Craftsman 14218839 Owner’s Manual

OperationManuaJ

MIN! PALM NAILER

Model 142.18839

CAUTION: Read, understand • Safety

and follow all Safety Rules • Know Your Nailer

and Operating instructions in

this manual before using this • Operation

product. • Maintenance

PRECAUCION:Lea, comprenda y • Troubleshooting

sigatodas las reglas de seguridad y

las instruccionesde operaci6n en este • Espa_ol

manual antes deoperar este producto

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

www.craftsman.com

• Parts List

Warranty......................................2

Safetylnstructions....................2-3

KnowYourNailer.........................4

Operation.................................5-6

Maintenance................................6

Troubleshooting..........................7

Espa_ol..................................8-13

PartsandIllustrationsList..........14

CRAFTSMAN ONE YEAR FULL

WARRANTY

FOR ONE YEAR from the date of

purchase, this product is warranteed

against any defects in material or

workmanship. A defective product will

be replaced free of charge.

For warranty coverage details to

obtain free replacement, visit the

web site: www.craftsman.com

This ONE YEAR warranty is void

if this product is ever used while

providing commercial services or if

rented to another person. For 90 DAY

commercial use terms, see listing

on Craftsman warranty web page.

This warranty gives you specific legal

rights, and you may also have other

rights which vary from state to state.

Sears Brands Management Corp.

Hoffman Estates, IL 60179

Read and follow all safety rules and

operating instructions in this manual

and on warning label of tool before us-

ing this tool. Failure to follow warnings

could result in DEATH or SERIOUS

INJURY.

WARNING: Some dust created by

using power tools contains chemicals

known to the State of California to

cause cancer and birth defects or

other reproductive harm.

WORK AREA

Keep your work area clean

and well lit. Cluttered benches

and dark areas invite accidents.

Do not operate power tools in

explosive atmospheres, such

as in the presence of flam-

mable liquids, gases, or dust.

Power tools create sparks which

may ignite the dust of fumes.

Keep bystanders, children and

visitors away while operating

a power tool. Distractions can

cause you to lose control.

PERSONAL SAFETY

Eye protection which con-

forms to ANSI specifications

and provides protection

against flying particles both

from the FRONT and SIDE

should ALWAYS be worn by

the operator and others in

the work area when loading,

operating and servicing this

tool. Eye protection is required

to guard against flying fasteners

and debris, which could cause

severe eye injury.

Additional safety protection

will be required in some

environments. For examples,

the working area my include ex-

posure to noise level which can

lead to hearing damage. The

employer and user must ensure

that any necessary hearing

protection is provided and used

by the operator and others in the

work area. Some environments

will require the use of head

protection equipment. When

required, the employer and user

must ensure that head protection

conforming to ANSI Z89.1-1997

is used.

Stay alert, watch what you

are doing and use common

sense when operating a power

tool. Do not use tool while tired

or under the influence of drugs,

alcohol or medication. A moment

of inattention while operating

power tools may result in serious

personal injury.

Dress properly. Do not wear

loose clothing or jewelry. Contain

long hair. Keep your hair,

clothing and gloves away from

moving parts. Loose clothes,

jewelry, or long hair can be

caught in moving parts.

Keep fingers away from trig-

ger when not driving fasteners

to avoid accidental firing.

Do not overreach. Keep proper

footing and balance at all times.

Proper footing and balance

enables better control of the tool

in unexpected situations.

Use safety equipment. Always

wear eye protection. Dust mask,

nonskid safety shoes, hard hat,

or hearing protection must be

used for appropriate conditions.

Do not use a ladder or unsta-

ble support. Stable footing on

a solid surface enables better

control of the tool in unexpected

situations.

Store idle tools out of reach of

children and other untrained

persons. Tools are dangerous in

the hands of untrained users.

may result. Do not interfere with

the proper operation of the work-

piece contact mechanism.

Use only the size and type

of fasteners designated in

the Specifications list in this

manual,

Keep the tool and its handle

dry, clean and free from oil

and grease. Always use a

clean cloth when cleaning.

Never use brake fluids, gasoline,

petroleum-based products, or

any strong solvents to clean

your tools. Following this rule

will reduce the risk of loss of

control and deterioration of the

enclosure plastic.

Do not use oxygen, combus-

tible gases or bottled gases

as a power source for this tool

as tool will explode, possible

causing injury or death.

Do not use with an air com-

pressor which can potentially

exceed 200 psi as tool may

burst, possibly causing injury.

Always disconnect air supply:

1.

Before making adjustments

2.

When servicing the tool

3.

When clearing a jam

4.

When tool is not in use

5.

When moving to a different work

area, as accidental actuation

may occur, possibly causing

injury.

