Page 1

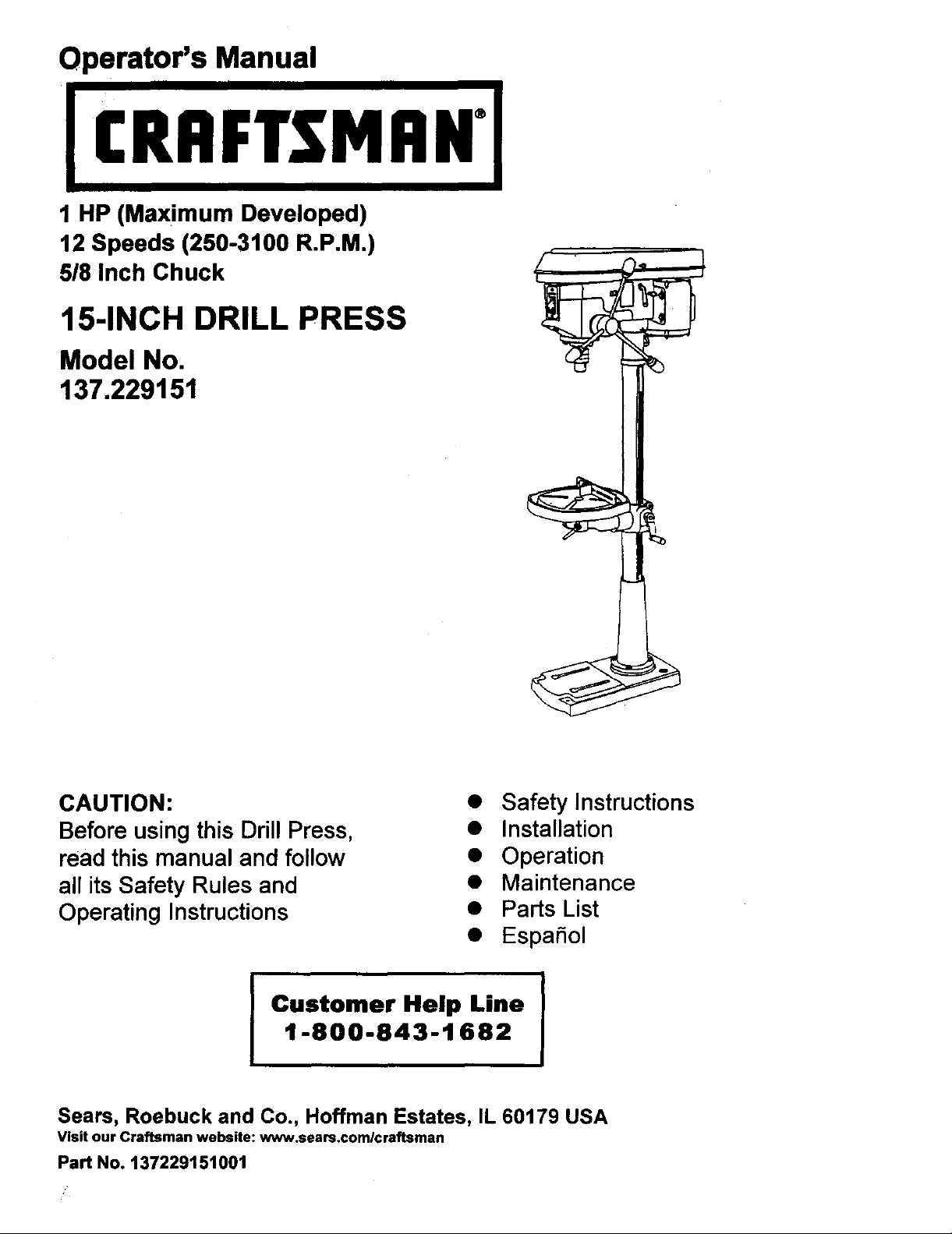

Operator's Manual

1 HP (Maximum Developed)

12 Speeds (250-3100 R.P.M.)

5/8 Inch Chuck

15-INCH DRILL PRESS

Model No,

137.229151

CAUTION:

Before using this Drill Press,

read this manual and follow

all its Safety Rules and

Operating Instructions

Customer Help Line

1-800-843-1682

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

Visit our Craftsman website: www.sears.comlcraftsman

Part No. 137229151001

• Safety Instructions

• Installation

• Operation

• Maintenance

• Parts List

• EspaSol

Page 2

SECTION PAGE

Warranty ................................................................................................................ 2

Product Specificattone ............................................................................................. 2

Safety Instructions .................................................................................................. 3

Accessories and Attachments .................................................................................. 6

Carton Contents ...................................................................................................... 6

Know Your Drill Press ............................... _.............................................................. 8

Glossary of Terms ....................................................................... ;........................... 9

Assembly and Adjustment ..................................................... _...................... ,............ 10

Operation ............................................................................................................... 15

Maintenance ........................................................................................................... 20

Troubleshooting Guide ............................................................................................ 21

Parts ...................................................................................................................... 22

Espafiol ............................................................ ;..................................................... 25

FULL ONE YEAR WARRANTY

If this Driss Press fails due to a defect in material or workmanship within one year of date of purchase,

Sears will at its option repair or replace it free of charge.

Return this Drill Press to a Sears Service Center for repair, or to place of purchase for replacement.

This warranty gives you specific legal rights, and you may also have other rights which may vary from

state to state.

Sears, Roebuck and Co., Dept. 817 WA, Hoffrnan Estates, IL 60179

_q

Some dust created by power sanding, sawing, grinding, drilling and other construction activities contains

chemicals known to the state of California to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

Your risk from these exposures varies, depending on how often you do this type of work. To reduce )/our

exposure to these chemicals work in a well-ventnated area and work with approved safety equipmentsuch as

dust masks that are spec a y des gned to filter out microscopic particles.

Chuck Size ............................ 5/8"

Speed ................................... 12 (250 ~ 3,100 RPM)

Motor .................................... 120V, 60 Hz, 8 Amps

Horsepower ........................... 1 HP (Max. Developed)

Built-in Light ......................... 60 Watt (Maximum)

Table Size ............................ 13-1/4" x 13-1/4"

Table Tilt ............................... 45 ° Right or Left

Spindle Travel ........................ 3-1/8"

Throat ................................. 7-1/2"

Base Size ............................. 11" x 20-3/8"

Height ...................... :........... 63-1/4"

• Lead from lead-based paints

• Crystalline silica from bricks, cement and other masonry products

• Arsenic and chromium from chemicallytreatsd lumber

To avoid electrical hazards, fire hazards, or damage to

the tool, use proper circuit protection.

(Bulb not included)

Your drill press iswired at the factory for 120V operation.

Connect to a 120V, 15 AMP branch circuit and use a 15

AMP time delay fuse or circuit breaker. To avoid shock or

fire, replace power cord immediately if it is worn, cut or

damaged in any way.

2

Page 3

GENERAL SAFETY INSTRUCTIONS 14.

BEFORE USING THE DRILL PRESS

Safety is a combination of common sense, staying alert

and knowing how to use your ddllpress. 15.

To avoid mistakes that could cause sedous injury, do not 16. NEVER STAND ON TOOL Sedous injurycould occur

plug the drillpress in untilyou have read and understood ifthe toolisUpped or ifthe cuffingtoolis unintentionally

the following: contacted.

REMOVE ADJUSTING KEYS AND WRENCHES.

Form the habitof checking to see that keys and

adjusting wrenches are removed from the tool before

turning =ON".

NEVER LEAVETOOL RUNNING UNATFENDED.

TURN THE POWER "OFF". Don't leave the tooluntil

itcomes to a complete stop.

1. READ and become familiar with this entire instruction

manual.LEARN the tool'sapplications,limitstJons,and

possiblehazards.

2. KEEP GUARDS IN PLACE and inworkingorder.

3. DON'T USE IN A DANGEROUS ENVIRONMENT.

Don't use power tools in damp or wet locations, or

expose them to rain.Keep work area well lighted.

4. DO NOT use power toolsinthe presence of flammable

liquidsor gases.

5. KEEP WORK AREA CLEAN. Cluttered areas and

benches inviteaccidents.

6. KEEP CHILDREN AWAY.AUvisitorsshouldbe keptat

a safe distance from the work area.

7. DON'T FORCE THE TOOL. It Willdothe job better

and safer at the rate for which it was designed.

8. USETHE RIGHTTOOL. Don't force tool or the

attachment to do a job for which it was not designed.

WEAR PROPER APPAREL DO NOT wear loose

.

clothing, gloves, neckties, rings, bracelets, or other

_lowelrywhich may get caught in moving parts.

onslip footwear is recommended. Wear protective

hair covering to contain long hair.

10. WEAR A FACE MASK OR DUST MASK.

Drillingoperation produces dust.

11. DISCONNECTTOOLS before servicing, and when

changing accessories, such as blades, bits, ct_ttem,

and the like.

12. REDUCETHE RISK OF UNINTENTIONAL STARTING.

Make sure the switchis in "OFF"positionbefore

plugging in.

13. USE RECOMMENDED ACCESSORIES. Consult the

owner's manual forthe recommended accessories.

The use of improperaccessories may cause risk of

injury to persons.

17. DON'T OVERREACH. Keep proper footing and

balance at all times.

18. MAINTAIN TOOLS WITH CARE. Keep toolssharp

and clean for best and safest performance. Follow

instructionsfor lubricating and changing accessories,

19. CHECK FOR DAMAGED PARrs. Beforefurther use of

the tool,a guard or other pert that is damaged should

be carefully checked to determine that it willoperate

propertyand perform its intended function.Check for

alignmentof movingparts,bindingof moving parts,

breakage of parts, mounting,and any otherconditions

that may affect its operation.A guard or other part that

is damaged shouldbe properly repairedorreplaced.

20. MAKE WORKSHOP laD PROOF withpadlocks,master

switches,or by removing starter keys.

21.

DO NOT operatethe toolif you are underthe influence

of any drugs,alcohol or medication that could affect

your abilityto use the tool properly.

22.

Dust generated fromcertain materials can be

hazardous to your health.Always operate the drill

press in a well-ventilatedarea and provide for proper

dust removal. Use dust coflection systems whenever

possible.

23. ALWAYS WEAR EYE

PROTECTION. Any ddll press

can throw foreignobjects into

the eyes which could cause

permanent eye damage.

ALWAYSwear SafetyGoggles

(not glasses) thatcomplywith

ANSI safety standard Z87.1. Everyday eyeglasses

have only impact-resistant lenses. They ARE NOT

safety glasses.SafetyGogglesare available atSeam.

NOTE: Glasses or goggles not in compliance with

ANSI Z87.1 could seriouslyhurtyou when they break.

SAVE THESE INSTRUCTIONS

3

Page 4

SPECIFIC SAFETY INSTRUCTIONS

FOR THE DRILL PRESS

For your ownsafety,do nottry to use yourdrill press or

plug itinuntilit iscompletelyassembled and installed

accordingtothe instructions,and untilyouhave read

and understoodthis instrucbonmanual:

14.SECURE WORK. Usa clampsorviseto holdthe

work when practical.It'ssafer than using yourhand

and itfrees bothhandsto operatetool,

15.WHEN usinga drill pressvise, always fasten tothe

table.

16.MAKE SURE allclamps and locksare firmly

tightenedbeforedrilling.

1. YOUR DRILL PRESS MUST BE BOLTED securely

to a workbench. Inaddition,if there is any tendency

for your drillpressto move duringcertainoperations,

boltthe workbenchtothe floor.

2. THIS DRILL PRESS isintendedfor usa indry

conditions,indooruseonly.

3. WEAR EYE PROTECTION. USE face ordustmask

alongwithsafety goggles ifdrillingoperationisdusty.

USE ear protectors,especially duringextended

periodsof operation.

4. DO NOT wear gloves, neckties, or looseclothing

5. DO NOT tryto drillmaterial too smallto be securely

held.

6. ALWAYS keephands out ofthe path of a drill bit.

Avoidawkward hand positionswherea suddenslip

couldcause yourhand to move into thedrillbit.

7. DO NOT installor use any drill bit thatexceeds 175

mm (7") in lengthor extends 150 mm (6") below

thechuckjaws.They can suddenly bendoutwardor

break.

8. DO NOT USE wire wheels, router bits, shaper cutters,

circle(fly) cutters,or rotary planerson thisdrill press.

17.SECURELY LOCK THE HEAD and table supper to

the column, and thetable to the table supportbefore

operatingthe drillpress.

18.NEVER turnyour drill presson before clearing the

table of allobjects (tools,scrapsof wood, etc.)

19.BEFORE STARTING the operation,jog the motor

switchto make sure the drillbitdoes notwobbleor

vibrate.

20.LET THE SPINDLE REACH FULL SPEED before

startingto drill.If your drillpress makes an unfamiliar

noiseor if it vibratesexcessively,stop immediately,

turnthe drillpress off and unplug. Do not restartuntil

the problem is corrected.

21.DO NOT perform layoutassembly or set up work on

the tablewhilethe drill press is in operation.

22.USE RECOMMENDED SPEED for drill accessory

and workpiecematerial. SEE INSTRUCTIONS that

comewiththe accessory

23.WHEN DRILLING largediameter holes,clamp the

workpiece firmlyto the table. Otherwise, the bitmay

grapand spinthe workpieceat high speed. DO NOT

USE fly cuttersor multiple-parf hole cutters,as they

cancome apart or become unbalancedin use.

9. WHEN cuttinga large piece ofmaterial make sure it

isfully supportedat the table height.

10.DO NOT perform any operation freehand. ALWAYS

holdtheworkpiece firmly against the table so itwill

notreck or twist. Use clamps or a visefor unstable

workpiece.

11.MAKE SURE there are no nailsor foreign objects in

the partofthe workpieceto be drilled.

12.CLAMP WORKPIECE OR BRACE against the left

side of the columnto prevent rotation.Ifit is too short

or the table istilted, clamp solidlyto the table and use

the fence provided.

13.IF THE WORKPIECE overhangs the table such that

it will fall or tip if not held, clamp it to the table or

provide auxiliary support.

SAVE THESEINSTRUCTIONS

24.MAKE SURE the spindle has come to a complete

stop before touching the workpiece.

25.TO AVOID INJURY from accidental starting,always

turnthe switch"OFF" and unplugthe drill press

beforeinstallingorremoving any accessoryor

attachmentor making any adjustment

26.KEEP GUARDS IN PLACE and inworkingorder.

27.USE ONLY SELF-EJECTING TYPE CHUCK KEY as

providedwiththe drill press

Page 5

GROUNDING INSTRUCTIONS

IN THE EVENT OF A MALFUNCTION OR

BREAKDOWN, groundingprovidesa path of least

resistanceforelectriccurrentand reduces the riskof

shock.Thistoolis equipped withan electriccordthat

hasan equipmentgroundingconductorand grounding

plug.The plugMUST be pluggedintoa matching

receptacle that isproperlyinstalledand grounded in

accordancewithALL localcodesand ordinances.

DO NOT MODIFY THE PLUG PROVIDED. If it willnotfit

the receptacle,have the properreceptacleinstalledbya

qualifiedelectdcian.

