Craftsman 13953976SRT Owner’s Manual

Owner's Manual/Manual Del Propietario

CRRFTSMRN°

1/2 HP

GARAGE DOOR OPENER

ABRIDOR DE PUERTA DE COCHERA

For Residential Use Only/S61o para uso residencial

ModellModelo 139.53976SRT

m

Z

CAUTION"

Read and follow all safety rules

and operating instructions before

first use of this product.

Fasten the manual near the garage

door after installation.

PRECAUCION:

Leer y seguir todas las regias de

seguridad y las instrucciones de

operaci6n antes de usar este

producto por primera vez.

Guardar este manual cerca de la

puerta del garaje.

!==,

m

m

"o

Z_

0

00°s

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A

www.sears.com/craftsman

TABLE OF CONTENTS

In troduc tion 2=7

Safety symbol and signal word review ........................ 2

Preparing your garage door ........................................ 3

Tools needed ............................................................... 3

Planning .................................................................. 4-5

Carton inventory .......................................................... 6

Hardware inventory ..................................................... 7

Assembly 8-11

Assemble the rail and install trolley ............................. 8

Fasten rail to motor unit and install idler pulley ..........9

Install chain/cable and attach sprocket cover ........... 10

Tighten the chain ....................................................... 11

Installa tion 11 =2 7

Installation safety instructions .................................... 11

Determine the header bracket location ................ 12-13

Install the header bracket .......................................... 14

Attach the rail to the header bracket ......................... 15

Position the opener ................................................... 16

Hang the opener ....................................................... 17

Install the door control ............................................... 18

Install the light and lens ............................................ 19

Attach the emergency release rope and handle ....... 19

Electrical requirements .............................................. 20

Install the safety reversing sensor ....................... 21-23

Fasten the door bracket ....................................... 24-25

Connect the door arm to the trolley ..................... 26-27

Adjustment 28-30

Adjust the travel limits ............................................... 28

Adjust the force ......................................................... 29

Test the safety reversal system ................................. 30

Test the safety reversing sensor ............................... 30

Operation 31=34

Operation safety instructions ..................................... 31

Using your garage door opener ................................ 31

Using the wall-mounted Door Control ....................... 32

To open the door manually ........................................ 32

Care of your garage door opener .............................. 33

Having a problem? .................................................... 34

Programming 35=36

To add a hand-held remote control ........................... 35

To erase all codes ..................................................... 35

3-Function Remotes .................................................. 35

To add or change a Keyless Entry PIN ..................... 36

Repair Parts 37=38

Rail assembly parts ................................................... 37

Installation parts ........................................................ 37

Motor unit assembly parts ......................................... 38

Accessories 39

Warranty

Service Numbers

Back cover

39

iNTRODUCTiON

Safety Symbol

and Signal Word Review

This garage door opener has been designed and tested to offer safe service provided it is installed, operated,

maintained and tested in strict accordance with the instructions and warnings contained in this manual.

When you see these Safety Symbols and Signal

Words on the following pages, they will alert you to

Mechanical

the possibility of serious injury or death if you do

not comply with the warnings that accompany them.

The hazard may come from something mechanical

or from electric shock. Read the warnings carefully.

Electrical

When you see this Signal Word on the following

pages, it will alert you to the possibility of damage to

your garage door and/or the garage door opener if

you do not comply with the cautionary statements

that accompany it. Read them carefully.

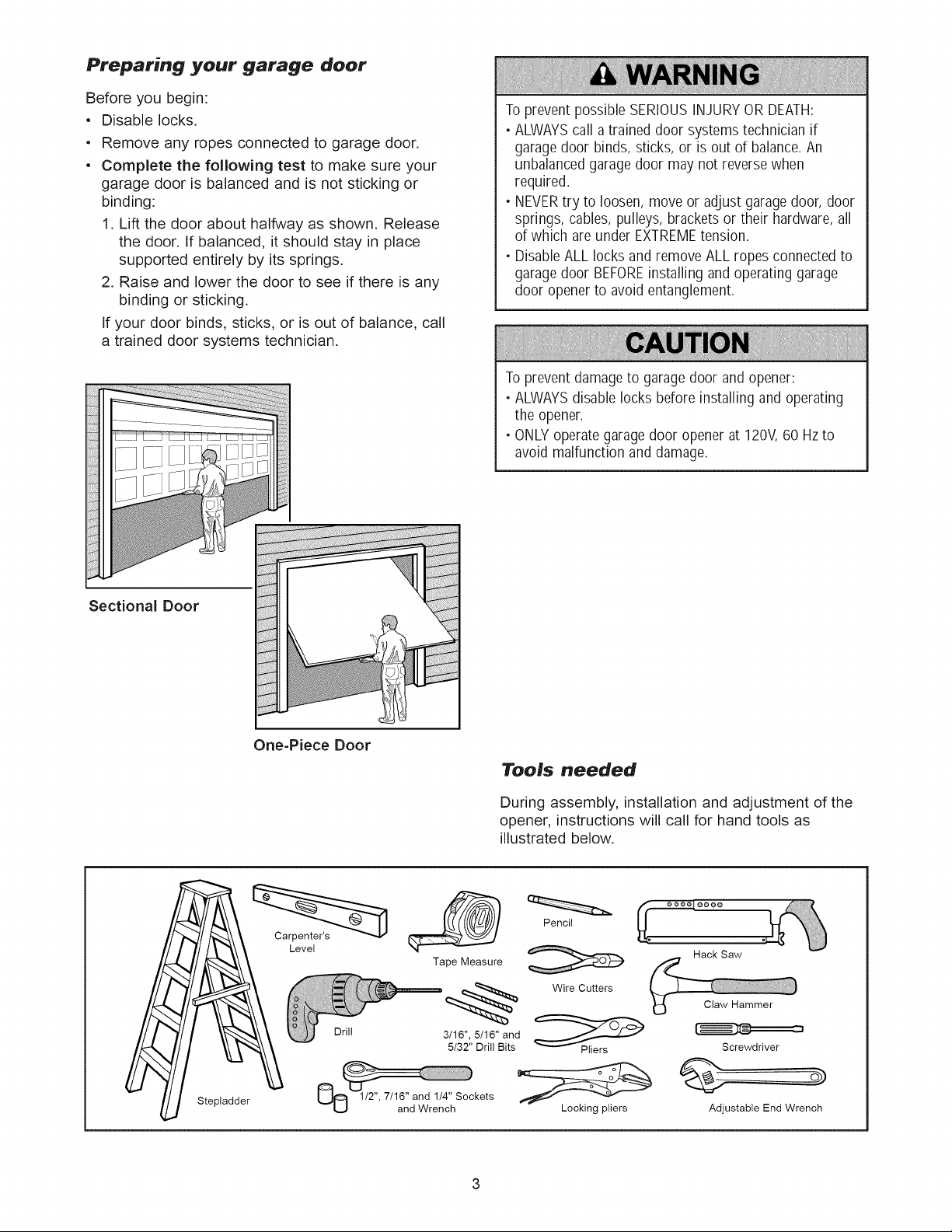

Preparing your garage door

Before you begin:

• Disable locks.

• Remove any ropes connected to garage door.

• Complete the following test to make sure your

garage door is balanced and is not sticking or

binding:

1. Lift the door about halfway as shown. Release

the door. If balanced, it should stay in place

supported entirely by its springs.

2. Raise and lower the door to see if there is any

binding or sticking.

If your door binds, sticks, or is out of balance, call

a trained door systems technician.

Topreventpossible SERIOUSINJURYOR DEATH:

, ALWAYScall a trained door systems technician if

garagedoor binds, sticks, or is out of balance.An

unbalancedgaragedoor may not reversewhen

required.

, NEVERtry to loosen, move or adjust garagedoor, door

springs, cables, pulleys, brackets or their hardware, all

of which are under EXTREMEtension.

, DisableALL locks and remove ALL ropes connected to

garagedoor BEFOREinstalling and operating garage

door opener to avoidentanglement.

Toprevent damageto garagedoor and opener:

, ALWAYSdisable locks before installing and operating

the opener.

, ONLYoperategaragedoor opener at 120V,60 Hzto

avoid malfunction and damage.

Sectional Door

One-Piece Door

Level

Drill

Tools needed

During assembly, installation and adjustment of the

opener, instructions will call for hand tools as

illustrated below.

Pencil

Tape Measure

Wire Cutters

3/16", 5/16" and

5/32" Drill Bits Screwdriver

Hack Saw

Stepladder

Locking pliers Adjustable End Wrench

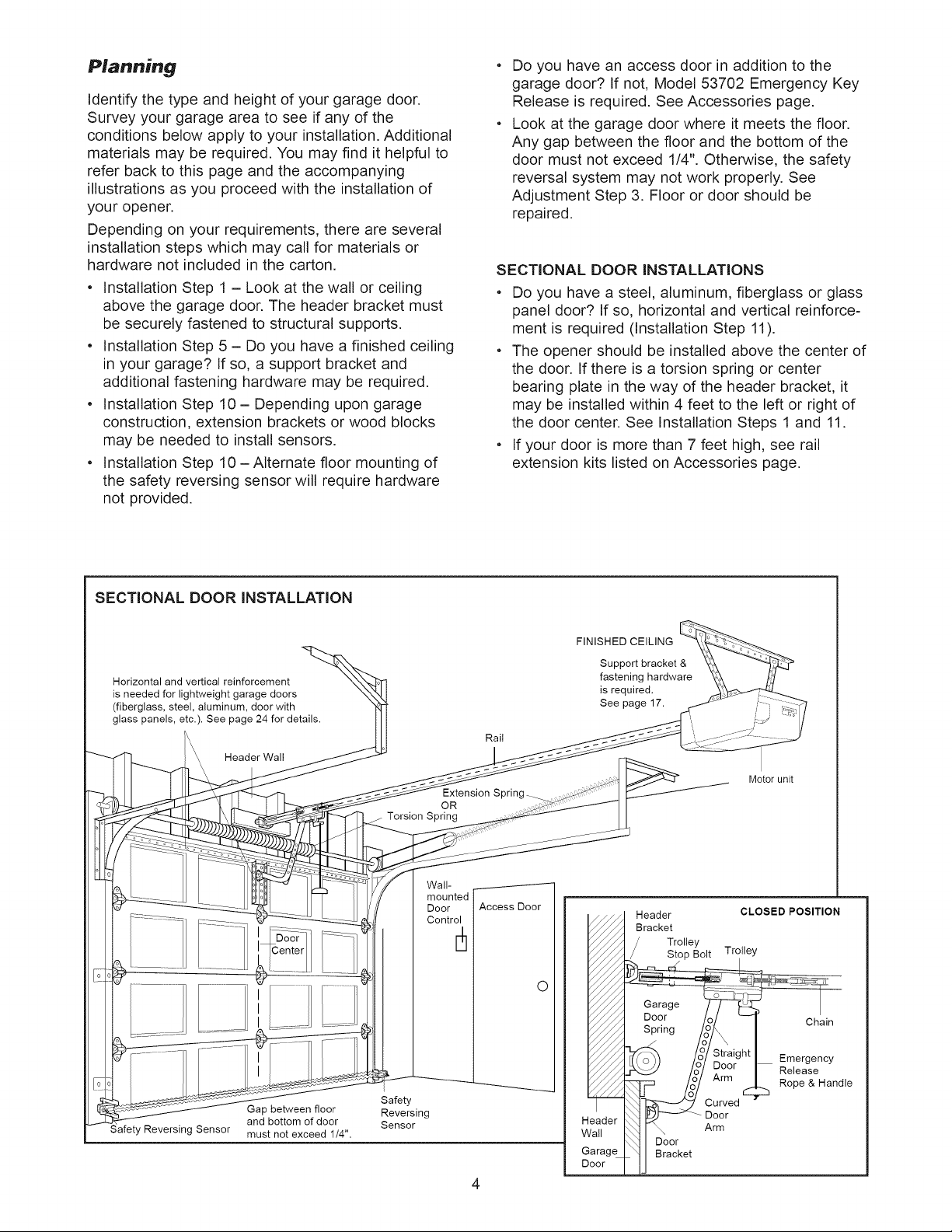

Planning

Identify the type and height of your garage door.

Survey your garage area to see if any of the

conditions below apply to your installation. Additional

materials may be required. You may find it helpful to

refer back to this page and the accompanying

illustrations as you proceed with the installation of

your opener.

Depending on your requirements, there are several

installation steps which may call for materials or

hardware not included in the carton.

• Installation Step 1 - Look at the wall or ceiling

above the garage door. The header bracket must

be securely fastened to structural supports.

• Installation Step 5 - Do you have a finished ceiling

in your garage? If so, a support bracket and

additional fastening hardware may be required.

• Installation Step 10- Depending upon garage

construction, extension brackets or wood blocks

may be needed to install sensors.

• Installation Step 10 -Alternate floor mounting of

the safety reversing sensor will require hardware

not provided.

Do you have an access door in addition to the

garage door? If not, Model 53702 Emergency Key

Release is required. See Accessories page.

Look at the garage door where it meets the floor.

Any gap between the floor and the bottom of the

door must not exceed 1/4". Otherwise, the safety

reversal system may not work properly. See

Adjustment Step 3. Floor or door should be

repaired.

SECTIONAL DOOR INSTALLATIONS

• Do you have a steel, aluminum, fiberglass or glass

panel door? If so, horizontal and vertical reinforce-

ment is required (Installation Step 11).

• The opener should be installed above the center of

the door. If there is a torsion spring or center

bearing plate in the way of the header bracket, it

may be installed within 4 feet to the left or right of

the door center. See Installation Steps 1 and 11.

• If your door is more than 7 feet high, see rail

extension kits listed on Accessories page.

SECTIONAL DOOR INSTALLATION

Horizontal and vertical reinforcement

is needed for lightweight garage doors

(fiberglass, steel, aluminum, door with

glass panels, etc.). See page 24 for details.

