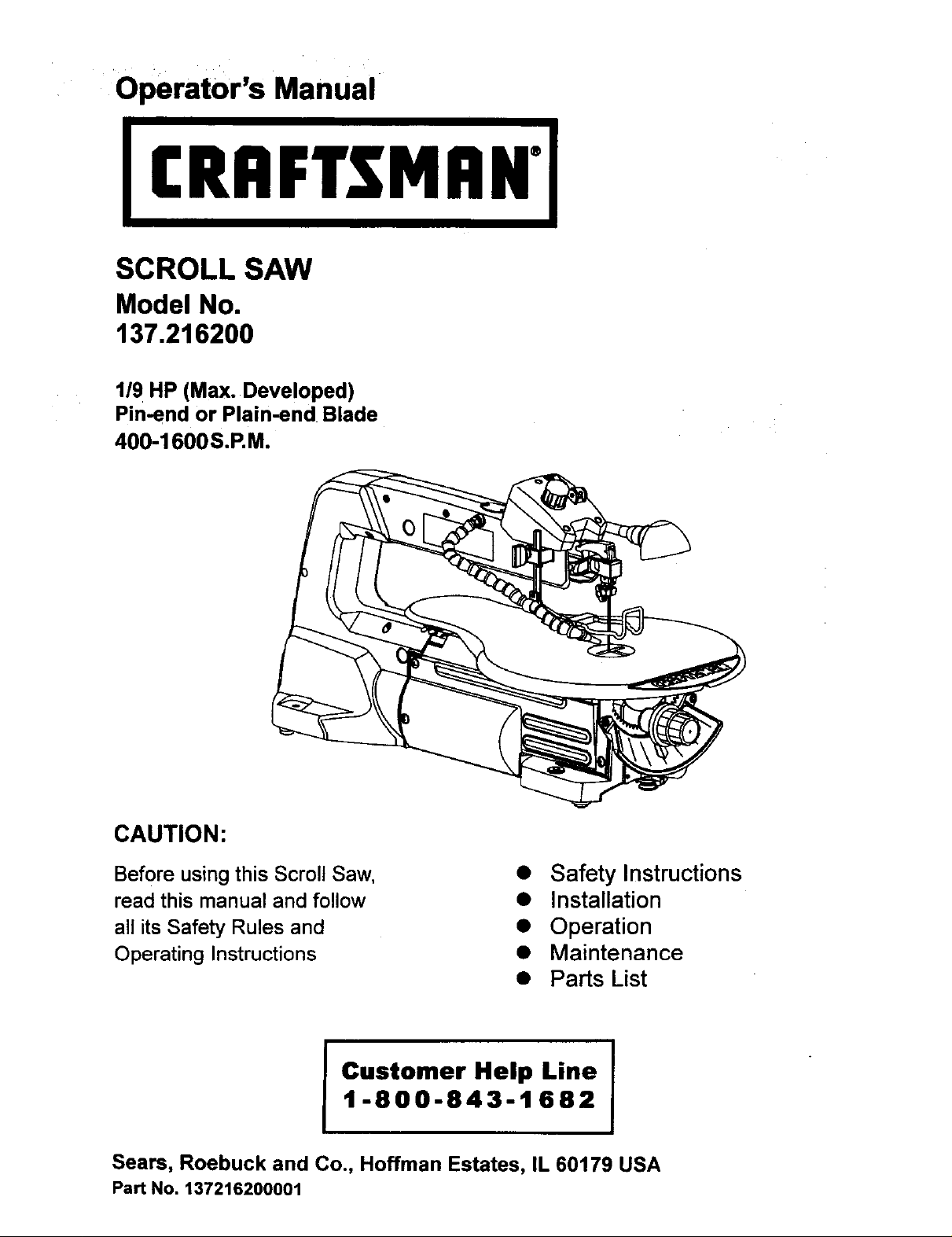

Craftsman 137216200 Owner’s Manual

Operator's Manual

iCRRFTSMRN'J

SCROLL SAW

Model No.

137.216200

1/9 HP (Max. Developed)

Pin-end or Plain-end Blade

400-1600S.RM.

CAUTION:

Before using this Scroll Saw,

read this manual and follow

all its Safety Rules and

Operating Instructions

Customer Help Line

1-800-843-1682

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

Part No, 137216200001

• Safety Instructions

• Installation

• Operation

• Maintenance

• Parts List

SECTION PAGE

Product Specifications ............................................................................................................... 2

Warning .................................................................................................................................... 2

Safety Instructions ..................................................................................................................... 3

Accessories and Attachments ...................................................................................................... 6

Carton Contents ......................................................................................................................... 6

Know Your Scroll Saw .................................................................................................................................. 8

Glossary of Terms ...................................................................................................................... 9

Assembly and Adjustments ......................................................................................................... t0

Bsalc saw Operation..................................................................................................................... 14

Maintenance .............................................................................................................................. 17

Troubleshooting Guide ............................................................................................................... 18

Parts ........................................................................................................................................ 20

FULL ONE YEAR WARRANTY

if this Scroll Saw fails due to a defect in material or workmanship within one year of date of purchase,

Sears will at its option repair or replace it free of charge.

