Page 1

Owner's Manual

CRRFTSMRNo

2.7 HP (Maximum Developed)

10" Inch Blade

5000 R.P.M.

TABLE SAW

Model No.

137,218250

E82443

USED 37J2

CAUTION:

Before using this Table Saw,

read this manual and follow

all its Safety Rules and

Operating Instructions.

• Safety Instructions

• Installation

• Operation

• Maintenance

• Parts List

• EspaSol

Customer Help Line

1-800-843-1682

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

Part No. 137218250001

Page 2

SECTION

PAGE

Warranty .................

Product Specifications ......

Safety Instructions .........

Accessories and Attachments

Tools needed for assembly ..

Carton Contents ...........

,e,,,oo,e==

=,.,,,,o=.,

,o=.,oe.,,o

°=,,°.o,e,.

q.°=,..=,..

.°e..e,...,

Know Your Table Saw .....................

Assembly and Adjustments ...............

Operation ...........................

Maintenance ........................

Troubleshooting guide .. ..............

Parts ............................. _i

Making a push stick .................

Espanol ...........................

°.°,lw,

=°,,e,°

,,o°,ow

e,°,lw,

.o,l.,,

,e,w,°w

.o.e..

.o.,i.,

• ,..eo.

.we=.le.

weg,,w,°J,w,°,.,q°,,

,Iwoe,°,l°,,*g,=*w,=

*..e...*,w.eJw,e..e.

e.,e.wee..e,=.e.w.e°

,,,,,°,=,e,,,e

,°e°,e,,*=.,e.

=,°,l,w,.°,e°,

..=,.oee..*..e

.*o°.._..=,.=e

*.o.e.w.,o.e,.

,..,.o.e..,.,°

.*l=..*,..,..e

e.=q°.°o... ..

el=.ei.°e=, e°

we °,,°,e°2

,e e°l.°=,2

°, ,e°,.°e3

w= e,,*,,° 6

• e e=.w°., 6

°. .w..e..6

e°e=.*.°6

• e =.°..e9

....... 16

........ 20

.......... 21

.......... 22

......... 33

........... 37

FULL ONE YEAR WARRANTY

If this product failsdue to a defect in material or workmanship within one year from the date of purchase, Sears

will repair it free of charge.

Contact a Sears Service Center for repair.

If this product is used for commercial or rental purposes, this warranty applies only for 90 days from the date of

purchase.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., Dept. 817 WA, Hoffman Estates, IL 60179

MOTOR

HP (Maximum developed) ...... 2.7

Type ....................... Universal

Amps ...................... 15

Voltage ..................... 120

To avoid electrical hazards, fire hazards, or damage to

the tool, use proper circuit protection.

Hz ........................ 60

RPM (no load) ............... 5000

Overload Protection ........... YES

Your table saw is wired at the factory for 120V operation.

Connect to a 120V, 15 AMP branch circuit and use a 15

AMP time delay fuse or circuit breaker. To avoid shock or

SAW

Table ...................... 26-7/64" x 19-3/32"

Table extension .............. Yes, with fence

fire, replace power cord immediately if it is worn, cut or

damaged in any way.

Extension fence capacity ....... 24"

Blade ...................... 10"

Rip scale ................... YES

Rip fence .................. YES

Miter gauge ................. YES

Leg set ..................... YES

Maximum Depth of cut at 90 ° .... 3"

Maximum Depth of cut at 45 ° .... 2-1/2"

Maximum Dado cut width ....... 1/2"

Net weight .................. 61.6 Lbs.

2

Page 3

GENERAL SAFETY INSTRUCTIONS

BEFORE USING THE TABLE SAW

Safety is a combination of common sense, staying alert

and knowing how to use your table saw.

To avoid mistakes that could cause serious injury, do not

plug the table saw in until you have read and understood

the following:

.

READ and become familiar with this entire instruction

manual. LEARN the tool's applications, limitations, and

possible hazards. 13.

.

KEEP GUARDS IN PLACE and in working order.

3.

REMOVE ADJUSTING KEYS AND WRENCHES.

Form the habit of checking to see that keys and

adjusting wrenches are removed from the tool before

turning ON.

4. KEEP WORK AREA CLEAN. Cluttered areas and

benches invite accidents.

5.

DON'T USE IN A DANGEROUS ENVIRONMENT.

Don't use power tools in damp or wet locations, or

expose them to rain. Keep work area well lighted.

.

KEEP CHILDREN AWAY. All visitors should be kept at

a safe distance from the work area.

7,

MAKE WORKSHOP KID PROOF with padlocks, master

switches, or by removing starter keys.

8.

DON'T FORCE THE TOOL. It will do the job better

and safer at the rate for which itwas designed.

9.

USE THE RIGHT TOOL. Don't force tool or the

attachment to do a job for which it was not designed.

10. USE PROPER EXTENSION CORD. Make sure your

extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to

carry the current yourproductwilldraw. An undersized

cord will cause a drop inline voltage resulting in loss

of power and overheating.The table on page 5 shows

the correct size to use depending on cord length and

nameplate ampere rating. If in doubt, use the next

heavier gauge. The smaller the gauge number, the

heavier the cord.

11. WEAR PROPER APPAREL, DO NOT wear loose

clothing, gloves, neckties, rings, bracelets, or other

jewelry which may get caught in moving parts.

Nonslip footwear is recommended. Wear protective

hair covering to contain long hair.

12.

ALWAYS WEAR EYE

PROTECTION. Any table

saw can throw foreign

objects into the eyes which

could cause permanent eye

damage. ALWAYS wear

Safety Goggles (not glasses)

that comply with ANSI safety standard Z87.1.

Everyday eyeglasses have only impact-resistant

lenses. They ARE NOT safety glasses. Safety

Goggles are available at Sears. NOTE: Glasses or

goggles not in compliance with ANSI Z87.1 could

seriouslyhurt you when they break.

WEAR A FACE MASK OR DUST MASK.

Sawing operation produces dust.

14.

SECURE WORK. Use clamps or a vise to hold work

when practical. It's safer than using your hand and it

frees both hands to operate tool.

15. DISCONNECT TOOLS before servicing, and when

changing accessories, such as blades, bits, cutters,

and the like.

16.

REDUCE THE RISK OF UNINTENTIONAL STARTING.

Make sure the switch is in OFF position before

plugging in.

17.

USE RECOMMENDED ACCESSORIES. Consult the

owner's manual for the recommended accessories.

The use of improper accessories may cause risk of

injuryto persons.

18.

NEVER STAND ON TOOL. Serious injury could occur

ifthe tool is tipped or if the cuttingtool is unintentionally

contacted.

19.

CHECK FOR DAMAGED PARTS. Before further use of

the tool, a guard or other part that isdamaged should

be carefully checked to determine that it will operate

properly and perform its intended function. Check for

alignment of moving parts, binding of moving parts,

breakage of parts, mounting, and any other conditions

that may affect itsoperation. A guard or other part that

is damaged should be properly repaired or replaced.

20.

NEVER LEAVE TOOL RUNNING UNATTENDED.

TURN THE POWER OFF. Don't leave the tool until

it comes to a complete stop:

21.

DON'T OVERREACH. Keep proper footing and

balance at all times.

22. MAINTAIN TOOLS WITH CARE. Keep tools sharp

and clean for best and safest performance. Follow

instructionsfor lubricating and changing accessories.

23. DIRECTION OF FEED. Feed work into a blade or cutter

against the direction of rotationof the blade orcutter

only.

SAVE THESE INSTRUCTIONS

3

Page 4

24. WARNING: Dust generated from certain materials can

be injurious to your health. Always operate saw in well

ventilated areas and provide for proper dust removal.

SPECIFIC SAFETY INSTRUCTIONS

FOR THE TABLE SAW

1.

ALWAYS USE SAW BLADE GUARD spreader and

anti-kickback pawls for every operation for which

they can be used, including through-sawing.

Through-sawing operations are those in which the

blade cuts completely through the workpiece

when ripping or cross-cutting.

2.

ALWAYS HOLDTHE WORK FIRMLY against the

miter gauge or rip fence.

3.

USE A PUSH STICK when required. Always use a

push stickfor ripping narrow stock. Refer to ripping

applications in the instruction manual where the

push stick is covered in detail. See the push stick

pattern included in this Owner's Manual.

4.

NEVER PERFORM ANY OPERATION

"FREE HAND", which means using your hands

only to support or guide the workpiece. Always

use either the fence or the miter gauge to position

and guide the work.

5.

NEVER STAND or have any part of your body

in line with the path of the saw blade, Keep your

hands out of the line of the saw blade.

6. NEVER REACH behind or over the cutting tool

for any reason.

7. REMOVE the rip fence when cross-cutting.

14. AVOID AWKWARD OPERATIONS and hand

positions where a sudden slip could cause your

hand to move into the cuffing tool.

15.

NEVER USE SOLVENTS to clean plastic parts.

Solvents could possibly dissolve or otherwise

damage the material. Only a soft damp cloth should

be used to clean plastic parts.

16.

MOUNT your table saw before performing any

cuffing operations. Refer to installation instructions.

17.

NEVER CUT METALS or materials which may make

hazardous dust.

18. ALWAYS USE IN A WELL VENTILATED AREA.

Remove sawdust frequently. Clean out sawdust from

the interior of the saw to preventa potentialfire

hazard.

19. NEVER LEAVE THE TOOL running unattended.

Don't leave the tool until it comes to a complete stop.

20.

For proper operation follow the instructions of this

owner's manual titled "SAW MOUNTED TO WORK

SURFACES" Failure to provide sawdust fall-through

and removal hole will allow sawdust to build up in

the motor area, which may result in a fire hazard or

cause motor damage.

21. ALWAYS USE THE TABLE EXTENSION for support

when cutting a long workpiece. Never use an

unstable surface or another person to hold a long

workpiece. Adjust the table extension for maximum

stability and length of the workpiece before cutting.

22. ALWAYS LOCKTHETABLE EXTENSION securely

in place before cutting workpiece.

8. DO NOT USE molding head set with this saw.

9. FEEDWORK INTOTHE BLADE against the

direction of rotation only.

10. NEVER use the fence as a cut-off gauge when

cross-cutting.

11. NEVER ATTEMPT TO FREE A STALLED SAW

BLADE without first turning the saw OFF. Turn

power switch OFF immediately to prevent motor

damage.

12. PROVIDE ADEQUATE SUPPORT to the rear and

sides of the saw table for wide or long workpieces.

13. AVOID KICKBACKS (work thrown back towards

you) by keeping the blade sharp, keeping the rip

fence parallel to the saw btade, and by keeping the

spreader, anti-kickback pawls, and guard in place

and functioning. Do not release work before it is

pushed all the way past the saw blade. Do not rip

work that is twisted, warped, or does not have a

straight edge to guide along the fence.

SAVE THESE INSTRUCTIONS

ELECTRICAL REQUIREMENTS

POWER SUPPLY AND MOTOR

SPECIFICATIONS

To avoid electrical hazards, fire hazards, or damage to

the tool, use proper circuit protection. Use a separate

electrical circuit for your tools.Your saw is wired at the

factory for 120V operation. Connect to a 120V, 15 Amp

circuit and use a 15 Amp time delay fuse or circuit

breaker. To avoid shock or fire, if power cord is worn or

cut, or damaged in any way, have it replaced

immediately.

