Page 1

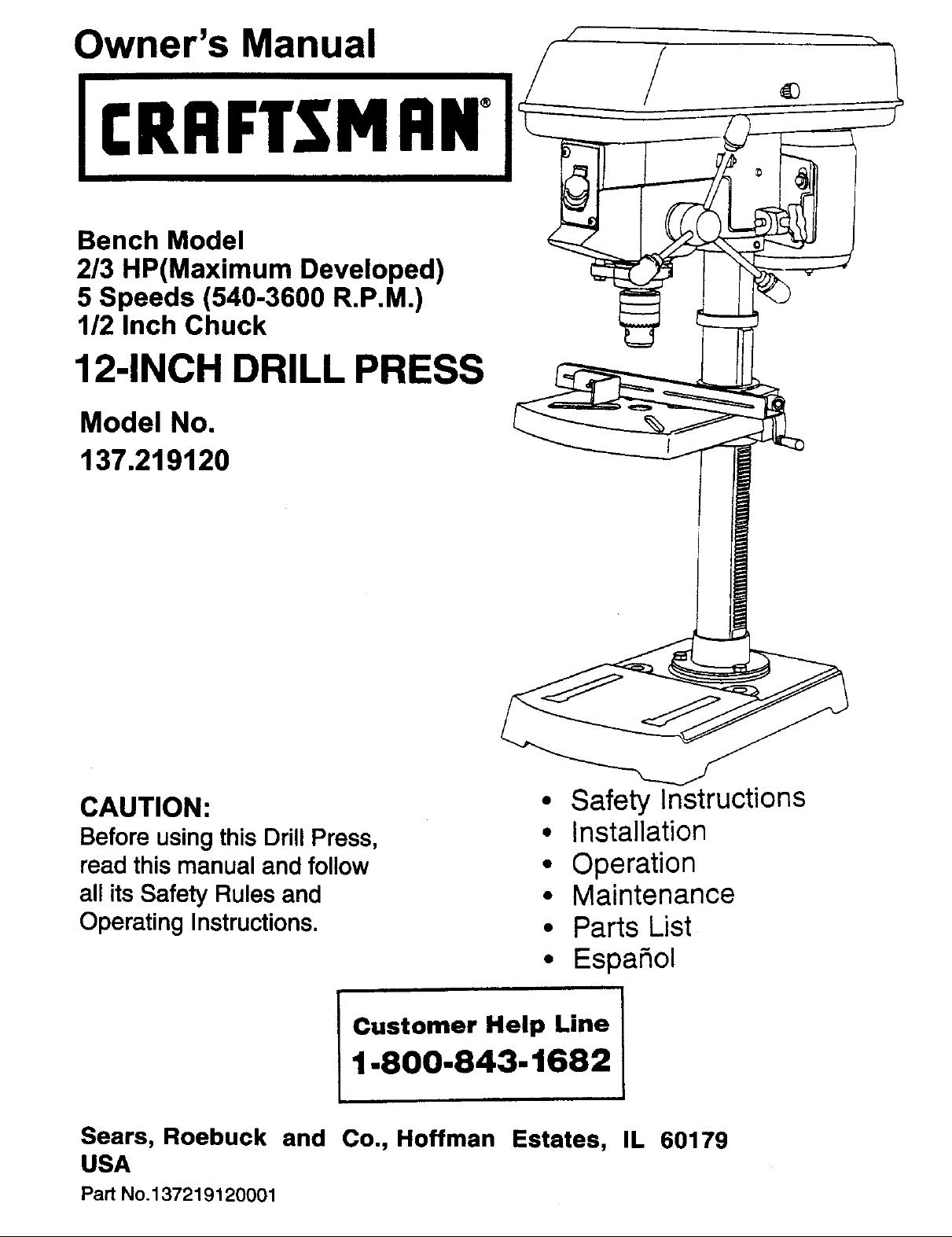

Owner's Manual

CRRFTSMRN°

Bench Model

2/3 HP(Maximum Developed)

5 Speeds (540-3600 R,P.M.)

1/2 Inch Chuck

12-INCH DRILL PRESS

Model No.

137.219120

CAUTION:

Before usingthis Drill Press,

read this manual and follow

all itsSafety Rules and

Operating Instructions.

• Safety Instructions

• Installation

• Operation

• Maintenance

• Parts List

• Espa_ol

Customer Help Line

1.800-843-1682

Sears, Roebuck and Co., Hoffman Estates, IL 60179

USA

Part No.137219120001

Page 2

SECTION PAGE

Warranty ...........................

Product Specifications ................

Safety Instructions ...................

Accessories and Attachments ..........

Carton Contents .....................

Know Your Drill Press .................

Glossary of Terms ...................

Assembly and Adjustments ............

Operation ...............................................

Maintenance .............................................

Troubleshooting guide .....................................

Parts ...................................................

CHUCK SIZE ......... I/2"

SPEEDS ............. 5 (540-3,600 RPM)

MOTOR .............. !20V, 50 HZ, 6 AMPS,

HORSEPOWER ........ 2/3 HP (Max. Develo_3ed)

TABLE SIZE ......... 10-5/t6" x 8-2!/32"

TABLE TILT ........... 45oRIGHT OR LEFT

SPINDLE TRAVEL ..... 2-3/8"

THROAT ............ _"

°.,o.,o,,°,..=,,,,=,

.ooo,.oooo°o,.,,o°,o

°o°oo.o.o°°°.°°o°°°o

,°°o°oo°°°,°o,°o,Jo°

°oo°,°°°°o.oo°o°o,°o

o°o°°oo°°°,°..oo°,l,

,Jo°,°°oo°°o°,oo°°o,

=o°,l,°°,ooill,,,mlm

°n =°oJl°°l°

°° °°°°=l =°

°° OI°°°Q °°

°° =°_=° °l

°° °°=°° ng

°° =°'°_°

°° lloo°

Qm °ll==

oo OOJ°°

,gql=,°

= ,OOo°,,

11 mi,w,a

oo 118

• • m i_

...10

.... 16

.... 20

.... 21

.... 22

To avoid electrical hazards, fire hazards, or damage to

the tool. use proper circuit protection.

Your drill press is wired at the factory for 120V operation

Connect to a 120V, !5 AMP branch circuit and use a

15 AMP time delay fuse or circuit breaker. To avoid shod

or fire, replace power cord immediately if it is worn, cut or

damaged in any way.

..2

..2

,,3

.,6

°,6

BASE SIZE ........... 14-3/8" x 8-1/4"

HEIGHT ............. 37-3/32"

Some dust created by power sanding, saw=ng, grinding, drilling, and other construction activities

contains chemicals known [to the State of California] to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce

your exposure to these chemicals:work in a well ventilated area, and work with approved safety

eauipment, such as those dust masks that are specially designed to ,filter out microscopic particles.

2

Page 3

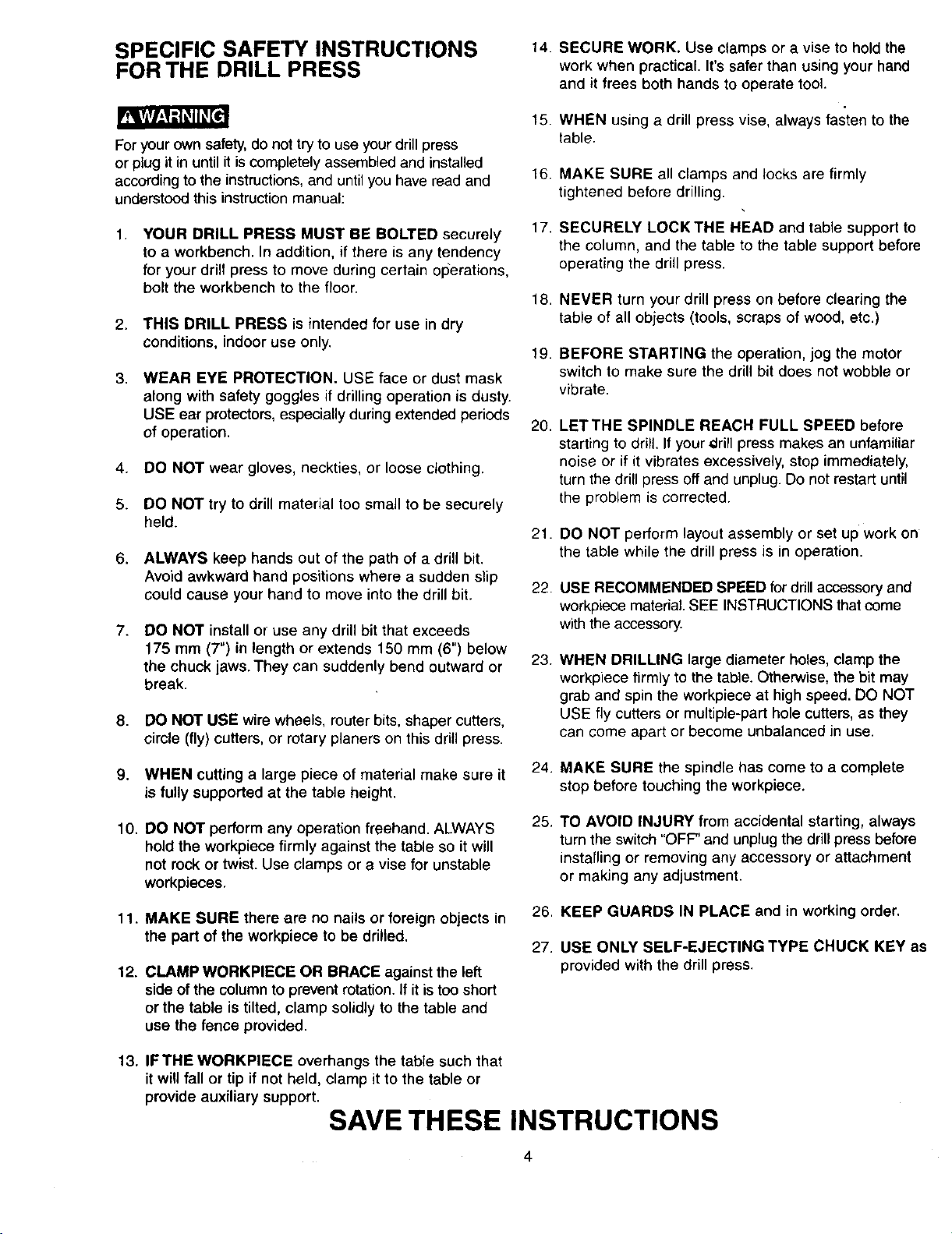

GENERAL SAFETY INSTRUCTIONS 14.

BEFORE USING THE DRILL PRESS

Safety is a combination of common sense, staying alert

and knowing how to use your drill press. 15.

To avoid mistakes that could cause serious injury, do not 16. NEVER STAND ON TOOL. Serious injui'y could occur

plug the drill press in until you have read and understood if the toolis tipped or ifthe cutting toolis unintentionally

the following: contacted.

REMOVE ADJUSTING KEYS AND WRENCHES.

From the habit of checking to see that keys and

adjusting wrenches are removed from the tool before

turning "ON".

NEVER LEAVE TOOL RUNNING UNATTENDED.

TURNTHE POWER "OFF". Don't leave the tool until

it comes to a complete stop.

1. READ and become familiar with this entire instruction

manual. LEARN the tool'sapplications, limitations, and

possible hazards,

2. KEEP GUARDS IN PLACE and in working order.

3. DON'T USE IN A DANGEROUS ENVIRONMENT.

Don't use power tools in damp or wet locations, or

expose them to rain. Keep work area well lighted.

4. DO NOT use power tools inthe presence offlammable

liquids or gases.

5. KEEP WORK AREA CLEAN. Cluttered areas and

benches invite accidents.

6. KEEP CHILDREN AWAY.All visitorsshould be kept at

a safe distance from the work area.

7. DON'T FORCE THE TOOL. It will do the job better

and safer at the rate for which it was designed.

8. USE THE RIGHT TOOL. Don't force tool or the

attachment to do a job for which it was not designed.

9, WEAR PROPER APPAREL. DO NOT wear loose

clothing, gloves, neckties, rings, bracelets, or other

jewelry which may get caught in moving parts.

Nonslip footwear is recommended. Wear protective

hair covering to contain long hair.

10. WEAR A FACE MASK OR DUST MASK.

Drilling operation produces dust.

11. DISCONNECTTOOLS before servicing, and when

changing accessories, such as blades, bits, cutters,

and the like.

12. REDUCETHE RISK OF UNINTENTIONAL STARTING.

Make sure the switch is in"OFF" position before

plugging in.

13. USE RECOMMENDED ACCESSORIES. Consult the

owner's manual for the recommended accessories.

The use of improper accessories may cause risk of

injury to persons.

17. DON'T OVERREACH. Keep proper footing and

balance at all times.

18. MAINTAIN TOOLS WITH CARE. Keep tools sharp

and clean for best and safest performance. Follow

instructionsfor lubricating and changing accessories.

19. CHECK FOR DAMAGED PARTS. Before further use of

the tool, a guard or other part that is damaged should

be carefully checked to determine that it will operate

properly and perform its intended function. Check for

alignment of movingparts, binding of moving parts,

breakage of parts, mounting,and any other conditions

that may affect itsoperation. A guard or other partthat

is damaged should be properly repaired or replaced.

20. MAKE WORKSHOP KID PROOF with padlocks, master

switches, or by removing starter keys.

21. DO NOT operate the tool if you are under the influence

of any drugs, alcohol or medication that could affect

your ability to use the tool properly.

22.

Dust generated from certain materials can be

hazardous to your health. Always operate the drill

press in a well-ventilated area and provide for proper

dust removal. Use dust collection systems whenever

possible.

23. ALWAYS WEAR EYE

PROTECTION. Any drill press

can throw foreign objects into

the eyes which could cause

permanent eye damage.

ALWAYS wear Safety Goggles

(not glasses) that comply with

ANSI safety standard Z87.1. Everyday eyeglasses

have only impact-resistant lenses. They ARE NOT

safety glasses. Safety Goggles are available at Sears.

NOTE: Glasses or goggles not in compliance with

ANSI Z87.1 couldseriously hurt you when they break.

SAVE THESE INSTRUCTIONS

3

Page 4

SPECIFIC SAFETY INSTRUCTIONS

FOR THE DRILL PRESS

For your own safety, do not try to use your drill press

or plug it in untilit is completely assembled and installed

according to the instructions, and until you have read and

understood this instruction manual:

1. YOUR DRILL PRESS MUST BE BOLTED securely"

to a workbench. In addition, if there is any tendency

for your drill press to move during certain operations,

bolt the workbench to the floor.

2. THIS DRILL PRESS is intended for use in dry

conditions, indoor use only.

3.

WEAR EYE PROTECTION. USE face or dust mask

along with safety goggles if drilling operation is dusty.

USE ear protectors,especially during extended periods

of operation.

4. DO NOT wear gloves, neckties, or loose clothing.

5. DO NOT try to drill material too small to be securely

held.

6. ALWAYS keep hands out of the path of a drill bit.

Avoid awkward hand positions where a sudden slip

could cause your hand to move into the drill bit. 22.

7.

DO NOT install ol use any drill bit that exceeds

!75 mm (7") in length or extends 150 mm (6") below

the chuck jaws. They can suddenly bend outward or

break.

8. DO NOT USE wire wheels, muter bits, shaper cutters,

circle (fly) cutters, or rotary planers on this drill press.

9. WHEN cutting a large piece of material make sure it

is fully supported at the table height.

14.

SECURE WORK. Use clamps or a vise to hold the

work when practical. It's safer than using your hand

and it frees both hands to operate tool.

15.

WHEN using a drill press vise, always fasten to the

table.

16.

MAKE SURE all clamps and locks are firmly

tightened before drilling.

17.

SECURELY LOCK THE HEAD and table support to

the column, and the table to the table support before

operating the drill press.

18.

NEVER turn your drill press on before clearing the

table of all objects (tools, scraps of wood, etc.)

19.

BEFORE STARTING the operation, jog the motor

switch to make sure the drill bit does not wobble or

vibrate.

20.

LETTHE SPINDLE REACH FULL SPEED before

starting to drill. If yourdrill press makes an unfamiliar

noise or if it vibrates excessively, stop immediately,

turn the drill press off and unplug.Do not restart until

the problem is corrected.

21.

DO NOT perform layout assembly or set up work on

the table while the drill press is in operation.

