Craftsman 139653100, 139653000 Owner’s Manual

S__kL_i

]

_!iii___i!_i_iiii_i!i_:_ii__:_!__:_'::_s:_'_i

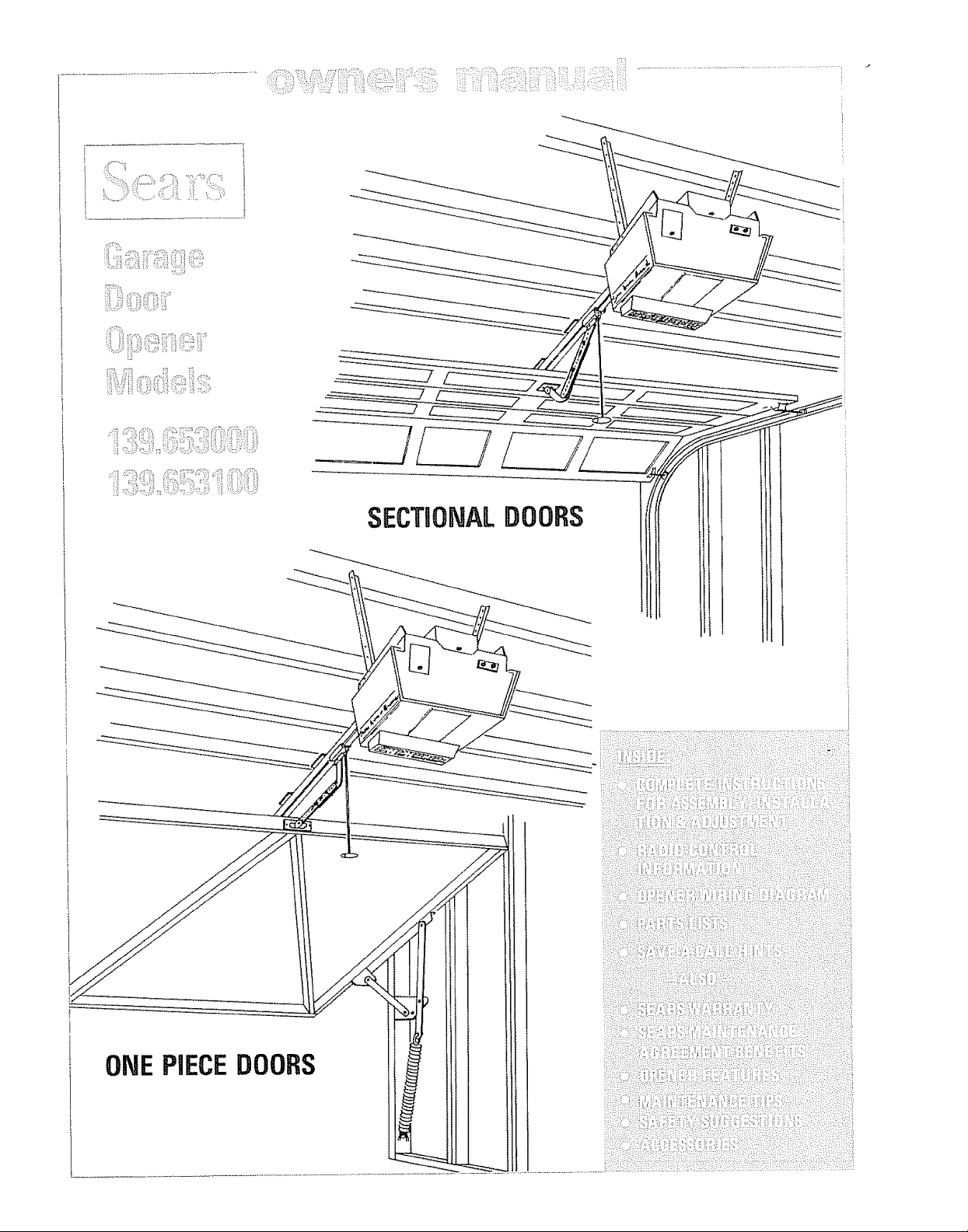

SECTgOHALDOORS

ONEPIECEDOORS

BeforeYouStart.,.