Page 5

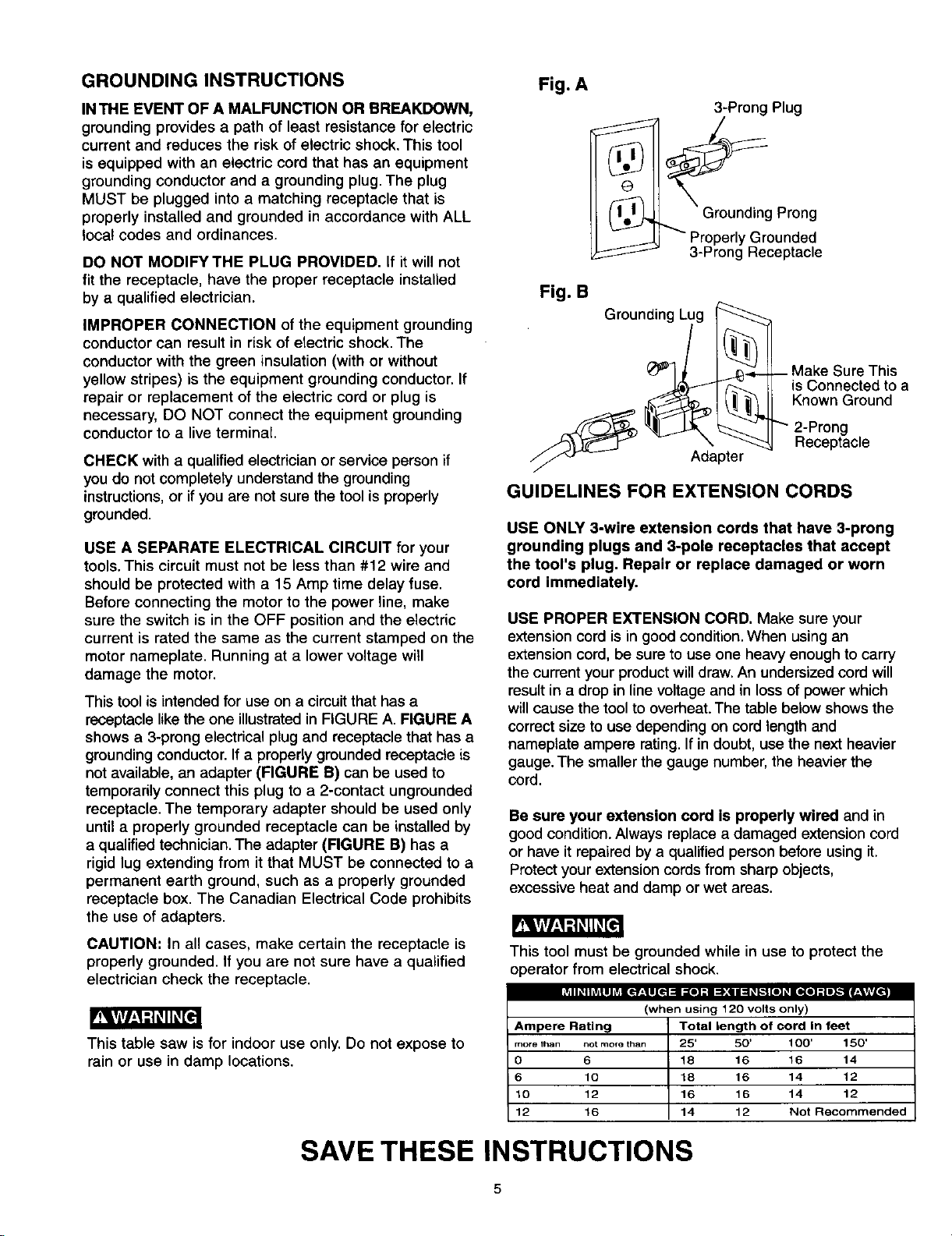

GROUNDING INSTRUCTIONS

IN THE EVENT OF A MALFUNCTION OR BREAKDOWN,

grounding provides a path of least resistance for electric

current and reduces the risk of electric shock, This tool

is equipped with an electric cord that has an equipment

grounding conductor and a grounding plug, The plug

MUST be plugged into a matching receptacle that is

properly installed and grounded in accordance with ALL

local codes and ordinances.

DO NOT MODIFYTHE PLUG PROVIDED. If it will not

fit the receptacle, have the proper receptacle installed

by a qualified electrician.

IMPROPER CONNECTION of the equipment grounding

conductor can result in risk of electric shock. The

conductor with the green insulation (with or without

yellow stripes) is the equipment grounding conductor. If

repair or replacement of the electric cord or plug is

necessary, DO NOT connect the equipment grounding

conductor to a live terminal.

CHECK with a qualified electrician or service person if

you do not completety understand the grounding

instructions, or if you are not sure the tool is properly

grounded.

USE A SEPARATE ELECTRICAL CIRCUIT for your

tools. This circuit must not be less than #12 wire and

should be protected with a 15 Amp time delay fuse.

Before connecting the motor to the power line, make

sure the switch is in the OFF position and the electric

current is rated the same as the current stamped on the

motor nameplate. Running at a lower voltage witl

damage the motor.

This tool is intended for use on a circuit that has a

receptacle like the one illustrated in FIGURE A. FIGURE A

shows a 3-preng electrical plug and receptacle that has a

groundingconductor. If a properly grounded receptacle is

not available, an adapter (FIGURE B) can be used to

temporarily connect this plug to a 2-contact ungrounded

receptacle. The temporary adapter should be used only

until a properly grounded receptacle can be installed by

a qualified technician.The adapter (FIGURE B) has a

rigid lug extending from it that MUST be connected to a

permanent earth ground, such as a properly grounded

receptacle box. The Canadian Electrical Code prohibits

the use of adapters.

CAUTION: In all cases, make certain the receptacle is

properly grounded. If you are not sure have a qualified

electrician check the receptacle.

This table saw is for indoor use only. Do not expose to

rain or use in damp locations.

Fig. A

3-Prong Plug

r

I I g Pronn

b J_

B _

J _ Properly Grounded

/ 3-Prong Receptacle

f

Fig. B

Grounding Lug

-- Make Sure This

is Connected to a

Known Ground

"_ 2-Preng

Receptacle

GUIDELINES FOR EXTENSION CORDS

USE ONLY 3-wire extension cords that have 3-prong

grounding plugs and 3-pole receptacles that accept

the tool's plug. Repair or replace damaged or worn

cord immediately.

USE PROPER EXTENSION CORD. Make sure your

extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to carry

the current your productwill draw. An undersized cord will

resultin a drop in line voltage and in loss of power which

will cause the toolto overheat. The table below shows the

correct size to use depending on cord length and

nameplate ampere rating.If in doubt, use the next heavier

gauge. The smaller the gauge number, the heavier the

cord.

Be sure your extension cord is properly wired and in

good condition.Always replace a damaged extension cord

or have it repaired by a qualifiedperson before using it.

Protect yourextension cords from sharp objects,

excessive heat and damp or wet areas.

This tool must be grounded while in use to protect the

operator from electrical shock.

lJI I_ I1LTJ| | JkT_l[14r-'l | [L_IOil _[O] ?,] =1_4111I b?I,."_[el _.

(when using 120 volts only)

i Ampere Rating Total length of cord in feet

more than not more than 25' 50* 100' 1 SO'

O 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not Recommended

: [IKI] =111_._ !q_-VAtLJ.

SAVE THESE INSTRUCTIONS

Page 6

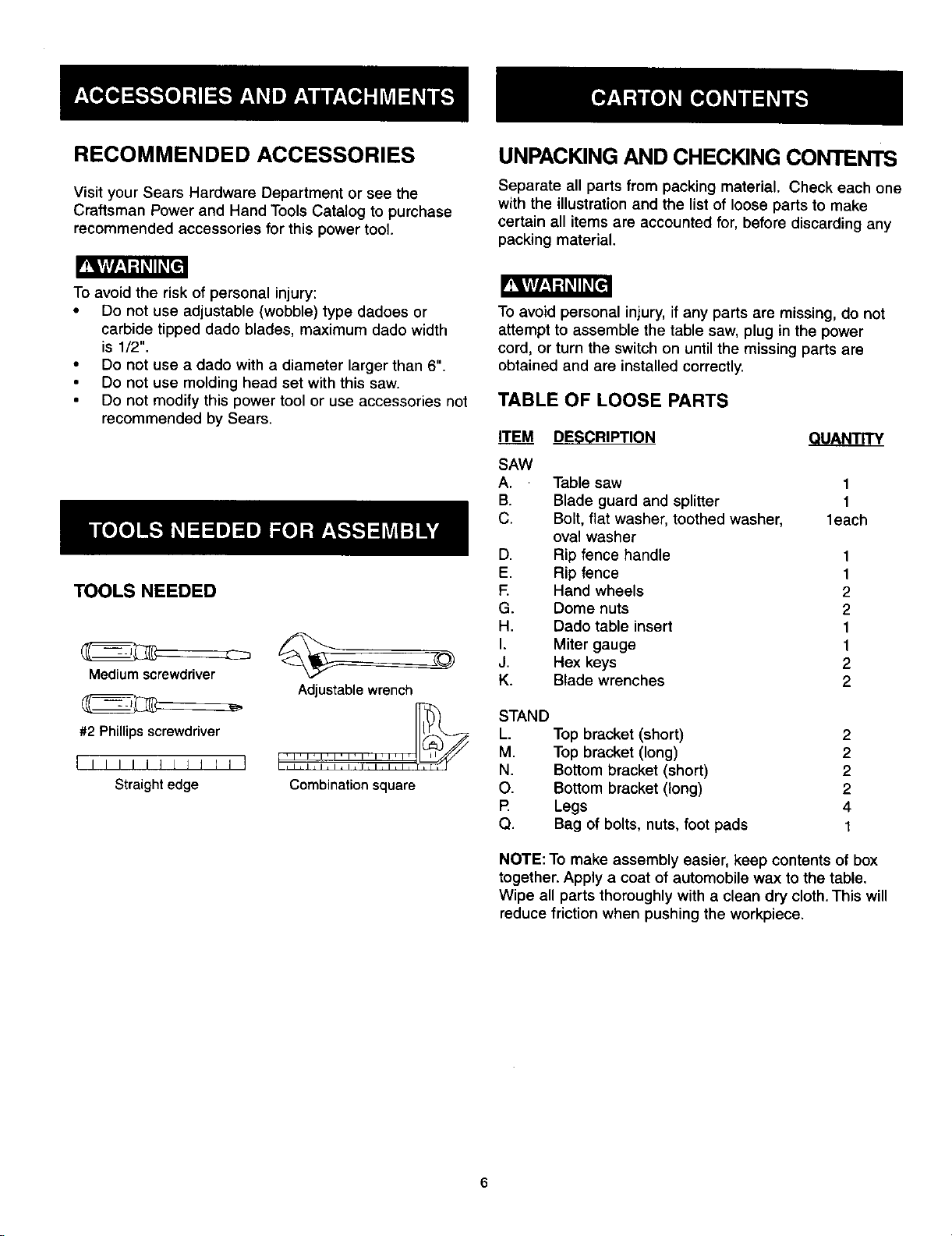

RECOMMENDED ACCESSORIES

UNPACKING AND CHECKING CONTENTS

Visit your Sears Hardware Department or see the

Craftsman Power and Hand Tools Catalog to purchase

recommended accessories for this power tool.

