Craftsman 137.219000 Operator's Manual

Operator's ManuaM

10 in. DRILL PRESS

With Laser Trac ®

Model No, 137,219000

.3

CAUTION:

Before using this DriJl Press,

read this manual and follow

all its Safety Rules and

Operating Instructions

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

Visit our Oraftsman website: www.sears.com/craftsman

Part No. 137219000001

o Safety Instructions

o Installation

® Operation

o Maintenance

• Parts List

Customer He_p Line

1-80@-843-1682

SECTmON PAGE

Warranty ........................................ 2

Product Specifications ....................... 2

Power Tool Safety ............................. 3

Drill Press Safety .................................. 4

Electrical Requirements and Safety ...... 5

Accessories and Attachments .............. 6

Tools Needed For Assembly ................ 6

Carton Contents .................................... 7

SECTmON PAGE

Know Your Drill Press ........................... 8

Glossary of Terms ............................. 9

Assembly and Adjustments ................. 10

Operation ........................................ 16

Maintenance ................................... 20

Troubleshooting Guide ........................ 21

Parts List ........................................... 22

ONE-YEAR FULL WARRANTY ON CRAFTSMAN TOOL

If this Craftsman too! fails due to a defect in material or workmanship within one year from the date of purchase,

CALL 1-800-4-MY-HOME ®TO ARRANGE FOR FREE REPAIR

If this too! is used for commercial or rental purposes, this warranty wil! apply for only ninety days from the date of

purchase. This warranty applies only while this tool is in the United States.

This warranty gives you specific bgal rights, and you may also have other rights, which vary, from state to state.

Sears, Roebuck & Co., Dept. 817 WA, Hoffman Estates, JL 60179

AWAn.I.G]

Some dust crested by power sanding, sawing, grinding, drilling and other construction activities contains

chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these

chemicals are:

Lead from lead-based paints

Crystalline silica from bricks, cement and other masonry products

Arsenic and chromium from chemically treated lumber

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in s well ventilated area and work with approved safety equipment such as

dust masks that are specially designed to filter out microscopic particles.

[AWAR"I"GI

To avoid electrical hazards, fire hazards or damage to the toot, use proper circuit protection.

This tool is wired st the factory for 110-120 Volt operation. It must be connected to s 110-120 Volt / 15 Ampere

time delay fuse or circuit breaker. To avoid shock or fire, replace power cord immediately if it is worn, cut or

damaged in any way.

Before using your tool, it is critics1 that you read and understand these safety rules. Failure to follow these

rules could result in serious injury to you or damage to the tool

GENERAL SAFETY mNSTRUCTmONS

BEFORE USING THIS DRILL PRESS

Safety is a combination of common sense, stay alert

and knowing how to use your dril! press.

[AWARN NGI

14.REMOVE ADJUSTING KEYS AND WRENCHES.

Form habit of checking to see that keys and adjusting

wrenches are removed from the too! before turning it

ON.

15NEVER LEAVE A TOOL RUNNING UNATTEND.

TURN THE POWER "OFF". Don't leave the tool until

it comes to a complete stoG

To avoid mistakes that could cause serious injury,

do not plug the drill press in until you have read and

understood the following.

1. READ and become familiar with the entire instruction

manual. LEARN the tool's application, limitations and

possible hazards.

2. KEEP GUARDS tN PLACE and in working order.

3. DON'T USE tN DANGEROUS ENVIRONMENT.

Don't use power tools in damp and wet locations, or

expose them to rain. Keep work area well lighted.

4. DO NOT use power tools in the presence of

flammable liquids or gases.

5. KEEP WORK AREA CLEAN. Cluttered areas and

benches invited accidents.

6. KEEP CHILDREN AWAY. All visitors should be kept

safe distance from work area.

7. DON'T FORCE THE TOOL. It wi!l do the job better

and safer at the rate for which it was designed.

8. USE THE RIGHT TOOL. Do not force a tool or an

attachment to do a job for which it was not designed.

9. WEAR PROPER APPAREL. Do not wear loose

clothing, gloves, neckties, rings, bracelets, or other

jewelry which may get caught in moving parts.

Nonslip footwear is recommended. Wear protective

hair covering to contain long hair.

10.WEAR A FACE MASK OR DUST MASK. Sawing

operation produces dusL

11.DISCONNECT TOOLS before servicing; when

changing accessories such as blades, bits, cutters,

and the like.

12REDUCE THE RiSK OF UNINTENTIONAL

STARTING. Make sure the switch is in the off

position before plugging in.

1&USE RECOMMENDED ACCESSORIES. Consult

the owner's manual for recommend accessories. The

use of improper accessories may cause risk of injury

to persons.

16NEVER STAND ON THE TOOL. Serious injury

could occur if the tool is tipped or if the cutting tool is

unintentionally contacted.

17DON'T OVERREACH. Keep proper footing and

balance at al! times.