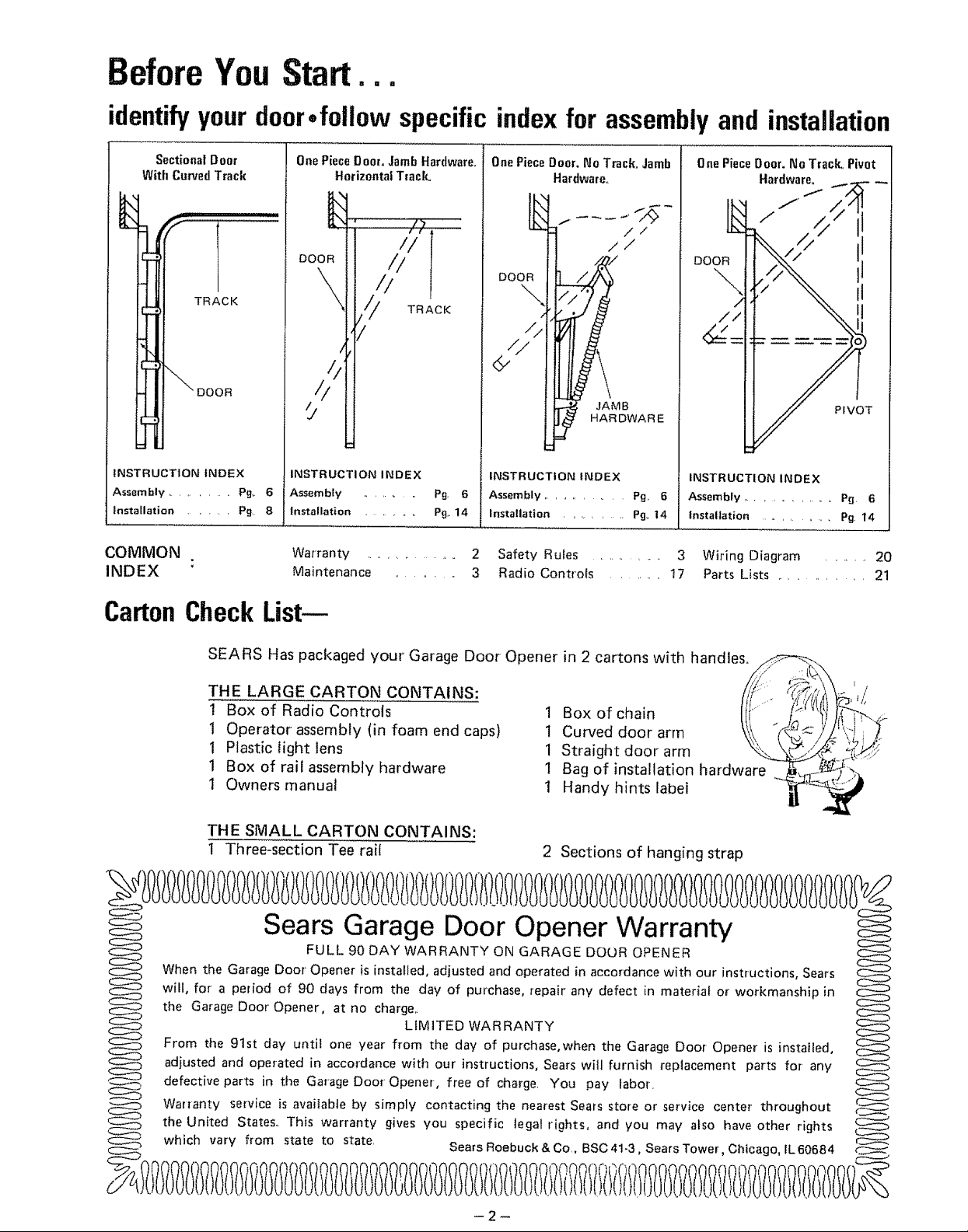

identify your door

Sectional DDOt

With Curved Track

UX

gx

TRACK

DOOR

iNSTRUCTiON INDEX

Assembly ......... Pg_ 6

installation ...... Pg, 8

COMMON

INDEX :

•follow specificindexfor assemblyand installation

One Piece Door. Jamb Hardware_

Horizontal Track°

,,/_, ,,

/il

DOOR

\

\

\

/ TRACK

!

One Piece Door, No Track. Jamb

Hardware,,

//

//

One Piece Door. No Track, Pivot

Hardware,

.f

/

DOOR

\

//

//

//

9

iNSTRUCTION INDEX

Assembly ......... pg. 6

installation ....... Pg., 14

Warranty ............ 2 Safety Rules ........... 3 Wiring Diagram ....... 20

Maintenance ......... 3 Radio Controls ........ 17 Parts Lists ............. 21

INSTRUCTION iNDEX

Assembly ........... pg, 6

Installation .......... Pg. 14

JAMB

HARDWARE

INSTRUCTION INDEX

Assembly .............. P_ 6

Installation ............ Pg 14

PIVOT

CartonCheckList--

SEARS Has packaged your Garage Door Opener in 2 cartons with handles,,_

THE LARGE CARTON CONTAINS: "_J_!Ji_i!#_

1 Box of Radio Controls I Box of chain

1 Operator assembly (in foam end caps) 1 Curved door arm _,_ '

1 Plastic light lens 1 Straight door arm

1 Box of rail assembly hardware 1 Bag of installation hardware

1 Owners manual 1 Handy hints labeF

THE SMALL CARTON CONTAINS:

I Three-section Tee rai!

Sears Garage Door Opener Warranty

FULL 90 DAY WARRANTY ON GARAGE DOOR OPENER

When the Garage Door Opener is installed, adjusted and operated in accordance with our instructions, Sears

will, for a period of 90 days from the day of purchase, repair any defect in material or workmanship in

the Garage Door Opener, at no charge,.

From the 91st day until one year from the day of purchase, when the Garage Door Opener is instatled,

adjusted and operated in accordance with our instructions, Sears will furnish replacement parts fm any

defective parts in the Garage Door Opener, free of charge. You pay labor,

Warranty service is available by simply contacting the nearest Sears store or service center throughout

the United States., This warranty gives you specific tegal rights, and you may also have other rights

which vary from state to state. Sears Roebuck & Co., BSC 41-3, Sears Tower, Chicago, _L60684

