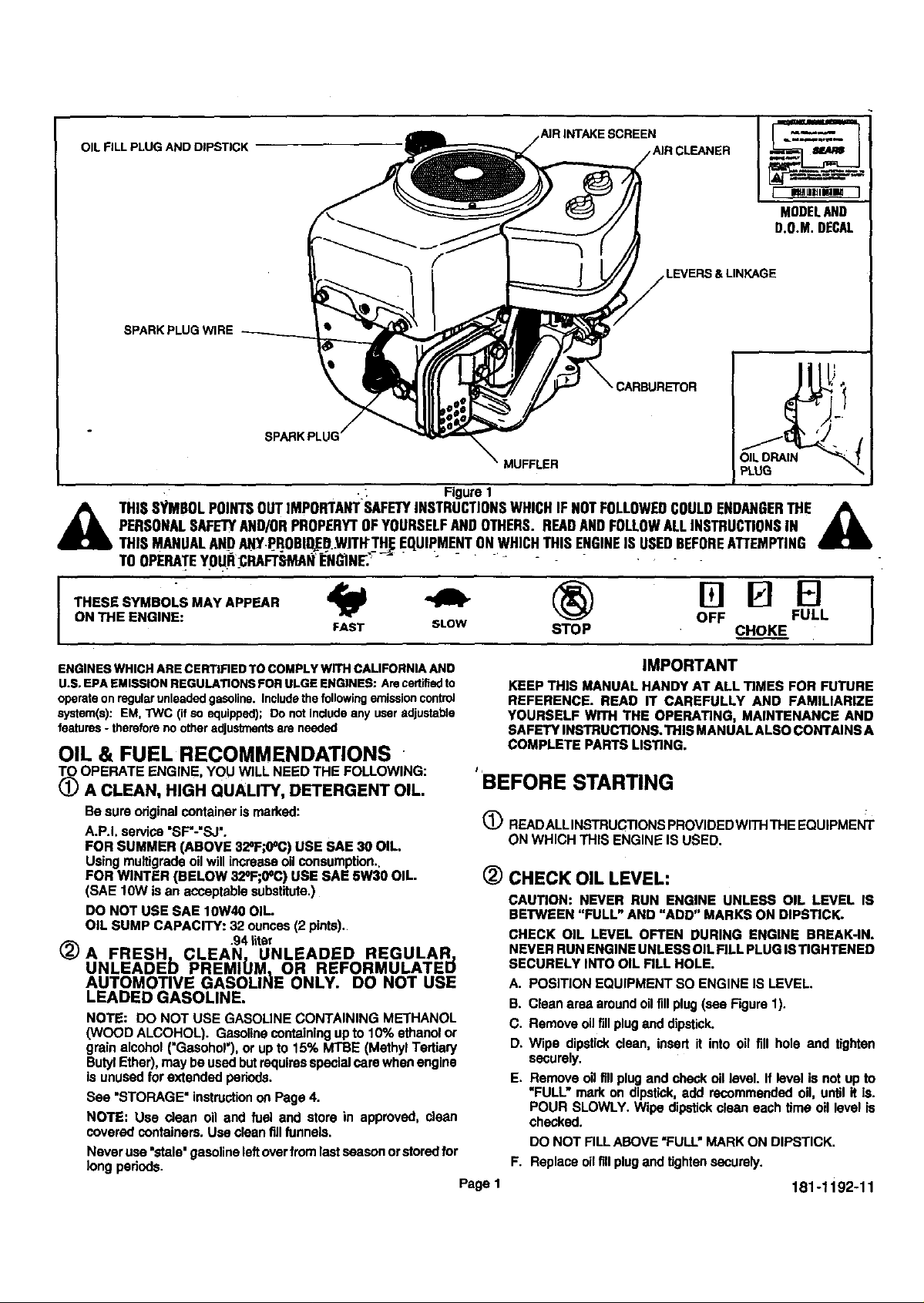

OIL FILL PLUG AND DIPSTICK

SPARK PLUG WIRE

SPARK PLUG'