Return this Scroll Saw to a Sears Service Center for repair, or to place of purchase for replacement.

This warranty gives you specific legal rights, and you may also have other rights which may vary from

state to state.

Sears, Roebuck and Co., Dept. 817 WA, Hoffman Estates, IL 60179

Some dustcreatedbypowersanding sawing,grinding,drillingand otherconstructionactivitiescontainschemicals

knownto the state of Californiato cause cancer, birthdefectsor otherreproductveharm Someexamplesof these

chemicalsare:

• Lead from lead-basedpaints

• Crystalline silicafrom bricks, cementandother masonry products

• Arsenic and chromiumfrom chemicallytreatedlumber

Yourriskfrom these exposuresvades, dependingon howoftenyoudothistype of work. To reduceyour exposureto

these chemicals,work in a well ventilatedarea andworkwith approvedsafetyequipmentsuch as dustmasksthatare

speciallydesignedto filter out microscopicparticles.

Motor

Power source ......... 120 V, 60 Hz, 1.4Amp., Ac

Speed ...................... 400 ~ 1600 spm

Speed control .......... Electronic

Blade

Type ..................... Pin-end or Plain-end

Depth of Throat ....... 20-114"

Blade Stroke .......... 3/4"

Depth of 45"Cut .... 1-1/8" Left; 3/4" Right

Depth of 90"Cut .... 2-1/4"

Table

Size ...................... 23-23/32" X 15-11/16"

Tilt ........................ 45"Left; Right

SAWDUST BLOWER ...... Yes

To avoid electrical hazards, fire hazards, or damage to

the tool, use proper circuit protection. Use a separate

electrical circuit for your tools.

Your scrollsaw is wired at the factory for 120V operation.

Connect to a 120V, 15 AMP branch circuit and use a 15

Amp time delay fuse or circuit breaker. To avoid shockor

fire, replace power cord immediately if it is worn, cut or

damaged in any way.

GENERAL SAFETY INSTRUCTIONS

BEFORE USING THE SCROLL SAW

Safety is a combinationofcommon sense, stayingalert

and knowinghowto useyour scrollsaw.

_k_ll_ [_

Toavoidmistakesthatcould cause seriousinjury,donot

plugthe ScrollSaw in untilyou have roadand

understoodthefollowing.

1. READ and become familiar with the entireOperator's

Manual.LEARN the tool'sapplication,limitationsand

possiblehazards.

2. KEEP GUARDS IN PLACE and inworkingorder.

3. REMOVE ADJUSTING KEYS AND WRENCHES.

Fromthe habitof checkingto see that keysand

adjustingwrenches are removed from the toolbefore

turningON.

4. KEEP WORK AREA CLEAN. Clutterodareas and

benchesinviteaccidents.

5. DON'T USE IN DANGEROUS ENVIRONMENT.

Don'tuse power toolsin damp and wet locations,or

exposethemto rain. Keepwork area well lighted.

12.ALWAYSWEAR EYE PROTECTION. Any scrollsaw

can throw foreignobjectsinto theeyes and could

cause permanenteye damage.ALWAYSwear Safety

Goggles(notglasses)thatcomply withANSI Safety

standardZ87.1. Everydayeyeglasseshave only

impact-rosistancelenses.They ARE NOT safety

glasses.Safety Gogglesare availableat Sears.

NOTE: Glasses or gogglesnotin compliance with

ANSI Z87.1 couldcause seriousinjurywhenthey

break.

13.WEAR A FACE MASK OR DUST MASK. Sawing

operationproducesdust.

14.SECURE WORK. Use clamps ora vise toholdwork

when practical.It's saferthan usingyourhand andit

frees bothhandsto operatetool.

15.DISCONNECT TOOLS beforeservicing;when

changingaccessoriessuchas blades, bits,cutters,

and thelike.

16.REDUCE THE RISK OF UNINTENTIONAL

STARTING. Make sureswitchis inOFF position

before pluggingin.

17.USE RECOMMENDED ACCESSORIES. Consultthe

Operator'sManualfor recommendedaccessories.

The useof improperaccessoriesmay cause riskof

injurytopersons.

6. KEEP CHILDREN AWAY.All visitorsshouldbe kepta

safe distancefromwork area.