Header Wall

Torsion Spring

OR

Wall-

mounted

Door

Control

Rail

Extension Spring

Access Door

FINISHED CEILING

O

Support bracket &

fastening hardware

is required.

See page 17.

Motor unit

-- Header CLOSED POSITION

Bracket

I_A / Trolley

,-'_ __ _ _ ......

__OltGarage Trolle

Door Chain

m

/

Safety Reversing Sensor

Gap between floor

and bottom of door

must not exceed 1/4".

Safety

Reversing

Sensor

__ j ___Straight Emergency

Spnng o I

io pot I Release

_ /O_/ _rm _ Rop e&Handle

H:_lder /_ _DDoor Arm

Garage_J I Bracket

Door[iJ

Planning (continued)

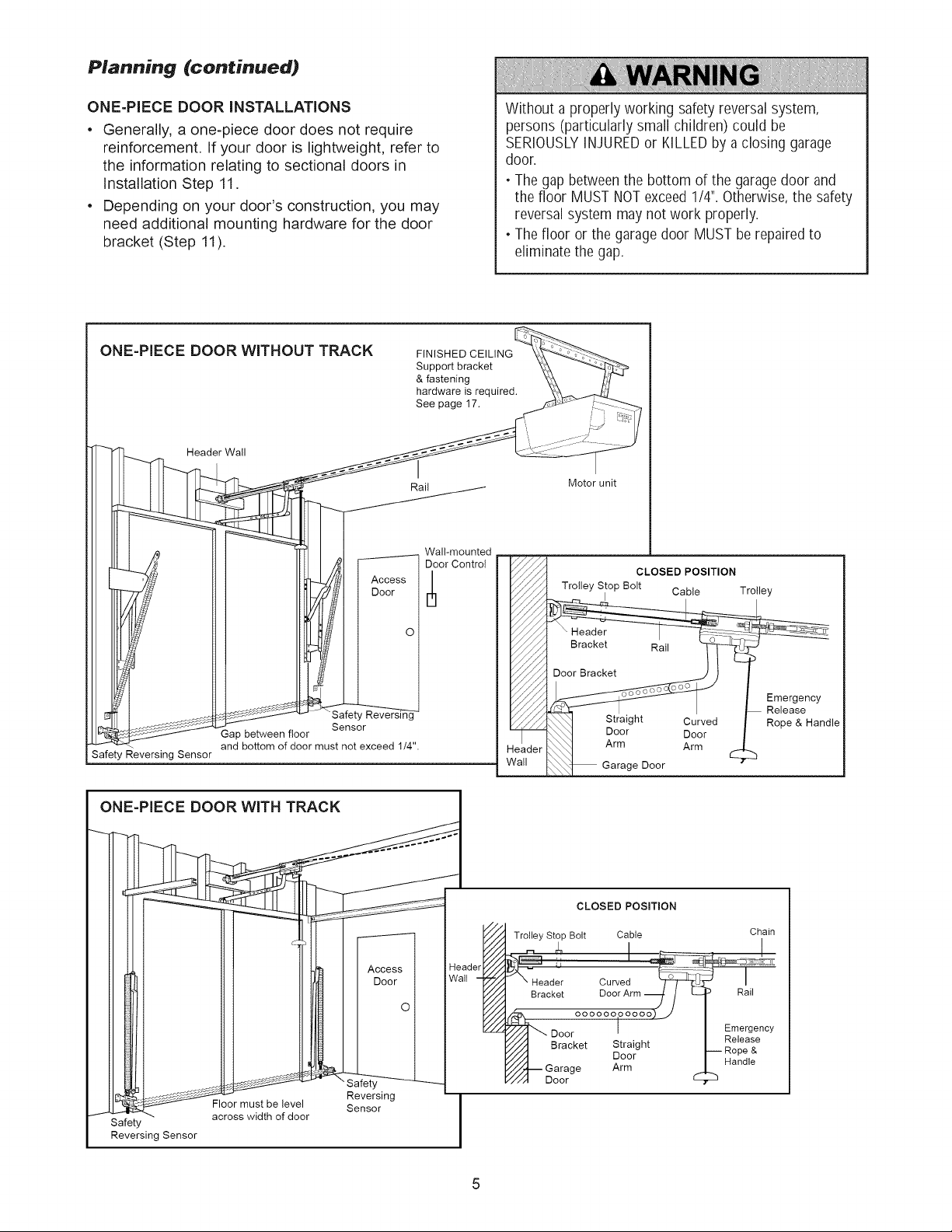

ONE-PIECE DOOR iNSTALLATiONS

• Generally, a one-piece door does not require

reinforcement. If your door is lightweight, refer to

the information relating to sectional doors in

Installation Step 11.

• Depending on your door's construction, you may

need additional mounting hardware for the door

bracket (Step 11).

Without a properly working safetyreversal system,

persons (particularly small children) could be

SERIOUSLYINJUREDor KILLEDby a closing garage

door.

. The gap betweenthe bottom of the garagedoor and

the floor MUST NOTexceed1/4". Otherwise,the safety

reversal system may not work properly.

. The floor or the garage door MUSTbe repaired to

eliminate the gap.

ONE-PIECE DOOR WITHOUT TRACK FINISHEDCEILING

Support bracket __L_

& fastening _',_::_ [!t -

h:rdware is required. __

T'_Y?q Header Wall __'_ L_ _:2 "

"Motor unit

I III t ,_ tt I TFr I I _ Wall-mounted

I c.os o os...o.

_o F_ I -_<:-_:__--__-- -:

...... Rope & Handle

Safety Reversing Sensor I ,_,_,_' I\_1 ...... _

and bottom of door must not exceed 1/4". I Header l_q Arm Arm f

I wall _ Garage Door

ONE-PIECE DOOR WiTH TRACK

i

¢

Safety

Reversing Sensor

Floor must be level

across width of door

Reversing

Sensor

Trolley Stop Bolt Cable

_ Head'elr Cu

_...._ Door° ° ° ° ° °_°°°°°') j

CLOSED POSITION

Bracket rm

racket t;o pt

Goaroage Arm ¢-

i Rope &

Chain

Rail

Emergency

Release

Handle

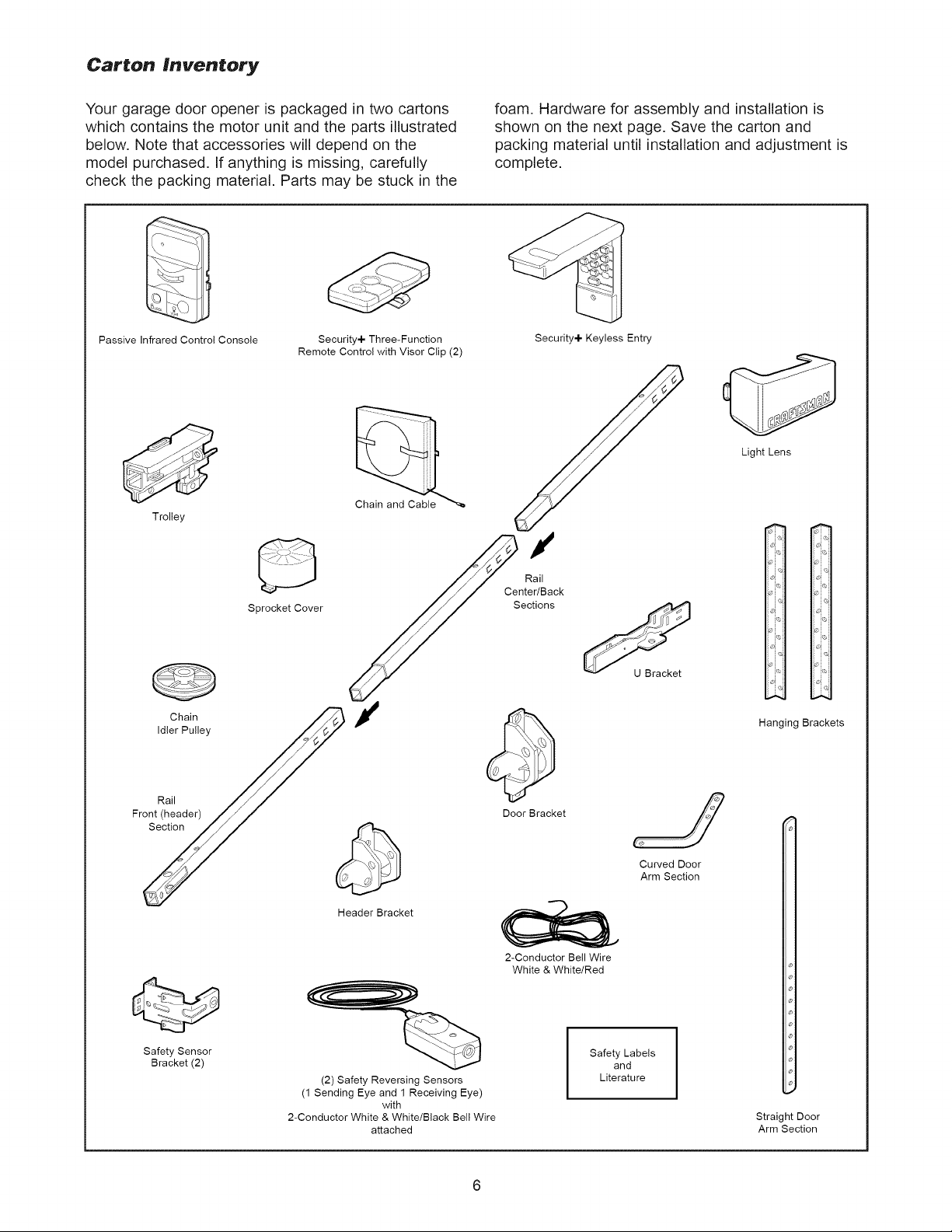

Carton Inventory

Your garage door opener is packaged in two cartons

which contains the motor unit and the parts illustrated

below. Note that accessories will depend on the

model purchased. If anything is missing, carefully

check the packing material. Parts may be stuck in the

Passive Infrared Control Console

Trolley

Security+ Three-Function

Remote Control with Visor Clip (2)

Chain andCabl_

foam. Hardware for assembly and installation is

shown on the next page. Save the carton and

packing material until installation and adjustment is

complete,

Security+ Keyless Entry

Light Lens

#

Sprocket Cover

'dICrhpiu_ley _ #

Rail ///

Front (header) ///

Rail

Center/Back

Sections

U Bracket

Hanging Brackets

Door Bracket

Curved Door

Arm Section

Header Bracket

2-Conductor Bell Wire

White & White/Red

Safety Sensor

Bracket (2)

(2) Safety Reversing Sensors

(1 Sending Eye and 1 Receiving Eye)

2-Conductor White & White/Black Bell Wire

with

attached

Safety Labels

and

Literature

Straight Door

Arm Section

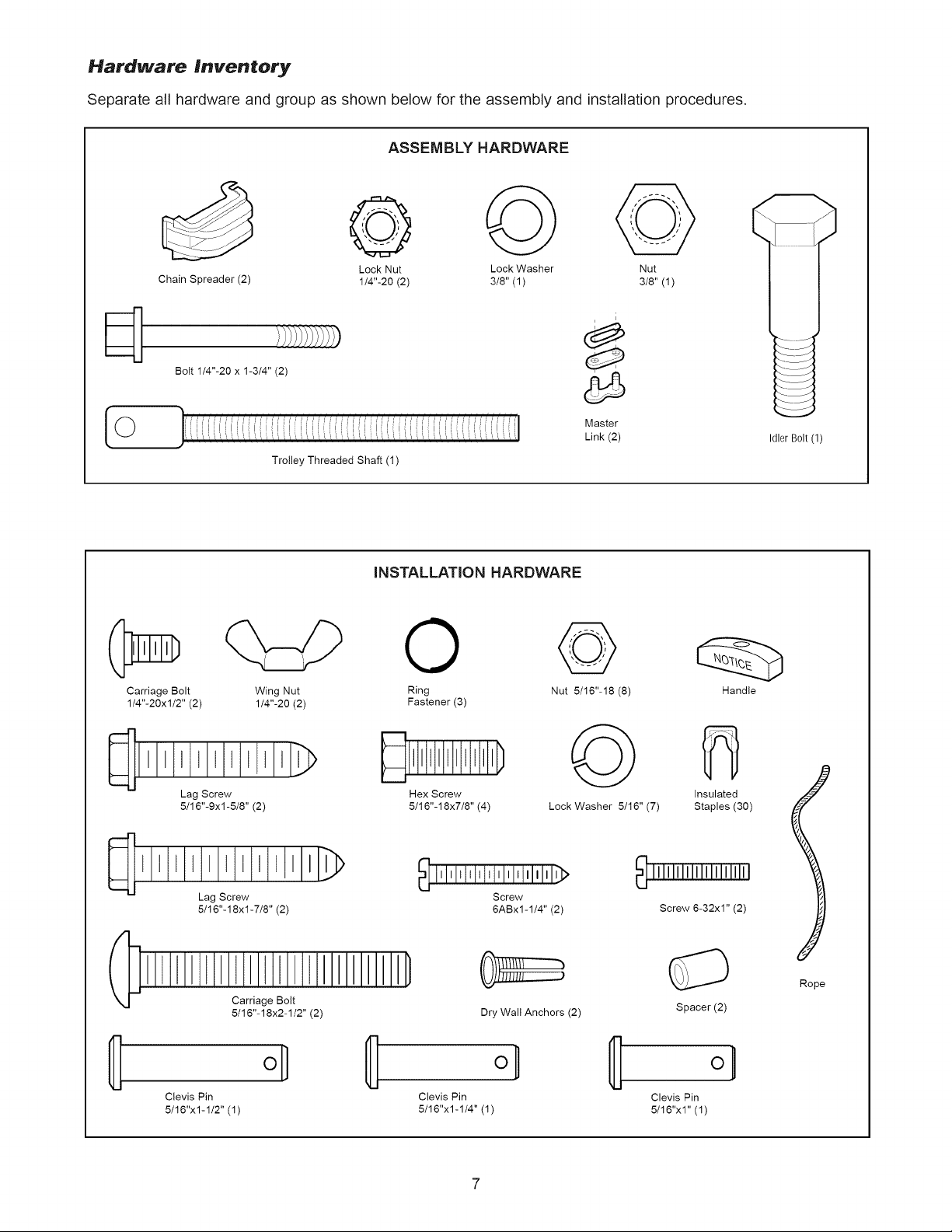

Hardware Inventory

Separate all hardware and group as shown below for the assembly and installation procedures.

