Craftsman 143.625082 Owner's Manual

Sears

MODEL NUMBER:

143.625082

5 H.

P.

owners

manual

CRAFTSMAN

ENGINES

~AUT

Read

Carefully

ION

Instructions

Assembly

Operating

Repair Parts

Form

No.

692719

SEARS,ROEBUCK AND

SIMPSONS - SEARS LIMITED.

CO.

U.S.A.

CANADA

Printed in U.S.A.

-

Be

Sure

To

Observe

CAUTION

I

1. Stop the engine whenever you

all moving parts

away

specting or repairing.

2.

Check fuel before

always handle

3. Do

deadly poison.

provide sufficient ventilation.

4.

tions in

5.

guards in

6.

from

is

hot. Wipe

not

run engine indoors, exhaust

For

engines equipped

your

Disengage self propelling

place.

Don't

protect

change governor settings

the engine

have

stopped, disconnect the spark plug wire

plug

to

prevent accidental starting before cleaning, making any adjustments, in-

each

off

any spilled gasoline before starting engine - - gasoline

with

care.

If

for

some

with a No

engine manual.

from

using. Do

reason

unit

damaging, excessive

Safety

Precautions

I

To

Prevent

leave

the equipment,

not

fill

gasoline

gases

contain carbon monoxide which

engine must

Pull Starter, be

or

drive clutch on units

or

overspeed the engine. The governor controls the

speeds.

even

for

a moment. Make sure blades and

from

tank

when engine

be

run indoors, open all doors

sure

and

read

the handling and safety precau-

so

equipped before starting engine- - Keep

Excessive

speeds

Accidents

the plug and keep wire

is

running

are

or

is

highly

is

odorless

and

dangerous.

while engine

flammable-

and

windows

speed

to

and

v

Don't

7.

open flame

8.

Never

9. Keep

equ

10.

If

parts. Vibration generally

1.

READ

2.

MAKE

3. FOR

ROEBUCK

SALES

store equipment

or

spark. Let the engine cool before storing in any enclosure.

leave

engine running unattended.

all screws, nuts

ipment clean

your

equipment should start vibrating, stop the engine and check

ALL

INSTRUCTIONS

ONLY

ANY

THE

MAJOR ADJUSTMENTS OR REPAIRS CONTACT

AND

OFFICE

with

fuel in the

and

bolts

tight

to

be

at

all times.

is

a warning

IMPORTANT

CAREFULLY

SIMPLE ADJUSTMENTS AS

CO. OR SIMPSON-SEARS

STORE.

tank

inside a building where fumes may reach

sure

equipment

of

trouble.

BEFORE OPERATING

OUTLINED

RETAIL,

is

in

IN

MAIL

safe

THIS

THIS

YOUR

OP.erating

for

ENGINE.

BOOK.

NEAREST SEARS,

ORDER

damage

condition.

or

OR

CATALOG

an

~

Keep

loose

4. KEEP

CAREFULLY

ANCE INSTRUCTIONS.

THIS

BOOK

AND

HANDY

FAMILIARIZE

AT

THIS

ALL

TIMES

YOURSELF

BOOK

ALSO

2

FOR

CONTAINS

WITH

FUTURE

THE

REFERENCE .

OPERATING

A COMPLETE PARTS

AND

MAINTEN-

READ

LISTING.

IT

CRAfTSMAN

We

guarantee all Craftsman Engines

ship. When

stall,

without

proves, upon

properly used, cared

cost

to

you, for a period

our

examination,

QUALITY

GUARANTEE

to

be

free

from

for

, and maintained,

of

one (1) year

to

be defective under normal

ENGINE

defects in material

we

will

replace at our

from

date

of

use

.

and

option

sale,

any part which

workman-

and in-

This guarantee does

of

spark plu

by

normal

care,

lubricants.

