Craftsman 137218780 Owner’s Manual

Owner's Manual

2.5 HP (Ma×imum Deveioped)

10" inch Blade

5000 R.P.M.

TABLE SAW

ModeJ No.

!37.218780

CAUTION..

Before using this Table Saw,

read this manual and follow

all its Safety Rules and

Operating Instructions.

o Safety Instructions

o Installation

,, Operation

• Maintenance

® Parts List

,, EspaSol

Customer Help Line

1-800-843-1682

Sears, Roebuck and Co., Hoffman Estates, mL60179 USA

Part No. 137218780001

SECTION PAGE

Warranty ................................................................ 2

Product Specifications ..................................................... 2

Safety instructions ........................................................ 3

Accessories and Attachments ................................................ 6

Tools needed for assembly ................................................. 6

Carton Contents .......................................................... 6

Know Your Table Saw ...................................................... 8

Assembly and Adjustments .................................. : .... .. ........ 9

Operation .............................................................. 14

Maintenance ............................................................ 18

Troubleshooting guide .................................................... 19

Parts .................................................................. 20

Making a push stick ...................................................... 29

EspaSol ................................................................ 33

FULL ONE YEAR WARRANTY

If this product fails due to a defect in material or workmanship within one year from the date of purchase, Sears

will repair it free of charge.

Contact a Sears Service Center for repair.

if this product is used for commercial or rentat purposes, this warranty applies only for 90 days from the date of

purchase.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., Dept. 817 WA, Hoffman Estates, IL 60179

MOTOR

HP (Max. developed) ............ 2.5

Volts ........................ 120

Amperes ..................... 13

To avoid electrical hazards, fire hazards, or damage to

the tool, use proper circuit protection.

Hertz ....................... 60

RPM (no load) ................ 5000

Overload protection ............. YES

Your table saw is wired at the factory for 120V operation. :i::i::

Connect to a t20V, 15 AMP branch circuit and use a t5 :::

AMP time delay fuse or circuit breaker. To avoid shock or

SAW

Table ....................... 17-1/2" x 26-!/2"

fire, replace power cord immediately if it is worn, cut or

damaged in any way.

Blade ...................... 1i0 i!i

Maximum depth of cut at 90° ..... 3"

Maximum depth of cut at 45° ..... 2-1/2'!

Maximum width of dado ......... 1/2"

Weight ...................... 35.4 Ibs.

:! [; :

_,!:•:_::::i,:i::•i::!::_:::!:•:?_¸_i:;::::!:::/•:_:/?,i!::::::::_:::::/::•:,:_::?i::!:_:::'ii::;ii::i_:::::i!::f!:!:i:::ii::::_:_;:::i:i;::;i:::,!:!::,ii::i¸i::;il!i:il:i!i_:i¸!::ii::i_:i_::!:i:i!:ii__:!ii:::!:!i!_i::_ifi_•_!_i_i:iii:!i:_:¸i:i::_:_:ii::¸il:ii;:ii

,j

GENERAL SAFETY INSTRUCTIONS

12.

WEANYOUR ALWAYS WEAR EYE

PROTECTION. Any table

BEFORE USING THE TABLE SAW

saw can throw foreign

objects into the eyes which

!i_i:i

Safety is a combination of common sense, staying alert

and knowing how to use your table saw.

could cause permanent eye

damage. ALWAYS wear

Safety Goggles (not glasses)

that comply with ANSI safety standard Z87.1.

Everyday eyeglasses have only impact-resistant

lenses. They ARE NOT safety glasses. Safety

Goggles are available at Sears. NOTE: Glasses or

goggles not in compliance with ANSI Z87.! could

seriously hurt you when they break.

13.

WEAR A FACE MASK OR DUST MASK.

Sawing operation produces dust.

t4. SECURE WORK. Use clamps or a vise to hold work

when practical. It's safer than using your hand and it

frees both hands to operate tool.

i:! :i

: i

To avoid mistakes that could cause serious injury, do not

plug the table saw in until you have read and understood

the following:

t.

i

i

READ and become familiar with this entire instruction

manual. LEARN the tool's applications, limitations, and

possible hazards.

.

KEEP GUARDS IN PLACE and in working order.

3.

REMOVE ADJUSTING KEYS AND WRENCHES.

Form the habit of checking to see that keys and

adjusting wrenches are removed from the tool before

15. DISCONNECT TOOLS before servicing, and when

changing accessories, such as blades, bits, cutters,

and the like.

REDUCE THE RISK OF UNINTENTIONAL STARTING.

16.

Make sure the switch is in OFF position before

plugging in.

