Craftsman 13953974SRT Owner’s Manual

Owner's

Manual

Model No.

139.53974SRT

For Residential Use

Only

ICRRFTSNRN1

GARAGE DOOR OPENER

Caution:

Read and follow all

safety rules and

operating instructions

before first use of this

product.

Fasten the manual

near the garage door

after installation,

1/2 HP

• Safety Precautions

• Assembly

• Installation

• Adjustment

• Care and Maintenance

• Operation

• Troubleshooting LIBRARY:

• Parts List

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Mist(Mr Craftsman website: www.sears.com/craftsman

--- MODEL ! ENTRY INSTRUCTIONS

O

_ATEtZ-ZI-qq' CYCLE 14X._.__.

JEW • SUPERCEDE CHANGE_DELETE,

)_..._ON O q PmCEusr 13__.

IODELNUMBER I_ I • J397_

THIS FORM ACCOMPANIES A PARTS BREAKDOWN FOR A NEW MODEL INTO THE SYSTEM.

ALSO ATTACH AN OWNERS MANUAL TO BE PUT INTO THE M/bXSERV LIBRARY.

C

PI

A :O

L

G

G Y F N

PART NIJMBER

ri_,.iON

t

I iBr)An,v-

i-,

Copi_

Entered

US-_.-.

II I I'll I I I

I II I I

Received_ "

:OMMENTS:

/

tk'I-i'ACHMENTS: (y_ _._,,.20 - _(P-O-J _'/i_ _///_/

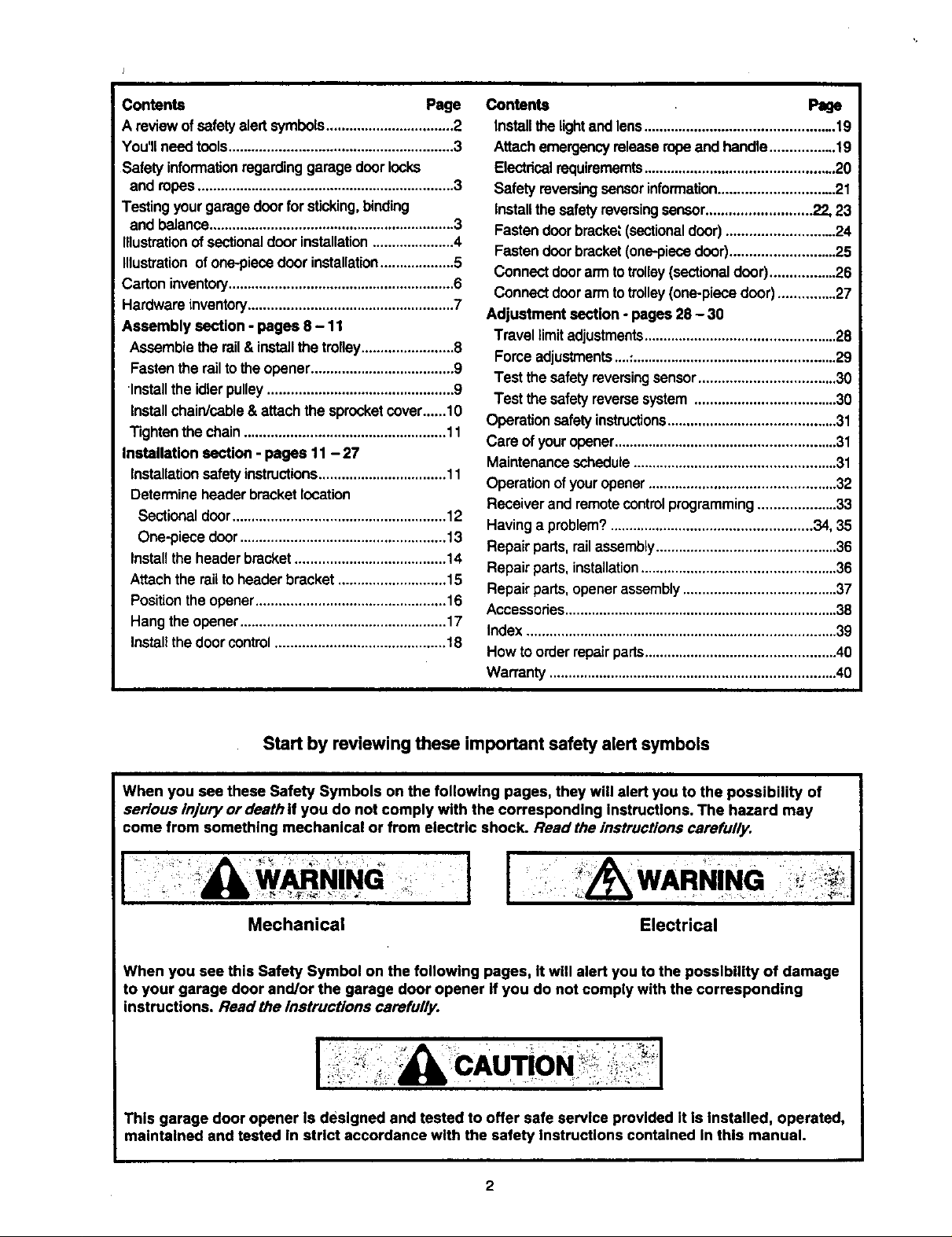

Contents Page

A reviewofsafetyalert symbols.................................2

You'llneedtools..........................................................3

Safety informationregardinggarage doorlocks

and ropes..................................................................3

Testingyourgaragedoorforsticking,binding

and balance...............................................................3

Illustrationofsectionaldoor installation.....................4

Illustrationofone-piecedoor installation...................5

Carton inventory..........................................................6

Hardware inventory.....................................................7

Assembly section - pages 8 - 11

Assemblethe rail&installthe trolley........................8

Fastentherailto the opener.....................................9

Installthe idlerpulley................................................9

Installchain/sable&attach the sprocketcover......10

Tightenthe chain....................................................11

Installation section - pages 11 - 27

Installationsafety instructions.................................11

Determineheaderbracketlocation

Sectionaldoor.......................................................12

One-piecedoor.....................................................13

Installtheheaderbracket.......................................14

Attachthe railtoheaderbracket............................15

Positiontheopener.................................................16

Hangtheopener.....................................................17

Installthedoorcontrol............................................18

Contents Page

Installthe lightandlens.................................................19

Attachemergencyreleaseropeand handle.................19

Electricalrequirememts.................................................20

Safety reversingsensorinformation............................. 21

InstaUthe safetyreversingsensor...........................22, 23

Fastendoorbracket(sectionaldoor)............................24

Fastendoorbracket(one-piecedoor)...........................25

Connect doorarm totrolley(sectionaldoor).................26

Connectdoorarmtotrolley(one-piecedoor)...............27

Adjustment section - pages 28 - 30

Travel limitadjustments.................................................28

Forceadjustments....:....................................................29

Test thesafety reversingsensor...................................30

Test the safetyreversesystem....................................30

Operationsafety instructions...........................................31

Care of youropener.........................................................31

Maintenanceschedute....................................................31

Operationofyouropener................................................32

Receiverand remotecontrolprogramming....................33

Havinga problem?....................................................34, 35

Repair parts,railassembly..............................................36

Repair parts,installation..................................................36

Repair parts,openerassembly.......................................37

Accassories......................................................................38

Index................................................................................39

How to orderrepairparts.................................................40

Warranty..........................................................................40

Start by reviewing these important safety alert symbols

When you see these Safety Symbols on the following pages, they will alert you to the possibility of

serious injury or death if you do not comply with the corresponding instructions. The hazard may

come from something mechanical or from electric shock. Read the instructions carefully.