,P_l,vlvl_,1r,|_,II_[e

To avoid the risk of personal injury:

• Do not use adjustable (wobble) type dadoes or

carbide tipped dado blades, maximum dado width

is 1/2".

• Do not use a dado with a diameter larger than 6".

• Do not use molding head set with this saw.

• Do not modify this power tool or use accessories not

recommended by Sears.

TOOLS NEEDED

Mediumscrewdriver

Adjustable wrench

#2 Phillips screwdriver

LI','_"'""''':',I '_

I-Illllllll Ill

Straight edge

Combination square

Separate all parts from packing material. Check each one

with the illustration and the list of loose parts to make

certain all items are accounted for, before discarding any

packing material.

To avoid personal injury, if any parts are missing, do not

attempt to assemble the table saw, plug in the power

cord, or turn the switch on until the missing parts are

obtained and are installed correctly.

TABLE OF LOOSE PARTS

ITEM DESCRIPTION A_

SAW

A.

B.

C.

D,

E.

F.

G.

H.

I.

J.

K.

STAND

L. Top bracket (short)

M. Top bracket (long)

N. Bottom bracket (short)

O. Bottom bracket (long)

R Legs

Q. Bag of bolts, nuts, foot pads

Table saw 1

Blade guard and splitter 1

Bolt, flat washer, toothed washer, leach

oval washer

Rip fence handle 1

Rip fence 1

Hand wheels 2

Dome nuts 2

Dado table insert 1

Miter gauge 1

Hex keys 2

Blade wrenches 2

2

2

2

2

4

1

NOTE: To make assembly easier, keep contents of box

together. Apply a coat of automobile wax to the table.

Wipe all parts thoroughly with a clean dry cloth. This will

reduce friction when pushing the workpiece.

Page 7

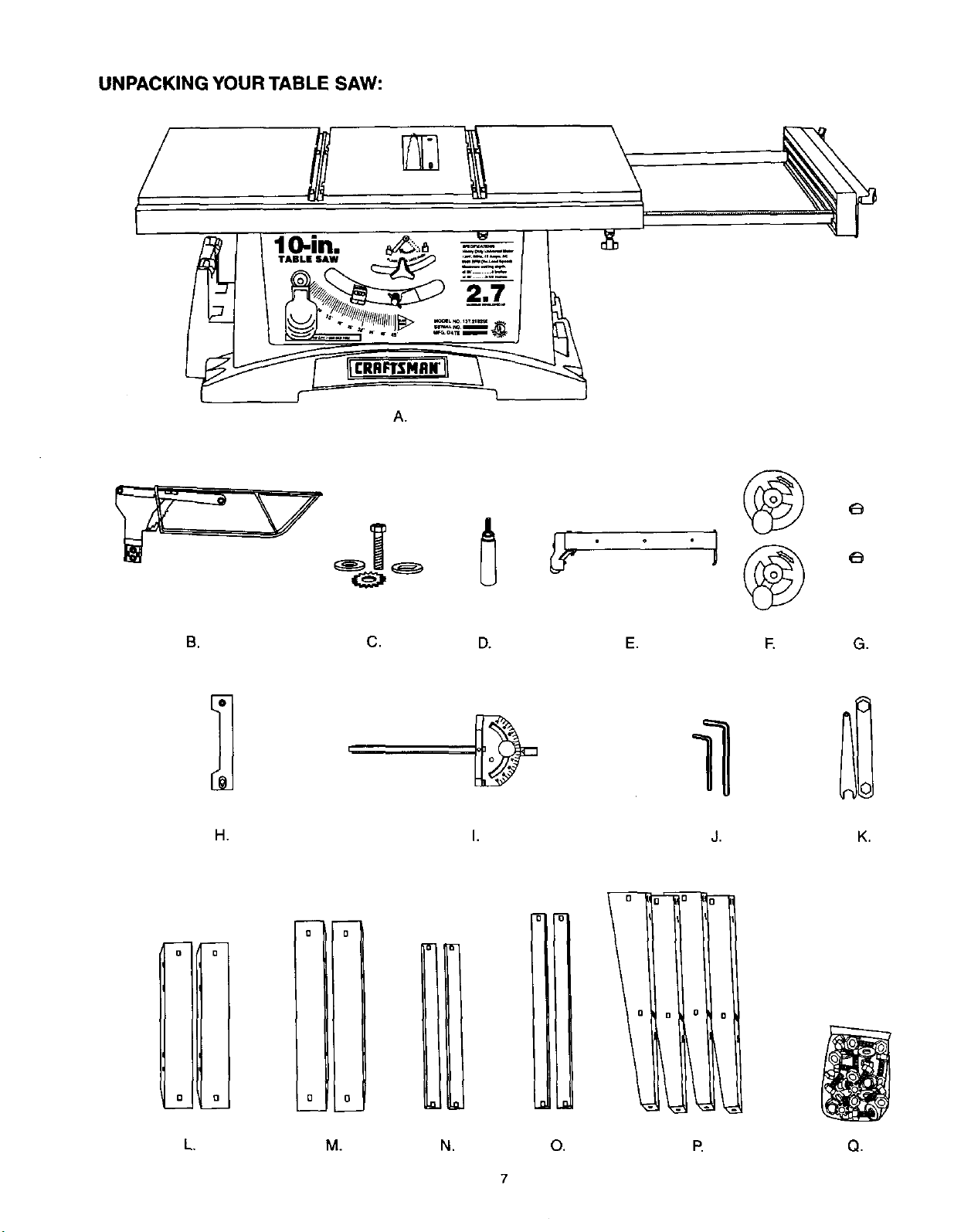

UNPACKING YOUR TABLE SAW:

A.

B. C. D. E. G.

H.

J. K,

o _-_

o l

o

i

I

6

0

13

L.

o o

M. N, O, R a.

Page 8

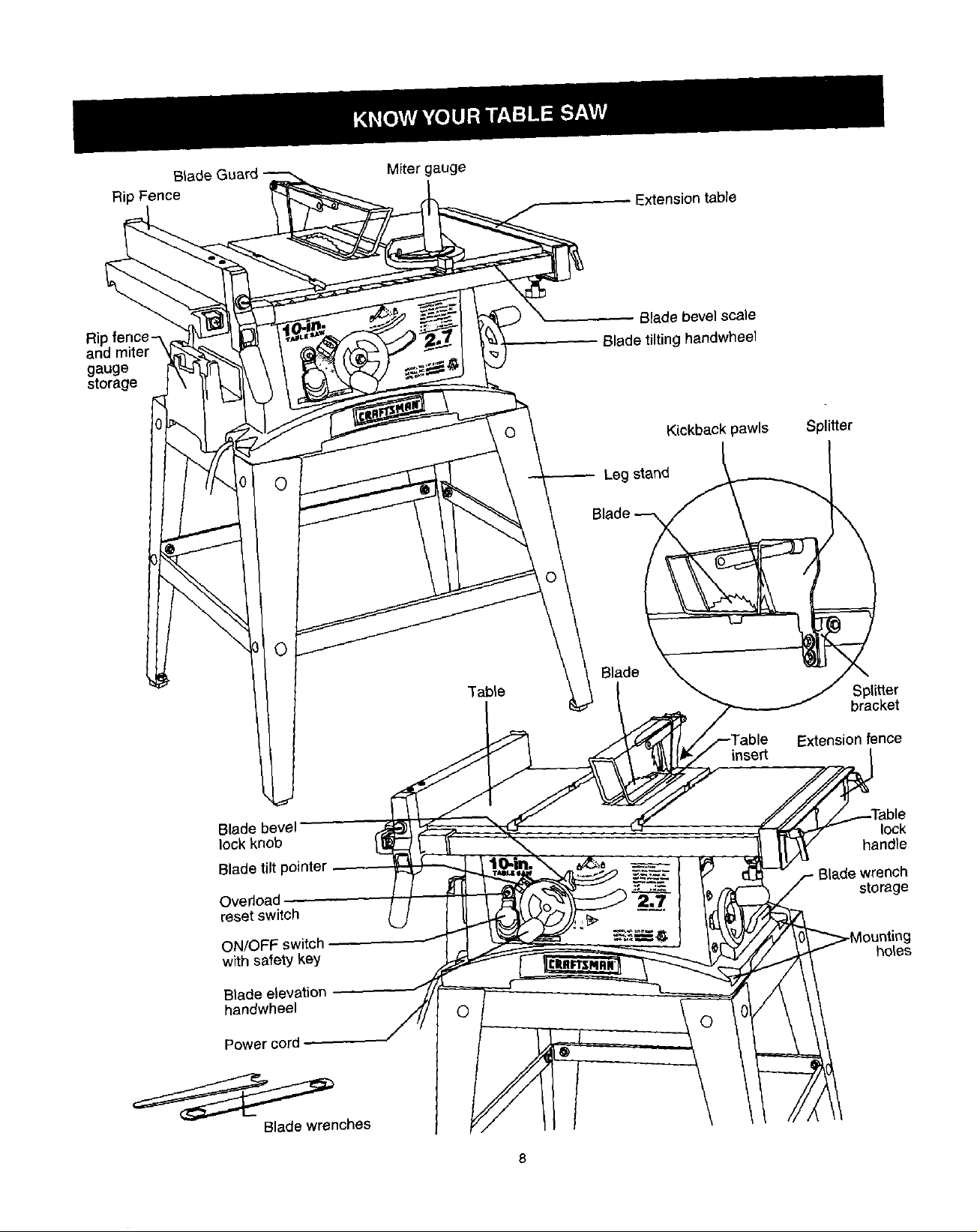

Rip Fence

Rip

gauge

storage

Blade Gl

Miter gauge

Extension table

Blade bevel scale

Blade tilting handwheel

Kickback pawls Splitter

Leg stand

Blade

Blade bevel

lock knob

Blade tilt pointer

Overload

reset switch

ON/OFF switch

with safety key

Blade elevation

handwheel

Power¢

Table

Blade

Splitter

bracket

Extension fence

insert

lock

handle

wrench

storage

holes

Blade wrenches

Page 9

ASSEMBLY INSTRUCTIONS

For your own safety, never connect plug to power source

outlet until all assembly steps are complete, and you have

read and understood the safety and operating instructions.