. : Figure 1

MUFFLER

SCREEN

MODELAND

D.O.M. DECAL

LEVERS & LINKAGE

OIL D

PLUG

,_IL THIS S'MBOL POINTS OUTIMPORTANTSAFETY INSTRUCTIONS WHICH IF NOT FOLLOWEDCOULDENDANGERTHE ,_hb

I,,osoo--O.SM,,,,,,, ® mnB

ENGINES WHICH ARE CERTIRED TO COMPLY WITH CALIFORNIA AND

U.S, EPA EMISSION REGULATIONS FOR ULGE ENGINES: Arecertifiedto

operate on regularunleaded gasoline. Includethe followingemission control

system(s): EM, TWC (if so equipped); Do not include any user adjustable

features - therefore no other adjustments are needed

OIL & FUEL RECOMMENDATIONS

TO OPERATE ENGINE, YOU WILL NEED THE FOLLOWING:

(_ A CLEAN, HIGH QUALITY, DETERGENT OIL.

(_ .94 |iter

PERSONALSAFETYAND/OR PROPERYTOF YOURSELF AND OTHERS. READAND FOLLOWALL INSTRUCTIONS IN

, THIS MANUAL AND ANY PROBID_ED.WJTI.i'_TH_.EqUIpMENT ON WHICH THIS ENGINEIS USEDBEFOREATTEMPTING

TO OPERATEYJ)UR_CRAFTSMAN'E"NG1NE" " " .... - - " ....

ON THE ENGINE: FAST SLOW STOP OFF CHOKE FULL

IMPORTANT

KEEP THIS MANUAL HANDY AT ALL TIMES FOR FUTURE

REFERENCE. READ IT CAREFULLY AND FAMILIARIZE

YOURSELF WITH THE OPERATING, MAINTENANCE AND

SAFETY INSTRUCTIONS. THIS MANUAL ALSO CONTAINS A

COMPLETE PARTS LISTING.

"BEFORE STARTING

Be sure originalcontainer is marked:

A.P.I. service "SF'=-'SJ".

FOR SUMMER (ABOVE 32°F;0°C) USE SAE 30 OIL

Using muitigrade oil will increase oilconsumption.,

FOR WINTER (BELOW 32°F;0=C) USE SAE 5W30 OIL.

(SAE lOW isan acceptable substitute.)

DO NOT USE SAE 10W40 OIL

OIL SUMP CAPACITY: 32 ounces (2 pints).

A FRESH. CLEAN, UNLEADED REGULAR,

UNLEADED PREMIUM, OR REFORMULATED

AUTOMOTIVE GASOLINE ONLY. DO NOT USE

LEADED GASOLINE.

NOTE: DO NOT USE GASOLINE CONTAINING METHANOL

(WOOD ALCOHOL). Gasoline containing upto 10% ethanol or

grain alcohol ("Gasohoi'), or up to 15% M'I'BE (Methyl Tertiary

ButylEther), may be used butrequiresspecial care when engine

is unused for extended periods.

Sea "STORAGE" instructionco Page 4.

NOTE: Use clean oil and fuel and store in approved, clean

covered containers. Use clean till funnels.

Never use "stale"gasoline leftoverfrom lastseason or storedfor

long periods.

_JJ READALL INSTRUCTIONS PROVIDED WITH THE EQUIPMENT

ON WHICH THIS ENGINE IS USED.

(_) CHECK OIL LEVEL:

CAUTION: NEVER RUN ENGINE UNLESS OIL LEVEL IS

BE'PNEEN "FULL" AND "ADD" MARKS ON DIPSTICK.

CHECK OIL LEVEL OFTEN DURING ENGINE BREAK-IN,

NEVER RUN ENGINE UNLESS OIL RLL PLUG ISTIGHTENED

SECURELY INTO OIL FILL HOLE.