[ WARNING J

Mechanical

When you see this Safety Symbol on the following pages, It will alert you to the possibility of damage

to your garage door and/or the garage door opener ifyou do not comply with the corresponding

instructions. Read the instructions carefully.

Electrical

CAUTION

This garage door opener ls designed and tested to offer safe service provided It Is Installed, operated,

maintained and tested in strict accordance with the safety instructions contained in this manual.

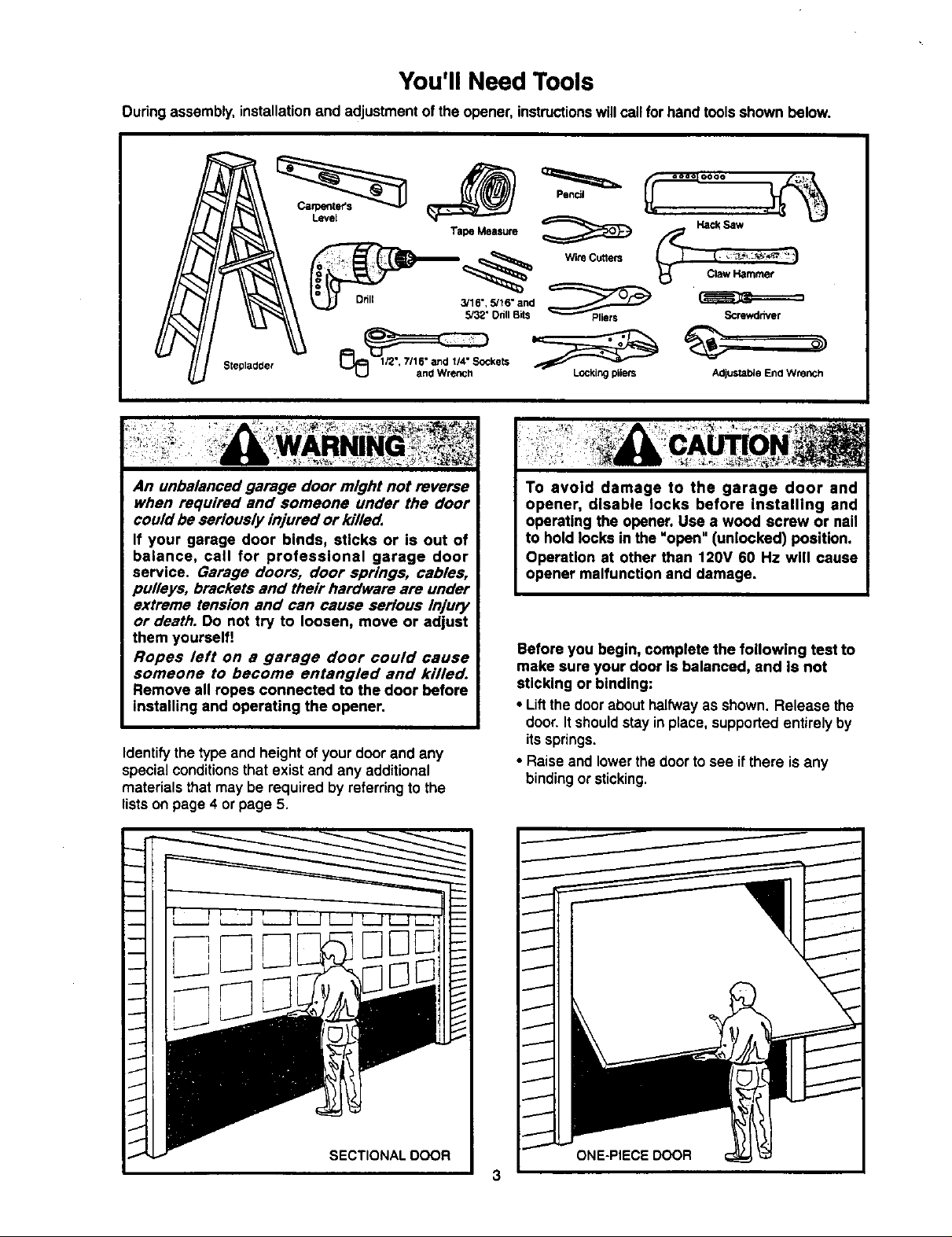

You'll Need Tools

During assembly,installationand adjustmentofthe opener, instructionswillcallfor handtoolsshown below.

Stepladder

An unbalanced garage door might not reverse

when required and someone under the door

could be seriously injured or killed.

If your garage door binds, sticks or is out of

balance, call for professional garage door

service. Garage doors, door springs, cables,

pulleys, brackets and their hardware are under

extreme tension and can cause serious injury

or death. Do not try to loosen, move or adjust

them yourself!

Ropes left on a garage door could cause

someone to become entangled and killed.

Remove all ropes connected to the door before

installing and operating the opener.

Identify the type and height of your door and any

specialconditionsthat existand any additional

materials that may be required by referring to the

lists on page 4 or page 5.

Adjustal_e End Wrench

To avoid damage to the garage door and

opener, disable locks before installing and

operating the opener, Use a wood screw or nail

to hold locks in the "open" (unlocked) position.

Operation at other than 120V 60 Hz will cause

opener malfunction and damage.

Before you begin, complete the following test to

make sure your door Is balanced, and is not

sticking or binding:

• Liftthe doorabouthalfwayas shown. Release the

door.Itshouldstayin place,supportedentirelyby

itssprings.

• Raise andlowerthe door to see if there isany

binding or sticking.