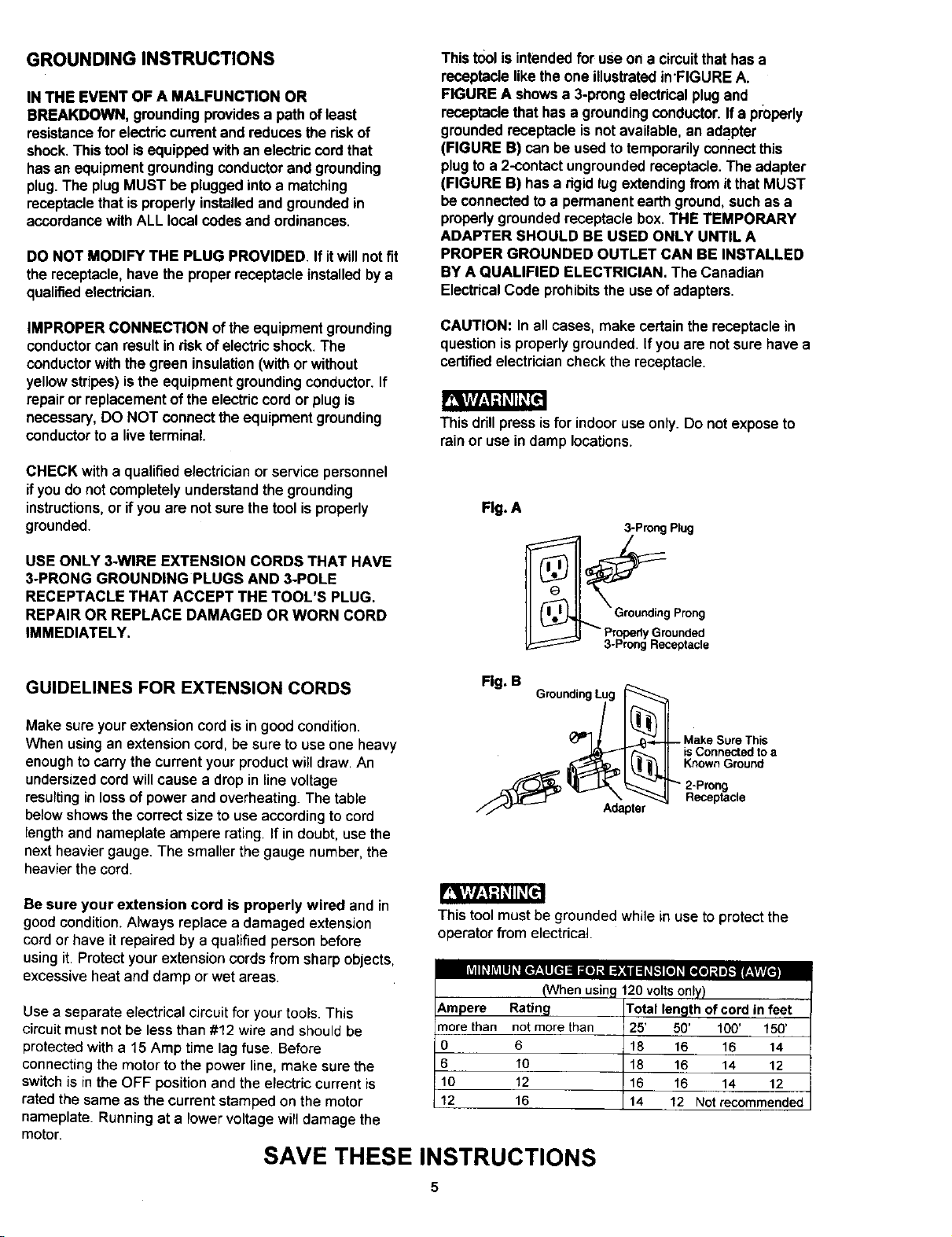

Thistoolis intendedfor use on a circuitthathas a

receptaclelike theone illustratedin'FIGURE A.

FIGURE A shows a 3-prongelectricalplug and

receptaclethathas a groundingconductor.If a pmparly

groundedreceptacle isnotavailable, an adaPter

(FIGURE B) can be usedto temporarilyconnectthis

plugto a 2-contact ungroundedreceptacle.The adapter

(FIGURE B) hasa rigid lug extendingfrom it that MUST

be connectedtoa permanent earth ground,such as a

properlygrounded receptacle box. THE TEMPORARY

ADAPTER SHOULD BE USED ONLY UNTIL A

PROPER GROUNDED OUTLET CAN BE INSTALLED

BY A QUALIFIED ELECTRICIAN. The Canadian

ElectricalCode prohibitsthe use of adapters.

IMPROPER CONNECTION of the equipmentgrounding

conductorcan result inrisk ofelectricshock.The

conductorwiththe green insulation(withor without

yellowstripes)is the equipment groundingconductor.If

repair or replacementofthe electriccord or plug is

necessary,DO NOT connectthe equipmentgrounding

conductorto a liveterminal.

CHECK with a qualified electrician orservice personnel

ifyou do notcompletelyunderstandthe grounding

instructions,orifyou are notsure the toolisproperly

grounded.

USE ONLY 3-WIRE EXTENSION CORDS THAT HAVE

3oPRONG GROUNDING PLUGS AND 3-POLE

RECEPTACLE THAT ACCEPT THE TOOL'S PLUG.

REPAIR OR REPLACE DAMAGED OR WORN CORD

IMMEDIATELY.

GUIDELINES FOR EXTENSION CORDS

Make sure yourextension cord is ingood condition.

When usingan extensioncord, be sureto use one heavy

enoughto carrythe currentyour productwilldraw. An

undersizedcordwill cause a dropin line voltage

resultingin lossof power and overheating.The table

belowshowsthecorrectsize to use accordingto cord

length and nameplate ampere rating. Ifin doubt, usethe

nextheaviergauge. The smallerthe gauge number,the

heavierthecord.

CAUTION: In all cases, make certain the receptaclein

questionis properlygrounded. If you are notsure have a

certifiedelectriciancheck the receptacle.

This drill press is for indoor use only. Do not expose to

rain or use in damp locations.

Flg. A

3-Prong Plug

_" p.rGprroP_o°nl_;_o_nrin;e

Fig. B

GroundingLug

is Connected to a

Known Ground

Adapter

Be sure your extension cord is properly wired and in

goodcondition.Always replace a damaged extension

cordor have itrepaired by a qualifiedperson before

usingit. Protectyourextensioncordsfrom sharpobjects,

excessiveheatand damp orwet areas

Use a separate electrical circuit for your tools. This

circuit must not be less than #12 wire and should be

protected with a 15 Amp time lag fuse. Before

connecting the motor to the power line, make sure the

switch is in the OFF position and the electric current is

rated the same as the current stamped on the motor

nameplate. Running at a lower voltage will damage the

motor.

SAVE THESE INSTRUCTIONS

This tool must be grounded while in useto protect the

operator from electrical.

rdI_ hV_lll_[e_-*ll[el naal] :s :1,:(ii :1_K'I[el _ [l(e] _|i},.llr:t tjLt/t.

(When usinc

6,mpere Rating

more than notmore than

0 6

6 10

10 12

12 16

120 volts only)

Total length of cord in feet

25' 50' 100' 150'

18 16 16 14

18 16 14 12

16 16 14 12

14 12 Not recommended

Page 6

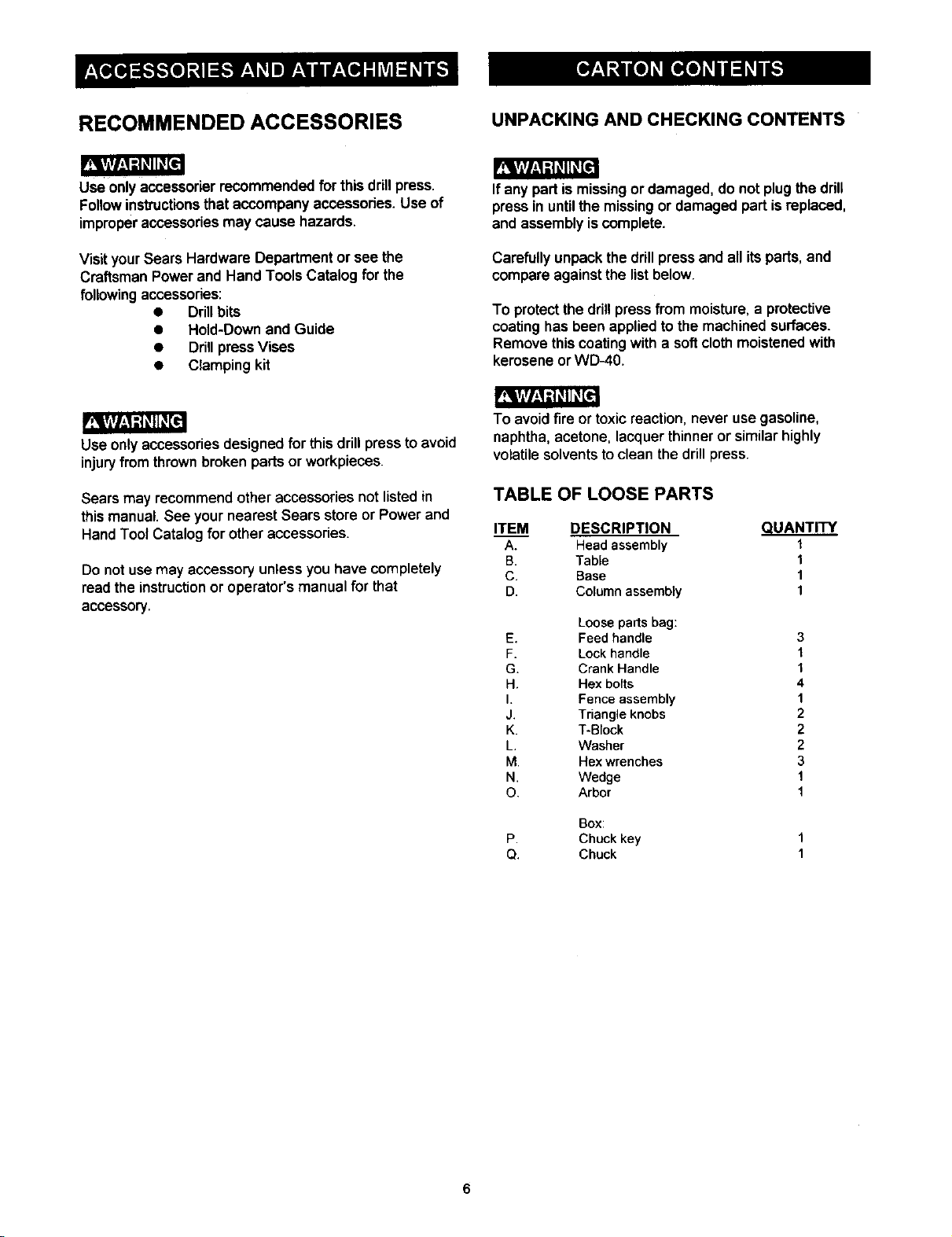

RECOMMENDED ACCESSORIES UNPACKING AND CHECKING CONTENTS

r_r/_J=-KqKE=]

Use onlyaccessorierrecommended for this drillpress.

Followinstructionsthat accompany accessories.Use of

improperaccessoriesmay cause hazards.

Ifany part is missingor damaged, do not plugthe drill

pressin untilthe missingordamaged partis replaced,

and assemblyis complete.

Visityour Sears Hardware Department or see the

CraftsmanPower and Hand Tools Catalog for the

following accessories:

• Drill bits

• Hold-Down and Guide

• DrillpressVises

• Clamping kit

Use only accessoriesdesigned for this drill pressto avoid

injuryfrom thrownbrokenparts or workpieces.

Sears may recommend otheraccessoriesnot listed in

this manual. See your nearest Sears store or Power and

Hand Tool Catalog for other accessories.

Do not use may accessoryunless you have completely

readthe instruction oroperator'smanual for that

accessory.

Carefullyunpackthe drill pressand all its parts, and

compare againstthe list below.

To protectthe drillpress from moisture,a protective

coatinghas been applied to the machinedsurfaces.

Remove thiscoating with a softclothmoistenedwith

keroseneor WD-40.

.r_rArl,_1d_11_[e

To avoidfire or toxic reaction, neveruse gasoline,

naphtha,acetone, lacquerthinneror similarhighly

volatilesolventstoclean the drillpress.

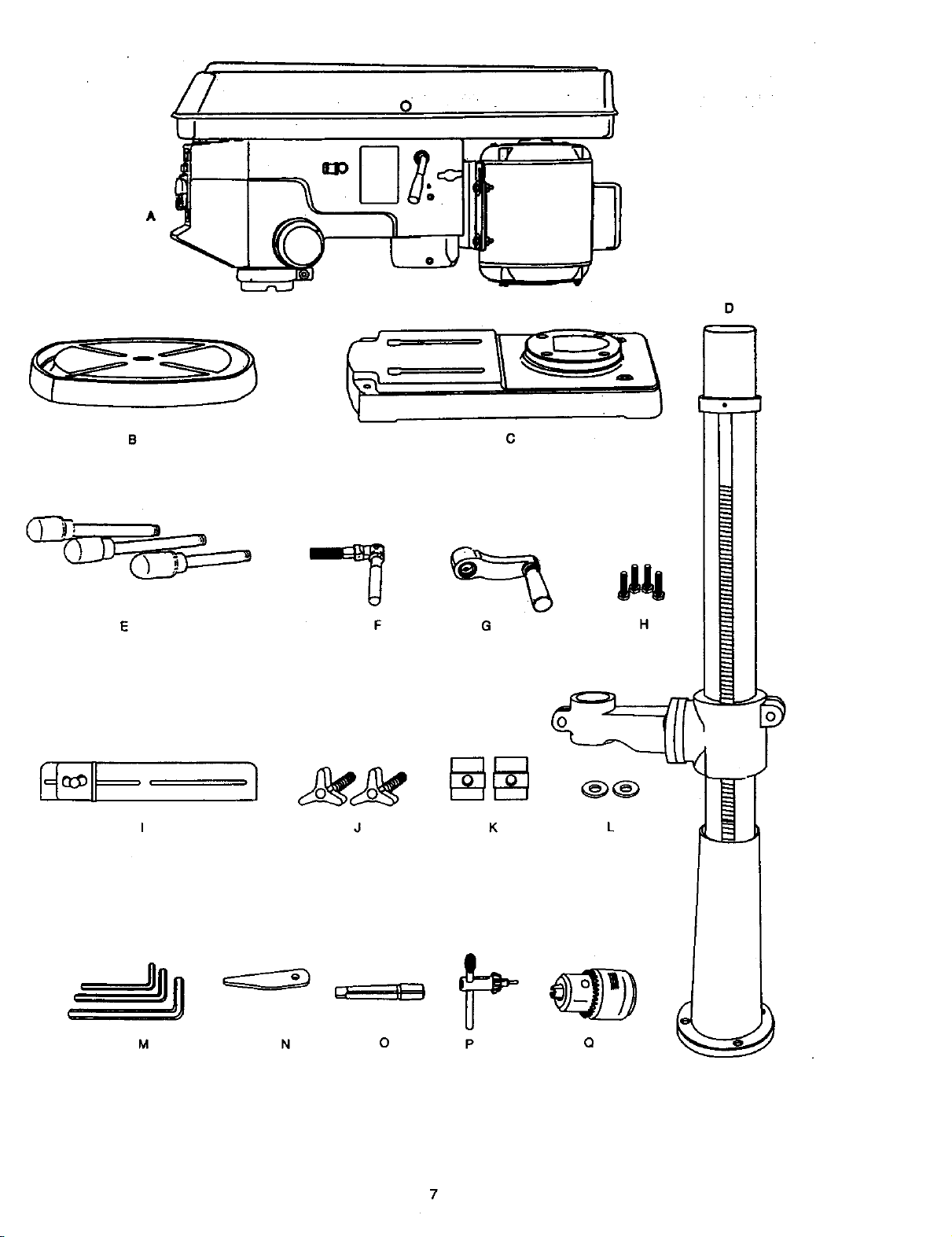

TABLE OF LOOSE PARTS

ITEM DESCRIPTION QUANTITY

A. Head assembly t

B. Table 1

C. Base 1

D. Column assembly 1

E. Feed handle

Loose partsbag:

F. Lock handle

G. Crank Handle

H. Hex botts

I. Fence assembly

J. Triangle knobs

K. T-Block

L, Washer

M. Hex wrenches

N. Wedge

O. Arbor

3

1

1

4

1

2

2

2

3

1

1

Boxz

P. Chuckkey

Q. Chuck

Page 7

8

I

0

7

Page 8

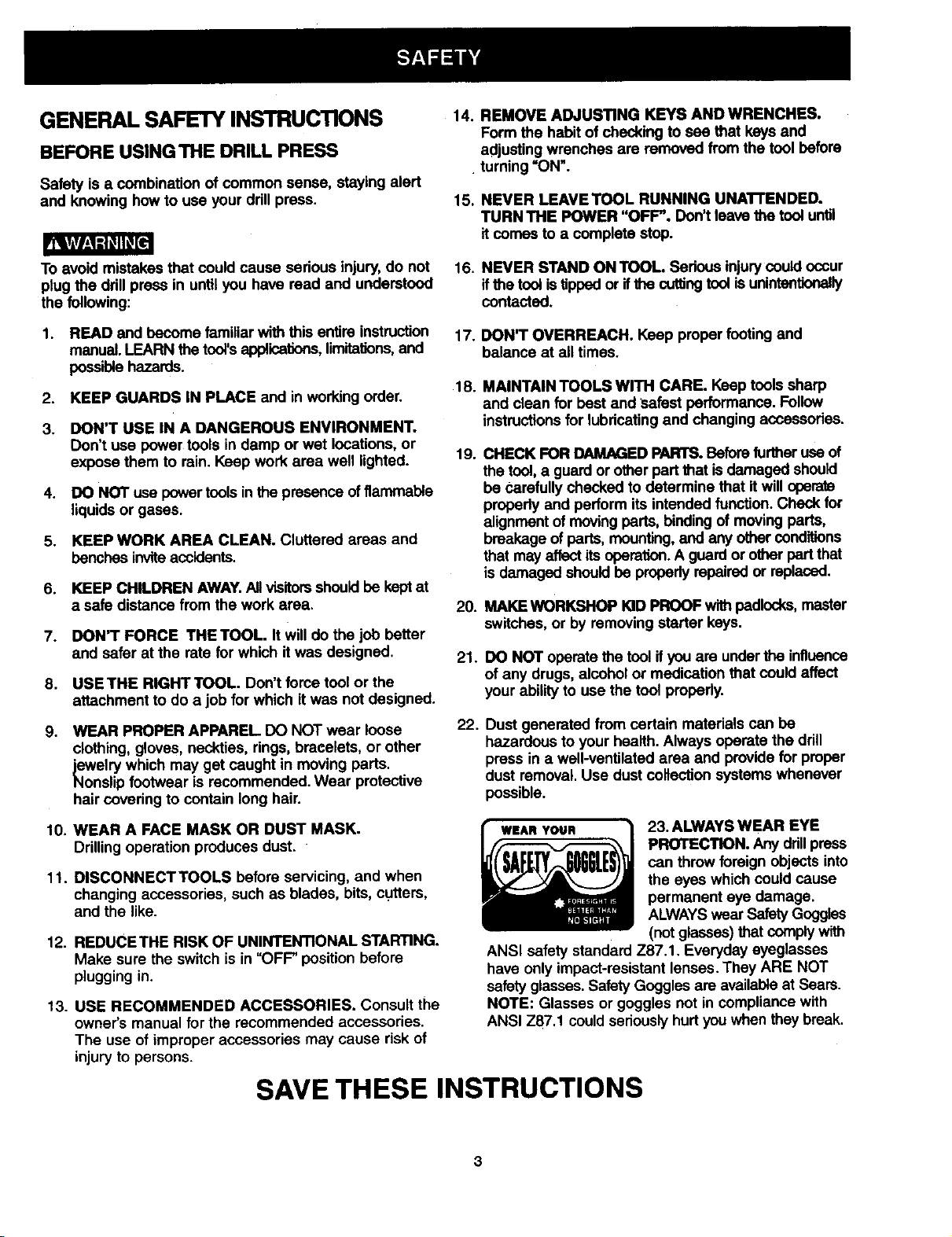

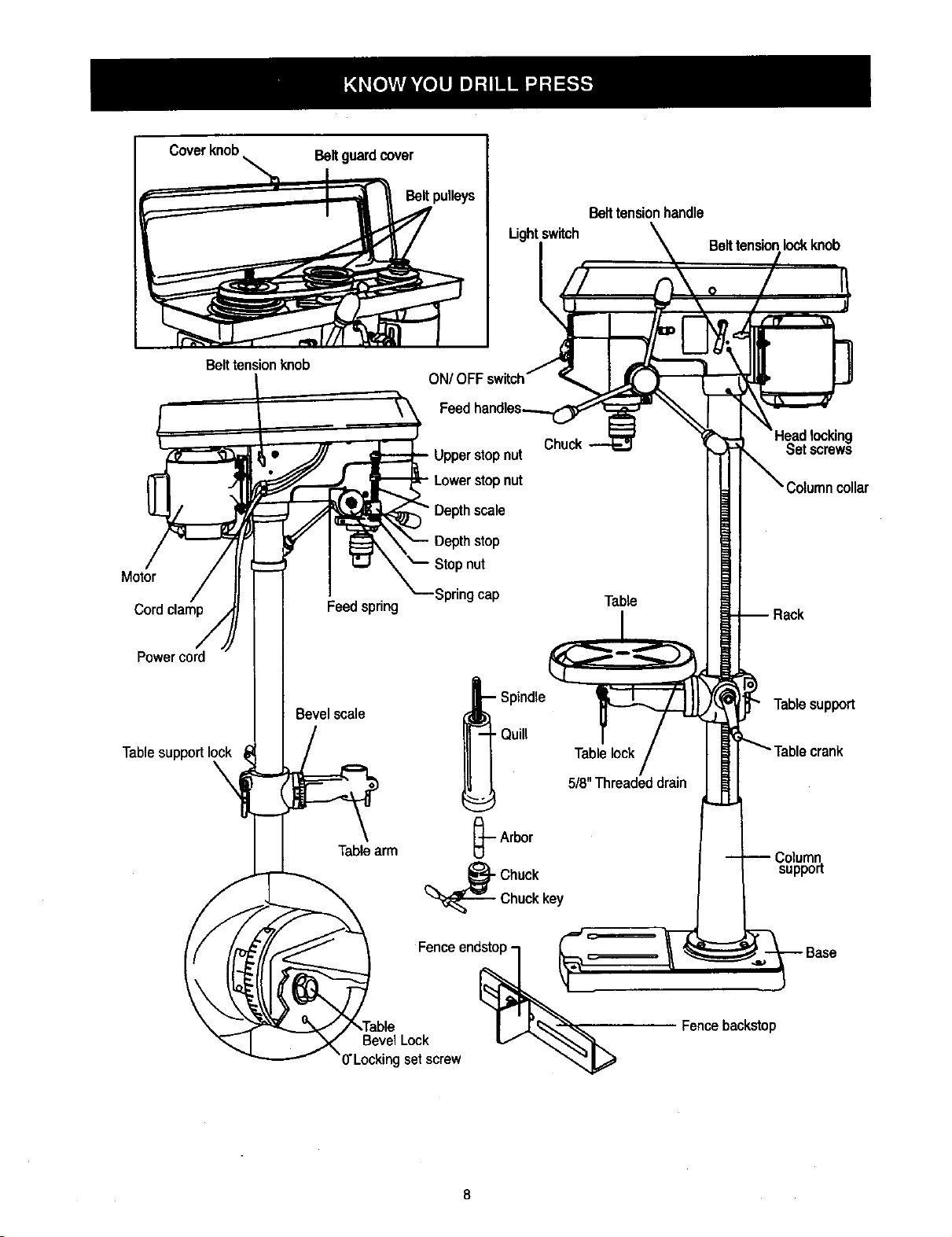

Coverknob

Belttensionknob

\

Beltguardcover

Beltpulleys

Lightswitch

Belttensionhandle

Belttensionlock knob

Motor

Cordclamp

Power cord

Table support I(

Feedspring

Bevelscale

Tablearm

• Upperstopnut

- Lowerstopnut

Depthscale

Depthstop

Stopnut

Springcap

-- Spindle

• Quill

-.-Arbor

(_Chuck

Chuckkey

Set screws

Table

Tablesupport

Tablelock

5/8"Threadeddrain

Column

support

Fenceend_\

BevelLock V _"_,,_

)'Locking setscrew

Fencebackstop

Page 9

BASE - Supportsdrill press. For additionalstability,

holesare providedin base to boltdrillpressto floor.

(See "Specific Safety Instruction for DrillPresses.")

DRILLING SPEED - Changed by placingthe belt in any

of the steps (grooves) inthe pulleys.See the Spindle

Speed Chart insidebeltguard.

BACKUP MATERIAL - Apiece ofscrapwood placed

betweenthe workpieceand table. The backup beard

preventswood in the workpiecefrom splintedngwhen

the drillpassesthroughthe backsideof the workpiece.It

alsoprevents drillingintothe table top.

BELT GUARD ASSEMBLY - Covers the pulleysand

beltduringoperationof the drillpress.

BELT TENSION - Referto the "Assembly" Section,

"InstallingandTensioning Belt.".

BELT TENSION HANDLE - Turn the handle clockwise

toapply tensionto belt, turnthe handle counterclockwise

to release belttension.

BELT TENSION LOCK KNOBS - Tighteningthe knobs

locksthe motor bracket supportand the belttension

handle,maintainingcorrect beltdistance and tension.

BEVEL SCALE - Shows degree of table tilt for bevel

operaions. The scale ismounted on the side of the arm.

CHUCK - Holdsdrill bit or other recommended

accessoryto performdesired operations.

CHUCK KEY - A self-ejectingchuckkey whichwill pop

outof the chuckwhen you let go of it.This actionis

designedto help preventthrowingof the chuck keyfrom

thechuckwhen the peer isturned ON. Do not use any

otherkey as a substitute; ordera newone if hamaged or

lost.

COLUMN - Connects the head, table, and base on a

one piecetube for easy alignment and movement.

COLUMN COLLAR - Holds the rack to the column.

Rack remains movablein the collarto permit table

support movements.

COLUMN SUPPORT - Supports the column, guides the

rack and providesmountingholesfor columnto base.

DEPTH SCALE STOP NUTS - Lock the spindle to the

selected depth.

DEPTH SCALE - Indicates depth of hole being drilled.

DRILL BIT - The cutting tool used in the drill press to

make holes in a workpiece.

DRILL ON/OFF SWITCH - Has lockingfeature. This

feature is intended to help preventunauthorizedand

possible hazardous use by children and others. Insert

the key into the switch to turn the drill press on.

FEED HANDLE - Moves the chuckup or down.IF

necessary, one ortwo ofthe handles may be removed

whenevertheworkpiece isof suchunusualshape thatit

interfereswith the handles.

FENCE - Attaches to the table to alignthe workpieceor

for fast repetitivedrilling.Removable. Removefence

when itinterfereswith otherdrillpress accessories.

HEAD LOCKS - Locks the head tothe column.

ALWAYS lockthe head in placewhile operatingthedrill

press.

RACK - Combines withgear mechanism to provide

easy elevationofthe table by thehandoperated table

crank.

REVOLUTION PER MINUTE (R.P.M.)- The numberof

turns completedbya spinningobjectin one minute.

SPINDLE SPEED - The RPM. of the spindle.

SPRING CAP - Adjusts quill spring tension.

TABLE SUPPORTS LOCK - Tighteninglocksthe table

supportto column. Always have it lockedin placewhile

operatingthe dirll press.

TABLE - Provides a working surface to supportthe

workpiece.

TABLE ARM - Extends beyond the tablesupportfor

mounting and aligning the table.

TABEL BEVEL LOCK - Locks the table in any position

from 0° - 45°

TABLE CRANK - Elevates and lowers the table. Turn

clockwise to elevate the table. Support lock must be

released before operating the crank.

TABLE LOCK - Locksthe table after it is rotated to

variouspositions.

TABLE SUPPORT - Rides on the column to supportthe

table arm and table.

THREADED DRAIN (518")- Attach a 5/8" (pipe

threaded) metal pipe to the threaded opening for

drainingexcees oil into container.For a non-draining

surfaceattach a threaded metal plug.Pipe and plugnot .

included.

WORKPIECE - Material being drilled.

Page 10

ASSEMBLY INSTRUCTIONS

Foryourownsafety, neverconnectplugto power

sourceoutletuntilall assemblyand adjustmentsteps

arecompleted, andyou have readand understood

the safetyandoperatinginstructions.

TOOLS NEEDED

8"S 10"AdJustab__

Rg. B

_ w_encb

Comb_e_m_tre

III t lilt IIIt_

Frw_ing

The DdlTPressis very heavy and MUST be liftedwiththe

helpof 2 PEOPLE OR MORE, to safetyassembly it.

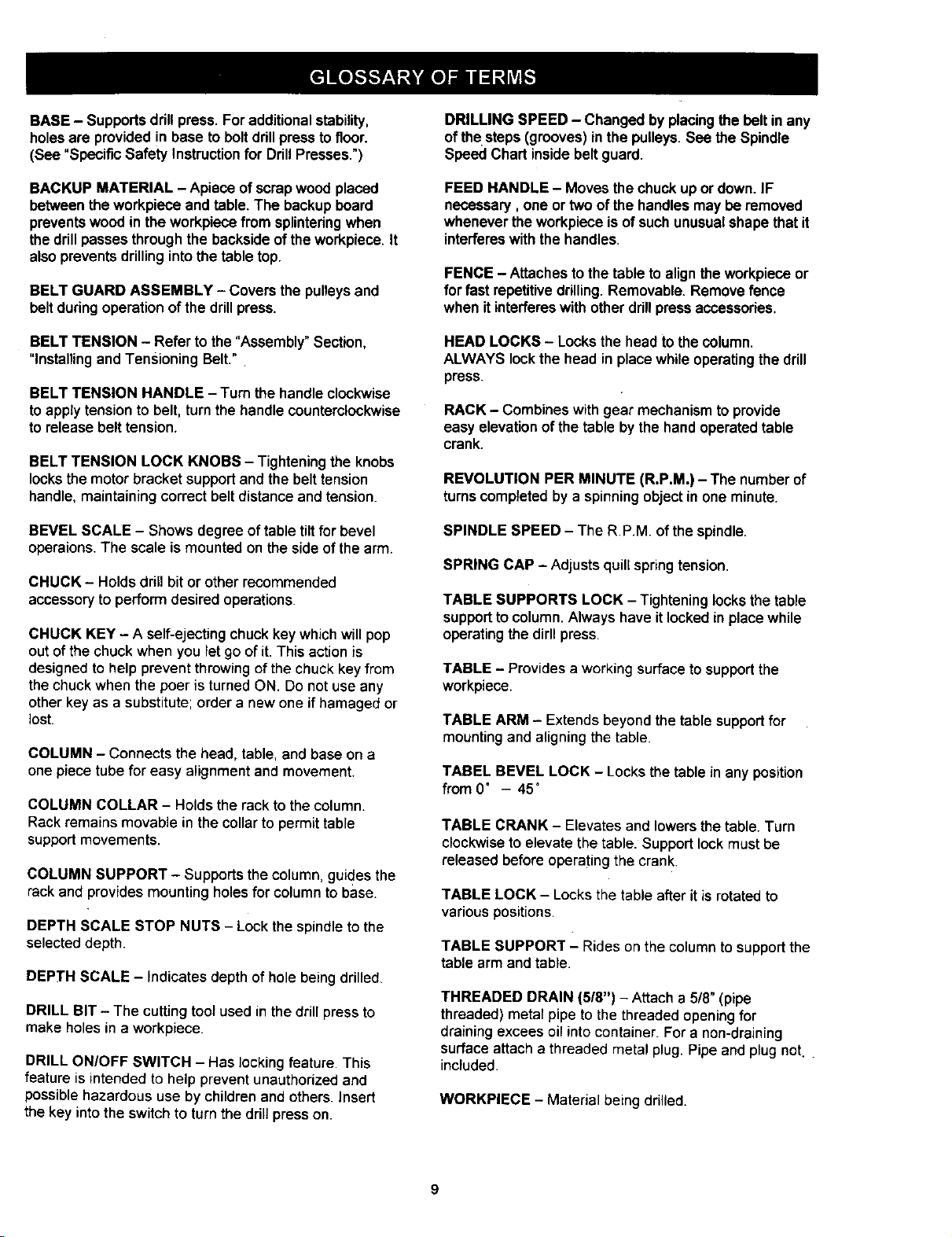

COLUMN SUPPORT TO BASE (FIG. A)

1. Position the base (1) on the floor.

2. Place the column (2) on the base, aligning the

holes in the column support with the holes in the

base.

