Craftsman 143989005 Owner’s Manual

, .ARS

operator's

manual

MODEL NO. 143.989005

SOLID STATE IGNITION

ENGIN

CAUTION:

Read RULES for

Safe OPERATION

and INSTRUCTIONS

Carefully

A

PrintedinU.S.A. 9-1-97 181-11.,51-11

California Proposition 65 WARNING: The=,gi,,o_,_a,,,, from this product contains chemicals [

known to theState of California to cause cancer, birthdefects or other reproductive harm.

Sold by SEARS, ROEBUCK AND CO., CHICAGO/IL 60684 U.S.A.

and SEARS CANADA, INC., TORONTO, ONTARIO, CANADA

• Operating

• Maintenance

• Repair Parts

I

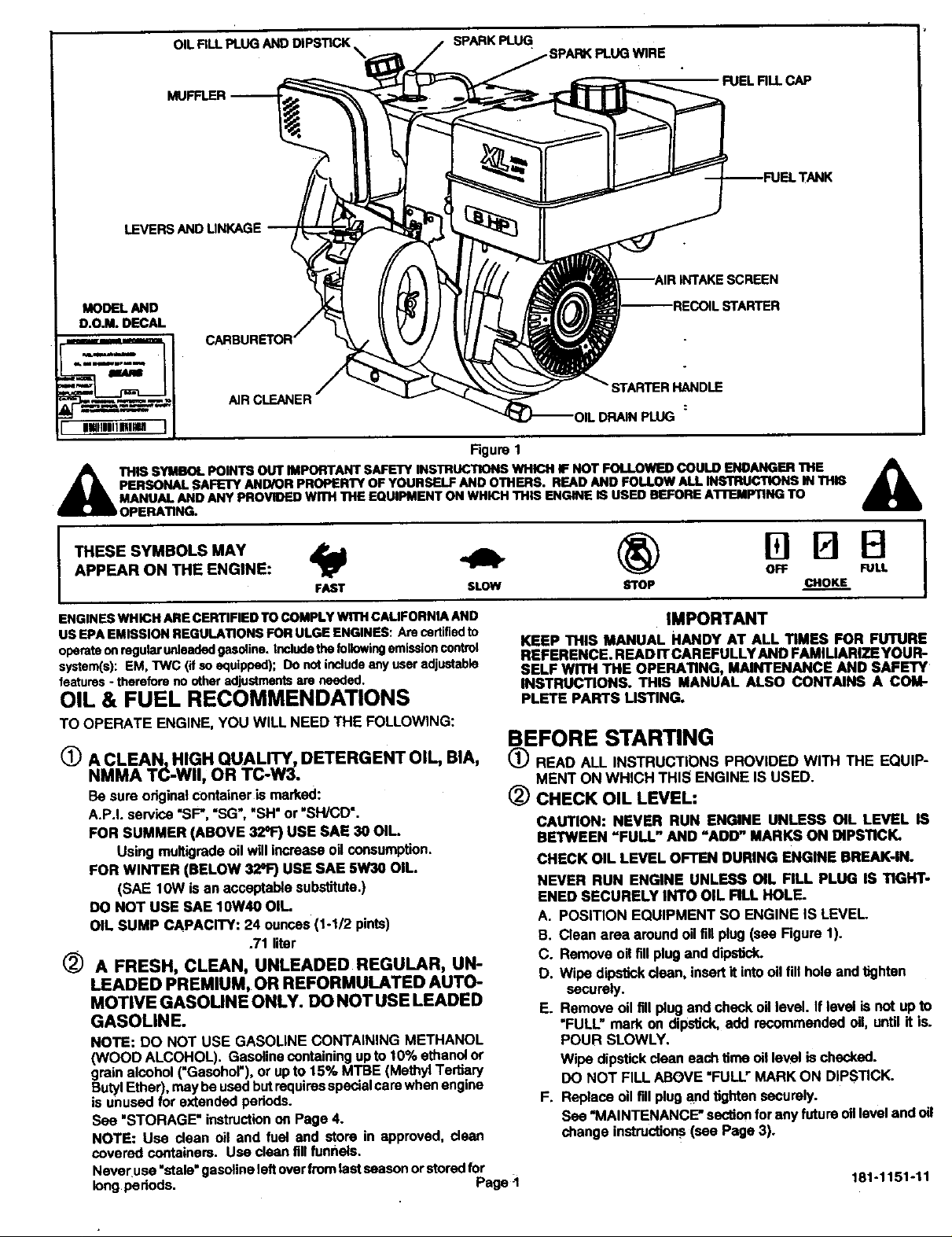

LEVERSAND LINKAGE

MODEL AND

D.O.M. DECAL

OIL FILLPLUGANDDIPSTICK \ SPANKPLUG. _1WIRE

FUELRLL CAP

TANK

NR CLEANEI

I lllllllllllllllJ I

STARTER HANDLE

Figure1

A 11"11SSYMBOL POINTSOUT IMPORTANTSAFETYINSTRUCTIONSWHICH IFNOT FOLLOWEDCOULD F.NOANGER11tE h

ENGINESWHICH ARECERTIFIEDTO COMPLY wrnt CALIFORNIA AND

US EPA EMISSION REGULATIONS FORULGE ENGINES: Are certifiedto

operateonregularunleadedgasoline.Includethe followingemissioncontrol

system(s): EM, "nNC(ifso equipped); Donot includeanyuseradjustable

features- therefore nootheradjustmentsare needed.

OIL & FUEL RECOMMENDATIONS

TO OPERATE ENGINE, YOU WILL NEED THE FOLLOWING:

PERSONAL SAFETYAND/OR PROPERTY OFYOURSELFAND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN

MANUAL AND ANY PROVIDEDwrrH THEEQUIPMENT ON WHICHTHIS ENGINE ISUSED BEFORE ATI--/=MPTINGTO

OPERATING.

APPEAR ON THE ENGINE: SLOW CHOKE

IMPORTANT

KEEP THIS MANUAL HANDY AT ALL TIMES FOR FUTURE

REFERENCE. READITCAREFULLY AND FAMIMARIZEYOUR-

SELF WITH THE OPERATING, MAINTENANCE AND SAFETY

INSTRUCTIONS. THIS MANUAL ALSO CONTAINS A COM-

PLETE PARTS LISTING.

BEFORE STARTING

(_) A CLEAN, HIGH QUALITY, DETERGENT OIL, BIA,

NMMA TC-WII, OR TC-W3.

Besure originalcontainerismarked:

A.P.I. service"SF*,"SG', "SH"or "SWCD'.

FOR SUMMER (ABOVE 32q=)USE SAE 30 OIL.

Usingmultigradeoilwillincreaseoilconsumption.

FOR WINTER (BELOW32_') USESAE 5W30 OIL.

(SAE 10W isanacceptablesubstitute.)

DO NOT USE SAE 10W40 OIL

OIL SUMP CAPACITY: 24 ounces(1-1/2 pints)

.71 liter

(_) A FRESH, CLEAN, UNLEADED REGULAR, UN-

LEADED PREMIUM, OR REFORMULATED AUTO-

MOTIVE GASOLINE ONLY. DO NOT USE LEADED

GASOLINE.

NOTE: DO NOT USE GASOLINE CONTAINING METHANOL

(WOOD ALCOHOL). Gasoline containing up to 10% ethanol or

grain alcohol (=Gasohol'), or up to 15% MTBE (Methyl Tertiary

Butyl Ether), may be used but requires special care when engine

is unused for extended pedods.

See "STORAGE" instruction on Page 4.

NOTE: Use clean oil and fuel and store in approved, clean

covered containers. Use clean fill funnels.