18.1VIAtNTAIN TOOLS WITH CARE. Keep tools sharp

and clean for best and safest performance. Follow

instructions for lubricating and changing accessories.

1&CHECK FOR DAMAGED PARTS. Before further

use of the tool, a guard or other part that is damaged

should be carefully checked to determine that it will

operate properly and perform its intended function

= check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting, and any

other conditions that may affect its operation. A guard

or other part that is damaged should be properly

repaired or replaced.

2&MAKE WORKSHOP CHILD PROOF with pad!ocks,

master switches, or by removing starter key&

21 .DO NOT operate the tool if you are under the

influence of any drugs, alcoho! or medication that

could affect your ability to use the tool properly.

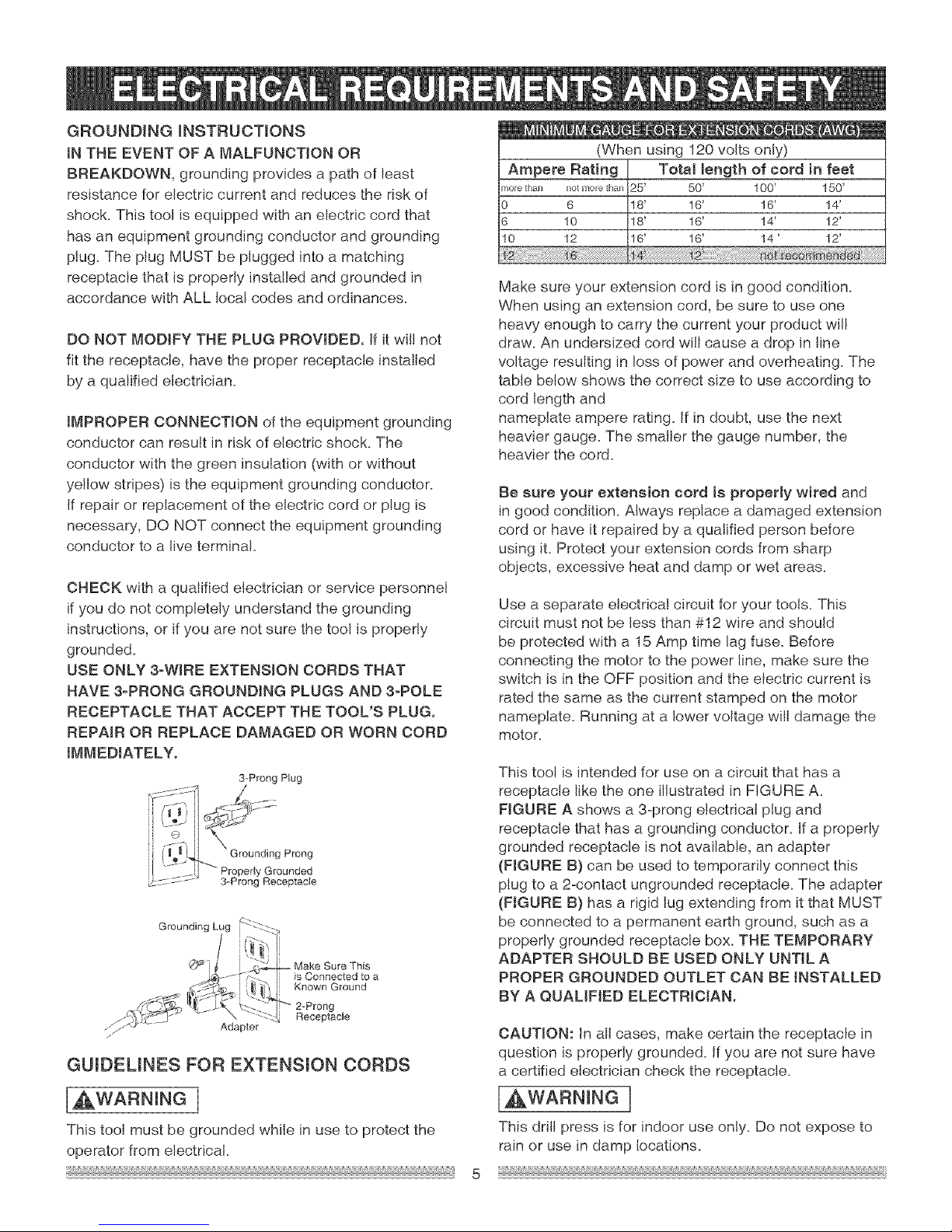

22.Dust generated from certain materiai can be

W_AR YOUR

2&ALWAYS WEAR EYE PROTECTION. Any drill

press can throw foreign objects into the eyes and

could cause permanent eye damage. ALWAYS

wear Safety Goggles (not glasses) that comply with

ANSi Safety standard Z87.1 Everyday eyeglasses

have only impact -resistance lenses. They ARE

NOT safety glasses. Safety Goggles are available at

Sears. NOTE: Glasses or goggles not in compliance

with ANSI Z87.1 could seriously hurt you when they

break.

hazardous to your health. Always

operate the drill press in a well-

ventilated area and provide for

proper dust removal. Use a dust

collection system whenever

possibb.