Damage

iron pipe, walk

Equipment

days.

neg

ligence,

resulting

gs,

use

used

cleanin

and wear

abuse,

from

edge,

for

C U S T 0 M E R' S R E S P 0 N S I B I L I T I E S

Always

moving parts, belts

Avoid striking

the

clean and check

and change

area

use

care when operating mechanical

or

running

of

foreign objects such

for

it

as

outlined

not

cover adjustments

g,

sharpening

nor

failure

striking solid

etc.)

is

rental

or

cha

ins. Do

into

loose bolt

in

to

carburetors, !gnition points, replacement

of

blades,

does

it

to

lubricate proper

or

foreign objects (rocks, tree roots, sprinkler

not

covered

or

commerci

not

solid objects

as:

sticks, stones, wire, etc. Keep

s, nuts and fasteners. Check the engine oil r

your

engine manual.

or

any

service

cover any failures which

ly

by

this

guarantee.

al

purposes

or

powered equipment. Keep clear

work

on equipment

or

debris in the area

or

or

use

is

guaranteed

SEARS, ROEBUCK

adjustment made

are

a result

of

contaminated fuels

only

with

the engine running .

to

be

your

necessary

of

improper

or

heads,

for thi

worked. Clear

rty

(30)

AND

CO.

equipment

egu

larly

of

Your

to

of

guarantee is intended

defects in material

parts due

to

normal wear

or workm

to

provide you w

ansh

or

use

nor

ip

but

does

ith

it

does

it

cover dam

3

adequate protection

not

cover adjustments

age

that may result

agai

nst failures due

or rep

lacem

in

use

.