A. POSITION EQUIPMENT SO ENGINE IS LEVEL.

B. Clean area aroundoiltill plug (see Figure 1).

C. Remove oil fillplugand dipstick.

D. Wipe dipstick clean, insert it into oil fill hole and tighten

securely.

E. Remove oil till plug and check oil level. If level is not up to

"FULL" mark on dipstick,add recommended oil, until it is.

POUR SLOWLY. Wipe dipstickclean each time oil level is

checked.

DO NOT FILLABOVE "FULL"MARK ON DIPSTICK.

F. Replace oil tillplug and tighten securely.

Page 1

181-1192-11

BEFORE STARTING (Continued)

TO ENSURE ADEQUATE OIL SUPPLY:

_'k G. DISCONNECT SPARK PLUG WIRE FROM SPARK PLUG I

AND KEEP IT AWAY FROM SPARK PLUG.

H. Crank engine a few times with starter.

,1_ NOTE - DO NOT USE MOWER CU'I'I"ING BLADE OR ANY

OTHER A'rrACHMENT ON POWER TAKE-OFF END OF

I CRANKSHAFT TO CRANK ENGINE.

I. Re-check oil level per instructionsC, D, E and F.÷

J. Connect spark plug wireto spark plug.

See =MAINTENANCE" section for any futureoil level and oil

change instructions(see Page 2). !

(_ FILL FUEL TAN K withgaso,ne asspecified inthe preceding

"OIL & FUEL RECOMMENDATIONS," item 2.

NEVER MIX OIL WITH GASOLINE

Never use Ustale"gasoline leftover fromlastseasonor storedfor

long periods.

_ NEVER FILL FUELTANKINDOORS. NEVER FILL FUELTANK

WHEN ENGINE IS RUNNING OR HOT. DO NOT SMOKE WHEN

FILLING FUEL TANK.

_k NEVER FILL FUEL TANK COMPLETELY. FILL TANK TO 1/2"

BELOW Bo'rroM OF FILLER NECK TO PROVIDE SPACE

I FOR FUEL EXPANSION. WIPE ANY FUEL SPILLAGE FROM

ENGINE-AND EQUIPMENT BEFORE STARTING ENGINE.

. _1_ ANY LIQUEFIED PETROLEUM (LPG) OR NATURAL GASl

m I-FUEL S_fSTEM MUST BE LEAKPROOF AND MEET ALL I

APPLICABLE CODES AND REGULATIONS.

(_) CHECK THE FOLLOWING:

_ILA. BE SURE EQUIPMENT IS IN NEUTRAL GEAR WITH I

CLUTCHES, BELTS, CHAINS AND SAFETY SWITCHESI

DISENGAGED. (FOLLOW EQUIPMENT I

MANUFACTURER'S INSTRUCTIONS). THIS SHOULD

POSITION.PLACEANY SAFETY SWITCHES IN SAFE STARTING

B. Be surespark plug wire isattachedto sparkplug(see Figure

1).

C. Be sure any ignitionswitchon angine orequipment is in ON,

RUN orSTART position.

STARTING

,_ NEVER RUN ENGINE INDOORS OR IN ENCLOSED, POORLY

VENTILATED AREAS. ENGINE EXHAUST CONTAINS

CARBON MONOXIDE, AN ODORLESS AND DEADLY GAS

(CARBON MONOXIDE IS ALSO PRESENT IN ENGINE

EXHAUST FROM LIQUID PETROLEUM (LPG) AND NATURAL

GAS FUEL SYSTEMS).

,_ KEEP HANDS, FEET, HAIR AND LOOSE CLOTHING AWAY

FROM ANY MOVING PARTS ON ENGINE AND EQUIPMENT.

,_BE SURE AIR INTAKE SCREEN (see Fig. 1) IS SECURELY IN

PLACE TO AVOID CONTACT WITH MOVING PARTS.