3. Locate the four long hex bolts (3) from the loose

parts bag.

4. Place a bolt in each hole through the column

support and the base. Tighten with an adjustable

wrench.

i

INSTALLING THE TABLE (FIG. B and C)

1. Locate the table crank (1) and support lock (2) from

the loose parts bag.

2. Insert the support lock handle into the hole (3) at

the rear of the table support assembly. Tighten by

hand.

3. InstaJIthe table crank handle (3) onto the small

shaft (4), aligning the set screw (5) with the flat

surface of the shaft (4), aligning the set screw (5)

with the fiat surface of the shaft. Tighten the set

screw with a hex wrench.

4. (FIG. C) Loosen the support lock (2). Raise the

table arm assembly by turning the crank handle (1)

clockwise. Tighten the support lock.

5. Place the table (6) in the table arm assembly.

Tighten the table lock handle (7).

Rg. C

INSTALLING EXTENSION WING

1. Place the handle (OWVG) onto the upper tube

(OWVH).

2. Place theflat washers (OT6T) onto the hex head

bolts (OJUB). Insert the bolt (OJUB) into the upper

tube (OWVH), and tighten.

3. Insert the hes head bolts (OJUB) onto the upper

tube (OJUB) and tighten.

4. Place the upper tube assembly under the table.

5. Place the set plate (OWVJ) onto the clamp bolt

(OWVK). Insert the set plate assembly into the

table and tighten.

NOTE: If length adjustment is necessary, loosen

the clamp bolt (OWVK) to the desired length and

tighten the clamp bolt.

OWVE

10

Page 11

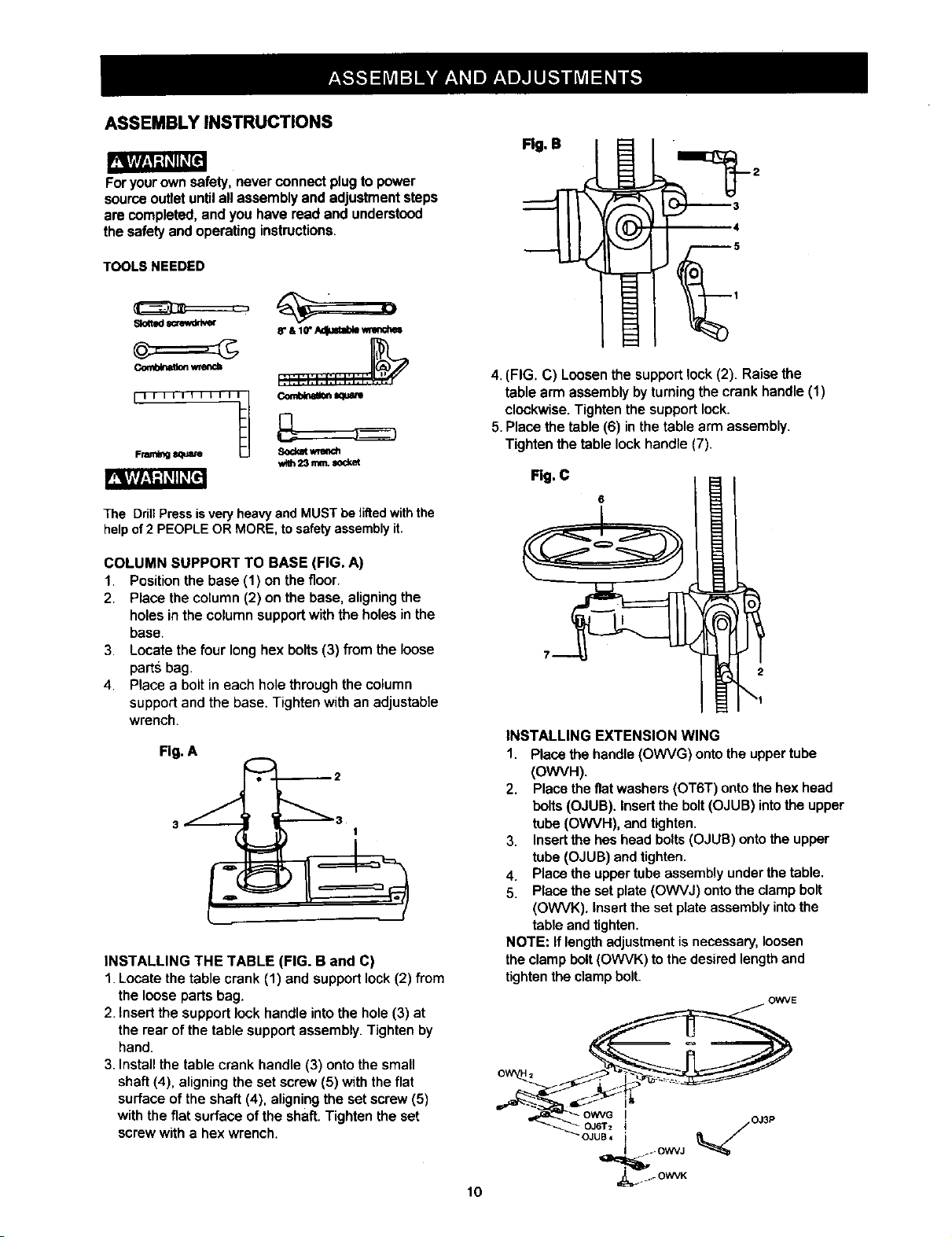

INSTALLING THE HF.AD (FIG. D)

mvl/_d_ql K_

The DrillPress h_d Is very heavy and MUST be lifted

with the help of 2 PEOPLE OR MORE,to safely

assemble the Drill Press head on the column.

1. Carefully lift the head (1) above the column (2) and

slide it ontothe column.Make sure the headslldea

down over the column as far as poealble.Algn the

head with the base.

2. Using the hexwrench, tighten the two head lock eat

screws (3) on the right side of the head.

Fig. D

"ry

J

_3

FENCE ASSEMBLY (FIG. F)

This drill press has a channeled table top.

1. Determine the desired location for the fence (1).Sllde

theT-blocks (2) Into the appropriate channels as

shown

2. Align the mounting holes ofthe fence over theT-block's

threaded hloes.

3. Place a washer (3) on the threaded end of the knob (4).

Insert the knob through the mounting hole of the fence

into the T-block,and Ugbetan.

4. Repeatfor the other knob andT-block.

Fig. F

INSTALLING FEES HANDLES(FIG. E)

1. Locate three feed handles in the loose parts bag.

2, Screw the feed handles (1) into the threaded holes (2)

in the hub (3), Tighten

11

Page 12

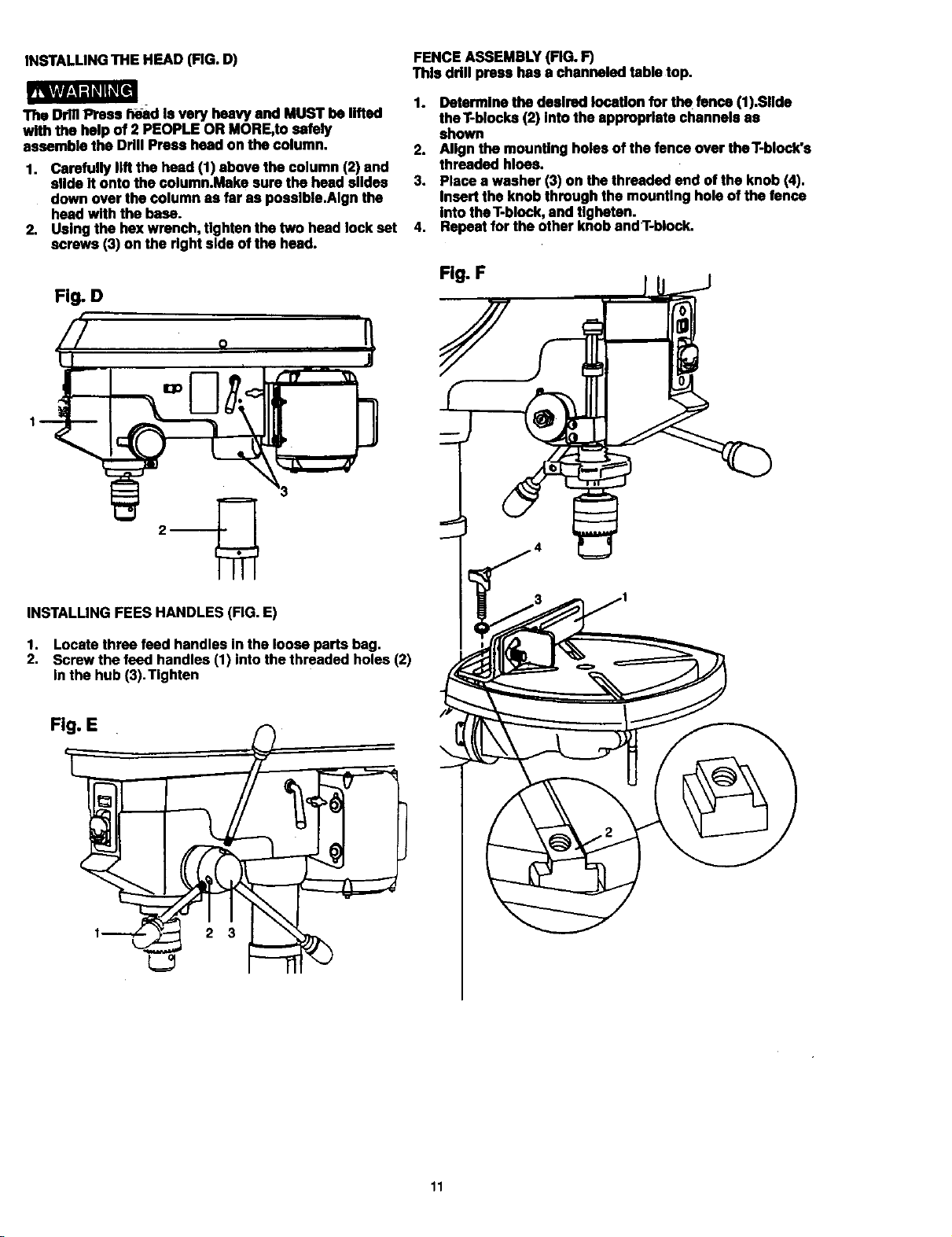

INSTALUNG THE CHUCK (FIG. G, H, and I

1. Clean out the tapered hole In the chuck(1) wltha

CkHlndoth.

2. Clean taperedsurfacasonthe arbor(2) and spindle(3).

CAUTION: Make sure there am no foreignparticles

stk:kingto the surfaces.The slightestpiece of dirt on

any of these surfaceswill prevent the chuck from

seating properly.This willcause the ddll chuck and

bit to wobble. If tapered hole is extremely dirty, use a

cleaning solvent.

Fig. G

7. Using a robber mallet, plastic-tippedhammer, or a

mOCKOTwood and a hammer, firmlytap the chuck

upward into posi_n on the spindle shaft.

Fig. I

3. 4(FIG. H) Push the chuck(1) ontothe spindle

arbor (2). Tap gently to ensure seat.

4. 5Lower the spindle byturning the feed handles (8)

countemlockwise, untilthe slot (4) appears on the

quill (5).

5. Push the chuck and spindlearborup into the spindle,

making sure the tang (6) (uppernarrow end of the

spindle arbor shank) is engaged and lockedin the

inner slot (7) of the spindle.This can be seen

throughthe outer slot (4) of the quillby rotatingthe

chuck and arbor untilthe two slotsare aligned.

6. Open the jaws of the chuck (1) by rotating the chuck

sleeve clockwise.To prevent damage, make sure the

jaws are completely receded intothe chuck.

Fig. H 4 _. "----,_ I

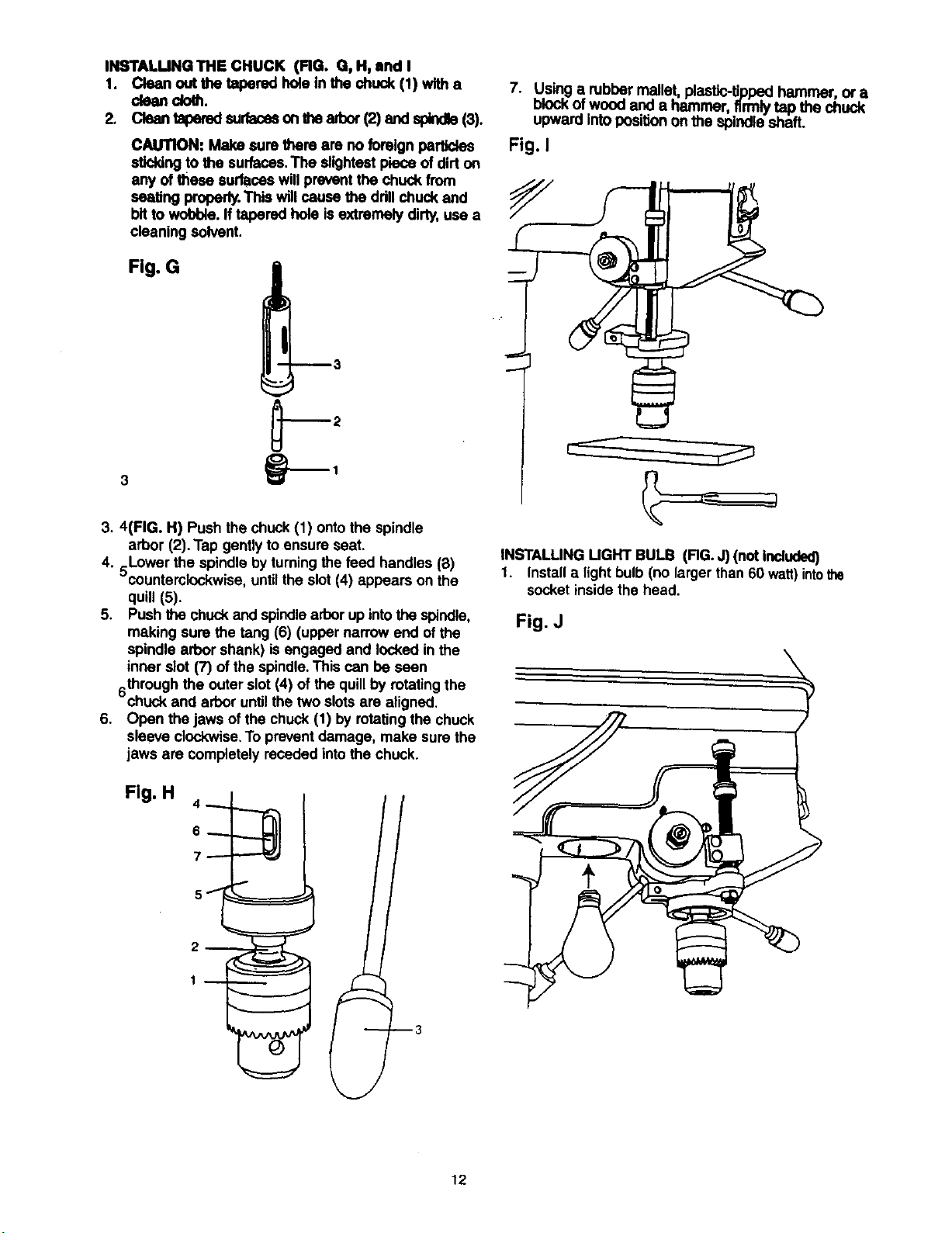

INSTALLING UGHT BULB (RG. J) (not Included)

1. Installa light bulb(no larger than 60 watt)intothe

socket inside the head.