2 Sections of hanging strap

LIMITED WARRANTY

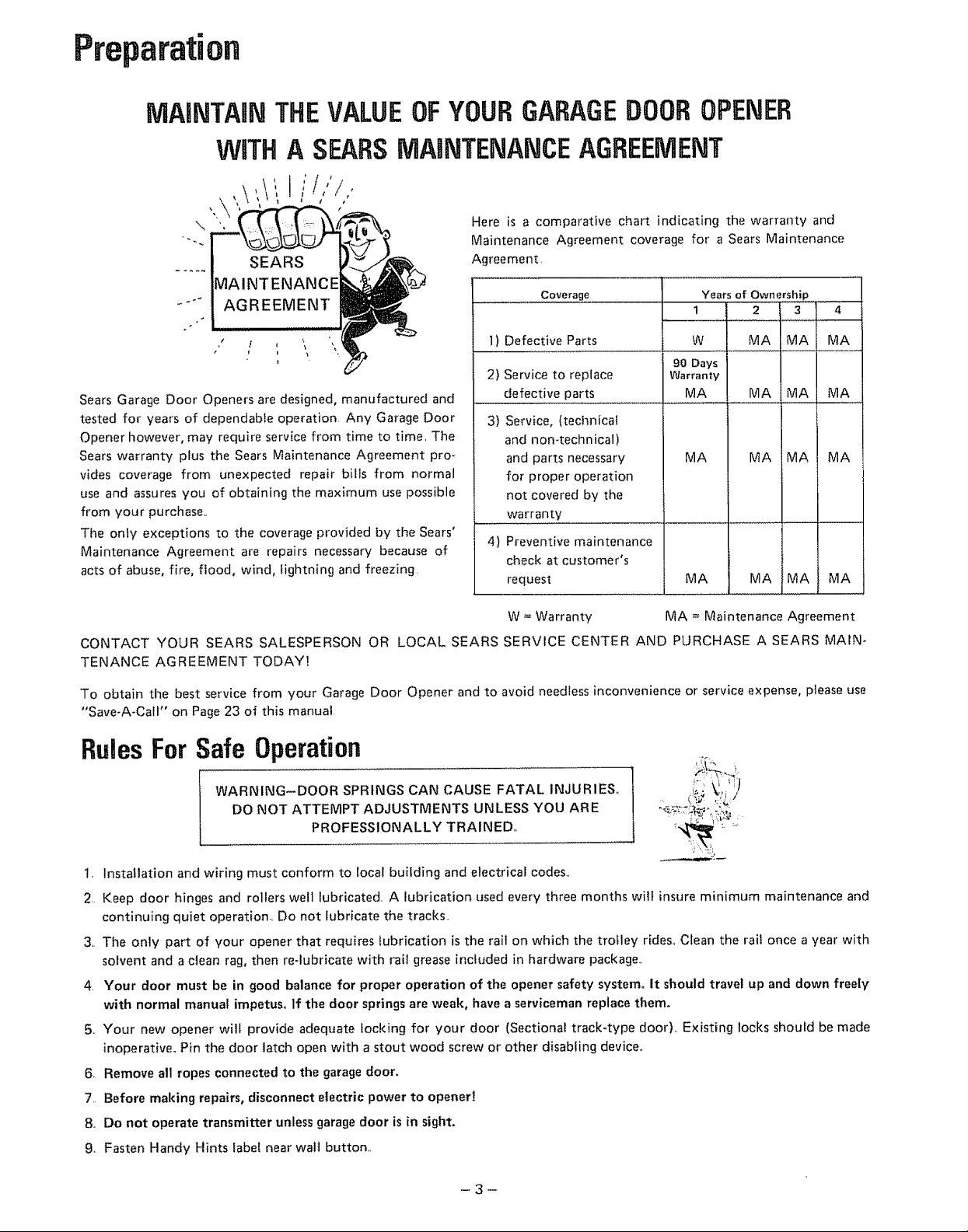

Preparation

MAiNTAiN

THEVALUEOFYOURGARAGEDOOROPENER

MAINTENANCEAGREEMENT

\

.... AGREEMENT

,' l \ 1) Defective Parts W

Sears Garage Door Openers are designed, manufactured and defective parts MA

tested for years of dependable operation Any Garage Door

Opener however, may require service from time to time, The

Sears warranty plus the Sears Maintenance Agreement pro m

vides coverage from unexpected repair bills from normal

use and assures you of obtaining the maximum use possible

from your purchase,,

The only exceptions to the coverage provided by the Sears'

Maintenance Agreement are repairs necessary because of

acts of abuse, fire, flood, wind, lightning and freezing.

Here is a comparative chart indicating the warranty and

Maintenance Agreement coverage for a Sears Maintenance

Agreement

..................Coverage Years of Ownership

2) Service to replace Warranty

3) Service, (technical

and non-technical)

and parts necessary

for proper operation

not covered by the

warranty

4) Preventive maintenance

check at customer's

request

90 Days

MA MA MA MA

MA MAiMA MA

1 2 3 4

MA MA MA

MA MA MA

W = Warranty MA = Maintenance Agreement

CONTACT YOUR SEARS SALESPERSON OR LOCAL SEARS SERVICE CENTER AND PURCHASE ASEARS MAIN-

TENANCE AGREEMENT TODAY!

To obtain the best service from your Garage Door Opener and to avoid needless inconvenience or service expense, please use

"Save-A-Call" on Page 23 of this manual

RulesFor Safe Operation

WARNING-DOOR SPRINGS CAN CAUSE FATAL INJURIES°

DO NOT ATTEMPT ADJUSTMENTS UNLESS YOU ARE

PROFESSIONALLY TRAINED.

t, Installation and wiring must conform to local building and electrical codes.,

2, Keep door hinges and rollers well lubricated, A lubrication used every three months wilf insure minimum maintenance and

continuing quiet operation. Do not lubricate the tracks,

3,, The only part of your opener that requires lubrication is the rail on which the trolley rides., Clean the rail once a year with

solvent and a clean rag, then re-lubricate with rail grease included in hardware package.,

4, Your door must be in good balance for proper operation of the opener safety system. It should travel up and down freely

with normal manual impetus° If the door springs are weal{, have a serviceman replace them_

5o Your new opener will provide adequate locking for your door (Sectional track-type door), Existing locks should be made

inoperative° Pin the door latch open with a stout wood screw or other disabling device°

6, Remove all ropes connected to the garage door.

