Craftsman 143001302 Owner’s Manual

SEARS

operator's

manual

MODEL NO. 143.001302

SOLID STATE IGNITION

ENGIN

CAUTION:

Read RULES for

Safe OPERATION

and INSTRUCTIONS

Carefully

] _ California Proposition65 WARNING: The engine exhaust from this product contains chemicals ]

Printed in U.S.A. 10-1-00 181-1251-11

known to the State of California to cause cancer, birth defects or other reproductive harm.

Sold by SEARS, ROEBUCK AND CO., CHICAGO, IL 60684 U.S.A.

and SEARS CANADA, INC., TORONTO, ONTARIO, CANADA

• Operating

• Maintenance

• Repair Parts

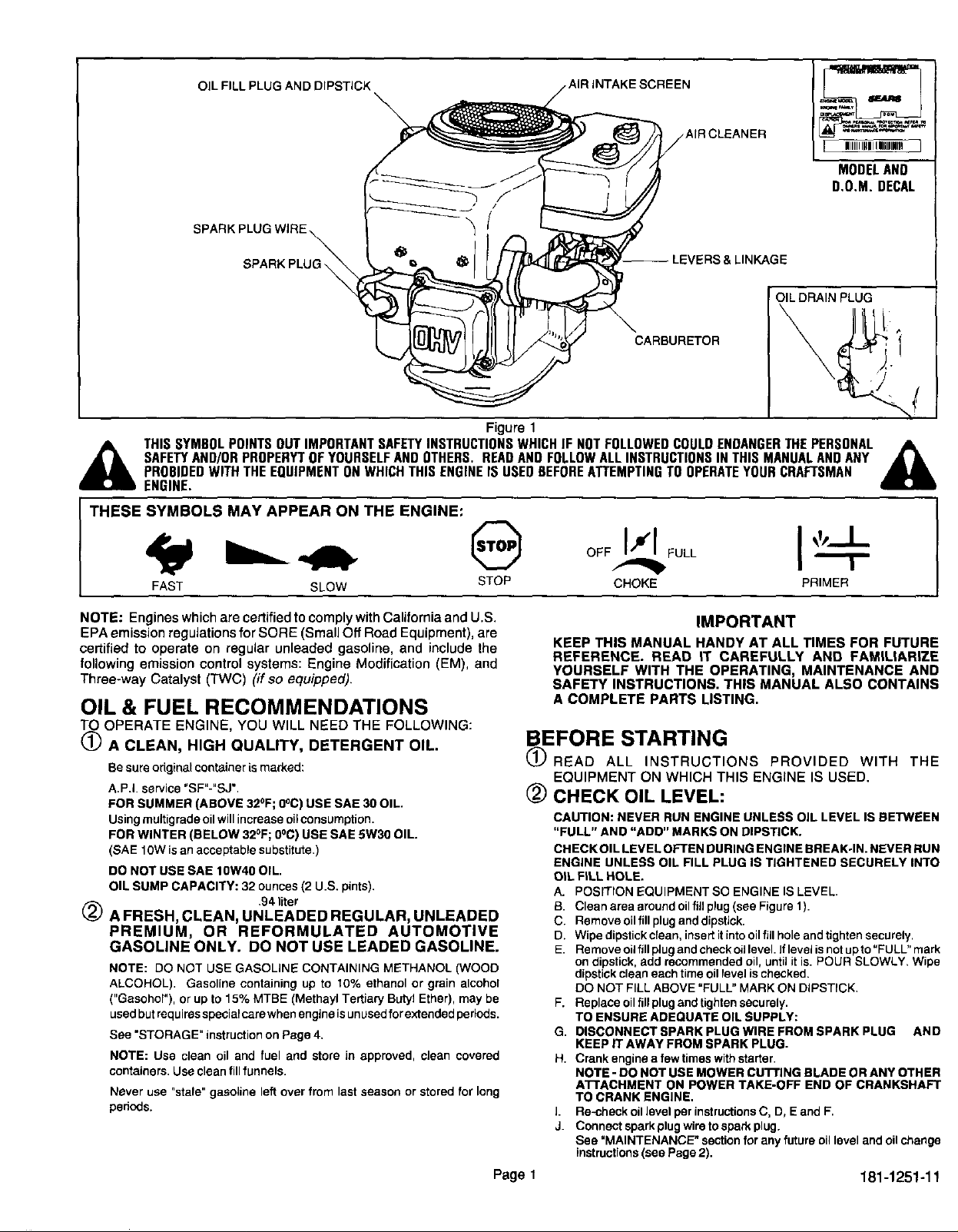

OIL FILL PLUG AND DIPSTICK

SPARK PLUG WIRE

\

'g,,_

|illlliPiilmlllllHrfl]

MODELAND

D,O.M. DECAL

SPARK PLUG_

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH iF NOT FOLLOWED COULD ENDANGER THE PERSONAL An,

SAFETY AND/OR PROPERYT OF YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL AND ANY

PROBIDEDWITHTHEEQUIPMENTONWHICHTHISENGINEISUSEDBEFOREATTEMPTINGTOOPERATEYOURCRAFTSMAN

ENGINE.

THESE SYMBOLS MAY APPEAR ON THE ENGINE:

FAST SLOW STOP

NOTE: Engines which are certified tocomply with California and U.S.

EPA emission regulations for SORE (Small Off Road Equipment), are

certified to operate on regular unleaded gasoline, and include the

following emission control systems: Engine Modification (EM), and

Three-way Catalyst (TWC) (if so equipped).

OIL & FUEL RECOMMENDATIONS

TO OPERATE ENGINE, YOU WILL NEED THE FOLLOWING:

(_) A CLEAN, HIGH QUALITY, DETERGENT OIL.