Fig. J

12

Page 13

DRILL PRESS ADJUSTMENTS

CAUTION: All the adjustments for the opera,on of the

ddl press have been completed at the lectory.Due to

normalwear and use, some occasionalmadjustmente

may be necessary.

!_W_,I -'l_l_[el

Fig. L

Topreventpersonalinjury,a dysciscor. thepaugfnxn

the powersourcewhen ma;dnganyadjustments

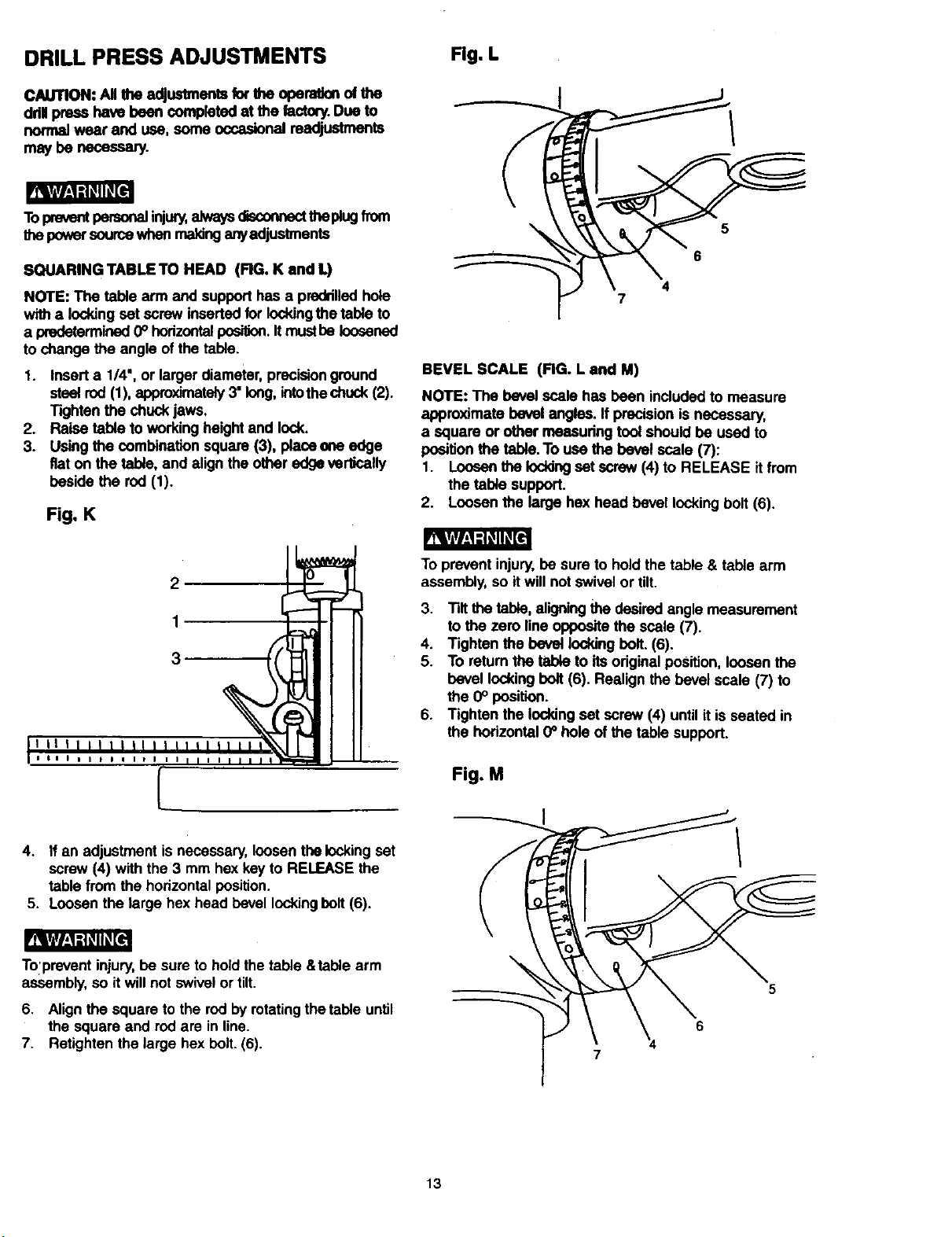

SQUARING TABLE TO HEAD (RG. K and L)

NOTE: The table arm and supporthas a preddlledhole

witha lockingset screw insertedfor lockingthe table to

a predetermined0° horizontal_. Itmust be loosened

to change the angle of the table.

1. Insert a 1/4",or larger diameter,precisionground

stsetrod (1), approximately3"long,intothechuck(2).

Tighten the chuckjaws.

2. Raise table to workingheightand lock.

3. Usingthe combinationsquare (3), placeena edge

fiat on the tebie, and alignthe other edge verlfoally

beside the rod (1).

Fig. K

2

1

3

I I I I I I I I I I I I

[

5

6

4

7

BEVEL SCALE (FIG. L and M)

NOTE: The bevelscale has been included to measure

approximate bevel angles. If precision is necessary,

a square or othermeasuring toolshould he used to

positionthe table.To use the bevel scale (7):

1. Loosenthe Ioddngset screw (4) to RELEASE it from

the table support.

2. Loosen the large hex head bevel locking bolt (6).

To prevent injury,be sure to holdthe table & table arm

assembly,so it willnot swivel or tilt.

3. Tilt the table,aligningthe desired angle measurement

to the zero line oppositethe scale (7).

4. Tighten the bevel lockingbolt. (6).

5. To returnthe table to itsoriginalposition, loosen the

bevel lockingbolt (6). Realign the bevel scale (7) to

the 0° position.

6. Tighten the lockingset screw(4) untilit is seated in

the horizontal 0_hole of the table support.

Fig. M

4. If an adjustment is necessary, loosen the lockingset

screw (4) with the 3 mmhex key to RELEASE the

table from the horizontal position.

5. Loosenthe large hex head bevellockingbolt(6).

Tolprevent injury,be sure to hold the table &table arm

assembly,so it willnot swivelor tilt.

6. Align the square to the red byrotating the table until

the square and rodare in line.

7. Retighten the large bex belt. (6).

5

6

7

13

Page 14

_[wr_,1=t_'llKl[e_

To prevent personal injury,always disconnect plug

from the power sourcewhen making any adjustment.

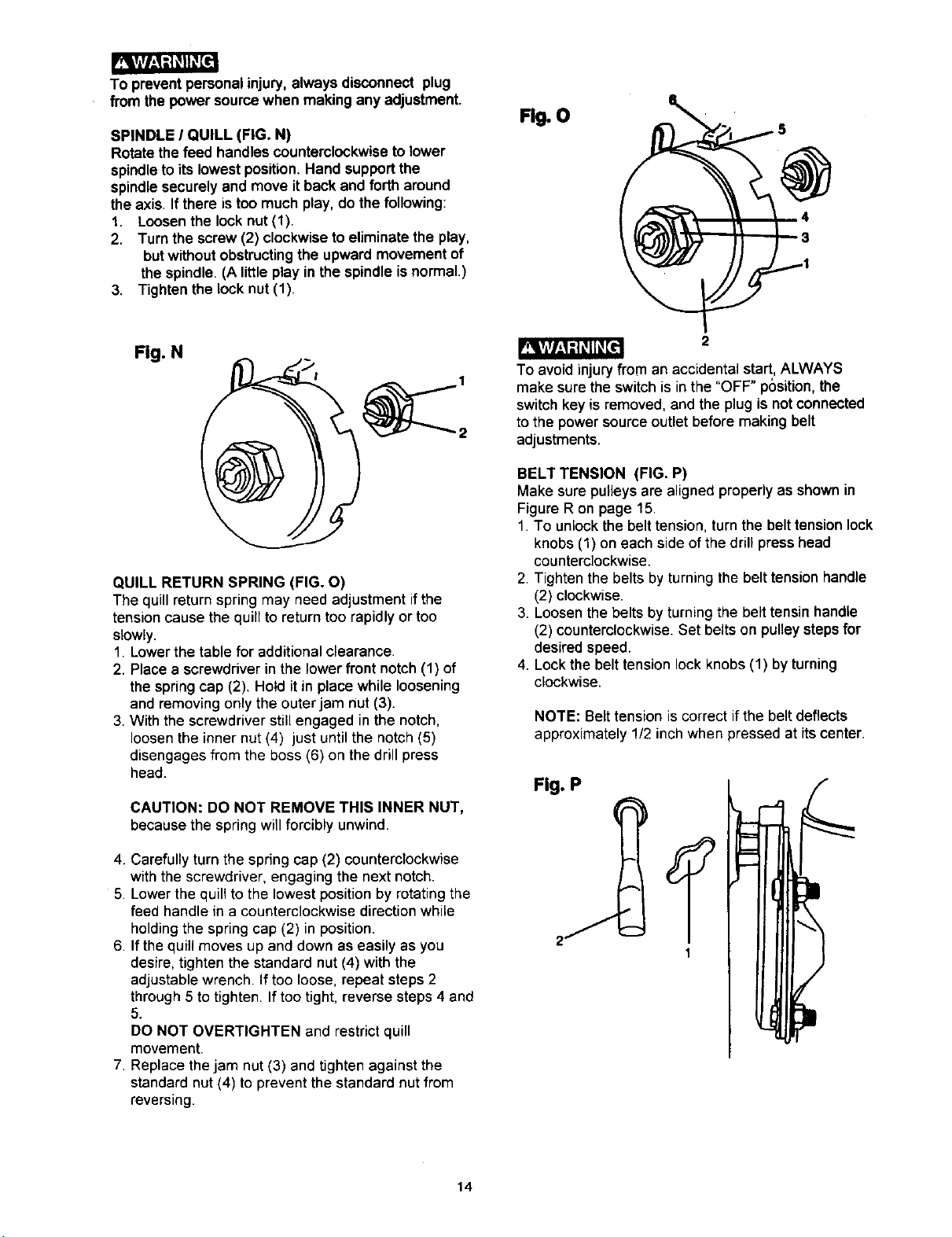

SPINDLE I QUILL (FIG. N)

Rotate the feed handles counterclockwiseto lower

spindleto its lowestposition.Hand supportthe

spindlesecurely and move itback and forth around

the axis. If there is too much play,do the following:

1. Loosenthe lock nut(1).

2. Turn the screw (2) clockwiseto eliminate the play,

butwithoutobstructingthe upward movement of

the spindle. (A little play in the spindleis normal.)

3. Tighten the lock nut(1).

Fig. O

Fig. N

QUILL RETURN SPRING (FIG. O)

The quillreturnspring may need adjustment ifthe

tensioncause the quillto returntoo rapidly ortoo

slowly.

1. Lowerthe table for additionalclearance.

2. Place a screwdriver in the lower front notch(1) of

the springcap (2). Hold it in place while loosening

and removingonly the outerjam nut(3).

3. With the screwdriverstillengaged inthe notch,

loosenthe inner nut(4) just untilthe notch(5)

disengagesfrom the boss (6) on thedrill press

head.

CAUTION: DO NOT REMOVE THIS INNER NUT,

because the springwill forcibly unwind.

2

To avoid injury from an accidental start, ALWAYS

make surethe switch is in the "OFF" position, the

switch key is removed, and the plug is not connected

to the power source outlet before making belt

adjustments.

BELT TENSION (FIG. P)

Make sure pulleysare alignedproperly as shown in

FigureR on page 15.

1. To unlockthe belt tension,turnthe belt tensionlock

knobs (1) oneach side of the drill presshead

counterclockwise.

2. Tighten the belts by turningthe belt tension handle

(2) clockwise.

3. Loosenthe beltsby turning the belt tensinhandle

(2) counterclockwise.Set belts on pulleystepsfor

desired speed.

4. Lockthe belt tensionlockknobs (1) byturning

clockwise.

NOTE: Belt tension is correct ifthe belt deflects

approximately 1/2 inch when pressed at itscenter.

Fig. P

4. Carefully turn the spring cap (2) counterclockwise

with the screwdriver, engaging the next notch.

5. Lower the quill to the lowest position by rotating the

feed handle in a counterclockwise direction while

holding the spring cap (2) in position.

6. If the quill moves up and down as easily as you

desire, tighten the standard nut (4) with the

adjustable wrench. If too loose, repeat steps 2

through 5 to tighten. If too tight, reverse steps 4 and

5.

DO NOT OVERTIGHTEN and restrict quill

movement.

7. Replace the jam nut (3) and tighten against the

standard nut (4) to prevent the standard nut from

reversing.

14

Page 15

_vlvh_=1_[I

To avoid injury from an accidental start, ALWAYS

make sure the switch is in the "OFF" position, the

switch key is removed, and the plug is not connected

to the power source outlet before making belt

adjustments.

ALIGNING THE BELT PULLEYS (FIG. N)

Open the head cover of the Drill Press. Check

alignment of the pulleys with a straight edge (5) such

as a framimg square, a level, or a piece of a wood.

Lay the straight edge across the top of the pulleys. If

all three pulleys are NOT aligned:

1. Release belt pressure by loosening the belt tension

lock knobs (4) on either side of the head, unlocking

the belt tension handle (1).

2. Loosen the motor mount nuts (2). Lift or lower the

motor (3) until the pulleys are in line.

3. Tighten the motor mount nuts (2) using an

adjustable wrench.

NOTE: To avoid rattles or other noise, the motor

housing should not touch the lower belt guard

housing.

BASIC DRILL PRESS OPEATIONS

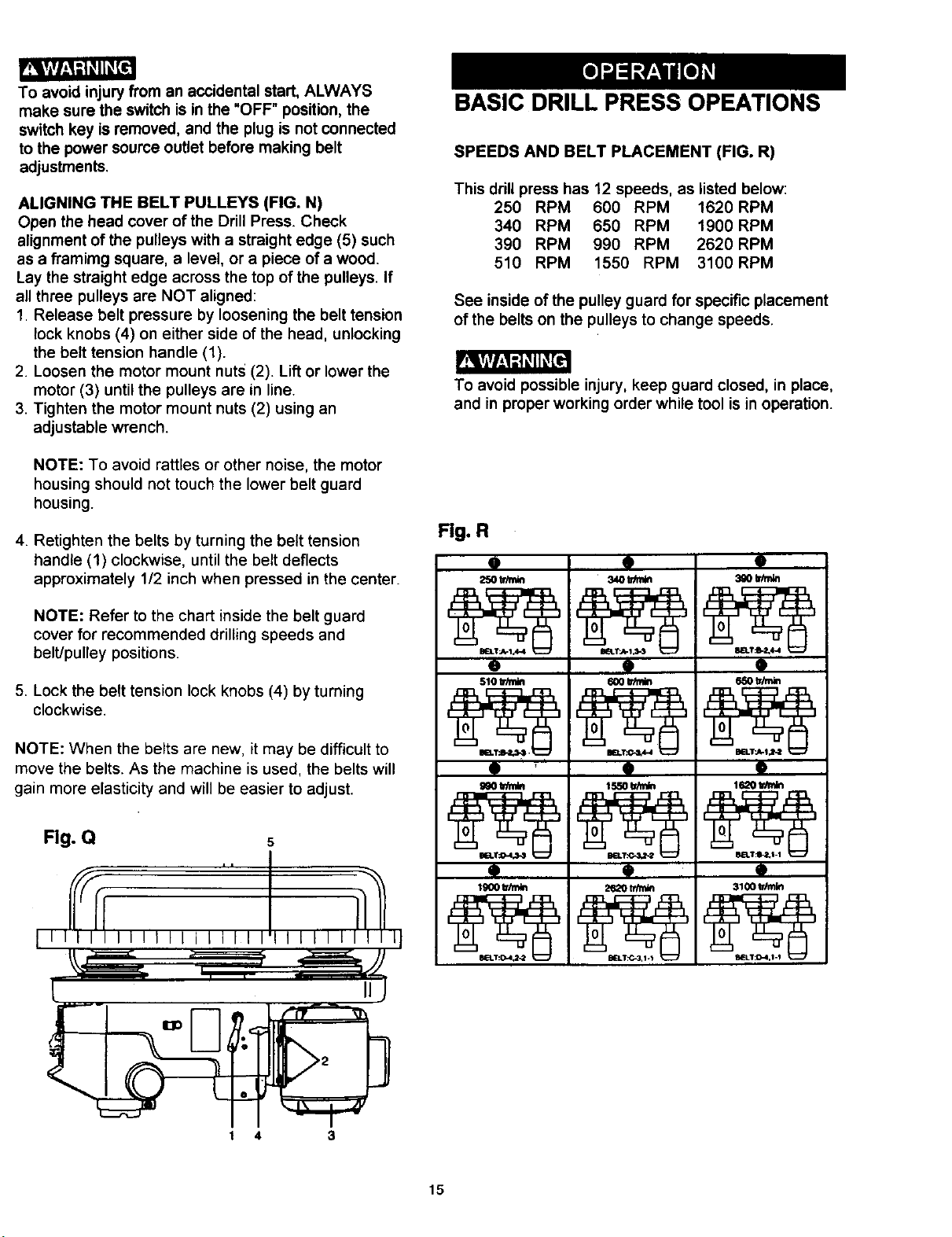

SPEEDS AND BELT PLACEMENT (FIG. R)

This drill press has 12 speeds, as listed below:

250 RPM 600 RPM 1620RPM

340 RPM 650 RPM 1900RPM

390 RPM 990 RPM 2620 RPM

510 RPM 1550 RPM 3100RPM

See inside of the pulley guard for specific placement

of the belts on the pulleys to change speeds.