USE RECOMMENDED SPEED for drillaccessory and

workpiecematerial. SEE INSTRUCTIONS that come

withthe accessory.

23.

WHEN DRILLING large diameter holes, clamp the

workpiece firmly to the table. Otherwise, the bit may

grab and spin the workpiece at high speed. DO NOT

USE fly cutters or multiple-part hole cutters, as they

can come apart or become unbalanced in use.

24.

MAKE SURE the spindle has come to a complete

stop before touching the workpiece.

10. OO NOT perform any operation freehand. ALWAYS 25.

hold the workpiece firmly against the table so it will

not rock or twist. Use clamps or a vise for unstable

workpieces.

11. MAKE SURE there are no nails or foreign objects in 26.

the part of the workpiece to be drilled.

12. CLAMP WORKPIECE OR BRACE against the left

side of the column to prevent rotation. If it istoo short

or the table is tilted, clamp solidly to the table and

use the fence provided.

13. IFTHE WORKPIECE overhangs the table such that

it will fallor tip if not held, clamp itto the table or

provide auxiliary support.

27.

SAVE THESE INSTRUCTIONS

4

TO AVOID INJURY from accidental starting, always

turnthe switch "OFF" and unplugthe drillpress before

installing or removing any accessory or attachment

or making any adjustment.

KEEP GUARDS IN PLACE and in working order.

USE ONLY SELF-EJECTING TYPE CHUCK KEY as

provided withthe drill press.

Page 5

GROUNDINGINSTRUCTIONS

INTHE EVENT OF A MALFUNCTION OR BREAKDOWN,

groundingprovides a path of least resistance for electric

current and reduces the risk of electric shock. This tool

is equipped with an electric cord that has an equipment

grounding conductor and a grounding plug. The plug

MUST be plugged into a matching receptacle that is

properly installed and grounded in accordance with ALL

local codes and ordinances.

DO NOT MODIFYTHE PLUG PROVIDED. If itwill not fitthe

receptacle, have the proper receptacle installed by a

qualified electrician.

IMPROPER CONNECTION of the equipment grounding

conductor can result in risk of electric shock. The

conductor with the green insulation (withor withoutyellow

stripes) is the equipment grounding conductor. If repair

or replacement of the electric cord or plug is necessary,

DO NOT connect the equipment grounding conductor to

a live terminal.

CHECK with a qualified electrician or service personnel if

youdo notcompletelyunderstandthe groundinginstructions,

or if you are not sure the tool is properly grounded.

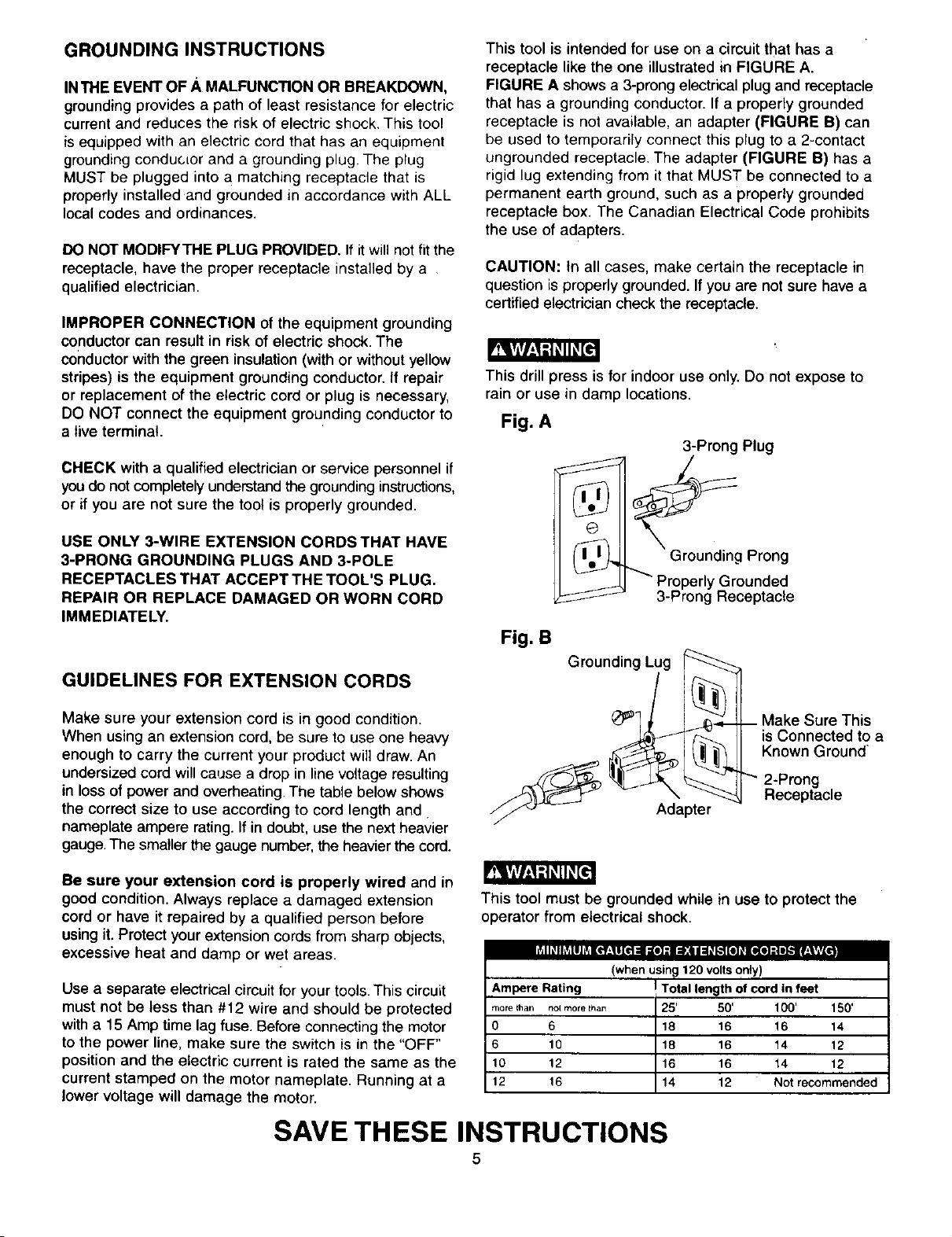

This tool is intended for use on a circuit that has a

receptacle like the one illustrated in FIGURE A.

FIGURE A shows a 3-prong electrical plug and receptacle

that has a grounding conductor. If a properly grounded

receptacle is not available, an adapter (FIGURE B) can

be used to temporarily connect this plug to a 2-contact

ungrounded receptacle. The adapter (FIGURE B) has a

rigid lug extending from it that MUST be connected to a

permanent earth ground, such as a properly grounded

receptacle box. The Canadian Electrical Code prohibits

the use of adapters.

CAUTION: tn all cases, make certain the receptacle in

question is properly grounded. If you are not sure have a

certified electrician check the receptacle.

This drill press is for indoor use only. Do not expose to

rain or use in damp locations.

Fig. A

3-Prong Plug

USE ONLY 3-WIRE EXTENSION CORDS THAT HAVE

3-PRONG GROUNDING PLUGS AND 3-POLE

RECEPTACLES THAT ACCEPT THE TOOL'S PLUG.

REPAIR OR REPLACE DAMAGED OR WORN CORD

IMMEDIATELY.

GUIDELINES FOR EXTENSION CORDS

Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one heavy

enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage resulting

in loss of power and overheating. The table below shows

the correct size to use according to cord length and.

nameplate ampere rating. If in doubt, use the next heavier

gauge. The smaller the gauge number, the heavier the cord.

Be sure your extension cord is properly wired and in

good condition. Always replace a damaged extension

cord or have it repaired by a qualified person before

using it. Protect your extension cordsfrom sharp objects,

excessive heat and damp or wet areas.

Use a separate electrical circuit for your tools. This circuit

must not be less than #12 wire and should be protected

with a 15 Amp time lag fuse. Before connectingthe motor

to the power line, make sure the switch is in the "OFF"

position and the electric current is rated the same as the

current stamped on the motor nameplate. Running at a

Jowervoltage will damage the motor.

)., Ground,n_ Prong

_- _ Properly Grounded

/

3-Prong Receptacle

Fig. B

Grounding Lug

-- Make Sure This

is Connected to a

Known Ground

"" 2-Prong

Adapter

/

This tool must be grounded while in use to protect the

operator from electrical shock.

viII_ Iht,l l j Ltl[_*f:ll[t1:11 ;[O] :1 [:l:a I :ll_I_',1Ill _.[l(e] :| e_.11r__ll,t,vl.

(when using 120 volts only)

Ampere Rating I Total length of cord in feet

morethan notmorethan 25' 50' 100' 150'

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not recommended

Receptacle

SAVE THESE INSTRUCTIONS

5

Page 6

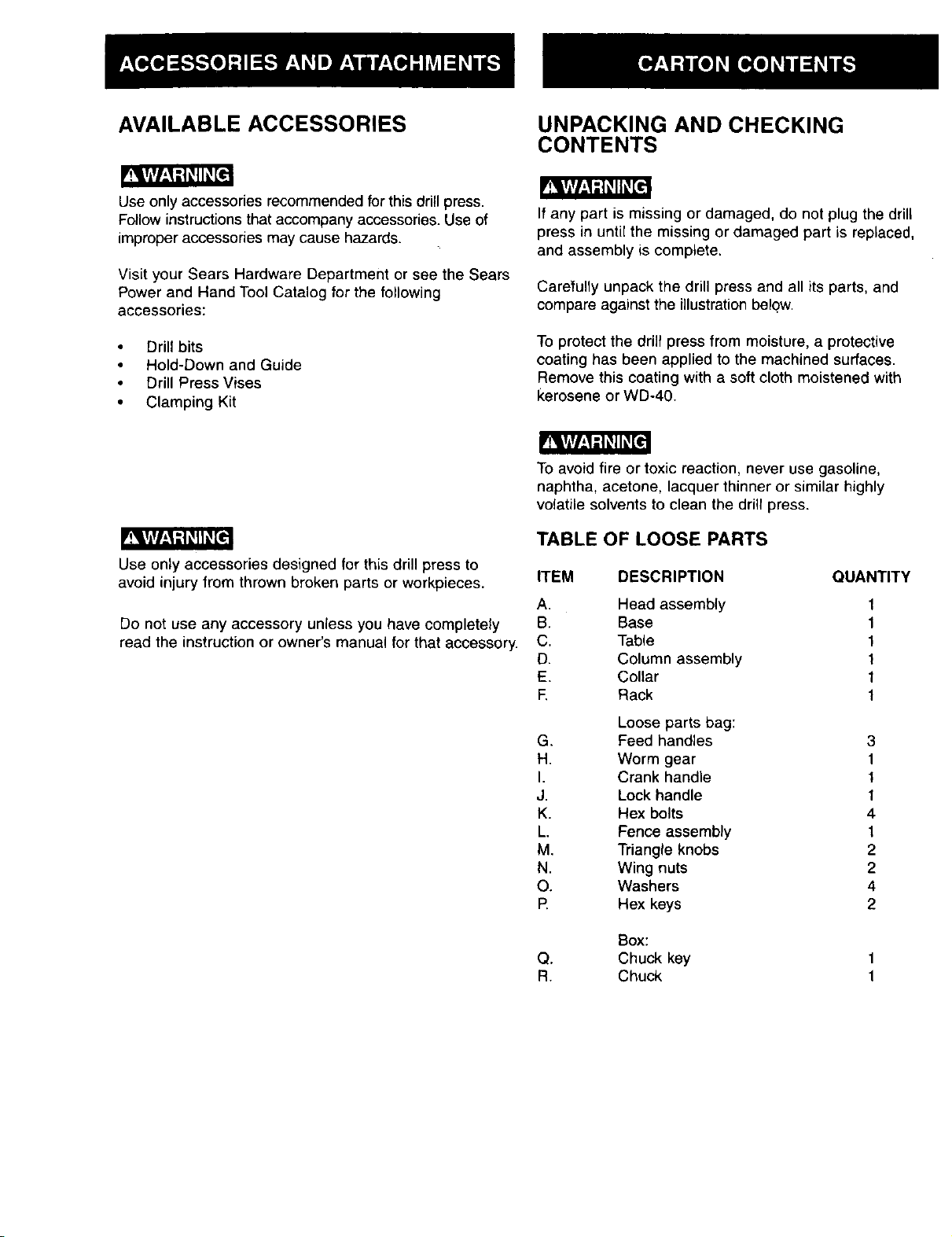

AVAILABLE ACCESSORIES

Use only accessories recommended for thisdrill press.

Follow instructions that accompany accessories. Use of

improper accessories may cause hazards.

Visit your Sears Hardware Department or see the Sears

Power and Hand Tool Catalog for the following

accessories:

UNPACKING AND CHECKING

CONTENTS

T!Ylv/_,1t,:l_ll_,[_

If any part is missing or damaged, do not plug the drill

press in until the missing or damaged part is replaced,

and assembly is complete.

Carefully unpack the drill press and all its parts, and

compare against the illustration below.

Drill bits

• Hold-Down and Guide

Drill Press Vises

• Clamping Kit

Use only accessories designed for this drill press to

avoid injury from thrown broken parts or workpieces.

Do not use any accessory unless you have completely

read the instruction or owner's manual for that accessory.

To protect the drill press from moisture, a protective

coating has been applied to the machined surfaces.

Remove this coating with a soft cloth moistened with

kerosene or WD-40.

To avoid fire or toxic reaction, never use gasoline,

naphtha, acetone, lacquer thinner or similar highly

volatile solvents to clean the drill press.

TABLE OF LOOSE PARTS

ITEM DESCRIPTION QUANTITY

A. Head assembly

B. Base

C. Table

D. Column assembly

E. Collar

F. Rack

Loose parts bag:

G. Feed handles

H. Worm gear

I. Crank handle

J. Lock handle

K. Hex bolts

L. Fence assembly

M. Triangle knobs

N. Wing nuts

O. Washers

P. Hex keys

1

1

1

1

1

1

3

1

1

1

4

1

2

2

4

2

Box:

Q. Chuck key

R. Chuck

Page 7

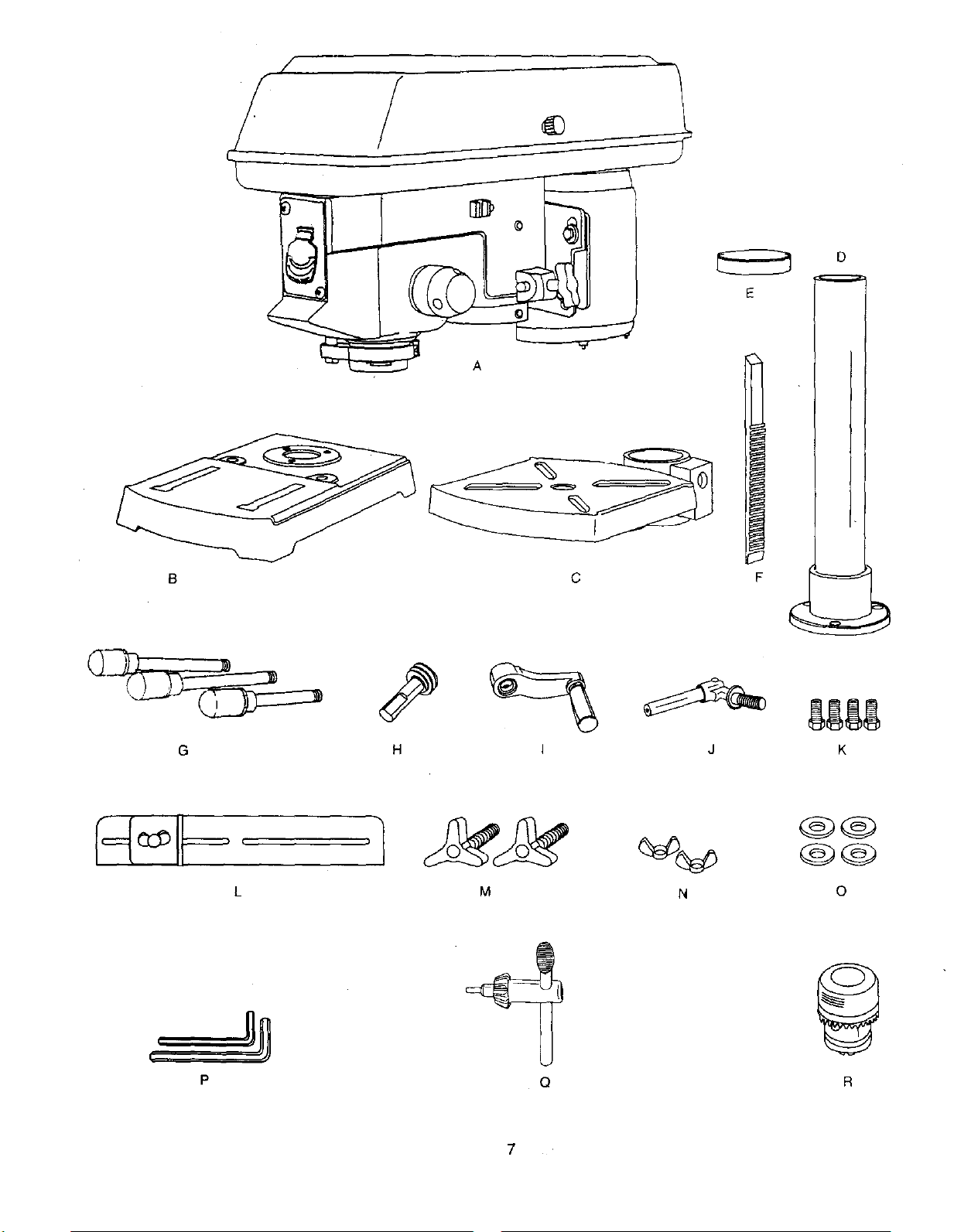

F

G H I J K

L

P

M N 0

Q R

7

Page 8

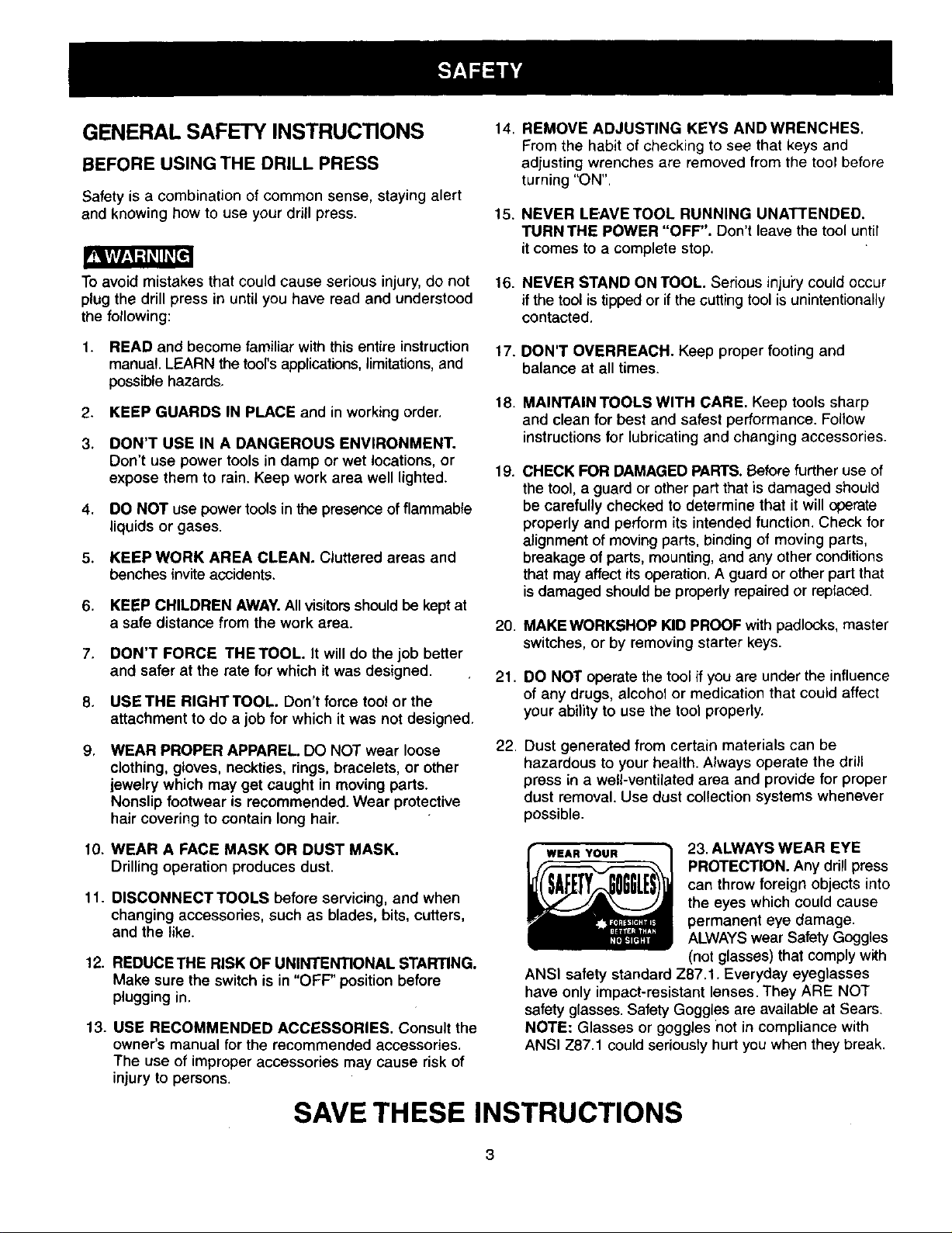

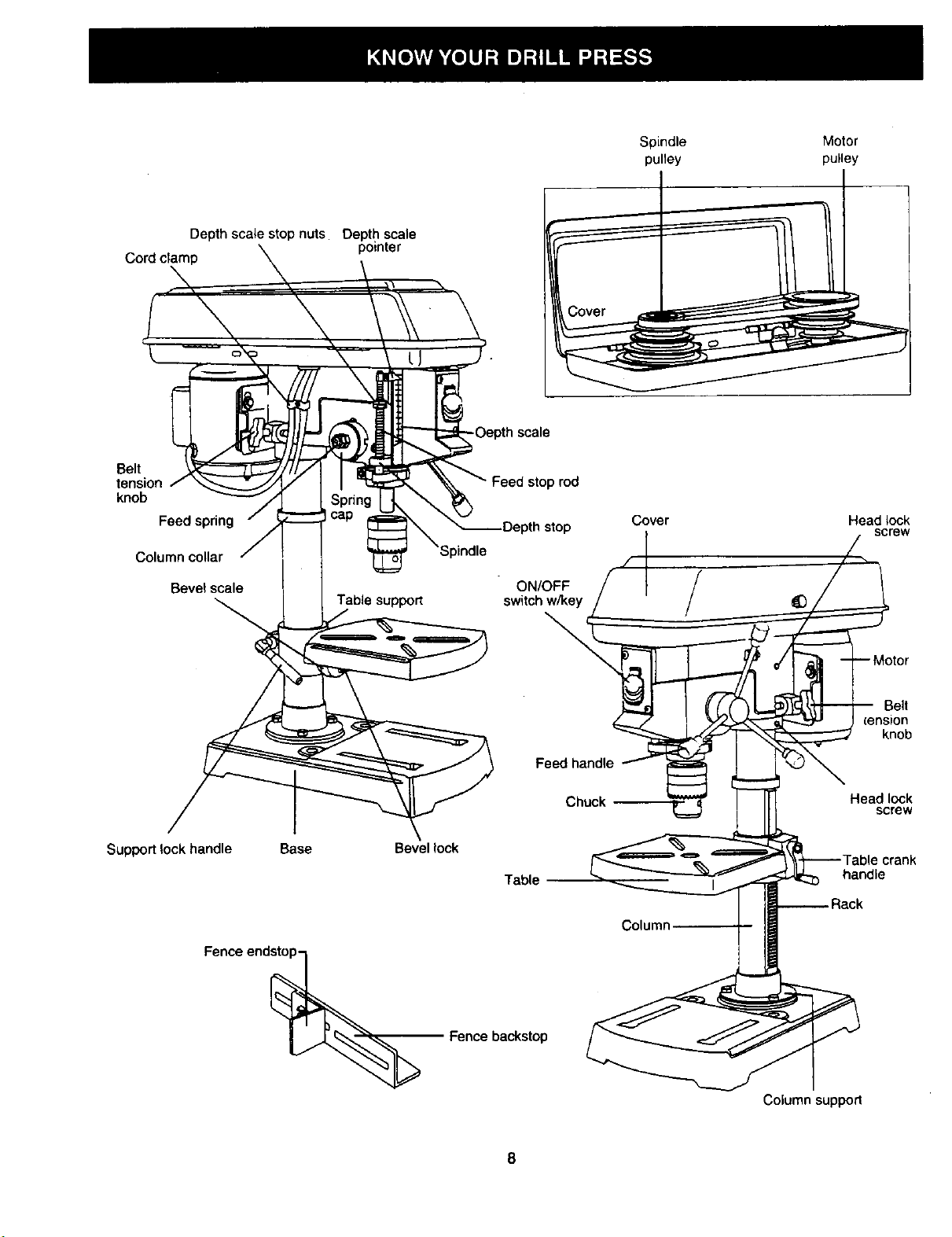

Spindle Motor

pulley pulley

Cord clamp

Belt

tension

knob

Feed spring

Column collar

Depth scale stop nuts Depth scale

pointer

Bevel scale

Table support

, rod

Depth stop Cover

Head lock

/ screw

( _.

/

;tor

Support lock handle Base

Fence end_

Bevel lock

Table

Fence backstop

elt

Head lock

screw

----_Table crank

handle

Rack

I

Column support

Page 9

BASE- Supports the drill press. For additional stability,

holes are provided in the base to bolt the drill press to

the floor.(See "Specific Safety Instructions for Drill Presses".)

BACKUP MATERIAL - A piece of scrap wood placed

between the workpiece and table. The backup board

prevents wood in the workpiece from splintering when the

drill passes through the backside of the workpiece. It also

prevents drilling into the table top.

BELT GUARD ASSEMBLY - Covers the pulleys and belt

during operation of the ddll press.

BELT TENSION - Refer to the "Assembly" Section,

"Installing and Tensioning Belt."

BELT TENSION KNOB - Tightening the knob locks

the motor bracket support maintaining correct belt distance

and tension.

BEVEL SCALE - Shows the degree of table tilt for bevel

operations.The scale is mounted on the side of the arm.

CHUCK - Holds the drill bit or other recommended

accessory to perform desired operations.

CHUCK KEY -A self-ejecting chuck key which will pop

out of the chuck when you let go of it. This action is

designed to help prevent throwing of the chuck key from

the chuck when the power is turned "ON". Do not use

any other key as a substitute;order a new one if damaged

or lost.

DRILL ON/OFF SWITCH - Has locking feature. This

feature is intended to help prevent unauthorized and

possible hazardous use by children and others. Insert the

key into the switch to turn the drill press on.

DRILLING SPEED - Changed by placing the belt in any

of the steps (grooves) in the pulleys. See the Spindle

Speed Chart inside the belt guard.

FEED HANDLE - Moves the chuck up or down. If

necessary, one or two of the handles may be removed

whenever the workpiece is of such unusual shape that it

interferes with the handles.

FENCE - Attaches to the table to align the workpiece or

for fast repetitive drilling.Removable. Remove fence when

it interferes with other drill press accessories.

HEAD LOCKS -Locks the head to the column. ALWAYS

lock the head in place while operating the drill press.

RACK - Combines with gear mechanism to provide easy

elevation of the table by the hand operated table crank.

REVOLUTION PER MINUTE (R.P.M.) - The number of

turns completed by a spinning object in one minute.

SPINDLE SPEED -The R.P.M. of the spindle.

SPRING CAP - Adjusts quill spring tension.

TABLE - Provides working surface to support workpiece.

COLUMN - Connects the head, table, and base on a

one-piece tube for easy alignment and movement.

COLUMN COLLAR - Holds the rack to the column.

Rack remains movable in the collar to permit table

support movements.

COLUMN SUPPORT - Supports the column, guides the

rack and provides mounting holes for column to base.

DEPTH SCALE - Indicates depth of hole being drillecl

DEPTH SCALE POINTER - Indicates the drilling depth

by pointing to the depth scale.

DEPTH SCALE STOP NUTS - Locks the depth scale to

selected depth.

DRILL BIT - The cuttingtool used in the drill pressto

make holes in a workpiece.

TABLE BEVEL LOCK - Locksthe table in any position

from 0°- 45°.

TABLE CRANK HANDLE - Elevates and lowers table.

Turn clockwise to elevate table. Support lock must be

released before operating crank.

TABLE SUPPORT LOCK -Tightening locks the table

support to the column. Always have it locked in place

while operating the drill press.

TABLE SUPPORT - Rides on the column to support the

table.

WORKPIECE - Material being drilled.

Page 10

ASSEMBLY INSTRUCTIONS

For your own safety, never connect plug to power source

outlet until all assembly and adjustment steps are

completed, and you have read and understood the safety

and operating instructions.

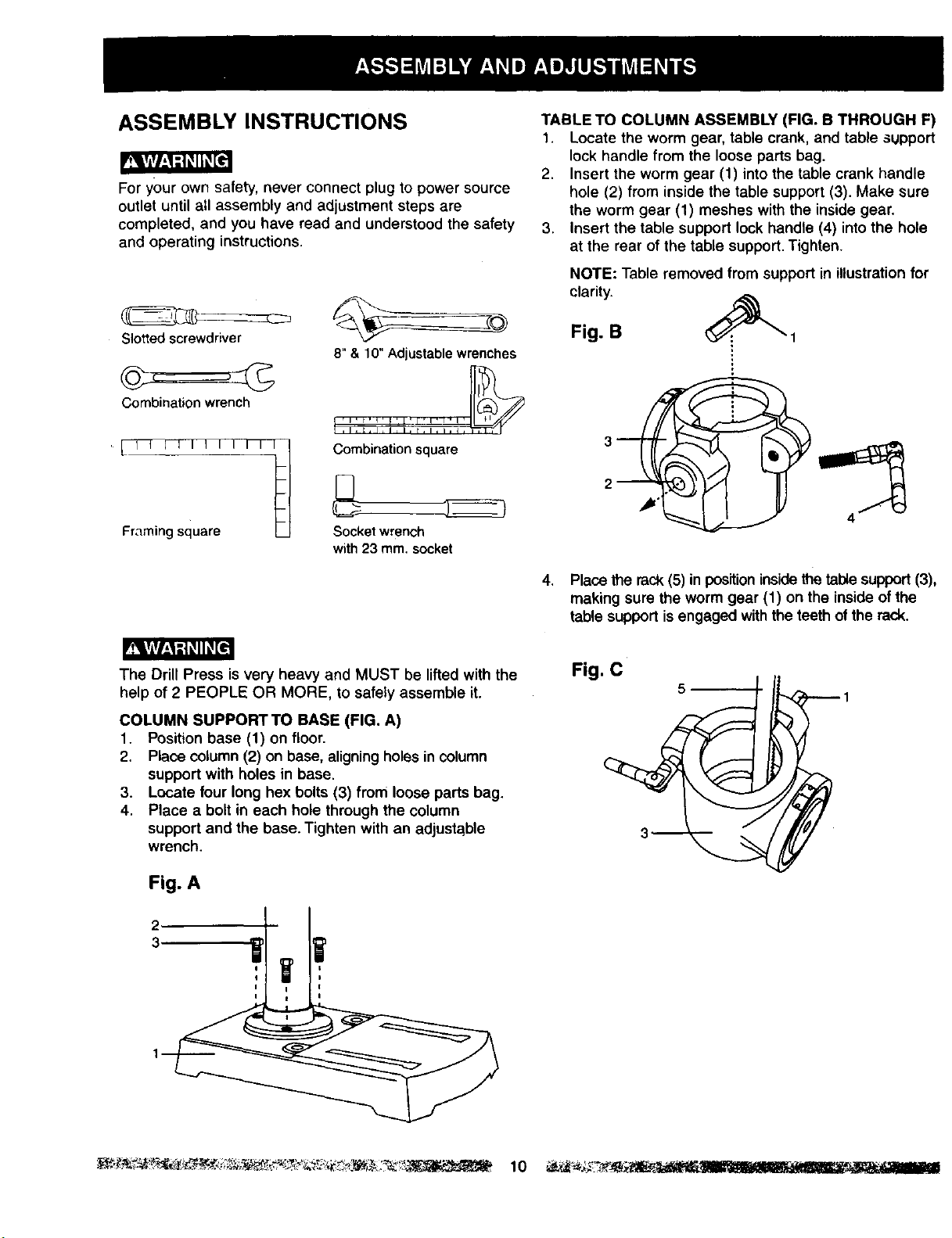

TABLE TO COLUMN ASSEMBLY (FIG. B THROUGH F)

1. Locate the worm gear, table crank, and table support

lock handle from the loose parts bag.

