Craftsman 14218882 Owner’s Manual

Operation Manual

T RN°

MAGNESIUM BRAD NAILER

t8 Gauge 518"-2-118" Brad Nailer

Model 142.18882

CAUTION: Read, understand and

• Safety

• KnowYour Nailer

follow all Safety Rules and Oper-

ating Instructions in this manual

before using this product.

PRECAUCION: Lea, comprenda y siga

todas las reglas de seguridad y las in-

strucciones de operaci6n en este manual

antes de operar este producto

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

www.craftsman.com

• Operation

• Maintenance

• Troubleshooting

• Espa_ol

• Parts List

Warranty ...................................................................... 2

Safety Instructions ...................................................... 2

Know Your Nailer ......................................................... 3

Operation ................................................................. 4-6

Maintenance ............................................................ 6-7

Troubleshooting ........................................................... 7

Espa_ol .................................................................. 8-13

Parts and Illustrations List......................................... 14

CRAFTSMAN ONE YEAR FULL WARRANTY

FOR ONE YEAR from the date of purchase, this

product is warranteed against any defects in material

or workmanship. A defective product will be replaced

free of charge.

For warranty coverage details to obtain free re-

placement, visit the web site: www.craftsman.com

This ONE YEAR warranty is void if this product is

ever used while providing commercial services or if

rented to another person. For 90 DAY commercial

use terms, see listing on Craftsman warranty web

page. This warranty gives you specific legal rights,

and you may also have other rights which vary from

state to state.

Sears Brands Management Corp. Hoffman Es-

tates, IL 60179

• Read and follow all safety rules and operating

instructions in this manual and on warning label of

tool before using this tool. Failure to follow warnings

could result in DEATH or SERIOUS INJURY. Keep

this manual with the tool.

• Keep work area clean and properly lighted.

• Keep children, bystanders and visitors at a safe

distance from work area while operating this tool.

• Air tool operators and all others in work area MUST

always wear safety goggles complying with the

United States ANSI Z87.1 to prevent eye injury from

fasteners and flying debris when loading, operating

and unloading this tool. Everyday eyeglasses have

only impact resistant lenses. These are NOT safety

glasses. ANSI Z87.1 safety glasses have perma-

nently attached rigid, hard plastic side shields and

will have "Z87.1" printed or stamped on them.

• Always wear ear protection. The work area may

include exposure to excessive noise levels which

will require necessary ear protection. Some envi-

ronments will require head protection: use head

protection conforming to ANSI Z89.1.

Do not alter or modify this tool in any way. Do not

use this tool for any application other than for which

it was designed.

Do not use oxygen, carbon dioxide, high-pressure

compressed gas or bottled gases as the power

source for this tool. The tool will explode and seri-

ous personal injury could result.

Never connect the tool to air pressure which could

potentially exceed 200 PSI. Use only clean, dry

regulated air within rated range as marked on tool.

The tool must have a male, free-flow hose coupling

so that all air pressure is removed from the tool

when the coupling joint is disconnected. Failure to

use proper coupling could cause accidental dis-

charge, possibly causing injury.

• Only use air hose that is rated for maximum work-

ing pressure of 150 PSI or 150% of the maximum

system pressure, whichever is greater.

• Do not pull trigger or depress contact trip while

connecting to the air supply, as the tool may cycle,

possibly causing injury.

• When loading the tool, do not pull trigger or de-

press contact trip. Do not point the tool at yourself

or others. Do not place hand or any part of body in

the fastener discharge area of the tool as accidental

actuation may occur and cause injury.

• Disconnect tool from air supply before loading or

unloading, performing tool maintenance, clearing

a jammed fastener, leaving work area, moving tool

to another location or handing the tool to another

person.

• Use only the size and type of fasteners designated

in the Specifications list in this manual.

• Do not load the tool until you are ready to use it.

• Always assume that the tool contains fasteners.

Keep the tool pointed away from yourself and others

at all times. Never engage in horseplay. Never pull

the trigger unless the contact trip is in contact with

the workpiece. Keep others at a safe distance from

the tool while the tool is in operation.

• Always remove finger from trigger when not driving

fasteners to avoid accidental firing. Never carry the

tool with finger on or under the trigger as accidental

actuation may occur and cause injury.

• Always keep hands and body away from the fas-

tener discharge area when air supply is connect-

ed to the tool. Grip tool firmly to maintain control

while allowing tool to recoil away from work surface

as fastener is driven. If contact trip is allowed to

recontact work surface before trigger is released, an

unwanted fastener may be driven.