Be sure original container is marked:

A.P.I. service "SF"-"SJ".

FOR SUMMER (ABOVE 320F; OoC)USE SAE 30 OIL.

Using multigrade oil will increase oilconsumption.

FOR WINTER (BELOW 32°F; 0°C) USE SAE 5W30 OIL.

(SAE 10W is an acceptable substitute.)

DO NOT USE SAE lOW40 OIL.

OIL SUMP CAPACITY: 32 ounces (2 U.S. pints).

.94 liter

A FRESH, CLEAN, UNLEADED REGULAR, UNLEADED

PREMIUM, OR REFORMULATED AUTOMOTIVE

GASOLINE ONLY. DO NOT USE LEADED GASOLINE.

NOTE: DO NOT USE GASOLINE CONTAINING METHANOL (WOOD

ALCOHOL). Gasoline containing up to 10% ethanol or grain alcohol

("Gasohol"), or up to 15% MTBE (Methayl Tertiary Butyl Ether), may be

used but requiresspecial care when engine is unused for extended periods.

See "STORAGE" instruction on Page 4.

NOTE: Use clean oil and fuel and store in approved, cJean covered

containers. Use clean fillfunnels.

Never use "stale" gasoline left over from last season or stored for long

pedods.

-- LEVERS & LINKAGE

OIL DRAIN PLUG

CARBURETOR

Figure 1

OFFI11FOL"

CHOKE

IMPORTANT

KEEP THIS MANUAL HANDY AT ALL TIMES FOR FUTURE

REFERENCE. READ IT CAREFULLY AND FAMILIARIZE

YOURSELF WITH THE OPERATING, MAINTENANCE AND

SAFETY INSTRUCTIONS. THIS MANUAL ALSO CONTAINS

A COMPLETE PARTS LISTING.

BEFORE STARTING

(_ READ ALL INSTRUCTIONS PROVIDED WITH THE

EQUIPMENT ON WHICH THIS ENGINE IS USED.

(_) CHECK OIL LEVEL:

CAUTION: NEVER RUN ENGINE UNLESS OIL LEVEL IS BETWEEN

"FULL" AND "ADD" MARKS ON DIPSTICK.