_WARNING TEMPERATURE OF MUFFLER AND NEARBY

AREAS MAY EXCEED 15(PF (65°C). AVOID THESE AREAS.

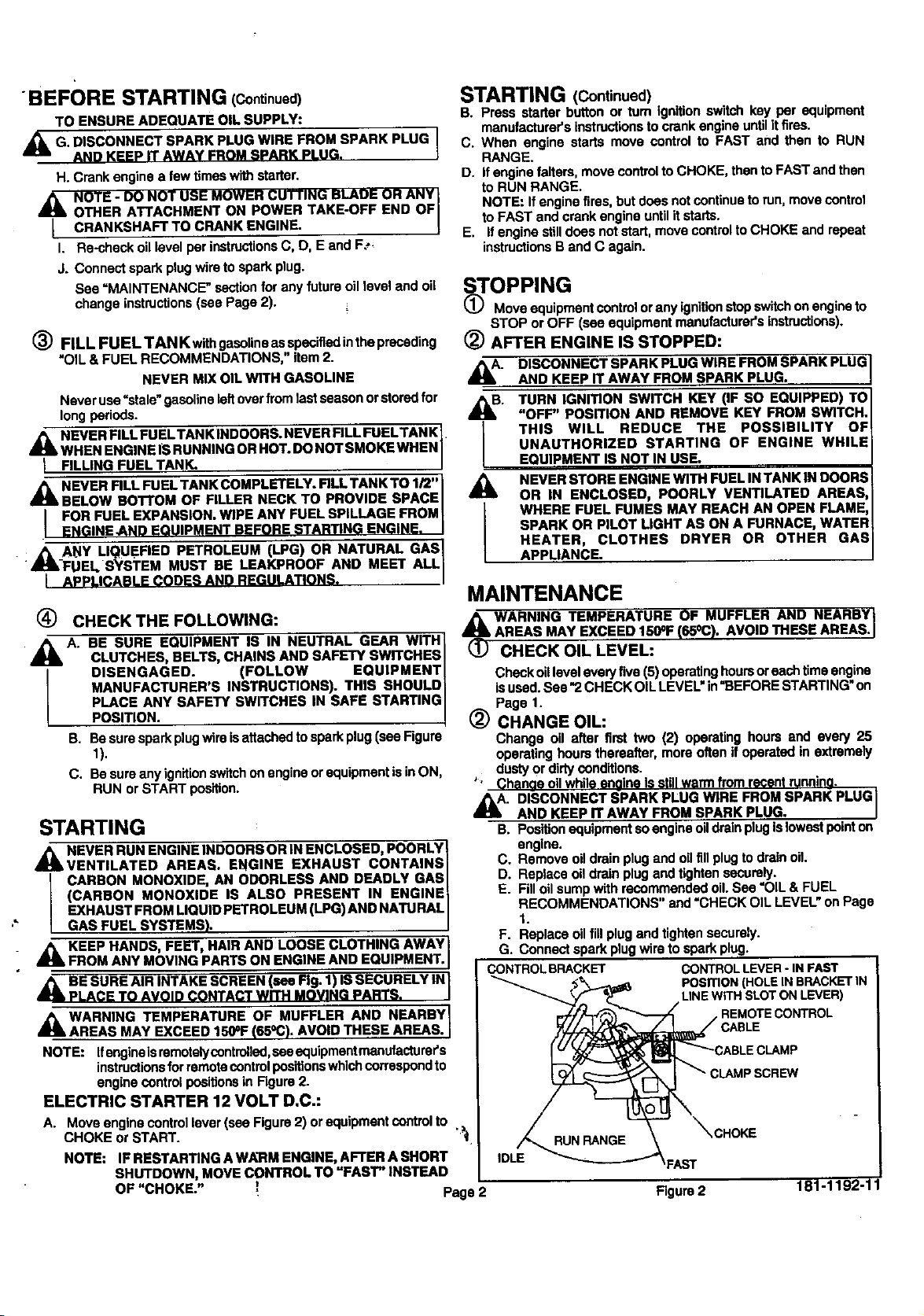

NOTE: Ifangine is mmotely controlled,seeequipmentmanufacturer's

ELECTRIC STARTER 12 VOLT D.C.:

A. Move anglne control lever (see Figure 2) or equipment control to

instructionsforremotecontrolpositionswhichcorrespondto

engine controlpositionsin Figure 2.