3

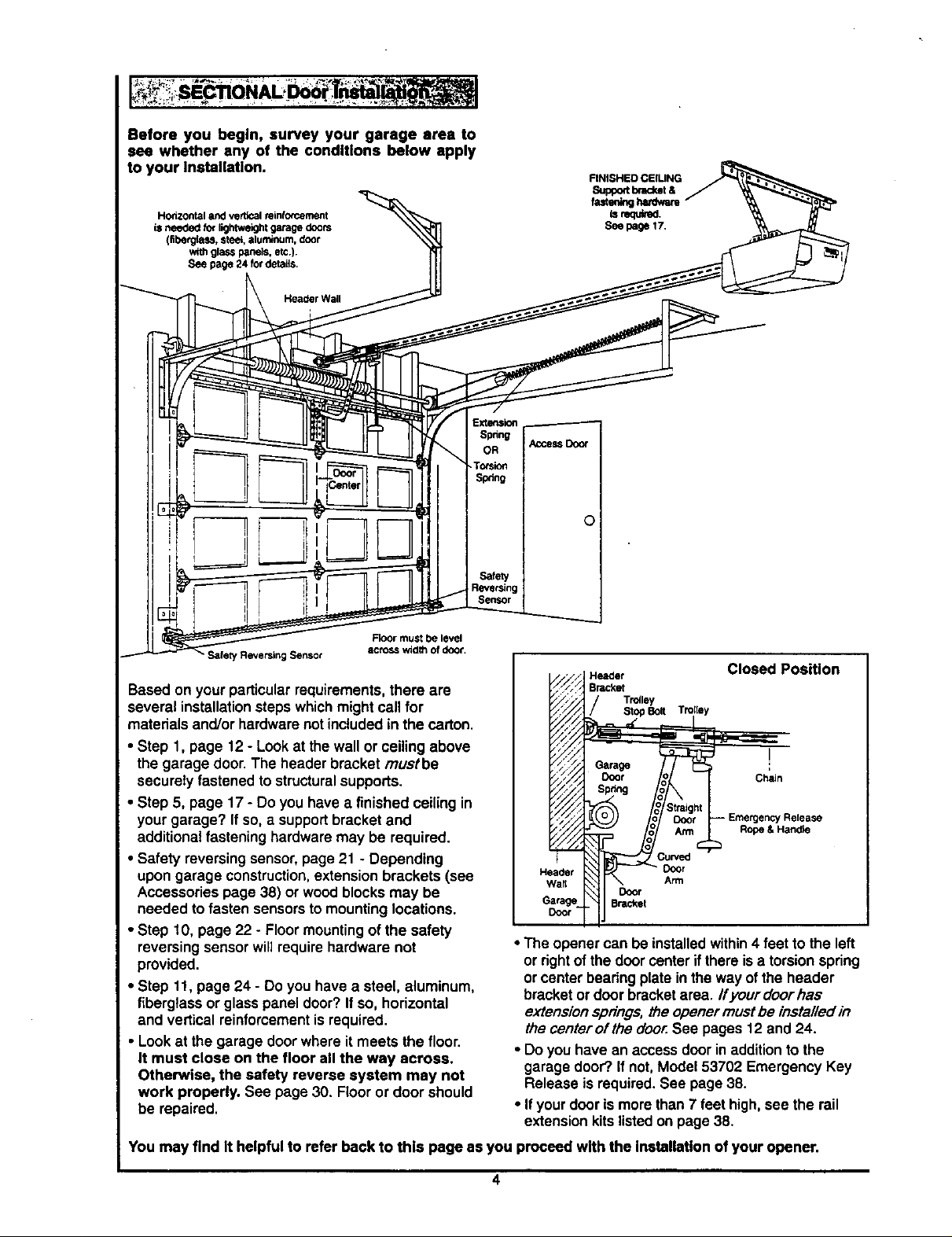

Beforeyoubegin,surveyyourgarageareato

seewhetheranyoftheconditionsbelowapply

toyourInstallation.

Horizontal and vertical rein_,T.ement

is needed _€ lightweight garage doors

(fiberglass, stee_,aluminum, door

withglass panels, etc.).

See page 24 fordeta_s.

Header Wall

Extensk>n

OR Access Door

Spring _el

Torsion

S_ng t

Safety I

ReversingI

Sensor I

0

Floor must be level

Safety Reversing Sensor

Based on yourparticular requirements,there are

several installationstepswhichmightcall for

across wld_ of door,

Header

Bracket

Trofley

Stop Bolt Tn

Closed Position

materials and/orhardwarenot includedinthe carton,

• Step 1, page 12 - Lookat the wallor ceilingabove

the garage door.The header bracket rnustbe

securelyfastened to structuralsupports.

• Step 5, page 17 - Do you have a finished ceiling in

yourgarage? If so, a supportbracketand

additionalfastening hardwaremay be required.

• Safety reversingsensor,page21 - Depending

upon garage construction,extensionbrackets (see

Accessoriespage 38) or woodblocksmay be

needed tofasten sensorsto mountinglocations.

Header Door

Wall Arm

Door

Bracket

I

Chain

r Release

Rope & Han_e

• Step 10, page 22 - Floor mountingof the safety

reversingsensorwill require hardware not

provided.

• Step 11, page 24 - Do you have a steel, aluminum,

fiberglass or glass panel door?If so, horizontal

and vertical reinforcementis required.

• Look at the garage door where it meets the floor.

It must close on the floor all the way across.

Otherwise, the safety reverse system may not

work properly. See page 30. Flooror door should

be repaired.

• The openercan be installedwithin4 feet to the left

or rightof the doorcenter ifthere is a torsionspring

orcenterbearing plate in the way ofthe header

bracketordoor bracketarea. ffyourdoorhas

extensionsprings,the openermustbe installed in

thecenter ofthe door.See pages 12 and 24.

• Do youhave an access doorinadditionto the

garage door?,ifnot, Model 53702 Emergency Key

Release is required.See page 38.

• If your door is morethan7 feet high,see the rail

extensionkitslistedon page38.

You may find it helpful to refer back to this page as you proceed with the installation of your opener.