7. MAKE WORKSHOP CHILD PROOF withpadlocks,

masterswitches,or byremovingstarterkeys.

8. DON'T FORCE THE TOOL. It will do the job better

and safer at the ratefor whichitwas designed.

9. USE THE RIGHT TOOL. Do not force toolor

attachmenttodo a job for which itwas notdesigned.

10.USE PROPER EXTENSION CORD. Make sureyour

extensioncordis in goodcondition.When usingan

extensioncord, be sure to use one heavy enoughto

carrythecurrantyour productwilldraw.An

undersizedcordwillresult ina drop inlinevoltage

and in lossof powerwhichwillcause the toolto

overheat.The table on page 5 showsthe correctsize

to use dependingoncord lengthand nameplate

ampere rating.If in doubt,use the next heaviergauge.

The smallerthe gaugenumber,the heavier thecord

11.WEAR PROPER APPAREL. Do not wear loose

clothing, gloves, neckties, rings, bracelets, or other

jewelry which may get caught in moving parts.

Non-slip footwear is recommended• Wear protective

hair covering to contain long hair.

18.NEVER STAND ON TOOL. Seriousinjurycould

occur ifthe toolis tippedor ifthe cuttingtoolis

unintentionallycontacted.

19.CHECK FOR DAMAGED PARTS. Beforefurther use

ofthe too!,a guardor other partthatis damaged

shouldbe carefully checkedto determinethatit will

operateproperlyandperformits intendedfunction -

checkfor alignmentof movingparts,bindingof

movingparts,breakage of parts,mounting,andany

otherconditionsthat mayaffect itsoperation.A guard

orotherpartthat isdamaged shouldbe properly

repairedor replaced.

20.NEVER LEAVE TOOL RUNNING UNATTENDED.

TURN POWER "OFF". Don't leavetooluntilitcomes

to a completestop.

21.DON'T OVERREACH. Keep properfootingand

balance at all times•

22.MAINTAIN TOOLS WITH CARE. Keep tools sharp

andclean for best and safest performance.Follow

instructionsfor lubricatingandchangingaccassodes.

23.DIRECTION OF FEED. Feed work into a blade or

cutter against the direction of rotation of the blade or

cutter only.

24.DO NOT operatethe toolif youare underthe

influence of any drugs,alcoholor medicationthat

couldaffectyourabilityto usethe toolproberly.

3

25.DUST GENERATED from certainmaterialscan be

hazardoustoyour health.Always operate the saw in

well-ventilatedarea and providefor properdust

removal.Use dustcollectionsystemswhenever

possible.

12.TO PREVENT INJURIES, avoid awkwardhandor

fingerpositions,where a suddenslipcouldcause a

handto move intothe blade whenoperatingthe saw.

13.HOLD WORKPIECE FIRMLY againstthescrollsaw

table top.

SPECIFIC SAFETY INSTRUCTIONS FOR

SCROLL SAWS

1. READ AND UNDERSTAND all safetyinstructions

and operatingproceduresthroughoutthe manual.

2. DO NOT operatethe scrollsaw untilitiscompletely

assembledand installedaccordingtothe instructions.

3. SHOULD any part of scrollsaw be missing,damaged,

or fail in any way,or any electricalcomponent fail to

performproperly,shutoffthe switchand removethe

plugfrom the powersupplyoutlet.Replace missing,

damaged, or failed parts before resumingoperation.

4. IF YOU ARE NOT thoroughlyfamiliar withthe

operationof the scrollsaw,obtainadvice from your

supervisor,instructor,orother qualifiedperson.

5. SERIOUS INJURY couldoccur ifthe tooltipsover or

you accidentallyhitthe cuttingtool.Do notstore

anythingaboveor near the tool.

6. AVOID INJURY from unexpectedsaw movement.

Placethe saw on a firm level surfacewhere thesaw

doesnot rock,and boltor clamp the saw to its

support.

7. YOUR SCROLL SAW MUST BE SECURELY

FASTENED to a standor workbench.Ifthere is any

tendencyfor the standor workbenchtomove during

operation,the standor workbenchMUST befastened

tothe floor.

8. THIS SCROLL SAW is intended for indooruseonly.

14.NEVER CUT MATERIAL that istoo smallto be held

safely.

15.DO NOT USE dullor bent blades.

16.TURN THE SAW OFF AND UNPLUG THE CORD if

the blade bindsin the saw kerf whilebeingbacked

out ofthe workpiece,usuallycaused by sawdust

cloggingthekerf. Ifthishappens, turnoff thescroll

sawand unplugthe powercord. Wedge open thekerf

and backthe bladeoutof theworkpieca.

17.DO NOT feed the materialtoo fast whilecutting.Only

feed the workpieceat therate thesaw willcut.