CHOKE or START.

NOTE: IFRESTARTING A WA'RM ENGINE, AFTER A SHORT

SHUTDOWN, MOVE CONTROL TO "FAST" INSTEAD

OF "CHOKE."

STARTING (Continued)

B. Press starter button or tum ignition switch key per equipment

manufacturer'sinstructionsto crank engine untilit fires.

C. When engine starts move control to FAST and then to RUN

I

RANGE.

D. Ifengine falters, move control to CHOKE, thento FAST and then

to RUN RANGE.

NOTE: If engine fires, butdoes not continue to run, move control

to FAST and crank engine untilitstarts.

E. If engine stilldoes notstart, move control to CHOKE and repeat

instructionsB and C again.

OPPING

Move equipment controlorany ignitionstop switchonengineto

STOP or OFF (see equipment manufacturer's instructions).

(_ AFTER ENGINE IS STOPPED:

,_A. DISCONNECT SPARK PLUG WIRE FROM SPARK PLUG

_. TURN IGNITION SWITCH KEY (IF SO EQUIPPED) TO

AND KEEP IT AWAY FROM SPARK PLUG.

"OFF" POSITION AND REMOVE KEY FROM SWITCH.

THIS WILL REDUCE THE POSSIBILITY OF

UNAUTHORIZED STARTING OF ENGINE WHILE

EQUIPMENT IS NOT IN USE.

NEVER STORE ENGINE WITH FUEL IN TANK IN DOORS

OR IN ENCLOSED, POORLY VENTILATED AREAS,

WHERE FUEL FUMES MAY REACH AN OPEN FLAME,

SPARK OR PILOT LIGHT AS ON A FURNACE, WATER

HEATER, CLOTHES DRYER OR OTHER GAS

APPLIANCE.

MAINTENANCE

_WARN NG TEMPERATURE OF MUFFLER AND NEARBY

AREAS MAY EXCEED 150°F (650C). AVOID THESE AREAS. J

_.) CHECK OIL LEVEL:

Check oillevel every five (5) operatinghoursoreach time engine

isused. See "2CHECK OIL LEVEL" in"BEFORE STARTING" on

Page 1.

(_ CHANGE OIL:

Change oil after first two (2) operating hours and every 25

operating hours thereafter, more often ifoperated in extremely

dusty or dirty conditions.

_' Chanoe oilwhile enoine isstillwarm from recent runnine.

,_A. DISCONNECT SPARK PLUG WIRE FROM SPARK PLUG

AND KEEP ITAWAY FROM SPARK PLUG.

B. Positionequipment so engine oildrain plugislowestpoint on

engine.

C. Remove oil drain plug and oilfill plugto drain oil.

D. Replace oil drain plug and tighten securely.

E. Fill oilsump with recommended oil. See "OIL & FUEL

RECOMMENDATIONS" and "CHECK OIL LEVEL" on Page

I.

F. Replace oil fillplug and tighten securely.

G. Connect spark plug wire to spark plug.

CONTROLBRACKET CONTROLLEVER- INFAST

POSITION(HOLEINBRACKETIN

LINEWiTH SLOTON LEVER)