CHECK OIL LEVEL OFTEN DURING ENGINE BREAK-IN. NEVER RUN

ENGINE UNLESS OIL FILL PLUG IS TIGHTENED SECURELY INTO

OIL FILL HOLE,

A. POSmON EQUIPMENT SO ENGINE IS LEVEL.

8. Cleanareaaroundoilfillplug(seeFigurel).

C. Remove oil fill plug and dipstick.

D. Wipe dipstick clean, insert it into oil fill hole and tighten securely.

E. Remove oilfill plug and check oillevel. If level isnct upto"FULL" rnark

on dipstick, add recommended oil, until it is. POUR SLOWLY. Wipe

dipstick clean each time oil level is checked.

DO NOT FILL ABOVE "FULL" MARK ON DIPSTICK.

F. Replace oil fill plugand tighten securely.

TO ENSURE ADEQUATE OIL SUPPLY:

G, DISCONNECT SPARK PLUG WIRE FROM SPARK PLUG AND

KEEP IT AWAY FROM SPARK PLUG.

H. Crank engine a few times with starter

NOTE- DO NOT USE MOWER CUTTING BLADE OR ANY OTHER

ATTACHMENT ON POWER TAKE-OFF END OF CRANKSHAFT

TO CRANK ENGINE.

L Re-check oil level per instructions C, D, E and F.

J. Connect spark plug wire to spark plug.

See =MAINTENANCE" section for any future oil level and oil change

instructions (see Page 2).

Page I

4k

181-1251-11

BEFORE STARTING (Continued)

r

A'_ THE ALUMINUM COMPONENTS OF YOUR NEW ENGINE HAVE BEEN

TREATED WITH A PRESERVATIVE INTENDED TO MAINTAIN THE

APPEARANCE OF THE ENGINE. THE PRESERVATIVE WILL CURE

DURING THE INITIAL USE OF THE ENGINE. A SMALL AMOUNT OF

SMOKE MAY BE PRESENT DURING THE INITIAL USE OF THE

PRODUCT AND SHOULD BE CONSIDERED NORMAL.

FILL FU EL TAN K withgasolineasspecifiedinthepreceding "OIL

& FUEL RECOMMENDATIONS," item 2.

NEVER MIX OIL WITH GASOLINE

Never use "stale" gasoline left over from last season or stored for long

periods.

r

_1 NEVER FILL FUEL TANK INDOORS. NEVER FILL FUEL TANK WHEN

ENGINE IS RUNNING OR HOT. DO NOT SMOKE WHEN FILLING FUEL

I TANK.

_i NEVER FILL FUEL TANK COMPLETELY. FILL TANK TO 1/2" BELOW

BOTTOM OF FILLER NECK TO PROVIDE SPACE FOR FUEL

EXPANSION. WIPE ANY FUEL SPILLAGE FROM ENGINE AND

EQUIPMENT BEFORE STARTING ENGINE.

_kANY LIQUEFIED PETROLEUM (LPG) OR NATURAL GAS FUEL

SYSTEM MUST BE LEAKPROOFAND MEETALLAPPLICABLE CODES

! AND REGULATIONS,

(_, CHECK THE FOLLOWING:

BE SURE EQUIPMENT IS IN NEUTRAL GEAR WITH CLU_

_k A. BELTS, CHAINS AND SAFETY SWITCHES DISENGAGEEL I

(FOLLOW EQUIPMENT MANUFACTURER S INSTRUCTIONS), I

T;ISRSHOUpLcDI;ILoANCE ANY SAFETY SWITCHES IN SAFE I

S. Be sure spark plug wire is attached to spark plug (see Figure 1)

C. BesureanyignitionswitchonengineorequipmentisinON, RUNor

START position.

STARTING

r

,_NEVER RUN ENGINE INDOORS OR IN ENCLOSED, POORLY

VENTILATED AREAS. ENGINE EXHAUST CONTAINS CARBON

MONOXIDE, AN ODORLESS AN D DEADLY GAS (CARBON MONOXIDE

ISALSO PRESENT IN ENGINE EXHAUST FROM LIQUID PETROLEUM

(LPG) AND NATURAL GAS FUEL SYSTEMS).