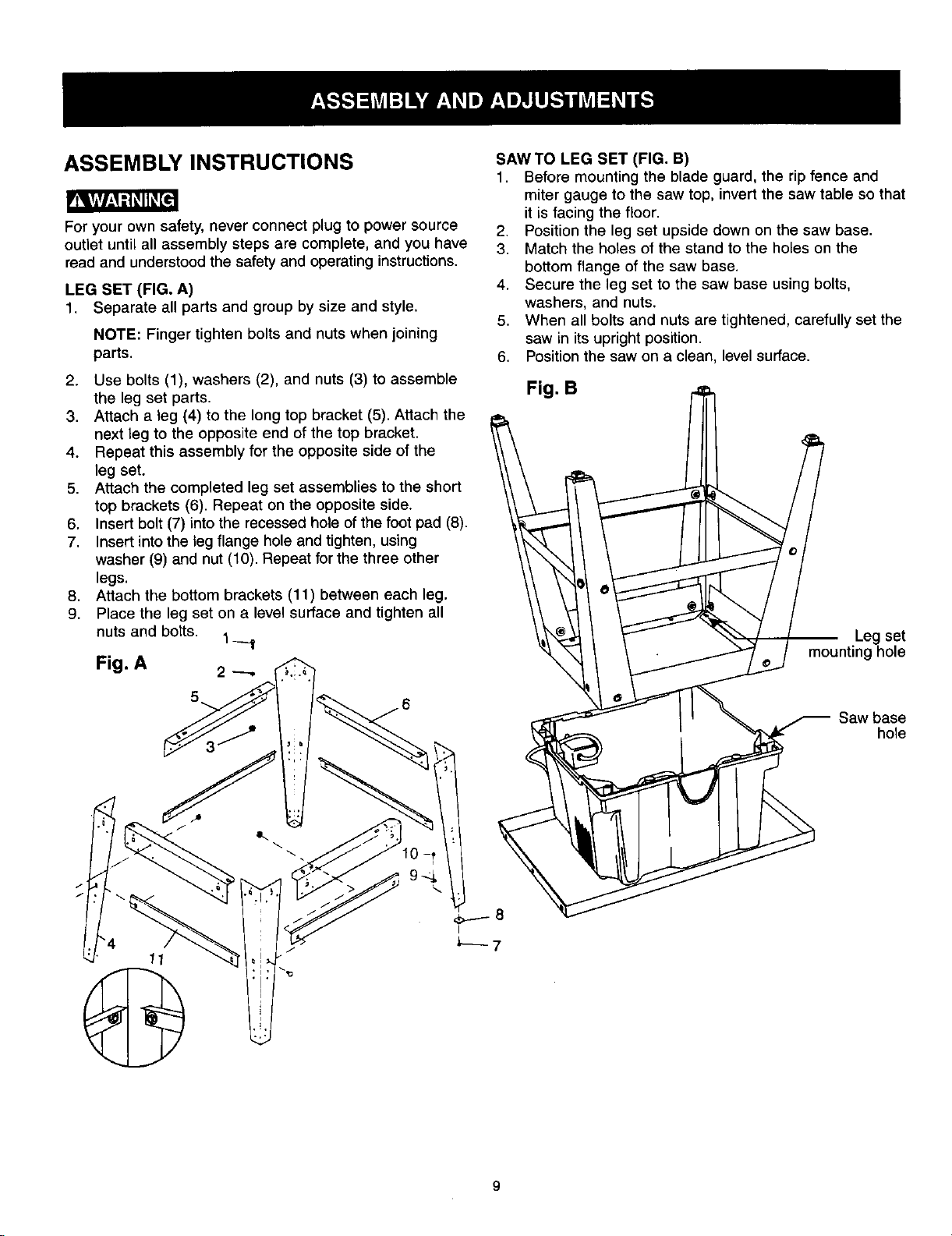

LEG SET (FIG. A)

1. Separate all parts and group by size and style.

NOTE: Finger tighten bolts and nuts when joining

parts.

2. Use bolts (1), washers (2), and nuts (3) to assemble

the leg set parts.

3. Attach a leg (4) to the long top bracket (5). Attach the

next leg to the opposite end of the top bracket.

4. Repeat this assembly for the opposite side of the

leg set.

5. Attach the completed leg set assemblies to the short

top brackets (6). Repeat on the opposite side.

6. Insert bolt (7) Lntothe recessed hole of the foot pad (8).

7. Insert into the leg flange hole and tighten, using

washer (9) and nut (10). Repeat for the three other

legs.

8. Attach the bottom brackets (11) between each leg.

9. Place the leg set on a level surface and tighten all

nuts and bolts. 1

Fig. A 2

SAW TO LEG SET (FIG. B)

1. Before mounting the blade guard, the rip fence and

miter gauge to the saw top, invert the saw table so that

it is facing the floor.

2. Position the leg set upside down on the saw base.

3. Match the holes of the stand to the holes on the

bottom flange of the saw base.

4. Secure the leg set to the saw base using bolts,

washers, and nuts.

5. When all bolts and nuts are tightened, carefully set the

saw in its upright position.

6. Position the saw on a clean, level surface.

Fig. B

Leg set

mounting hole

Saw base

hole

9

Page 10

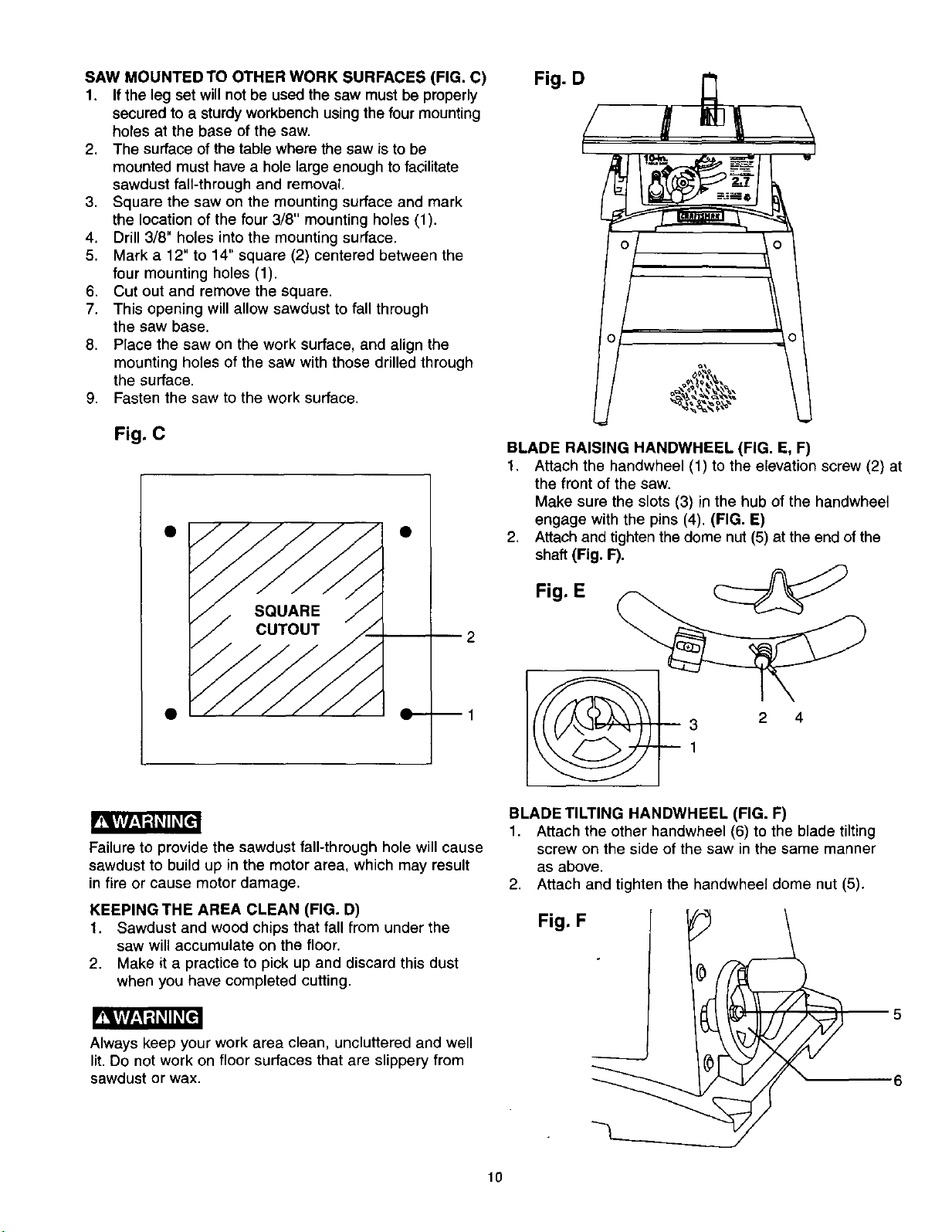

SAW MOUNTEDTO OTHER WORK SURFACES (FIG. C)

1. If the leg set will not be used the saw must be properly

secured to a sturdy workbench using the four mounting

holes at the base of the saw.

2. The surface of the table where the saw is to be

mounted must have a hole large enough to facilitate

sawdust fall-through and removal

3. Square the saw on the mounting surface and mark

the location of the four 3/8" mounting holes (1).

4. Drill 3/8" holes into the mounting surface.

5. Mark a 12" to 14" square (2) centered between the

four mounting holes (1).

6. Cut out and remove the square.

7. This opening will allow sawdust to fall through

the saw base.

8. Place the saw on the work surface, and align the

mounting holes of the saw with those drilled through

the surface.

9. Fasten the saw to the work surface.

Fig. D

Fig. C

2

Q--.m 1

Failure to provide the sawdust fall-through hole will cause

sawdust to build up in the motor area, which may result

in fire or cause motor damage.

KEEPING THE AREA CLEAN (FIG. D)

1. Sawdust and wood chips that fall from under the

saw will accumulate on the floor.

2. Make it a practice to pick up and discard this dust

when you have completed cutting.

BLADE RAISING HANDWHEEL (FIG. E, F)

1. Attach the handwheel (1) to the elevation screw (2) at

the front of the saw.

Make sure the slots (3) in the hub of the handwheel

engage with the pins (4). (FIG. E)

2. Attach and tightenthe dome nut (5) at the end of the

shaft(Fig. F).

Fig. E (__

3 2 4

1

BLADE TILTING HANDWHEEL (FIG. F)

1. Attach the other handwheel (6) to the blade tilting

screw on the side of the saw in the same manner

as above.

2. Attach and tighten the handwheel dome nut (5).

Fig. F

Always keep your work area clean, uncluttered and well

lit. Do net work on floor surfaces that are slippery from

sawdust or wax.