ASSEMBLY HARDWARE

Chain Spreader (2) 1/4"-20 (2) 3/8" (1) 3/8" (1)

Bolt 1/4"-20 x 1-3/4" (2)

Trolley Threaded Shaft (1)

Lock Nut Lock Washer Nut

Master

Link (2)

INSTALLATION HARDWARE

O

Carriage Bolt

1/4"-20xl/2" (2)

Wing Nut Ring

1/4"-20 (2) Fastener (3)

Nut 5/16"-18 (8)

Idler Bolt (1)

Handle

1111111111

Lag Screw

5/16"-9xl-5/8" (2)

1IIIIIIIIII1

Lag Screw

5/16"-18xl-7/8" (2)

Carriage Bolt

5/16"-18x2-1/2" (2)

Clevis Pin

5/16"x1-1/2" (1)

ol

Hex Screw

5/16"-18x7/8" (4)

Clevis Pin

5/16"x1-1/4" (1)

Lock Washer 5/16" (7)

Screw

6ABx1-1/4" (2) Screw 6-32x1" (2)

Dry Wall Anchors (2)

Insulated

Staples (30)

Spacer (2)

°1

Clevis Pin

5/16"x1" (1)

Rope

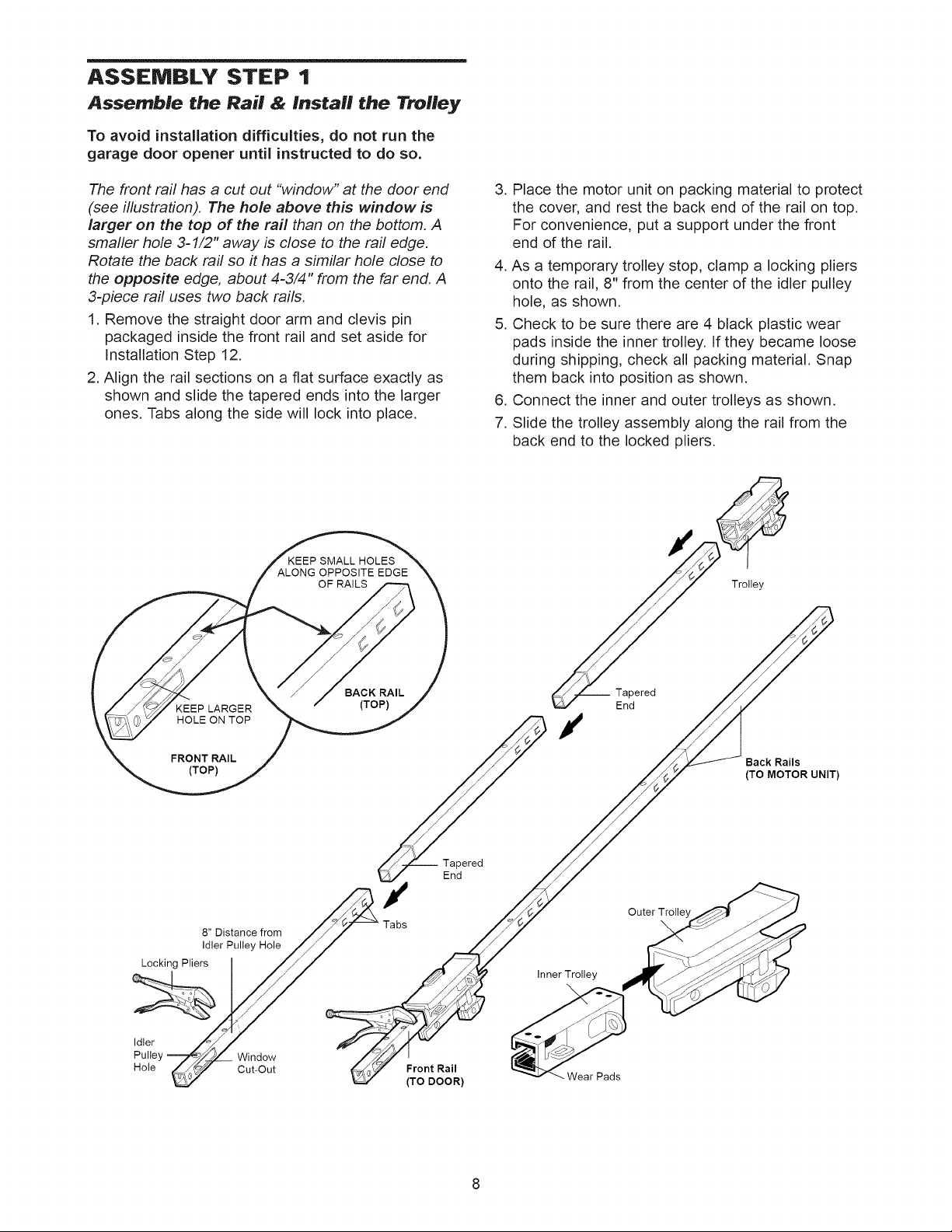

ASSEMBLY STEP 1

Assemble the Rail & Install the Trolley

To avoid installation difficulties, do not run the

garage door opener until instructed to do so,

The front rail has a cut out "window" at the door end

(see illustration). The hole above this window is

larger on the top of the rail than on the bottom. A

smaller hole 3-1/2" away is close to the rail edge.

Rotate the back rail so it has a similar hole close to

the opposite edge, about 4-3/4" from the far end. A

3-piece rail uses two back rails.

1. Remove the straight door arm and clevis pin

packaged inside the front rail and set aside for

Installation Step 12.

2. Align the rail sections on a flat surface exactly as

shown and slide the tapered ends into the larger

ones. Tabs along the side will lock into place.

SMALL HOLES

ALONG OPPOSITE EDGE

OF RAILS

.

Place the motor unit on packing material to protect

the cover, and rest the back end of the rail on top.

For convenience, put a support under the front

end of the rail.

4. As a temporary trolley stop, clamp a locking pliers

onto the rail, 8" from the center of the idler pulley

hole, as shown.

5. Check to be sure there are 4 black plastic wear

pads inside the inner trolley. If they became loose

during shipping, check all packing material. Snap

them back into position as shown.

6. Connect the inner and outer trolleys as shown.

7. Slide the trolley assembly along the rail from the

back end to the locked pliers.

BACK RAIL

KEEP LARGER

HOLE ON TOP

FRONT RAIL

(TOP)

(TOP)

End

8" Distance from _ Ta_bs

Idler Pulley Hole /_/

Idler /_/

Pulley ===7€_//_,/ Window

Hole _ Cut-Out _Tont Rao/ )

I

Back Rails

(TO MOTOR UNIT)

Inner Trolley

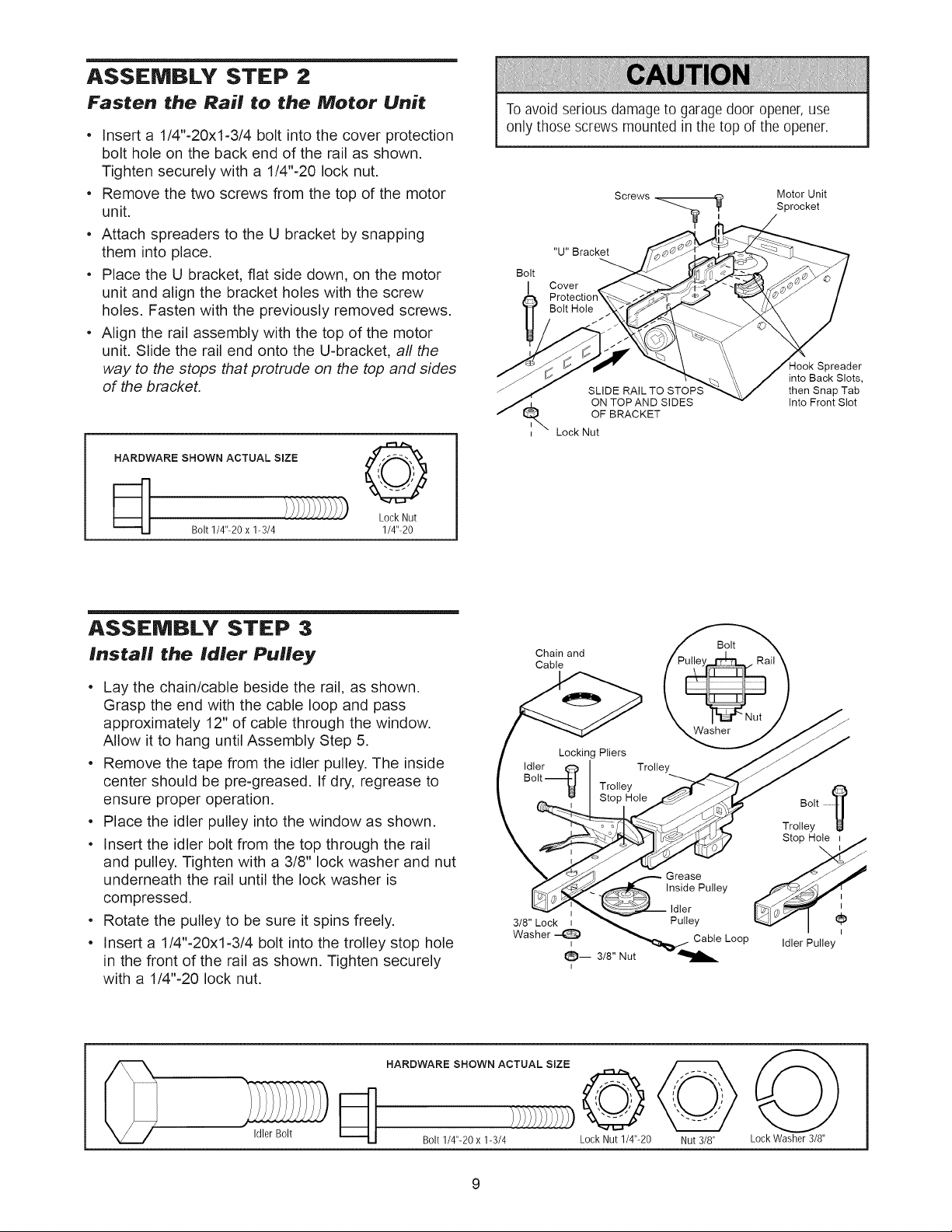

ASSEMBLY STEP 2

Fasten the Rail to the Motor Unit

• Insert a 1/4%20xl-3/4 bolt into the cover protection

bolt hole on the back end of the rail as shown.

Tighten securely with a 1/4%20 lock nut.

• Remove the two screws from the top of the motor

unit.

• Attach spreaders to the U bracket by snapping

them into place.

• Place the U bracket, flat side down, on the motor

unit and align the bracket holes with the screw

holes. Fasten with the previously removed screws.

• Align the rail assembly with the top of the motor

unit. Slide the rail end onto the U-bracket, all the

way to the stops that protrude on the top and sides

of the bracket.

HARDWARE SHOWN ACTUAL SIZE '_'_"_:'_','_'1

Toavoid serious damageto garage door opener,use

only those screws mounted in the top of the opener.

Motor Unit

Screws _ _ Sprocket

"U" Bracket

Bolt

Cover

SLIDE RAIL TO STOPS

ON TOP AND SIDES

OF BRACKET

Lock Nut

into Back Slots,

then Snap Tab

Into Front Slot

)reader

[_ Lock Nut

Bolt 1/4"-20 x 1-3/4 1/4"-20

ASSEMBLY STEP 3

Install the Idler Pulley

• Lay the chain/cable beside the rail, as shown.

Grasp the end with the cable loop and pass

approximately 12" of cable through the window.

Allow it to hang until Assembly Step 5.

• Remove the tape from the idler pulley. The inside

center should be pre-greased. If dry, regrease to

ensure proper operation.

• Place the idler pulley into the window as shown.

• Insert the idler bolt from the top through the rail

and pulley. Tighten with a 3/8" lock washer and nut

underneath the rail until the lock washer is

compressed.

• Rotate the pulley to be sure it spins freely.

• Insert a 1/4%20xl-3/4 bolt into the trolley stop hole

in the front of the rail as shown. Tighten securely

with a 1/4%20 lock nut.