ent

•

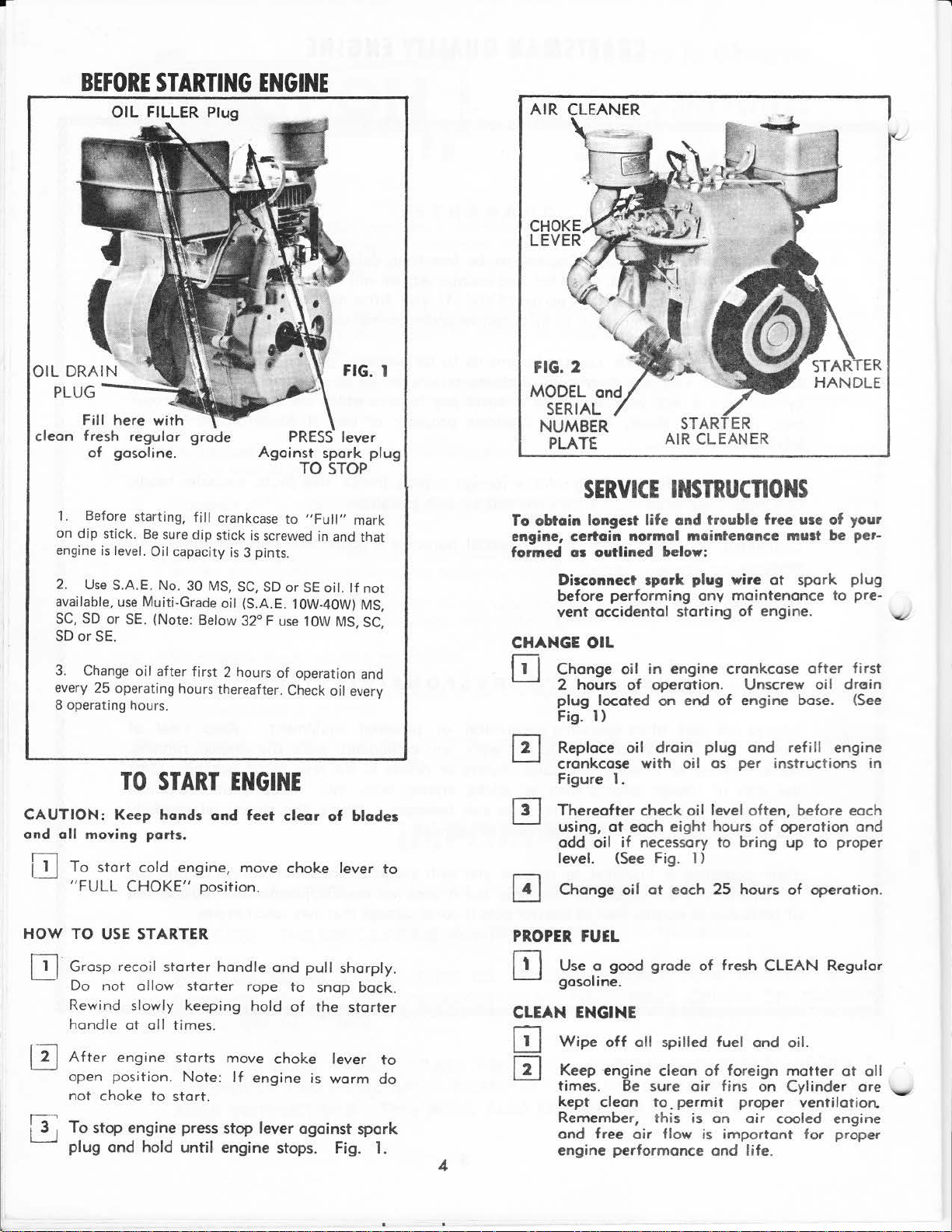

clean

1.

on

engine

dip

BEFORE

Fill

fresh

of

Before starting, fi

stick.

is

STARTING

OIL FILL

here

regular

gasoline.

level. Oil capacity

with

Be

ER

sure

Pl

ug

grade

ll

crankcase to

dip

stick

is

ENGINE

Against

is

screwed in and that

3 pints.

TO

"Full"

spark

STOP

lever

mark

plug

AIR CLEANER

FIG.

2

MODEL

SERIAL

NUMBER

PLATE

SERVICE

To

obtain

engine,

formed

longest

certain

as

outlined

and

life

normal mainte

STARTER

AIR CLEANER

INSTRUCnONS

and

trouble

below:

free

nance

use

must

of

be

your

per-

2.

Use

S.A.E. No. 30 MS,

available,

SC,

SO

3.

every 25 operating hours thereafter.

8 operating hours.

CAUTION:

and

all moving

[!] To

"FULL

HOW

[D. Grasp recoil

Do

Rewind slowly

handle

0

After

open

not

use

SO

or

or

SE.

SE.

Change

TO

Keep

start

CHOKE"

TO

USE

not

at

engine

position. Note:

choke

Muiti·Grade oil (S.A.E. 10W-40W)

(Note: Below 32°

oil

after first 2 hours

START ENGINE

hands

parts.

cold

STARTER

starter

allow

all times.

to

and

engine,

position.

starter

keeping

starts

start.

r::,

~

To

stop

plug

engine

and

press

hold until

SC,

feet

move

handle

rope

hold

move

If

engine

stop

engine

SO

or

SE

oil.

Fuse

10W

MS

of

operation and

Check

oil

clear

of

choke

and

to

of

choke

lever

stops. Fig. 1.

lever

pull sharply.

snap

the

lever

is

warm

against

If

not

MS,

SC

' '

every

blades

to

back.

starter

to

do

spark

Disconnect

before

vent

occidental

spark

performing

starting

plug

wire

any

maintenance

of

at

spark

engine.

to

plug

pre-

..._d

CHANGE OIL

[!]

PROP

QJ

Change

2

plug

Fig. 1)

Replace oil

crankcase

Figure 1.

Thereafter

using,

odd

level. (See Fig.