REMOTECONTROL

'_ _CHOKE

IDLE

Page 2 Figure 2

181-1192-1

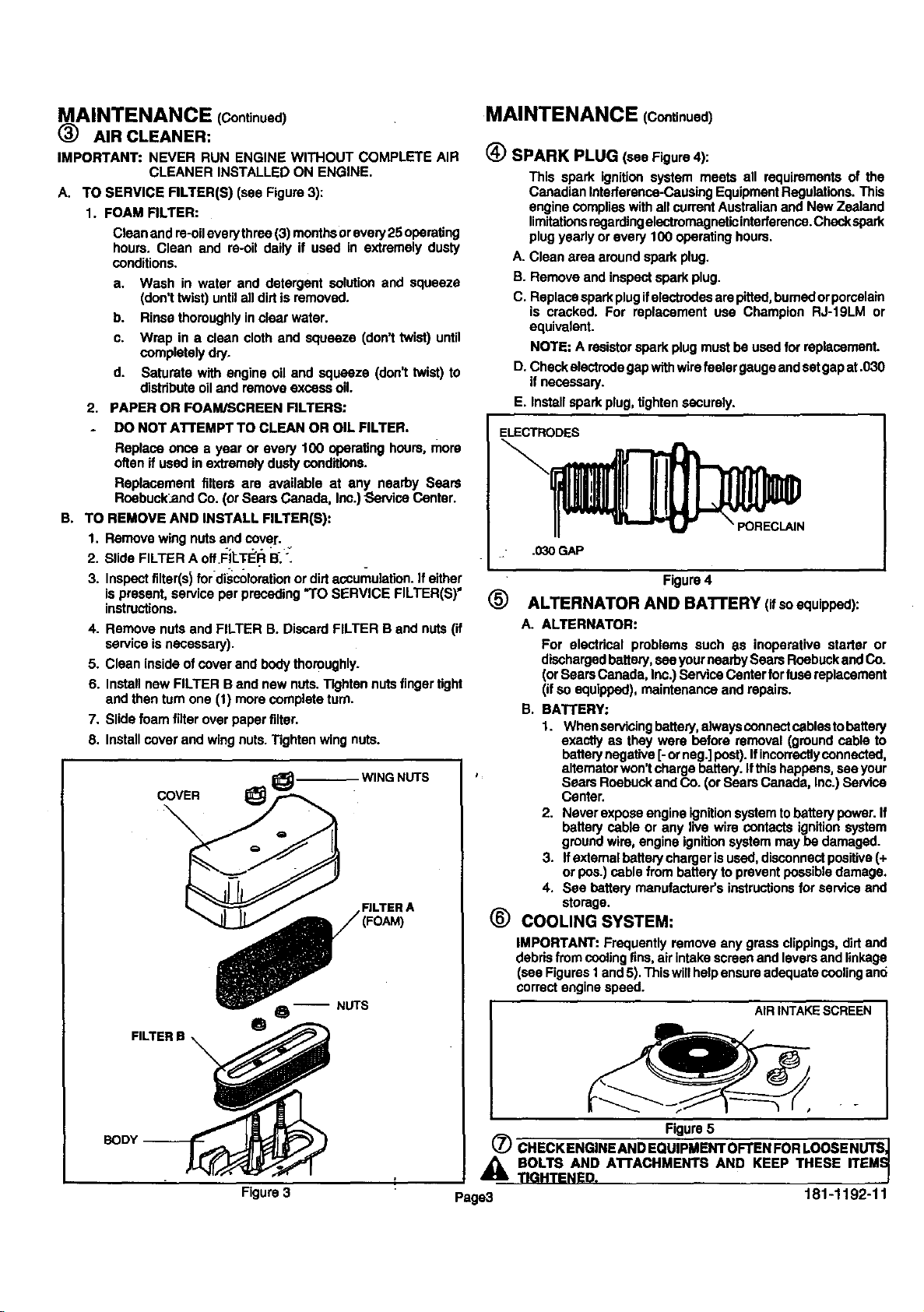

MAINTENANCE (Continued)

(_) AIR CLEANER:

IMPORTANT: NEVER RUN ENGINE WITHOUT COMPLETE AIR

A. TO SERVICE FILTER(S) (see Figure3):

1. FOAM FILTER:

2. PAPER OR FOAM/SCREEN RLTERS:

B. TO REMOVE AND INSTALL FILTER(S):

1. Remova wing nuts and cover.

2. Slide FILTER A Off.l_it.TF?l_l

3. Inspect tilter(s) fordiscoloration or dirt accumulation.If either

4. Remove nuts and FILTER B. Discard FILTER B and nuts(if

5. Clean inside of cover and body thoroughly.

6. Install new FILTER B and new nuts. Tighten nuts fingertight

7. Slide foam filter over paper tilter.

8. Installcover and wing nuts. Tighten wing nuts.

CLEANER INSTALLED ON ENGINE.

Clean and re-oilevery three(3) monthsorevery 25 operating

hours. Clean and re-oil daily if used in extremely dusty

conditions.

a. Wash in water and detergent solution and squeeze

(don't twist)untilall dirt is removed.

b. Rinse thoroughlyinclear water.

c. Wrap in a clean cloth and squeeze (don't twist) until

completelydry.

d. Saturate with engine oil and squeeze (don't twist) to

distributeoil and remove excess oil.

DO NOT A'rFEMPT TO CLEAN OR OIL FILTER.

Replace once a year or every 100 operating hours, more

often if used in extremelydusty conditions.

Replacement filters are available at any nearby Sears

Rcebuck_and Co. (or Seam Canada, Inc.)_ervice Center.

B.

is present, service per preceding "TO SERVICE FILTER(S)"

instructions.

service is necessary).

and then turnone (1) more complete turn.

WING NUTS

COVER

\

.RLTERA

6

FILTER B

MAINTENANCE (ConUnued)

(_ SPARK PLUG (see Figure 4):

This spark ignition system meets all requirements of the

Canadian Interference-Causing EquipmentRegulations. This

engine complies with all currentAustralianand New Zealand

limitationsregardingelectromagneticinterference.Checkspark

plugyeady orevery 100 operating hours.

A. Clean area around spark plug.

S. Remove and inspectspark plug.

C. Replacespark plugifelectrodes are pitted,bumed orporcelain

is cracked. For replacement use Champion RJ-19LM or

equivalent.

NOTE: A resistorspark plug must be used for replacemonL

D. Check electrode gapwith wirefeeler gauge andset gapat .030

if necessary.

E. Installspark plug, tighten securely.

ELECTRODES

: .030 GAP

Figure4

_) ALTERNATOR AND BATTERY (ifsoequipped):

/L ALTERNATOR:

For electrical problems such 8s inoperative starter or

dischargedbattery,see your nearbySears Roebuck and Ca.

(orSears Canada, Inc.) Service Center for fuse replacement

(ifso equipped), maintenance and repairs.

B. BATTERY:

1. Whan earvicin9 battery, always connect cablssto battery

exactly as they were before removal (groundcable to

batterynegative [- orneg.] post).If incorrecgyconnected,

alternator won't charge battery. If thishappens, see your

Sears Roebuckand Co. (orSears Canada, Inc.)Sewise

Center.

2. Neverexpose engine ignitionsystemto battery power. If

battery cable or any live wire contacts ignition system

groundwire, engine ignitionsystem may be damaged.

3. Ifexternalbatterycharger is used, disconnectpositive(+

or pos.) cable frombattery to prevent possibledamage.

4. See battery manufacturer's instructions for service end

storage.

I_) COOLING SYSTEM;

IMPORTANT: Frequently remove any grass clippings, dirtand

debrisfromcoolingfins, air intakescreen and levers and linkage

(see Figures 1 and 5), This willhelpensure adequate coolingand

correct engine speed.

AIRINTAKESCREEN

Figure3

Figure5

(_ CHECK ENGINE AND EQUIPMENT OFTEN FOR LOOSE NUTSJ

J

_lL BOLTS AND ATTACHMENTS AND KEEP THESE ITEMS_

TIGHTENED. /

Page3 t81-1192-11

Loading...

Loading...