• Check operation of the contact trip frequently. Nev-

er use the tool if the contact trip, trigger or springs

have become inoperable, missing or damaged. Do

not alter or remove contact trip, trigger or springs.

Never use a tool that is leaking air, has missing or

damaged parts, or requires repair.

• Never drive fasteners on top of other fasteners or

with the tool at too steep an angle. The fasteners

can ricochet and cause injury. Do not drive fasten-

ers close to the edge of the work piece. The work-

piece is likely to split, allowing the fastener to fly free

and cause injury. Do not attempt to drive fasteners

into hard or brittle materials such as concrete, steel

or tile.

• Do not overreach. Always place yourself in a firmly

balanced position when using or handling the tool.

Do not attach the hose or tool to your body.

• Do not operate tool without fasteners or damage to

tool may result.

• Do not use tool without safety warning label. If

label is missing, damaged or unreadable, contact

1-800-469-4663 to obtain a new label.

• Only qualified repair personnel must perform tool

service.

• When servicing a tool, use only identical repair

parts.

• Store tool out of reach of children and other un-

trained persons.

WARNING: Some dust created by using power tools

contains chemicals known to the State of California to

cause cancer and birth defects or other reproductive

harm.

2

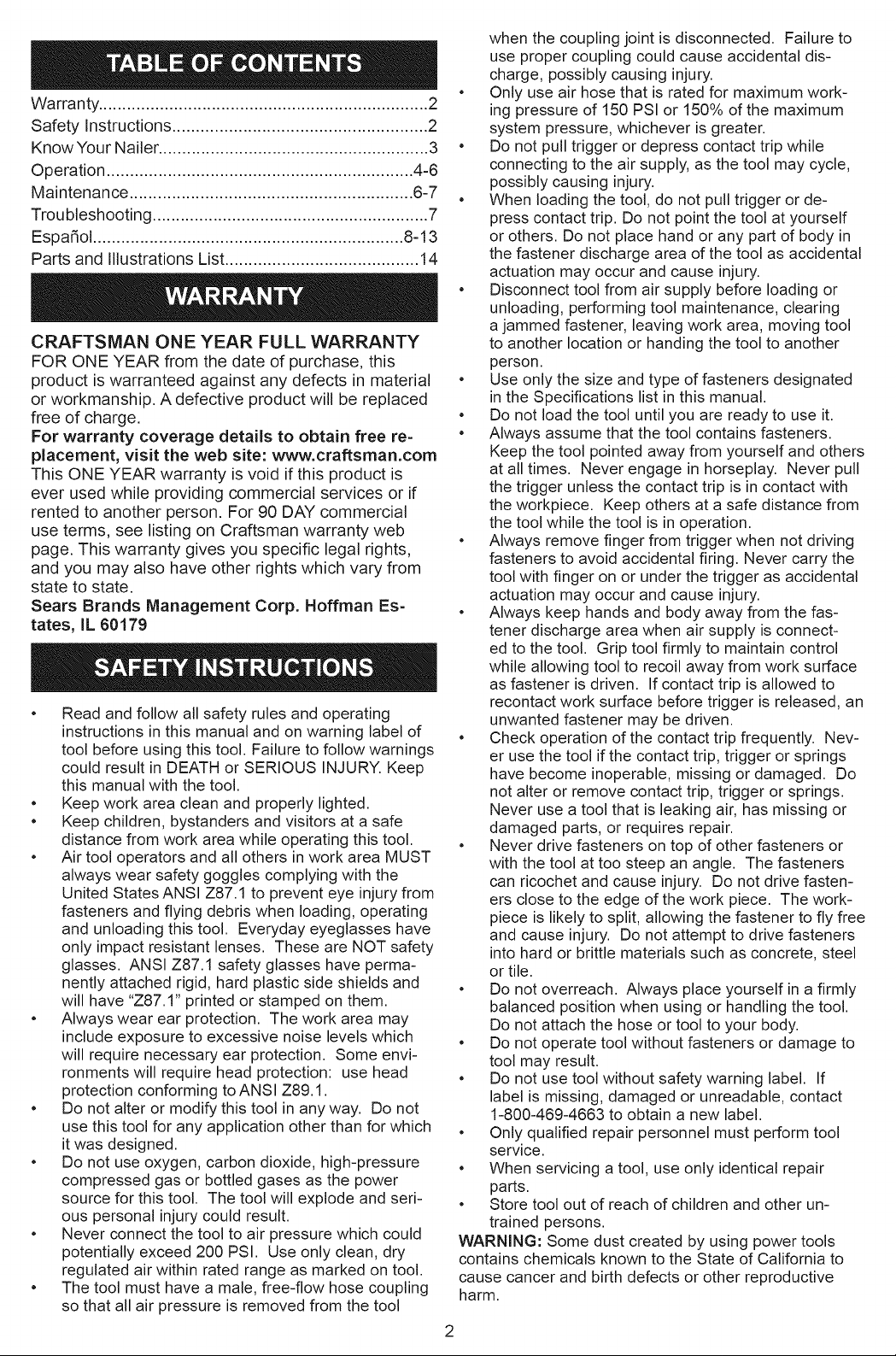