18.TURN THE POWER OFF, remove theswitchkey and

make surethescrollsaw comes toa completestop

beforeinstallingor removingan accessory,and

beforeleaving the workarea.

19.DO NOT START the saw with workpiecepressing

againstthe blade. Slowly feed theworkpieceinto the

movingblade.

20.WHEN CUTTING a largeworkpiece.MAKE SURE

thematerialissupportedat table height,

21.EXERCISE CAUTION when cuttingworkpiecesthat

are roundor irregularly shaped, workpiecescan pinch

theblade.

22.ALWAYSrelease blade tensionbefore looseningthe

bladeholderscrew.

23.MAKE CERTAIN tabletiltinglock is tightenedbefore

startingthe machine.

9. TENSION BLADE PROPERLY before startingthe

saw.Recheck and adjusttension as needed.

10.BLADE TEETH MUST POINT downwardtowardthe

table.

I1.TABLE MUST BE CLEARED of all debris before

operating saw, Do not perform layout, set up or

assemble work on the table when the saw is in

operation.

24.NEVER REACH underthe scrollsawtable when

motoris running.

25.CHECK FOR DAMAGED PARTS beforeeach use.

Checkfor alignmentofmovingparts, bindingof

movingparts,breakage ofparts, mountingor any

otherconditionsthat may affectoperation.Partsthat

aredamaged shouldbe properly repairedor replaced

before usingthe tool.

26.THINK SAFETY.

4

ELECTRICAL REQUIREMENTS

GROUNDING INSTRUCTIONS

IN THE EVENT OF A MALFUNCTION OR

BREAKDOWN, groundingprovidesa pathof least

resistance for electriccurrentand reducesthe risk of

electricshock.Thistool isequippedwith an electriccord

thathas an equipmentgroundingconductoranda

groundingplug.The plugMUST be pluggedinto a

matching receptaclethat is propertyinstalledand

groundedinaccordancewithALL localcodes and

ordinances.

DO NOT MODIFY THE PLUG PROVIDED. If itwill notfit

thereceptacle,have the properreceptacleinstalledbya

qualifiedelectrician.

IMPROPER CONNECTION of the equipmentgrounding

conductorcan resultin riskof electricshock.The

conductorwithgreen insulation(withor withoutyellow

stripes)is theequipmentgroundingconductor.If repair

or replacement of theelectriccordor plugis necessary,

DO NOT connectthe equipment groundingconductorto

a live terminal.