2. Insert the worm gear (1) into the table crank handle

hole (2) from inside the table support (3). Make sure

the worm gear (1) meshes with the inside gear.

3. Insert the table support lock handle (4) into the hole

at the rear of the table support. Tighten.

NOTE: Table removed from support in illustrationfor

clarity.

Slotted screwdriver

8"& 10"Adjustable wrenches

Combination wrench

Combination square

L I ] T_I I I I I I I I

Framing square

Socket wrench

with23 mm. socket

The Drill Press is very heavy and MUST be lifted with the

help of 2 PEOPLE OR MORE, to safely assemble it.

COLUMN SUPPORTTO BASE (FIG. A)

1. Position base (1) on floor.

2. Place column (2) on base, aligning holes incolumn

support with holes in base.

3. Locate four long hex bolts (3) from loose parts bag.

4. Place a bolt in each hole through the column

support and the base. Tighten with an edjust_ble

wrench.

Fig. B _ 1

4. Place the rack (5) in position inside the table support(3),

making sure the worm gear (1) on the insideof the

table support is engaged with the teeth of the rack.

Fig. C

3 !

Fig. A

2

Page 11

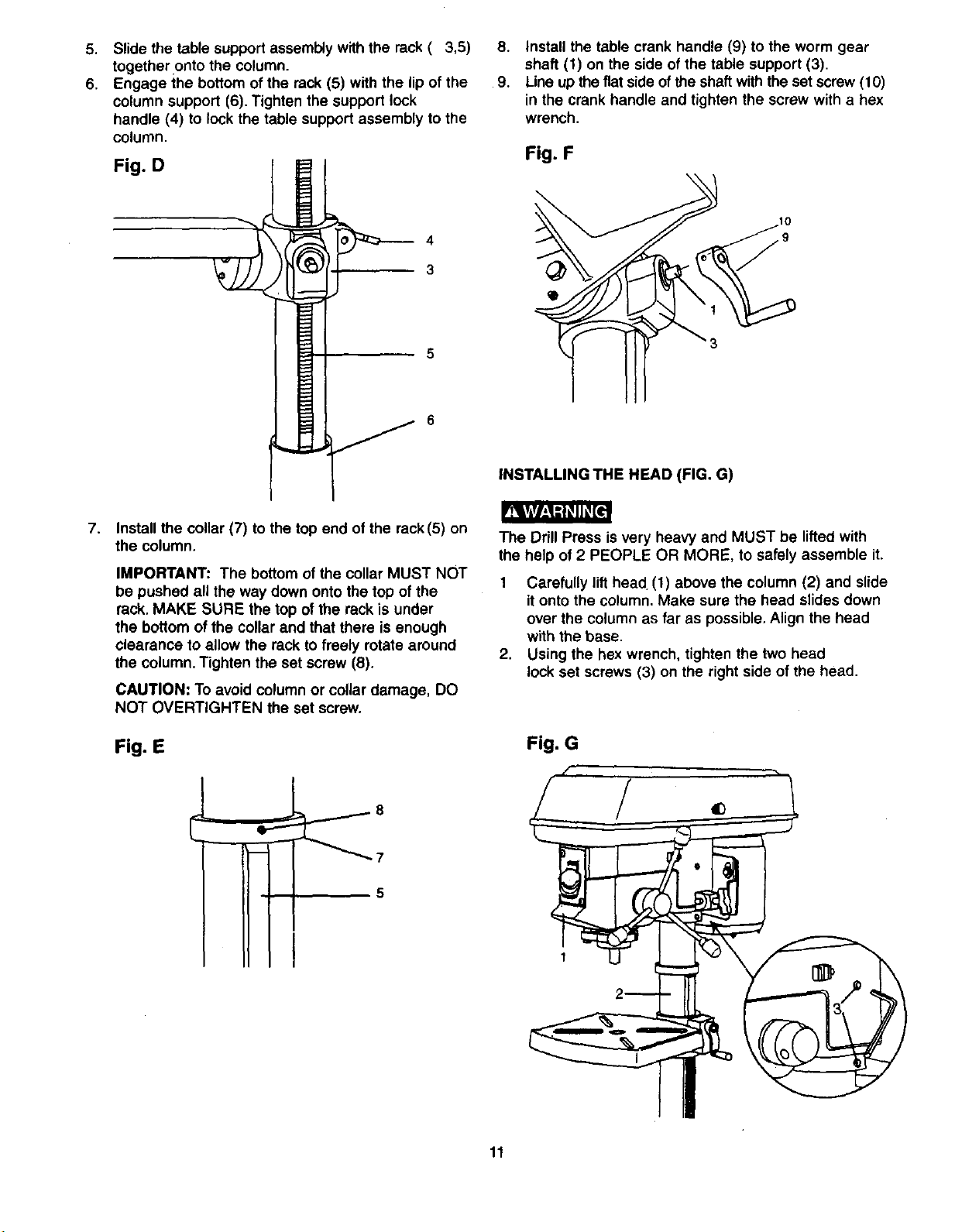

,

Slide the table support assemblywith the rack (3,5)

together onto the column.

6.

Engage the bottom of the rack (6) with the lip of the

column support (6). Tighten the support lock

handle (4) to lock the table support assembly to the

column.

Fig. D

8. Install the table crank handle (9) to the worm gear

shaft (1) on the side of the table support (3).

9. Line up the fiat side ofthe shaftwith the set screw (10)

in the crank handle and tighten the screw with a hex

wrench.

Fig. F

4

3

5

6

INSTALLING THE HEAD (FIG. G)

7,

Install the collar (7) to the top end of the rack (5) on

the column.

IMPORTANT: The bottom of the collar MUST NOT

be pushed all the way down onto the top of the

rack. MAKE SURE the top of the rack is under

the bottom of the collar and that there is enough

clearance to allow the rack to freely rotate around

the column. Tighten the set screw (8).

CAUTION: To avoid column or collar damage, DO

NOT OVERTIGHTEN the set screw.

Fig. E

The Drill Press is very heavy and MUST be lifted with

the help of 2 PEOPLE OR MORE, to safely assemble it.

1 Carefully lift head (1) above the column (2) and slide

it onto the column. Make sure the head slides down

over the column as far as possible. Align the head

with the base.

2, Using the hex wrench, tighten the two head

lock set screws (3) on the right side of the head.

Fig. G

11

Page 12

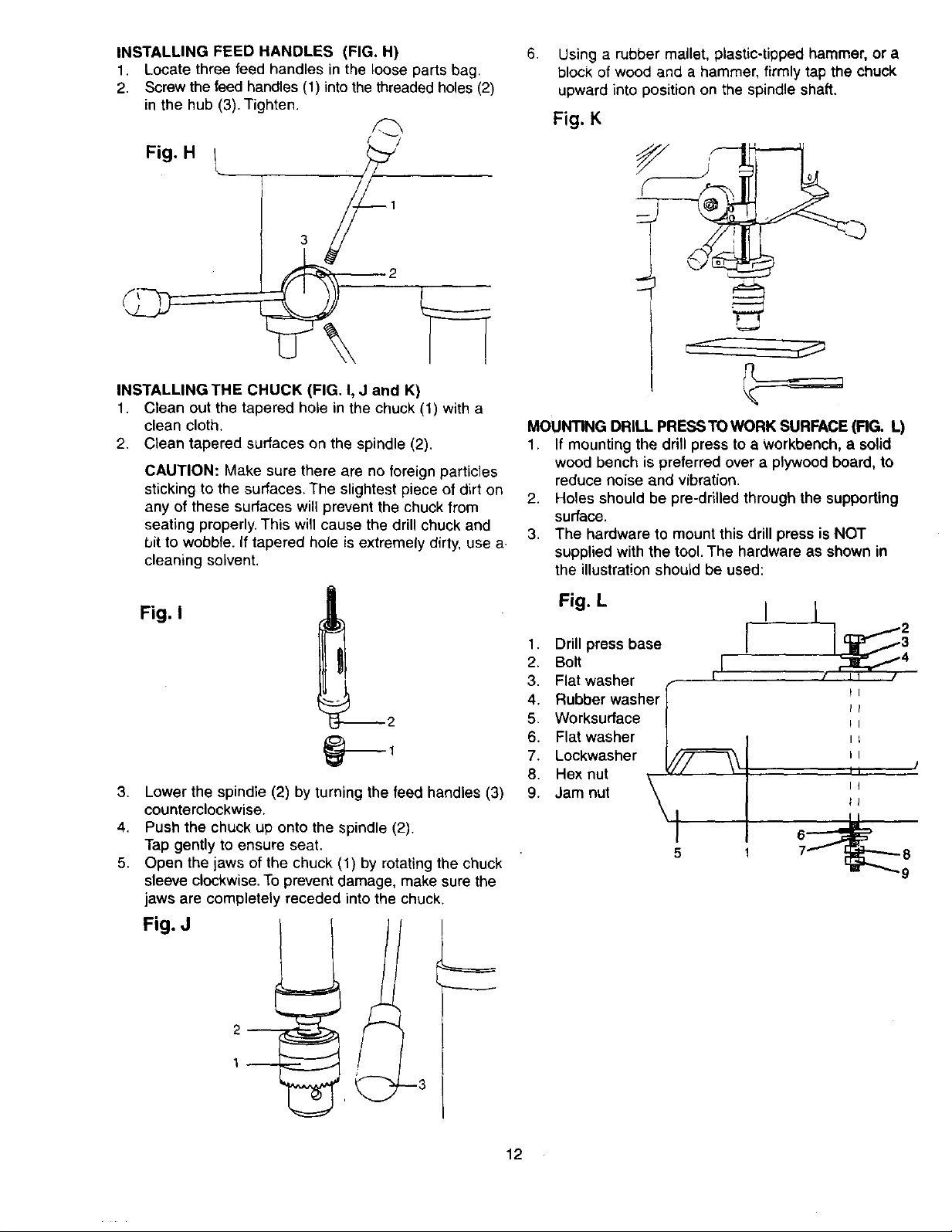

INSTALLINGFEEDHANDLES(FIG.H)

1. Locate three feed handles in the loose parts bag.

2. Screw the feed handles (1) into the threaded holes(2)

in the hub (3). Tighten.

Fig. H _ _

INSTALLING THE CHUCK (FIG. I, J and K)

1. Clean out the tapered hole in the chuck (1) with a

clean cloth.

2. Clean tapered surfaces on the spindle (2).

CAUTION: Make sure there are no foreign particles

sticking to the surfaces. The slightest piece of dirt on

any of these surfaces wilt prevent the chuck from

seating properly. This will cause the drill chuck and

bit to wobble. If tapered hole is extremely dirty, use a-

cleaning solvent.

6.

Using a rubber mallet, plastic-tipped hammer, or a

block of wood and a hammer, firmly tap the chuck

upward into position on the spindle shaft.

Fig. K

MOUNTING DRILL PRESSTOWORK SURFACE (FIG. L)

1. If mounting the drill press to a workbench, a solid

wood bench is preferred over a plywood board, to

reduce noise and vibration.

2. Holes should be pre-drilled through the supporting

surface.

3. The hardware to mount this drill press is NOT

supplied with the tool. The hardware as shown in

the illustration should be used:

Fig. I

3. Lower the spindle (2) by turning the feed handles (3)

counterclockwise.

4. Push the chuck up onto the spindle (2).

Tap gently to ensure seat.

5. Open the jaws of the chuck (1) by rotating the chuck

sleeve clockwise. To prevent damage, make sure the

jaws are completely receded into the chuck.

Fig. J

Fig. L

1. Drill press base

2. Bolt

3. Flat washer (--

4. Rubber washer |

5. Worksurface |

6. Flat washer

7. Lockwasher _

8. Hex nut

9. Jam nut _ ]

I I

II I

II

IJ

5

12

Page 13

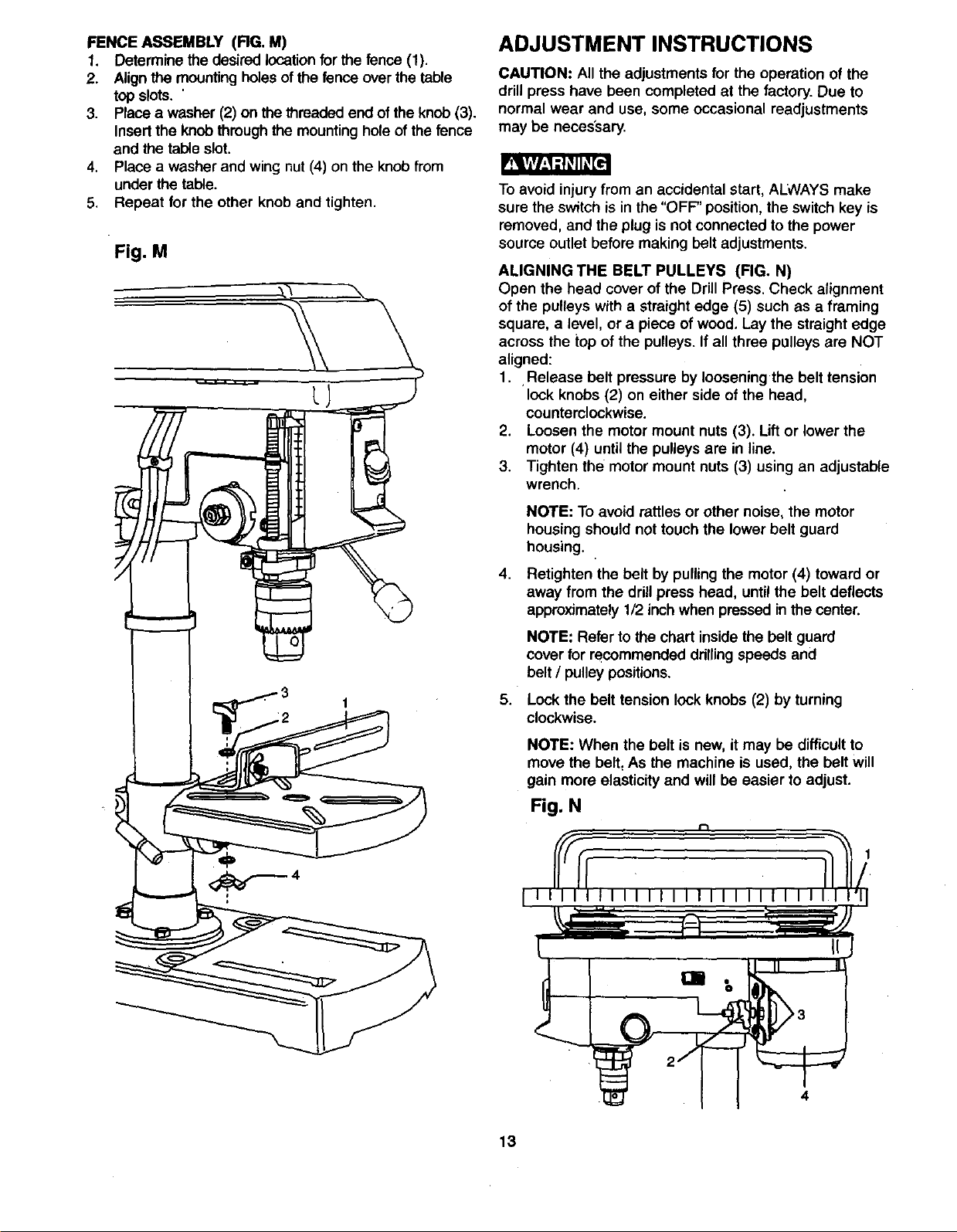

FENCE ASSEMBLY (RG, M)

1. Determine the desiredlocationfor the fence (1).

2. Align the mounting holesof the fence over the table

top slots. '

3. Place a washer (2) on the threaded end ofthe knob (3).

Insertthe knobthrough the mountinghole of the fence

and the table slot.

4. Place a washer and winGnut (4) on the knob from

under the table.

5. Repeat for the other knob and tighten.

Fig. M

ADJUSTMENT INSTRUCTIONS

CAUTION: All the adjustments for the operation of the

drill press have been completed at the factory. Due to

normal wear and use, some occasional readjustments

may be necessary.