Tool-free Depth Adjustment

(See Figure 8)

LED Light

Quick Jam

Selectable Trigger

Rear Exhaust with MufflerMale Coupling

Dust Cap

Reversible Belt Hook

With Hex Wrench storage

Magazine Cover Release Latch

Tool Noseplate

FEATURES BENEFITS

Tool-free Depth Adjustment adjustment.

LED Light Offers clearer view in darker areas.

Quick Jam Clearance

NO-MAR Contact Trip Pad

Reversible Belt Hook with

Wrench storage

Selectable Trigger 1. Single trigger pull firing.

Rear Exhaust with Muffler 2. Directs air away from the user during

1. Tool free design for user friendly

2. Control for precise countersinking.

Tool free mechanism for quick jam

clearance from tool nose.

Prevents making marks on the

workpiece.

Provides convenient tool carrying.

Trigger has two operation settings:

2. Continuous contact trip firing.

1. Ultra-quiet

operation.

SPECIFICATIONS

Capacity ......................................................... 100 Nails

Nail Size ........................................................ 18Gauge

Nail Lengths ............................................. 5/8" to 2-1/8"

Operating Pressure ..................................... 70-120 PSI

Air inlet ......................................................... 1/4" N.P.T,

No-Mar Tip Storage

(Reverse Side of Tool)

Magazine Cover

LED LIGHT

• Requires CR2023 battery (supplied)

• 15 minute automatic shut-off to conserve battery

power in case light is not turned off after tool use.