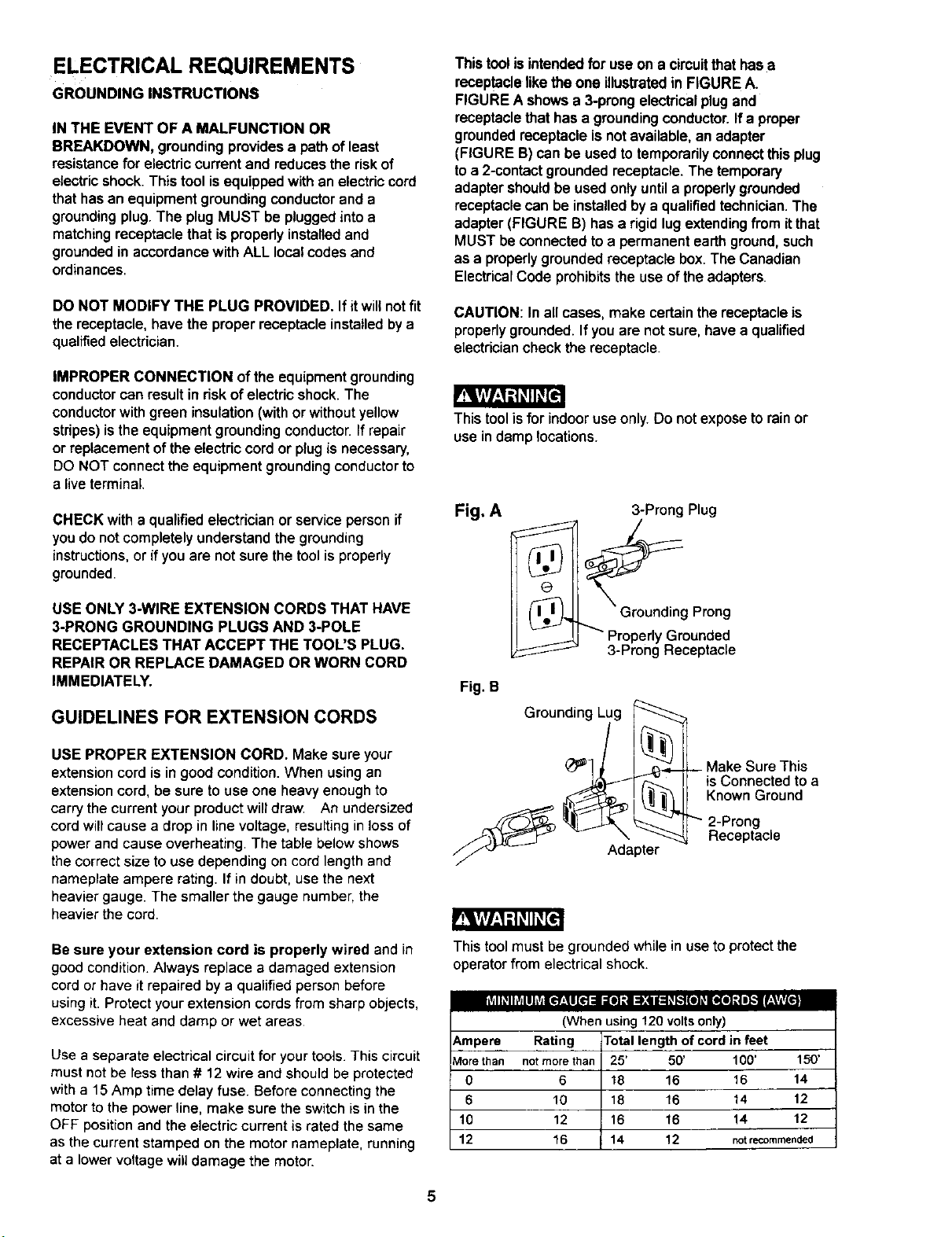

Thistool is intendedfor use ona circuitthat hasa

receptaclelikethe one illustratedin FIGURE A.

FIGURE A showsa 3-prong electricalplugand

receptaclethat has a groundingconductor.If a proper

groundedreceptacleisnotavailable, an adapter

(FIGURE B) can be used to temporarilyconnectthisplug

toa 2-contactgroundedreceptacle.The temporary

adaptershouldbe used onlyuntila properlygrounded

receptacle can be installedby a qualified technician.The

adapter(FIGURE B) hasa rigid lug extendingfrom it that

MUST be connected to a permanent earthground,such

as a properlygroundedreceptacle box.The Canadian

ElectricalCode prohibitsthe use ofthe adapters.

CAUTION: In all cases, make certain the receptacleis

properlygrounded.If youare not sure, havea qualified

electriciancheckthe receptacle.

Thistoolisfor indooruse only. Do not expose torainor

use indamp locations.

CHECK witha qualified electrician orservice person if

youdo notcompletelyunderstandthe grounding

instructions, or ifyou are not sure thetool isproperly

grounded.

USE ONLY 3-WIRE EXTENSION CORDS THAT HAVE

3-PRONG GROUNDING PLUGS AND 3-POLE

RECEPTACLES THAT ACCEPT THE TOOL'S PLUG.

REPAIR OR REPLACE DAMAGED OR WORN CORD

IMMEDIATELY.

GUIDELINES FOR EXTENSION CORDS

USE PROPER EXTENSION CORD. Makesure your

extensioncord is ingood condition. When using an

extension cord, be sure touse one heavyenoughto

carrythecurrentyour productwilldraw. An undersized

cord will causea drop in linevoltage, resulting inloss of

powerand cause overheating.The table belowshows

the correctsize to use dependingon cordlengthand

nameplateampere rating.If in doubt,use the next

heaviergauge. The smallerthe gauge number,the

heavier the cord.

Be sure your extension cord is properly wired and in

good condition. Always replace a damaged extension

cord or have it repaired by a qualified person before

using it. Protect your extension cords from sharp objects,

excessive heat and damp or wet areas

Use a separate electrical circuit for your tools. This circuit

must not be less than # 12 wire and should be protected

with a 15 Amp time delay fuse. Before connecting the

motor to the power line, make sure the switch is in the

OFF position and the electric current is rated the same

as the current stamped on the motor nameplate, running

at a lower voltage will damage the motor.

Fig, A

3-Prong Plug

J Z

! I Grounding Prong

ProperlyGrounded

_ 3-Prong Receptacle

Fig. B

Grounding Lug

-- Make Sure This

is Connected to a

Known Ground

_- 2-Prong

Receptacle

Thistool must be grounded while in useto protect the

operator from electrical shock.

V_llll hVdIlLVi[l_;111[l1:11;[el :l =t:l 1:1_I_-I[l] _ [_ll] _.|I1[€! F±VIVL_

(When using 120 volts only)

Ampere Rating Total length of cord in feet

Morethan not more than 25' 50' 100' 150'

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 notrecommended

5

AVAILABLE ACCESSORIES UNPACKING AND CHECKING CONTENTS

• Toavoid injury,do notattempt to modify thistoolor

anyaccessoriesnot recommendedfor use withthis

tool.Any suchalterationor modificationismisuse

and couldresultina hazardousconditionleadingto

possibleseriousinjury.