Chain and

Cable

Washer

_ ___Locking Pliers

Idler_ Trolley

B°lt_ Trolley

_ _StopHole

3/8" Lock i _Pulley

Washer --_l _ Cable Loop

_ Idler

Q_-- 3/8' Nut -

I

Bolt

Bolt

Trolley

Idler Pulley

HARDWARE SHOWN ACTUAL SIZE

1

Bolt 1/4"-20 x 1-3/4 Lock Nut 1/4"-20

Nut 3/8"

Lock Washer 3/8"

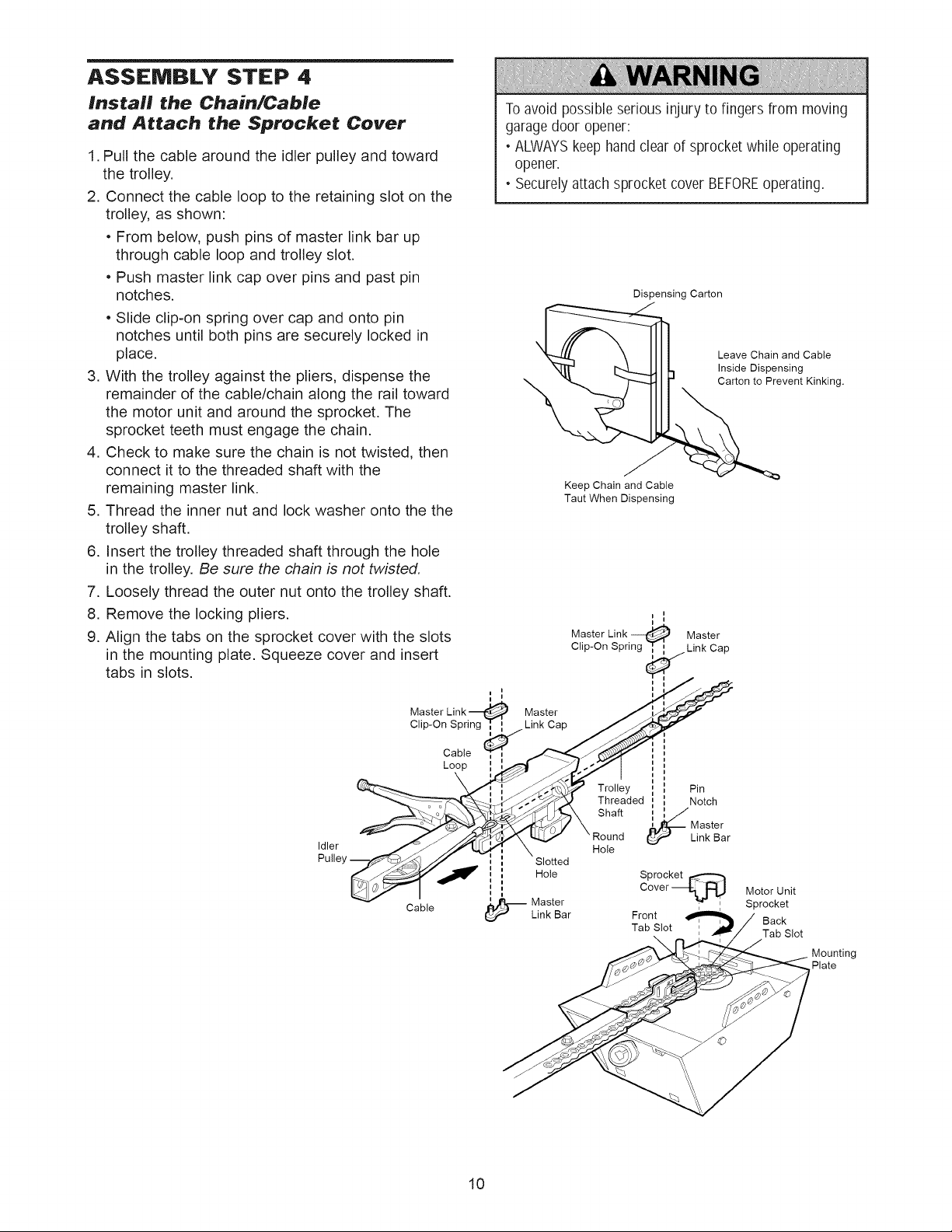

ASSEMBLY STEP 4

Install the Chain/Cable

and Attach the Sprocket Cover

1.Pull the cable around the idler pulley and toward

the trolley.

2. Connect the cable loop to the retaining slot on the

trolley, as shown:

• From below, push pins of master link bar up

through cable loop and trolley slot.

• Push master link cap over pins and past pin

notches.

• Slide clip-on spring over cap and onto pin

notches until both pins are securely locked in

place.

3. With the trolley against the pliers, dispense the

remainder of the cable/chain along the rail toward

the motor unit and around the sprocket. The

sprocket teeth must engage the chain.

4. Check to make sure the chain is not twisted, then

connect it to the threaded shaft with the

remaining master link.

5. Thread the inner nut and lock washer onto the the

trolley shaft.

6. Insert the trolley threaded shaft through the hole

in the trolley. Be sure the chain is not twisted.

Toavoid possible serious injury to fingers from moving

garagedoor opener:

, ALWAYSkeephand clear of sprocket while operating

opener•

, Securely attachsprocket cover BEFOREoperating•

Dispensing Carton

IcaSir_:nDlosppenvSinrgtKinking"

Leave Chain and Cable

Keep Chain and Cable

Taut When Dispensing

10

Motor Unit

Sprocket

Back

Tab Slot

Mounting

Plate

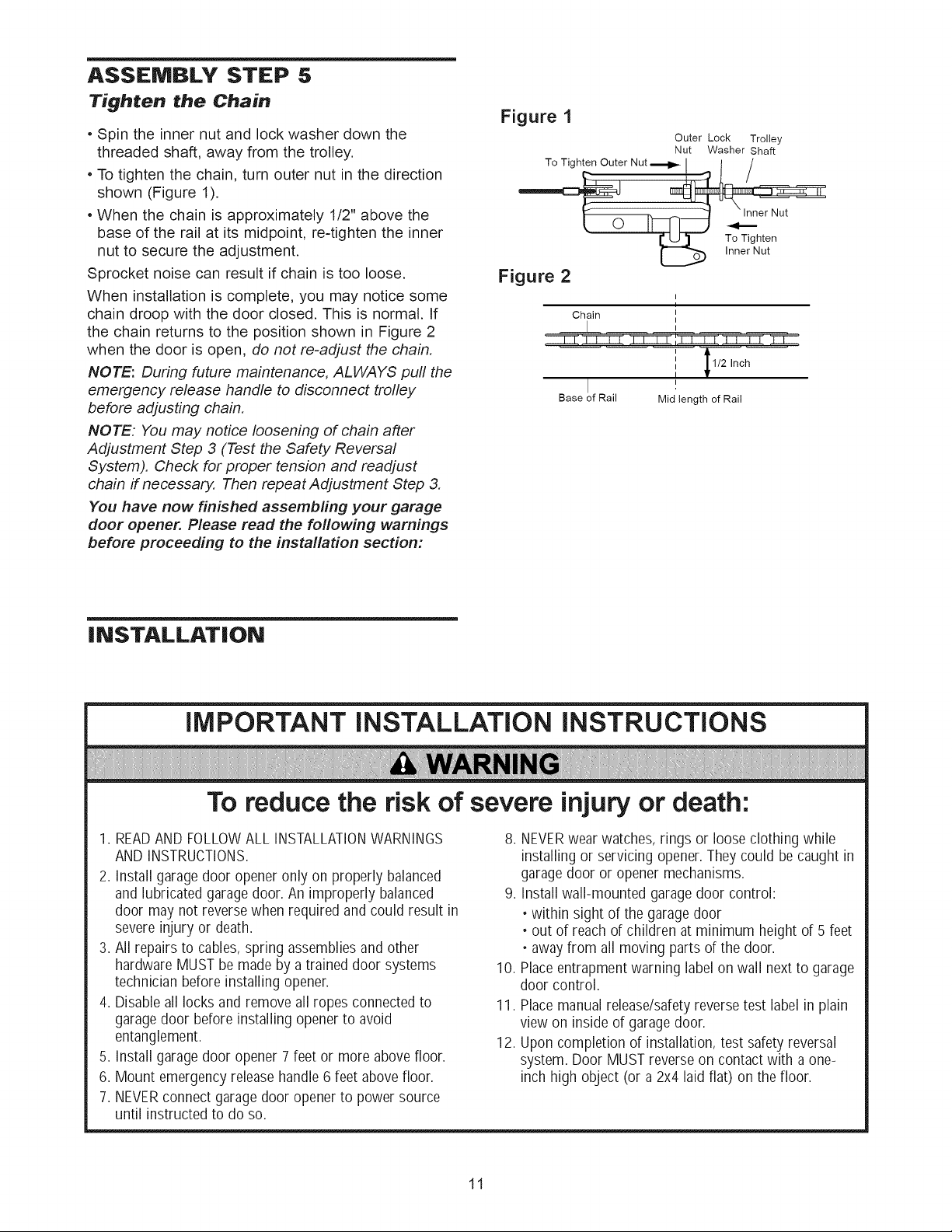

ASSEMBLY STEP 5

Tighten the Chain

• Spin the inner nut and lock washer down the

threaded shaft, away from the trolley.

• To tighten the chain, turn outer nut in the direction

shown (Figure 1).

• When the chain is approximately 1/2" above the

base of the rail at its midpoint, re-tighten the inner

nut to secure the adjustment.

Sprocket noise can result if chain is too loose.

When installation is complete, you may notice some

chain droop with the door closed. This is normal. If

the chain returns to the position shown in Figure 2

when the door is open, do not re-adjust the chain.

NOTE: During future maintenance, ALWAYS pull the

emergency release handle to disconnect trolley

before adjusting chain.

NOTE: You may notice loosening of chain after

Adjustment Step 3 (Test the Safety Reversal

System). Check for proper tension and readjust

chain if necessary. Then repeat Adjustment Step 3.

You have now finished assembling your garage

door opener. Please read the following warnings

before proceeding to the installation section:

Figure 1

Figure 2

Outer Lock Trolley

Nut Washer Shaft

,,

Chain i

1/2 Inch

I

I

Base of Rail Mid length of Rail

iNSTALLATiON

IMPORTANT INSTALLATION INSTRUCTIONS

To reduce the risk of severe injury or death:

1. READAND FOLLOWALL INSTALLATIONWARNINGS

AND INSTRUCTIONS.

2. Install garagedoor opener only on properly balanced

and lubricated garagedoor. An improperly balanced 9.

door may not reversewhen required and could result in

severeinjury or death.

3. All repairsto cables,spring assemblies and other

hardware MUSTbe made by a trained door systems 10.

technician beforeinstalling opener.

4. Disable all locks and remove all ropes connected to 11.

garagedoor before installing opener to avoid

entanglement. 12.

5. install garagedoor opener 7 feet or more abovefloor.

6. Mount emergencyreleasehandle 6 feet abovefloor.

7. NEVERconnect garage door openerto power source

until instructed to do so.

,

NEVERwear watches, rings or loose clothing while

installing or servicing opener.They could becaught in

garagedoor or opener mechanisms.

install wall-mounted garagedoor control:

, within sight of the garage door

, out of reach of children at minimum height of 5 feet

, awayfrom all moving parts of the door.

Placeentrapment warning label on wall next to garage

door control.

Placemanual release/safetyreverse test label in plain

view on inside of garagedoor.

Uponcompletion of installation, test safety reversal

system. Door MUSTreverse on contact with a one-

inch high object (or a 2x4 laid flat) on the floor.

11

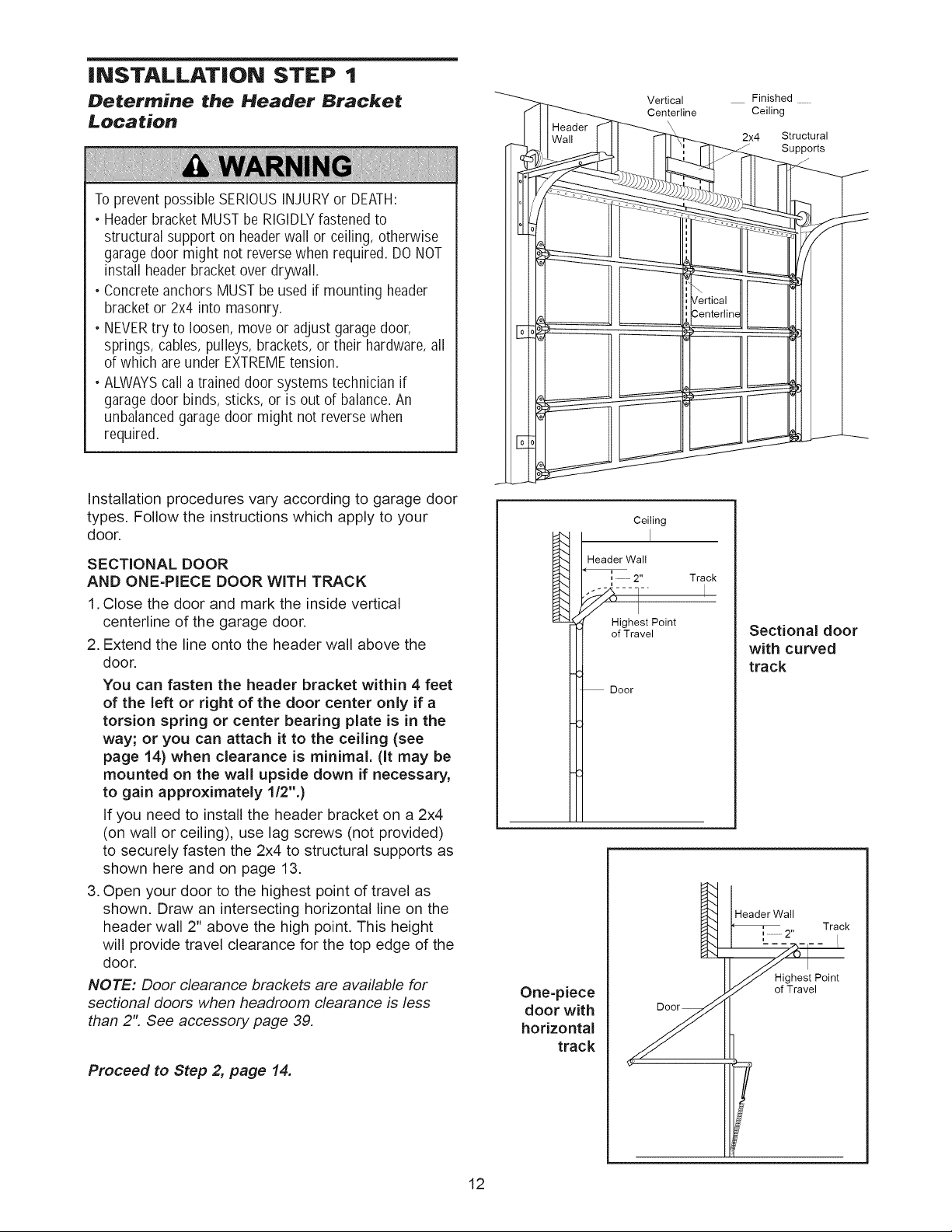

iNSTALLATiON STEP 1

Determine the Header Bracket

Location

Toprevent possible SERIOUSINJURYor DEATH:

, Header bracket MUSTbe RIGIDLYfastened to

structural support on headerwall or ceiling, otherwise

garagedoor might not reversewhen required. DONOT

install header bracketover drywall.

