Craftsman 137219090 Owner’s Manual

®

CAUTION:

Before using this Drill Press,

ream this manua_ and follow

a_l its S Rules and

Operating instructions°

Sears° Roebuck and Co. Hoffman Estates, IL 60179 USA

Part No. 157219090001

Installation

Operation

Maintenance

Parts List

_Ft .............. 120V, _ NZ, 2.2 AMP& Yo_r d_ press is _red _t _e _o_ _r _20V ope_on,

HO_8_P_ ........ 1_ HP (M_. D_) _nr_ to_ 120V, 15 AMP branch _r_ _n_ u_

TA_L_ $_E .......... 7o5/64" X 7o3/4" _5 AMP _ime de_ayfuse or circuit breake_oTo avoid shock

or _re_ rep_ _er co_ }mm_iete_y _ it'_sworn, cut or

Safety is a combination of common sense, staying atert

and knowing hew to use your drdl press.

I4. REPROVEADJUSTINGKEYSANDWRENCHES.

Fromthehabitofchecking;e seethatkeysaed

adjustingwrenchesareremovedfromthetoolbefore

NEVER LEAVE TOOL RUNNING UNATTENDED.

TURN THE POWER "OFF". Don't teave _hetoot until

it comes _o a comDle_e stop.

_b avoid mistakes that could cause serious _ntury, do not

plug the drHipress in unti_ you have reaa and understood

1. READ and become familiar with this entire instruction 17. DON'T OVERREACH. Keep proper footinq ano

manual LEARN the t_l's appii_tions, limitations and balance at a_l times.

possible hazards.

2. KEEP GUARDS IN PLACE and inworking order.

DON'T USE IN A DANGEROUS ENVIRONMENT.

Don't use power toots in dame or wet locations, or

exeese them to rain Keep work area well lighted.

DO NOT use power tools _nthe presence of flammable

liquids Or gases.

5 KEEP WORK AREA CLEAN. Cluttered areas and

benches invite accidents.

6. KEEP CHiILDREN AWAY. All visitors should be kept at

a safe distance from the work area,

DON'T FORCE THE TOOL. It win do the job better

and safer at the rate for which ff was designed.

USE THE R_GNT TOOL. Don't force tool or the

attachment to do a job for which it was net designee.

g. WEAR PROPER APPAREL, DO NOT wear _oose

c_othing, g}oves, neckties rings, bracelets, or other

jewelry which may get caught in moving par_s.

Nonslip footwear is recommended. Wear protective

hair covering to contain Jong hair,

16,

NEVER STAND ON TOOL. Serious injury could occur

if the toot is tipped or if the cutting _oo_is unintentionally

contacted.

18. _aA_NTAIN TOOLS W_TN CARE. Keep tools shard

and clean for best and safest pedormance. Follow

instructions for lubricating and changing accessories.

19

CHECK FOR DAY,AGED PA_S. Before further use of

the tool. a guard or other part that is damaged should

be carefully checked to determine [hat it wi# f_rate

propedy and aertorm its intended function. Check for

alignment of moving pa_ts, binding d moving part&

breakage of pars. mounting, and any other conditions

_hatmay affect its operation. A guard or other part that

/s damagea should be proper_y _paired or replaced.

20, MAKE WORKSHOP K_DPR_F with padlocks, master

switches, or by removing starter keys.

21 DO NOT operate the tc©_ityou are under the _nfluence

d any drugs, alcehol or medication that could affect

your ability to use the too_properJy.

22_

Dust generated from certain materials can be

hazardous to your heaffh. Always operate the drill

#ross lea weIFventi_ated area and provide to[ proper

dus[ removal. Use dust collection systems whenever

11. D_SCONNECTTOOLS before servicing, and when

changing accessories such as blades, bits, cutters

and the like.

12. REBUCETNE R_SKOF UNiNTENTiONAL STA_NG,

Make sure the switch _sin _'OFF" position before

plugging in

l& USE RECOMMENDED ACCESSOR_ESo Consult the

owner's manual for the recommenae_ accessories.

Th_ use of improper accessories may cause risk of

injury to persons.