• Use onlyaccessories availablefrom Sears for this

scrollsaw. Followinstructionsthat accompany

accessories.Use of improperaccessoriesmay

cause hazards.

V_sityourSears Hardware Departmentor see theSears

Powerand Handtool catalog for the following

accessodes:

ITEM

Pin-endsaw blades

Plain-endsaw blades

Scrollsaw handbook

Scrollsaw patternkit

Searsmay offer other accessoriesnot listed in this

manual.

See yournearest Sears storeor Power and HandTool

Catalogfor other accessories.

Do not use anyaccessoryunless youhave completely

read theinstructionsor Operator's Manual for that

accessory.

• To avoidinjury,if anypart is missingor damaged, do

not plugthe scrollsaw in untilthe missingor damaged

part isreplaced,and assemblyiscomplete.

• To avoidfire and toxicreaction,neverusegasoline,

naphtha,acetone, lacquer,thinner,orsimilarhighly

volatilesolventsto clean thescrollsaw.

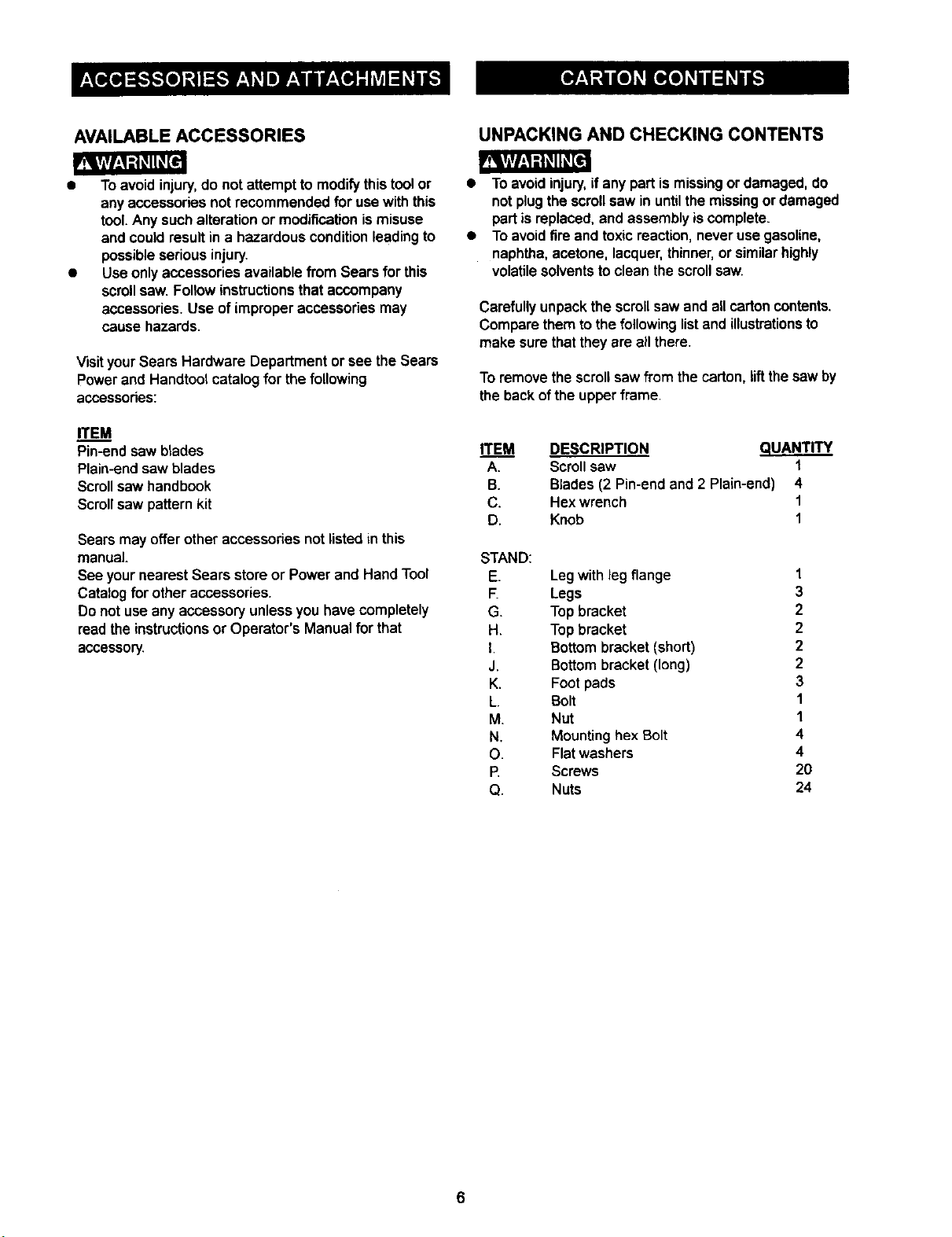

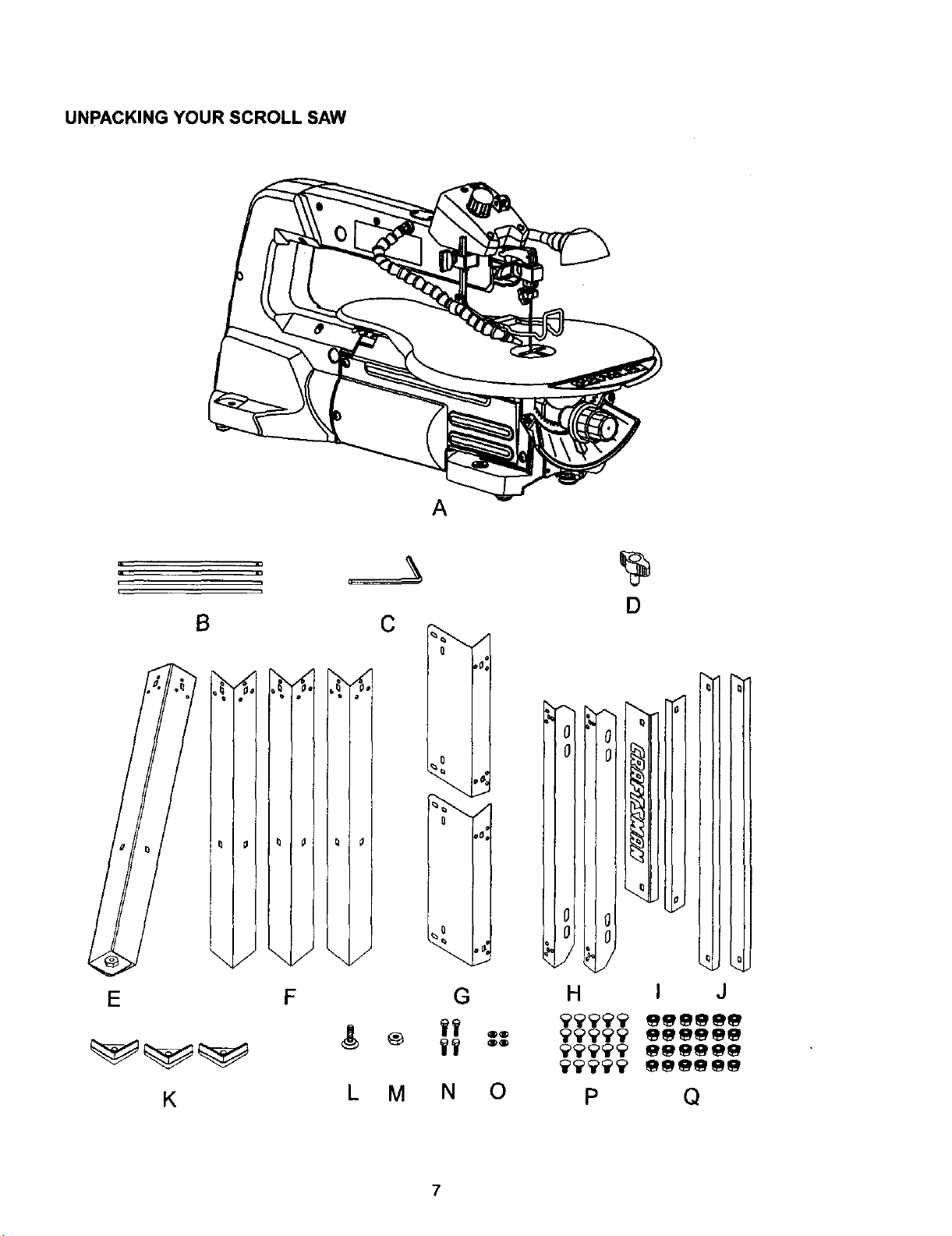

Carefullyunpackthe scrollsaw and all carton contents.

Compare themto the following list and illustrationsto

make surethatthey are all there.

To remove the scrollsaw from the carton, liftthe sawby

the back of the upperframe.