, Concrete anchors MUST be usedif mounting header

bracket or 2x4 into masonry.

, NEVERtry to loosen, move or adjust garagedoor,

springs, cables, pulleys, brackets, or their hardware, all

of which are under EXTREMEtension.

. ALWAYScall a trained door systems technician if

garagedoor binds, sticks, or is out of balance.An

unbalancedgaragedoor might not reversewhen

required.

Installation procedures vary according to garage door

types. Follow the instructions which apply to your

door.

SECTIONAL DOOR

AND ONE-PIECE DOOR WITH TRACK

1.Close the door and mark the inside vertical

centerline of the garage door.

2. Extend the line onto the header wall above the

door.

You can fasten the header bracket within 4 feet

of the left or right of the door center only if a

torsion spring or center bearing plate is in the

way; or you can attach it to the ceiling (see

page 14) when clearance is minimal. (It may be

mounted on the wall upside down if necessary,

to gain approximately 1/2".)

If you need to install the header bracket on a 2x4

(on wall or ceiling), use lag screws (not provided)

to securely fasten the 2x4 to structural supports as

shown here and on page 13.

3. Open your door to the highest point of travel as

shown. Draw an intersecting horizontal line on the

header wall 2" above the high point. This height

will provide travel clearance for the top edge of the

door.

NOTE: Door clearance brackets are available for

sectional doors when headroom clearance is less

than 2't See accessory page 39.

Proceed to Step 2, page 14.

One-piece

door with

horizontal

track

Vertical

Centerline

Ceiling

Header Wall

i

' ............2" Track

_- ..... I

Highest Point

of Travel

Door

Door

Finished ......

Ceiling

2x4 Structural

Supports

Sectional door

with curved

track

Header Wal_

2 Track

Highest Point

of Travel

12

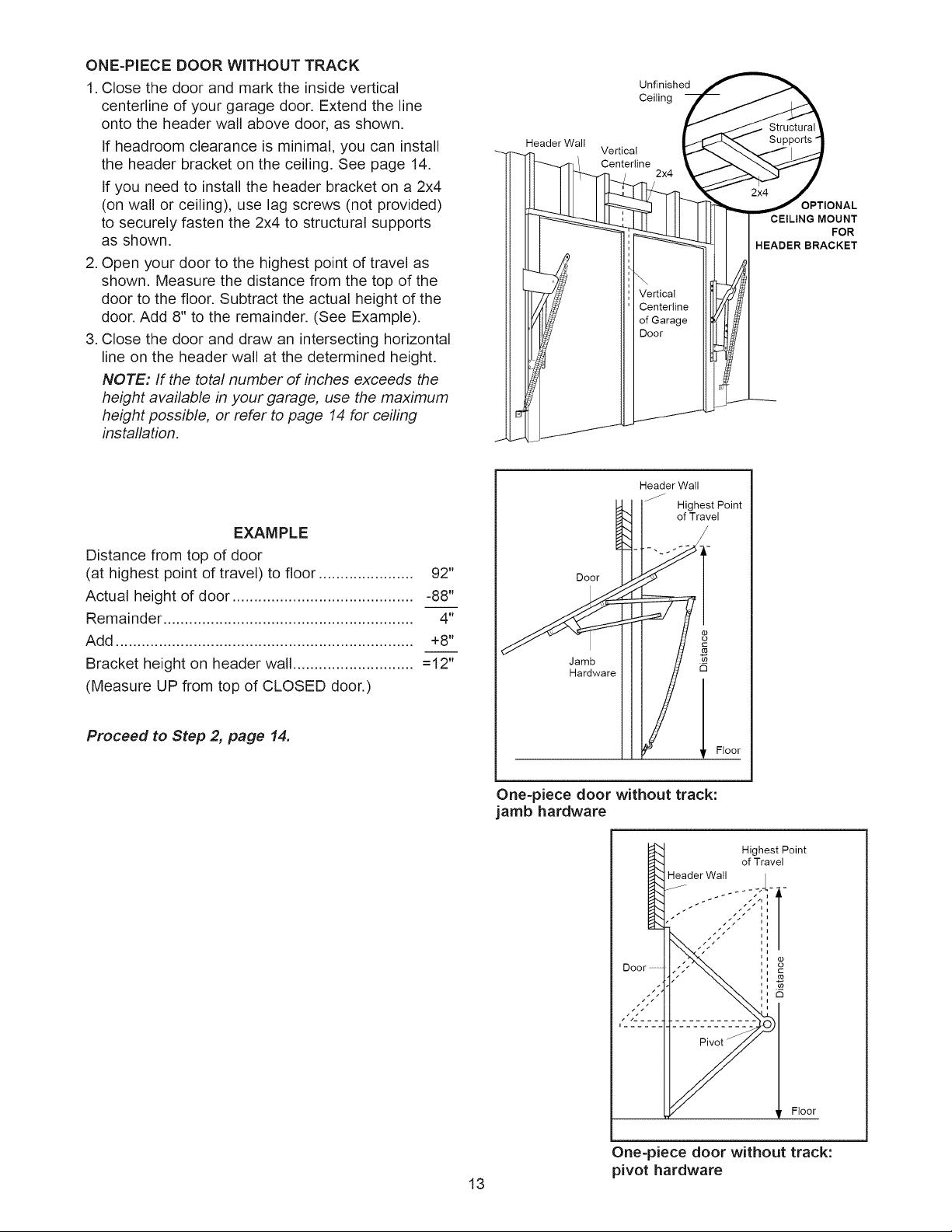

ONE-PIECEDOORWITHOUTTRACK

1.Closethedoorandmarktheinsidevertical

centerlineof yourgaragedoor.Extendtheline

ontotheheaderwallabovedoor,asshown.

Ifheadroomclearanceis minimal,youcaninstall

theheaderbracketontheceiling.Seepage14.

Ifyouneedtoinstalltheheaderbracketona 2x4

(onwallor ceiling),uselagscrews(notprovided)

tosecurelyfastenthe2x4tostructuralsupports

asshown.

2.Openyourdoortothehighestpointoftravelas

shown.Measurethedistancefromthetopofthe

doortothefloor.Subtracttheactualheightofthe

door.Add8"totheremainder.(SeeExample).

3.Closethedooranddrawanintersectinghorizontal

lineontheheaderwallatthedeterminedheight.

NOTE: If the total number of inches exceeds the

height available in your garage, use the maximum

height possible, or refer to page 14 for ceiling

installation.

EXAMPLE

Distance from top of door

(at highest point of travel) to floor ...................... 92"

Actual height of door .......................................... -88"

Remainder .......................................................... 4"

Add ..................................................................... +8"

Bracket height on header wall ............................ =12"

(Measure UP from top of CLOSED door.)

Header Wall

.Jamb

Vertical

Centedine

Door 1

Hardware

Unfinished

Ceiling

2x4

Header Wall

Highest Point

of Travel

OPTIONAL

CEILING MOUNT

FOR

HEADER BRACKET

¢u

C3

Proceed to Step 2, page 14.

One-piece door without track:

jamb hardware

Door

t

/

s

• J__

J ....

One-piece door without track:

13

pivot hardware

ii

Header Wall

Floor

Highest Point

of Travel

t t Jl

'J co

D

Floor

iNSTALLATiON STEP 2

Install the Header Bracket

You can attach the header bracket either to the wall

above the garage door, or to the ceiling. Follow the

instructions which will work best for your particular

requirements. Do not install the header bracket

over drywall. If installing into masonry, use

concrete anchors (not provided).

WALL HEADER BRACKET INSTALLATION

• Center the bracket on the vertical centerline with

the bottom edge of the bracket on the horizontal

line as shown (with the arrow pointing toward the

ceiling).

• Mark the vertical set of bracket holes. Drill 3/16"

pilot holes and fasten the bracket securely to a

structural support with the hardware provided,

-- Wall -

2x4

Structural

Support

Optional

Mounting Holes

Header

Wall Mount

Vertical

Centerline

Lag Screws

5/16"x9x1-5/8"

Spring

HARDWARE SHOWN ACTUAL SIZE

:]IIIIIIII1

Lag Screw

5/16"-9xl -5/8"

CEILING HEADER BRACKET INSTALLATION

• Extend the vertical centerline onto the ceiling as

shown.

• Center the bracket on the vertical mark, no more

than 6" from the wall. Make sure the arrow is

pointing away from the wall. The bracket can be

mounted flush against the ceiling when clearance

is minimal.

• Mark the side holes. Drill 3/16" pilot holes and

fasten bracket securely to a structural support with

the hardware provided.

Ceiling Mounting Holes

]" -- Door-

Highest Point of

Garage Door Travel Vertical

Header t

Bracket

6" Maximum

Door

Spring

[_ //SS - Finished Ceiling -

/

/

/

Vertical Centerline

Garage

Centerline

Lag Screws

5/16"x9x 1-5/8"

14

-- Header Wall --

senterline

__ Header Wall

Header Bracket

__ Idler Pulley

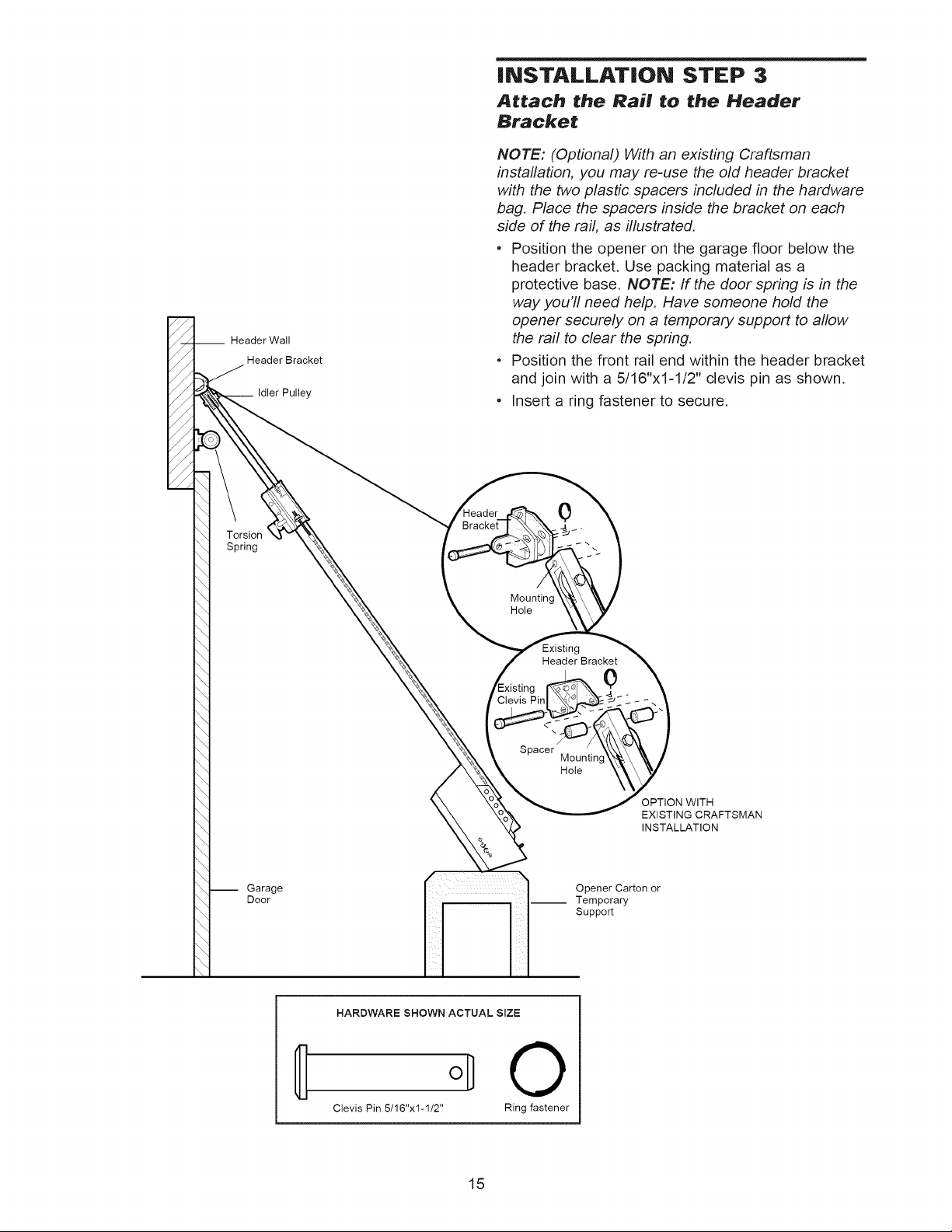

iNSTALLATiON STEP 3

Attach the Rail to the Header

Bracket

NOTE: (Optional) With an existing Craftsman

installation, you may re-use the old header bracket

with the two plastic spacers included in the hardware

bag. Place the spacers inside the bracket on each

side of the rail, as illustrated.

• Position the opener on the garage floor below the

header bracket. Use packing material as a

protective base. NOTE: If the door spring is in the

way you'll need help. Have someone hold the

opener securely on a temporary support to allow

the rail to clear the spring.

• Position the front rail end within the header bracket

and join with a 5/16"x1-1/2" clevis pin as shown.

• Insert a ring fastener to secure.

0

Spring

-- Garage

Door

Mounting

Hole

Existing

Header Bracket

Spacer

Mountin_

Hole

__ Temporary

0

OPTION WITH

EXISTING CRAFTSMAN

INSTALLATION

Opener Carton or

Support

HARDWARE SHOWN ACTUAL SIZE

O

Clevis Pin 5/16"x1-1/2" Ring fastener

15

iNSTALLATiON STEP 4

Position the Opener

Follow instructions which apply to your door type as

illustrated.