--5

6

10

Page 11

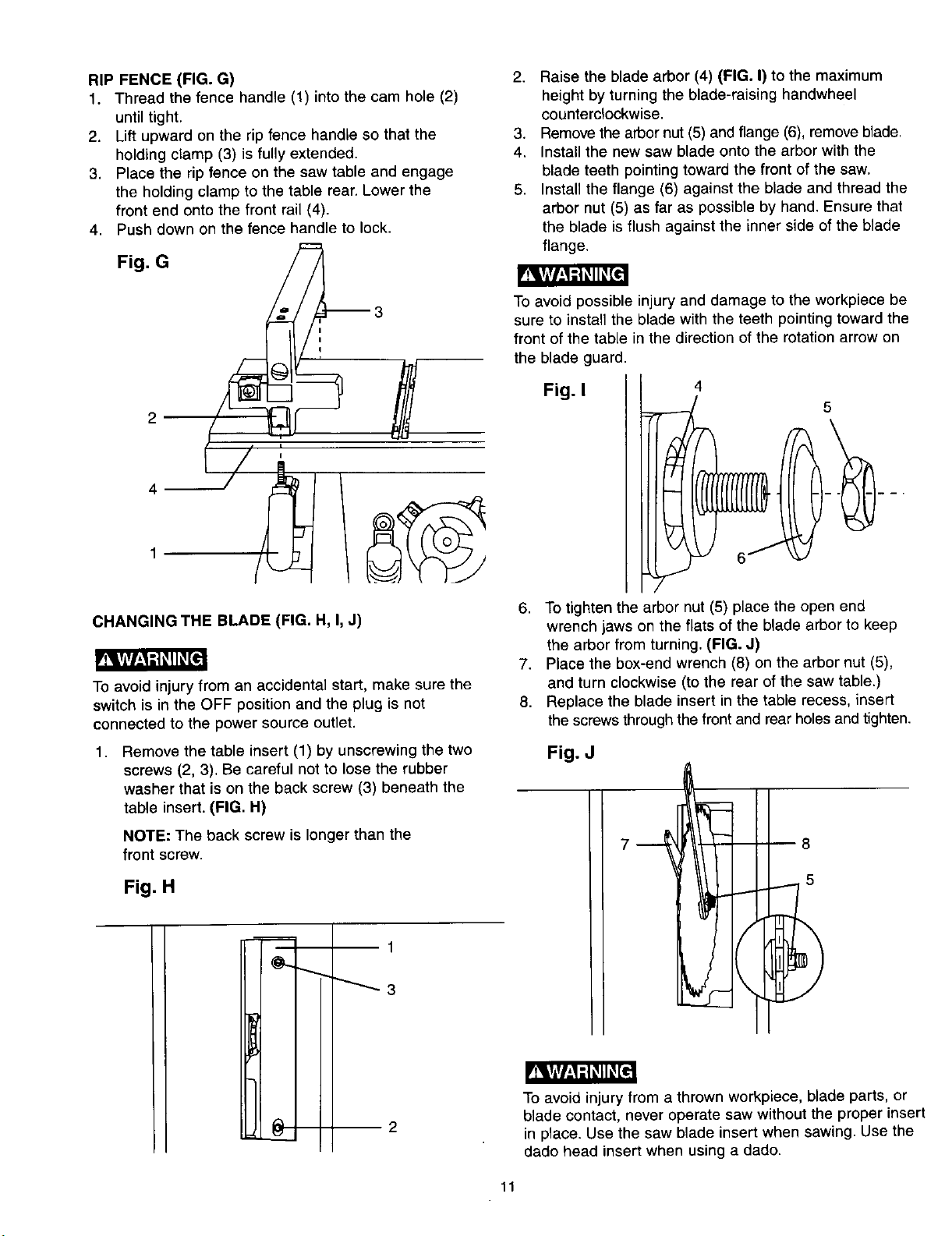

RIP FENCE (FIG. G)

1. Thread the fence handle (1) into the cam hole (2)

until tight.

2. Lift upward on the rip fence handle so that the

holding clamp (3) is fully extended.

3. Place the ripfence on the saw table and engage

the holding clamp to the table rear. Lower the

front end onto the front rail (4).

4. Push down on the fence handle to lock.

2. Raise the blade arbor (4) (FIG. I) to the maximum

height by turning the blade-raising handwheel

counterclockwise.

3. Remove the arbor nut (5) and flange (6), remove blade.

4. Install the new saw blade onto the arbor with the

blade teeth pointing toward the front of the saw.

5. Install the flange (6) against the blade and thread the

arbor nut (5) as far as possible by hand. Ensure that

the blade is flush against the inner side of the blade

flange.

To avoid possible injury and damage to the workpiece be

sure to install the blade with the teeth pointing toward the

front of the table in the direction of the rotation arrow on

the blade guard.

Fig. I

4

CHANGING THE BLADE (FIG. H, I, J)

To avoid injury from an accidental start, make sure the

switch is in the OFF position and the plug is not

connected to the power source outlet.

1. Remove the table insert (1) by unscrewing the two

screws (2, 3). Be careful not to lose the rubber

washer that is on the back screw (3) beneath the

table insert. (FIG. H)

NOTE: The back screw is longer than the

front screw.

Fig. H

3

6. To tighten the arbor nut (5) place the open end

wrench jaws on the flats of the blade arbor to keep

the arbor from turning. (FIG. J)

7. Place the box-end wrench (8) on the arbor nut (5),

and turn clockwise (to the rear of the saw table.)

8. Replace the blade insert in the table recess, insert

the screws through the front and rear holes and tighten.

Fig. J

• 8

To avoid injury from a thrown workpiece, blade parts, or

2

blade contact, never operate saw without the proper insert

in place. Use the saw blade insert when sawing. Use the

dado head insert when using a dado.

11

Page 12

BLADE GUARD ASSEMBLY (FIG. K, L, M)

1. Set the blade to maximum height and the tilt to zero

degrees on the bevel scale with the hand wheels.

Lock the blade lock knob.

2. Place the external toothed lock washer (1) and a

steel flat washer (2) onto the long hex. head bolt (3).

Insert the bolt into the splitter bracket (4) as shown.

(FIG. K)

Fig. K

3 2 1

3. Place the oval washer (5) on the pivot rod (6). (FIG. L)

4. Install the bracket assembly (4) into the rear of the

saw table. Thread the bolt (3) into the internally

threaded pivot rod.

Fig. M

anti-kickback pawl

8

S

-tfl I I I I I / I I

, i

,/

3

ADJUSTMENT INSTRUCTIONS

To avoid injuryfrom an accidental start, make sure the

switch is in the OFF position and the plug is not

connected to the power source, before making any

adjustments.

ADJUSTING THE TABLE EXTENSION (FIG. O)

NOTE: The table extension may be installed on the right

side of the table, as needed, to support long

workpieces.

NOTE: The splitter is removed from the illustration

for clarity.

Fig. L

6 5

5. Position the blade guard arm (7) to the rear of the

table. (FIG. M)

6. Using a straightedge, check that the blade guard

splitter (8) is aligned with the saw blade (9).

7. If straightening adjustment is necessary, loosen the

bolt (3) and shift the splitter assembly to the right or

left, or rotate.

8. When the splitter is properly aligned with the saw

blade, tighten the bolt.

NOTE: The splitter must always be correctly aligned

so the cut workpiece will pass on either side without

binding or twisting to the side.

12

Page 13

To adjust the table extension position (FIG. O):

1. Loosen the two clamp bolts (4) on the two

extension tube brackets.

2. Slide the extension tubes in or out until the scale on

the front tube is positioned at the desired distance.

3. Tighten the two lock handles.

To adjust the extension table fence:

1. Loosen the locking handle (5) on the fence (6).

2. Raise the fence to the desired height and tighten the

locking handle.

Fig, O

5 6

4

MITER GAUGE ADJUSTMENT (FIG. P)

1. Make sure that the miter gauge willslide freely through

both table grooves.

2. Loosen the lock knob (1). Set the pointer (2) to the 900

mark on the scale.

3. Make a 900 cut in a piece of scrap wood. Check cut

piece to see if itwas cut at 90°. If it is not, continueto

adjust the miter gauge body (3) until the wood piece

is cut at 90°. Refer to OPERATION section for cutting

instructions.

RIP FENCE ADJUSTMENT (FIG. Q)

,_lqllll[_

To avoid injury from an accidental start, make sure

the switch is in the OFF position and the plug is

not connected to the power source outlet.

1. The fence (1) is moved by lifting up on the handle (2)

and sliding the fence to the desired location. Pushing

down on the handle locks the fence in position.

2. Position the fence on the right side of the table, and

along one edge of the miter gauge grooves.

3. Lock the fence handle. The fence should be parallel

with the miter gauge groove.

4. If adjustment is needed to make the fence parallel to

the groove, do the following:

• Loosen the two screws (3) and lift up on the handle (2).

• Hold the fence bracket (4) firmly against the front

of the saw table. Move the far end of the fence

until it is parallel with the miter gauge groove.

• Tighten both screws and push the handle to lock.

5. If fence is loose when the handle is in the locked

(downward) position, do the following:

• Move the handle (2) upward and turn the adjusting

screw (5) clockwise until the rear clamp is snug.

Do not turn the adjusting screw more than 1/4

turn at a time.

• Over-tightening the adjusting screw will cause

the fence to come out of alignment.

Fig. Q _ il

Fig. P

RIP FENCE INDICATOR ADJUSTMENT (FIG, Q)

1. The rip fence indicator (6) points to the

o

©

2

measurement scale (8). The scale shows the

distance from the side of the fence to the nearest

side of the blade.

2. Measure the actual distance with a rule. If there is a

difference between the measurement and the

indicator, adjust the indicator (6).

3. Loosen the screw (7) and slide the indicator to the

correct measurement on the scale. Tighten screw

and remeasure with the rule.

13

Page 14

To avoid injury from an accidental start, make sure the

switch is in the OFF position and the plug is not

connected to the power source outlet.

ADJUSTING THE 90° AND 45° POSITIVE STOPS

(FIG. R, S)

Your saw has positive stops that will quickly position the

saw blade at 90° or 45° to the table. These stops were

set at the factory. Make adjustments only if necessary.

900 Stop

1. Disconnect the saw from the power source.

2. Turn the blade elevation handwheel and raise the

blade to the maximum elevation.

3. Loosen the blade bevel lock knob and move the

blade to the maximum vertical position. Tighten the

lock knob.

4. Place a combination square on the table and

against the blade (1') to determine if the blade

is 90° to the table. (FIG. R)

5. If the blade is not 90° to the table, loosen the two

set screws (4), located in the bottom of the table saw,

(FIG. S) with the 3mm hex key, and back off the

collar (5).

6. Loosen the bevel lock knob. Turn the blade tilting

handwheel to move the blade until it is 90° to the

table.

7. Adjust the collar (5) so it contacts the bracket (3)

when the blade is 90° to the table. Tighten the

two set screws (4).

4. Loosen the bevel lock knob; turn the tilting

handwheel to move the blade until it is 45° to the

table.

5. Adjust the collar (5) so it contacts the bracket (3)

when the blade is 45°. Tighten set screws (4).

Fig. S

345

BLADE TILT POINTER

1. When the blade is positioned at 90°, adjust the

blade tilt pointer to read 0° on the scare.

2. Loosen the holding screw, position the pointer over

0° and tighten the screw.

NOTE: Make a trial cut on scrap wood prior to making

critical cuts. Measure for exactness.

BLADE PARALLEL TO MITER GAUGE

GROOVE (FIG. T, U)

Fig. R

90 ° 45°

1 m

45° Stop

1. With the blade inthe upright 90° position, loosen the

bevel lock knob. Turn the blade tilting handwheel and

move the blade to the 45° position as far as it will go.

2. Place the combination square on the table as shown

in (FIG. R) to check if the blade is 45 o to the table.

3. If the blade is not 45° to the table, loosen the two set

screws (4) located under the table saw (FIG. S) with

a 3 mm hex key, and back off the collar (5).

This adjustment was made at the factory, but itshould

be rechecked and adjusted if necessary.

To prevent personal injury:

.Alwaysdisconnect plug from the power source when

making any adjustments.

• This adjustment must be correct or kickback could

result and accurate cuts cannot be made.

Initial adjustment (FIG.T)

1. Remove the yellow switch key and unplug

the saw.

2. Move the blade guard out of the way.

3. Raise the blade to the highest position and set at

the 0° angle (90° straight up).

4. Select and mark, with a felt tip marker, a blade

tooth having a "right set".

5. Place the combination square base (1) into the

right side miter gauge groove (2). (FIG.T)

6. Adjust the rule so it touches the front marked tooth

and lock the ruler so it holds its position in the

square assembly.

7. Rotate the blade bringing the marked tooth to the

rear and about 1/2 inch above the table.

14

Page 15

.

Carefully slide the combination square to the rear

untilthe ruler touches the marked tooth.

9.

If the ruler touches the marked tooth at the front and

rear positions, no adjustment is needed at this time.

If not, perform adjustment procedure described in

next section.

Fig. T

Additional blade adjustments (FIG. U)

1. If the front and rear measurements are not the

same, remove the combination square and loosen

the four adjusting screws (1) on the top of the table

about a half turn.