Never use "stale" gasoline left overfrom last season or stored for

long pedods. Page -1

(_ READ ALL INSTRUCTIONS PROVIDED WITH THE EQUIP-

MENT ON WHICH THIS ENGINE IS USED.

(_) CHECK OIL LEVEL:

CAUTION: NEVER RUN ENGINE UNLESS OIL LEVEL IS

BETWEEN =FULL" AND =ADD" MARKS ON DIPSlllCK.

CHECK OIL LEVEL OFTEN DURING ENGINE BREAK-IN.

NEVER RUN ENGINE UNLESS OIL RLL PLUG IS TIGHT-

ENED SECURELY INTO OIL FILL HOLE.

A. POSITION EQUIPMENT SO ENGINE IS LEVEL

B. Clean area aroundoilfillplug(see Figure1).

C. Removeoilfill plugand dipstick.

D. Wipe dipstickclean,insertitintooilfill hole andtighten

securely.

E. Removeoil fillplugand checkoillevel. If levelis not upto

=FULL"mark on dipstick,add recommendedoil,untilit is.

POUR SLOWLY.

Wipedipstickcleaneach timeoil level ischecked.

DONOT FILL ABOVE "FULL"MARK ON DIPSTICK.

F. Replace oilfillplug andtightensecurely.

See "MAINTENANCE" sectienforany futureoillevelandoil

changeinstructions(see Page3).

181-1151-11

BEF ORE STARTING (Con ued)

(_ RLL FUEL TANK withgasoline as specifiedinthe preced-

ing "OIL & FUELRECOMMENDATIONS" item2.

NEVER MIX OIL WITH GASOUNE

Neveruse"stale"gasolineleftoverIromlastseasonorstored for

longperiods.

NEVER FILL FUEL TANK INDOORS. NEVER FILL FUEL

TANK WHEN ENGINEIS RUNNINGOR HOT.DONOTSMOKE

WHEN FILUNG FUEL TANK.

NEVER FILL FUEL TANK COMPLETELY,FILL TANKTO1/2"

BELOW BOTTOM OF FILLER NECK TO PROVIDE SPACE

FOR FUEL EXPANSION.WIPE ANY FUEL SPILLAGE FROM

I ENGINE AND EQUIPMENT BEFORE STARTING ENGINE.

_P PETROLEUM (LPG) OR NATURAL GAS

_ST BE LEAKPROOF AND MEET ALLI

I APPUCABLE CODES AND REGULATIONS. I

(_) CHECK THE FOLLOWING:

_. BE SURE EQUIPMENT IS IN NEUTRAL GEAR WITH I

CLUTCHES, BELTS, CHAINS AND SAFETY SWITCHES I

DISENGAGED. (FOLLOW EQUIPMENT MANUFACTUR.I

ER'S INSTRUCTIONS.) THIS SHOULD PLACE ANY

SAFETY SWITCHES IN SAFE STARTING POS TION.

B. Besuresparkplugwireis attachedtosparkplug(see Figure

1).

C. Be surestopswitch(see Figure1) nexttosparkplugis not

contactingspark plug.

D. Besureany ignitionswitchonengineor equipmentisinON,

RUN or START position.

@

IGNITION SWITCH

STAR_R_

HANDLE 1- RECOIL

Figure 2

CHOKE LEVER

FULLCHOKE POSITION

\

2 - ELECTRIC

STARTING

_. NEVER RUN ENGINEINDOORSOR IN ENCLOSED,POORLY

VENTILATED AREAS. ENGINEEXHAUST CONTAINS CAR-

BON MONOXIDE, ANODORLESS AND DEADLYGAS (CAR-

BON MONOXIDE IS ALSO PRESENT IN ENGINE EXHAUST

FROM UQUID PETROLEUM (LPG) AND NATURAL GAS

I FUEL SYSTEMS).

_KEEP HANDS, FEET, HAIR AND LOOSE CLOTHING AWAY

FROM ANY MOVING PARTS ON ENGINE AND EQUIPMENT.