[AWARNINGI

For your own safety, do not try to use your drill press or

plug it in until it is completely assembled and installed

according to the instructions, and until you have read

and understood this instruction manual:

1. YOUR DRILL PRESS MUST BE BOLTED securely

to a workbench. In addition, if there is any tendency

for your drill press to move during certain operations,

bolt the workbench yo the floor.

2. THiS DRILL PRESS is intended for use in dry

conditions, indoor use only.

14SECURE THE WORK. Use clamps or a vise to hold

the work when practical, it's safer than using your

hand and it frees both hands to operate tool

1&WHEN using a dril! press vise, always fasten to the

table.

16MAKE SURE all clamps and locks are firmly

tightened before drilling.

17SECURELY LOCK THE HEAD and table support to

the column, and the table to the table support before

operating the drill press.

3. WEAR EYE PROTECTION. USE A face or dust

mask along with safety goggles if drilling operation

is dusty. USE ear protectors, especially during

extended periods of operation.

4. DO NOT wear gloves, neckties, or loose clothing.

5. DO NOT try to dril! material too small to be securely

held.

6. ALWAYS keep hands out of the path of a drill bit.

Avoid awkward hand positions where a sudden slip

could cause your hand to move intothe dril! biL

7. DO NOT install or use any dril! bit that exceeds 175

mm (7 in.) in length or extends 150 mm (6 in.) below

the chuck jaws. They can suddenly bend outward or

break.

8. DO NOT USE wire wheels, router bits, shaper

cutters, circle (fly) cutters, or rotary planers on this

dril! press.

9. WHEN cutting a large piece of materia! ,make sure it

is fully supported at the table height.

10DO NOT perform any operation freehand. ALWAYS

hold the workpiece firmly against the table so it will

not rock or twisL Use clamps or a vise for unstable

workpieces.

11.MAKE SURE there are no nails or foreign objects in

the part of the workpiece to be drilled.

12.CLAMP THE WORKPIECE OR BRACE tT against

the left side of the column to prevent rotation. If it is

too short or the table is tilted, clamp itsolidly to the

table and use the fence provide&

13JF THE WORKPIECE overhangs the table such that

it will fall or tip if not held, clamp it to the table or

provide auxiliary support.

1&NEVER turn your dril! press on before clearing the

table of all objects (tools, scraps of wood, etc.)

19BEFORE STARTING the operation, jog the motor

switch to make sure the dril! bit does not wobble or

vibrate.

20lET THE SPINDLE REACH FULL SPEED before

starting to drill, if your drill press makes an unfamiliar

noise or if it vibrates excessively, stop immediately,

turn the drill press off and unplug. If do not restart the

unit until the problem is correcte&

21 DO NOT perform layout assembly or set up work on

the table while the drill press is in operation.

22.USE THE RECOMMENDED SPEED for any drill

press accessory and for different workpiece material.

READ THE INSTRUCTIONS that come with the

accessory.

23.WHEN DRiLLiNG large diameter holes, clamp the

workpiece firmly to the table. Otherwise, the bit may

grap and spin the workpiece at high speeds. DO

NOT USE fly cutters or multiple-part hole cutters, as

they can come apart or become unbalanced in use.

24MAKE SURE the spindle has come to a complete

stop before touching the workpiece.

2&TO AVOID INJURY from accidental starting, always

turn the switch "OFF" and unplug the dri!! press

before installing or removing any accessory or

attachment or making any adjustmenL

26KEEP GUARDS tN PLACE and in working order.

27.USE ONLY THE SELF-EJECTING TYPE CHUCK

KEY as provided with the dril! press.

GROUNDINGINSTRUCTIONS

tNTHEEVENTOFA_,_ALFUNCTIONOR

BREAKDOWN,groundingprovidesapathofleast

resistanceforelectriccurrentandreducestheriskof

shock.Thistoolisequippedwithanelectriccordthat

hasanequipmentgroundingconductorandgrounding

plug.TheplugMUSTbepluggedintoamatching

receptaclethatisproperlyinstalledandgroundedin

accordancewithALLlocalcodesandordinances.

DONOTMODIFYTHEPLUGPROVIDED.Ifitwil!not

fitthereceptacle,havetheproperreceptacleinstalled

byaqualifiedelectrician.

IMPROPERCONNECTIONoftheequipmentgrounding

conductorcanresultinriskofelectricshock.The

conductorwiththegreeninsulation(withorwithout

yellowstripes)istheequipmentgroundingconductor.