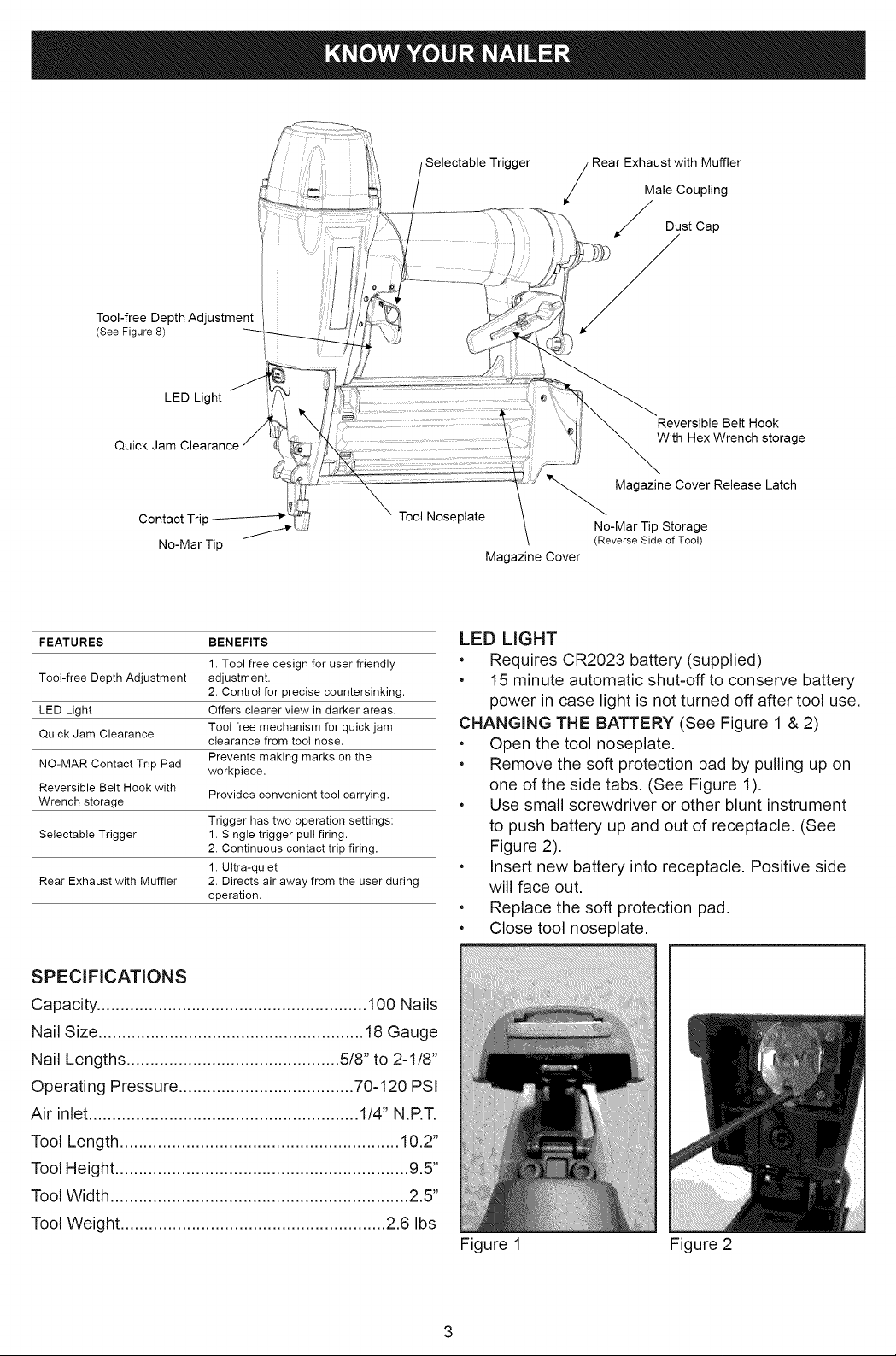

CHANGING THE BATTERY (See Figure 1 & 2)

• Open the tool noseplate.

• Remove the soft protection pad by pulling up on

one of the side tabs. (See Figure 1).

• Use small screwdriver or other blunt instrument

to push battery up and out of receptacle. (See

Figure 2).

• Insert new battery into receptacle. Positive side

will face out.

• Replace the soft protection pad.

• Close tool noseplate.

Tool Length ........................................................... 10.2"

Tool Height .............................................................. 9.5"

Tool Width ............................................................... 2.5"

Tool Weight ........................................................ 2.6 Ibs

Figure 1 Figure 2

DESCRIPTION

TheCraftsman18gaugeBradNailerdrivesbrads

from5/8"to2-1/8"long.Oillessdesigneliminates

dailyoilingandoilstainsonworkpiece.Diecastmag-

nesiumbodywithtexturedrubbergripminimizesop-

eratorfatigue.Largecapacity,sideloadingmagazine

withpositive,quickactionlatchmakesloadingeasy.

Nailerfeaturesrearexhaust,singlerapid-fireoper-

ation,adjustabledepthofdrivecontrol,no-martip

andstoragecase.Safetyfeaturedisablestoolunless

contacttipispressedagainstworkpiece.Tapered

toolnoseprovidesoperatorwithgreatervisibilityfor

precisefastnerplacement.Rigidtoolnosereduces

jamming.The18GuageBradNailerisexcellentfor

molding,furnituremakingandpictureframing.

AIRSUPPLYLINE

SeeFigure3

DANGER:Donotuseoxygen,carbondioxide,

high-pressurecompressedgasorbottledgasesas

thepowersourceforthistool.Thetoolwillexplode

andseriouspersonalinjurycouldresult.

• Theairtooloperatesoncompressedairatpres-

suresfrom70-120PSI

• Neverconnectthetooltoairpressurewhich

couldpotentiallyexceed 200 PSI. Use only

clean, dry, regulated air within rate range as

marked on tool.

Air delivery Required: 0.94 SCFM @ 90 PSI. (30

shots per minute).

WARNING: Keep hands and body away from

discharge area of tool when connecting air supply.

Always disconnect tool from air supply when servic-

ing or adjusting tool and when tool is not in use.

• Air operated tools require clean, dry, lubricated

compressed air to ensure top performance, low

maintenance and long life.

• Dirt and abrasive materials present in all air lines

will damage tool O-rings, valves and cylinders.

• Moisture will reduce tool performance and life if

not removed from compressed air.