17.

USE RECOMMENDED ACCESSORIES. Consult the

owner's manual for the recommended accessories.

The use of improper accessories may cause risk of

injury to persons.

18.

NEVER STAND ON TOOL. Serious injury could occur

if the tool is tipped or if the cutting tool is unintentionally

contacted.

CHECK FOR DAMAGED PARTS. Before further use of

19.

the tool, a guard or other part that is damaged should

be carefully checked to determine that it will operate

properly and perform its intended function. Check for

alignment of moving parts, binding of moving parts,

breakage of parts, mounting, and any other conditions

that may affect its operation. A guard or other part that

is damaged should be properly repaired or replaced.

20.

NEVER LEAVE TOOL RUNNING UNATTENDED.

TURN THE POWER OFF. Don't leave the toot until

it comes to a complete stop.

21.

DON'T OVERREACH. Keep proper footing and

balance at all times.

22.

MAINTAIN TOOLS WITH CARE. Keep tools sharp

and clean for best and safest performance. Follow

instructions for lubricating and changing accessories.

::::!i/ •

turning ON.

.

KEEP WORK AREA CLEAN. Cluttered areas and

benches invite accidents.

.

DON'T USE JN A DANGEROUS ENVIRONMENT.

Don't use power tools in damp or wet locations, or

expose them to rain. Keep work area well lighted.

.

KEEP CHILDREN AWAY. All visitors should be kept at

a safe distance from the work area.

,

MAKE WORKSHOP KID PROOF with padlocks, master

switches, or by removing starter keys.

,

DON'T FORCE THE TOOL. It will do the job better

and safer at the rate for which it was designed.

USE THE RIGHTTOOL. Don't force tool or the

attachment to do a job for which it was not designed.

USE PROPER EXTENSION CORD. Make sure your

extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to

carry the current your product wi!l draw. An undersized

cord will cause a drop in line voltage resulting in loss

of power and overheating. The table on page 5 shows

the correct size to use depending on cord length and

nameplate ampere rating. If in doubt, use the next

heavier gauge. The smaller the gauge number, the

heavier the cord.

1t. WEAR PROPER APPAREL. DO NOT wear loose

clothing, gloves, neckties, rings, bracelets, or other

jewelry which may get caught in moving parts.

Nonslip footwear is recommended. Wear protective

hair covering to contain long hair.

SAVE THESE iNSTRUCTIONS

,i

3 :: : i::; : : ::: :: : : : ::

23. DIRECTION OF FEED. Feed work into a blade or cutter

against the direction of rotation of the blade or cutter

only.

24. WARNING: Dust generated from certain materials can

be injurious to your health. Always operate saw in well

ventilated areas and provide for proper dust removal.

SPECIFMC SAFETY INSTRUCTmONS

FOR THE TABLE SAW

1.

ALWAYS USE SAW BLADE GUARD spreader and

anti-kickback pawls for every operation fer which

they can be used, including through-sawing.

Through-sawing operations are those in which the

blade cuts completely through the workpiece

when ripping or cress-cutting,

2. ALWAYS HOLD THE WORK FIRMLY against the

miter gauge or rip fence.

.

USE A PUSH STICK when required. Always use a

push stick for ripping narrow stock. Refer to ripping

applications in the instruction manual where the

push stick is covered in detail. See the push stick

pattern included in this Owner's Manual.

. NEVER PERFORM ANY OPERATION

"FREE HAND", which means using your hands

only to support or guide the werkpiece. Always

use either the fence or the miter gauge to position

and guide the work.

5. NEVER STAND or have any part of your body

in line with the path of the saw blade. Keep your

hands out of the line of the saw blade.

6. NEVER REACH behind or over the cutting tool

for any reason.

7. REMOVE the rip fence when cross-cutting.

8. DO NOT USE molding head set with this saw.

9. FEED WORK INTO THE BLADE against the

direction of rotation only.

10. NEVER use the fence as a cut-off gauge when

cross-cutting.

1i. NEVER ATTEMPTTO FREE A STALLED SAW

BLADE without first turning the saw OFR Turn

power switch OFF immediately to prevent motor

damage.

12.

PROVIDE ADEQUATE SUPPORT to the rearand

sides of the saw table for wide or long Wbrkpiece_i

13.

AVOID KICKBACKS (work thrown back towards

you) by keeping the blade sharp, keeping the rip

fence )arallel to the saw blade, and by keeping the

spreader, anti-kickback pawls, and guard in place

and functioning. Do not release work before it is

pushed all the way past the saw blade. Do not rip

work that is twisted, warped, or does not have a

straight edge to guide along the fence.

t4.