4

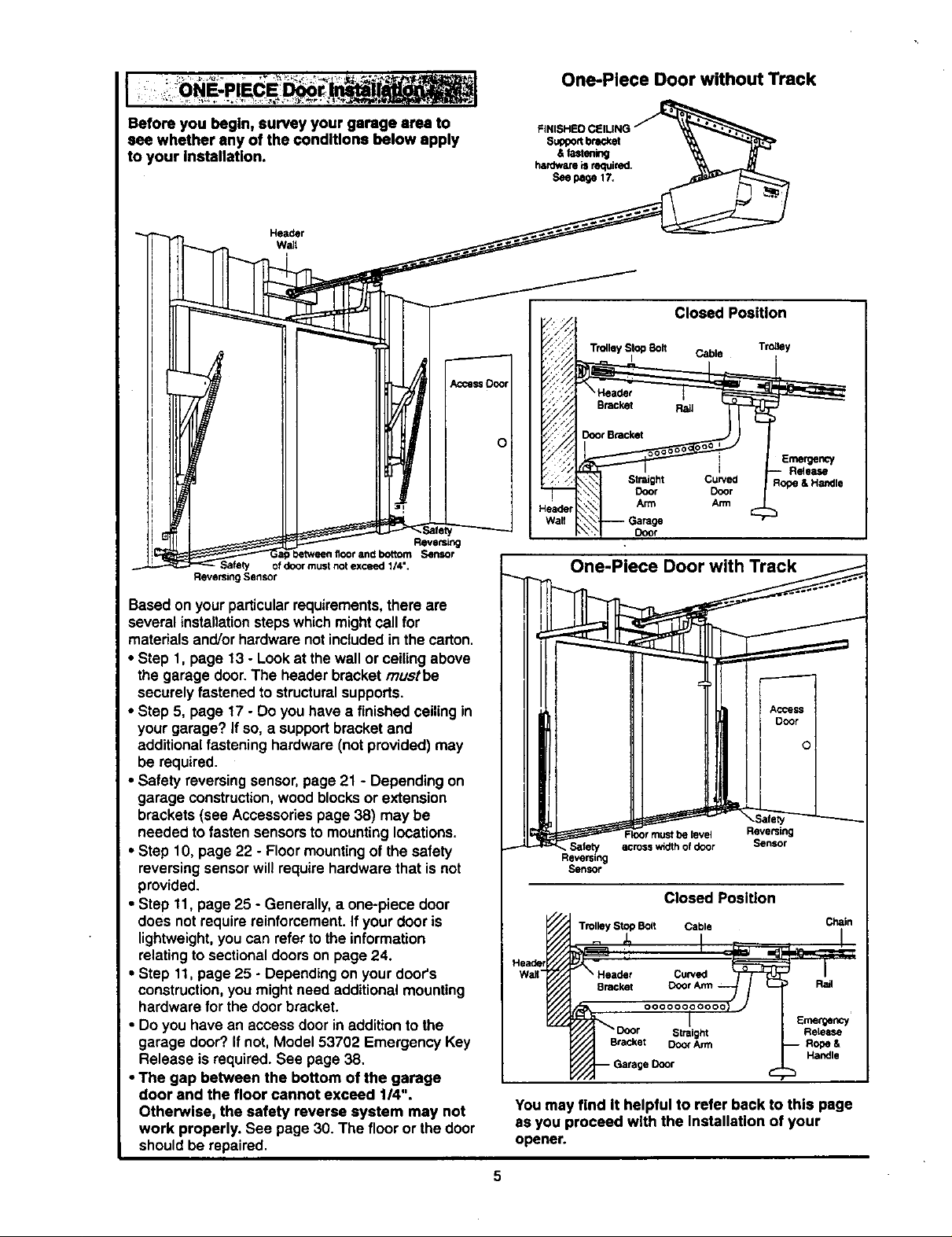

One-Piece Door without Track

Before you begin, survey your garage area to FNSHEDOEUNO / -_'_,_-_.

see whether any of the conditions below apply superbracket "_

to your installation. . &fastening _, _,

Header

nardwm is required.

See dege 17.

w,l

Zll//

Db':, Door Bracket

Ii II l !11 IIIPl I I I Fi i _i _%.,.

! 7;"; i Emergency

; ,; ,: -_ Slight Curved Rope l Handle

-_ {,. Door Door

Wall \7 Garage

Safely Ofdoor must not exceed 114".

Reversing Sensor

ap between floor and bottom Sensor

Based on yourparticularrequirements,there are

several installatien stepswhichmightcallfor

materials and/orhardware not includedin the carton.

• Step 1, page 13 - Lookat thewall er ceilingabove

the garage door.The header bracket rnustbe

securely fastenedto structuralsupports.

• Step 5, page 17 - Do you have a finished ceiling in

your garage? If so, a support bracketand

additionalfastening hardware (not provided) may

be required.

• Safety reversingsensor,page 21 - Depending on

garage construction,woodblocks or extension

brackets (see Accessoriespage 38) may be

needed tofasten sensors to mountinglocations.

• Step 10, page 22 - Floor mountingof the safety

reversingsensor will require hardwarethat is not

provided.

• Step 11, page 25 - Generally, a one-piece door

does not requirereinforcement.If your door is

lightweight,you can refer to theinformation

relatingtosectionaldoors on page 24.

• Step 11,page 25 - Dependingon your deor's

construction,you might need additionalmounting

hardware for the doorbracket.

• Do you have an access doorin additionto the

garage door?.If not, Model 53702 Emergency Key

Release is required. See page 38.

•The gap between the bottom of the garage

door end the floor cannot exceed 1/4".

Otherwise, the safety reverse system may not

work properly. See page 30. The floor or thedoor

shouldbe repaired.

i

Access

D°_o ---------

Floormustbe level Reversing

Reversing

Sensor

across wio_hof door

Closed Position

Trolley Stop Boll Cable

Chain

Handle

You may find It helpful to refer back to this page

as you proceed with the Installation of your

opener.

Carton Inventory

Your garage door opener is packagedin twocartons whichcontainpartsillustratedbelow,Accessorieswill

depend on model purchased. If anythingismissing,carefullycheckthepackingmaterial. Partsmay be "stuck"in

the foam. Hardware for assemblyand installationis shownon page 7.

StandardControlConsole

Trolley

Chain

Idter Pulley

Rml

Front (header)

Sactlon

Remote Contml with Visor Clip (2)

Spre<:ketCover

Security@Three-Function

/

Sacurlt_ Ks/less EnW

/

Rail

Center/Back

Sact_ne

Door Bracket

Light Lens

Hanging Brackets

J

Safety Sensor

Bracket

Header Bracket

==%

(2) Safety Reversing Sensors

(I Sending Eye and 1 Receiving Eye)