2. With a folded piece of cardboard covering the blade

to protect your hands, move the blade careful{y to

the left or right as much as needed to align

the blade correctly.

3. Tighten the four screws (1) and remeasure, as

described in steps 4 to 9 in the prior section.

4. If sufficient adjustment cannot be made by the four

adjusting screws (1), then also loosen the two

adjusting screws (2). Loosen these screws only

if necessary.

5. Recheck blade clearance making sure that the

blade does not hit the table insert or other parts

when at the 90° and 45° settings.

6. Tighten all screws.

Fig. U

15

Page 16

BASIC SAW OPERATIONS

RAISING THE BLADE (FIG. V)

To raise or lower the blade, turn the blade elevation

handwheel (1) to the desired blade height, and then

tighten lock handle (2) to maintain the desired blade

angle.

Fig. V

OVERLOAD PROTECTION (FIG. W)

This saw has a reset overload relay button (3) that will

restart the motor after it shuts off due to overloading or

low voltage. If the motor stops during operation, turn the

ON/OFF switch to the OFF position. Unplug the saw from

its power source. Wait about five minutes for the motor to

cool down. Push in on the reset button (3) and turn the

switch to the ON position.

To avoid injury, the ON/OFF switch should be in the OFF

position and the plug removed from the power source while

the motor cool down takes place, to prevent accidental

starting when the reset button is pushed. Overheating may

be caused by misaligned parts or dull blade. Inspect your saw

for proper setup before using it again.

USINGTHETABLE EXTENSION (FIG. X)

1 2

TILTING THE BLADE (FIG. V)

To tilt the saw blade for bevel cutting, loosen the

lock handle (2) and turn the tilting handwheel (3). Tighten

the lock handle (2) to secure.

ON / OFF SWITCH (FIG. W)

The ON / OFF switch has a removable key. With the key

removed from the switch, unauthorized and hazardous use

by children and others is minimized.

1. To turn the saw ON, insert key (1) into the slot in the

switch (2). Move the switch upward to the ON position.

2. To turn the saw OFF, move the switch downward.

3. To lock the switch in the OFF position,grasp the sides

(or yellowpart) of the switchtoggle (1), and pull it out.

4. With the switchkey removed,the switchwillnot operate.

5. If the switch key is removed while the saw is running,

itcan be turned OFF but cannot be restarted without

inserting the switch key (1).

Fig. W

I

1. Remove the stopscrews from the ends ofthe tubes.

2. Slide the ends of the tubes through both support

brackets on the side your workpiece will be needing

support, and replace the two stop screws.

3. Rotate the front tube to display the scale as an

extension of the table top scale.

4. Slide the extension out until the correct measurement

is displayed on the tube scale.

5. Loosen the fence handles, and raise or lower the

fence as needed.

6. Tighten all extension support handles and knobs.

Fig. X

2

16

Page 17

CU'B'ING OPERATIONS

There are two basic types of cuts: ripping and

crosscutting. Ripping is cutting along the length and

the grain of the workpiece. Crosscutting is cutting

either across the width or across the grain of the

workpiece. Neither ripping nor crosscutting may be

done safely freehand. Ripping requires the use of the

rip fence, and crosscutting requires the miter gauge.

Before you use the saw each and every time, check

the following:

1. Blade is tight on the arbor.

2. Bevel angle lock knob is tight.

3. If ripping, fence knob is tight and fence is

parallel to the miter gauge grooves.

4. Blade guard is in place and working properly.

5. You are wearing safety glasses.

The failure to adhere to these common safety

rules, and those printed in the front of this manual,

can greatly increase the likelihood of injury.

Fig.Y

RIPPING (FIG.Y,Z)

To prevent serious injury:

• Do not allow familiarity gained from the frequent use

of your table saw to cause careless mistakes.

Remember that even a careless fraction of a second

is enough to cause a severe injury.

• Keep both hands away from the blade and path of the

blade.

• The workpiece must have a straight edge against the

fence and must not be warped, twisted, or bowed.

1. Remove the miter gauge. Secure the rip fence to

the table.

2. Raise the blade so it is about 1/8" higher than the

top of the workpiece.

3. Place the workpiece flat on the table and against the

fence. Keep the workpiece about 1" away from the blade.

4. Turn the saw ON and wait for the blade to come up

to speed.

5. Slowly feed the workpiece into the blade by pushing

forward only on the workpiece section (1) that will

pass between the blade and the fence. (FIG.Y)

6. Keep your thumbs off the table top. When both of your

thumbs touch the front edge of the table (2), finish the

cut with a push stick. Make a push stick using the

pattern on page 33.

7. The push stick (3) should always be used when the

ripped workpiece is 2" or narrower (1). (FIG. Y)

8. Continue pushing the workpiece with the push stick (3)

until it passes the blade guard and clears the rear of

the table.

9. Never pull the workpiece back when the blade is

turning. Turn the switch OFF. When the blade

completely stops raise the anti-kickback pawls on

each side of the splitter and slide the workpiece out.

Fig. Z

F_k_Vg-'_l_II_[€

AVOID KICKBACK by pushing forward only on that

section of the workpiece that will pass between the blade

and the fence.

17

Page 18

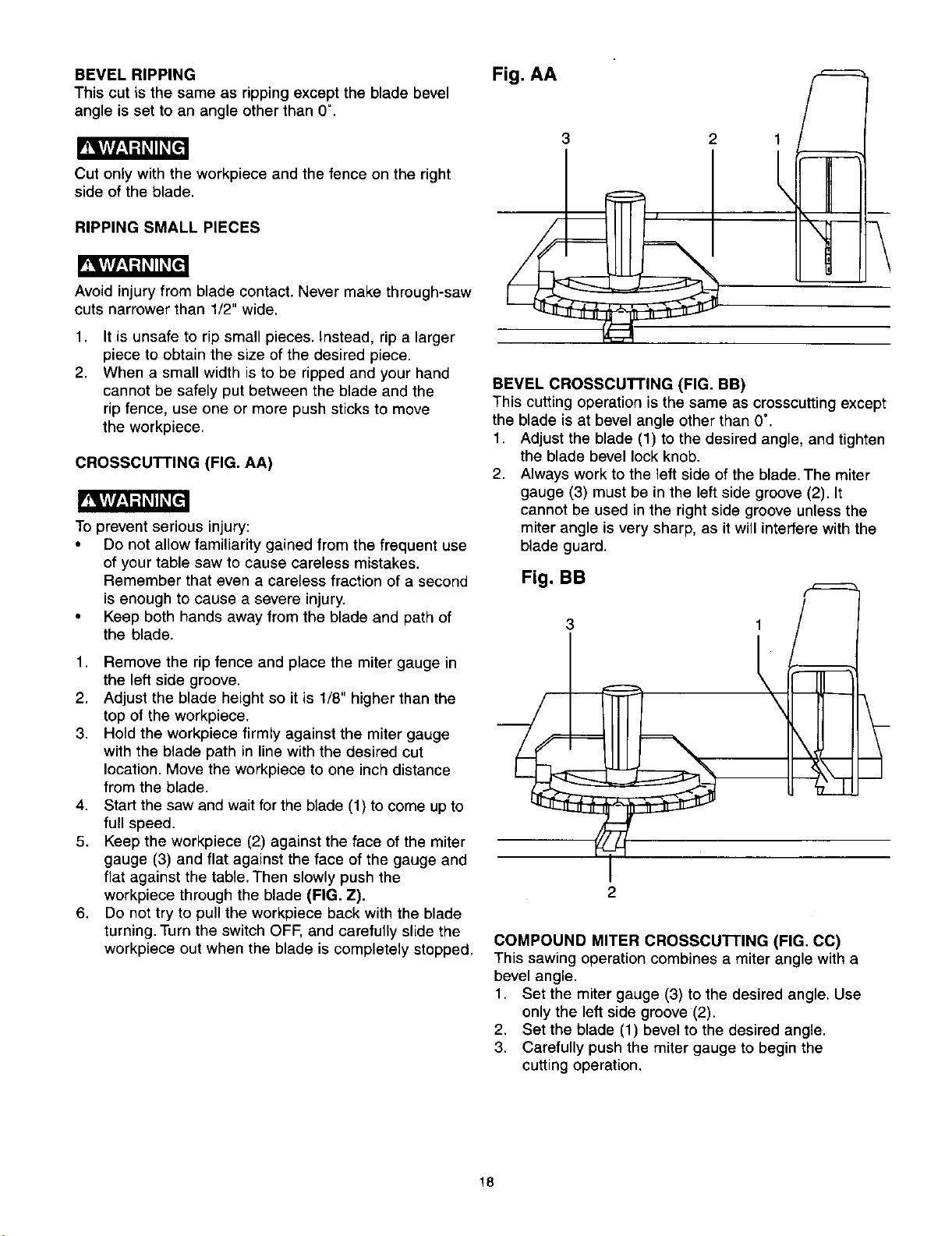

BEVEL RIPPING

This cut is the same as ripping except the blade bevel

angle is set to an angle other than 0°.

r,._kVlV/_,1d_,II_,[_

Cut only with the workpiece and the fence on the right

side of the blade.

RIPPING SMALL PIECES

Avoid injury from blade contact. Never make through-saw

cuts narrower than 1/2" wide.

1.

It is unsafe to rip small pieces. Instead, rip a larger

piece to obtain the size of the desired piece.

2.

When a small width is to be ripped and your hand

cannot be safely put between the blade and the

rip fence, use one or more push sticks to move

the workpiece,

CROSSCUTTING (FIG. AA)

To prevent serious injury:

• Do not allow familiarity gained from the frequent use

of your table saw to cause careless mistakes.

Remember that even a careless fraction of a second

is enough to cause a severe injury.

• Keep both hands away from the blade and path of

the blade.

1

Remove the rip fence and place the miter gauge in

the left side groove.

2.

Adjust the blade height so it is 1/8" higher than the

top of the workpiece.

3.

Hold the workpiece firmly against the miter gauge

with the blade path in line with the desired cut

location. Move the workpiece to one inch distance

from the blade.

4,

Start the saw and wait for the blade (1) to come up to

full speed.

5.

Keep the workpiece (2) against the face of the miter

gauge (3) and flat against the face of the gauge and

flat against the table. Then slowly push the

workpiece through the blade (FIG. Z).

6.

Do not try to pull the workpiece back with the blade

turning. Turn the switch OFF, and carefully slide the

workpiece out when the blade is completely stopped.

Fig. AA

2

BEVEL CROSSCUTTING (FIG. BB)

This cutting operation is the same as crosscutting except

the blade is at bevel angle other than 0°.

1. Adjust the blade (1) to the desired angle, and tighten

the blade bevel lock knob.

2. Always work to the left side of the blade. The miter

gauge (3) must be in the leftside groove (2). It

cannot be used in the right side groove unless the

miter angle is very sharp, as it will interfere with the

blade guard.

Fig. BB

1

,J/-------

\Pt

I.V.

]\ _-r"

h

2

COMPOUND MITER CROSSCUTTING (FIG. CC)

This sawing operation combines a miter angle with a

bevel angle.

1. Set the miter gauge (3) to the desired angle. Use

only the left side groove (2).

2. Set the blade (1) bevel to the desired angle.

3, Carefully push the miter gauge to begin the

cutting operation,

18

Page 19

Fig. CC

Fig. EE

3 2

MITERING (FIG. DD)

This sawing operation is the same as crosscutting except

the miter gauge is locked at an angle other than 90°.