7,, Before making repairs, disconnect electric power to opener!

8,, Do not operate transmitter unless garage door is in sight.

g, Fasten Handy Hints label near walt button,,

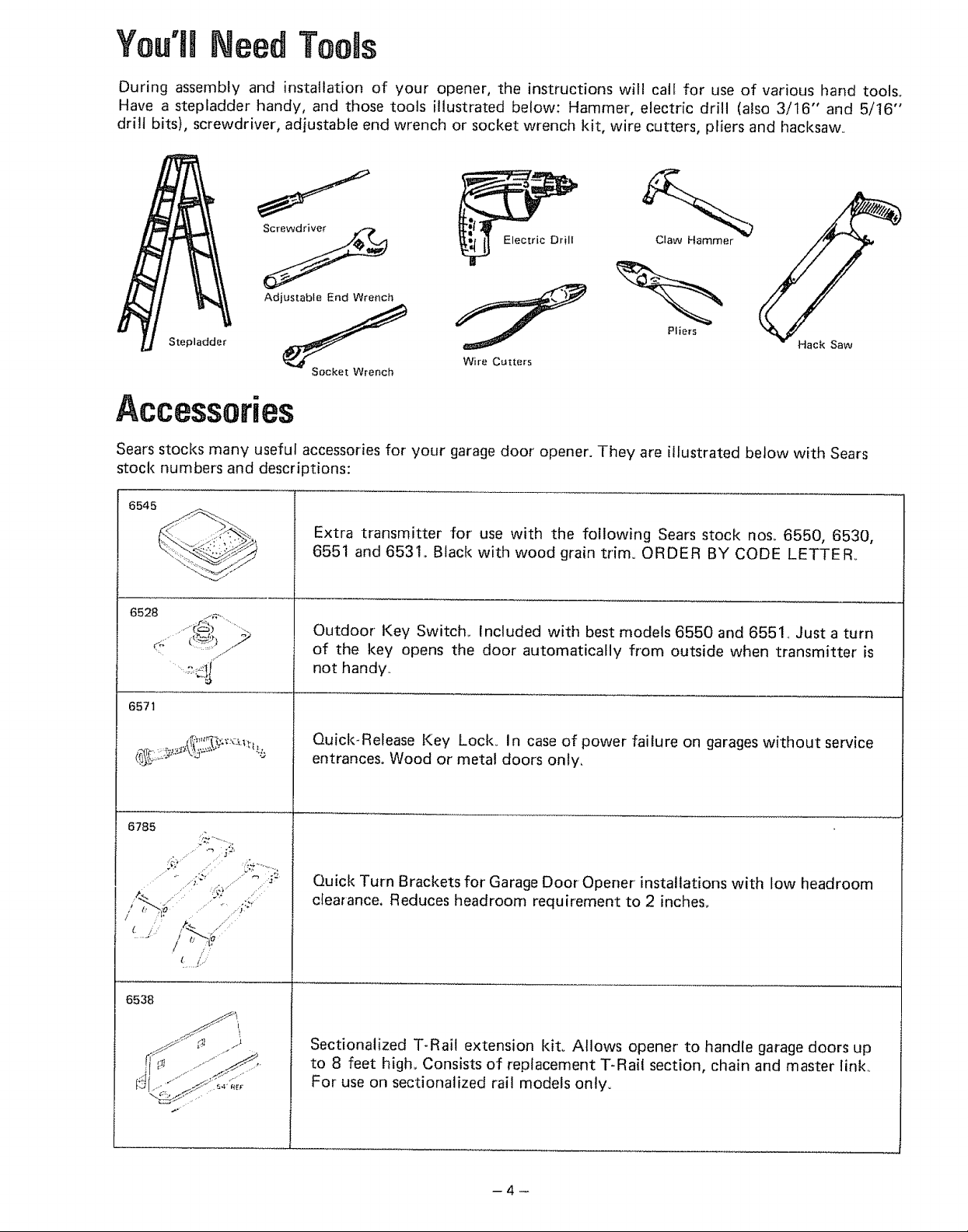

You'll Need Toels

During assembly and installation of your opener, the instructions will call for use of various hand tools_

Have a stepladder handy, and those tools illustrated below: Hammer, electric drill (also 3/16" and 5/16"

drill bits), screwdriver', adjustable end wrench or socket wrench kit, wire cutters, pliers and hacksaw..

Adjustable End Wrench

Stepladder

Socket Wrench

Wire Cutters

Pliers

Accessories

Sears stocks many useful accessories for your garage door' opener. They are illustrated below with Sears

stock numbers and descriptions:

6545

Extra transmitter for use with the following Sears stock nos, 6550, 65.30,

6551 and 6531., Black with wood grain trim° ORDER BY CODE LETTER°

6528 j_,....

6571

f4,_

J (_-.3) .......

Outdoor Key Switch., Included with best models 6550 and 6551.. Just a turn

of the key opens the door automatically from outside when transmitter' is

not handy..

Quick-Release Key Lock. In case of power failure on garages without service

entrances° Wood or metal doors only.

6785

6538

Quick Turn Brackets for Garage Door Opener installations with low headroom

clearance, Reduces headroom requirement to 2 inches.

Sectionalized T-Rail extension kit. ALlows opener to handle garage doors up

to 8 feet high,. Consists of replacement T-Rail section, chain and master link.,

For use on sectionalized rail models only.