2-Conductor White & White.lack Bell Wire

vim

at_a_ed

6

2-Co_luctor Bell Wire

White &White/ned

Safety Labels

and

literature

Cu_ Door

A,'m Section

Straight Door

Arm Section

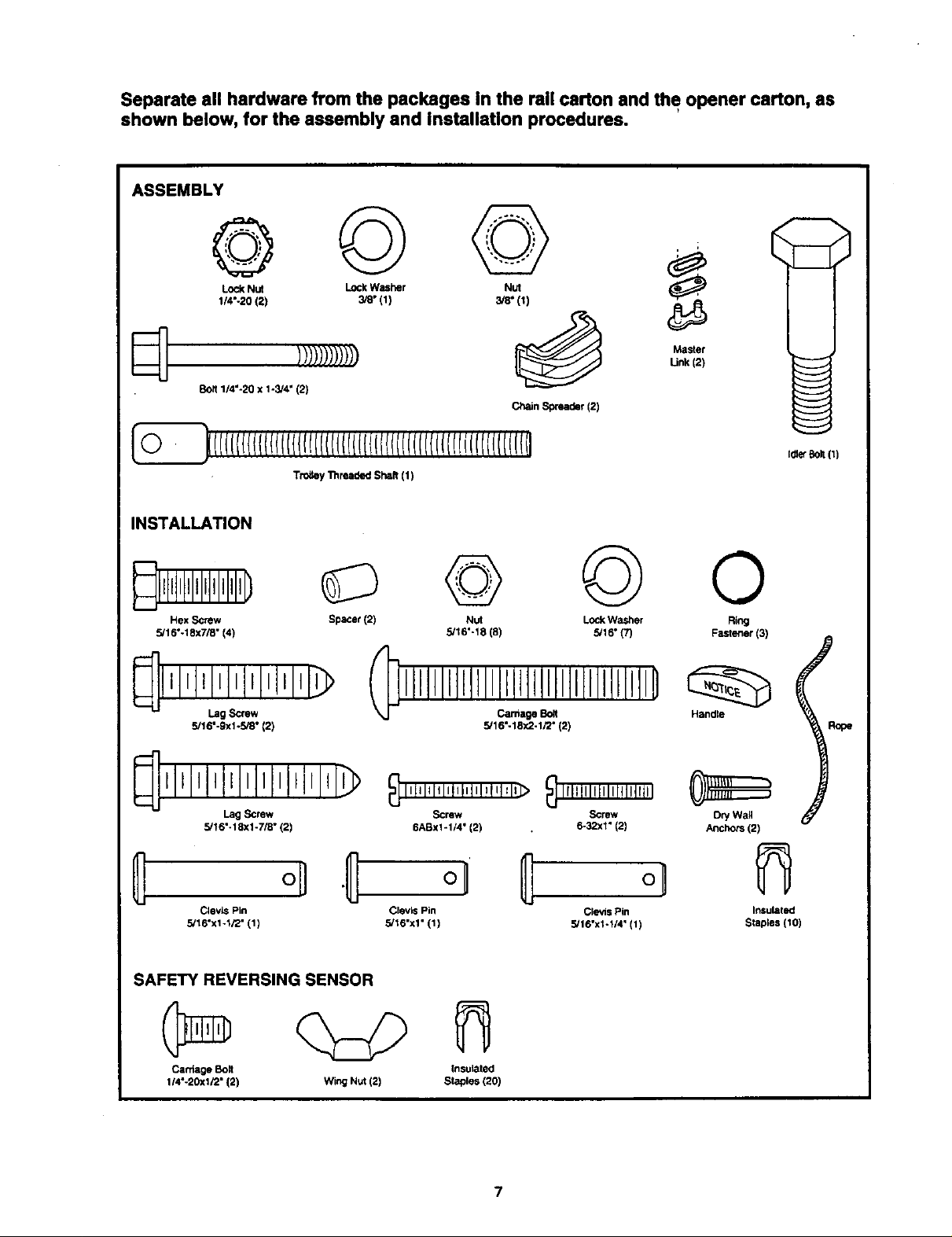

Separate all hardware from the packages In the rail carton and the opener carton, as

shown below, for the assembly end installation procedures.

ASSEMBLY

Lock Nut Lock Washer Nut

1/4"-20 (2) 3/8" (1) 3/8" (I)

q

BOR1/4"-20 x 1-3/4" (2)

Tro_ey Tilreaded ShaR (1)

INSTALLATION

Hex Screw Spacer (2)

5/16"-18x7/8" (4)

l'l,l,l,l,l l,l,l,I>

Lag Screw

5/16"-9xl-5/8" (2)

Lag Screw

5/16"-18xl-7/8" (2)

1!/////////) "n'_i:;

Chain Spreader (2)

© @ o

Nut Lock Washer Ring

5/16"-18 (8) 5/16" (7) Fastener (3)

5/16"-18X2-1/2" (2)

Screw Screw Dry Wag

6ABx1-1/4" (2) 6-32xl" (2) Anchors (2)

ol} o1

CJevisPin Clevis Pin

5/16"x1-1/2" (1) 5/16"x1" (1)

SAFETY REVERSING SENSOR

Catdage Bo_t

1/4"-20Xl/2" (2)

Wing Nut (2) Staples (20)

Clevis Pin Insuleted

5/16"xi-1/4" (1) Staples (10)

Insulated

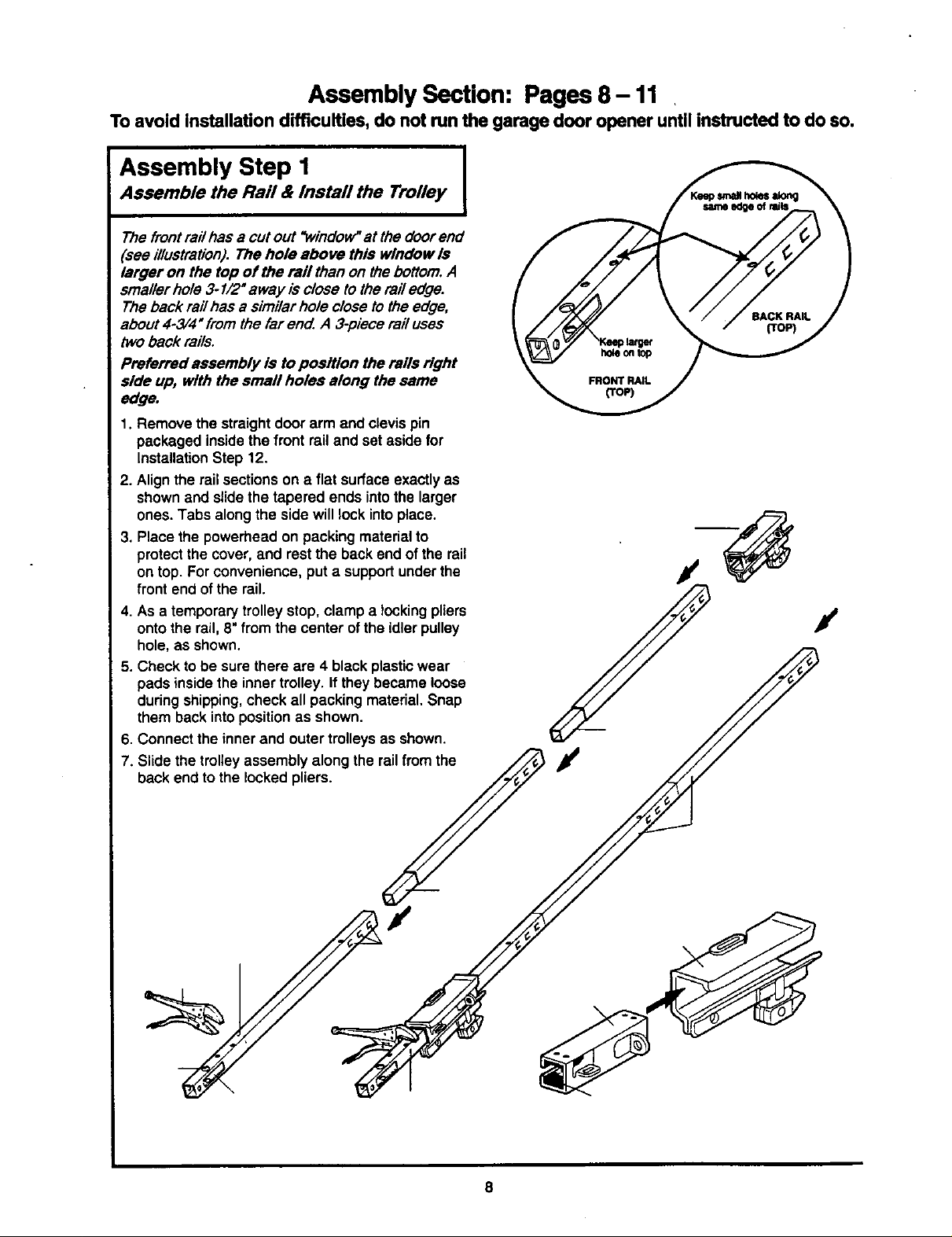

Assembly Section: Pages 8 - 11

To avoid installation difficulties, do not run the garage door opener until instructed to do so.