Ifrepairorreplacementoftheelectriccordorplugis

necessary,DONOTconnecttheequipmentgrounding

conductortoa liveterminal.

CHECKwitha qualifiedelectricianorservicepersonnel

ifyoudonotcompletelyunderstandthegrounding

instructions,orifyouarenotsurethetoolisproperly

grounded.

USEONLY3-WIREEXTENSIONCORDSTHAT

HAVE3-PRONGGROUNDINGPLUGSAND3-POLE

RECEPTACLETHATACCEPTTHETOOL'SPLUG.

REPAIRORREPLACEDAMAGEDORWORNCORD

IMMEDIATELY.

3-Prong Ptug

ig Prong

Grounded

Grounding Lug

:ure This

is Connected to a

Known Ground

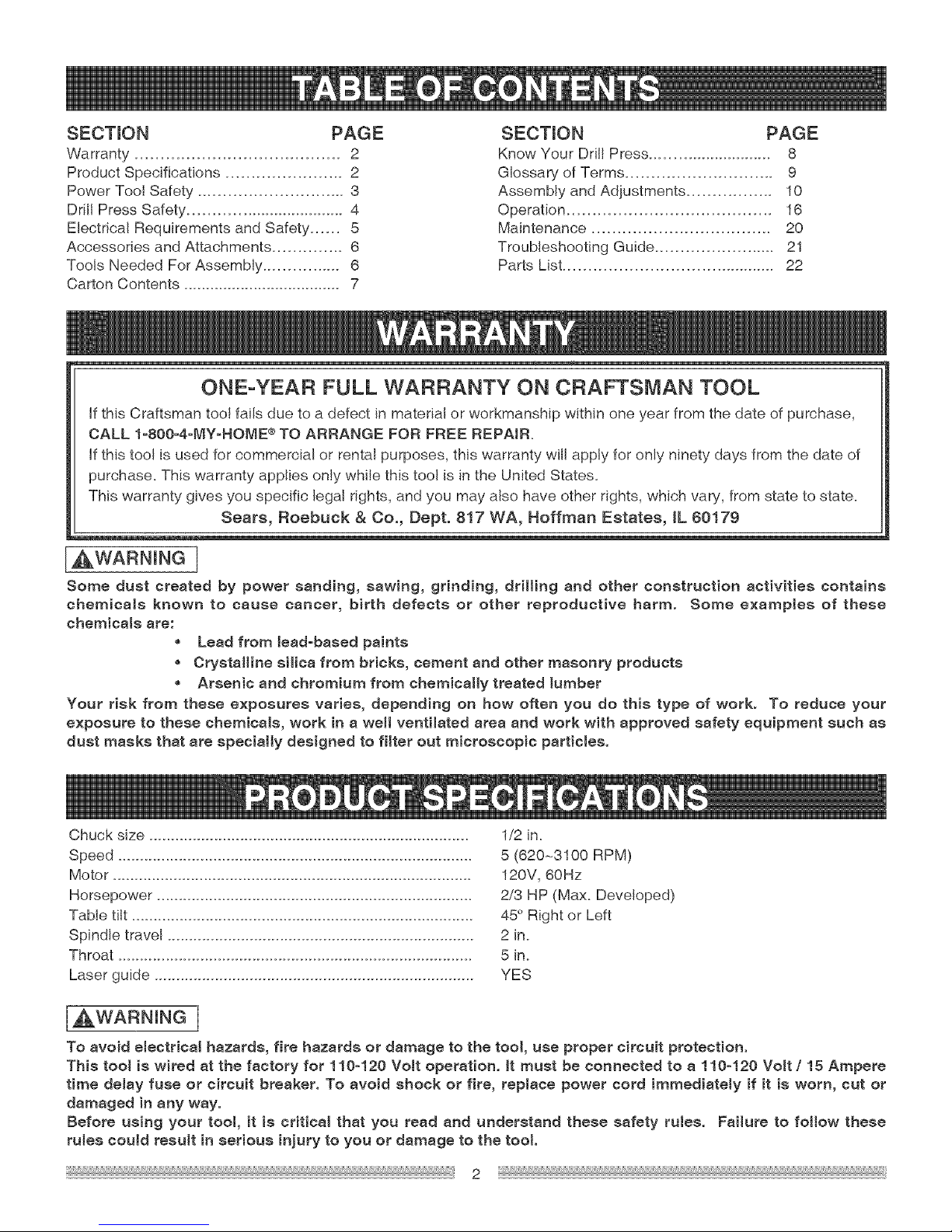

(When using 120 volts only)

Ampere Rating Total length of cord in feet

_lole than not mole than 25' 50' 100' 150'

0 6 18' 16' 16' 14'

10 18' 16' 14' 12'

16' 16' 14 ' 12'

Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one

heavy enough to carry the current your product will

draw. An undersized cord wi!! cause a drop in line

voltage resulting in loss of power and overheating. The

table below shows the correct size to use according to

cord length and

nameplate ampere rating. If in doubt, use the next

heavier gauge. The smaller the gauge number, the

heavier the cord.