• The air supply system must be able to provide

air pressure of 70-120 pounds per square inch at

tool.

• All hoses and pipes in the air supply system must

be clean and free of moisture and foreign parti-

cles. Hoses must be rated for maximum working

pressure of 150 PSI or 150% of maximum system

pressure, whichever is greater.

• Do not mount swivel connector in air supply line.

• The air pressure should be properly regulated.

• Different workpiece materials and different

fastener lengths will require different operating

pressure.

• Be sure all connections in air supply system are

sealed to prevent air loss.

WARNING: This tool is equipped with a male, free-

flow coupling for air supply connection. To prevent

accidental discharge and possible injury, NEVER

remove the male coupling to replace with afemale

coupling.

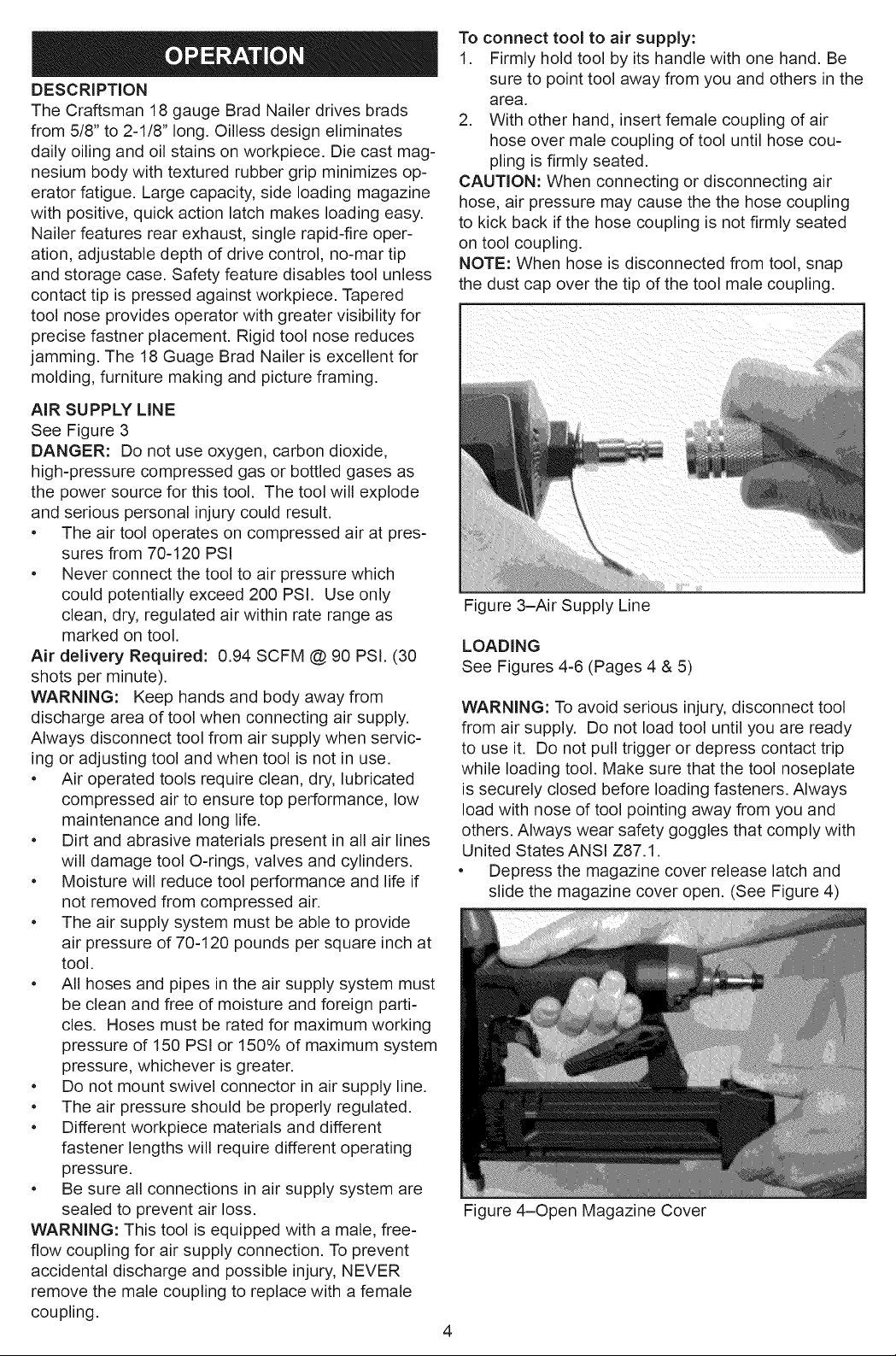

To connect tool to air supply:

1. Firmly hold tool by its handle with one hand. Be

sure to point tool away from you and others in the

area.