V_rI_,_{_I_ [e

To avoid injury from an accidental start, ALWAYS make

sure the sw_tchis in the "OFF" position, the switch key is

removed, and the plug is not connected to the power

source outlet before making belt adjustments.

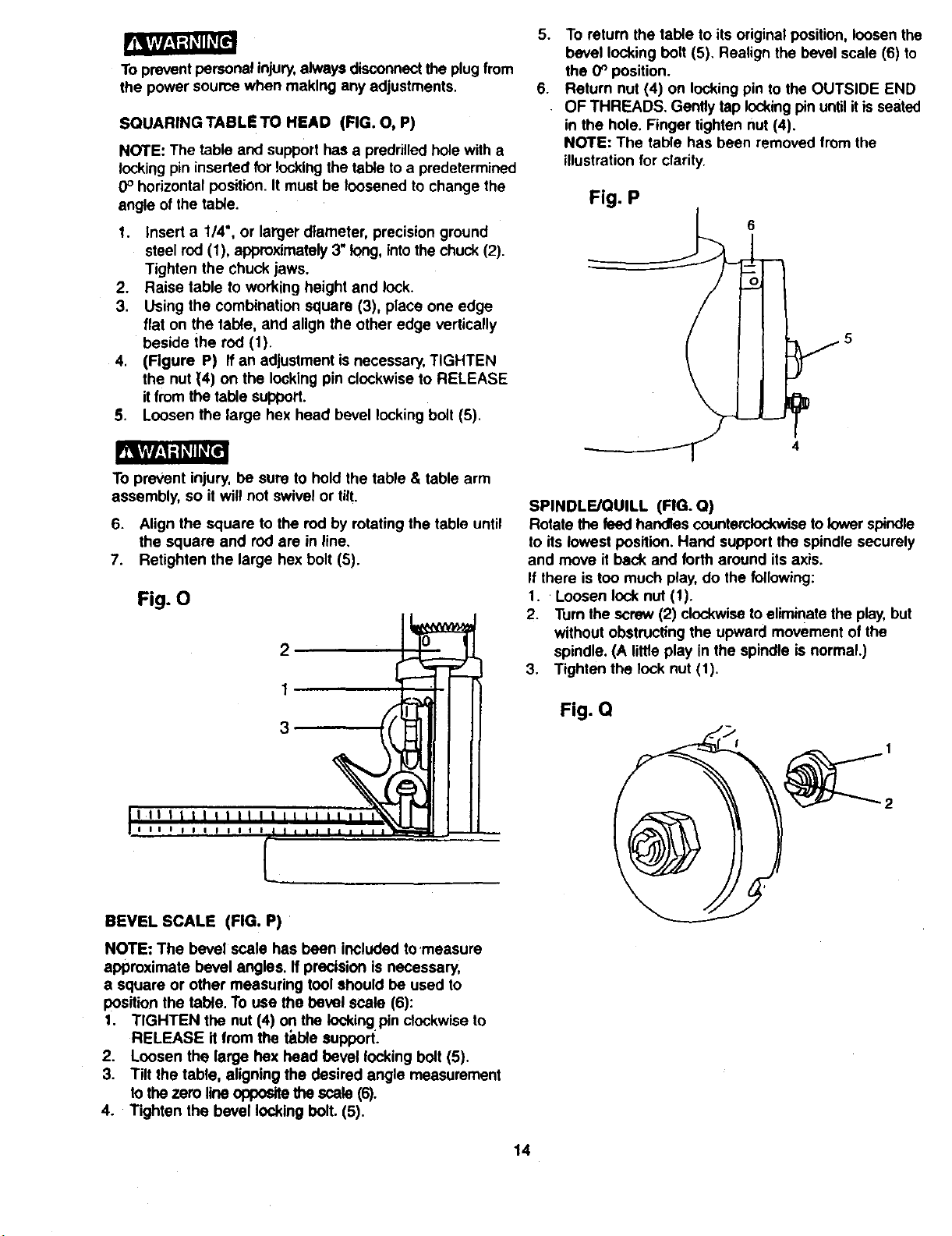

ALIGNING THE BELT PULLEYS (FIG. N)

Open the head cover of the Drill Press. Check alignment

of the pulleys with a straight edge (5) such as a framing

square, a level, or a piece of wood, Lay the straight edge

across the top of the pulleys. If all three pulleys are NOT

aligned:

1.. Release belt pressure by loosening the belt tension

lock knobs (2) on either side of the head,

counterclockwise.

2. Loosen the motor mount nuts (3). Lift or lower the

motor (4) until the pulleys are in line.

3. Tighten the motor mount nuts (3) using an adjustable

wrench.

NOTE: To avoid rattles or other noise, the motor

housing should not touch the lower belt guard

housing.

4.

Retighten the belt by pulling the motor (4) toward or

away from the drill press head, until the belt deflects

approximately 1/2 inch when pressed in the center.

NOTE: Refer to the chart insidethe belt guard

cover for recommended ddllingspeeds and

belt / pulley positions.

5.

Lock the belt tension lock knobs (2) by turning

clockwise.

NOTE: When the belt is new, it may be difficult to

move the belt, As the machine is used, the belt will

gain more elasticity and will be easier to adjust.

Fig. N

13

Page 14

To prevent personal injury,always disconnectthe plug from

the power source when making any adjustments.

SQUARINGTABLETO HEAD (FIG. O, P)

NOTE: The table and support has a predrilledhole with a

locking pin inserted for locking the table to a predetermined

0° horizontal position. It must be loosened to change the

angle of the table.

1. Insert a 1/4", or larger diameter, precision ground

steel rod (1), approximately 3"long, intothe chuck (2).

Tighten the chuck jaws.

2. Raise table to working height and lock.

3. Using the combination square (3), place one edge

flat on the table, and align the other edge vertically

beside the rod (1).

4. (Figure P) If an adjustment is necessary,TIGHTEN

the nut (4) on the looking pin clockwise to RELEASE

it from the table support.

5. Loosen the large hex head bevel locking bolt (5).

To prevent injury, be sure to hold the table & table arm

assembly, so it will not swivel or tilt.

6. Align the square to the rod by rotating the table until

the square and rod are in line.

7. Retighten the large hex bolt (5).

Fig. O

2

1

3

5. To return the table to its original position, loosenthe

bevel locking bolt (5). Realign the bevel scale (6) to

the 0_position.

6. Return nut (4) on lockingpin to the OUTSIDE END

OF THREADS. Gently tap lockingpinuntil itis seated

in the hole. Finger tighten nut (4).

NOTE: The table has been removed from the

illustration for clarity.

Fig. P

6

SPINDLE/QUILL (RG. Q)

Rotate the feed handles counterclockwiseto lowerspindle

to itslowest position. Hand support the spindle securely

and move it back and forth around its axis.

If there is too much play,do the following:

1. Loosen lock nut (1).

2. Turn the screw (2) clockwiseto eliminate the play, but

without obstructing the upward movement of the

spindle. (A little play in the spindle is normal.)

3. Tighten the lock nut (1).

Fig. Q

BEVEL SCALE (FIG. P)

NOTE: The bevel scale has been included to'measure

approximate bevel angles. If precision is necessary,

a square or other measuring tool should be used to

position the table. To use the bevel scale (6):

1. TIGHTEN the nut (4) on the locking pinclockwise to

RELEASE it from the table support.

2. Loosen the large flex head bevel locking bolt (5).

3. Tilt the table, aligning the desired angle measurement

to the zero line oppositethe scale (6).

4. Tighten the bevel locking bolt. (5).

14

Page 15

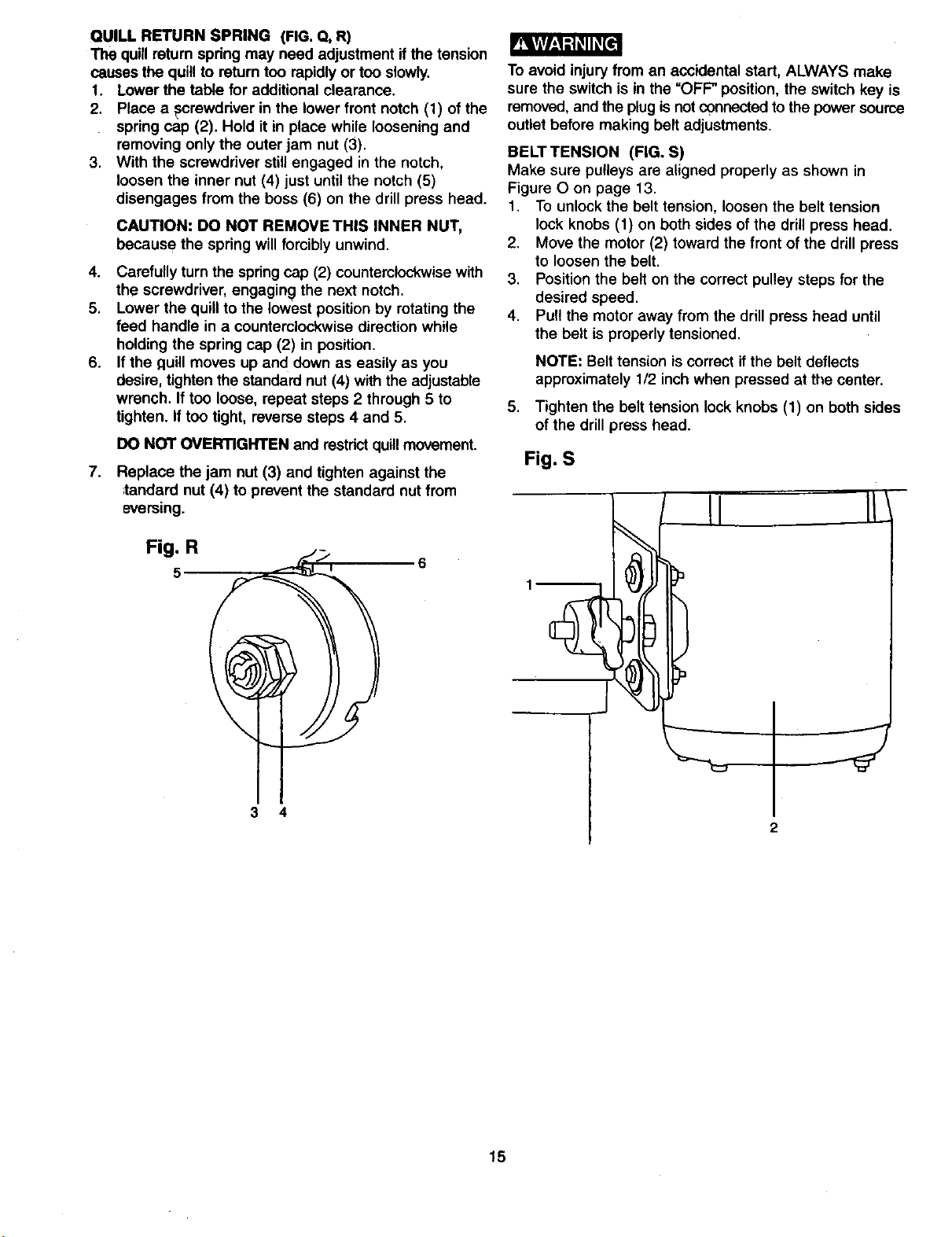

QUILL RETURN SPRING (FIG. Q, R)

The quillreturn spring may need adjustment if the tension

causes the quill to return too rapidlyor too slowly,

1. Lower the table for additional clearance.

2. Place a pcrewdr_ver in the lower front notch (1) of the

spring cap (2). Hold it inplace while loosening and

removing only the outer jam nut (3).

3. With the screwdriver stillengaged in the notch,

loosen the inner nut (4) just until the notch (5)

disengages from the boss (6) on the drill press head.

CAUTION: DO NOT REMOVETHIS INNER NUT,

because the spring will forciblyunwind.

4. Carefully turn the spring cap (2) counterclockwise with

the screwdriver, engaging the next notch.

5. Lower the quillto the lowest position by rotating the

feed handle in a counterclockwise direction while

holding the spring cap (2) in position.

6. If the quill moves up and down as easily as you

desire, tighten the standard nut (4) with the adjustable

wrench. If too loose, repeat steps 2 through 5 to

tighten. If too tight, reverse steps 4 and 5.

DO NOT OVERTIGHTEN and restdct quillmovement.

7. Replace the jam nut (3) and tighten against the

,tandard nut (4) to prevent the standard nut from

eversmg.

_vlvl-1_l L'ql_(

To avoid injury from an accidental start, ALWAYS make

sure the switch is in the =OFF" position, the switch key is

removed, and the plugis not connectedto the power source

outlet before making belt adjustments.

BELTTENSION (FIG. S)

Make sure pulleys are aligned properly as shown in

Figure O on page 13.

1. To unlockthe belt tension, loosen the belt tension

lock knobs (1) on both sides of the drill press head.

2. Move the motor (2) toward the front of the drill press

to loosen the belt.

3. Position the belt on the correct pulley steps for the

desired speed.

4. Pull the motor away from the drill press head until

the belt is properly tensioned.

NOTE: Belt tension is correct if the belt deflects

approximately 1/2 inch when pressed at the center.

5. Tighten the belt tension lock knobs (1) on both sides

of the drill press head.

Fig. S

Fig. R

1

J

3 4

15

Page 16

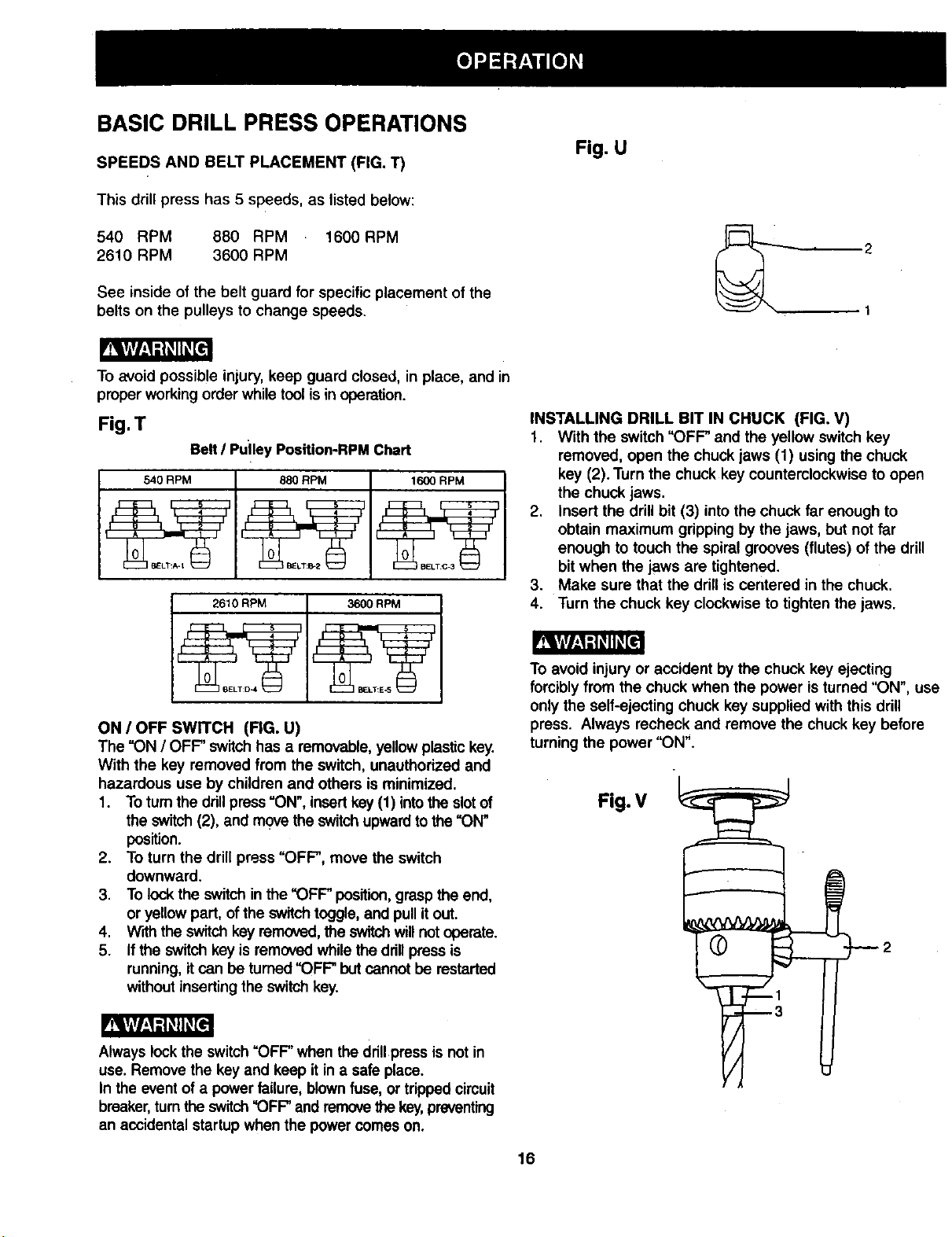

BASIC DRILL PRESS OPERATIONS

SPEEDS AND BELT PLACEMENT (FIG. T)

This drill press has 5 speeds, as listed below:

540 RPM 880 RPM 1600RPM

2610 RPM 3600 RPM

See inside of the belt guard for specific placement of the

belts on the pulleys to change speeds.