,_lb KEEP HANDS, FEET, HAIR AND LOOSE CLOTHING AWAY FROM

ANY MOVING PARTS ON ENGINE AND EQUIPMENT.

STOPPING

_) Move equipment control or any ignition stop switch on engine to STOP or

OFF (see equipment manufacturer's instructions).

(_ AFTER ENGINE IS STOPPED:

A. ISCONNECT SPARK PLUG WIRE FROM SPARK PLUG AND

KEEP IT AWAY FROM SPARK PLUG.

, i

4. TURN IGNITION SWITCH KEY (IF SO EQUIPPED) TO "OFF"

POSITION AND REMOVE KEY FROM SWITCH. THIS WILL

I REDUCE THE POSSIBIU'rY OF UNAUTHORIZED STARTING OFENGINE WHILE EQUIPMENT IS NOT IN USE.

_li NEVER STORE ENGINE WITH FUEL IN TANK INDOORS OR IN

ENCLOSED, POORLY VENTILATED AREAS, WHERE FUEL

FUMES MAY REACH AN OPEN FLAME, SPARK OR PILOT LIGHT

AS ON A FURNACE, WATER HEATER, CLOTHES DRYER OR

OTHER GAS APPLIANCE,

MAINTENANCE

WARNING: TEMPERATURE OF MUFFLER AND NEARBY

AREAS MAY EXCEED 150°F (65°C). AVOID THESE AREAS. J

1_ CHECK OIL LEVEL:

Check oil level every five (5) operating hours or each time engine isused.

See "2 CHECK OIL LEVEL" in"BEFORE STARTING" on Page 1.

@ CHANGE OIL:

Change oilafter first two (2) operating hours and every 25 operating hours

thereafter, more often ifoperated in extremely dusty ordirty conditions.

, Chanqe oilwhile enqine isstill warm from recent running.

4. DISCONNECT SPARK PLUG WIRE FROM SPARK PLUG AND

KEEP IT AWAY FROM SPARK PLUG.

B. Position equiprnent so engine oil drain plug is lowest point on engine.

C. Remove oil drain plug and oilfill plug to drain oil.

D. Replace oil drain plug and tighten securely.

E, Fill oil sump with recommended oil. See "OIL & FUEL

RECOMMENDATIONS" and =CHECK OIL LEVEL" on Page 1.