SAVE THESE NSTRUCT ONS

2& ALWAYS WEAR EYE

the eyes which could cause

permanent eye damage_

ALWAYS wear Safa#¢ G_ggles

(not g}a_es) that comply with

ANS_ safety standard Z87.1. Everyday eyeglasses

have only impact_resistaet lenses. They ARE NOT

safety gta_eso Safety Goggles are available at Sea_.

NOTE: Glasses o_-Doggies not in compliance with

ANSi Z87.1 could seriously hu_ you when they break.

SPECiFiC SAFETY NSTRUCTJONS

FOR THE DRILL PRESS

R_r your _n sabLv, _ not try to use your ddit press

or plug i_in until ff is completely &ssembled and isstailed

a_o_ing © the i_stmctions, arm uctil you have read and

u this instrd_on manual:

YOUR DR_LL PRESS _UST BE 8OLTE# securely

_e a workbench. _nadditioe, if there is any tendency

for your ddl_ press to move during certain operations

bolt the workbench to the floo£

2.

THiS DRILL PRESS is intended for use tn dry

conditions, indoor use oniyo

3_

WEAR EYE PROTEO[ION. USE race or dust mask

a_ong with safe_ goggles ff ddlJing operation is dusty_

USE ear prote_ore, esp_ialIy dudng extended periods

4 DO NOT wear #Joves, neckties or I_se c_othing.

5 DO NOT tr_ to dril_ materia_ too small m be securely

held.

6 ALWAYS keep hands out ot tb_ path of a drill bit.

Avoid awkward hand positions where a sudden slip

coupe cause your hand to move into the dd_ bit.

7_

DO N_ install or use any drill bit that exceeds

175 mm _7") in length or ex_ends 150 mm {6"} be{ow

the chuck }aws_They can suddenly bend outward o_

break

8. _ NOT USE wire wheels router b_ts sneer c_ers

circ_e (fly) cubers, or rotary p_aners on th_s dr#| pre_

14 SECURE WORK. Use damps or a vise to hold the

work when pract}caL ft's safer than using your hand

and ff frees both hands to operate tool

15.

WHEN using a ddll press vise, always fasten to the

_Me.

16. P_AKE SURE aHclamps and _ocks are firmly

17.

SECURELY LOC_ THE HEAD and fable support to

the column, and the taMe 'tothe table support before

o_ratin_ the drill press.

18.

NEVER turn your ddll press on before deadng the

taMe of a_lobjects (tools, scraps of wood, etc.)

19.

BEFORE STARTING the operation, jog the motor

switch to q_ake sure the ddH bit does not wobble or

vibrate,

20.

LET TR_ SPINDLE REACH FULL SPEE# before

Starting to rid& ff yourdd_! press makes an unfamiliar

noise or ff it vibrates excessively, stop immediately,

turn the dd_lpre_ off and unplug. Do not restart until

the proMem is corrected

21.

DO NOT pediorm _ayout assemMy or set up work on

the table while the ddtl press is in operation.

22,

USE RECOMMENd# _EED for dntl accessory and

matedaL SEE t NS that come

23.

WHEN DRILUNG large diameter ho}es,clamp the

woCKpiecefirmly to the table. Otherwise, the b_ may

grab and spin the workpiece at high speed. DO NOT

USE fly c_e_ or multiple-part hole cubers, as they

can come _art or become unbatan_ in use.

9. WNE_ t cu_ing a large piece of mateda_ make sure it

_sfu#y supported at the table height.

I0. DO NOT pedorm any o#eration _reehand, ALWAYS

ho_dthe workpiece firm{y a£ainst the tame se it will

r_o[_ck or twist. Use c_amps or a wse for unstable

_vorKi )i_es.

_ _A_.E SUR_ there are no na_s _r _oreign objects in

the part ot the wor_piece to be dd_led,

2. C_P WOR_P_ECE OR BRACE against the _e/t

side ot the column to prevent rotation, ff it is t(_ shod

or the table is fl_tedoc_amp solidly to the table and

use the fence provided.

_, _FTHE WOR_P_KCK overhangs the tame such Ihat

it will fa_ or t_# _1not he_d, c_amp it to the ,taMe or

provide auxiliary suppor_,

SAVE THESE NSTRUCT ONS

24° _AKE 8NR_ the spind}e has come to a complete

stop before toucMng the workp_ece.