To avoid possible injury, keep guard closed, in place, and in

proper working order while tool is in operation.

Fig. T

Belt I Puiley Position-RPM Chart

540 RPM 880 RPM 1600 RPM

2610 RPM 3600 RPM

Fig. U

INSTALLING DRILL BIT IN CHUCK (FIG. V)

1. With the switch "OFF" and the yellow switchkey

removed, open the chuck jaws (1) using the chuck

key (2). Turn the chuck key counterclockwise to open

the chuck jaws.

2. Insert the drill bit (3) into the chuck far enough to

obtain maximum gripping by the jaws, but not far

enough to touch the spiral grooves (flutes) of the drill

bit when the jaws are tightened.

3. Make sure that the drill is centered in the chuck.

4. Turn the chuck key clockwise to tighten the jaws.

ON / OFF SWITCH (FIG. U)

The "ON / OFF' switchhas a removable, yellowplastickey.

With the key removed from the switch, unauthorized and

hazardous use by children and others is minimized.

1. To turnthe drillpress "ON", insert key (1) intothe slotof

the switch (2), and move the switch upwardto the "ON"

position.

2. To turn the drill press "OFF", move the switch

downward.

3. To lock the switch inthe "OFF position, graspthe end,

or yellow part, ofthe switchtoggle, and pullit out.

4. With the switchkey removed,the switchwillnotoperate.

5. If the switch key is removedwhile the ddllpress is

running,it can be turned"OFF" but cannot be restarted

without insertingthe switch key.

Always lock the switch"OFF" when the drill press is not in

use. Remove the key and keep it in a safe place.

In the event of a powerfailure, blownfuse, or tripped circuit

breaker,turn the switch"OFF' and removethe key,preventing

an accidental startup when the power comes on.

To avoid injury or accident by the chuck key ejecting

forcibly from the chuck when the power is turned "ON", use

only the self-ejecting chuck key supplied with this drill

press. Always recheck and remove the chuck key before

turning the power "ON".

Fig. V

16

Page 17

Fig. X

To prevent the workpiece or backup material from being

torn from your hands whiledrilling,you MUST positionthe

workpiece against the LEFT side of the column. If the

workpiece or the backupmaterial is not longenough to

reach the column, clamp them to the table, or use the fence

providedwith the drillpressto brace theworkpiece. Failure

to secure the workpiece could result inpersonal injury.

USINGTHE FENCE (FIG. W)

The fence provides a way of accurately and quickly

setting up the workpiece for more precision or repetitive

drillingoperations.

1. Using the centerpunch or sharp nail, make an

indentation in the workpiece where you want to drill.

2. Lower the drillbit to align with the indentation on the

workpiece. See =HOLDING A DRILLING LOCATION"

page 19.

3. Loosen the knobs(1) and slide the fence back stop (2)

firmly against the longside of the workpiece. Tighten

the knobs when in position.

4. Loosenthe wing nut(3) and slide theend stop (4) along

the fence until it is firmly against the leftside of the

workpiece. Tighten the wing nut.

5. Check the accuracy by drillinga scrap workpiece.

Adjust if needed.

6. Hold with your hand orclamp the top surface ofthe

workpiece firmly to prevent it from liftingoff the table

when the bit is raised.

Fig, W

1

2

Depth scale method (FIG. Y)

NOTE: With the chuck up, the tip of the drill bit must be

just slightly above the top of the workpiece.

!. With the switch "OFF', turn the feed handle until

the pointer (7) points to the desired depth on the

depth scale (4). Hold the feed handles inthat position.

2. Spin the lower nut (3) down to contact the depth stop

lug (6) on the head.

3. Spin the upper stop nut (5) against the lower stop nut

and tighten.

4. The and drill bit will now stop after traveling the

distance selected on the depth scale.

Drilling a hole

Using a center punch or a sharp nail, dent the workpiece

where you want the hole. Before turning the switchon,

bring the drillbit down to the workpiece, lining it up with

the hole location.Turn the switch on and pull down on

the feed handles with only enough effort to allow the drill

to cut.

FEEDING TOO SLOWLY might cause the drill bit to turn.

FEEDING TOO RAPIDLY mightstop the motor,cause the

belt or drillto slip, tear the workpiece loose, or break the

drillbit.When drilling metal, it will be necessary to

lubricate the tip of the drill bitwith oil to prevent it from

overheating.

DRILLING TO A SPECIFIC DEPTH

Drilling a blind hole (not all the way throughworkpiece)

to a given depth can be done two ways:

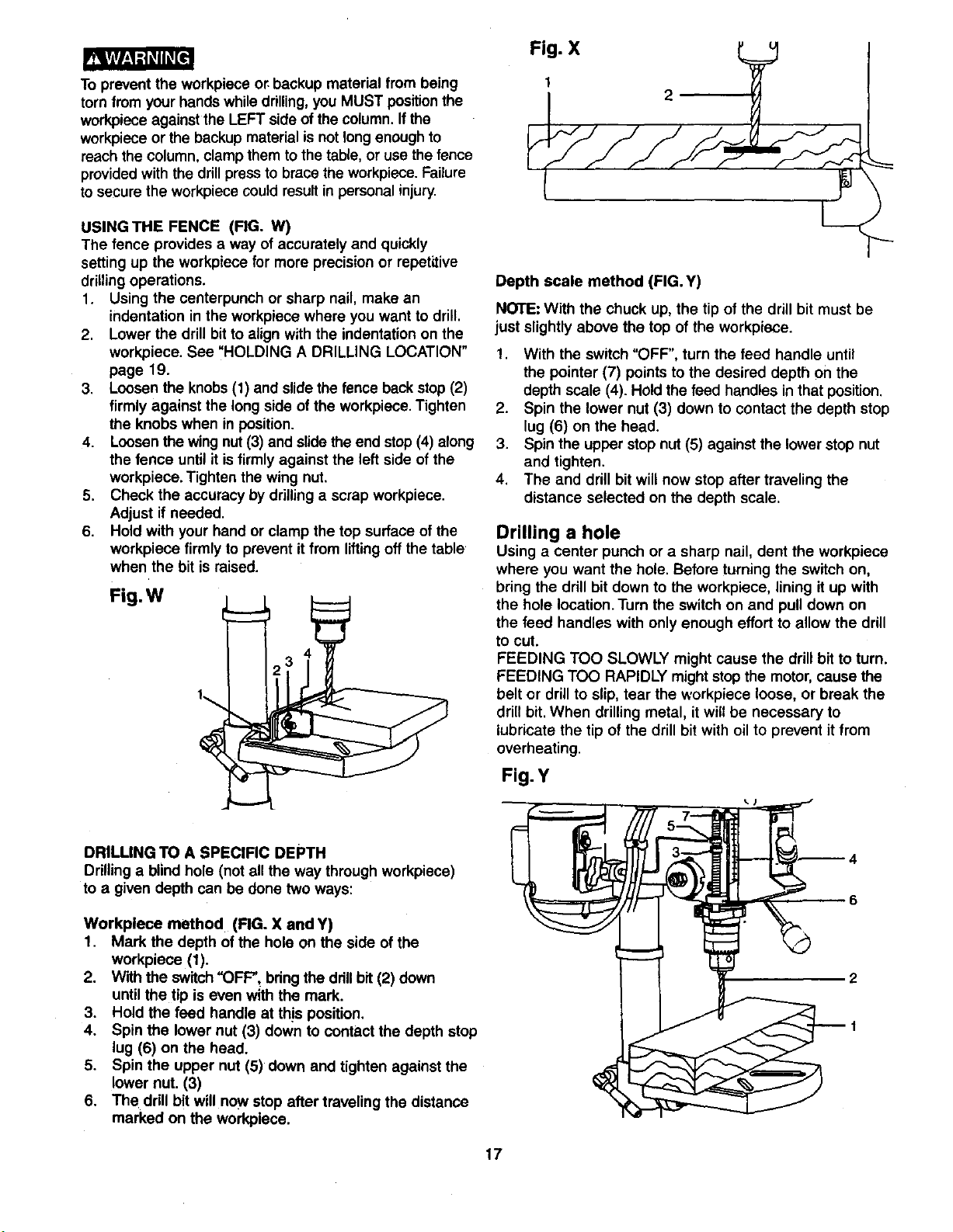

Workplece method (FIG. X and Y)

1. Mark the depth of the hole on the side of the

workpiece (1).

2. With the switch "OFF", bdng the drillbit (2) down

until the tip is even with the mark.

3. Hold the feed handle at th!s position.

4. Spin the lower nut (3) down to contact the depth stop

lug (6) on the head.

5. Spin the upper nut (5) down and tighten against the

lower nut. (3)

6. The drill bitwill now stop after traveling the distance

marked on the workpiece.

Fig. Y

17

Page 18

REMOVING CHUCK (FIG. Z)

1. With the switch=OFF", open the jaws of the chuck as

wide as possiblebyturningthe chuckcounterclockwise.

2. Tap the chuck (1) lightly with a plastictipped hammer

at the top of chuck, until the chuck releases.

NOTE: Place one hand belowthe chuckto catchit when

it'fallsout.

Fig. Z

To avoid injury from an accidental start, ALWAYS make

sure the switch is in the "OFP position, the switch key is

removed, and the plug is notconnected to the power

source outlet before removing or installingthe chuck.

BASIC OPERATION INSTRUCTIONS

To get the best results and minimize the likelihood of

personal injury,follow these instructionsfor operating your

drill press.

For your own safety, always observe the safety

INSTRUCTIONS listed here and on pages 3, 4, and 5

of the instruction manual.

YOUR PROTECTION

b. Whenever possible, positionthe WORKPIECE to

contactthe leftside of the column.If it istoo short

or the table is tilted, use the fence provided or

clamp solidly to the table, using the table slots.

c. When using a drillpress vise, always fasten it to

the table.

d. Never do any work freehand (hand-holding the

workpiece rather than supporting iton the table),

except when polishing.

e. Securely lock the head and table supportto the

column,and the table to the table support, before

operating the drill press.

f. " Never move the head or the table while the tool

is running.

g. Beforestarting an operation,log the motorswitch

to make sure the drill or other cutting tool does

not wobble or cause vibration,

h. If a workpiece overhangs the table so itwill fall

or tip if not held, clamp it to the table .or provide

auxiliary support.

i. Use the fence provided or other fixtures for

unusual operations to adequately hold, guide,

and position workpiece.

j. Use the SPINDLE SPEED recommended for the

specific operation and workplace material. Check

the panel on the inside pulley cover or the chart

below for drillingspeed information.

Foraccessories, referto the instructionsprovided

with each accessory.

5. Never climb on the drill press tablet it couldbreak or

pull the entire drillpress down on you.

6. Turn the motor switch "OFF", and put away the switch

key when leaving the drill press.

7. To avoid injury from thrown work or tool contact, do

not perform layout, assembly, or set up work on the

table while the cutting tool is rotating.

_I:_ -'_ II_[e_

To avoid being pulled into the power tool, do not wear

loose clothing, gloves, neckties, or jewelry. Always tie

beck long hair.

1. ffany part of your drillpress is missing,malfunctioning,

damaged or broken, stop operation immediately until

that part ispropedy repaired or replaced.

2. Never place your fingers in a position where they

could contact the drill bit or other cutting tool.The

workpiece may unexpectedly shift, or your hand

could slip.

3. To avoid injuryfrom partsthrown by the spring,foUow

instructionsexactly when adjustingthe springtension

of the quill.

4. To prevent the workpiece from being torn from your

hands, thrown, spun by the to01,or shattered, always

properly support your workpiece as follows:

a.

Always position BACKUP MATERIAL (used

beneath workpiece) so that it contactsthe left side

of the column, or use the fence provided and

clamp to brace a smaller workplece.

18

DRILLING SPEED TABLE (rpm)

DrillBit

Diam.

(Inches)

1/16

1/8

3/16

1/4

5/16

3/8

1/2

Wood Alum.,Zlnc,Bnm

3600 3600

2610

Material

Iron,Steel

2610

1600

88O

36OO

2610

1600

88O

540

Page 19

POSITIONING THE TABLE AND WORKPIECE

(FIGURE AA and BB)

1. Lock the table (1) to the column (2) at a position so

the tip of the dnll bit (3) is Justabove the top of the

workpiece (4).

2. ALWAYS place a BACK-UP MATERIAL (scrap wood)

on the table beneath the workpiece. This will prevent

splintering or heavy burring on the underside of the

workpiece. To keep the back-up material from spinning

out of control, it MUST contact the LEFT side of the

column.

To prevent the workplace or backup material from being

torn from your hands while drilling, you MUST positionit

against the left side of the column. If the workpiece or

the backup material iS not longenough to reach the

column use the fence provided with the drill press to

brace the workpiece, or clamp it to the table. Failure to

do this could result in personal injury.

HOLDING A DRILLING LOCATION

1. Using a centerpunch or sharp nail, make an

indentation in the workplace where you want the hole.

2. Using the feed handles, bring the drill down to align

with the indentation before turning the drill "ON".

TILTING THE TABLE (FIGURE CC)

NOTE: The table and support (t) has a predrilled hole

with a locking pin inserted for locking the table into a

predetermined 0° horizontal position.

1. To use the table in a bevel (tilted) position, TIGHTEN

the nut (2) on the lockingpin clockwise to RELEASE

itfrom the table support.

2. Loosen the large hex head bevel lockingbolt (3).

To prevent injury, be sure to hold the table & table arm

assembly, so it will not swivel or tilt.

.,Fig. AA

3. For small pieces that cannot be clamped to the table,

use a drill press vise (optional accessory).

_Y/zI_iI_

The drill pf'ess vise MUST be clamped or bolted tq the

table to avoid injuryfrom a spinningworkplace, or

damaged vise or bit parts.

Remove the drill press fence when it interferes with other

drill press accessories.

Fig. BB

Fig. CC

/- ,m,,==_,_==_m

,mm_mmma_m='

I

k3 1

2

3. Tilt the table, aligningthe desired angle measurement

tothe zero line oppositethe scale (4).Tighten the bevel

locking bolt.

4. To return the table to its original position, loosen the

bevel locking bolt,(3). Realign the bevel scale (4) to

the 0° position.

5. Loosen the nut (2) on the locking pin to the OUTSIDE

END OF THREADS. Gently tap the locking pin untilit

is seated in the hole. Finger tightenthe nut.

To avoid injury from spinning workor tool breakage, always

clamp workpiece and backup material securely to the

table before operating the drill press with the table tilted,

FEEDING

1. Pull down the feed handles with only eno_ugheffort to

allow the drill bit to cut.

2. Feeding too slowly might cause the drill bit to burn.

Feeding too rapidly might stop the motor, cause the

belt or ddUto slip, or tear the workplece loose and

break the drillbit.

3. When drillingmetal, it may be necessary to lubricate

the drillbit tip with motor oil,to prevent burningthe tip.

19

Page 20

MAINTAINING YOUR DRILL PRESS

For your own safety, turn the switch OFF and remove the

plug from the power source outlet before maintaining or

lubricating your drill press.

To avoid shock or fire hazard, if the power cord is worn

or cut in any way, have it replaced immediately.

LUBRICATION

Frequently blow out using an air compressor or dust

vacuum, any dust that accumulates inside the motor.

A coat of automotive" paste wax applied to the table and

column will help to keep the surfaces clean.

All of the drill press ball bearings are packed with grease

at the factory. They require no further lubrication.

Periodically lubricate the gear and rack, table elevation

mechanism ofthe spindle and the rack(teeth) of the quill.

2O

Page 21

TROUBLESHOOTING GUIDE

To avoid,injury from an accidental start, turn the switch OFF and always remove the plug from the power source

before making any adjustments.