F. Replace oil fill plug and tighten securely.

G. Connect spark plug wire to spark plug.

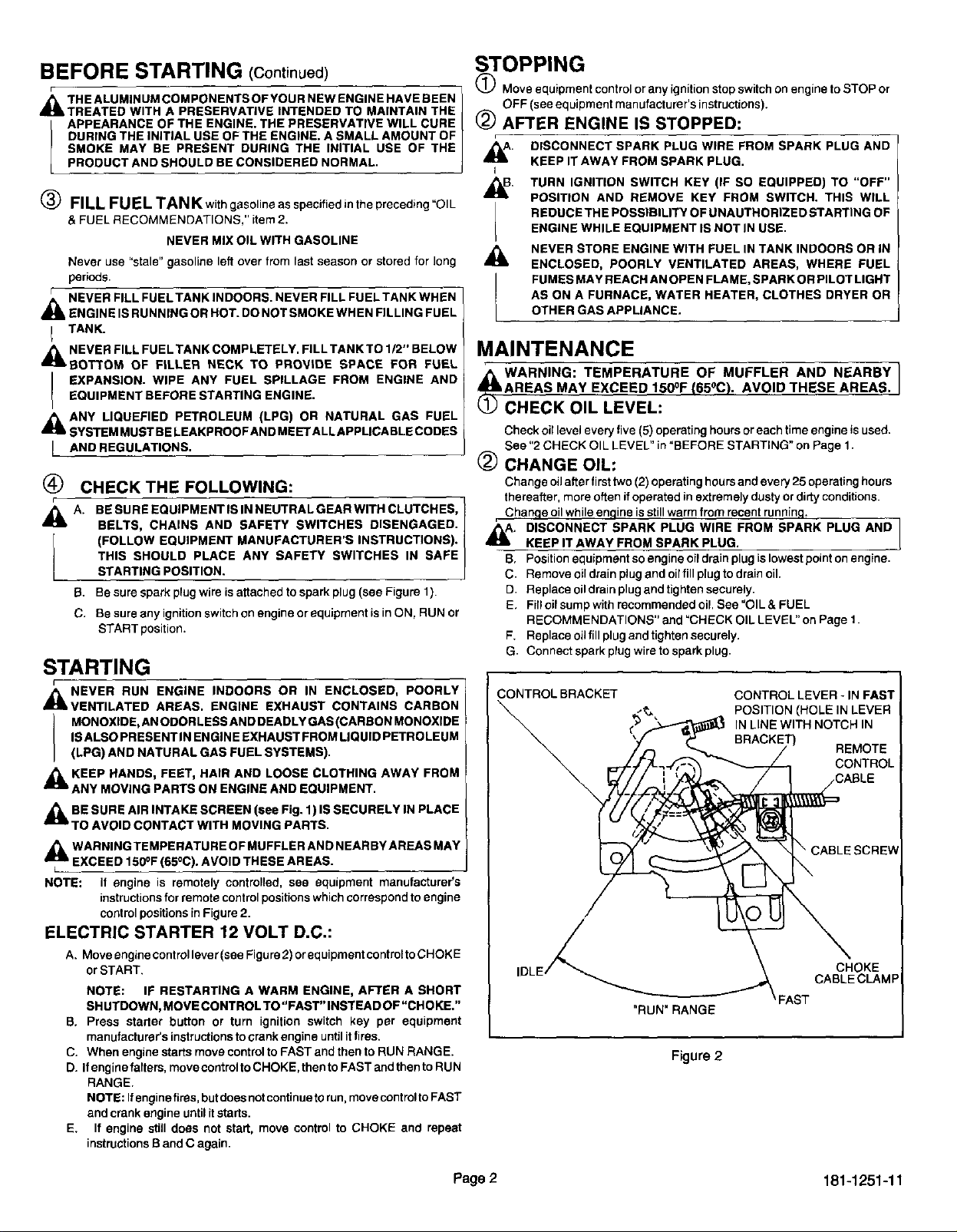

CONTROLBRACKET

I

,_BE SURE AIR INTAKE SCREEN (see Fig. 1) IS SECURELY IN PLACE

TO AVOID CONTACT WITH MOVING PARTS.

L_li WARNING TEMPERATURE OF MUFFLER AND NEARBY AREAS MAY

EXCEED 150°F (65°C)` AVOID THESE AREAS.

NOTE: If engine is remotely controlled, see equipment manufacturer's

instructionsfor remote control positions which correspond to engine

control positions in Figure 2.

ELECTRIC STARTER 12 VOLT D.C.:

A. Move engine controllever (see Figure 2) orequipment controlto CHOKE

or START,

NOTE: IF RESTARTING A WARM ENGINE, AFTER A SHORT

SHUTDOWN, MOVE CONTROL TO"FAST"INSTEAD OF"CHOKE."

B. Press starter button or turn ignition switch key per equipment

manufacturer's instructions tocrank engine until itfires.

C. When engine starts move control to FAST and then to RUN RANGE.

D. Ifengine falters, move controlto CHOKE, then to FAST and then to RUN

RANGE.

NOTE: Ifengine fires, butdoes notcontinue to run, move control to FAST

and crank engine until itstarts.

E. If engine still does not start, move control to CHOKE and repeat

instructions B and C again.

/

CHOKE

IDLE_ _FAST

"RUN"RANGE

Figure 2

Page2 181-1251-11

CABLECLAMF

MAINTENANCE (Continued)

(_) AIR CLEANER:

IMPORTANT: NEVER RUN ENGINE WlTHOUTCOMPLETE AIR CLEANER

INSTALLED ON ENGINE.