25. _ AVO_# I_NJURYfrom accidenta_ starting, aiways

turn _e switch "OFP ano unplug the dd_press before

installing or removing any accessory or a#.achmenl

or making any adjus_mento

26. _EP GUARDS _NPLACE and in working order.

27. _8E ONLY SELFoEJECT_NG _P_ CHUC_ _EY as

provided with the ddll press.

GROUNDING INSTRUCTIONS

iN THE EVENT OF A MALFUNCTBON OR BREAKDOWN,

grounding provides a path of least resistance for etectdc

current andreduces the risk of electric shock. This tool

is equippea with an electric cord that has ar equipment

grounding conductor and a grounding plug. The pJug

MUST be plugged m_o a matching receptacle that is

propedy installed and grounded in accordance with ALL

local codes and ordinances

DO NOT MODIFYTHE PLUG PROVIDED. ff itWill no[ fit the

receptacle, have the prober receotae{e installed by a

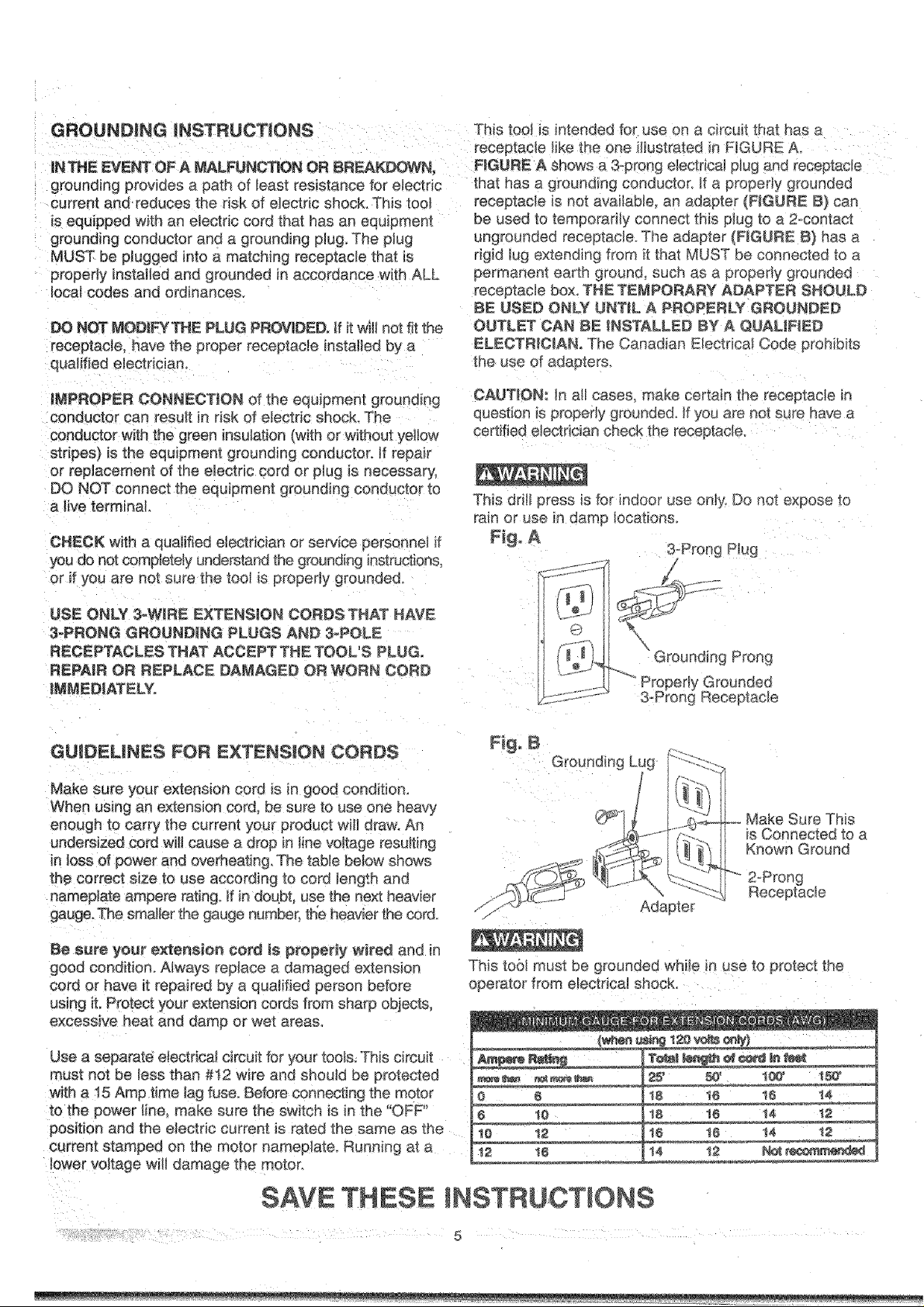

This toot is ntended for use on a circuit [hat has a

receptacle _ikethe one i_ustrated in FIGURE A.

FIGURE, A shows s 3-prong electrica; plug and receptaae

that has a grounding conductor_ ff a properJy grounded

receptacle is qo_available an adap[er (FIGURE B} can

be used to Temporarily connect this p_ug to a 2-contact

ungrounaea receetacle. The adapter (FIGURE B) has a

rigid _ug extending from it that MUST be connected to a

permanent earth ground, suet as a propedy grounded

receptacle box, THE TEMPORARY ADAPTER SHOULD

BE USED ONLY UNTIL A PROPERLY GROUNDED

OUTLET CAN BE iNSTALLED BY A QUALIFIED

ELECTRICIAN. The Canadian Hectdcal Code orohibits

the use of adapters.

iMPROPER CONNECTION of the equIpment grounding

conductor can result in risk of electric shock. The

conductor with the green insulation (with or without yel!ow

stripes) is the equipment grounding conductor, If repair

oFreplacement of the electde cord or plug is necessary,

DO NOT connect the eeuipment grounding conductor to

a live terminal.