Be sure your extension cord is properly wired and

in good condition. Always replace a damaged extension

cord or have it repaired by a qualified person before

using it. Protect your extension cords from sharp

objects, excessive heat and damp or wet areas.

Use a separate electrical circuit for your tools. This

circuit must not be less than #12 wire and should

be protected with a 15 Amp time lag fuse. Before

connecting the motor to the power line, make sure the

switch is in the OFF position and the electric current is

rated the same as the current stamped on the motor

nameplate. Running at a lower voltage wil! damage the

motor.

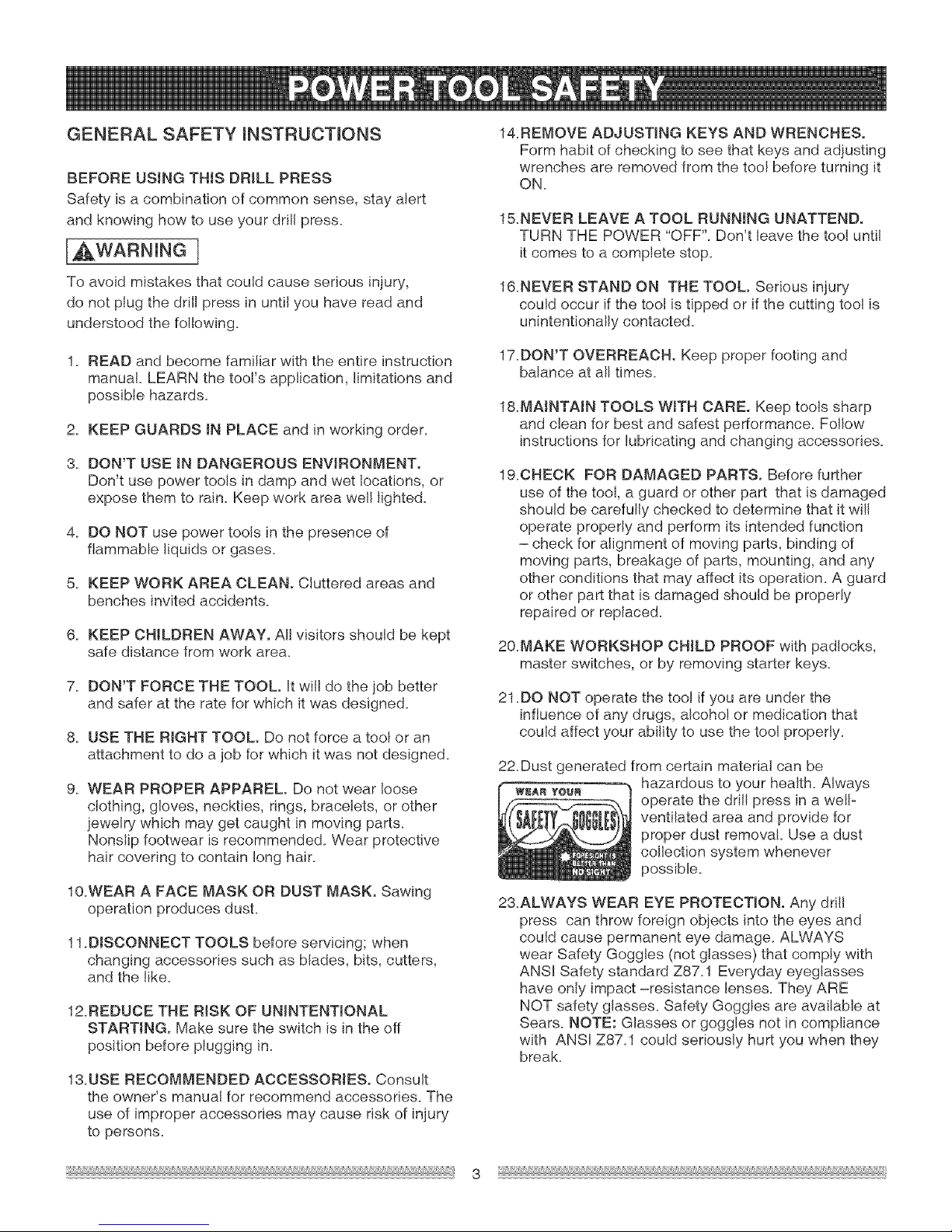

This tool is intended for use on a circuit that has a

receptacle like the one illustrated in FIGURE A.