ITEM DESCRIPTION QUANTITY

A. Scrollsaw 1

B. Blades (2 Pin-endand 2 Plain-end) 4

C. Hex wrench 1

D. Knob 1

STAND:

E. Leg withleg flange 1

F. Legs 3

G. Top bracket 2

H. Top bracket 2

I. Bottom bracket (short) 2

J. Bottom bracket (long) 2

K. Foot pads 3

L. Bolt 1

M Nut 1

N. Mounting hex Bolt 4

O. Flatwashers 4

P. Screws 20

Q. Nuts 24

6

UNPACKINGYOURSCROLLSAW

la • i

,• • p

L

B

J

D

¢

/

o

_lJ o

t I

E

K

J

I

\/

i

o

i

I

J

I

Q

I

/

o

A

0

r_

I

I

\/

F

L M

I

G

V_

N

/

®Q

Q_

0

0

0

J

H

P

I J

Q

7

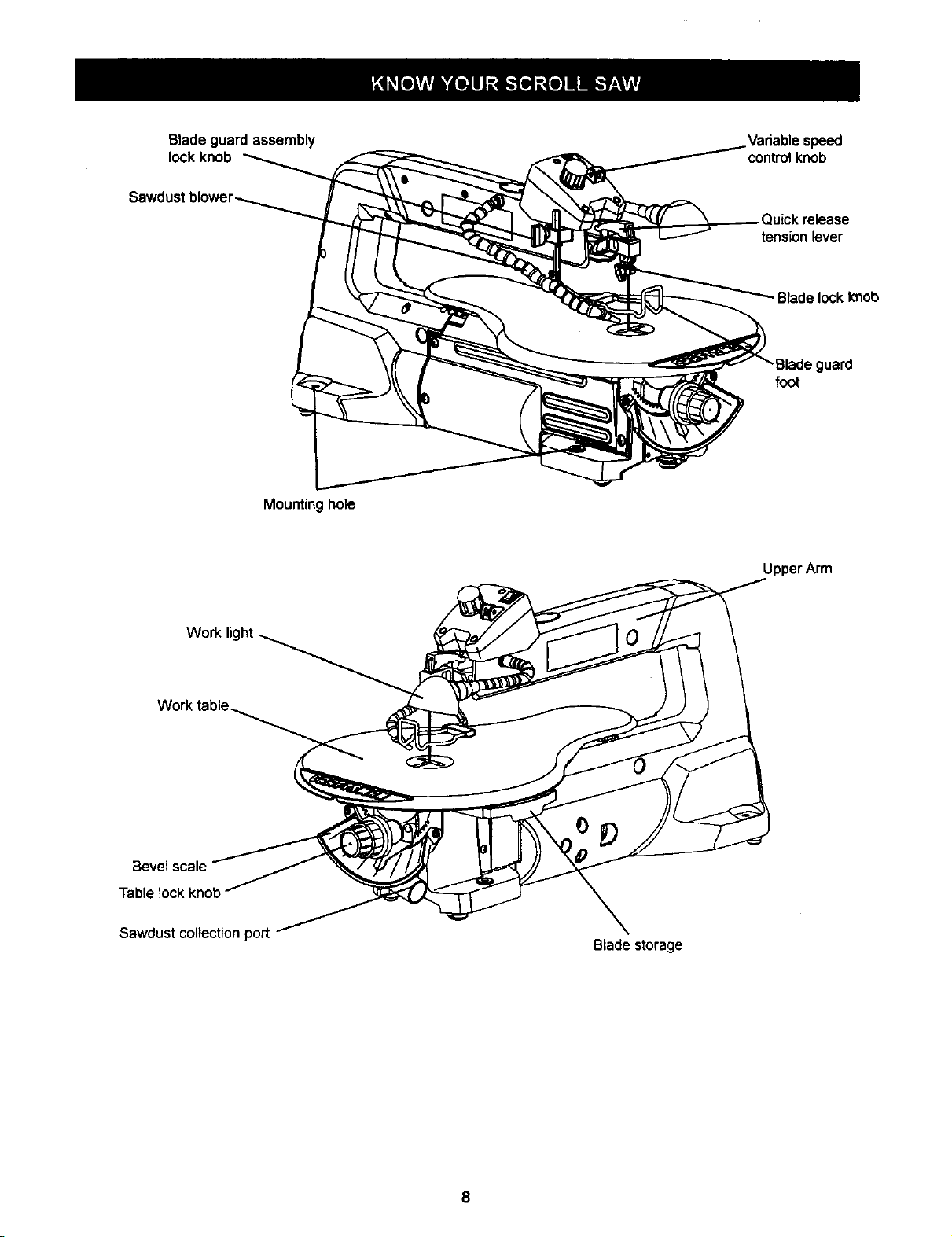

Bladeguardassembly Variablespeed

lockknob controlknob

tensionlever

-Bladelockknob

adeguard

foot

Mountinghole

UpperArm

Work light

Worktable

Bevel scale

Table lock knob

Sawdust collection

Blade storage

8

Loading...

Loading...