To avoid possible injury, keep guard closed, in place,

and in proper working order while tool is in operation.

4. Retighten the belts by turning the belt tension

handle (1) clockwise, until the belt deflects

approximately 1/2 inch when pressed in the center.

NOTE: Refer to the chart inside the belt guard

cover for recommended drilling speeds and

belt/pulley positions.

5. Lock the belt tension lock knobs (4) by turning

clockwise.

NOTE: When the belts are new, it may be difficult to

move the belts. As the machine is used, the belts will

gain more elasticity and will be easier to adjust.

Fig. Q

Fig. R

9

250 trim_

o

510 tdmin

9

9

9

i

9

9

9

Q

9

9

3100 tr_lin

1 4 3

15

Page 16

ON I OFF SWITCH PANEL (FIG. S)

The "ON I OFF" switchhas a removable, yellow

plastickey. With the key removed from the switch,

unauthorizedand hazardous use bychildrenand

otheris minimized.

1. To turnthe drillpress "ON', insert key (1) intothe

slotof the switch(2), aqd move the switchupward

to the "ON" position

2. To turn the drillpress"OFF', move the switch

downward.

3. To lockthe switchinthe =OFF"position, graspthe

end,or yellowpart,of the switchtoggle, and pullit

out.

4. Withthe switchkey removed, the switchwill not

operate.

5. If theswitchkey is removedwhilethe drillpress is

running,itcan be turned "OFF"butcannot be

restartedwithoutinsertingthe switchkey.

6. To turnthe worklight"ON", pressthe rocker switch

(3).

7. Never leavethe drillpressunattended. Turn the

lightswitchand power switch"OFF" and waituntilit

comesto a completestop.

f

Rg. S

m

_3

--2

BI

ALWAYS lock theswitch"OFF" whenthe drill press is

not in use. Remove the key and keep it in a safe place.

In the event of a power failure, blown fuse, or tripped

circuit breaker, turn the switch "OFF" and remove the

key, preventing an accidental startup when power comes

on.

Fig.T

To preventthe workpieceor backup materialfrom being

tom from your hands while drilling, you MUST position

the workpiece against the LEFT side of the column. If the

workpiece or the backup material is not long enough to

reach the column, clamp them to the table, or use the

fence provided with the drill press to brace the workpiece.

Failure to secure the workpiece could result in personal

injury.

USING THE FENCE (FIG. U)

The fence provides a way of accuratelyand quickly

settingup the workpiecefor more precisionorfor repitive

drillingoperations.

1. Usingthecenterpunchor sharp nail, make an

indentationinthe workpiecewhere _ou wantto drill.

2. Lowerthe drillbit toalignwith the indentationonthe

workpiece.See "HOLDING A DRILLING LOCATION"

page 19.

3. Loosenthe knobs (1) and slidethe fence backstop (2)

firmly against the longside of the workpiece.Tighten

the knobswhen inposition.

4_ Loosenthe wingnut (3) and slidethe end stop(4)

alongthe fence untilit isfirmly againstthe leftsideof

the workpiece.Tightenthe wing nut.

5. Check the accuracybydrillinga scrapworkpiece.

Adjust ifneeded.

6. Holdwithyourhand or clamp the top surface of the

workpiecefirmly toprevent it from liftingoff thetable

when the bit is raised.

Fig. U

INSTALLING DRILL BIT IN CHUCK (FIG. T)

1.With theswitch"OFF" and the yellow switchkey

removed, open the chuckjaws (1) usingthe chuckkey

(2). Turn the chuck key counterclockwiseto openthe

chuckjaws (1).

2. Insertthe drillbit (3) into the chuck far enoughto

obtainmaximum grippingby the jaws, butnot far

enoughtotouch the spiralgrooves(flutes) of the drill

bitwhenthe jaws are tightened.

3. Make surethat the drillis centered inthe chuck.

4. Turn the chuckkey clockwiseto tightenthejaws.

To avoid injury or accident by the chuckkey ejecting

forcibly from the chuck when the power is turned "ON",

use only the self-ejecting chuck key supplied with this

drill press. ALWAYS recheck and remove the chuck key

before turning the power"ON".

234

16

Page 17

DRILLING TO A SPECIFIC DEPTH (FIG. V)

Drillinga blindhole (not all the way throughworkpiece)

toa givendepth can be done twoways:

Workpleca method

1. Mark the depth(1) ofthe holeon the side of the

workpiece.

2. W'_ththe switch"OFF",bringthe drill bitdown until

thetip is even with the mark.

3. Hold the feed handle (2) at thisposition.

4. Spin the lowernut (3) downto contactthe depth

stop(4) on the head.

5. Spin the upper nut(5) down and tightenagainst the

lower nut (3)..

6. The drillbitwill nowstopafter travelingthe distance

marked onthe workpiece.

Depth scale method

Note: With the chuckup the tipof'the drillbit must be

just slightlyabove thetop of theworkpiece.

1.With the switch"OFF", turn the feed handle (2) until

depth stop (4) points to the desired depth on the

depth scale (6) and hold the feed handle inthat

position.

2. Spin the lower nut (3) down to contact the depth

stop (4).

3. Spin the upper nut (5) against the lower stop nut (3)

and tighten.

4. The drill bit will stop after traveling the distance

selected on the depth scale.

Fig. V

LOCKING THE CHUCK AT THE DESIRED DEPTH

(FIG. W)

1. With the switch"OFF",turnthe feed handlesuntilthe

chuck (1) is at the desireddepth_Holdthe feed

handlesat this position.

2. Turn the stopnut (2), located underthe depthstop

(3), counterclockwiseand upwards,untilitisagainst

the depth stop.

3. The chuckwillnow be held at this positionwhen the

feed handlesare released.

Flg.W

REMOVING CHUCK AND ARBOR (FIG. X)

1. With the switch"OFF", adjust thedepth stopnut(1) to

holdthe drillat a depth ofthree inches. (See

instructionsfor "LOCKING CHUCK AT DESIRED

DEPTH").

2. Align the keyholes inthe spindle(2) and quill(3) by

rotatingthe chuckbyhand.

3. Insertthe key wedge (4) into the key holes(2 & 3).

4. Tap the key wedge (4) lightlywith a plastictipped

hammer, until the chuckand arborfall out ofthe

spindle.

NOTE: Place one hand below the chuck to catch it

when it falls out.

Fig. X

S

4

17

Page 18

BASIC OPERATION INSTRUCTIONS

To getthe best resultsand minimizethe likelihoodof

personalinjury,follow these instructionsfor operating

yourdrillpress.

Foryourownsafety, always observe the SAFETY

INSTRUCTIONS listedhere and on pages 3, 4 and 5

ofthe instructionmanual.

YOUR PROTECTION

To avoidbeing pulledintothe power tool,do notwear

looseclothing,gloves,neckties, orjewelry. Always tie

backlonghair.

1. If any part of your drill press is missing, malfunctioning,

damaged or broken, stopoperation immediatelyuntil

that partis properlyrepaired or replaced.

2. Never placeyourfingers in a positionwhere they

couldcontactthe drillbitor othercuttingtool. The

workpiecemay unexpectedly shift,or your handcould

slip.

3. To avoid injuryfrom partsthrownbythe spring,follow

instructionsexactly when adjustingthe springtension

of the quill.

4. To preven the workpiecefrom being torn from your

hands,thrown,spunby the tool,or shattered, always

properlysupportyourworkpiece as follow:

a. Always positionBACKUP MATERIAL (used

beneathworkpiece) so that itcontactsthe left

sideof the column,or use the fence providedand

a clamp to brace a small workpiece.

b. Whenever possible,positiontheWORKPIECE to

contactthe left side of the column. Ifit is too short

or the table istilted, usethe fence providedor

clampsolidlyto the table, usingthe table slots.

c. When usinga drillpressvise, always fasten itto

thetable.

d. Neverdo any work freehand (hand-holdingthe

workpiecerather than supportingiton the table),

exceptwhen polishing.

e. Securelylockthe headand supporttothe column,

thetable arm to the support,and the table to the

tablearm, before operatingthe drill press.

f. Never movethe heador the table while thetool is

running.

g. Beforestartingan operation,jog the motor switch

tomake sure the drillor other cuttingtooldoes not

wobble orcause vibration.

h. If a workpieceoverhangsthe table so itwill fall or

tip if not held,clamp it to the table or provide

auxiliarysupport.

i. Use fixturesfor unusualoperationsto adequately

hold,guide, and positionworkpiece.

j. Use the SPINDLE SPEED recommended for the

specificoperationand workpiecematerial. Check

the panel on the insidepulleycover or the chart

belowfor drillingspeed information.For

accessories,refer tothe instructionsprovidedwith

eachaccessory.

5. Never climbon the drill presstable, it couldbreak

or pullthe entiredrill pressdown on you.

6. Turn the motorswitch"OFF", and putaway the

switchkey when leaving the drillpress.

7. To avoid injuryfrom thrownwork or tool contact,do

notperfornlayout, assembly,or set up work on the

table while the cuttingtool isrotating.

DRILLING SPEED TABLE (rpm)

Drill Bit Material

Diam. Wood 6.1umi- Plastic Mild Stain-

(Inches) mum Steel less

1/32 3100 3100 3100 3100 3100

1620

1/16 2620

1620 990

1/8 2620 1550

990 600

3/16 1550 650

1620 1620

1/4 2620 2620

600 340

5/16 650 510

990 990

3/8 1550 1550

1630 340 250

7/16 2620 510

600 600

1/2 650 650

9/16

5/8

18

Page 19

POSITIONING THE TABLE AND WORKPIECE

(FIG. Y and Z)

1. Lockthetable (1) to thecolumn(2) at a positionso

thetipof the drillbit (3) is just abovethe topofthe

workpiece(4).

2. ALWAYS place a BACK-UP MATERIAL (scrap

wood)on the table beneath the workpiece.Thiswill

preventsplinteringorheavyburringonthe

undersideof the workpiece. To keep the back-up

material from spinning out of control, it MUST

contact the LEFT side of the column.

To prevent the workpiece or backup material from being

torn from your hands while drilling, you MUST position it

against the LEFT side of the column. If the workpiece or

the backup matedal is not long enough to reach the

column, use the fence provided with the drill press to

brace the workpiece. Failure to do this could result in

personal injury.

HOLDING A DRILLING LOCATION

1. Usinga centerpunchor sharpnail,make an

indentationinthe workpiecewhereyouwantthe

hole.

2. Usingthefeed handles,bdng thedrilldowntoalign

withthe indentationbeforeturningthedrillON.

TILTING THE TABLE (FIG. AA)

NOTE: The table arm and support (1) has a preddlled

hole with a locking set screw inserted for locking the

table into a predetermined 0 ° horizontal position.

1. To use the table in a bevel (tilted) position, turn the

locking set screw (2) with the hex key

counterclockwise to release it from the table

support.

2. Loosen the large hex head bevel locking bolt (3).

_t

To prevent injury,be sure to hold the table& table

arm assembly, so it will not swivel or tilt.

Fig. Y

3. For small pieces that cannot be clamped to the

table, use a drill press vise (optinal accessory).

The drill press vise MUST be clamped or bolted to the

table to avoid injury from a spinning workpiece, or

damaged vise or bit parts.

Remove the drill press fence when it interferes with other

drill press accessories.

Fig. Z

2

Fig. AA

\

3. Tilt the table, aligning the desired angle

measurement to the zero line opposite the scale (4).

Tighten the bevel locking bolt.

4 To return the table to its original position, loosen

the bevel locking bolt (3). Realign the bevel scale (4)

to the 0° position

5 Using the hex key, turn the locking set screw (2)

clockwise to seat into the hole.

To avoid injury from spinning work or tool breakage,

always clamp workpiece and backup material

securely to the table before operating the drill press

with the table tilted

FEEDING

1. Pull down the feed handles with only enough effort

to allow the drill bit to cut.

2 Feeding too slowly might cause the drill bit to burn.

Feeding too rapidly might stop the motor, cause the

belt or drill to slip, or tear the workpiece loose and

break the drill bit

3. When drilling metal, it may be necessary to

lubricate the drill bit tip with motor oil, to prevent

burning the tip.

19

Page 20

MAINTAINING YOUR DRILL PRESS

Foryourownsafety, turnthe switch=OFF"and remove

theplugfrom the powersource outletbeforemaintaining

or lubricatingyourdrillpress.

Frequentlyblow out, usingan air compressoror dust

vacuum,anydustthat accumulatesinsidethe motor.

A coatofautomotivepaste wax appliedto thetable and

columnwillhelpto keep the surfaceclean.

To avoidshock or fire hazard, ifthe power cordiswornor

cutin anyway, have itreplaced immediately.

LUBRICATION

Allofthe drillpressball bearingsare packedwith grease

at the factory. They require no further lubrication.

Periodicallylubricatethe gear and rack, table elevation

mechanismofthe spindlethe rack(teeth) ofthequill.

20

Page 21

TROUBLESHOOTING GUIDE

To avoid injuryfrom an accidentalstart,turnthe switch"OFF" and always removethe plugfrom thepowersourcebefore

makingany adjustment.

• ConsultyourlocalSears Service Center iffor any reason themotorwill notrun.

PROBLEM

Noisyoperation

Drill bit burn.

Runoutof drill bit point -

drilled holenot round.

Wood splinters on

underside.

Workpiece torn loose from

hand.

POSSIBLE CAUSES

1. Incorrectbelttension.

2. Dry spindle.

3. Loose spindlepulley.

4. Loosemotor pulley.

1. Incorrect speed.

2. Chips notcomingout of

hole.

3. Dull drill bit.

4. Feeding too slowly.

5. Not lubricated.

1. Hand grain in wood or

lengths of cutting flutes

and/or angles not equal.

2. Bent drill bit.

1. No backup material under

workpiece.

1.Not supported or clamped

properly.

REMEDY

1. Adjust tension. See Section

"ASSEMBLY - TENSIONING BELT"

2. Lubricate spindle.See Section

"LUBRICATION".

3. Check tightness of retaining nut on pulley, and

tighten if necessary.