FIGURE A shows a 3-prong electrical plug and

receptacle that has a grounding conductor, if a properly

grounded receptacle is not available, an adapter

(FIGURE B} can be used to temporarily connect this

plug to a 2-contact ungrounded receptacle. The adapter

(FIGURE B) has a rigid lug extending from it that MUST

be connected to a permanent earth ground, such as a

properly grounded receptacle box. THE TEMPORARY

ADAPTER SHOULD BE USED ONLY UNTIL A

PROPER GROUNDED OUTLET CAN BE INSTALLED

BY A QUALIFIED ELECTRICIAN.

Adapter

GUmDEUNES FOR EXTENSmON CORDS

[AWAR" "GI

This too! must be grounded while in use to protect the

operator from electrical.

CAUTION: In all cases, make certain the receptacle in

question is properly grounded. Ifyou are not sure have

a certified electrician check the receptacle.

IAWARNRNGI

This drill press is for indoor use only. Do not expose to

rain or use in damp locations.

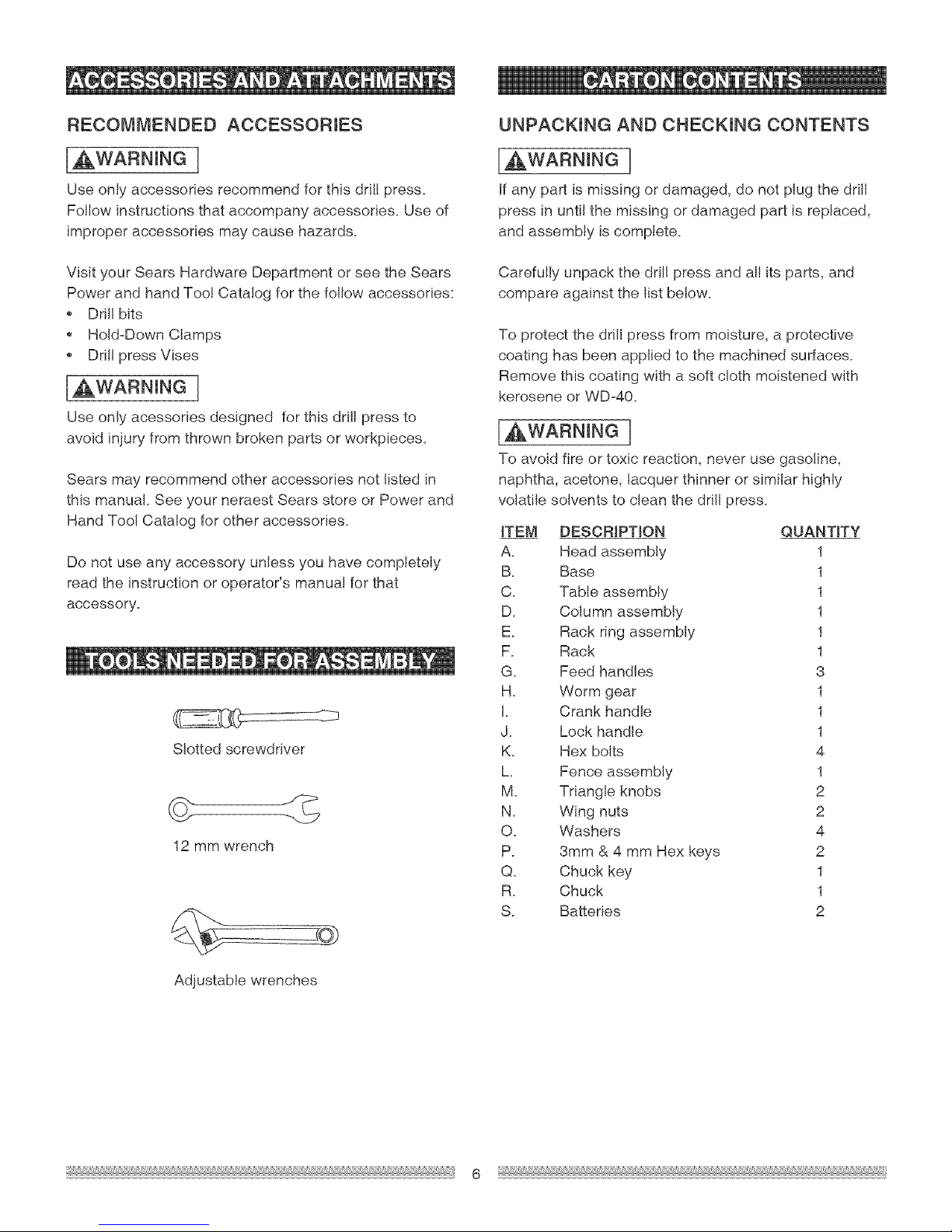

RECOMMENDED ACCESSORmES

UNPACKING AND CHECKING CONTENTS

[AWARN NGI

Use only accessories recommend for this drill press.

Follow instructions that accompany accessories. Use of

improper accessories may cause hazards.