CHECK with a oualified electrician er se_tce oersonnel ,_

you do not completely undePstandthe grounding instructions

or if you are not sure the tool is propedy grounded,

USE ONLY 3oWIRE EXTENSION CORDS THAT HAVE

3-PRONG GROUNDING PLUGS AND 3*POLE

RECEPTACLES THAT ACCEPT THE TOOL'S PLUG,

REPAIR OR REPLACE DAMAGED OR WORN CORD

IMMEDIATELY°

GUIDEL_NES FOR EXTENS!ON CORDS

Make sure your extension cord _sin good condition

When using an extension cord. be sure to use one heavy

enough to carry the current your product wit/draw. An

undersized cord wi_lcause a drOP in Hnevoltage resulting

in loss of power and overheating, The table below shows

the correct size to, _seaccordino to cord _ength and

nameplate ampere rating. # in doqbt, use the next heavier

gauge. The smaller the gauge number, taleheavier the _rd.

CAUTION: in a_ cases, make certain the receptacle in

question is propedy grounded, ff you are not sure have a

ceRified electrician check the receptacle_

This ddR press is for indoor use only. Do not expose to

rain or use in dame locations

/

_nd_ng Pronq

-"" Properly Grounded

3-Prong Receptacle

Grounding Lug

Sure This

is Connected to a

Known Ground

g

Receotacle

Be s#re your extension cord is p_perly wired and in

good condition. A_ways reolaee a damaged extension

cord or have it repaired bV a qualified person before

using it. Protect your extension cords from sharp objects.

excessNe heat and damp or wet areas

Use a separate electrical circuit for your tools. Th_sc_rcuit

must not be tess than #12 wire and shoutd be #roteeted

with a 15 Amp time lag fuse. Before connecting the motor

to the power _ine.make sure the switch is in the "OFF"

position and the electric current is rated the same as the

current stamped on the motor nameplate. Running at a

lower voltage win damage the motor_

SAVE THESE NSTRUCT ONS

This too_ must be grounded while in use to protect t#e

operator from electdca! shocK.