SECTIONAL DOOR OR ONE-PIECE DOOR WITH

TRACK

A 2x4 laid flat is convenient for setting an ideal door-

to-rail distance.

• Raise the opener onto a stepladder. You will need

help at this point if the ladder is not tall enough.

• Open the door all the way and place a 2x4 laid flat

on the top section beneath the rail.

• If the top section or panel hits the trolley when you

raise the door, pull down on the trolley release arm

to disconnect inner and outer sections. Slide the

outer trolley toward the motor unit. The trolley can

remain disconnected until Installation Step 12

is completed.

olley

elease Arm ------_ J

ENGAGED RELEASED V

Toprevent damageto garagedoor, rest garagedoor

opener rail on 2x4 placedon top section of door.

Outer Trolley Inner Trolley

Door

2x4

ONE-PIECE DOOR WITHOUT TRACK

• With the door fully open and parallel to the floor,

measure the distance from the floor to the top of

the door.

• Using a stepladder as a support, raise the top of

the opener to this height.

• The top of the door should be level with the top of

the motor unit. Do not position the opener more

than 2" above this point.

16

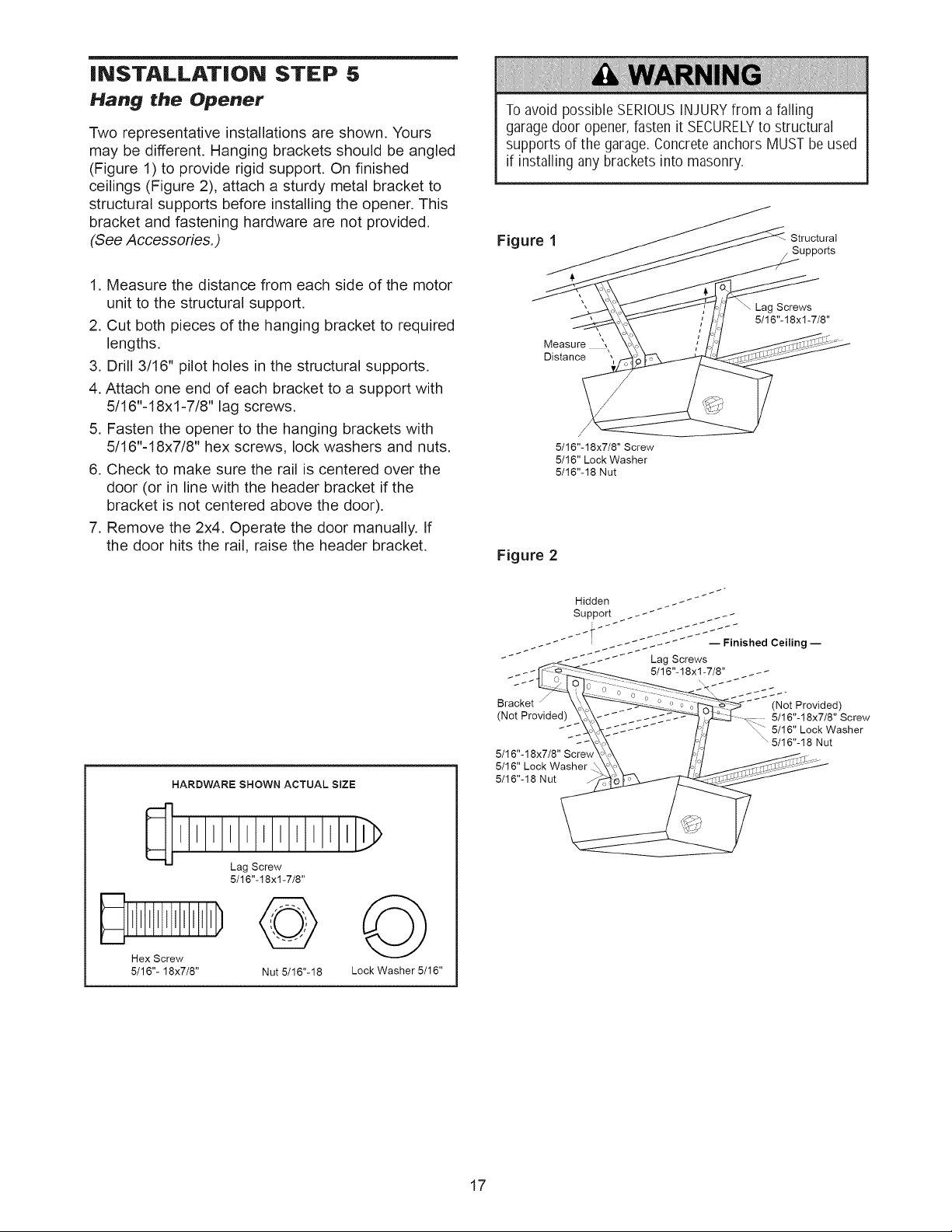

iNSTALLATiON STEP 5

Hang the Opener

Two representative installations are shown. Yours

may be different. Hanging brackets should be angled

(Figure 1) to provide rigid support. On finished

ceilings (Figure 2), attach a sturdy metal bracket to

structural supports before installing the opener. This

bracket and fastening hardware are not provided.

(See Accessories.)

1. Measure the distance from each side of the motor

unit to the structural support.

2. Cut both pieces of the hanging bracket to required

lengths.

3. Drill 3/16" pilot holes in the structural supports.

4. Attach one end of each bracket to a support with

5/16"-18xl-7/8" lag screws.

5. Fasten the opener to the hanging brackets with

5/16"-18x7/8" hex screws, lock washers and nuts.

6. Check to make sure the rail is centered over the

door (or in line with the header bracket if the

bracket is not centered above the door).

7. Remove the 2x4. Operate the door manually. If

the door hits the rail, raise the header bracket.

Toavoid possible SERIOUSINJURYfrom a falling

garage door opener,fasten it SECURELYto structural

supports of the garage.Concreteanchors MUSTbe used

if installing any brackets into masonry.

Figure 1 Structural

Measure >

Distance ,

\\

i

5/16"-18x7/8" Screw

5/16" Lock Washer

5/16"-18 Nut

Supports

Lag Screws

5/16"-18xl -7/8"

Figure 2

HARDWARE SHOWN ACTUAL SIZE

I I I I I I I I I IILILI

Lag Screw

5/16"-18xl -7/8"

@

Hex Screw

5/18"- 18x7/8" Nut 5/18"-18 Lock Washer 5/16"

Bracket / (Not Provided)

(Not Provided) 5/16"-18x7/8" Screw

5/16" Lock Washer

5/16"-18 Nut

_ 5/16" Lock Washer

5/16"-18 Nut

17

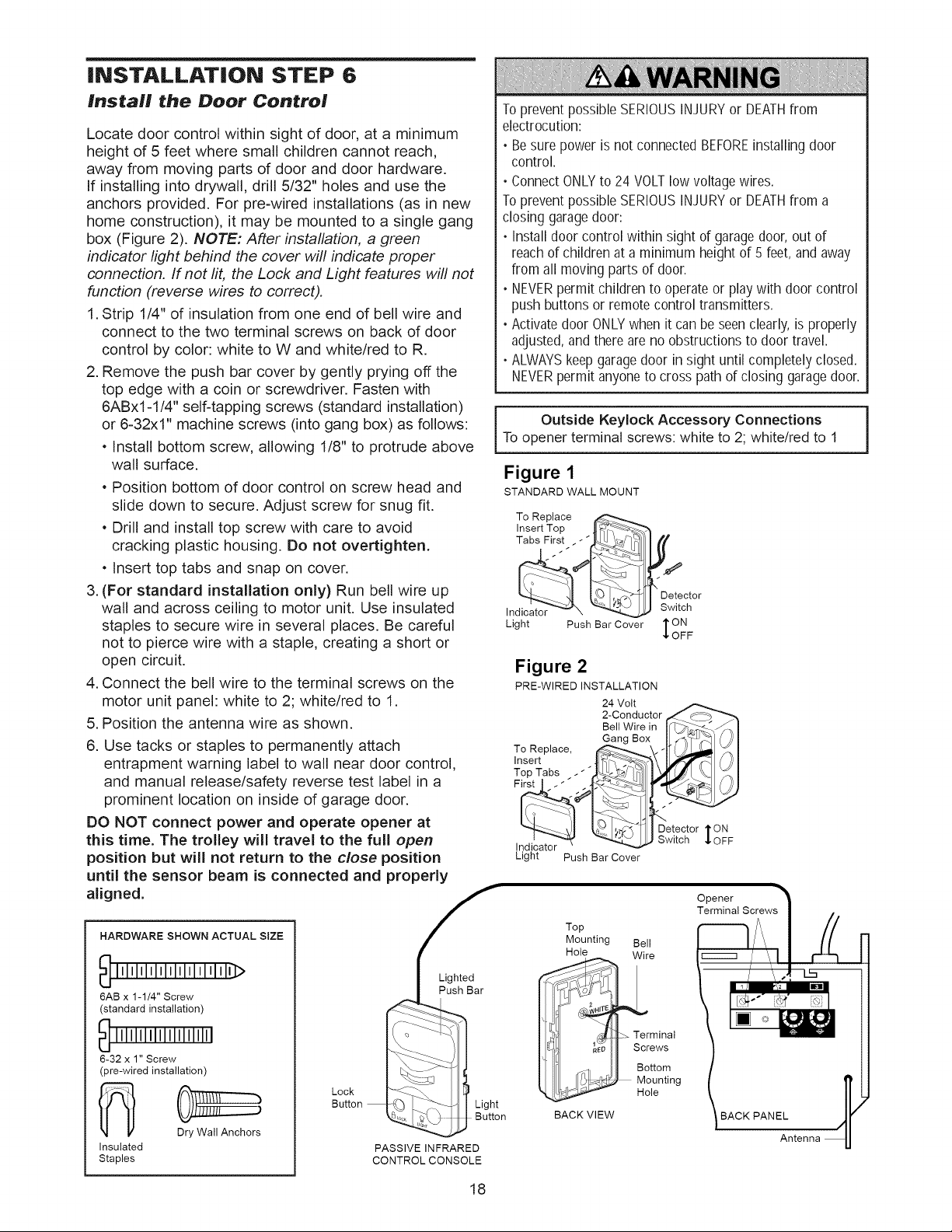

iNSTALLATiON STEP 6

install the Door Control

Locate door control within sight of door, at a minimum

height of 5 feet where small children cannot reach,

away from moving parts of door and door hardware.

If installing into drywall, drill 5/32" holes and use the

anchors provided. For pre-wired installations (as in new

home construction), it may be mounted to a single gang

box (Figure 2). NOTE: After installation, a green

indicator light behind the cover will indicate proper

connection. If not lit, the Lock and Light features will not

function (reverse wires to correct).

1.Strip 1/4" of insulation from one end of bell wire and

connect to the two terminal screws on back of door

control by color: white to W and white/red to R.

2. Remove the push bar cover by gently prying off the

top edge with a coin or screwdriver. Fasten with

6ABx1=1/4" self-tapping screws (standard installation)

or 6-32x1" machine screws (into gang box) as follows:

• Install bottom screw, allowing 1/8" to protrude above

wall surface.

• Position bottom of door control on screw head and

slide down to secure. Adjust screw for snug fit.

• Drill and install top screw with care to avoid

cracking plastic housing. Do not overtighten.

• Insert top tabs and snap on cover.

3. (For standard installation only) Run bell wire up

wall and across ceiling to motor unit. Use insulated

staples to secure wire in several places. Be careful

not to pierce wire with a staple, creating a short or

open circuit.

4. Connect the bell wire to the terminal screws on the

motor unit panel: white to 2; white/red to 1.

5. Position the antenna wire as shown.

6. Use tacks or staples to permanently attach

entrapment warning label to wall near door control,

and manual release/safety reverse test label in a

prominent location on inside of garage door.

DO NOT connect power and operate opener at

this time. The trolley will travel to the full open

position but will not return to the close position

until the sensor beam is connected and properly

aligned.

HARDWARE SHOWN ACTUAL SIZE

_ IIlllMIMlllllllllIIIIIll]>

6AB x 1-1/4" Screw

(standard installation)

6-32 x 1" Screw

(pre-wired installation)

Dry Wall Anchors

Insulated

Staples

Lock

PASSIVEINFRARED

CONTROLCONSOLE

Lighted

Push Bar

TopreventpossibleSERIOUSINJURYor DEATHfrom

electrocution:

• Besurepower is notconnectedBEFOREinstallingdoor

control.

• ConnectONLYto 24 VOLTlowvoltagewires.

TopreventpossibleSERIOUSINJURYor DEATHfrom a

closing garagedoor:

• Install door control within sight ofgaragedoor,out of

reachof childrenat a minimum heightof 5 feet,and away

from all moving parts of door.

• NEVERpermitchildrento operateor playwith doorcontrol

pushbuttons or remotecontrol transmitters.

• Activatedoor ONLYwhenit can be seenclearly,isproperly

adjusted,andthereare no obstructionsto door travel.

• ALWAYSkeepgaragedoor in sight until completelyclosed.