Visit your Sears Hardware Department or see the Sears

Power and hand Tool Catalog for the follow accessories:

Drill bits

Hold-Down Clamps

Drill press Vises

[ WARN NGJ

Use only acessories designed for this drift press to

avoid injury from thrown broken parts or workpieces.

Sears may recommend other accessories not listed in

this manual See your neraest Sears store or Power and

Hand Tool Catalog for other accessorie&

Do not use any accessory unless you have completely

read the instruction or operator's manual for that

accessory.

Slotted screwdriver

12 mm wrench

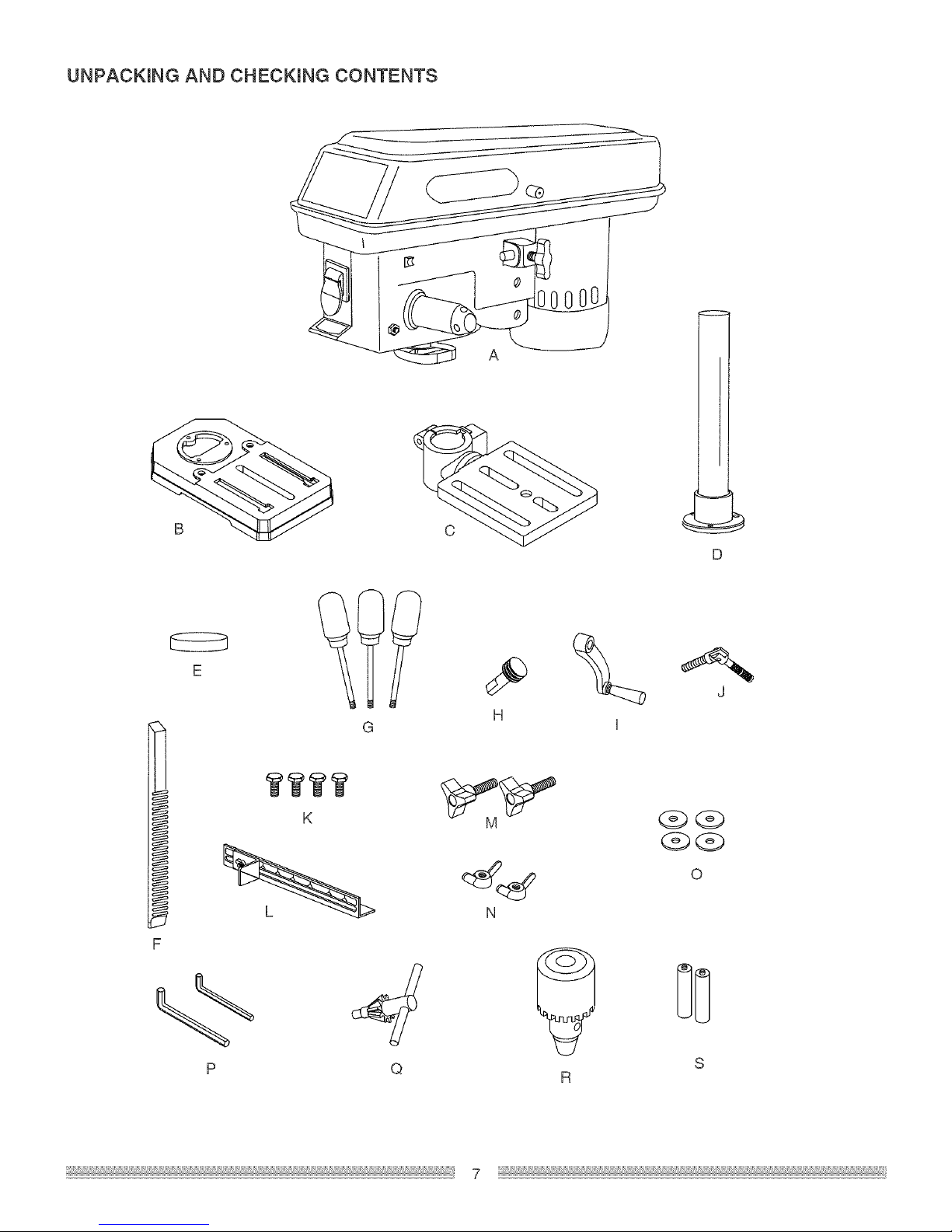

[AWARNmNG ]

If any part is missing or damaged, do not plug the drill

press in until the missing or damaged part is replaced,

and assembly is complete.

Carefully unpack the drift press and al! its parts, and

compare against the list below.

To protect the drill press from moisture, a protective

coating has been applied to the machined surfaces.

Remove this coating with a soft cloth moistened with

kerosene or WDo40.

[, ,WARNING J

To avoid fire or toxic reaction, never use gasoline,

naphtha, acetone, lacquer thinner or similar highly

volatile solvents to clean the dril! press.