4. Tighten set screw in motor pulley.

1. Change speed. See Section" BASIC DRILL

PRESS OPERATION - SPINDLE SPEEDS"

2. Restract drill frequently to clear chips.

3. Resharpen drill bit.

4. Feed fast enough - allow drill to cut.

5. Lubricate drill. See Section "BASIC DRILL

PRESS OPERATION-FEEDING"

1. Resharpen drill bit correctly.

2. Replace drill bit.

1. Use backup material. See Section "BASIC

DRILL PRESS OPERATION".

1. Support workpiece or clamp it. See Section

"BASIC DRILL PRESS OPERATION".

Drill bit binds inworkpiece.

Excessive drill bit runout

orwobble.

Quill returns too slow or

too fast.

Chuck will not stay

attached to spindle. It falls

off when trying to install.

1. Workpiece pinching drill bit,

or excessive feed presure.

2. Improper belt tension.

1. Bent drill bit.

2. Worn bearings.

3. Drill bit not propedy installed

in chuck.

4. Chuck not properly installed.

1. Spring has improper tension.

1. Dirt, grease, or oil on the

tapered inside surface of

chuck or on the spindle's

tapered surface.

1. Support workpiece or clamp it. See Section

"BASIC DRILL PRESS OPERATION".

2. Adjust tension. See Section" ASSEMBLY -

TENSIONING BELT".

1. Use a straight drill bit.

2. Replace bearings.

3. Install drill properly. See Section "BASIC

DRILL PRESS OPERATION" and

"ASSEMBLY".

4. Install chuck properly. See Section

"ASSEMBLY - iNSTALLING THE CHUCK".

1. Adjust spring tension. See Section

"ASSEMBLY - ADJUSTMENTS -QUILL

RETURN SPRING".

1. Using a household detergent, clean the

tapered surface of the chuck and spindle to

remove all dirt, grease and oil. See Section

"ASSEMBLY - INSTALLING THE CHUCK".

21

Page 22

15" DRILL PRESS PARTS LIST

When servicing use onlyCRAFTSMAN replacementparts•Use ofany other parts may create a HAZARD or cause

productdamage,

Any attempt to repairot replace electricalparts on this Ddll Press may create a HAZARD unlessrepair is done by a

qualifiedservice technician.Repair service is availableat yournearest Sears Service Center•

Alwaysorder by PART NUMBER, not by key number

Key Descdpfon

0SUE BASE

0583" BODY COLUMN

0JQO HEX. HD, BOLT

05UW WORM

05UY CRANK HANDLEASS'Y

05VO TABLE BRACKET

05V8 TILTING SCALE

06RZ CENTERING SCALE

0KgX ORIVE SCREW

(_GF COLUMN LOCK HANDLE

05VD TABLE LOCK HANDLE MtO*I_S OK7K CR_ BE_ ROUND WASHES HO_ SCBE MI8"1_0.12 5

0WVE TABLE

(]SVQ RACK

0b_rF RACK RING

(]SWE HEAD ASS'Y

0JXL HF.._SOC. SET SCREEN M10"I .5-12

0KDG CB RE. PAN HD. SCREW M5"0.8-6

05hVJ HANDLE SHIFTER

05WL MOTOR BAR SHIFTER ASS'Y

05WN MOTOR ROD

OSGN BH3FTERBOLT

05WV MOTOR BASE

OJgM SPBING WASHER _112

HEX.NUT M12*1_75T=|0

05X2 FEED SHAFT ASS_F

OSGG HANDLE BARABS'Y

05XK SCALERING

OVJK BPR_NGCAP

05YI SPRING RETA_NEB

OKPV HF.X.NUT II2*20UNF T=IS

05Y2 OUILL SET SCREW M10"1_5-28

SKMV HEX_NUT M16*1_ST=8

05YD SP_NBLEABS'Y

05YN DRMNG SLEEVE ASS'Y

05YS PULLEYBET NUT

05Z0 SP_NBLE PULLEY

OHY8 DRILUNG ARBOR MT2*JT3

0J28 CHUCKS KEY

OSGZ CHUCK RJ3-16L

OSHO CHUCK KEY

05Z2 WEDGE BHIFTER

OQ3S MOTOR

0K17 HEX_HD_SCRE_NAND WASHER M8"I__S-20

OJ7F FLAT WASHER 5J16"715-5i64

OfO_Y HEY..NUT M6.1_5 •T=6_5

058W MOTOR PULLEy

OJG4 PARALLELKEy 5*5-20

06SV CLAMPJCORD

OKDU CR RB_PAN HD_SCREW M6"I_0-12

0L66 POWER CASLE

OKUW TERMINAL

OLWG ROCKER BWiTCH ELEMENT

Size Qty. Key Description

0e07

SWITCH BOX 1

M10"1.5_I0

_.5-5 0KDH

CR. RE. PAN HD. SCREW M5"0.8-12 3

0e0T

PULLEY COVERASS'Y I

0VME

CENTER PULLEY 1

OJKH

V-BELT I_28 I

0JBF

FLATWASHER 114"3/4_/16 4

0t_oX

HEX. NUT 1FJ'20UNFT==6.5 1

04A4

CLAMP-CORD 3

CR. RE. PAN HD. SCREW M6"0.8-8 3

0JKC V-BELT kk24 1

06TB SWITCH COVER 1

01<94 CR. RE. TRUSS HO. TAPPING SCRE_M5"12-16 2

061Y MOTOR ROO 1

0JCM SPRING PIN 6-25 2

0V86 WARNING LABEL 1

22BG MOTOR LABEL 1

228E SPEED DIAGRAM 1

GWVR TRADEJA_RK LABEL 1

0_gX DRIVE SCREW _ Z3-5 4

0SG3 PARALLEL _=P,ACKET ASS"{ 1

O711 LOCK KNOB M8"1.25 2

0JTJ FLATWASHER 3/8"1_32-7,_4 2

0712 PARALLEL BRACKET 1

0713 SLIDE PLATE 2

0KJO CAP HD, $QNECK BOLT M6"t,0-16 1

0714 PLATE 1

0KQ5 WING NUT M6Xl.0 1

01_F CR. RE. PAN HD. SCREW M5"0._8 2

01AF EXTERNALTOOTHLOCKWASHER _5 2

OKDZ CR_ RE_ PAN HD_ SCREW M6"1 _0-35 2

06HB HEX. NUT 1

0t_MU SET BOLT M10"1.5 T-_B 1

06CR NUT M16"2.0 2

_6CQ WASHER rp24 T=1/16 1

0JUY HEX. SOC, HD, CAP BOLT M_'1.25_5 1

06HF SET RING 1

IToHG CIRCULAR NUT 1

0J93 SPRtNG WASHER _10 1

OJ3M WRENCH HEY-. 3_57 1

0J3Q WRENCH HEX. 5-70 1

0J3R WRENCH HEX. 6-83 1

0LRT ROCKER SWITCH 1

0KYN LEADWIRE ASS'Y 1

0KSQ STRAIN REUEF 2

06SK BULB SOCKET BRACKET 1

G_GE SET BOLTASS_ 1

04Q4 LABEL 1

0JUS HEX.SOC,HD.CAPBOLT M5"0,8-12 4

0J6T FLATWASHER 3/16"3/14-1/16 2

0WVG HANDLE 1

0WVH UPER TUBE 2

0WVK CLAMP BOLT 1

0WVJ SET PLATE 1

0J3P WRENCH HEX. 4-64 1

Size Qty.

1Mt 2"1.75-35 061R CHUCK KEy HOLDER

22

Page 23

15" DRILL PRESS PARTS LIST

MODEL NO. 127. 229151

/

23

Page 24

24

Page 25

Manual de Operaci6n

CRIIFTSMllN"

1 HP (Potencia M&xima)

12 Velocidades (250-3100 R.P.M.)

Mandril de 518Pulg.

PRENSA TALADRADORA

DE 15 PULG.

Modelo No.

137.229151

CUIDADO:

Antes de user esta Prensa •

Taladradora leer este manual •

y seguir todas las Reglas de •

Seguridad e Instrucciones •

de Operaci6n. •

Tel6fono para

Ayuda al Cliente

1-800-843-1682

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

Part No. 137229151001

Instrucciones de Seguridad

Instalaci6n

Operaci6n

Maintenimiento

Lista de Partes

Page 26

SECCI6N PAGINA

Garania ................................................................................................................. 26

Especiflcaciones de la Herramienta ................................................... ............................. 26

Instrucciones de Segutidad ....................................................................................... 27

Accosorios y Aditamentos ....................................................................................... 30

Contenido de la Caja ................................................................................................ 30

Farniliarizares con la Prensa Taladradora ................................................................ 32

Glosario de T6rminos ............................................................................................. 33

Ensamblaje y Regulaci6n ........................................................................................ 34

Operaci6n ................................................................................................................ 39

Mantenimiento ............................ _........................................................................... 44

Guia para Diagn6stico de Problemas ......................................................................... 45

Partes ...................................................................................................................... 46

GARANTJA TOTAL DE 1 ANO

Siesta herramienta presentase defectos de material o fabricacibn dentro del primer argoa partir de la fecha de

compra, Sears la reparar_ sin costo alguno

Contactarse con un Centro de Servicio de Sears pare la reparacibn.

Siesta herramienta se usa para fines comerciales o para alquiler, esta garantia se aplica s61o per los primeros 90

a partir de la fecha de compra.

Esta garantia le otorga derechos legaLes espec{ficos y tambi_n podrla usted tener otros derechos que varian de un

estado a otto

Sears, Roebuck and Co., Dept. 8t7 WA, Hoffman Estates, IL 60179

r.,_

Certaines poussieresprovenant d'activit6ssur outils_lectdques, comme ponc..age,sciage, meulage, pelage et d'autres activit_s

relatives a la construction contiennent des produits chimiques connues pour causer cancer, anomalies congenitales ou autres dsques

pour la reproduction. Certains exemples de cosproduits chimiques sont :

• plomb provenant de peintures _ base de plomb ;

• silice cristallisee provenant des bdques et du ciment et d'autres produits de ma<;onnerie, et

• arsenic et chrome provenant du bois chimiquement traite.

Vos dsques d'6tre expos6 _ces produits vadent selon le temps pass6 &faire ce type de travail. Afin de reduire rexposition & cos

produits chimiques, il faut travailler dans un endroit bien a6r6, et porter de I'_quipement de securit6 approuve comme des masques

poussi6re congus sp6cialement pour ]e filtrage de particules microscopiques.

TAMAI;IO DEL MANDRIL..5/8°(16 ram)

VELOCIDADES ............... 12 (250 ~ 3,100 RPM)

MOTOR ......................... 120V, 60 Hz, 8 AMPS

CABALLAJE ...................... 1 HP (Desarrollo Max.)

LUZ INCORPORADA .........60 Wats (Mdximo)

(No incluye el foco)

TAMAI;IO DE LA MESA.....13-1/4"x13-1/4" (33.6 cm x 33.6 cm)

INCLINACION

DE LA MESA...................... 45 ° A LA DERECHA O IZQUIERDA

DESPLAZAMIENTO

DEL EJE.............................. 3-1/8"(8 cm)

CUELLO ............................... 7-1/2"(19 cm)

TAMA_IO DE LA BASE-=....11")(20-3/8" (28 cm x 52 cm)

ALTURA ............................... 63-1/4"(1.61 m)

El polvocreado per el lijado mecanico, aserrado, rectificado,

taladrado y otras actividades empleadas en construcci6n

contiene productos quimicos que se sabe causan cancer,

defectos congenitos u otros daSos al sistema reproductor.

Algunos de estos productos quimicos son :

• plomo proveniente de pinturas a base de plomo

• silicecristalizada de ladnllos y cemento y otros productos de

alba_ileria y,

• arsenico y cromo de madera tratada quimicamente.

Su riesgo de exposicibn a estos productos varia dependiendo

de cuan a menudo usted hace este tipo de trabajo. Para reducir

su exposicibn a estos productos quimicos :trabaje en lugares

bien ventiladosy utilice equipo de seguridad aprobado, tal

como mdscaras contra el polvo especialmente disefladas para

filtrar particulas microscopicas.

Page 27

INSTRUCCIONES GENERALES DE 14.

SEGURIDAD

ANTES DE USAR LA PRENSATALADRADORA

Laseguridadesunacombinaci6ndesenlidocomdn,mantenerse 15.

alertaysabercomousarla PrermaTaladradera.

'RETiPJ_I_VI_I_eg

Paraevitarermresquepuedancausarlesionesserias,no

conectareltaladrobasrahaderle|doyentendidoIosiguiente:

1 LEERyfamiUarizarsocontodeestemanualde

instrucoionesENTENDERlasapiicaciones,limitacinoesy

riesgasposibles

2 MANTENERLOSPROTECTORESENPOSlCI(_Nyen

buenascondicionesdeoperadbn

3. NOOPERARENAMBIENTIESPELIGROSOS.Nousarla

herramientaenlugaresht_medos,mojadeso e._puestosa la

Iluvia.Mantenereldreade trabajobieniluminada.

4. NO USARherramientaseldctricasen la presenciade

Ifquidosogasesinflamables.

5. MANTIENEREL AREA DETRABAJOUMPIA. Lasdreasy

mesasdetrabajocongestJonadasinv_tanaqueocurran

accidentes.

6. MANTENERA LOSNIl;lOSALEJADOS.Todoslos

visitantesdebenmantenersea unadistanciaseguradel

_reade trabajo

7. NOFORZARLAHERRAMIENTA.Laherramientahardun

mejortmbajoy rodssegurous_ndolaS61Oenlaformapara

laquefuedisefiada.

8. USARLAHERRAMIENTAADECUADA.Noforzarla

herramientaalhaceruntrabajoparaelcoalnohaside

diseSada.

9 USARROPAADECUADANO usarropasuelta,guantes,

corbatas,anillos,brazaletesnijeyasquepuedanquedar

atrapadosanlaspiezasmoviblesdelaherramientaSe

recomiendausarcalzadoantJmsbalanteUsarprendasde

cabezaparacubrirocontenerelcabetlolargo.

10. USARUNAM/t,SCARAPARALA CARAO PARAPOLVO.

Lostrabajoscontatadroproducenpolvo.

11 DESCONECTARLAS HERRAMIENTASantesde cambiarle

accesoriostalescomo:hojas,brocas,cortadoresy similares

12. REDUCIRELRIESGODEARRANQUESACCIDENTALES.

Cerciorarsequeei interruptordeenergiaest_enlaposicibn

=OFF"(Apagado)antesdeenchufarlaherramientaa la

corfienteeldctrica.

13. USAR ACCESORIOS RECOMENDADOS. Consultarcon

el manualdel opemdorpara determinar cualesson los

acoesoriosrecomendados.El usode accesorios

inapropiadospuede ser peligrosoygenemr riesgode

lesionespersonales,

16. NUNCAPARARSESOBRELAHERRAMIENTA.Pusden

17. NOESTIRARSEM/t,SALLADELALCANCEDEUNO.

18. DARMANTENIMIENTOCUIDADOSOA LAS

t9. INSPECClONARPAPADETECTARPIEZASDANADAS.

20. ASEGURARSEQUELOSNINOSNOTENGANACCESO

21 NOoperarla herramientabajolainfluenciadedrogas,

22.

CONSERVAR ESTAS INSTRUCCIONES

RETIRAR LAS HERRAMIENTAS DE

REGULACI_N. Formarseel tk_oitodeverificarquelas

herramientasy lasIlavesde regulaci6nhayansideretJradas

deltaladroantesdeactivarlo.

NUNCADEJARDESATENDIDAUNAHERRAMIENTA

ELI_CTRICACUANDOESTI_FUNClONANDO.

DESCONECTARLA FUENTEDEENERG|A.Noalejarse

dellugarhastaquela herramientasehayadetenidopor

compieto.

ocurdrlesionesseriassilaherramientasevolteaosise

entraen contactoconeltaladro.