A. TO SERVICE FILTER(S) (see Figure 3):

1. FOAM FILTER:

Clean and re-oil every three (3) months or every 25 operating hours.

Clean and re-oil daily if used inextremely dusty conditions.

a. Wash in water and detergent solution and squeeze (don't twist)

untilall dirt is removed.

b. Rinse thoroughly in clear water.

c. Wrap inaclean clothand squeeze (don'ttwist) untilcompletely dry.

d. Saturata with engine oil and squeeze (don't twist) to distdbuta oil

and remove excess oil.

2. PAPER OR FOAM/SCREEN FILTERS:

DO NOT A'rI'EMPT TO CLEAN OR OIL FILTER.

Replace once ayear orevery 100 operating hours, more often if used

in extremely dusty conditions.

Replacement filters are available at any nearby Sears Roebuck and

Co. (or Sears Canada, Inc.) Service Center.

B. TO REMOVE AND INSTALL FILTER(S):

1. Remove wing nuts and cover.

2. Slide FILTER A off FILTER B.

3. Inspect filter(s) for discoloration or dirtaccumulation. Ifeither ispresent,

service per preceding "TO SERVICE FILTER(S)" instructions.

4. Remove nuts and FILTER B. Discerd FILTER B and nuts (if service is

necessary).

5. Clean inside of cover and body thoroughly.

6. Install new FILTER B and new nuts. Tighten nuts finger tight and then

tam one (1) more complete turn.

7. Slide foam filter over paper filter.

8. Install cover and wing nuts. Tighten wing nuts.

-- FILTER A

(FOAM)