_k WARNING: TEMPERATURE OFMUFFLER AND NEARBY

a AREAS MAY EXCEED 150°F (65_C). AVOID THESE AREAS.

(_ RECOIL STARTER (see Figures2and 3):

A. MoveCHOKE LEVERto FULLCHOKE POSITION.

NOTE: IF RESTARTING A WARM ENGINE AFTER A

SHORT SHUTDOWN, MOVE CHOKE LEVER TO

"NO CHOKE POSITION."

B. Move EQUIPMENT CONTROL to START (see equipment

manufacturer's !nstructions).

C. Grasp starter handle (see Figure 2) and pull rope out, slowly,

until it pulls slightly harder. Let rope rewind slowly.Then pull

rope with a rapid full arm stroke. Let rope rewind SLOWLY.

Do not let starter handle snap back against starter.

D. Repeat instruction C until engine rims. When engine starts,

move CHOKE LEVER to 1/2 CHOKE until engine runs

smoothly and then to NO CHOKE POSITION.

If engine falters, move CHOKE LEVER to 1/2 CHOKE until

engine runs smoothly and then to NO CHOKE POSITION.

NOTE: If engine rims, but does not continue to run, move

If engine again rims, but does not continue to run, move

CHOKE LEVER to FULL CHOKE POSITION and repeat

instruction C and D until engine starts.

®

ELECTRIC STARTER (see Figures 2 and 3):

A. Move CHOKE LEVER to FULL CHOKE POSITION.

NOTE: IF RESTARTING A WARM ENGINE AFTER A SHORT

B. Move EQUIPMENT CONTROLto START (see equipment

manufacturer'sinstructions).

C. Pushstarterbuttonorturnignitionswitchkey(seeequipment

manufacturer'sinstructions)tocrank engine.

D. Crank engine untilit fires. When it starts,release starter

buttonor ignitionswitchkeyand move choke lever to 1/2

CHOKE untilenginerunssmoothlyandthento NO CHOKE

POSITION.

If engine falters, move CHOKE LEVER to 1/2 CHOKE until

enginerunssmoothlyand then to NO CHOKEPOSITION.

NOTE: If engine rims, but does not continueto run, move

CHOKE LEVER to NO CHOKE POSITION and

repeat instruction C until engine starts.

SHUTDOWN, MOVE CHOKE LEVER TO "NO CHOKE

POSITION."

CHOKE LEVER to NO CHOKE POSITION and repeat

instructionsC and D untilenginestarts.

Figure 3

Page 2 181-1151-11

S[TOPPING

Moveequipmentcontrolorany ignitionstopswitchonengineto

STOP orOFF (see equipmentmenufactumr'sinstructions).

_) Pushstopswitch(see Figure 1) locatednextto spark plugon

engineagainstsparkplugandholditinthispositionuntilengine

iscompletelystopped.

AFTER ENGINE IS STOPPED:

_A. DISGONNEGTSPARK PLUG WIRE FROM SPARKPLUG

AND KEEP IT AWAY FROM SPARK PLUG.

_kB. TURN IGNmON SWITCH KEY (IF SO EQUIPPED) TO

"OFF" POSITION AND REMOVE KEY FROM SWITCH.

RIZED STARTING OF ENGINE WHILE EQUIPMENT IS

NOT IN USE.

THIS WILL REDUCE THE POSSIBILITY OF UNAUTHO-

NEVER STORE ENGINE WITH FUEL IN TANK INDOORS I

OR IN ENCLOSEO, POORLY VENTILATED AREAS I

WHERE FUEL FUMES MAY REACH AN OPEN FLAME,[

SPARK OR PILOT LIGHT AS ON A FURNACE, WATER I

HEATER, CLOTHES DRYER OR OTHER GAS APPLI-I

ANcE. : I

MAINTENANCE

_WARNING: TEMPERATURE OF MUFFLER AND NEARBY

AREAS MAY EXCEED 150=F (65°C). AVOID THESE AREAS.