MantenerlosdospiesbienapoFadosyelequilibroen

todomomento.

HERRAMIENTAS.Pareunaoperaci6nmejor,mdsseguray

rdpida,mantanerlesherramientasaflladasy limpias.Seguir

lasinstruccionesparalalubricack_ycambiodeaccesorios.

Antesdeusarlaherramienta,siempreinspeccionada

cuidadosamenteparecemioraressilosprotectoresu otras

piezasest_ndahadasydeterminarsiva a operar

adecuadamenteenelusoqueselevaa dar.Inspecolonar

sihaypiezasmoviblesdesalineadaso atracadas;partes

rotasorealmontadas,ycoalquierotracondici6nquepueda

afectarlaoperaci6nde laherramienta.Siunprotectoro

cualquierotrapiezaestuvieseda_adadeberepamrse

adesuadamenteo reemp_azarse.

ALTALLERDETRABAJO.Usarcandados,intenuptores

maestrosy quitarlosIlavesdeactivaci_n.

alcoholo medicamentosquepudiesenafectarlahabilidad

paraoperarlaherramientaadecuadamente

Elpolvogeneradoporciertosmaterialespuedesernocivo

parala salud.Siempreoperarla PrensaTaladmdoraenun

areabienventiladaparaeliminarelpolvo.Cuandofuese

posible,usarsisternasrecolectoresdepotvo.

23 SIEMPREUSAR

PROTECCIONPAPALOSOJOS

CualquierPrensaTaladradora

puedearrojarcuerposextrahosa

losojosquepuedencausar

dafiospermanentesa lavista

SIEMPREusarGalasde

Seguridad (no anteojos) que cumplancon la norrna Z87.1

de ANSI. Los anteojosde usodiafiosSIotienen ]entes

resistentes a losimpactos, estos NO SON galas de

seguridad. I.as Gatas de Seguridad pueden adquirirse en

Sears. NOTA: Los anteojos o galas que no cumplen con la

norma Z87.1 de ANSI pueden causar daSosserlos al

romperse.

27

Page 28

REGLASDE SEGURIDADESPEC|FICAS

PARALA PRENSATALADRADOFIA

RBIJI_=I_I=K_

Porsupropiaseguddad,nobatarde usarlaPrensaTaladradorani

enchufarlahastaqueest6cornpletamenteensambladae instalada

deacuerdoconlasistmcciones,y hastahaberlefdoyentendido

estemanualdeinstnJcciones:

LA PRENSATALADRADORA DEBE ESTAR

EMPERNADA en formaseguraal bancode trabajo.

Adicionalmente,sihubiesela tendenciaa que el

bancode trabajoTaladradorase muevadurante

ciertasoperaciones,empernarla prensaal piso.

2,

ESTAPRENSATALADRADORAs61oesparaucameen

condidonessecasyen intedores.

3.

DSARPROTECCK_NOCULAR.USARmdscaraprotectora

paralacarao parapolvosjuntocongalasdesegundadsi

laoperacibngenerapoivo.USARprotectoresde ofdo,

especialmentedurantepedodoslargosdeoperackSn.

4.

NOusarguantes,corbataniropasuelta.

5.

NOintentartaladrarobjetosqueseandemasiadopequerios

comeparafijarlosconsujetadores.

6.

SIEMPREmantenerlasmanosfueradetcaminodelas

brocas.Evitarcolocarlasmanosenposicionesen las

cualesunresbal6ns0bitopuedahacerquelasmanos

entrenencontactoconlabroca.

7.

NOinstalarniusarbrocascuyolargoexceda175mm(7")o

queseproyecten150mm(6")pordebajode lasquijadas

delmandril.Puedendoblarses6bitarnentehaciaafuera

oromperse.

8.

NOUSARruedasdealambre,brocasparaburiladoras,

cuchillasformadoras,cortadoresde cfmulosnicepillos

giratoriosenestaPrensaTaladradora.

9. CUANDOseestetaladrandounapiezagrandedematerial,

cerciorarsequeest_cornpletarnentesujetaala altura

delamesa.

10. NOraalizaroperacibnalgunaa manolibre.SIEMPRE

sujetarla piezaquesaest_trabajandoenforrnafirme

contrala mesaparaquenosemuevaotuerza.Usar

sargentaso prensassisetaladranpiezasinestables.

11. CERCIORARSEquenohayanclavosniobjetosextrarios

enlaparte de lapiezaquesevaa taladrar.

12. FIJARLAPIEZADETRABAJOCONSUJETADORES

contrael ladoizquierdodela columnaparaevitarque gire.

Si fuesemuycortaosila mesadelaherramientaestuviese 27.

indinada,sujetadafirmementeala mesayusarla

guiaprovista.

13. SI LA PIEZA DETRABAJO se proyecta fuera de la mesa

de forma tal que se caiga o inclinesi no estuviese sujeta,

sujetadaa la mesa o proveer unsoporteauxiliar.

14.

FIJARLA PIEZADE"rRABAJO,Cuandofuese_,

usarsargentasounaprensaparasujetarla plezadetrabaJo.

Esn_a seguroqueusarla _ y dejalibreambasmanoe

paraoperarlaherramlerCa.

15.

AL USAR unaprensaparataJadro,siempresujetadaa

la mesa.

t6.

CERCIORARSEQUEtodosloselement.smec._nicosde

sujeci6nest6najustadosfirmementeantesdecomenzar

a taladrar.

17.

ASEGURARELCABEZALCONELSEGUROy sujetarel

soportedelamesaa la columna,y la rnesaalsoporteantes

deoperarlaPrensaTaladradora.

18.

NUNCAhacerfuncionarlaPrensaTaladradoraantes

dehaberdespejadotodoobjetodela mesa(henamientas,

_hos de madera,etc.).

19.

ANTESDECOMENZARlaoperadbn,hacerfuncionarel

taladrobrevementeabajavelocidadparacarciorarsequeno

sebamboleeovibre.

20.

PERMmRQUE EL EJEALCANCESUVELOCIDAD

MAXIMAantesdecomenzaraa taladrar.Sieltaladrohaca

alg_nruidoquenoseafamiliarovibraexcesivamente,

detenereltrabajoinmediatamente,apagareltaladroy

desenchufadode la corriente.Novotverloaponeren

operaci6nhastahabercorregidoelproblema.

21.

NOraalizarlaboresdetrazado,ensamblajenipraparaci6n

sobrelamesacuandola herramientaest_enoperacibn.

22.

USARLAVELOCIDADRECOMENDADAparael accesorio

y tipode materialde lapiezaqueseest6trabajando.VER

I_ASINSTRUCCIONESquevienenconelaccecorio.

23.

ALTALADRARorificiosdedidmetmgrande,fijarla pieza

de trabajocon sujetadoresenformafirmea la mesa.De

Iocontrariolabrocapuedeagarrarlapiezaqueseestd

trabajandoy hacerlagirara granvelocidad.NOUSAR

cuchillasdefresadoranielementosquetaladrenoriflcios

rndltiplesporquepuedendesarmarsaodesbalancearse

coneluso.

24.

CERCIORARSEqueeleje sehayadetenidocompletamente

antesde entrarencontactocontapiezadetrabajo.

25.

PARAEVITARLESIONESdebidasa arranques

accidentales,siemprecolocarel interruptorenla posicibnde

"OFF"(Apagado)ydesanchufarel taladroantesdeinstalaro

ratiraraccesorioso de realizarcualquierajusteo regulacibn.

26.

MANTENER LOS PROTECTORES EN POSICI(_N y en

buenas condicionesde operaci6n.

SOLOUSARUNALLAVEDELMANDRILTIPOAUTO

EXPULSANTEcomola provistaconla Pransa

Taladradora.

CONSERVAR ESTAS INSTRUCCIONES

28

Page 29

INSTRUCCIONESPARA LA CONEXI6N ATIERRA

ENELEVF.N10DEUNAFALLAO MALFUNClONAMIENTO,

laconex_na_rra Ixoveeunavl'ademanorrosistenoiaparala

cordenteekY_foa,redudendoas(elriesgodechoqueel_'trico.

Estaherramientaestdequipadaconuncord6nel6ctricoqua

tieneunconductorparaconexk_na IJerraytambi#nconun

enchufeconespigaparaelmismofin.ElenchufeDEBE

conectarseenuntomacorrientequelehagajuegoy queest6

debidamenteinstaladoyconectadoa tierrade acuerdocon

TODOSloscddigosyordenanzaslocales.

NOMODIRCARELENCHUFIEPROVISTO.Si noentraenel

tomacordente,hacerquaunelectricistacalificadoinstaleun

tomacordenteadecuado.

LACONEXJ6NINADECUADADELCONDUCTORparalJerra

deunequipopuedegenemrdesgodechoqueeldctdco.El

conductorconformaislanteverde(cono sinrayasamarillas)es

elconductorparaconexibna tierra.Sielcordbnel_"tricooel

enchuferequierenreparacioneso reemplazo,NOconectarel

conductorparatierradelequipoaunterminalvivo.

AVERIGUARcon unelectricistaopersonaldeserviciosise

tienecualquiardudeencuantoala con_6n correctaatierra

delequipo,osilasinstrucoionosparalaconexi6na tierrano

_st_nclaras.

SOLOUSARCORDONESDEEXTENSIONQUETENGAN

ENCHUFEDETRESESPIGASYUNTOMACORRIENTEQUE

_,CEPTEELENCHUFEDELA HERRAMIENTA.REPARARO

REEMPLAZARINMEDIATAMENTELOSCORDONES

DAI_ADOSO GASTADOS.

Estaherramlentaostd_ parausarseenundrcuitoque

teogauntomacorrlentecomoelilustradoeftla RGURAA.

La RGURA(A) muestmunenchufeel_K_o y untornacontente

pe 3contactos,unode loscualesesun_onductorpare

cor_J6na _erra.Sinosedisponedeuntomacordentecon

conductorparaconooddna _erra,tempoPalmentesepuedeusar

unadaptader(RGURAB) paraenchufarfoenuntomacorriente

de 2 contactossinconex_ a lJerra.Eladaptader(RGURA13)

liene unanillodgidoquelesobresaley queDEBEconectarse

fisicameflteenformapermanen_aIJerra,talcomolacajade un

tomaconientedebidamenteconectadoa_erra.ElC6digo

EldctricoCanadienseprohibeel usodeestosadaptadere_

CUIDADO:Entodo6loscasos,carciorarsequeel tomacorriente

encuesti_ est6adecuadamenteconectadoa tierra.Si nose

estuvioseseguro,hacerquaunelecldcistalicenciado

inspeccioneel tomacordente.

EstaPrensaTaladraderaestddiseSadadnicamenteparausoen

intedores.Noexponedaa laIluvianiusarlaenlugaresh_medes.

Fig. A

Enchufede3 espigas

®

,_ eJ'_ _Temacorriente para

enchufede3espigas

debidamente

conectadoatierra

RECOMENDACIONES PARA LOS CORDONES

DE EXTENSION

Cerciorarsequeelcordbndeextensibnest_enbuenas

condiciones.AIusaruncord6nde extensi6n,cerciorarseque

seaIo suficientemente_]mesoparaconducirlacorrientequela

herramientademandera.Uncordensubdimensionadecausar-_

unacaideen elvoltajede la lineacausandounap_rdidade

cotenciay recalentamiento.Latabtaqueaparecoenesta

paginamuestraloscalibrescorrectosdeloscordonesseg_n

suextensi6ny elamperajerequeddopot laherramientaque

apareceen la placa.Encasode dude,usarel siguientecalibre

n_s grueso.CuantomenoretnL_merodelcalibre,mayorel

di_,metrodelalambre.

Cerciorarsequael cord6nde extensi6ntenga losalambres

adecuadosy queest_en buenascondicioneseldctdcas.

Siemprereemplazarloscordonesdeextensi6ndaSadoso

hacerlosrepararperunapersonacalificadaantesdeusarlos.

Protegerloscordenesdeextensi6ndelosobjetosfilosos,del

caloro humedadexcesivay delasareash_medaso mojadas.

Usar un ramal de circuito independiente para esta herramienta.

Este circuito debe ser de un alambre cuyo calibre no sea menor

a 12 y debe estar protegido con un fusi_e de retardo de 15

Amps. Antes de conectar el motor a la Iinea de suministro

el@ctrico,carciorarse que el interruptor est@en la posici6n de

='OFF"(Apagado) y que lacorriente el_}ctdcasea la indicada en la

placa de datos del motor.Operar la herramienta con un voltaje

manor puede daSar el motor.

Fig. B cAoninllOxiPara

Cerciorarseque

estoest_

-- conectadoa una

conexi6na

tierraconocida.

Adaptador

Tomacorriente

de 2 contactos

Paraproteccidedeloperadercontrachoquesel_ctdcos,esta

herramientadebeestarconectadaa tierra.

ii#;! i i:t 11=l_ydl_ll_[el i] =lllo],,-,ll(o]=1i[t]# i_.-tle]=1_:11=1_k"t[_]_ll_|_f[_l

($61oal usar 120volUos)

Amperaje Especificado

m_s de norods

0 6

6 10

10 12

12 16

Longltud total del cordbn en pies

25' 50' 100' 150'

18 16 16 14

18 16 14 12

16 16 14 12

14 12 norecomendado

CONSERVAR ESTAS INSTRUCCIONES

29

Page 30

ACCESORIOS DISPONIBLES

$61ousaraccesoriosrecomendadosparaestaPrensa

Taladradera.Seguirlosinstrucoionesqueacompa_ana los

accesorios.[] usodeaccesoriosinadecuadospuede

generarriesgos.

Visitarel Departamantode Ferretedade la liendaSears

mdscercanaover elCatdlogode HerramientasEI6cbicas/

Neun_ticasy Manualesde Searsparalossiguiantos

_cesorios:

BrocasparaTaladro

• Sujetadory Gu(a

PrensasparaPransaTaladradera

• JuegodeMortajay EspigaparaPrensa

Taladradora

• JuegodeSujetadores

• Cincely BrocastipoMortajay Espiga

• TamboresLijadores

RusdasPulidorasdehasta4" (10cm)de

DidmetroM_ximo

• SierraparaOrificiosde hasta2-1/2' (6.35cm)

DESEMBALAJE Y VERIFICACI( N DEL

CONTENIDO

Sifaltasanpiezasohubiesenpiezasder3ades,noenohufarla

PrensaTaladradorahastaconseguirlaspiezasfaltanteso de

reemplazarlasda_adasy basrahabercompletadeelensam_aje.

Desempaquetarcuidadosamentela PrensaTaladradoraytodas

suspartesyverificadascontralarelaci6nqueestda

con_nuaci6n.

Paraprotegerla PrensaTaladraderacontralahumedad,las

partesmaquinadashansiderecubiertasconunacapaprotectora

quesadeberemoverconunpasohumedecidoconkerosene

oWD-40.

rRBligPJ_l_J_l_

Paraevitarincendiosoreacoionest6xicas,nuncausargasolina,

naffa,acetona,tinerparalacaso solventessimilaresdealta

volatilidadparalimpiarla PrensaTaladradora.

ART DESCRIPCI(_N CANTIDAD

ParaovitarIosionoscausadasporpiezasrotaso piezasde

trabajomtasexpedidas,s61ousaraccesoriosrecomendados

paraestaPrensaTaladradora.

Searspuederecomenderotrosaccesoriosnolistadoseneste

manual.VisitarlatiendaSearsn_s cercanaoverelCatdlogode

HerramientasEldctdcas/Neumdticasy ManualesdeSears.

Nousaraccesorioalgunoa manosdehaberleido

completamenteelmanualde instrucoionesuoperaci6nde ese

acoesorio.

A. Cabezai

B. Mesa

C. Base

D. Columna

E.

E

G.

H.

I.

J.

K.

L

M.

N,

O.

P.

Q.

Balsaconpiezassueltas:

Manijasde Avance

ManijadelSeguro