Assembly Step 1

Assemble the Rail & Install the Trolley

The front railhas a cutout "window'at the doorend

(see illustration). The hole above this window Is

larger on the top of the rail than on thebottom.A

smallerhole 3-1/2" away isclose tothe railedge.

Theback rail has a similar hole close tothe edge,

about 4-3/4" fromthe far end. A 3-piece rail uses

twoback rails.

Preferred assembly is to position the rails right

side up, with the small holes along the same

edge.

1. Remove the straightdoor arm and clevispin

packaged insidethefront rail and set asidefor

InstallationStep 12.

2. Alignthe railsectionson a flat surface exactly as

shownand slide the tapered ends intothe larger

ones.Tabs along the side will lock intoplace.

3, Place the powerhead onpacking materialto

protectthe cover, and restthe backend of the rail

on top. For convenience, put a supportunderthe

front end ofthe rail.

4. As a temporary trolleystop, clamp a locking pliers

ontothe rail, 8"from the center of the idlerpulley

hole, as shown.

5. Check to be sure there are 4 black plasticwear

pads inside the innertrolley. If theybecame loose

duringshipping,check all packingmaterial.Snap

them back intopositionas shown.

6. Connect the inner and outer trolleysas shown.

7. Slide the trolleyassembly along the rail fromthe

back end to the locked pliers.

/

/

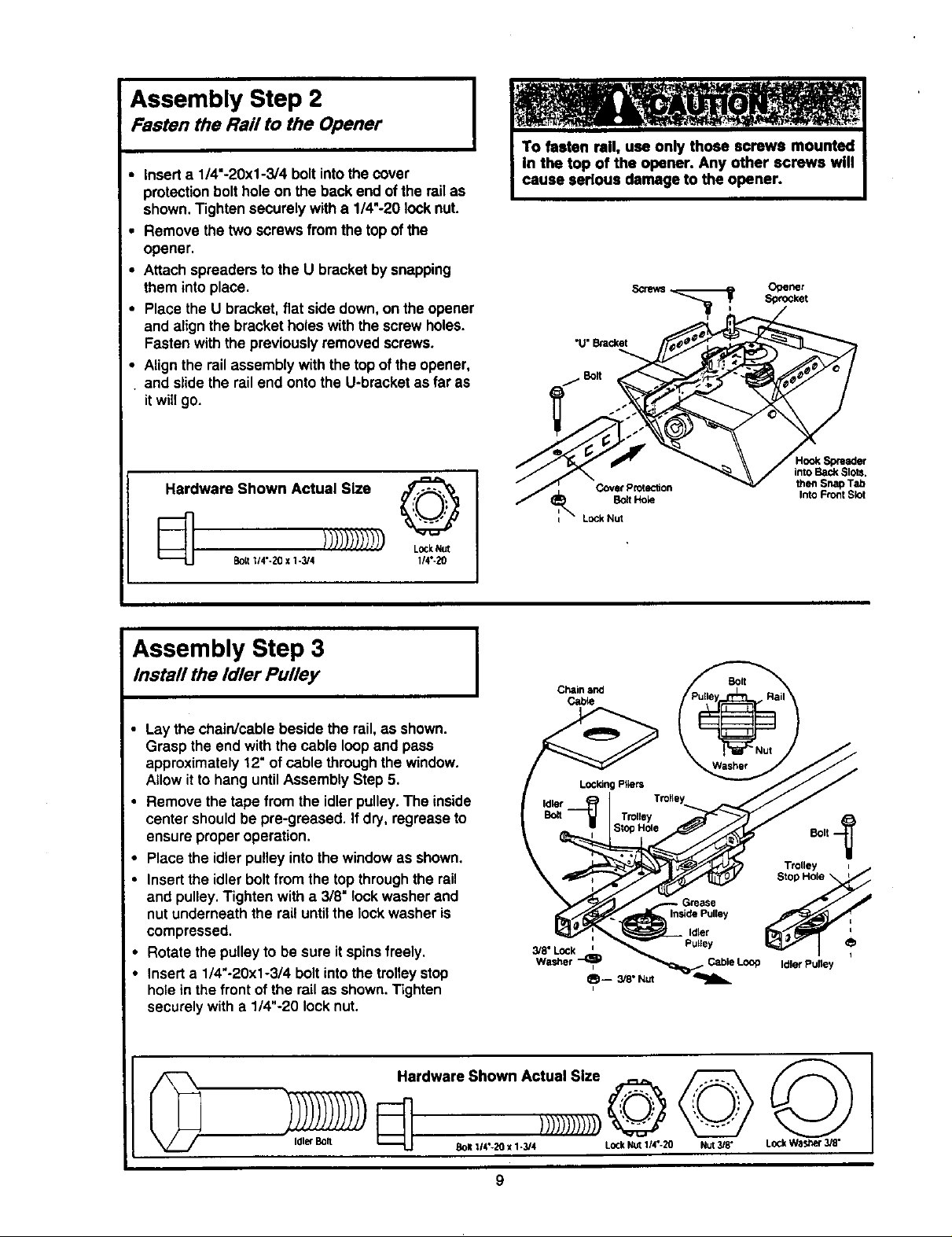

Assembly Step 2

Fasten the Rail to the Opener

• Inserta 1/4"-20xl-3/4 bolt intothe cover

protectionbolthole on the back end ofthe railas

shown.Tighten securelywith a 1/4"-20 locknut.

• Remove the two screws from the top ofthe

opener.

• Attach spreadersto the U bracket bysnapping

them intoplace.

• Place the U bracket, flat side down,on the opener

and alignthe bracketholes withthe screw holes.

Fasten withthe previouslyremoved screws.

• Alignthe railassembly with the topof the opener,

and slide the rail end ontothe U-bracket as far as

itwillgo.

Hardware Shown Actual Size

Covet Protection

Bo_ Hok_

L_k Nut

into Back Slots,

then Snap Tab

Into Front Slot

Bolt 1/4"- _0 x 1-3/4 114"-L>0

1)))))1))!1)

Assembly Step 3

Install the Idler Pulley

Lay the chain/cable beside the rail,as shown.

Grasp the end with the cable loopand pass

approximately 12" ofcable through the window.

Allow it to hang untilAssembly Step 5.

Remove the tape from the idlerpulley. The inside

center shouldbe pre-graased. If dry, regreaseto

ensureproperoperation.

Place the idler pulleyintothe window asshown.

• Insertthe idler boltfrom the topthroughthe rail

and pulley. Tighten witha 3/8" lock washerand

nut underneaththe rail untilthe lockwasher is

compressed.

• Rotate the pulleyto be sure it spinsfreely.

• Insert a 1/4"-20xl-3/4 boltintothe trolleystop

hole in the front of the rail as shown. Tighten

securelywith a 1/4"-20 locknut.