1_ 14

I8 18 14 12

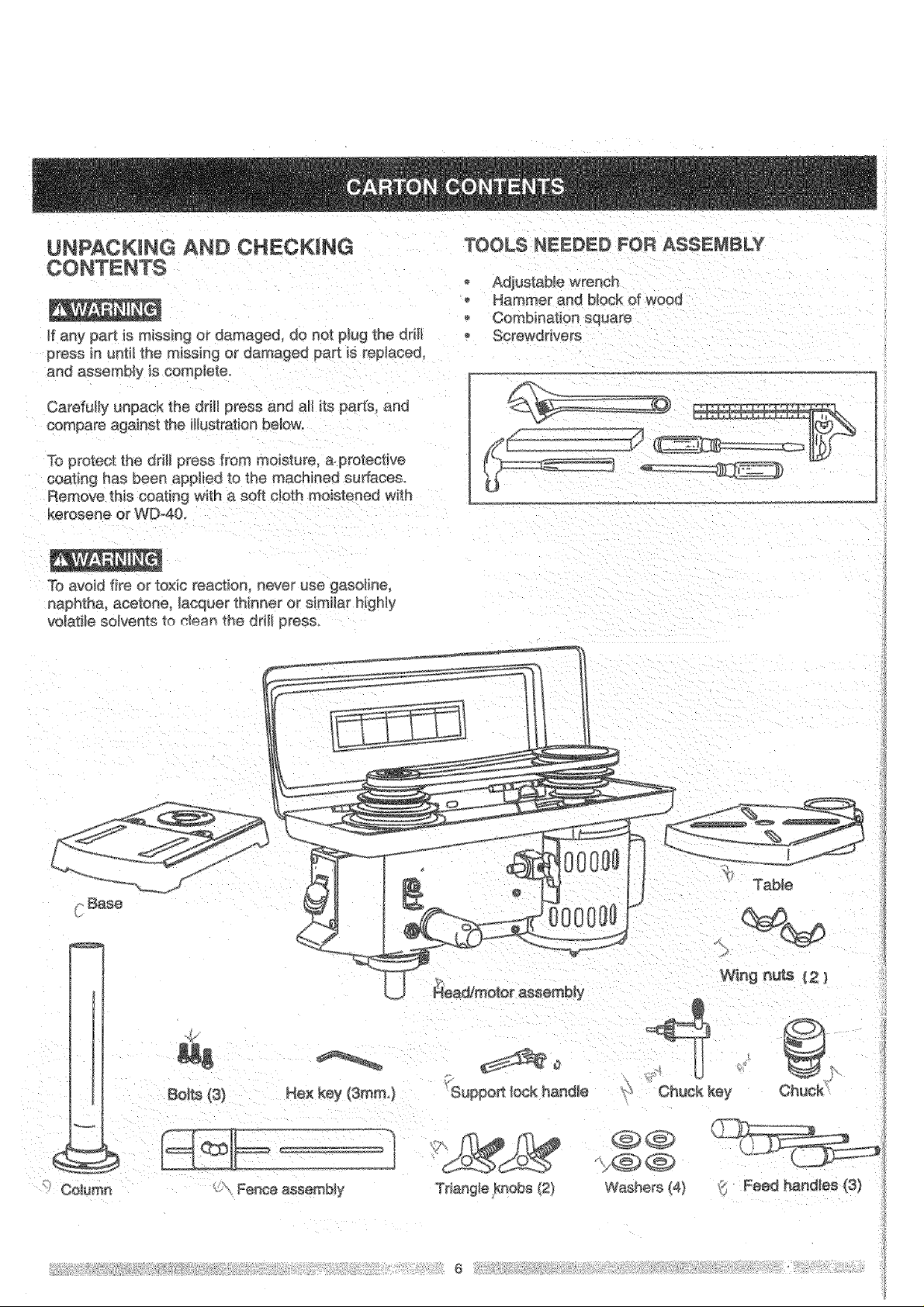

UNPACKING AND CHECKING

TOOLS NEEDED FOR ASSEMBLY

CONTE NTS

Hammer and block of wood

o Combination square

If any part is missing or damaged dO nol plug the ddll Screwdrivers

press in until the missing or damaged parl is replace&

and assemb|y is complete_

Carefully unpack the ddH press ann all its paris, and

compare against the illustration h÷low.

To protect the dr#! press trom moisture, a protectwe

coating has been applied to the machined surfaces.

Remove this coating with a soft cloth moiste;ned with

kerosene or WD-40.