2. With other hand, insert female coupling of air

hose over male coupling of tool until hose cou-

pling is firmly seated.

CAUTION: When connecting or disconnecting air

hose, air pressure may cause the the hose coupling

to kick back if the hose coupling is not firmly seated

on tool coupling.

NOTE: When hose is disconnected from tool, snap

the dust cap over the tip of the tool male coupling.

Figure 3-Air Supply Line

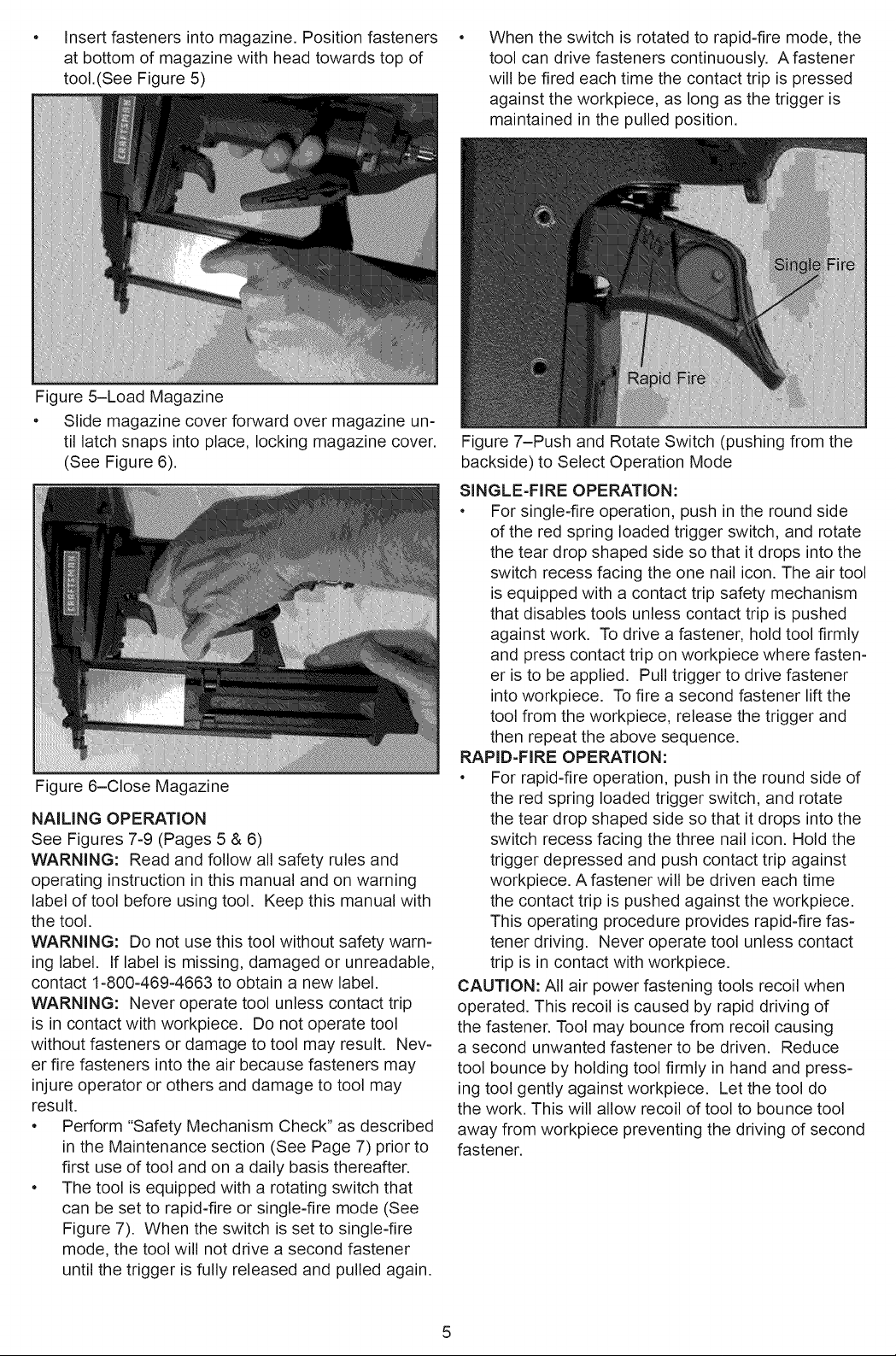

LOADING

See Figures 4-6 (Pages 4 & 5)