.......J

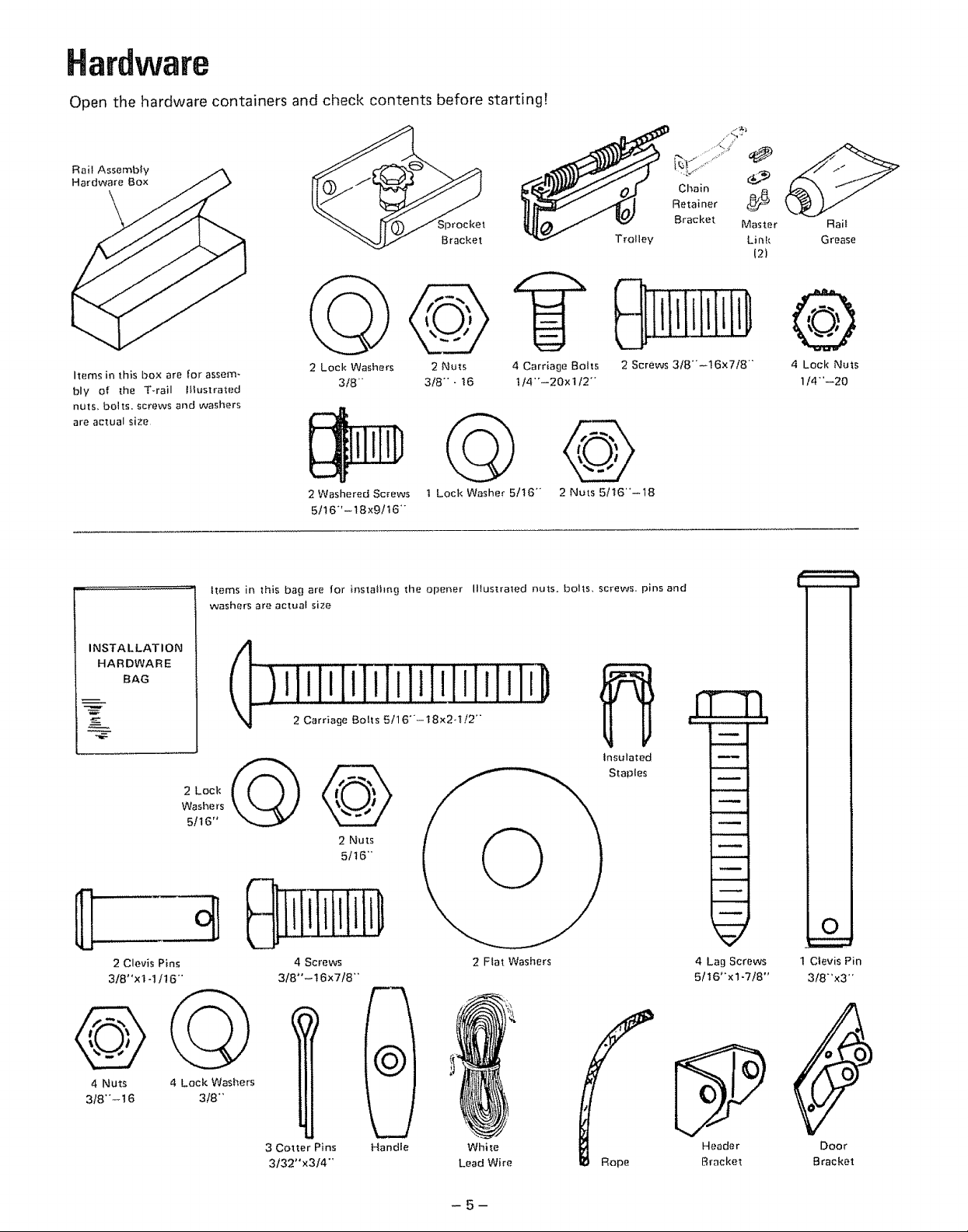

Hardware

Open the hardware containers and check contents before startingF

Rail Assembly

Hardware Box

Trolley

Chain

Retainer

Bracket

Master

Link

12)

Rait

Grease

@

Items in this box are for assem- 2 Nuts

bly of the T.rail IHustrated 3/8--16

nuts, bolts, screws and washers

are actual size

Items in this bag are for instalhng the opener Illustrated nuts. bolts, screws, pins and

washers are actual size

INSTALLATION

HARDWARE

BAG

2 Lock

Washers

5/16"

) _I_IiIi_w!_I_1_iiii]]]_

2 Lock Washers

3f8"

2 Washered Screws

5116"'-18x9tt6""

2 Nuts

51t6"

t Lock Washer 5!16-

4 Carriage Bolts

1!4'°-20x 1/2'"

2 Nuts 5/t6--18

2 Screws 3/8"'-16x7/8"

Insulated

Staples

4 Lock Nuts

1/4--20

2 Clevis Pins

318"xl -1/t6"

4 Nuts

3/8-- t 6

4 Lack Washers

3!8"'

4 Screws

3/8"-t6x7/8"

3 Cotter Pins Handle

3132"x3/4-

l

2 Ftat Washers 4 Lag Screws

5/t6"xl-7!8"

..5__ "-

'_' Header Door

Lead Wire Rope Bracket Bracket

Clevis Pin

318'x3"