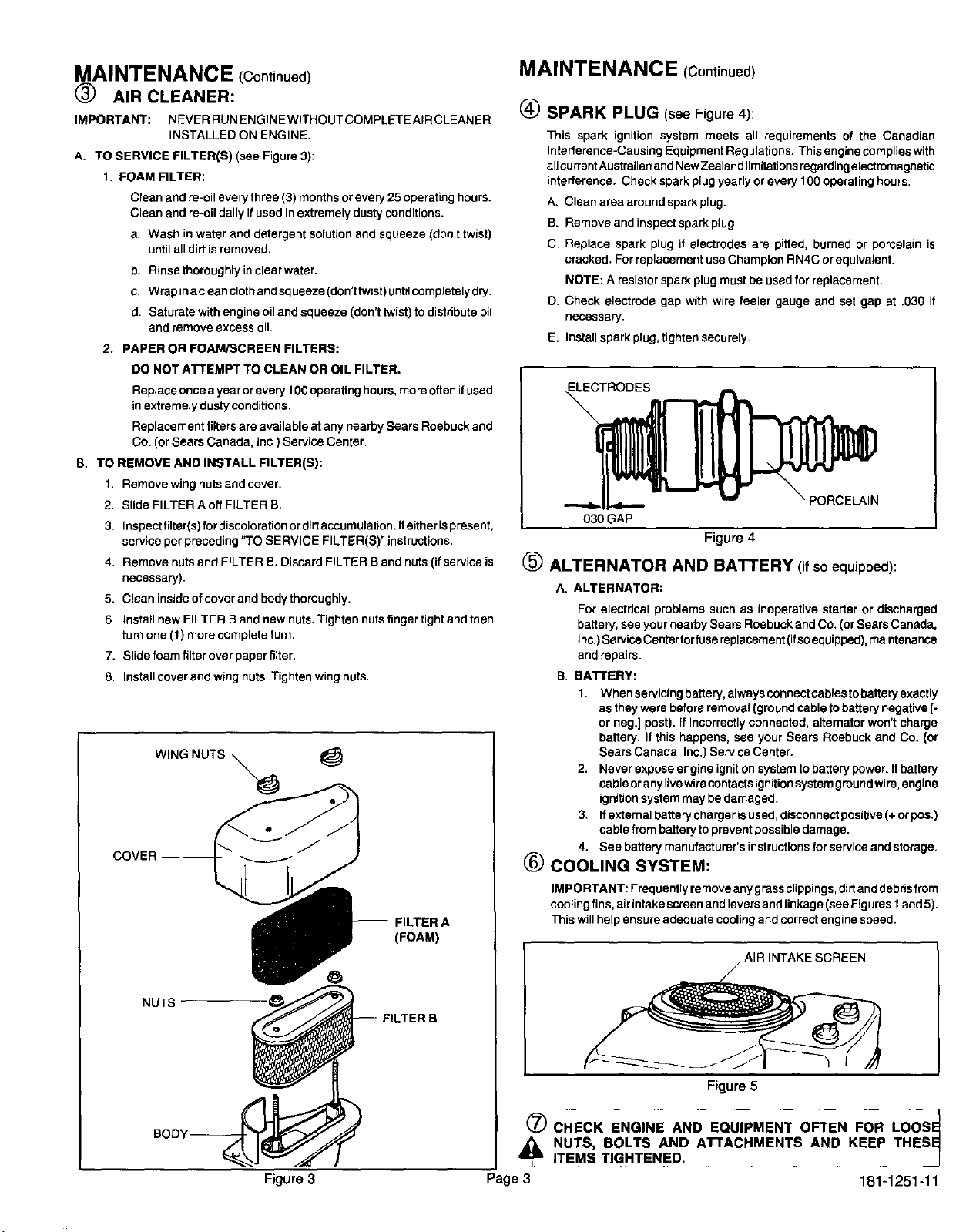

MAINTENANCE (Continued)

®

SPARK PLUG (see Figure 4):

This spark ignition system meets all requirements of the Canadian

Interference-Causing Equipment Regulations. This engine complies with

allcurrentAustralian and New Zealand limitationsregardingelectromagnetic

interference. Check spark plug yearly or every 100 operating hours.

A. Clean area around spark plug.

B. Remove and inspect spark plug.

C. Replace spark plug if electrodes are pitted, burned or porcelain is

cracked. For replacement use Champion RN4C or equivalent.

NOTE: A resistor spark plug must be used for replacement.

D. Check electrode gap with wire feeler gauge and set gap at .030 if

necessary.

E. Install spark plug, tighten securely.

CTRODES

'PORCELAIN

.030 GAP

Figure4

(_) ALTERNATOR AND BATTERY (ifso equipped):

A. ALTERNATOR:

For electrical problems such as inoperative starter or discharged

battery, see your nearby Sears Roebuck and CO. (or Sears Canada,

Inc.)Service Center forfuse replacement (if so equipped), maintenance

and repairs.

B. BATrERY:

1. Whenservicingbattery, alwaysconnectcablestobatteryexactly

as they were before removal (ground cable to battery negative [-

or neg.] post). If incorrectly connected, altemator won't charge

battery. If this happens, see your Sears Roebuck and Co. (or

Sears Canada, Inc.) Service Center.

2. Never expose engine igniti0n system to battery power. If battery

cable or any live wirecontacts ignitionsystem groundwire, engine

ignition system may be damaged.

3. Ifexternal battery charger is used, disconnect positive (+ or pus.)

cable from batteryto prevent possible damage.

4. See battery manufacturer's instructions for service and storage.

(_) COOLING SYSTEM:

IMPORTANT: Frequently remove any grass clippings, dirt and debris from

cooling fins, air intake screen and levers and linkage (see Figurss 1and 5).

This will help ensure adequate cooling and correct engine speed.

AIR INTAKE SCREEN

NUTS

Figure 3

FILTER B

Figure 5

@CHECK ENGINE AND EQUIPMENT OFTEN FOR LOOS_

NUTS, BOLTS AND ATTACHMENTS AND KEEP THES_

ITEMS TIGHTENED.

==,

Page3 181-1251-11

J

Loading...

Loading...