Change

ER

Use a good

gasoline.

hours

located

oil

FUEL

oil in

at

if

oil

engine

of

operation. Unscrew oil

on

drain

with oil

check

each

eight

necessary

at

each

grade

crankcase

end

of

plug

as

oil level

hours

to

1)

25

of

fresh CLEAN Regular

engine

and

per

ofte

bring

hours

bose. (See

refill

instructions in

n,

before

of

operation

up

of

after

first

dr"in

engine

each

and

to

proper

operation.

CLEAN ENGINE

[!]

[I]

4

Wipe

off

Keep ·

engine

times. Be

kept

clean

Remember,

ond

free

engine

performance

all spilled fuel

clean

sure

to.

this

air

permit

flow

of foreign

air

fins

is

on

is

important

and

and

on

proper

air

cooled

life.

oil.

matter

Cylinder

at

ventilation.

engine

for

proper

all

ore

Your

cleaner

cleaned

~nce.

engine

SERVICE

is

equipped

and

must

be

to

maintain

AIR

CLEAN

with o dry

periodically

maximum

ER

removed

engine

type

air

and

perform-

CA

RBURETOR

Do

not

make unnecessary

tory

settin~s

If

adjustments

After

below (Fig .

Turn

word

runs

unit

Hold

making

"High

or

back

smoothly.

is in

use

throttle

ADJUSTMENT

are

correct for

are

needed

initial

4)

start

Speed

l/t1

turn at a time

If

engine

open

lever

adjustments.

most

proceed

adjustments

engine

Adjusting

tends

needle

in

%

idle

aeplication

as

.

Needle"

until

to

turn.

position

follows:

os

engine

stall

.

Fac-

s.