To avoid tire or toxic reaction, never use gasoline,

naphtha_ ace[one, lacquer thinner or s_mHarhigh y

volatfle solvents T_ clean the drilt press=

BAse

Column

Bo_s (3}

Fence assembly

Read/motor assembbJ

J

Triangle '(hobs (2)

Washers f4_

Table

Feed handles {3)

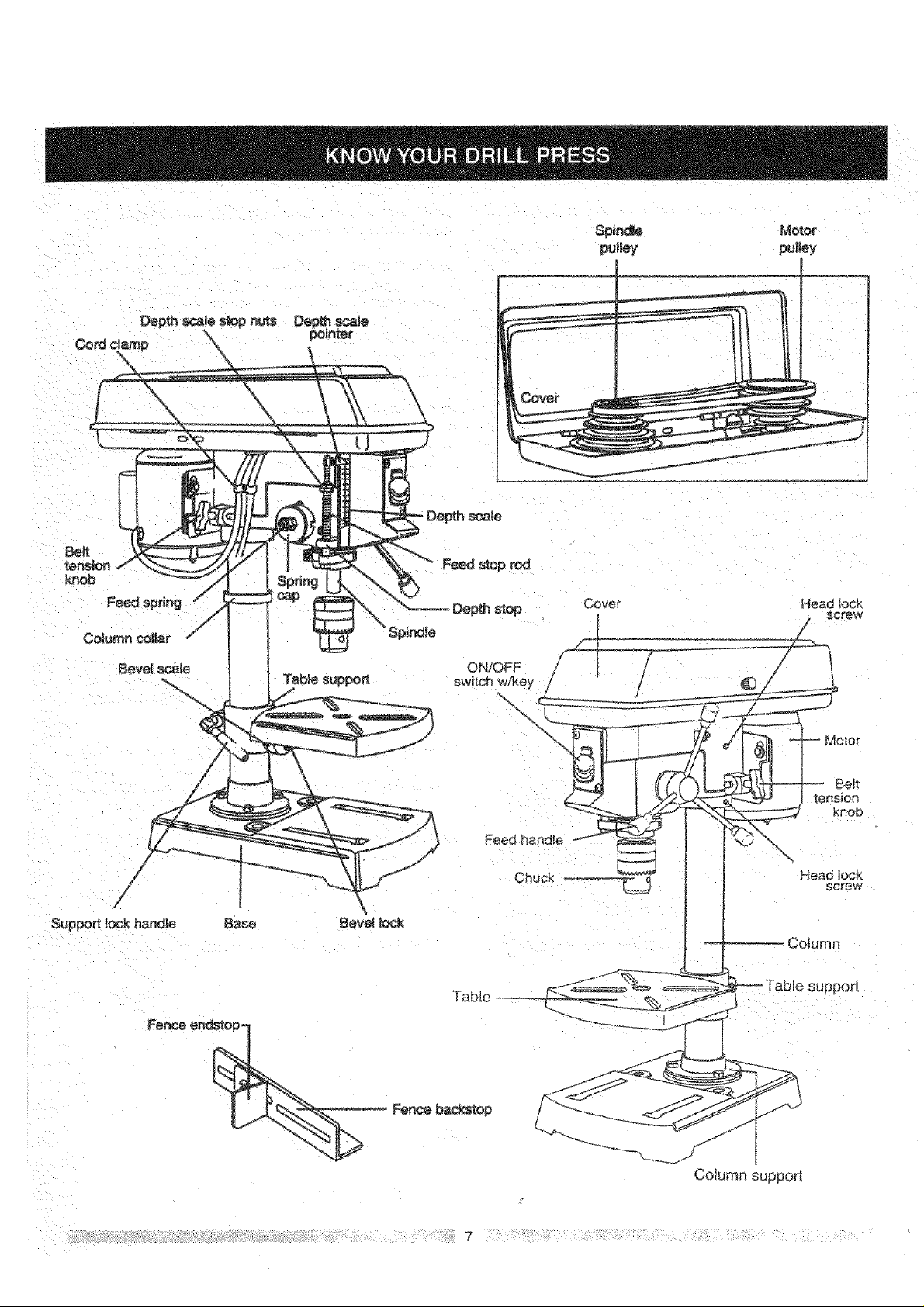

suppotl

Motor

pulley

Depth stop

f

/

/

\

/

Support lock handle

Base

Bevel I_k

TabJe

Fence backstop

Chuck

Column supporl

Headlock

Column

support

screw

Loading...

Loading...