Ttoltsy =

\

Idler _

Inside Pulley

Pugey

Cable Loop Idler Pulley

Stop Hole t

Hardware Shown Actual Size _

Idler Bolt Bolt 114"-20 x 1-3/4 LOCkNut 1/4°-20 Nut 3/8" L_k Wastler 3/8"

9

Assembly Step 4

Install the Chain/Cable

and Attach the Sprocket Cover

1. Pullthe cable aroundthe idlerpulley and toward

the trolley.

2. Connect the cableloopto the retaining sloton

thetrolley,as shown:

• From below, pushpins of master link bar up

through cable loopand trolleyslot.

• Push master linkcap over pins and past pin

notches.

• Slideclip-on springover cap and onto pin

notchesuntilboth pins are securely locked in

place.

3. Withthe trolleyagainstthe pliers,dispense the

remainderofthe cable/chain along the rail toward

the powerheadand around the sprocket.The

sprocketteeth must engage the chain.

4. Check to make surethe chain is nottwisted, then

connectitto thethreaded shaftwith the

remainingmaster link.

5. Thread the inner nutand lockwasher ontothe

the trolleyshaft.

6. Insertthe trolleythreaded shaftthrough the hole

inthe trolley.Be sure the chainis not twiste_.

7. Looselythread the outer nutonto the trolley

shaft.

8. Remove the lockingpliers.

9. Align the tabs on the sprocketcover withthe slots

inthe mountingplate. Squeeze cover and insert

tabs in slots.

DiSpensing Canon

Leave Chain and Cable

Inside Dis_oenstng

Carton to Prevent Kinking.

\

Keep Chain and Cable

Taut When Dispensing

, i

Master Link ---_ Master

DiilPOn Spnng _ Link Cap

Idlat

'"_ : , Link Cap

Loop :

r_st_e

10

Hble

Master

(_'_- Link Bat

Trolley : Pin

Threaded : Notch

_ Master

Shaft ,_,

Round

Hole

Sprocket

Cover ---_ Opener

Front _ Back

Tab Skit Tab Slot

Unk Bar

, , SprOcket

Mounting

Plate

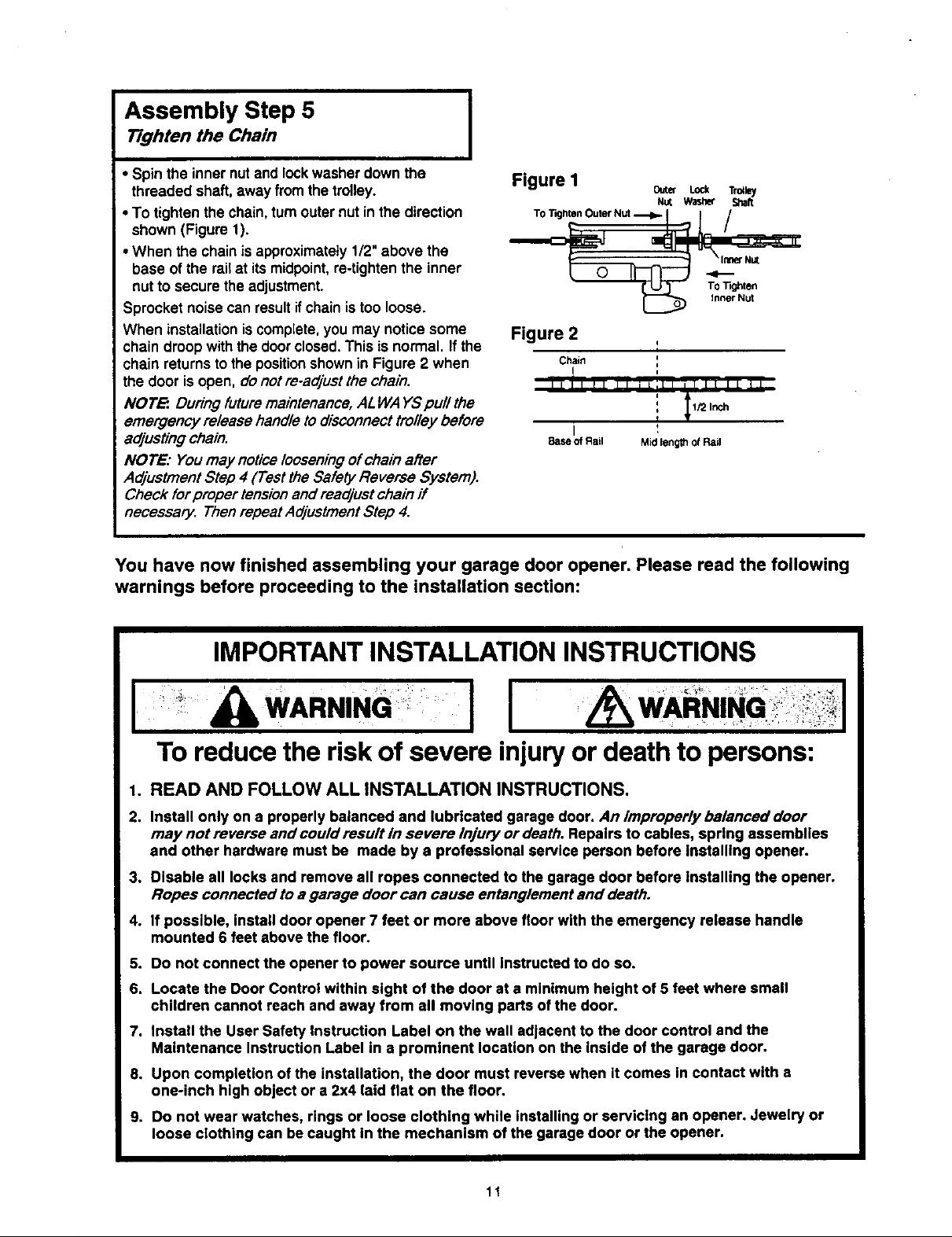

Assembly Step 5

Tighten the Chain

I

• Spin the inner nutand lockwasher down the

threaded shaft, away fromthe trolley.

• To tightenthe chain,turnouternut inthe direction

shown (Figure 1).

•When the chain is approximately1/2" above the

base of the railat its midpoint,re-tightenthe inner

nut tosecure the adjustment.

Sprocket noisecan resultif chainistoo loose.

When installation is complete,you may notice some

chain droopwiththe doorclosed.This isnormal. If the

chain returnstothe positionshownin Figure 2 when

the door is open, do not re.adjust the chain.

NOTE:. During future maintenance,ALWA YSpull the

emergency release handle to disconnecttrolley before

adjusting chain.

NOTE: Youmay noticelooseningof chain after

AdjustmentStep 4 (Test the Safety Reverse System).

Check for proper tensionand readjust chain if

necessary. Thenrepeat AdjustmentStep 4.