1(!) CHECK OIL LEVEL:

Checkoilleveleveryfive(5)opamtinghoursoreachtimeengine

isused. See "2 CHECK OIL LEVEL"in "BEFORE STARTING"

on Page 1.

(_) CHANGE OIL:

Change oil after first two (2) operating hours and every 25

operating hours thereafter, more often if operated in extremely

dusty or dirty condltlens. Change oil while engine is still warm

from recent running.

A. Position equipment so engine oil drain plug is lowest pointon

engine (see Rgure 1).

B. Remove oil drain plug and oil fill plug to drain oil.

C. Replace oil drain plug and tighten securely.

D. Fill oil sump with recommended oil. See "OIL & FUEL

RECOMMENDATIONS" and "CHECK OIL LEVEL" on Page

1.

E. Replace oilfigplugandtighten securely.

F. Wipeup anyspilledoil.

(_) AIR CLEANER (see Figure4):

NEVER RUN ENGINEWITHOUT COMPLETE AIR CLEANER

INSTALLED ON ENGINE.

A. TO SERVICE RLTER(S) (see Figura 4):

1. FOAM RLTER:

Clean and re-oilevery three (3) monthsor every 25

operatfilg hours. Clean and re-oil dally if used in

extremelydustyconditions.

a. Washinwateranddstergentsolutionandsqueeze

(don'ttwist)untilall didisremoved.

b. Rinsethoroughly in dear water.

c. Wrap ina clean clothand squeeze (don't twist)

untilcompletelydry.

d. Saturatewithengineoil andsqueeze(don_twist)

to distributeoil and removeexcessoil.

2. PAPER RLTER:

DO NOTATTEMPT TO CLEAN OR OIL FILTER.

Replace oncea year or every 100 operatinghours,

more oftenifusedin extremely dustyconditions.

Replacementfiltersare availableat any Sears Roe-

buckandCo.(orSears Canada, inc.)ServiceCenter.

MAINTENANCE (continued)

B. TO REMOVE AND INSTALL FILTER(S)

1. Removewingnutand cover.

2. Slidefoam filteroffpapertilter.

3. Inspectfiltersfordiscolorationordirtaccumulation.If

eitheris present,serviceperpreceding"TOSERVICE

FILTER(S)"instructions.

4. Cleaninsideof base and coverthoroughly.

5. Installnewpaperfilteron base.

6. Slidefoam filter over papertilter.

7. Installcoverandwingnut. Tightenwingnutsecurely.

BASE APERRL1 (__t

(_) SPARK PLUG (see Figure5):

Thissparkign_on systemmeetsall requirementsoftheCana-

dianInterference-CausingEquipmentRegulations.Thisengine

complies withallcurrentAustralianandNew Zealandlimitations

regardingelectromagneticinterference.Checksparkplugyear-

ly orevery100 operatinghours.

A. Clean area aroundsparkplug.

B. Remove andinspectsparkplug.

C. Replacesparkplugifelectrodesarepitted,burnedorporce-

lainis cracked.For replacementuse ChampionRJ17LM.

NOTE: A resistorsparkplugmust beusedfor replacement.

D. Checkelectrodegapwithwire feelergauge and setgapat

.030 ifnecessary.

E. Installsparkplug,tightensecurely.

ELECTRODES PORCELAIN

.O3OGAP

(_ COOUNG SYSTEM

IMPORTANT: Frequentlyremoveanygrassclippings,dirtand

debrisfrom coolingfins,airintakescreenandleversandlinkage

(see Figure 6). This will help ensure adequate coolingan_

correctenginespeed.

LINKAGE

Page 3

FOAMNL'I_R

Figure4

Figure5

COOLING FINS

INTAKE SCREEN

Figure 6 181-1151-11

Loading...

Loading...