WARNING: To avoid serious injury, disconnect tool

from air supply. Do not load tool until you are ready

to use it. Do not pull trigger or depress contact trip

while loading tool. Make sure that the tool noseplate

is securely closed before loading fasteners. Always

load with nose of tool pointing away from you and

others. Always wear safety goggles that comply with

United States ANSI Z87.1.

• Depress the magazine cover release latch and

slide the magazine cover open. (See Figure 4)

Figure 4-Open Magazine Cover

Insertfastenersintomagazine.Positionfasteners

atbottomofmagazinewithheadtowardstopof

tool.(SeeFigure5)

Figure5-LoadMagazine

• Slidemagazinecoverforwardovermagazineun-

tillatchsnapsinto3lace,lockingmagazinecover.

(SeeFigure6).

Figure6-CloseMagazine

NAILINGOPERATION

SeeFigures7-9(Pages5&6)

WARNING:Readandfollowallsafetyrulesand

operatinginstructioninthismanualandonwarning

labeloftoolbeforeusingtool.Keepthismanualwith

thetool.

WARNING:Donotusethistoolwithoutsafetywarn-

inglabel.Iflabelismissing,damagedorunreadable,

contact1-800-469-4663toobtaina newlabel.

WARNING:Neveroperatetoolunlesscontacttrip

isincontactwithworkpiece.Donotoperatetool

withoutfastenersordamagetotoolmayresult.Nev-

erfirefastenersintotheairbecausefastenersmay

injureoperatororothersanddamagetotoolmay

result.

• Perform"SafetyMechanismCheck"asdescribed

intheMaintenancesection(SeePage7)priorto

firstuseoftoolandona dailybasisthereafter.

• Thetoolisequippedwitharotatingswitchthat

canbesettorapid-fireorsingle-firemode(See

Figure7). Whentheswitchissetto single-fire

mode,thetoolwillnotdriveasecondfastener

untilthetriggerisfullyreleasedandpulledagain.

Whentheswitchisrotatedtorapid-firemode,the

toolcandrivefastenerscontinuously.Afastener

willbefiredeachtimethecontacttripispressed

againsttheworkpiece,aslongasthetriggeris

maintainedinthepulledposition.

Figure7-PushandRotateSwitch(pushingfromthe

backside)toSelectOperationMode

SINGLE-FIREOPERATION:

• Forsingle-fireoperation,pushintheroundside

oftheredspringloadedtriggerswitch,androtate

theteardropshapedsidesothatitdropsintothe

switchrecessfacingtheonenailicon.Theairtool

isequippedwitha contacttripsafetymechanism

thatdisablestoolsunlesscontacttripispushed

againstwork.Todriveafastener,holdtoolfirmly

andpresscontacttriponworkpiecewherefasten-

eristobeapplied.Pulltriggertodrivefastener

intoworkpiece.Tofireasecondfastenerliftthe

toolfromtheworkpiece,releasethetriggerand

thenrepeattheabovesequence.

RAPID-FIREOPERATION:

• Forrapid-fireoperation,pushintheroundsideof

theredspringloadedtriggerswitch,androtate

theteardropshapedsidesothatitdropsintothe

switchrecessfacingthethreenailicon.Holdthe

triggerdepressedandpushcontacttripagainst

workpiece.Afastenerwillbedriveneachtime

thecontacttripispushedagainsttheworkpiece.

Thisoperatingprocedureprovidesrapid-firefas-

tenerdriving.Neveroperatetoolunlesscontact

tripisincontactwithworkpiece.

CAUTION:Allairpowerfasteningtoolsrecoilwhen

operated.Thisrecoiliscausedbyrapiddrivingof

thefastener.Toolmaybouncefromrecoilcausing

asecondunwantedfastenerto bedriven.Reduce

toolbouncebyholdingtoolfirmlyinhandandpress-

ingtoolgentlyagainstworkpiece.Letthetooldo

thework.Thiswillallowrecoiloftooltobouncetool

awayfromworkpiecepreventingthedrivingofsecond

fastener.

5

Loading...

Loading...