NEVERpermitanyoneto crosspathof closing garagedoor.

i Outside Keylock Accessory ConnectionsTo opener terminal screws: white to 2; white/red to 1

Figure 1

STANDARD WALL MOUNT

To Replace

Insert Top

Tabs First .-

Indicator Switch

Light Push Bar Cover T °N

OFF

Figure 2

PRE-WIRED INSTALLATION

24 Volt

2-Conductor

Bell Wire in

Gang Box

Insert

TOsP qlabt s

To Replace,

I Switch OFF

Light Push Bar Cover

Top

Mounting

Hole

Light

Sutton

BACK VIEW

Detector ION

Bell

Wire

Terminal

Screws

Bottom

Mounting

Hole

Opener

Terminal Screws

Antenna

18

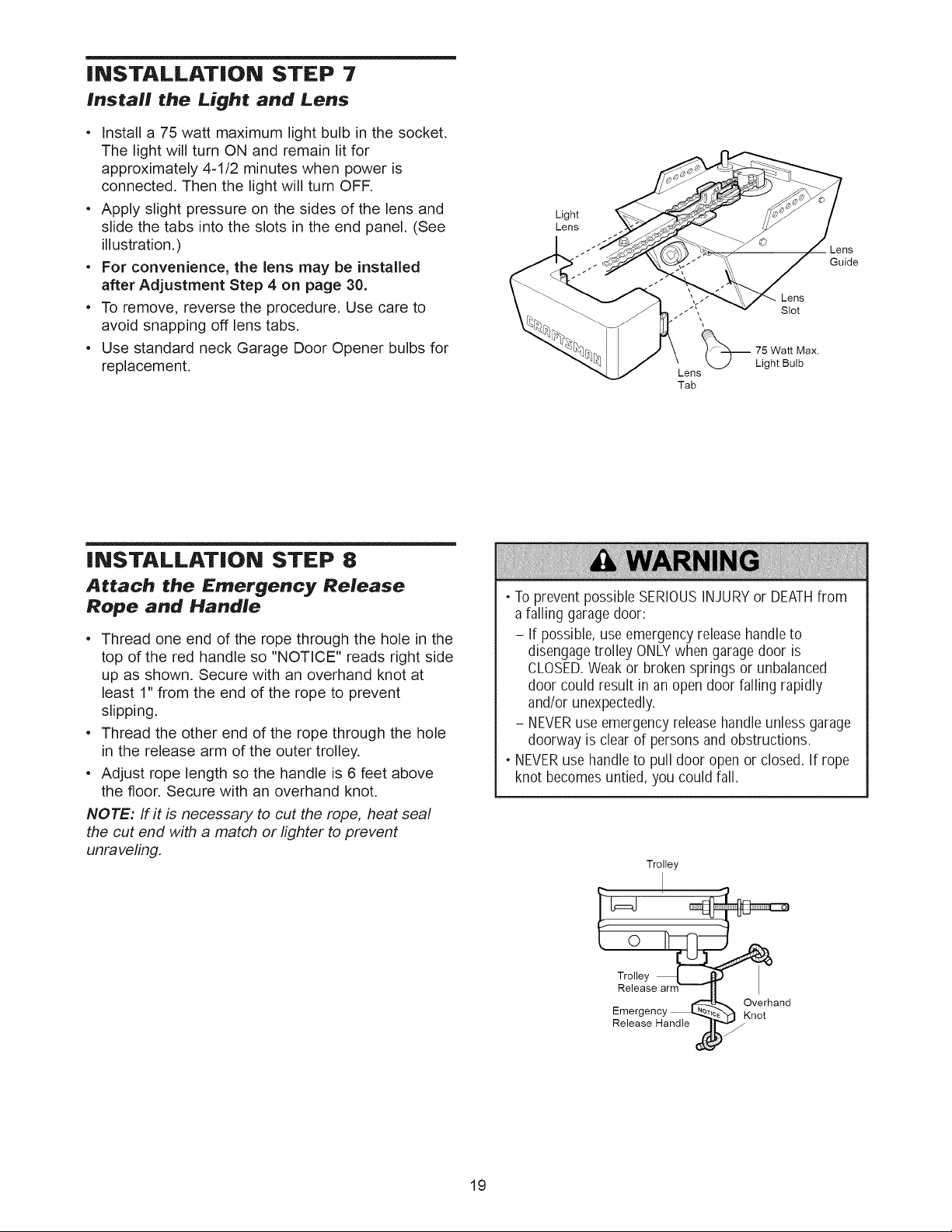

iNSTALLATiON STEP 7

Install the Light and Lens

• Install a 75 watt maximum light bulb in the socket.

The light will turn ON and remain lit for

approximately 4-1/2 minutes when power is

connected. Then the light will turn OFF.

• Apply slight pressure on the sides of the lens and

slide the tabs into the slots in the end panel. (See

illustration.)

• For convenience, the lens may be installed

after Adjustment Step 4 on page 30.

• To remove, reverse the procedure. Use care to

avoid snapping off lens tabs.

• Use standard neck Garage Door Opener bulbs for

replacement.

Light

Lens

' Lens

75 Watt Max.

Lens

Tab

Light Bulb

Lens

Guide

Slot

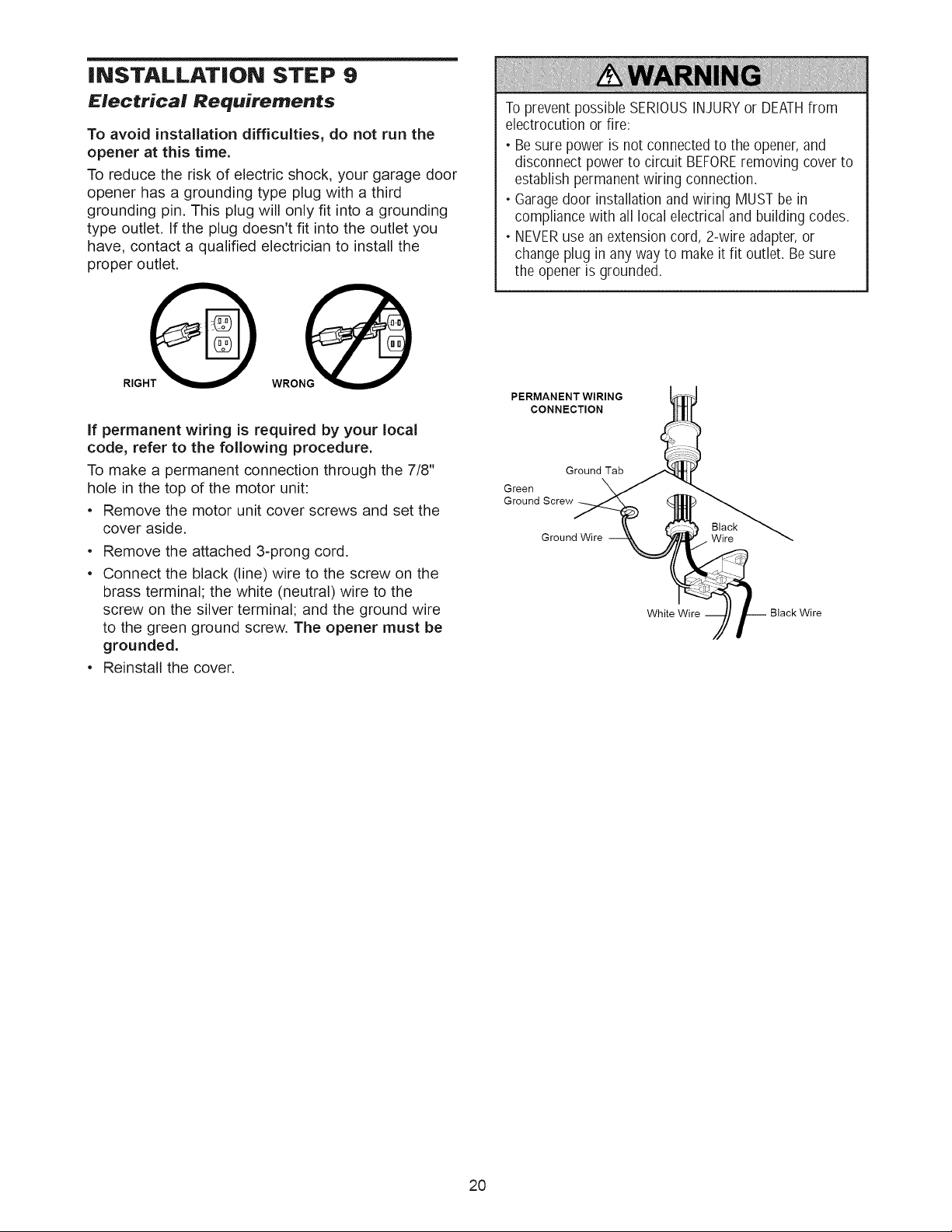

iNSTALLATiON STEP 8

Attach the Emergency Release

Rope and Handle

• Thread one end of the rope through the hole in the

top of the red handle so "NOTICE" reads right side

up as shown. Secure with an overhand knot at

least 1" from the end of the rope to prevent

slipping.

• Thread the other end of the rope through the hole

in the release arm of the outer trolley.

• Adjust rope length so the handle is 6 feet above

the floor. Secure with an overhand knot.

NOTE: If it is necessary to cut the rope, heat seal

the cut end with a match or lighter to prevent

unra veling.

. To prevent possible SERIOUSINJURYor DEATHfrom

a falling garagedoor:

- If possible, use emergency releasehandleto

disengagetrolley ONLYwhen garagedoor is

CLOSED.Weakor brokensprings or unbalanced

door could result in an open door falling rapidly

and/or unexpectedly.

- NEVERuse emergency releasehandle unless garage

doorway is clear of persons and obstructions.

. NEVERuse handle to pull door open or closed. If rope

knot becomesuntied, you could fall.

Trolley

Emergency ..................l_ _ Overhand

Release Handle )_

E_ Knot

19

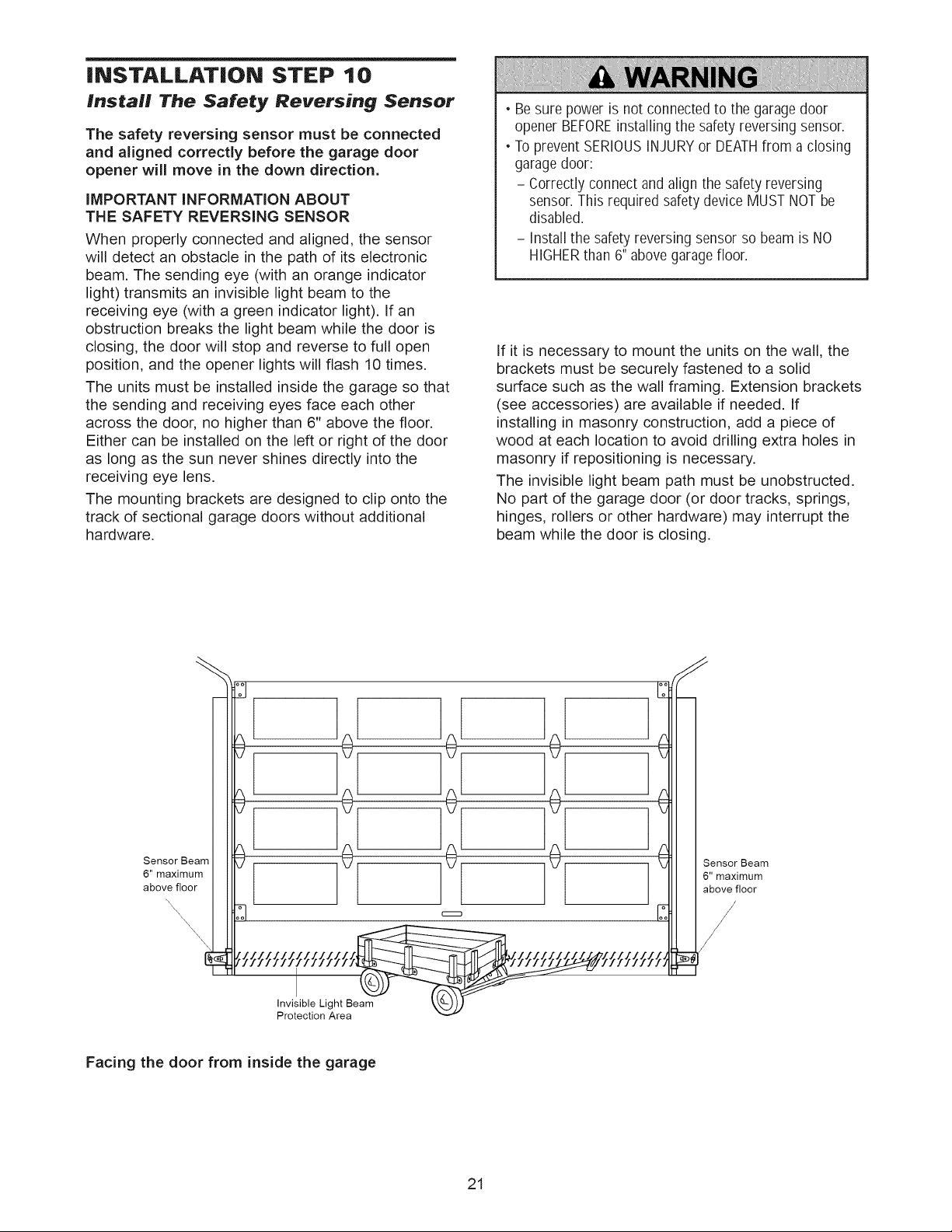

iNSTALLATiON STEP 9

Electrical Requirements

To avoid installation difficulties, do not run the

opener at this time.

To reduce the risk of electric shock, your garage door

opener has a grounding type plug with a third

grounding pin. This plug will only fit into a grounding

type outlet. If the plug doesn't fit into the outlet you

have, contact a qualified electrician to install the

proper outlet.

RIGHO WRONG

If permanent wiring is required by your local

code, refer to the following procedure.

To make a permanent connection through the 7/8"

hole in the top of the motor unit:

• Remove the motor unit cover screws and set the

cover aside.

• Remove the attached 3-prong cord.

• Connect the black (line) wire to the screw on the

brass terminal; the white (neutral) wire to the

screw on the silver terminal; and the ground wire

to the green ground screw. The opener must be

grounded.

• Reinstall the cover.

Toprevent possible SERIOUSINJURYor DEATHfrom

electrocution or fire:

. Be sure power is not connectedto the opener,and

disconnect powerto circuit BEFOREremoving cover to

establish permanentwiring connection.

. Garagedoor installation and wiring MUST be in

compliancewith all local electricaland building codes.

. NEVERuse an extension cord, 2-wire adapter,or

changeplug in anyway to make it fit outlet. Be sure

the opener is grounded.