ITEM DESCRIPTION QUANTITY

A. Head assembly 1

B. Base 1

C. Table assembly 1

D. Column assembly 1

E. Rack ring assembly 1

F. Rack 1

G. Feed handles 3

H. Worm gear 1

L Crank handle 1

J. Lock handle 1

K. Hex bolts 4

h Fence assembly 1

M. Triangle knobs 2

N. Wing nuts 2

O. Washers 4

P. 3mm & 4 mm Hex keys 2

Q. Chuck key 1

R. Chuck 1

S. Batteries 2

Adjustable wrenches

UNPACKING AND CHECKING CONTENTS

D

E

H

I

WWWW

K

O

N

# DD

Q S

R

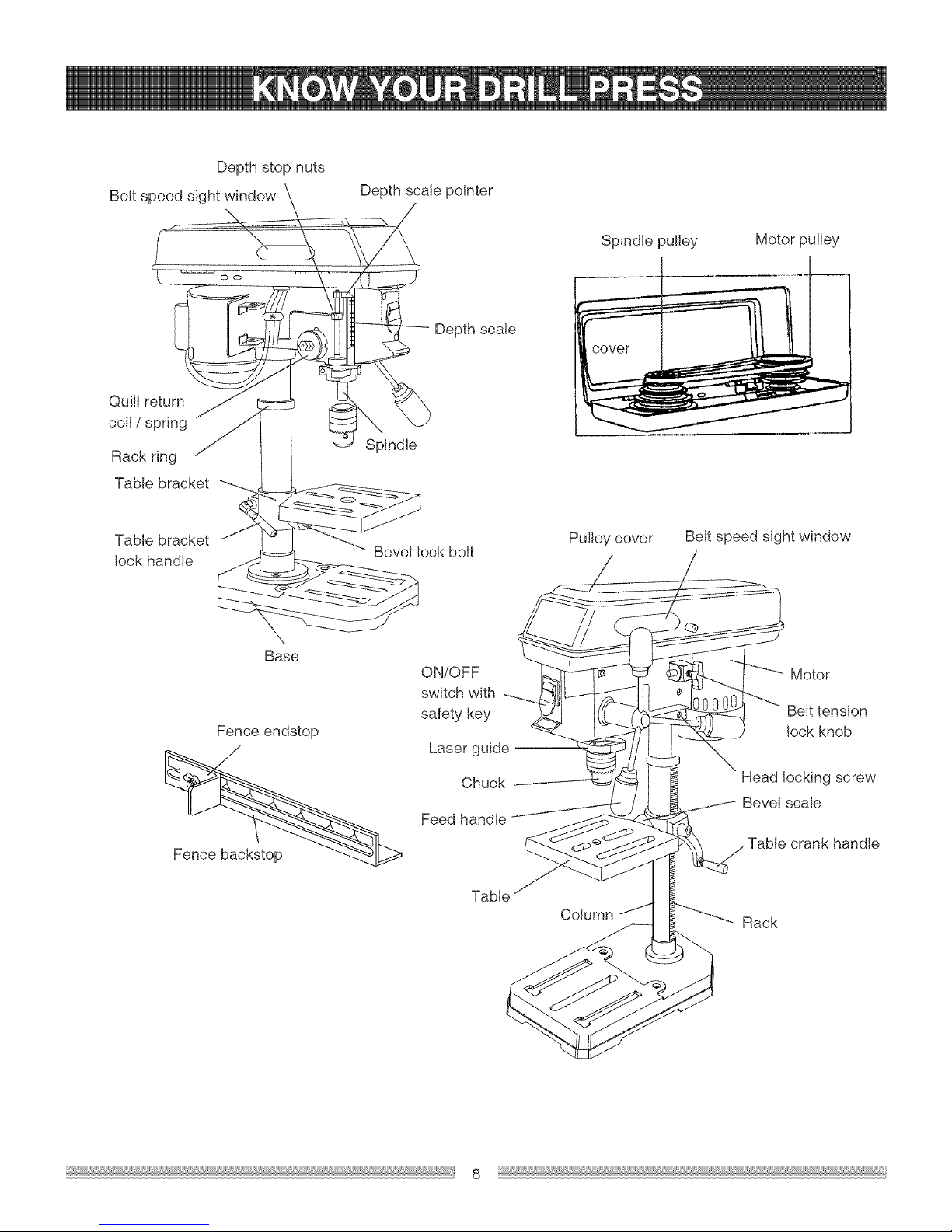

Beltspee_

Quill retu

coil / spring

Rack ring

Table bracket

Depth stop nuts

Oo

Depth scale pointer

- --C /

in

Depth scale

Spindle pulley

Motor pulley

Table bracket

lock handle

Base

Fence endstop

Bevel lock bolt

ON/OFF Motor

switch with

safety key Belt tension

Laser guide

Feed handle

Pulley cover

Belt speed sight window

lock knob

Chuck Head locking screw

Bevel scale

Table

Column

Rack

Loading...

Loading...