shown

for

when

.-

BODY

/

/

~ATTACHING

SCREW

To

clean,

brocket. Twist

then

OJ

W

m

0

loosen

proceed

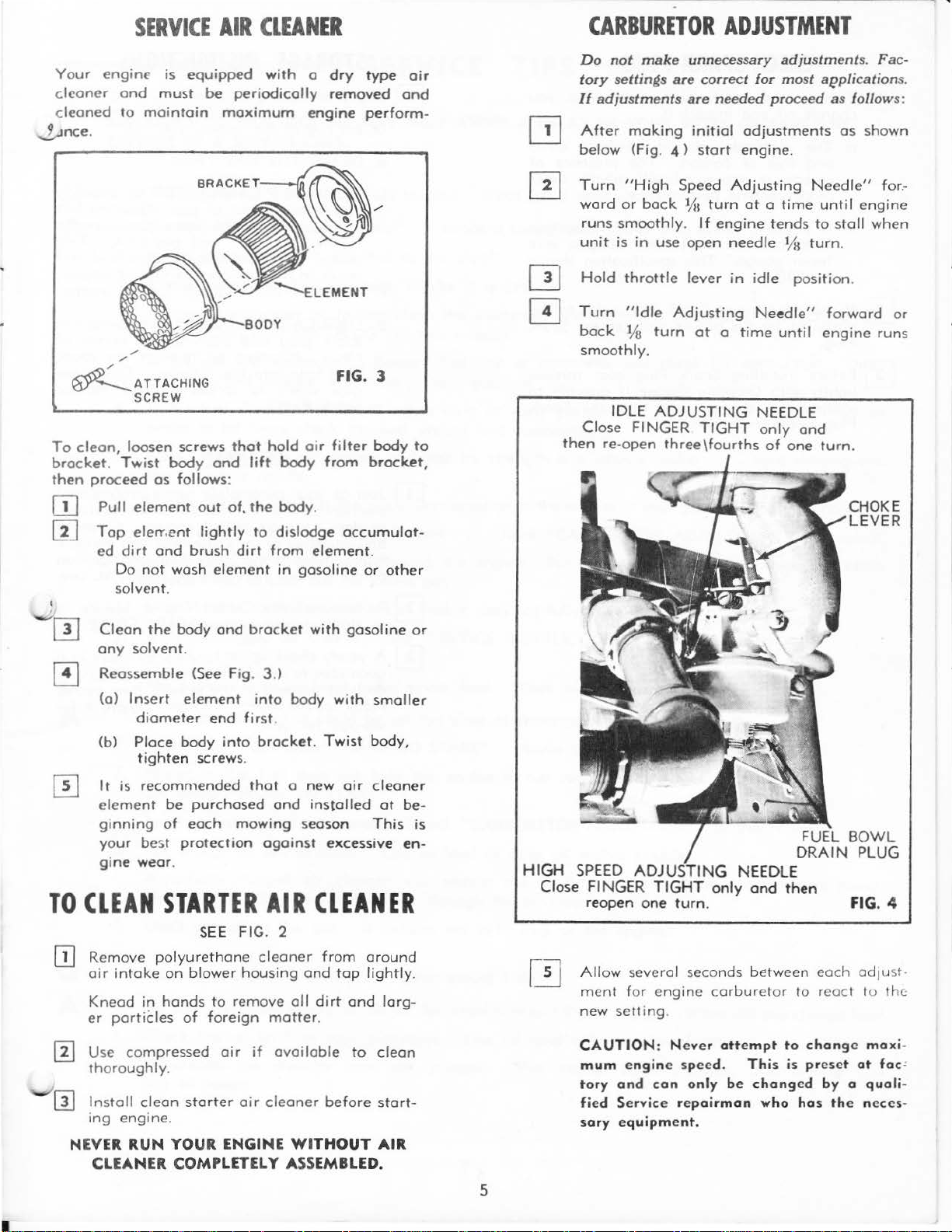

Pull

Top

ed

Clean

any

Reassemble

(o)

(b)

os

element

elerr.ent

dirt

Do

not

solvent.

the

solvent.

Insert

diameter

Place

tighte

screws

body

follows :

out

lightly

and

brush

wash

body

(See Fig. 3.)

element

body

n screws.

that

and

lift

of.

the

to

dirt

element

and

brocket

end

first

into

hold

body

body

dislodge

from

in

into body

brocke

FIG. 3

air

filter

body

from

brocket,

.

accumulat-

element.

gasoline

with

t. Twist body,

gasoli

with

or other

smaller

ne

to

or

Turn

back

smoothly.

Close

then

re-open

"Idle

1fs

IDLE

FINGER

Adjusting

turn

ot a time

ADJUSTING

TIGHT

three

\fourths

Needle"

until

NEEDLE

only

and

of

one

forward

engine

turn.

CHOKE

LEVER

or

runs

m

TO

It

is

element

ginning

your

gine

wear

CLEAN

Remove

air

intake

Knead

er

particles

Use

compressed

th

oroughly.

Install

ing

engine.

NE

VER

RUN

CLEANER

recommended

be pur

of

best

chased

each

protection

.

STARTER

SEE FIG. 2

polyurethane

on

blower

in

hands

clean

to

remove

of

foreign

air

starter

YOUR

ENGINE

COMPLETELY

that

and

mowing

against

AIR

cleaner

housing

matter.

if

available

air

cleaner

0 new

installed

seaso

exc

CLEANER

from

and

tap lightly.

all

dirt

before

WITHOUT

ASSEMBLED

air

clea

ot

n

Th

is is

essive en-

around

and

larg-

to

clean

start-

AIR

.

ner

be-

HIGH SPEED ADJ NG NEEDLE

Cl

ose

FINGER T I

re

op

en

Allow

ment

new

setting.

CAUTION:

mum eng

tory

a nd

fied Se rvi

sary

equipment

GHT

one turn

several

for

seconds

engine

Neve r

ine speed.

can only

ce repairman

.

5

FU

L

BOWL

DRAIN PLUG

only

and

the

n

. FIG. 4

between

carburetor

attempt

Thi

be

chang

who

each

adju

to react to the:

to

chan

ge maxi-

s is preset at

ed by a

has the neces-

fac

quali

st.

-

-

Loading...

Loading...