-5-

O

Assembly

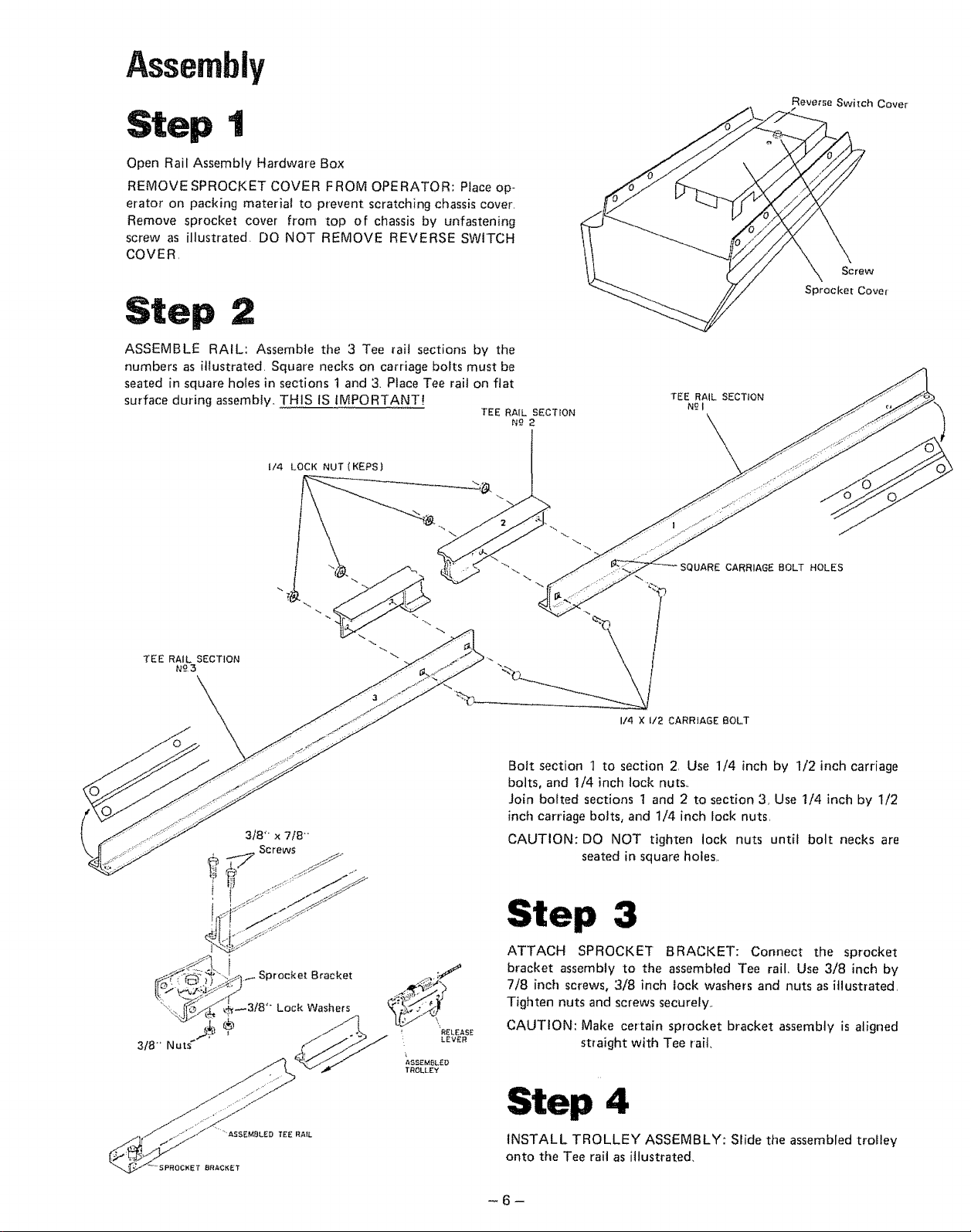

Step 1

Open Rail Assembly Hardware Box

REMOVE SPROCKET COVER FROM OPERATOR: Place op-

erator on packing material to prevent scratching chassis cover.

Remove sprocket cover from top of chassis by unfastening

screw as illustrated. DO NOT REMOVE REVERSE SWITCH

COVER,

ASSEMBLE RAIL: Assemble the 3 Tee rail sections by the

numbers as illustrated. Square necks on carriage bolts must be

seated in square holes in sections t and 3. Place Tee rail on flat

surface during assembly,. THIS IS IMPORTANT!

1/4 LOCK NUT (KEPS)

TEE RAIL SECTION

N_-2

TEE RAIL SECTION

N£1

Reverse Switch Cover

Screw

Sprocket Cover

TEE RAIL SECTION

N£3

R_:LEASE

: LEVER

_SSEMBL_D

TROLLEY

SQUARE CARRIAGE BOLT HOLES

I/4 X I/2 CARRIAGE BOLT

Bolt section 1 to section 2, Use 1/4 inch by 1/2 inch carriage

bolts, and !/4 inch loci( nuts.

Join bolted sections 1 and 2 to section 3, Use 1/4 inch by 1/2

inch carriage bolts, and 1/4 inch lock nuts,

CAUTION: DO NOT tighten lock nuts until bolt necks are

seated in square holes,,

Step 3

ATTACH SPROCKET BRACKET: Connect the sprocket

bracket assembly to the assembFed Tee rail Use 3/8 inch by

7/8 inch screws, 3/8 inch lock washers and nuts as itlust[ated,

Tighten nuts and screws securely..