PERMANENT WIRING

CONNECTION

Ground Tab

Green

Ground Screw

Black

Ground Wire Wire

White Wire Black Wire

2O

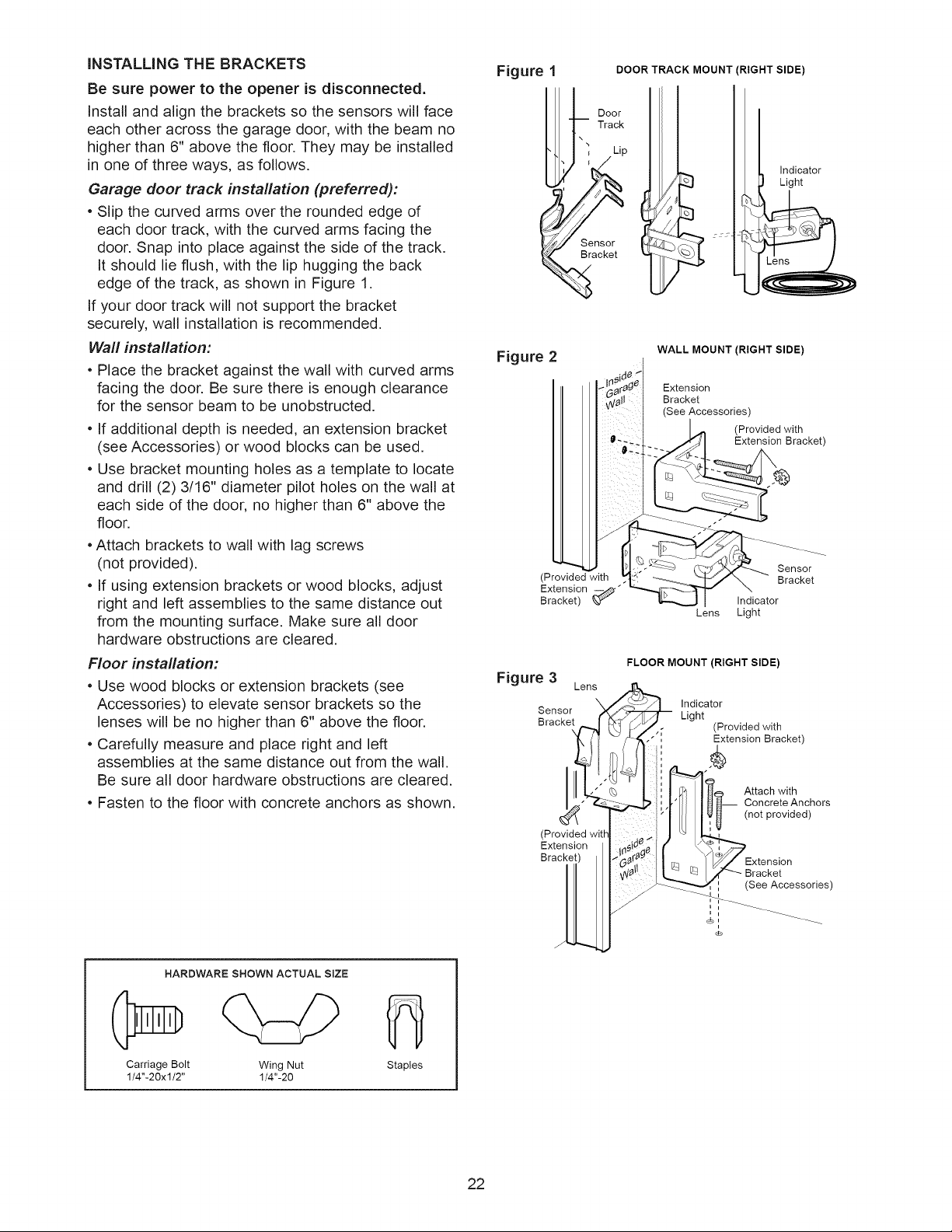

INSTALLATION STEP 10

Install The Safety Reversing Sensor

The safety reversing sensor must be connected

and aligned correctly before the garage door

opener will move in the down direction.

iMPORTANT iNFORMATiON ABOUT

THE SAFETY REVERSING SENSOR

When properly connected and aligned, the sensor

will detect an obstacle in the path of its electronic

beam. The sending eye (with an orange indicator

light) transmits an invisible light beam to the

receiving eye (with a green indicator light). If an

obstruction breaks the light beam while the door is

closing, the door will stop and reverse to full open

position, and the opener lights will flash 10 times.

The units must be installed inside the garage so that

the sending and receiving eyes face each other

across the door, no higher than 6" above the floor.

Either can be installed on the left or right of the door

as long as the sun never shines directly into the

receiving eye lens.

The mounting brackets are designed to clip onto the

track of sectional garage doors without additional

hardware.

. Be sure power is not connectedto the garagedoor

opener BEFOREinstalling the safety reversing sensor.

, To prevent SERIOUSINJURYor DEATHfrom a closing

garagedoor:

- Correctly connect and align the safety reversing

sensor.This required safety device MUST NOT be

disabled.

- installthe safety reversing sensor so beamis NO

HIGHERthan 6" abovegarage floor.

If it is necessary to mount the units on the wall, the

brackets must be securely fastened to a solid

surface such as the wall framing. Extension brackets

(see accessories) are available if needed. If

installing in masonry construction, add a piece of

wood at each location to avoid drilling extra holes in

masonry if repositioning is necessary.

The invisible light beam path must be unobstructed.

No part of the garage door (or door tracks, springs,

hinges, rollers or other hardware) may interrupt the

beam while the door is closing.

Sensor Beam

6" maximum

above floor

x\\\

Xx\\

\

Invisible Light Beam

Protection Area

Facing the door from inside the garage

1÷[ I÷

10[ 0

10[ ÷

21

Sensor Beam

6" maximum

above floor

/

/

iNSTALLiNG THE BRACKETS

Be sure power to the opener is disconnected.

Install and align the brackets so the sensors will face

each other across the garage door, with the beam no

higher than 6" above the floor. They may be installed

in one of three ways, as follows.

Garage door track installation (preferred):

• Slip the curved arms over the rounded edge of

each door track, with the curved arms facing the

door. Snap into place against the side of the track.

It should lie flush, with the lip hugging the back

edge of the track, as shown in Figure 1.

if your door track will not support the bracket

securely, wall installation is recommended.

Wall installation:

• Place the bracket against the wall with curved arms

facing the door. Be sure there is enough clearance

for the sensor beam to be unobstructed.

• If additional depth is needed, an extension bracket

(see Accessories) or wood blocks can be used.

• Use bracket mounting holes as a template to locate

and drill (2) 3/16" diameter pilot holes on the wall at

each side of the door, no higher than 6" above the

floor.

• Attach brackets to wall with lag screws

(not provided).

• If using extension brackets or wood blocks, adjust

right and left assemblies to the same distance out

from the mounting surface. Make sure all door

hardware obstructions are cleared.

Floor installation:

• Use wood blocks or extension brackets (see

Accessories) to elevate sensor brackets so the

lenses will be no higher than 6" above the floor.

• Carefully measure and place right and left

assemblies at the same distance out from the wall.

Be sure all door hardware obstructions are cleared.

• Fasten to the floor with concrete anchors as shown.

Figure 1

Figure 2

(Provided with

Extension

Bracket) _"

Figure 3

Sensor

Bracket

DOOR TRACK MOUNT (RIGHT SIDE)

Door

Track

jLip

racket

WALL MOUNT (RIGHT SIDE)

Extension

Bracket

(See Accessories)

Lens Light

FLOOR MOUNT (RIGHT SIDE)

Lens

Indicator

Light

I

(Provided with

Extension Bracket)

Sensor

Indicator

(Provided with

Extension Bracket)

.¢

Indicator

Light

Bracket

HARDWARE SHOWN ACTUAL SIZE

Carriage Bolt

1/4"-20xl/2"

Wing Nut Staples

1/4"-20

22

Extension

Bra_

iii

sl

g

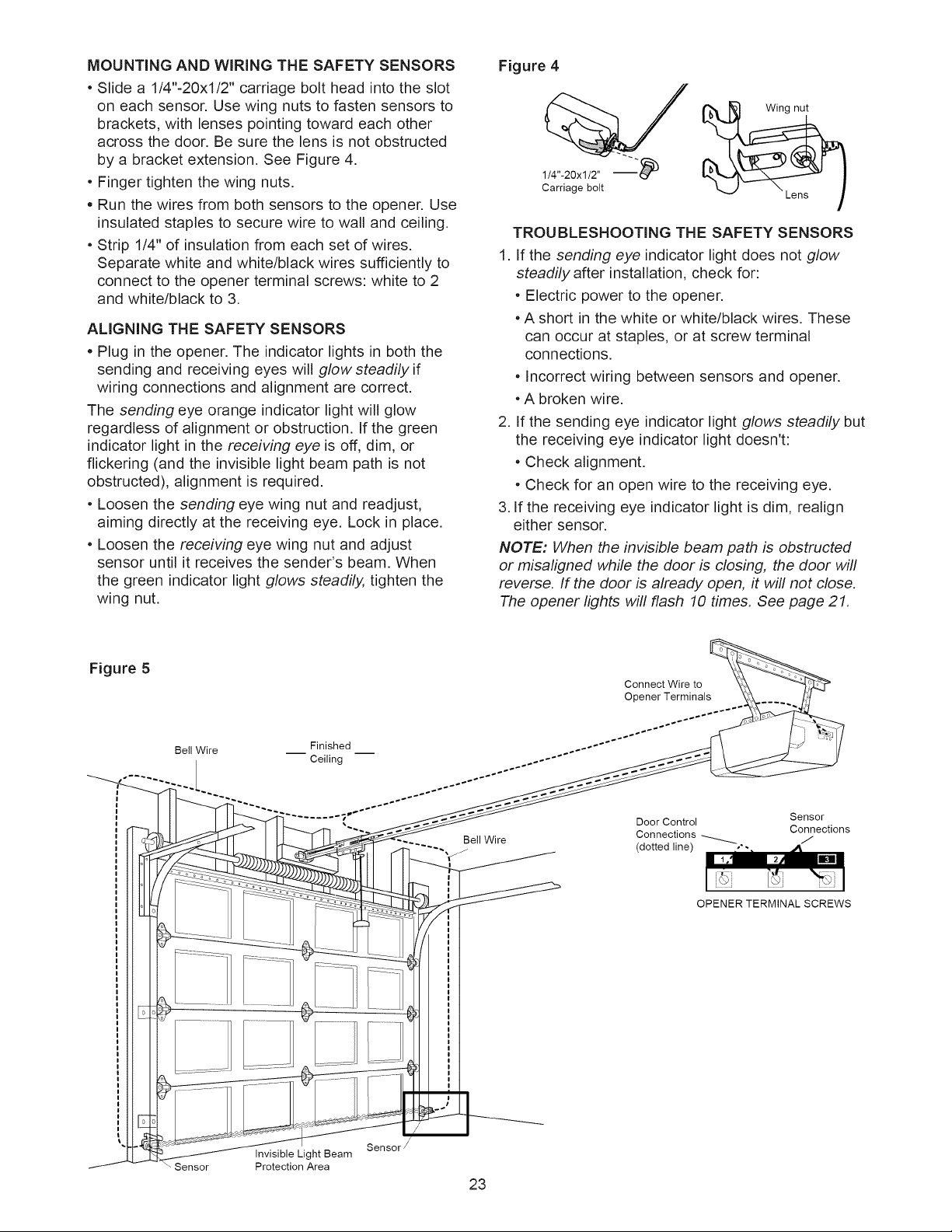

MOUNTING AND WiRiNG THE SAFETY SENSORS

, Slide a 1/4"-20xl/2" carriage bolt head into the slot

on each sensor. Use wing nuts to fasten sensors to

brackets, with lenses pointing toward each other

across the door. Be sure the lens is not obstructed

by a bracket extension. See Figure 4.

• Finger tighten the wing nuts.

• Run the wires from both sensors to the opener. Use

insulated staples to secure wire to wall and ceiling.

• Strip 1/4" of insulation from each set of wires.

Separate white and white/black wires sufficiently to

connect to the opener terminal screws: white to 2

and white/black to 3.

ALiGNiNG THE SAFETY SENSORS

• Plug in the opener. The indicator lights in both the

sending and receiving eyes will glow steadily if

wiring connections and alignment are correct.

The sending eye orange indicator light will glow

regardless of alignment or obstruction. If the green

indicator light in the receiving eye is off, dim, or

flickering (and the invisible light beam path is not

obstructed), alignment is required.

• Loosen the sending eye wing nut and readjust,

aiming directly at the receiving eye. Lock in place.

• Loosen the receiving eye wing nut and adjust

sensor until it receives the sender's beam. When

the green indicator light glows steadily, tighten the

wing nut.

Figure 4

1/4"-20x 1/2"

Carriage bolt

TROUBLESHOOTING THE SAFETY SENSORS

1. If the sending eye indicator light does not glow

steadily after installation, check for:

• Electric power to the opener.

•A short in the white or white/black wires. These

can occur at staples, or at screw terminal

connections.

• Incorrect wiring between sensors and opener.

•A broken wire.

2. If the sending eye indicator light glows steadily but

the receiving eye indicator light doesn't:

• Check alignment.

• Check for an open wire to the receiving eye.

3. If the receiving eye indicator light is dim, realign

either sensor.

NOTE: When the invisible beam path is obstructed

or misaligned while the door is closing, the door will

reverse. If the door is already open, it will not close.

The opener lights will flash 10 times. See page 21.

Figure 5

Bell Wire __ Finished __

Ceiling

Connect Wire to

Opener Terminals

Door Control

Bell Wire Connections _

/ (dotted line)

Sensor

Connections

/

OPENER TERMINAL SCREWS

Sensor

Invisible Light Beam

Protection Area

Sensor /

23

Loading...

Loading...