AVOID AWKWARD OPERATIONS and hand

positions where a sudden slip could cause your

hand to move into the cutting tool.

15.

NEVER USE SOLVENTS to clean plastic parts.

Solvents could possibly dissolve or otherwise

damage the material. Only a soft damp cloth should

be used to clean plastic parts.

16. MOUNT your table saw before performing any

cutting operations. Refer to installation instructions.

17. NEVER CUT METALS or materials which may make

hazardous dust.

18.

ALWAYS USE IN A WELL VENTILATED AREA.

Remove sawdust frequently. Clean out sawdust from

the interior of the saw to prevent a potential fire

hazard.

19. NEVER LEAVE THE TOOL running unattended.

Don't leave the too! until it comes to a complete stop.

20.

For proper operation follow the instructions of this

owner's manual titled "SAW MOUNTED TO WORK

SURFACES." Failure to provide sawdust falFthrough

and removal hole will allow sawdust to build up in

the motor area, which may result in a fire hazard or

cause motor damage.

ELECTRICAL REQUIREMENTS

POWER SUPPLY AND MOTOR

SPECIFICATIONS

To avoid electrical hazards, fire hazards, or damage to

the tool, use proper circuit protection. Use a separate

electrical circuit for your tools.Your saw is wired at the

factory for t20V operation. Connect to a 120V, 15 Amp

circuit and use a I5 Amp time delay fuse or circuit

breaker. To avoid shock or fire, if power cord is worn or

cut, or damaged in any way, have it replaced

immediately.

GROUNDING INSTRUCTIONS

IN THE EVENT OF A MALFUNCTmONOR BREAKDOWN,

grounding provides a path of least resistance for electric

current and reduces the risk of electric shock. This too!

is equipped with an electric cord that has an equipment

grounding conductor and a grounding plug. The plug

MUST be plugged into a matching receptacle that is

properly installed and grounded in accordance with ALL

local codes and ordinances.

DO NOT MODIFY THE PLUG PROVIDED. If it will not

fit the receptacle, have the proper receptacle installed

by a qualified electrician.

IMPROPER CONNECTION of the equipment grounding

conductor can result in risk ef electric shock. The

conductor with the green insulation (with or without

yellow stripes) is the equipment grounding conductor. If

repair or replacement of the electric cord or plug is

necessary, DO NOT connect the equipment grounding

conductor to a live terminal.

CHECK with a qualified electrician or service person if

you do not completely understand the grounding

instructions, or if you are not sure the tool is properly

grounded.

USE A SEPARATE ELECTRICAL CIRCUIT for your

tools. This circuit must not be less than #12 wire and

should be protected with a 15 Amp time delay fuse.

Before connecting the motor to the power line, make

sure the switch is in the OFF position and the electric

current is rated the same as the current stamped on the

motor nameplate. Running at a !ower voltage will

damage the motor.