OPERATION

Check operations of the

workpiece contact mechanism

frequently. Do not use the tool

if the workpiece contact mecha-

nism is not working correctly as

accidental driving of a fastener

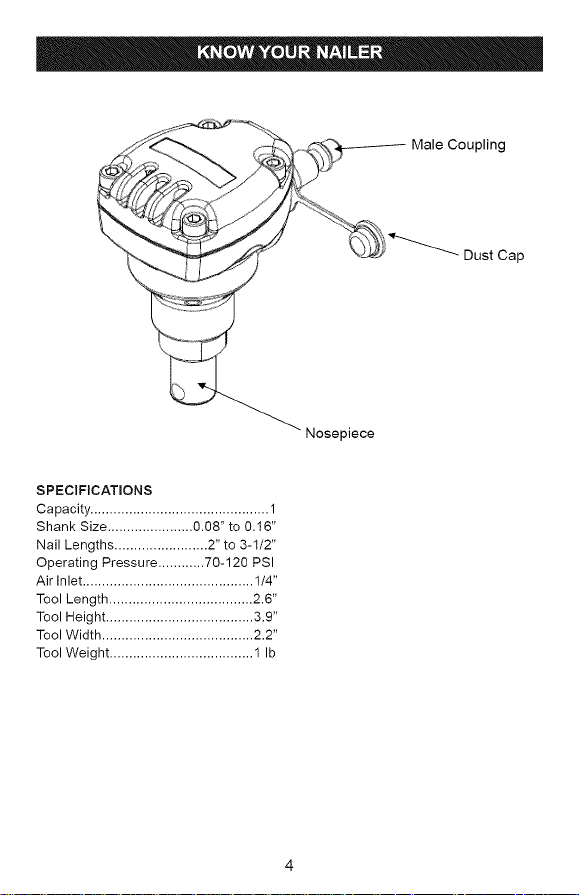

SPECIFICATmONS

Capacity..............................................1

ShankSize......................0.08"to0,t6"

NailLengths........................2"to3-1/2"

OperatingPressure............70-120PSI

AirInlet............................................1/4"

ToolLength.....................................2.6"

ToolHeight......................................3.9"

ToolWidth.......................................2,2"

ToolWeight.....................................1Ib

MaleCoupling

Nosepiece

NOTE:Whenhoseisdisconnected

PREPARINGTHETOOLFORUSE

Undernormalconditions,thetool

shouldbelubricatedbeforeconnecting

thetooltoanairsupply.Addairtool

lubricantintothemalecouplingonthe

tooloncedailywithminimaluse,or

twiceadaywithheavyuse.Onlya

fewdropsofoilatatimeisnecessary.

Toomuchoilwillonlycollectinside

thetoolandwillbenoticeableinthe

exhaustcycle.

Beforeconnectingthetool,checkthe

aircompressorgaugetobesureitis

functioningwithintheproperrangeof

70-120PSI.

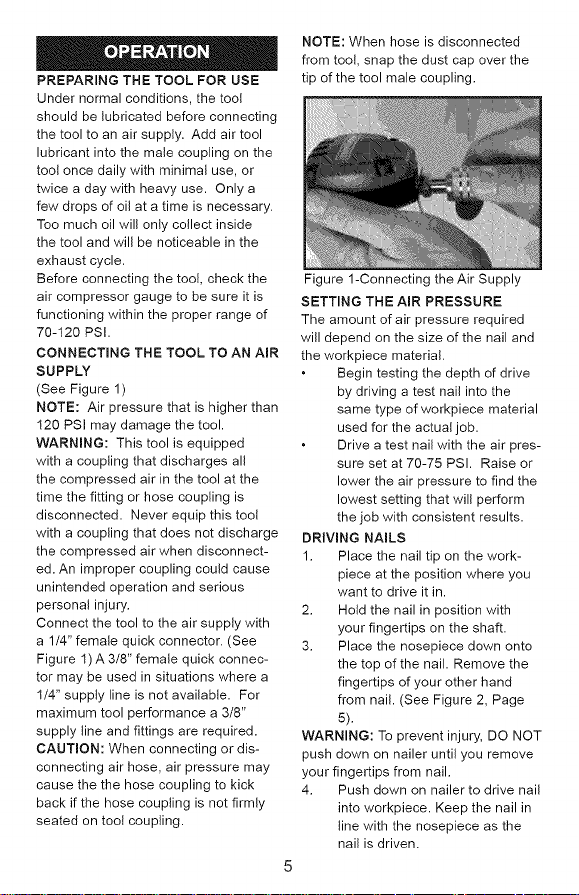

CONNECTmNGTHETOOLTOANAIR

SUPPLY

(SeeFigure1)

NOTE:Airpressurethatishigherthan

120PSImaydamagethetool.

WARNING:Thistoolisequipped

withacouplingthatdischargesall

thecompressedairinthetoolatthe

timethefittingorhosecouplingis

disconnected.Neverequipthistoot

withacouplingthatdoesnotdischarge

thecompressedairwhendisconnect-

ed.Animpropercouplingcouldcause

unintendedoperationandserious

personalinjury.

Connectthetooltotheairsupplywith

a1/4"femalequickconnector.(See

Figure1)A3/8"femalequickconnec-

tormaybeusedinsituationswherea

1/4"supptylineisnotavailable.For

maximumtoolperformancea3/8"

supplylineandfittingsarerequired.

CAUTmON:Whenconnectingordis-

connectingairhose,airpressuremay

causethethehosecouplingtokick

backifthehosecouptingisnotfirmly

seatedontoo!coupling.

fromtool,snapthedustcapoverthe

tipofthetoolmalecoupling.

Figure1-ConnectingtheAirSupply

SETTINGTHEAIRPRESSURE

Theamountofairpressurerequired

willdependonthesizeofthenailand

theworkpiecematerial.

DRIVmNGNAmLS

1. Placethenailtiponthework-

2. Holdthenailinpositionwith

3. Placethenosepiecedownonto

WARNING:Topreventinjury,DONOT

pushdownonnaileruntilyouremove

yourfingertipsfromnail.

4. Pushdownonnailertodrivenail

Begintestingthedepthofdrive

bydrivingatestnailintothe

sametypeofworkpiecematerial

usedfortheactualjob.

Driveatestnailwiththeairpres-

suresetat70-75PSI.Raiseor

lowertheairpressuretofindthe

lowestsettingthatwillperform

thejobwithconsistentresults.

pieceatthepositionwhereyou

wanttodriveitin.

yourfingertipsontheshaft.

thetopofthenail.Removethe

fingertipsofyourotherhand

fromnail.(SeeFigure2,Page

5).

intoworkpiece.Keepthenailin

linewiththenosepieceasthe

nailisdriven.

Loading...

Loading...