CAUTION: Make certain sprocket bracket assembly is aligned

straight with Tee rait,

Step 4

INSTALL TROLLEY ASSEMBLY: Slide the assembled trolley

onto the Tee rait as illustrated,

-6-

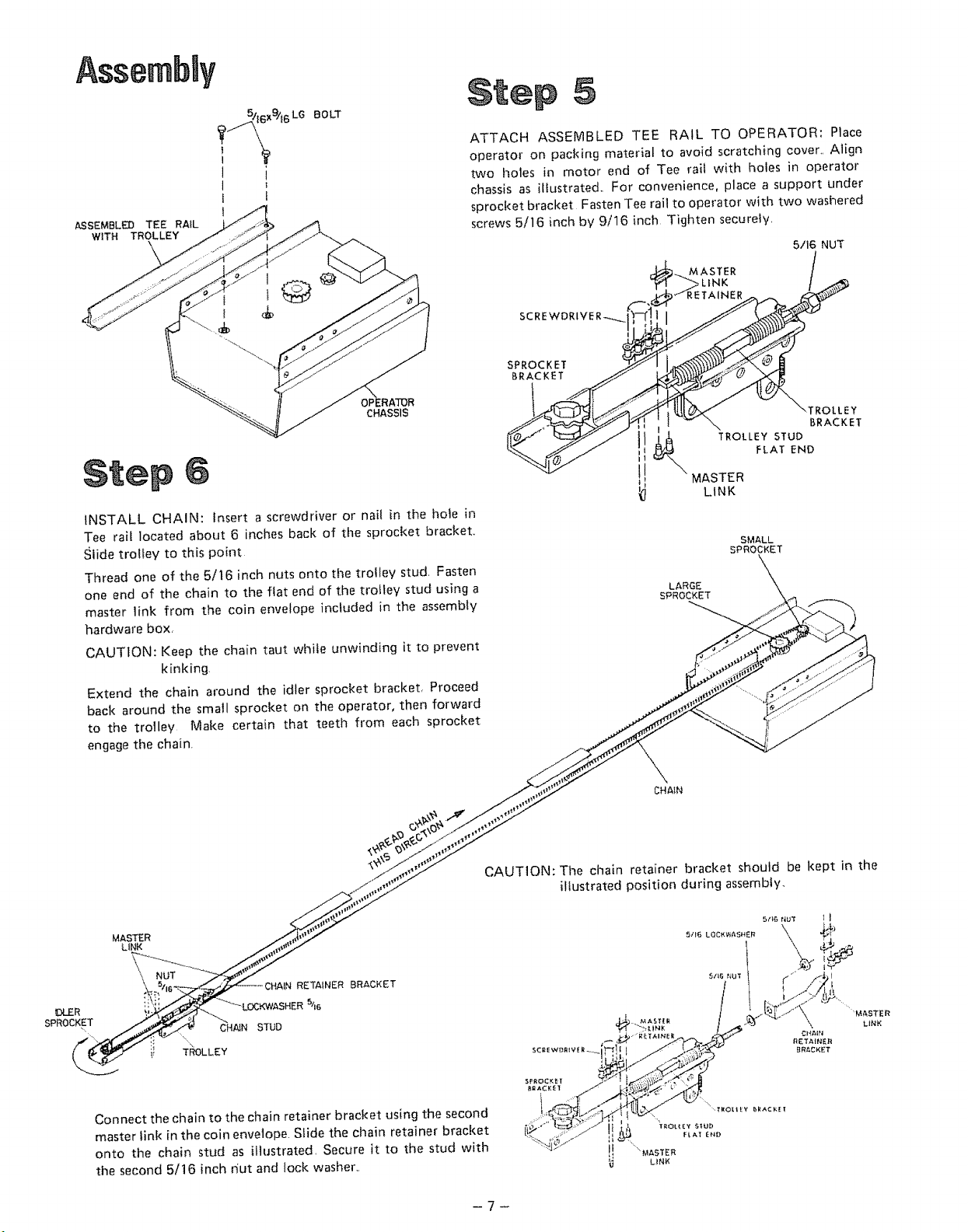

Assembty

'i6x_t6 LG BOLT

ASSEMBLED TEE RAIL

WITH TROLLEY

OPERATOR

CHASSIS

INSTALL CHAIN: Insert a screwdriver or nail in the hole in

Tee rai! located about 6 inches back of the sprocket bracket,,

Slide trolley to this point

Thread one of the 5/16 inch nuts onto the trolley stud Fasten

one end of the chain to the fiat end of the t_'olley stud using a

master link from the coin envelope included in the assembly

hardware box,

CAUTION: Keep the chain taut white unwinding it to prevent

kinking

Extend the chain around the idler sprocket bracket, Proceed

back around the small sprocket on the operator, then forward

to the trolley Make certain that teeth from each sprocket

engage the chain

5

ATTACH ASSEMBLED TEE RAIL TO OPERATOR: Place

operator on packing material to avoid scratching cover,, Align

two holes in motor end of Tee rail with holes in operator

chassis an illustrated, For convenience, place a support under

sprocket bracket Fasten Tee rail to operator with two washered

screws 5/16 inch by 9/16 inch Tighten securely,

5/I6 NUT

SCREWDRIV

SPROCKET

BRACKET

\TROLLEY

BRACKET

MASTER

LARGE

SPROCKET

TROLLEY STUD

FLAT END

LINK

SMALL

SPROCKET

DLER

SPROCKET

MASTER

LINK

RETAINER BRACKET

DC_WASHER_6

CHiN STUb

TROLLEY

J

Connect the chain to the chain retainer bracket using the second

master tink in the coin envelope Slide the chain retainer bracket

onto the chain stud as illustrated Secure it to the stud with

the second 5/16 inch nut and lock washer,,

CAUTION: Tile chain retainer bracket should be kept in the

illustrated position during assembiy_

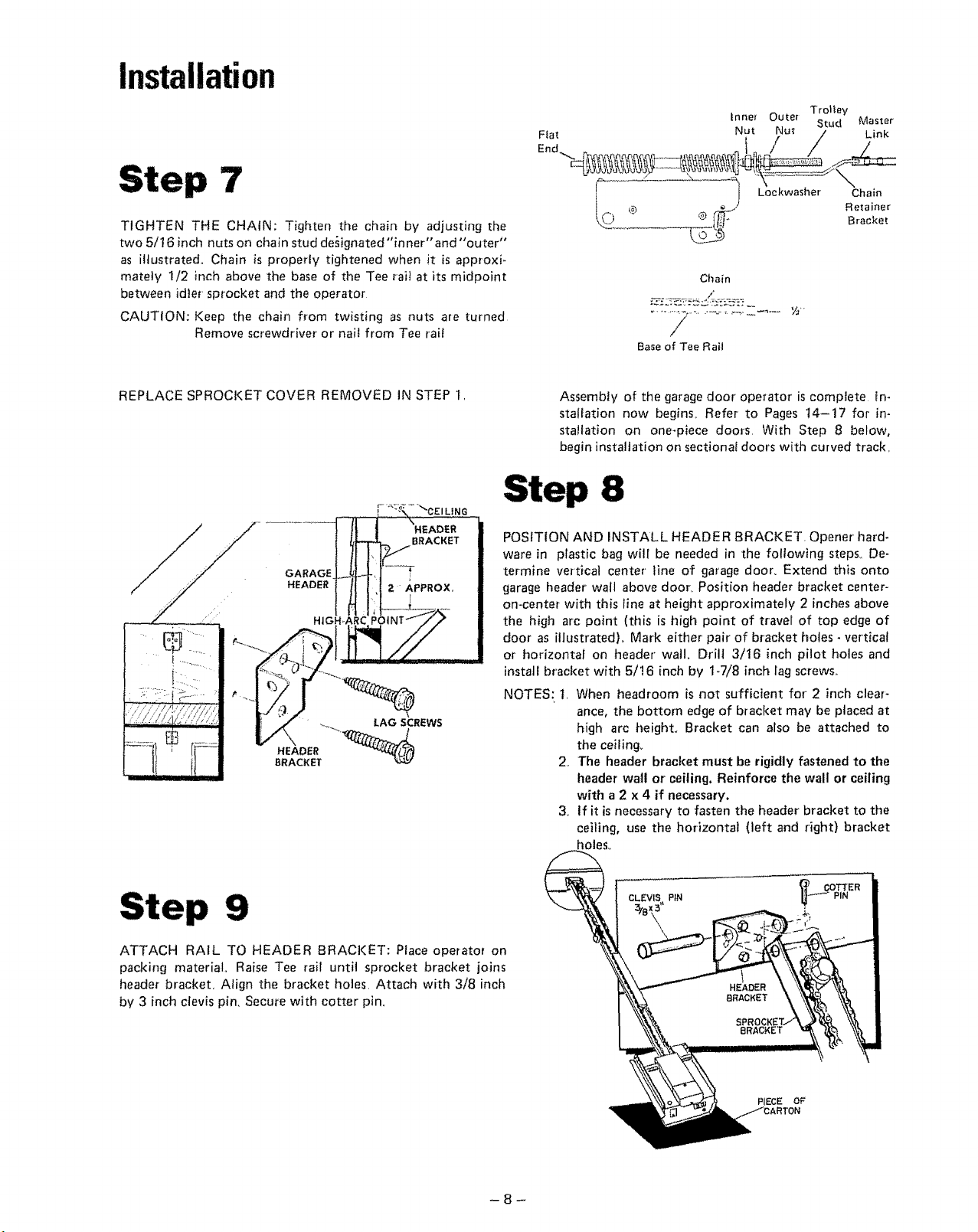

Installation

Step 7

TIGHTEN THE CHAIN: Tighten the chain by adjusting the