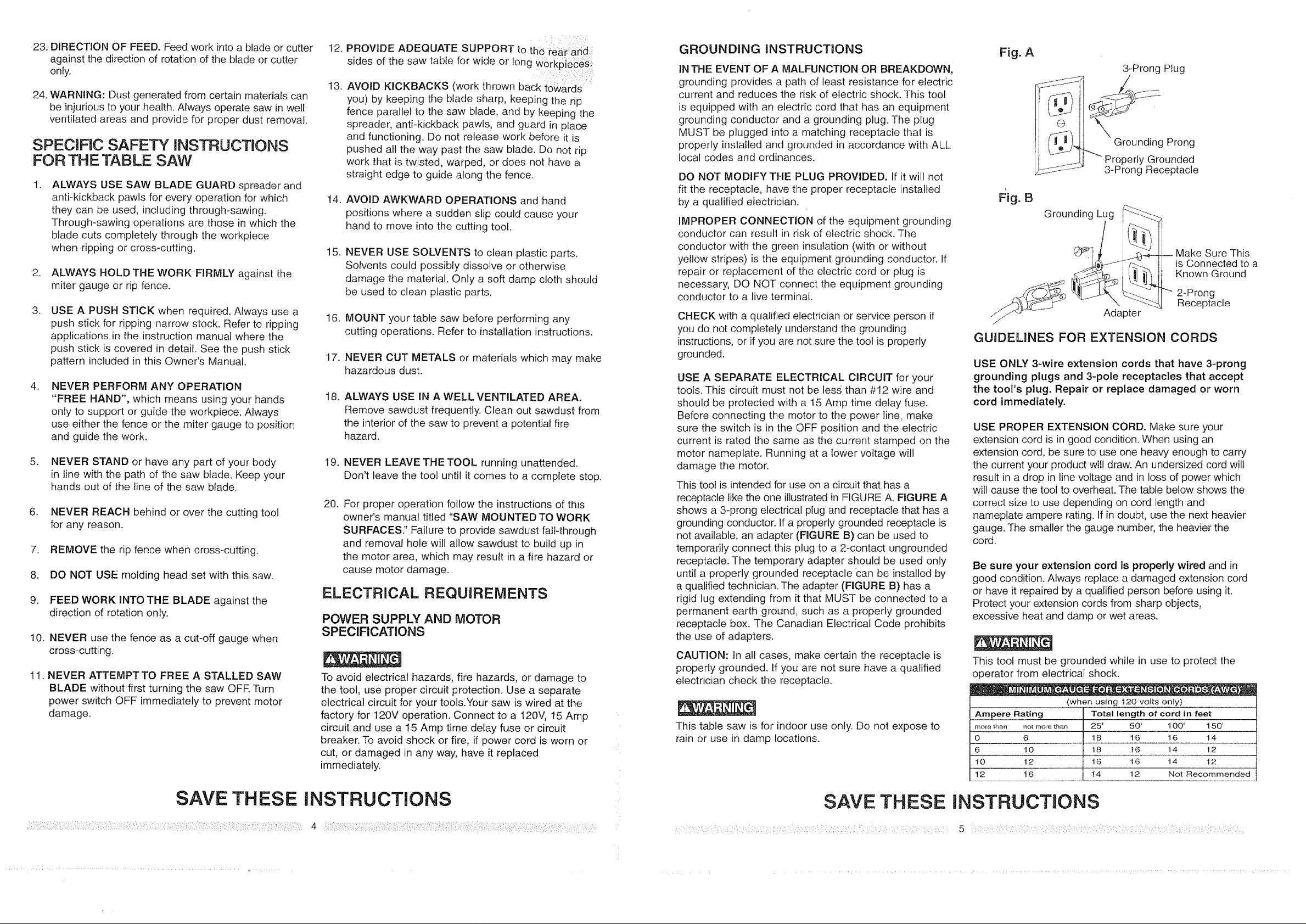

This toot is intended for use on a circuit that has a

receptacle like the one illustrated in FIGURE A. FIGURE A

shows a 3-prong electrical plug and receptacle that has a

grounding conductor. If a properly grounded receptacle is

not available, an adapter (FIGURE B) can be used to

temporarily connect this plug to a 2-contact ungrounded

receptacle. The temporary adapter should be used only

until a properly grounded receptacle can be installed by

a qualified technician. The adapter (FIGURE B) has a

rigid lug extending from it that MUST be connected to a

permanent earth ground, such as a properly grounded

receptacle box. The Canadian Electrical Code prohibits

the use of adapters.

CAUTION: tn all cases, rnake certain the receptacle is

properly grounded, if you are not sure have a qualified

electrician check the receptacle.

This table saw is for indoor use only. Do not expose to

rain or use in damp locations.

Fig. A

3-Prong PIug

® i

---....

Properly Grounded

3-Prong Receptacle

Fig. B

Greunding_qiLug _[_'_i_

_-- Adapter

GUIDELINES FOR EXTENSION CORDS

USE ONLY 3-wire extension cords that have 3-prong

grounding plugs and 3-pole receptacles that accept

the tool's plug. Repair or replace damaged or worn

cord immediately.

USE PROPER EXTENSION CORD. Make sure your

extension cord is in good condition. When using an

extension cord, be sure te use one heaW enough to carry

the current your product will draw. An undersized cord will

result in a drop in line voltage and in loss of power which

will cause the tool to overheat. The table below shows the

correct size to use depending on cord length and

nameplate ampere rating. If in doubt, use the next heavier

gauge. The smaller the gauge number, the heavier the

cord.

Be sure your extension cord is properly wired and in

good condition. Always replace a damaged extension cord

or have it repaired by a qualified person before using it.

Protect your extension cords from sharp objects,

excessive heat and damp or wet areas.

This toot must be grounded while in use to protect the

operator from electrical shock.

(when using 120 volts only)

Ampere Rating Total length of cord in feet

more than not more than 25' 50' 100' 150'

0 6 18 16 16 14

6 10 18 t6 14 12

10 12 16 t6 14 12

12 16 t 4 12 Not Recommended

j Prong

_ Make Sure This

is Connected to a

Known Greund

"" 2-Prong

Receptacle

SAVE THESE

INSTRUCTIONS

5 : ::': : ::

Loading...

Loading...