• Consult your local Sears Service Center if for any reason the motor will not run.

PROBLEM PROBABLE CAUSE REMEDY

1.

Noisy operation. 1. Adjust tension. See Section

Incorrect belt tension.

2.

Dry spindle.

3.

Loose spindle pulley.

4.

Loose motor pulley.

"ASSEMBLY - TENSIONING BELT"

2. "Lubricate spindle. See Section "LUBRICATION".

3. Check tightness of retaining nut'on pulley, and

tighten if necessary.

4. Tighten set screw in motor pulley.

Drill bit burns. 1.

1.

Incorrect speed.

Change speed. See Section "BASIC DRILL

PRESS OPERATION - SPINDLE SPEEDS"

2.

Chips not coming out of hole.

3.

Dull drill bit.

4.

Feeding too slowly.

5.

Not lubricated.

2. Retract drill frequently to clear chips.

3. Resharpen drift bit.

4. Feed fast enough - allow drill to cut. •

5. Lubricate drill. See Section "BASIC DRILL

PRESS OPERATION - FEEDING"

Run out of drill bit point - 1. Hard grain in wood or 1. Resharpen drill bit correctly.

drilled hole not round, lengths of cutting flutes

and/or angles not equal.

2. Bent drill bit. 2. Replace drill bit.

Wood splinters on 1. No backup material 1. Use cackup material. See Section

underside, under workpiece. "BASIC DRILL PRESS OPERATION".

Workpiece torn 1. Not supported or 1. Support workpiece or clamp it. See Section

loose from hand. clamped properly. "BASIC DRILL PRESS OPERATION".

Drill bit binds in workpiece. 1. Workpiece pinching drill bit, 1. Support workpiece or clamp it. See Section

or excessive feed pressure. "BASIC DRILL PRESS OPERATION".

2. Improper belt tension. 2. Adjust tension. See Section

"ASSEMBLY - TENSIONING BELT."

Excessive drill bit 1. Bent drill bit. 1. Use a straight drill bit.

runout or wobble. 2. Worn bearings. 2. Replace bearings.

3. Drill bit not properly 3. Install drill properly. See Section "BASIC DRILL

installed in chuck. PRESS OPERATION" and "ASSEMBLY".

4. Chuck not properly installed. 4. Install chuck properly. See Section

"ASSEMBLY -INSTALLING THE CHUCK".

Quill returns 1. Spring has improper tension. 1. Adjust spring tension. See Section"ASSEMBLY-

too slow or too fast. ADJUSTMENTS - QUILL RETURN SPRING".

Chuck will not stay 1. Dirt, grease, or oil on the 1. Using a household detergent, clean the

attached to spindle, tapered inside surface of tapered surface of the chuck and spindle to

It falls off when chuck or on the spindle's remove all dirt, grease and oil. See Section

trying to install, tapered surface. "ASSEMBLY - INSTALLING THE CHUCK"

21

Page 22

CRAFTSMAN 12" DRILL PRESS MODEL NO, 137.2191,20

When servicing use only CRAFTSMAN replacement parts. Use of any other parts may create a HAZARD or cause

product damage. Any attempt to repair or replace electrical parts on this Table Saw may create a HAZARD unless

repair is done by a qualified service technician. Repair service is available at your nearest Sears Service Center.

PARTS UST FORSCHEMATIC A

Always order by PART NUMBER, not by key number

Key Part No.

1 10300105

2A 10300202A2.

3 2601BBDAg0

4 13902202

5A 10300603A11

6 10602003

7A 10302301A1

8A 10601009A3

9A 10838202A1

Description

BASE

COLUMN HOLDER ASS'Y

HEX. SOC. SET SCREW

RACK

TABLE BRACKET ASS'Y

TABLE LOCK HANDLE

RACK RING ASS'Y

CRANK HANDLE ASS'Y

FENCE ASS_

Size Qty

1

1

M8x1.25-25

4

1

1

1

1

1

1

22

Page 23

CRAFTSMAN12" DRILLPRESS

SCHEMATICA

MODEL NO. 137.219120

?A

"gA

I

23

Page 24

CRAFTSMAN 12" DRILL PRESS MODEL NO. 137.219120

PARTSLIST FOR SCHEMATIC B

Kf0y Part No. Description

11 10301004 SET BOLT

12 10201201 POINTER

13A 2135CNO132 CHUCK ASS'Y

14A 10305602A1 QUILL ASS'Y

15 2701FBD106 HEX NUT

16 10361701 SET RING

17 2602BBLA27 HEX. SOC. HD,CAP BOLT

18 N/A

19 2898D08G24 ROCKER SWITCH

10518401 NUT

S ize

M1Ox1.5

M6X1,0

M5 x 0.8-16

aty

2

1

1

1

1

1

1

1

..........."2"_...........26t_,lMr_oE]:f..............."(3RTR'ETTRO_;RI3";9"¢RItW ....................................I_Y:1"6"-"_2......................................":P...........

21 10312704 SWITCH COVER 1

22 2668BBDA24 CR. RE. PAN HD. SCREW M5x0.8-12 3

23 10308805 SWITCH BOX 1

24 2805U5HN16 TERMINAL 1

25 10384902 SCALE 1

26 2668BZDA23 CR.RE.PAN HD SCREW M5x0.8-8 2

27 2504MZC005 EXTERNAL TOOTH LOCK WASHER 2

28 10305401 QUILL SET SCREW M8x1.25-18 1

29 2701FBD113 HEX. NUT M8x1.25 1

..........._ ..........."_'_'0"_'_0i_........................"_PRIR_3RET;_II_ER................i......................................................................................................t..........

31A 10305001A2 SPRING CAP ASS'Y 1

32 2701QZD611_ HEX. NUT I/2x20UNF 2

33 2668BBDA24 CR. RE. PAN HD. SCREW M8 x 0.8-12 1

34 10808301 CLAMP-CORD 1

35 10604204 SHIFTER BOLT 2

36 2603BBLA52 HEX. SOC. SET SCREW M8x1.25-8 2

37 2603BBLA52 HEX. SOC. SET SCREW M8x1.25-8 1

38 2536MBE623 SPRING PIN 2

39 13902503 HEAD 1

...........;41_...........2_0"=I'I_B_;_...............FIE'XTR'D'_i31LT.............................................................................................................................."_.........

41 2501NBDN27 FLAT WASHER 5116x718-5164 8

42A 8220A21104 MOTOR 1

43 13916403 LABEL 1

44 2701FBD113 HEX. NUT M8xl.25 4

45 2701FBD110 HEX. NUT M10xl.5 1

46 2502ABC410 SPRING WASHER 2

47 10303401 MOTOR BASE 1

48 10303202 MOTOR ROD 1

49 2501NNVN11 FLAT WASHER 1/4x3/4-3/16 4

..........._ ..........."_'_'0"_1502........................"_i3";_[It"R'll_.................................................................................................................................._..........

51 10316208

52 2658MZDU36

53A 10304402A1

54A 10303825A1

55 2641BBDA39

56 10611201

LABEL

DRIVE SCREW 2.3-5

HANDLE BAR ASS'Y

FEED SHAFT

CR. RE. ROUND WASHER HD. SCREW M6"1.0-12

CHUCK KEY HOLDER

1

4

1

1

1

1

24

Page 25

CRAFTSMAN12" DRILL PRESS

SCHEMATICB

MODEL NO. 137.219120

45

54A

35

it0

11

25

Page 26

CRAFTSMAN 12" DRILL PRESS

PARTSUST FOR SCHEMATIC C

MODEL NO. 137.2t912C

Key Part No. Description

57 2138MBL704 WRENCH HEX

58 2138MBL703 WRENCH HEX

59 2807BY06H2 POWER CABLE

60 13916905 LABEL

61 2801ABRF04 STRAIN RELIEF

62 2572ARK340 V-BELT

63 10306901 PULLEY SET NUT

6_4 10307005 SPINDLE PULLEY

65A 10306512A1 DRIVING SLEEVE ASS_'

66 13916602 LABEL

67 2641BBDA39

68 10208302

69 2668BBDA23

70A 10307908A2

71 2571MNC307

CR. RE, ROUND HD.SCREW

CLAMP-CORD

CR. RE, PAN HD,SCREW

MOTOR PULLEY ASS'Y

PARALLEL KEY

Size

4-64

3-57

M6X1.0-12 4

Qty

1

1

1

1

2

1

1

1

1

1

4

4

1

1

72A 10409011A3

PULLEY COVER ASS'Y

1

26

Page 27

CRAFTSMAN12" DRILL.PRESS

SCHEMATICC

MODEI.NO.137.219120

59

72A

64

71

70A

65A

69

J

68

61

27

60

Page 28

For repair of major brand appliances in your own home...

no matter who made it, no matter who sold it!

1,800-4-MY-HOME s"Anytime, day or night

(1-800-469-4663)

www.sears.com

To bring in products such as vacuums, lawn equipment and electronics

for rePair, cell for the location of your nearest Sears Parts & Repair Center

1.800-488-1222 _., dayorn_ht

www.sears.com

For the replacement parts, accessories and owner's manuals

that you need to do-it-yourself, call Sears PartsDirect =_!

1-800-366-PART 6a.m.-11p.m.CST,

(1-800-366-7278) 7 daysa week

www.sears.com/partsdirect

To purchase or inquire about a Sears Service Agreement:

1-800-827-6655

7 a.rn.'- 5 p.m. CST, Mon. - Sat.

.Pard pedir serviciode reparaclbna domidlio, Au Canada pour sewics en fran_ais:

y pard ordenar piezas con entmga a domicilio: 1.877.LE.FOYER =.

1-888-SU-HOGAR TM

{1-888-784-6427)

SEARS

o,,,,,.,.=_,,.=, HomeCentrar ®.,.,=.,,,,,-.-,'-,,.-_ ,,=..,.P-=_..,=.

J ® Matca Registrada_ Mamade F_brk_ deSeam,Roebu_ andCO.

FULLONEyEAR WARRANTY

If_ i_uCt failsduetOa defe<_inmateri_d_ v,_kmansh_owi_-_ o_e_u _ _ _ _ _. _

_ re_t_ it_ ofch_ge.

ConUtcta SearsSer_e C_mUvfo_"m_.

If G_isl_ct i.Jusedfor€ommerdaiorrentalpurpo_s, thiswamu_ _ onlyf_' g0dlys fromlhe _ _

pufcJuse.

'n_ *tmtr¢/g_,,es you_ legaldg_s_end_oumaymo h=_ oG_"rklt_tswNchvsry _'om_ _ s_

_an=, Roeb_mk and Co., DepL 817 WA, Hoffrmm Eatates, IL eO179

11/200(

Page 29

Manual de Operacibn

CRRFTSMRN°

2/3HP (Potencia M_xima)

5 Velocidades (540-3600 R.P.M.)

Mandril de 1/2 Pulg.

PRENSA TALADRADORA

DE 12 PULG.

Modelo No.

137,219120

CUIDADO:

/

Antes de usar esta Prensa

Taladradora leer este manual

y seguir todas las Reglas de

Seguridad e instrucciones

de Operaci6n

1.800-843-1682

Sears, Roebuck and

USA

Part No.137219120001

Co., Hoffman Estates, IL 60179

Instrucciones de Seguridad

Instalaci6n

Operaci6n

.0

Mantenimiento

Lista de Partes

Tel6fono para

Ayuda al Cliente

Page 30

SECCION PAGINA

Garantia ............................................................................ 30

Especificaciones de la Herramienta ...................................................... 30

Instrucciones de Seguridad ........................................................... :31

Accesorios y Aditamentos ............................................................. :34

Contenido de la Caja ................................................................. :34

Familiarizarse con la Prensa Taladradora ................................................. :36

Glosario de Terminos ................................................................. 37

Ensamblaje y Regulacibn .............................................................. 38

Operaci6n ................................................................. )......... 43

Mantenimiento ..................................................................... .48

Guia para Diagn6stico de Problemas ................ "................................... 49

Partes : ............................................................................ 50

TAMANODEL MANDRIL .1/2"(13ram)

VELOC]DADES ........ 5 (540-3,600 RPM)

MOTOR ........ '...... 120V._0 HZ, 6 AMFS.

CABALLAJE ........... 2/3 HP(Desarroflo Maxi.)

LUZ INCORPORADA ...... 60 Wars(Maximo)

(Notnduye el foco)

TAMA_IODELA MESA

INCL]NACION

DE LA MESA ............

DESPLAZAMIENTO

DEL EJE ...............

CUELLO ...............

TAMAI_IODE LA BASE .... 14-3/8" X 8-1/4" (36.6cm X 21cm)

ALTURA ............. 37-3/32"/94.2cm)

10-5/16" X 8-2!/32"

(26.2 cmx 22 cm)

450A LAOERECHAC IZQUJEROA

•2-3/8" (6 cm)

.6" (15.2cm)

Usar protecci6n adecuada en elcircuito paraevitar rles_os

e!e_ncos, de incenaio o_ah,os a la herramiema.

La PrensaT_Jaaraaoraesta cabteadaen la fa._ncaparacperara

120V. Conectarla_ un circuito de 120V.15Amps. yusar un

merrup[orce c:rcuito ofusibie de ,'etardode 15Amos.S;el

cora6nelec:ricoestuvlese gas{ado,cortadoo dar_aao,=n

cualquierform& reempiazarto de Inmediatopara witar

eleotrocuci0no Incendio.

Alogunos polvos creados por el lijado mec_mico, el aserrado, el esmedtado, el taladrado y otras

actividades de construccibn contienen sustancias quimicas conocidas [pot le Estado de California]

como agentes cancerigenos, defectos ¢ongenitos y otros daSos reproductores. Algunos

ejemplos de estas sustancias quimicas son:

• El plomo de las pinturas a base de plomo,

• El silice cristalino de los ladriltos y ¢emento y otros productos de mamposteria, y

• El arsenico y el ¢romo de la madera tratada quimicamente.

.El riesgo resultante de la exposition varia segQn la frecuencia con que se realiza este tipo de

trabajo. Para reducir la exposition a esta sustancias quimicas: trabaje en un lugar bien ventiiado y

realice el trabajo utilizando el equipamiento apropiado, tal como las re&scares para el oplvo

especialmente diser_ados para eliminar las pa.,'ticulas minQscutas.

30

Page 31

INSTRUCCIONES GENERALES DE

SEGURIDAD

ANTES DE USARLAPRENSATALADRADORA

La seguridad esuna combinaci6n de sentidocomdn,mantenerse

alertay sabercomo usarla PrensaTaladradora.

Para evitarerroresque puedancausarlesionesserias,no

conectarel taladro hasta haberleido y entandido Iosiguiente:

1.

LEER y familiarizarsecontodoeste manualde

instrucciones.ENTENDERlas aplisaciones, limitacionesy

riesgos posib_es,

.

MANTENER LOS PROTECTORESEN POSICI(_Ny en

buanascondicionesde operacibn.

3,

NO OPERAR ENAMBIENTES PEMGROSOS.Nousarla

herramientaen lugaresh0medos,mojadosoexpuestosa la

Iluvia.Mantenerel area de trabajobienUuminada.

4.

NO USARherramiantaseldctficasen la presenciade

Iiquidoso gases inflamables.

5.

MANTENER EL AREA DETRABAJO UMPIA. Lasdreas y

mesasde trabajocongestionadasinvitana quaocurran

accidantes.

6.

MANTENERA LOS NINOS ALEJADOS. To<loslos

visitantesdeben mantenerse aunadistanciaseguradel

area de trabajo.

7.

NO FORZARLA HERRAMIENTA,La herramientahard un

mejortrabajoy mas segurousandolas61oen la brma para

la que fue disefiada.

8.

USARLA HERRAMIENTAADECUADA,Noforzarla

herramientaal hacer un trabajo parael cual no ha sido

dise_ada.

9. USAR ROPAADECUADA.NO usarropasuelta,guantes,

corbatas,anillos,brazaletesni joyasque pusdanquedar

atrapadosan laspiezasmoviblesde la herramienta.Se

recomiendausarsalzado antiresbalante.Usarprendasde

sadeza paracubrir o contener elcabeUolargo.

!0. USAR UNAMASCARA PARA LA CARAO PARAPOLVO.

Los trabajoscon taladro producanpolvo.

11. DESCONECTARLAS HERRAMIENTASantes decambiade

accesori0stalescomo: hojas,brocas,cortadoresysimilares.