1. Hold the workpiece (2) firmly against the miter

gauge (3).

2. Feed the workpiece slowly into the blade (1) to

prevent the workpiece from moving.

Fig. DD

2 1

3

USING WOOD FACING ON THE RIP FENCE (FIG. EE)

When performing some special cutting operations, add

a wood facing (1) to either side of the rip fence (2):

1. Use a smooth straight 3/4" thick wood board (1) that

isas long as the rip fence.

2. Attach the wood facing to the fence with wood

screws (3) through the boles in the fence. A wood

fence should be used when ripping material such as

thin paneling to prevent the material from catching

between the bottom of the fence and the table.

DADO CUTS (FIG. FF)

1. The dado table insert is included with this saw.

Remove the saw blade, the blade guard, and the

table insert.Install the dado and dado table insert.

2. Instructions for operating the dado are packed with

the separately purchased dado set.

3. The arbor (1) on this saw restrictsthe maximum

width of the cut to 1/2".

4. It is not necessary to install the outside flange (2)

before screwing on the arbor nut (3). Make sure that

the arbor nut istight, and that at least one thread

of the arbor sticks out past the nut.

5. Use only the 6" dado set and keep the width 1/2" or

less. It will be necessary to remove the blade guard

and splitter when using dado. Use caution when

dado is operating.

6. Use onlythe correctnumber of roundoutsideblades

and inside chippersas showninthe dado set'sinstruction

manual.Blade or chippermust notexceed 1/2".

7. Check saw to ensure that the dado will not strike the

housing, insert, or motor when in operation.

For your own safety, always replace the blade, blade

guard assembly, and blade insert when you are finished

with the dado operation.

Fig. FF

I iloll

/2

J

J

19

\

\

"3

Page 20

MAINTAINING YOUR TABLE SAW

GENERAL MAINTENANCE

For your own safety, turn the switch OFF and remove the

switch key. Remove the plug from the power source outlet

before maintaining or lubricating your saw.

!. Clean out all sawdust that has accumulated inside

the saw cabinet and the motor.

2. Polish the saw table with an automotive wax to keep

it clean and to make it easier to slide the workpiece.

3. Clean cutting blades with pitch and gum remover.

4. A worn, cut, or damaged power cord should be

replaced immediately.

All electrical or mechanical repairs should be attempted

only by a trained repair technician. Contact the nearest

Sears Service Center for service. Use only identical

replacement parts. Any other parts may create a hazard.

5. Use liquid dish washing detergent and water to

clean all plastic parts.

NOTE: Certain cleaning chemicals can damage

plastic parts.

6. Avoid use of the following cleaning chemicals or

solvents: gasoline, carbon tetrachloride, chlorinated

solvents, ammonia and household detergents

containing ammonia.

Fig. GG

4

Place a small amount of dry lubricant such as graphite

or silicon on screw rod (1) at thrust washer (5). Do not

oil threads of screw rods (1). Screw rod (1) must be

kept clean and free of sawdust, gum, pitch, and other

contaminants for smooth operation.

If excessive looseness is observed in any other part of the

blade raising mechanism or tilting mechanism, take the

complete unit to a Sears Service Center.

BLADE RAISING ANDTILTING MECHANISM (FIG. GG)

After each five hours of operation, the blade raising

mechanism and tilting mechanism should be checked for

looseness, binding, or other abnormalities. With the saw

disconnected from the power source, turn the saw

upside down and alternately pull upward and downward

on the motor unit. Observe any movement of the motor

mounting mechanism. Looseness or play in the blade

raising screw (1) should be adjusted as follows:

1. Using a wrench, loosen nut (2).

2. Adjust nut (3) until it is finger-tight against the

bracket (4), then back off the nut (3) 1/6 turn.

3. Tighten nut (2) with the wrench, while holding nut (3)

in place. Maximum allowable play of screw rod (1)

is 4 mm.

LUBRICATION

All motor bearings are permanently lubricated at the

factory and require no additional lubrication.

On all mechanical parts of your table saw where a

pivot or threaded rod are present, lubricate using

graphite or silicone. These dry lubricants will not

hold sawdust as would oil or grease.

20

Page 21

TROUBLESHOOTING GUIDE

To avoid injury from an accidental start, turn the switch OFF and always remove the plug from the power source

before making any adjustments.

• Consult your local Sears Service Center if for any reason the motor will not run.

SYMPTOM POSSIBLE CAUSES CORRECTIVE ACTION

Saw will not start. 1. Saw not plugged in. 1. Plug in saw.

2. Fuse blown or circuit breaker tripped. 2. Replace fuse or reset circuit breaker,

3. Cord damaged. 3. Have cord replaced by a Sears

Service Center.

Does not make

accurate 45° and

90° rip cuts.

Material pinches blade

when ripping.

Material binds on splitter.

Saw makes

unsatisfactory cuts.

Material kicked back

from blade.

Blade does not 1. Sawdust and dirt in raising 1. Brush or blow out loose dust and dirt.

raise or tilt freely, and tilting mechanisms.

Blade does not 1. Extension cord too light 1. Replace with adequate size cord.

come up to speed, or too long.

Machine vibrates 1. Saw not mounted securely to 1. Tighten all mounting hardware.

excessively, workbench.

1. Positive stop not adjusted correctly. 1. Check blade with square and adjust

positive stop.

2. Blade tilt pointer not set accurately. 2. Check blade with square and adjust

pointer to zero.

1. Rip fence not aligned with blade. 1. Check and adjust rip fence.

2. Warped wood, edge against 2. Select another piece of wood.

fence is not straight.

1. Splitter not aligned correctly 1. Check and align splitter with blade.

with blade.

1, Dull blade.

2. Blade mounted backwards.

3. Gum or pitch on blade.

1. Replace blade.

2. Turn blade around.

3. Remove blade and clean with

turpentine and coarse steel wool.

4. Incorrect blade for work being done.

5. Gum or pitch on table

causing erratic feed.

1,

Rip fence out of alignment. 1.

2.

Splitter not aligned with blade. 2.

3.

Feeding stock without rip fence. 3.

4.

Splitter not in place. 4.

5.

Dull blade. 5.

6.

The operator letting go of material 6.

before it is past saw blade.

7,

Miter angle lock knob is not tight. 7.

4. Change the blade.

5. Clean table with turpentine

and steel wool.

Align rip fence with miter gauge slot.

Align splitter with blade.

Install and use rip fence.

Install and use splitter (with guard).

Replace blade.

Push material all the way past saw

blade before releasing work.

Tighten knob.

2. Low house voltage. 2. Contact your electric company.

2. Bench on uneven floor. 2. Reposition on flat level surface.

Fasten to floor if necessary.

3. Damaged saw blade. 3. Replace blade.

Does not make accurate 1. Miter gauge out of adjustment. 1. Adjust miter gauge.

45° and 90° cross cuts.

21

Page 22

Key aONoOescr, ,,onS,z. K.,P.oNo S'z. 2

1 2615BBDDS0 Hex head screw M6"1.0-40 1 40 2501MBDN06 Flat washer 6 6"13-1 _ .

& washer 41 14212501 Spring _ _. o _ _1 _-I_11

2 2501MBDN06 Fiat washer 6"13-1 1 42 14910208 Rear clamp "_ _ _ _ _1

3 2705FBD106 Nutchuck M6"I.0 T=6 I 43 14910104 Lockingrod ! o 3 5"

4 14994501 Warning label 1 44 14903101 Insert 1 _ _ _r-_l

5 2690MZD514 Rivet 2 45 26218BDA18 Pan head screw M5X0.8-12 2 _o or_ = Z

6A 14912206 B1 Blade guard assembly 1 & washer r_ .Q _

6 14912206 Blade guard 1 46 14962201 Side cover 1 -r c'< o =

7 14994103 Caution label 1 47 14962301 Upper tube 1 _ --.._,<

8 2570DBN606 Self-locking ring 2 , 48 14960103 Extension wing 1 _ _'_ O

9 14912301 Arm 1 49 14962401 Scale 1 t_ _ _ _, r'

10 14912906 Splitter 1 50 26378BDA70 Trusshead round M6X1.0-23 1 _ <__-I-n Ill

11 14912801 Bush 2 neck screw _ 5"_ Go (D

12 14206901 Roll pin 1 51 19600101A2 Locking handle 2 _ ___>_'mE

13 14913201 Bush 2 assembly _ _ z

14 14206601 Kick back pawl 2 52 14961601 Auxiliary fence 1 o -_'_:-_

15 14208001 Kick back pawl 2 53 2704FBD106 Square nut M6"1.0 T=5 3 a, _[__

16 2570DBN606 Self-locking ring 2 54 2651PBDK17 Countersunk head M5"16-12 2 cr_ PE_m"m

17 2615BBDD22 Hex head screw M6"1.0-20 2 tapping screw "< _D 3

& washer 55 14961401 Side cover 1 _ .ocD_¢0

I r- Q._

,p

................ ................................................................i....... .............2.....

19 2536MBE613 Spring pin 5-24 1 & washer z _ _

20 14914701 Damper 2 57 14961201 Guide holder 4 c

21 14915401 Caution label 1 58 26028BLA25 Hex socket head M5"0.8-16 8 E 5"-_ c

22A 14910008A1 Parallel bracket assembly 1 cap bolt m -.: ¢D

22 14910008 Parallel bracket 1 59 19500203 Clamp bolt 2 _ _ _ o

23 2601BBDA40 Hex head bolt M6"1.0-16 2 60 2675BNHA42 Pan head screw M6X1.0-20 2 _ _ _ m

24 2504MBC006 External tooth 6 6 2 61 14961001 Upper tube 1 o m=-.-_

25 14910505 Width body 1 63 14902909 Scale 1

26 14212501 Compression spring 1 64 14902813 Table 1 R ,< _-o

28 15218801 Hex nut 1 66 2601BBDA47 Hex head bolt M6"1.0-50 1 m

27 14915701 Cap screw 1 65 14915105 Warning stick label 1 _ o o_

29 18622601 Pointer 1 67 2504MBC006 External tooth 6 6 1 _ 3

30 2641BBDA22 Round washer M5"0.8-6 1 lock washer _ ,<

31 14916901 Grip 1 69 14205001 Guard bracket 1 _ _ _ {:_

32A 14911301A1 Bolt clamp assembly 1 70 2701FBD106 Hex. nut M6"1.0 T=5 2 _ •

32 14211203 Bolt clamp 1 71 14914901 Washer 1 ,^-r_m 1-

33 2701FBD113 Hex. nut M8*1.25,T=6.5 1 72 2604BBLA42 Hex socket M6"1.0-25 6 _"__'_N _)

lock washer 62 2668BBDA23 Pan head screw M5"0.8-8 2 "< E_--I._

head screw 68 2501NBDN16 Fiat washer 114"314-1116 1 _ o._(D r_

cb_(n

_O--_

-_(_

Q

Gg_b_

m

............... ................................................................................................................... ................................