two 5/16 inch nuts on chain stud de_ignated"inner" and "outer"

as illustrated,, Chain is propmty tightened when it is approxi-

mately 1/2 inch above the base of the Tee rait at its midpoint

between idler sprocket and the operator

CAUTION: Keep the chain from twisting as nuts are turned

Remove screwdriver or nait from Tee rail

Chain

/

Base of Tee Rail

REPLACE SPROCKET COVER REMOVED IN STEP 1,

GARAGE

HEADER

" +._ LAG SCREWS

HEADER _"_

BRACKET

Assembly of the garage door operator is complete in-

statlation now begins+ Refer to Pages t4-17 for in-

stallation on one-piece doors, With Step 8 below,

begin installation on sectional doors with curved track,

Step 8

POSITION AND INSTALL HEADER BRACKET. Opener"hard-

ware in plastic bag will be needed in the following steps,, De-

termine vertical center" line of garage door+ Extend this onto

garage header wall above door+ Position header bracket center-

on-center with this line at height approximately 2 inches above

the high arc point (this is high point of travel of top edge of

door as illustratedL Mark either' pair of bracket holes - vertical

or horizontal on header" watlo Drill 3/16 inch pilot holes and

instatl bracket with 5/16 inch by 1-7/8 inch lag screws,.

NOTES: t, When headroom is not sufficient for 2 inch clear-

ance, the bottom edge of bracket may be placed at

high arc height. Bracket can also be attached to

the ceiling+

2,, The header bracket must be rigidly fastened to the

header' walt or ceiling. Reinforce the wall or ceiling

with a2 x 4 if necessary.

& If it is necessary to fasten the header bracket to the

ceiling, use the horizontal (left and right) bracket

holes°

Step 9

ATTACH RAIL TO HEADER BRACKET: Place operator on

packing material° Raise Tee rail until sprocket bracket joins

header bracket, Align the bracket holes, Attach with 3/8 inch

by 3 inch clevis pin, Secure with cotter pin+

PIN

PIECE OF'

Loading...

Loading...