12. REDUCIREL RIESGODE ARRANQUESACCIDENTALES.

Cerciorarsequeel interruptordeenergfaesteen laposici6n

"OFF"(Apagado)antes de enchu_rla herramientaa la

corrienteeldctrica..

13. USARACCESORIOS RECOMENDADOS.Consultar con

e! manualdel operador.paradeterminarcualessonlos

acossodosrecomendados.Elusode accesodos

inapropiadospuedeser peligrosoyganerarriesgode

lesionespersonales.

CONSERVAR ESTAS INSTRUCClONES

14. RETIRAR LAS HERRAMIENTAS DE

REGULACI6N. Formarseel habitodeverificarqualas

herramientasy lasIlavesde regulaci6nhayansidoretirades

del taladroantesde activado.

15.

NUNCADEJARDESATENDIDAUNAHERRAMIENTA

ELI_CTRICACUANDOESTE FUNCIONANDO.

DESCONECTARLA FUENTEDE ENERGIA.Noalejarse

del lugar hastaque la herramientase haya detenidopor

completo.

"16.

NUNCAPARARSESOBRE LA HERRAMIENTA.Pueden

ocurnrlesionessedassi la herramientase volteaosise

entraencontactoconel taladro.

NO ESTIRARSEMAS ALI,.ADELALCANCEDE UNO.

17.

Mantenerlosdospiesbienapoyadosy el equilibroen

todomomento.

18.

DARMANTENIMIENTOCUIDADOSOA LAS

HERRAMIENTAS.Paraunaoperaci6nmejor,mas seguray

rapida,mantenertasherramientasafiladesy limpias.Seguir

lasinstrucoionespara lalubdcaci6ny carnbiodeaccesorios.

19. INSPECClONARPARADETECTARPIEZAS DANADAS,

Antesdeusarlaharramienta,siempreinspeccionarla

_idadosamante parecercioraressilosprotectoresu otras

piezasestdndeSadasy determinarsiva a operar

adecuadamenteen el usoquese le vaa dar.Inspeccionar

sihaypiezasmoviblesdesatineadaso atrasadas;partes

rotas o malmontadas,y cualquierotracondiciSnquepueaa

afectarlaoperaci6nde la herrarnienta.Si unprotectoro

cuaJquierotrapiezaestuvtesedefiada deberepararse

adecuadamenteo reemplazarse.

20. ASEGURARSEQUE LOSNItrOS NOTENGAN ACCESO

ALTALLER DETRABAJO.Usarcandados,interruptores

maestrosy quitarlas Ilavesdeactivaci6n.

21.

NO operarla herramientabajo la influenciade drogas,

alcoholo medicamentosque pudiesenafectarla habilidad

para operarla herramientaadecuadamente.

22.

Et polvogeneradeporciertosmaterialespuede sernoctvo

parala salud.SiempreoperarlaPrensaTaladradoraen un

areabien ventiladaparaeliminarel polvo.Cuandofuese

posib_e,usar sistemasrecolectoresde polvo.

23. SIEMPREUSAR

PROTECCI(_NPARALOS OJOS.

CualquierPrensaTaladradora

puedearrojarcuerposextrafiosa

losojosquapuedancausar

dafiospermanentesa la vista.

SIEMPREusarGafasde

Segurided(noanteojos) quecumplancon la norma7_87.1

de ANSI. Losanteojosde usodiadoS61otienen lentes

resistantesa los impactos,estos NOSONgalas de

seguridad,l.as Galas deSeguridad puedenadquirirseen

Sears. NORA: Los anteojos o galasqua nocumplenconla

norma Z87.1de ANSI puedencausardafios serios al

romperse.

31

Page 32

REGLASDESEGURIDADESPEC{FICAS

14.

PARALA PRENSATALADRADORA

15.

Porsu propiaseguddad,nottatarde usarla PrensaTaladradorani

enchufarlahastaque est_completamente-ensambladae instalada 16.

de acuerdocon lasistrucciones,y hastahaberleido yentendido

este manualde instrucclones:

1.

LA PRENSA TALADRADORA DEBE ESTAR - 17.

EMPERNADA en forma segura al banco de trabajo.

Adicionalmente,si hubiese la tendenciaa que el

banco de trabajoTaladradora se muevadurante

ciertas operaciones, empernar taprensa al piso. 18.

2.

ESTAPRENSATALADRADORAs61oes parausarse en

condicionessecasyen interiores.

USARPROTECClONOCULAR,USARm&scaraprotectora 19.

3.

parala carao parapolvosjunto congafasde seguridadsi

laoperaci6ngenerapolvo.USARprotectoresde ofdo,

especialmenteduranteperiodoslargosde operaci6n. 20.

4.

NOusar guantes,corbatani ropasuelta.

5.

NOintentartaladrarobjetosque seandemasiadopeque5os

como parafijarlos con sujetadores.

SIEMPREmantener lasmanosfuera delcamino de las

6.

brocas.Evitarcolocarlasmanosen posicionesen las

cualesunresbal6ns_b_topuedahacerque lasmanos

entrenen contactoconla broca.

7.

NO instalarni usar brocascuyolargoexceda175 mm(7") o

que se proyecten150 mm (6")por debajode las quijadas

del mandril. PuedendoblarsesL_bitamentehaciaafuera

o romperse.

8.

NO USAR ruedasde alambre,brocasparaburiladoras,

cuchillasformadoras,cortadoresdecirculosnicepillos

giratoriosen estaPrensaTaladradora.

9. CUANDO se est_ taladrandouna piezagrandede material,

cerciorarseque est_completamentesujetaa taaltura

de tamesa.

10. NO realizaroperaci6nalgunaa manolibre.SIEMPRE

sujetarla piezaque sa est_trabajandoenforrnaflrrne

contrala mesaparaque nosemuevaotuerza.Usar

sargentaso prensassise taladranpiezas inestables.

11. CERCIORARSEque nohayanclavosniobjetosextrahos

en lapartede la pieza que se vaa taladrar.

12. RJAR LA PIEZADETRABAJO CONSUJETADORES

contrael lade izquierdode lacolumnaparaevitarquegire.

Sifuesemuycortao sila mesadelaherramientaestuviese 27.

inclinada,sujetariafirmementea la mesay usarla

guiaprovista.

13. St LA PIEZA DETRABAJOseproyectafuera de la mesa

de formatal quese caigaoinclinesinoestuviesesujeta,

sujetartaa la mesa o proveerunsoporteauxiliar,

21.

22.

23.

25.

26.

RJAR LA PIEZADETRABAJO.Cuandofuesaprdctico,

usarsargentasouna prensaparasujetar1_piezade tmbajo.

Esrodssaguro queusarla manoy deia librearnbasmanos

paraoperarla hermmienta.

AL USAR una prensa para taladro,siempresujetariaa

la mesa.

CERCIORARSEQUE todoslos elementosmecdnicosde

sujecionesten ajustadosflrrnemente.antesdecomenzar

a taladrar.

ASEGURARELCABEZAL CONEL SEGUROy sujetarel

soporte de lamesa a lacolumna,y la mesaal soporteantes

de operarla PrensaTatadradora.

NUNCAhacerfunoionarla PrensaTaladradoraantes

de haber despejadotodo objetode la mesa (henamientas,

desechosde madera,etc.).

ANTESDE COMENZARla operacibn,hanerfuncionarel

taladrobrevementea bajavelocldedparacerclorarseque no

se bamboleeo vibre.

PERMITIRQUE ELEJE ALCANCESUVELOClDAD

M,_XIMAantes de comenzaraa taladrar,Si el taladrohace

atg,',nruidoquenosea familiaro vibraexcesivamente,

detenereltrabajoinmediatamente,apagarel taladroy

desenchufadode lacorriente.Novolverioa poneren

operacl6nhasta habercorregidoel problema.

NO realizarlaboresdetrazado,ansamblaje nipreparaci6n

sobrelamesa cuandolaherramientaest_enoperaclbn.

USARLAVELOCIDADRECOMENDADAparael accesorio

y tipode materialde lapiezaque seest_tmbajando.VER

I_ASINSTRUCCIONESquevienenconel accosorio.

ALTALADRARorificiosde di_netm grande,fijarlapieza

detrabajoconsujetadoresenformafirmea lamesa.De

Iocontrariolabrocapuedeagarmrlapiezaque se est_

trabajandey hacerlagimra granvelocldad.NO USAR

cuchillasde fresadorani elementosquetaJadrenofifidos

m,',ltiplesporquepuedendesarmarseo desbalancearse

conel uso.

4,

CERCIORARSEque eleje sehayadetenidocompletamante

antesde entraren _cto conla pieza detmbajo.

PARAEVITARLESlONESdebidasa arranques

accidentales,siemprecolocarelinterruptoren la posici6nde

"OFF"(Apagado)ydesanchufarel taladroantesde instalaro

retiraraccesorioso de realizarcualquierajusteo regulaclbn.

MANTENERLOS PROTECTORESEN POSICl0N y en

buenascondicionesdeoperaci6n.

SOLO USARUNA LLAVEDEL MANDRILTIPO AUTO

EXPULSANTEcomola provistaconla Prensa

Taladradora.

CONSERVAR ESTAS INSTRUCCIONES

32

Page 33

INSTRUCCIONES PAPA LA CONEXI(_N ATIERRA

EN EL EVENTODE UNA FALLAO MAL FUNCIONAMIENTO,

la conexi6na tierraproveeunavia de menor resistenciaparela

corrienteel_'trica, reduciendoasi el fiesgo dechoqueel_-tfico.

Estaherramientaest_equipedaconuncord6n el_ctfico que

tJeneunconductor paraconexi6na tJerray tambi_nconun

enchufeconespigapareel mismotin.ElenchufeDEBE

conectarseen untomacomentequele hagajuegoyque este

debidamenteinstaladoy conectadoa tJerrade acuerdocon

TODOSlosccktigosy ordenanzaslocales.

NO MODIFICAREL ENCHUFEPROVISTO.Si noentraen et

tomacordente,hacerque unetectricistacaliflcadeinstaleun

tomacorrienteadecuado.

LA CONEXlON INADECUADADEL CONDUCTORparetierra

de unequipopuedegenerarriesgode choqueel#,._"ico.El

conductorconform aislanteverde(cono sinrayasamarillas)es

elconductorpareconexi6na tJerra.Si elcord6nel_.'tricoo et

enchuferequierenraeparacioneso reemplazo,NO conectarel

conductorparatierradesequipoa unterminalvivo.

AVERIGUARcon unelectdcistao personaldese_cio si se

tiene cualquierdudeen cuanloala conexi_ correctaa tierra

delequipo,o silesinstruccionesparala conexi6na tierrano

est_ndares.

SOLOUSAR CORDONESDE EXTENSIONQUETENGAN

ENCHUFEDETRES ESPIGASY UNTOMACORRIENTEQUE

ACEPT1EEL ENCHUFEDE LA HERRAMIENTA.REPARARO

REEMPI.AZAR INMEDIATAMENTELOSCORDONES

DA_IADOSO GASTADOS.

Estaherramientaest_disefiadapera usarseen uncimuitoque

tengauntomacorrientecomo elilustradoen la FIGURAA.

LaRGURA (A) muestraunenchufeelL_.--tricoyuntomacorriente

d_3 contactos,unodelos cualesesunconductorpare

conexi6na tierra.Si no se disponede untomacorfientecon

conductorpareconex_na tierra,temporalmentese puedeusar

unadaptador(FIGURAB) paraenchufarloen untomacorfiente

de2 contactossinconexi6na tierra.El adaptador(RGURA B)

tieneunanillofigido quele sobresaley queDEBEconectarse

fisicamenteen formapermanentea tierra,telcomo iacaja deun

tornacorrientedebidamenteconectadoatierra.ElC_ligo

Et_ctficoCanadienseprohibeelusode estosadaptadores.

CUIDADO:Entodosloscases,cerciorarseque eltomacorriente

encuestJ6nest_adecuadamenteconectadoa tierra.Si nose

estuvieseseguro,hacerqueunelectficistalicenciado

inspeccioneeltomacorriente.

EstaPrensaTaladradoraes_ disefiadaunicarnenteparauso en

interiores.No exponedaala Iluvianiusaria en lugareshtimedos.

Fig. A

Enchufede3 espigas

®

_----_ _Tomacordente pare

enchufede3 espigas

debidamente

conectadoatierra

RECOMENDACIONESPAPALOS CORDONES

DEEXTENSION

Cerciorarseque elcordbnde extensi6nest_en buenas

condiciones.AI usaruncordbndeextensi6n,corciorarseque

sea Iosuficientemente_]ruesopareconducirla cordentequela

herramientademandara.Un cord(_nsubdimensionadocausam

unacafda en elvoltajede la tfneacausandounap_rcrldede

petenciay recalentamiento.Latableque apareceen esta

pdgina muestralos calibrescorrectesdelos cordonesseg_n

suextensibny el arnpe_e requerido perla herramientaque

aparaceen la place.Enca.sode dude, userel siguientecalibre

m_.sgrueso.Cuantomenor el ndmero del calibre,mayorel

di_metmdel alambre.

CercJorarseque elcord6n de extensldntenga losalambres

adecuadosy queestden buenascondicionesel_'tricas.

Siempreresmplazarloscordonesde extensi_ da_adoso

hacedesrepararper unapersonacalificadaantesdeusades.

Protegerloscordonesde extensi6nde losobjetosfilosos,del

caforo humedadexcesivay de las_ffeash_medesomojadas.

Usar un ramalde circuitoindependientepara_ta herramienta.

Estedrcuitodebeserd.eun elambracuyocalibrenoseamenor

a 12 ydedeestarpmtegidoconun fusiblede retardode 15

Amp_.Antesdeconectarel motorala Iinea desuministro

ekY_trico,corciorarsequeel interruptorest_en laposici6nde

"OFF"(Apagado)yqua lacQrrienteel_-'tdcasea laindicadaan la

placede datesdelmotor.Operarlaherramientacon unvoltaje

menor puededa_ar el motor.

Fig. B _leOxPara

atierra / I _ "[_

/ I/ | I__

ACCESORIOS DISPONIBLES

S61ousar accesoriosrecomendadosparaestaPrensa

TaladradoraSeguirlas instruccionesqueacompafiana los

accesoriosEl uso deaccesoriosinadecuadospuede

generar riesgos

DESEMBALAJE Y VERIFICACI6N DEL

CONTENIDO

Sit&itasenpiezaso hubiesenpiezasda_adas,no enchufarla

PrensaTaladradorahastaconseguirlas piezast<anteso de

reemplazarlasdafiadas y hastahaber ¢ompletadeel ensambt&je

VisitarelDepartamentode Ferretedade latiendaSears

mascercana overelCat&logode HerramientasEIL_tricas/

Neum_,ticasy Manualesde Searsparalossiguientes

accesorios:

BrocasparaTaladro

• SujetadoryGuia

PrensasparaPrensaTaladradora

• Juegode Mortajay Espigapara Prensa

Taladradora

• Juegode Sujetadores

• Cincely Brocastipo Mortajay Espiga

• TamboresLijadores

• RuedasPulidorasde hasta4" (10cm) de

DiametroM_imo

• SierraparaOrificiosde hasta2-1/2"(6.35cm)

Paraevitarlesionescausadasporpiezas rotasopiezas de

trabajorotasexpedidas,s61ousaraccesoriosrecomendados

paraesta PrensaTaladradora.

Searspuederecomendarotrosaccesoriosnolistadesen este

manuel VisitarlatiendaSearsmas cercanao vet el Cat&logod_

HerramientasEl_ctricas/Neumdticasy ManualesdeSears

Npusaraccesorioalgunoa menosde haberleido

completamenteel manualde instruccionesu operacionde ese

accesorio

Desempaquetarcuidadosamentela PrensaTatadraderay todas

suspartesy vedficadascontralarelacionque est&a

continuaci6n.

Paraproteger ta PrensaTaladradoracontralahumedad,las

partes maquinadashan siderecubiertasconunacapaprotectora

que sedebe removerconun patiohumedecidoconkerosene

o WD-40

Paraevitarinoendiosoreaccionestbxicas,nuncausargasolina,

nafta,acetona,tinerparatacaso solventessimitaresde alta

volatilidadparalimpiarlaPrensaTaladradora.

TABLE OF LOOSE PARTS

ART DESCRIPCI6N

A. Cabezal

B. Mesa

C. Base

D. Columna

E. Anillo

F. Cremallera

G,