You have now finished assembling your garage door opener. Please read the following

warnings before proceeding to the installation section:

Figure I 0=,_ Lo_ r,=_v

Figure 2

Chain

Base of Rail Mid lengltl of Rail

NUt Washer Shaft

i

i

,,

IMPORTANT INSTALLATION INSTRUCTIONS

I ' &WARNING: I I

To reduce the risk of severe injury or death to persons:

1. READ AND FOLLOW ALL INSTALLATION INSTRUCTIONS.

2. Install only on a properly balanced and lubricated garage door. An improperly balanced door

may not reverse and could result In severe Injury or death. Repelrs to cables, spring assemblies

and other hardware must be made by a professional service person before Installing opener.

3. Disable all locks and remove all ropes connected to the garage door before installing the opener.

Ropes connected to a garage door can cause entanglement and death.

4. If possible, install door opener 7 feet or more above floor with the emergency release handle

mounted 6 feet above the floor.

5. Do not connect the opener to power source until instructed to do so.

6. Locate the Door Control within sight of the door at a minimum height of 5 feet where small

children cannot reach and away from all moving parts of the door.

7. Install the User Safety Instruction Label on the wall adjacent to the door control and the

Maintenance Instruction Label in a prominent location on the inside of the garage door.

8. Upon completion of the installation, the door must reverse when it comes in contact with a

one-inch high object or a 2x4 laid flat on the floor.

9. Do not wear watches, rings or loose clothing while installing or servicing an opener. Jewelry or

loose clothing can be caught In the mechanism of the garage door or the opener.

11

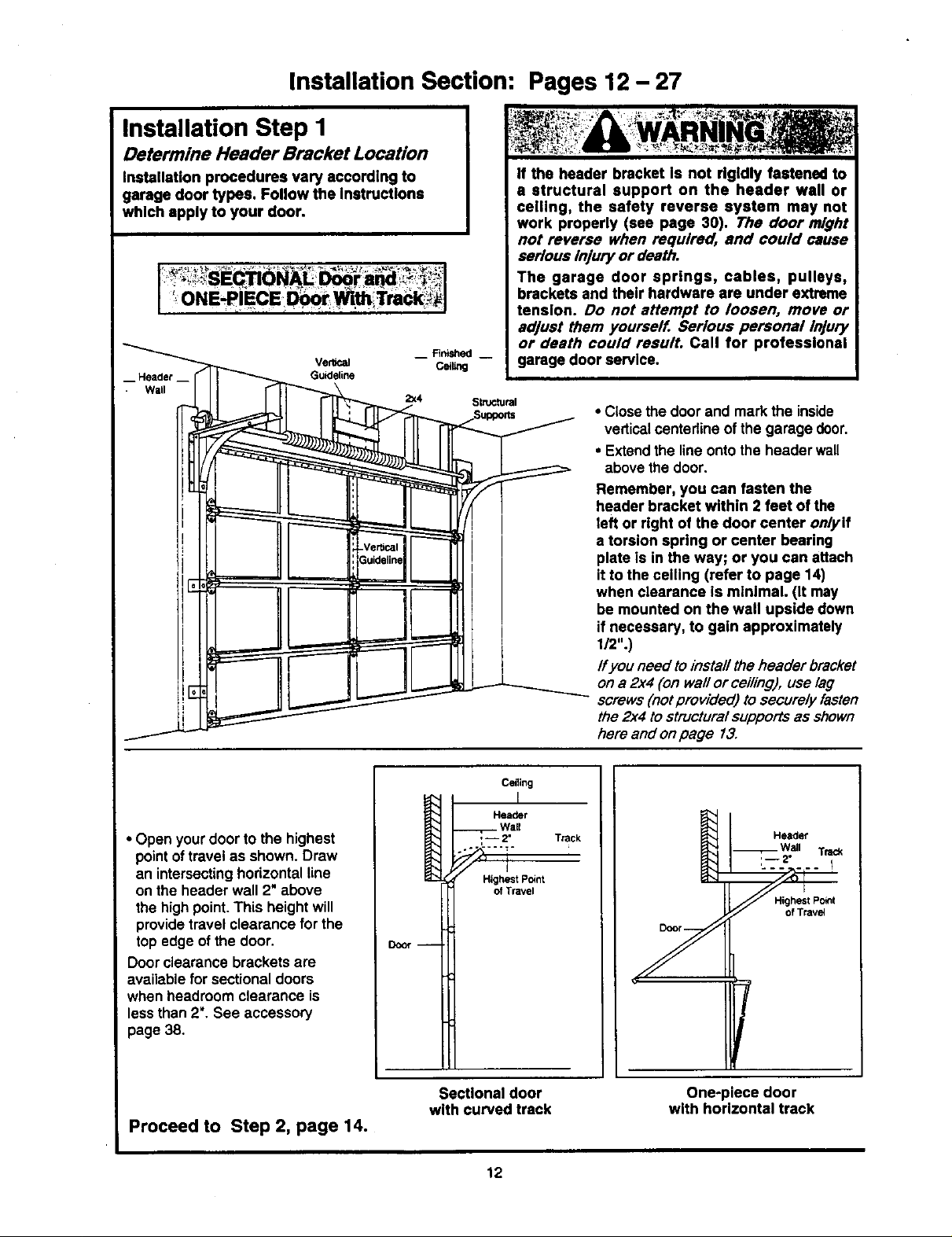

Installation Section: Pages 12- 27

Installation Step I

Determine Header Bracket Location

Installation procedures vary according to

garage door types. Follow the Instructions

which apply to your door.

Ver_cei

-- Header __

Wall

Guideline

2:<4 Structural

J

i Rnished --

cei_g

If the header bracket Is not rigidly fastened to

a structural support on the header wall or

ceiling, the safety reverse system may not

work properly (see page 30). The door might

not reverse when required, and could cause

serious Injury or death.

The garage door springs, cables, pulleys,

brackets and their hardware are under extreme

tension. Do not attempt to loosen, move or

adjust them yourself. Serious personal Injury

or death could result. Call for professional

garage door service.

• Closethe door and mark the inside

verticalcenterline of the garage door.

• Extendthe line ontothe header wall

above the door.

Remember, you can fasten the

header bracket within 2 feet of the

left or right of the door center on/yif

a torsion spring or center bearing

plate is in the way; or you can attach

it to the ceiling (refer to page 14)

when clearance is mthlmal. (It may

be mounted on the wall upside down

if necessary, to gain approximately

1/2".)

Ifyou need toinstall theheader bracket

on a 2x4 (on wail or ceiling), use lag

screws(notprovided) to securely fasten

the2x4 tostructuralsupportsas shown

here and onpage 13.

• Open your door to the highest

pointof travel as shown. Draw

an intersectinghodzontal line

on the header wall 2"above

the highpoint.This height will

providetravel clearance for the

top edge ofthe door.

Doorclearance brackets are

availablefor sectionaldoors

when headroom clearance is

lessthan 2". See accessory

page 38,

Proceed to Step 2, page 14.

Door --

Sectional door

with curved track

Ceiling

Header

Wall

,,-- 2" Track

Highest POint

of Travel

12

Header

Wall Tr_c_

:--2"

Highest Point

of Trave_

One-piece door

with horizontal track

Loading...

Loading...