35 14911007 Link 1 73 2801ABRG01 Strain relief 1 _D:_u .._

36 14917202 Spring plate 1 74 2636BBDAA9 Countersunk M6* 1.0-50 4 e_._(_C_o _lCa

37 2660PBCK16 Pan head MSX16-10 1 head screw _ _ o 1,o

screw 75 2668BDDA43 Pan head screw 1 _ =

38 2536MBE627 Spring pin 1 76 2668BDDA44 Pan head screw 1 _ ,_ _1_

39 2536MBE638 Spring pin 5-30 1 180 2636BBDB48 Countersunk M6"1.0-55 1

181 280655545N Lead wire ass'y 1

182 14994601 Warning label 1

Page 23

22A

2

0

r-

Z

43

42

41

44

12

13

15

PJ

48

40

27

5O

32A

52

4g

m

56

64

61

54

o_

_n

0

Page 24

Key Part Description

77 14916901 Grip

78A 14911601A1 8olt clamp assembly

78 14211201 Bolt clamp

79 2501NBDN16 Flat washer

80A 14911402A5 Mitre gauge assembly

80 14911402 Mitre gauge

81 14608001 Pin

82 14911802 Angle pointer

83 29835L5006 Steel ball

84 14523301 Com# spring

SS 260388LA38 Hex socket set

86 14911707 Sheet bar

87 260888LA32 Hex socket truss

88 14937101 Wheel

88A 14937101A2 Hand wheel assembly

89 257088N209 E-ring E-9

90 2536MBE605 Spring pin 3-24

91 2536MBE629 Spring pin 3-14

92 bar

t_

93 14936501 Parrie ring

94 2603BBLA36 Hex socket set screw M6"1.0-6 4

95 14936701 Caution label 1

96 2668BBDA39 Pan head screw M6"1.0-12 4

97 2501NBDN12 Flat washer 114"518-1116 2

98 14906107 Warning label 1

99 2501NBDN16 Flat washer 1/4"314-1/16 4

100 2709FBDA02 Hexagon nut & flat washer 4

101 2707FBN107 U-type nut

102 14903104 insert .............................................

he ad so'few

................ ...................... 11

104 14904402 Wrench 1

105 2138MBL704 Wrench hex 1

106 2138MBL709 Wrench hex

107A 28078806AFA1 Power cable assembly 1

107 28078B06AF Power cable

108 2801ABRF01 Strain relief 1

109 13601201 Cord clamp

110 2660MBCE14 Pan head tapping M4"16-16 2

screw

Size

114"3/4-1116

0-10

M6

Qty

Key Part Description Size Qty

111 18402702 Dust shield 4

1

1

112 2801DBHA04 Strain relief 2

113 14902302 Switch box 1

1

114 14900136 Body shell 1

1

115 14909401 Trade mark label 1

1

116 26688ZDA07 Pan head screw M4"0,7-8 3

1

117 2504MZC004 External tooth 6 4 3

I

1

118 2853U55501 Circuit breaker 1

1

1

1

1

2

120 2653MBDE11

121A 2898D10G06 Rocker switch 1

1

1

2

2

121 2851D55G06 Rocker switch element 1

122 286058H101 Switch key 1

123 14901704 Needle pointer

124 2668BBDA32 Pan head screw M5"0.8-10 1

1

125 2701FBD113 Hex nut ..............................

1

"126"'"250"i"MBDNO8 Flat washer 8X16-2.5 1

2

127 14901503 Pointer bracket 1

128 14901103 Height regulating bolt 1

129A 14900609A2 Hand wheel assembly 1

129 14900609 Whee_

130 2703FMD108 Crown nut MS*l.25T=12-5 2

131 14909001 Grip 2

132. 14900801 Bolt 2

6

133 14900703 Clamp handle M10"1.5 T=8 2

134 2701FBD110 Hex nut ......................

.....................................................................•_.................................... 1

135 15100801 Lock kno

136 2501NBDN16 Flat washer 114.314-1116 1

137 14905804 Retaining clip 1

183 14994701 Warning label 1

lock washer

screw

M8*1.25,T=6.5 1

1

1

2

Page 25

r

m

\

93

Ol

104

116/_

117

118

_106

105

109

111

112

113

B9

136

135

lZ9A

.,A

01

0

k_

Page 26

Key Part No. Description Size Qty Key Part No. Description Size Qty

138 14930002 Set nut

139 14930102 Arbor collar

140 14930203 Blade

141 8387129942 Motor

142 2620BBDC18 Pan head screw

M5"0.8-12

& washer

143 14936201 Bearing seat

144 14936301 Shaft

.............................................................................................................................................................................. r...................................................................................................................

1 158 14901302

1 159 2603BBLA66

1 160 2701FBD111

1 161 2701FBD110

1 162 2615BBDD25

I 163 2672BBDA40

1

Spring

Hex. socketsetscrewM10*l.5-12

Hex. nut M10"1.5 T=4

Hex. nut M10"1.5 T=8

Hex head screw M8"1.25-16

& washer

Cap head square M6"1.0-16

neck bolt

145 14935904 Stiffener 1 164 2570BBN116 C-ring A-16 1

146 2708FBD107 Serrated toothed M6"1.0 T=6

hex. flange nut

147 14921307 Angle rod

148 14921403 Strap

149 2502NBC406 Spring washer 6 1/4"

150 2708FBD107 Serrated toothed M6"1.0 T=6

ro

hex flange nut

151 14921001 Plunger housing 1

152 14921703 Bracket 1

153 2501NBDN03 Flat washer 3/16"3/8-0.022 1

154 2617BBLC11 Hex socket head M5"0.8-20 1

cap screw

155 2501NNHN34 Flat washer 3/8"314-5/64 2

156 14921802 Bracket 1

157 14901203 Saddle 1

2 165 14935102

166 14935001

1 167 2672BBDA44

6

6 168 14922901

6 169 2701FBD106

170 2501NBDN09

171 2502ABC417 Flat washer 6 6

172 2701FBD106 Hex nut M6"1.0 T=5

173 2709FBDA02 Hex nut M6"1.0

174 14920003 Motor bracket

175 14920301 Spacer

176 2701FBD105 Hex nut MS*0.8T=4

177 2615BBDC25 Hex head screw M8"1.25-16

Supporting plate

Nut

Cap head square M6"1.0-35

neck bolt

Spacer

Hex nut M6"1.0 T=5

Flat washer 1/4"3/4-7/64

& flat washer

and washer

I

r-

I

I

I

I

2

m

0_

1

1

1

1

1

1

1

1

1

1

1

1

4

178 2672BBDB50 Cap head square M8"1.25-16 4

neck bolt

179 2536MBE621 Spring pin 8-90 1

* 137218250001 Owner's Manual 1

* Not Shown

o

¢O

Fo

QO

fo

¢n

O

Page 27

m

147

/

148

r-

m

(/)

/

149

/

150

/

138

139 "_

r_

--4

155

156

153

164

165

166

167

141

169

171

172

140

Page 28

CRAFTSMAN 10" TABLE SAW LEG STAND

PARTSLIST FOR SCHEMATIC D

Key Part No. Description Size Qty

1 17050106 Leg 4

2 2672BBDA54 Cap head square neck bolt M8x1.25-16 16

3 17050407 Bottom support bracket (long) L=563 2

4 2601BBDA69 Hex head bolt M 10xl .5-20 4

5 14000304 Spacer (foot pad) 4

6 2501MBDN 11 Flat washer 610x20-2 4

7 2701FBD109 Hex nut M10x1.5 T=8 4

8 2708FBD112 Serrated toothed hexagon flange nut MSx1.25 T=7.5 20

9 17050307 Upper support bracket (short) L=413 2

10 2601BBDA57 Hex head bolt M8xl.5-30 4

11 2501MBDN08 Flat washer 68x16-2.5 4

12 17050209 Upper support bracket (long) L=491 2

13 17050505 Bottom support bracket (short) L=475 2

MODEL NO. 137.218250

28

Page 29

CRAFTSMAN 10" TABLE SAW

SCHEMATIC D

MODEL NO. 137.218250

10

12

<

11

9

7

6

13

5

4

3

2

29

Page 30

Key Part No. Description Size Qty

1 2620B8DB26 Pan head screw MSX0.8-30 4

2 83871271 Support plate 1

3 2603BBLA23 Hex socket set screw M5X0.8-8 2

4 87840021 Motor housing 1

5 83962491A1 Brush holder assembly 2ST

23

6 83990291A1 Brush assembly 2ST

7 83990301 Brush cover 2

8 87840081 Bearing bushing 1

9 83870111A2 Field assembly 1

10 2662MZDE41 Pan head tapping screw M5X12-60 2

11 87840131 Baffle

12 87840122A2 Armature assembly

13 83871141 Motor nameplate

14 2801UBHA07 Strain relief bushing

15 83871161 Bracket

16 2001AH1010 Needle bearing 1

CO

17 , ,.- 2570BBN117 C-ring 1

18 87840171 Helix gear 1

19 83871201 Collar 1

20 2001 LU6204 Ball bearing 6204LLU 1

21 83870221 Bearing retainer

22 2504MZF004 External tooth lock washer 64

23 2636BZDA07 Countersunk head screw M4x0.7-8

24 2571MNC252 Parallel key

25 83870253 Arbor shaft

1

1

1

1

1

1

4

4

1

1

.=

!

III

io

CO

01

o

Page 31

08

O0

01

0

Page 32

32

Page 33

i

PUSH STICK

Make from 1/2" or 3/4"

\

c!tof

push 1/4 wood.

o_

Cut off here to

push 1/2" wood.

J

wood or thickness

less than width of

material to be cut.

CAUTION!

Use only good

strong wood

or plywood.

Use a jigsaw or

bandsaw to

cut out.

1/2" Squares.

Notch to help

prevent hand

from slipping.

\

\

Optional

hanging hole.

Page 34

For repair of major brand appliances in your own home...

no matter who made it, no matter who sold it!

ii_ii

1-800-4-MY-HOME sMAnytime, day or night

(1-800-469-4663)

www.sears.com

To bring in products such as vacuums, lawn equipment and electronics _:_:_:_!!iiii!_i

for repair, call for the location of your nearest Sears Parts & Repair Center. !!!!_!i!i!!

......

1-800-488-1222 Anytime, day or night

www.sears.com

For the replacement parts, accessories and owner's manuals

that you need to do-it-yourself, call Sears PartsDirect "_ !

1-800-366-PART 6am- 11pmCST,

(1-800-366-7278) 7 days a week

www.sears.com/partsdirect

To purchase or inquire about a Sears Service Agreement:

1-800-827-6655

7 a.m. - 5 p.m. CST, Men. - Sat.

Para pedir servicio de reparacibn a dornicilio,

y para ordenar piezas con entrega a domicilio:

1-888-SU-HOGAR s.

(1-888-784-6427)

::::::::_:::

r:::::::_:::::

:.:*:.:.:.:.:.:

_.::_::::::::,:

iii!i!iiiill

ii!iiiiiiiiiiil

:,:4:,:::

iiiiiiiiiiii_

:.:.7:.:,:,:,:

:,::::::

:._:*:.>_:,:

::_:::::::t:_:

:::+:,::,

_:_::::::::::::

:::::::_

Au Canada pour service en franc_ais: _:_:_:_:_:_............

1 877 LE FOYER _" .............

(1 877 533-6937) ...............

:::::::

::.:::.:.:

:ii_;!_!:!

::_:,:::*:

.::.:.:::.:

::::::::

.... [°°'°°!

© Se_rs, Roobuck and Co.

® Regislered T_ademark I " Trademark o€Seam. Roebuck and Co.

® Marca Regist rada I TM Marca de F&bnca de Sears, Roebu_:kand CO.

HomeCentral"

:::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

3/2000

Loading...

Loading...