Craftsman 137212940 Owner’s Manual

Owner's anual

137.285941

137.212940 (US)

E82443

IVlD

37J2 LISTD

:v /: •L •: : : ¸I¸:I :

•_i_!" _:_/ _,i _'_:;_<_

_:•i:¸¸::?ii!:: ,•::::_•:_:_•:,,i:

sing this mitre saw,

_::::read thiS_manua and follow

and

nstructions.

i

, Safety In

o Installation

,, Operation

o Maintenance

o Parts List

Lions

Customer HeJp Line

1-800=843°1682

Inc., Toronto M5B 288

)41001

SECTION PAGE

War_a_y ................................................................... 2

Product Specifications ...................................................... 2

Safety Instructions ............................................................ 3

Accessories and A'_tachrnen_s ................................................. 8

Carto_1 Conten__s ........................................................... 8

Know Your SHding B)_itre Saw .................................................. !0

Giossary of _rer.ms ......................................................... 11

.Assemb@" and Adiustments ................................................. 12

Operation ................................................................ 20

_ltainte_ance ............................................................ 26.

Troubieshoo_.ing guidr_ ...................................................... 27

Parts .................................................................. 28

FULL TWO YEAR WARRANTY

If this product fails due to a defect in rnatenal or workmanship within two years from [he date of purchase. Sears

will at its option repair or replace it free of charge.

Contact a Sears Service Center for repair.

of purchase.

This warranty _sin addition to any statutory warranty.

f If [his products !s used for commerctal or rental purposes, this warranty applies only for 90 days from the date

l Sears Canada _nc.,Toronto M5B 2B8

MOTOR

Power source ..........

Horsepower ...........

Speed ...............

Brake ................

Double insulateci .......

120V AC, 60 HZ, 10 AMPS

2 HP (Max. Developed)

5000 R.RM.

Electric

Yes

BLADE S_ZE ............. 8-1/2"

ARBOR SIZE ............ 5/8"

TABLE D_AMETEP, ........ 10-1/2"

BASE S_ZE ............. 20-3/4" x 12"

DUSi" COLLECTION ....... Yes

CUTTING CAPACFY

0° Mkre - 0° Bevel ......

45° Mitre - 0° Bevel ....

0° Mitre - 45° Bevel .....

450 Mitre - 450 Bevel ....

2-5/8" x 12"

2-5/8" x 8-1/2"

! -3/4" x 12"

1_3/4"x 8-!/2"

VISE CLABJ_P ............. Yes

To avoid electnca! hazards, fire hazards, or damage to

MITRE DETENT STOPS ....

BEVEL POS_TSVESTOPS ..

CARRIAGE SYSTEM ......

0, 15, 22.5, 31.6,

45 ° R & L. 60_ R

0°, & 450 L

3 Rail, ball bearing slide

the tool, use proper circuit protection.

Your sliding mitre saw is wired at the factory for 120V

operation. Connect to a 120V, 15 AMP time delay [use or

circuit breaker. To avoid shock or fire, replace power cord

immediately tfit is worn, cut or damaged in any way.

GEMER_-_L SAFETY _'_,->TRUCT, uN_

BEFOR,... USING TF-_ESUDING _'_TRE SAW

Safety is a combination of common sense, szaying alert

and knowing how [o use yobr n1_[i-esaw.

To avoid mistakes thai could cause serious injury, do not

plug Ihe mitre saw in until you have read and understood

the following:

!. READ and become familiar with this entire instruction

manual. LEARN [he tool's apphcalions, limilations, and

possible hazards, t 3.

2. KEEP GUARDS mNPLACE and in working order.

3. REMOVE ADJUSTING KEYS AND WRENCHES.

Form the habit of checking to see that keys and

adjusting wrenches are removed from the tool before

turning ON. !5.

4. KEEP WORK AREA CLEAN° Cluttered areas and

benches invite accidents.

.

DON'T USE _NA DANGEROUS ENVIRONMENT.

Don't use power tools in damp or wet locations, or

expose them to rain. Keep work area welt lighted.

,

KEEP CHILDREN AWAY. All visitors should be kept at

a safe distance from the work area.

7.

_V_AK-=WORKSHOP KID PROOF with padlocks, master

switches, or by remowng starter keys_

,

DON'T _-_

and safer at the rate for which it was designed.

.

USE THE R_GHTTOOL. Dont force tool or the

attachment to do a job for which it was not designed.

!0.

USE PROPER EXTENSION CORD. Make sure your

exiension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to

carry the current your product will draw. An undersizecl

cord wilf cause a drop in Iine voltage resulting in loss

of power and overheating. The table on page 7 shows

the correct size to use depending on cord length and

nameplate ampere rating. If in doubL use the next

heavier gauge. The smaller the gauge number, the

heavier the cord.

WEAR PROPER APPAREL. DO NOT wear loose

11,

clothing, gloves, neckties, rings, bracelets, or other

jewelry which may get caught in moving parts.

Nonslip footwear is recommended. Wear protective

hah covenng [o contain long hair.

r.JRCE THETOOL. It will do the job better

SAVE THESE

I2.

WEA_YOU_ ALWAYS WEAR EYE

that comply with ANSi safety standard Z87.1.

Everyday eyeglasses have only impact-resistant

lenses. They ARE NOT safety glasses. Safety

Goggles are available at Sears. NOTE: Glasses or

goggles not in compliance wiLhANSI Z87.1 could

seriously hurl you when they break.

WEAR A FACE MASK OR DUST MASK.

Sawing operation produces dust.

14.

SECURE WORK. Use clamps or a vise to hold work

when practical. It's safer than using your hand and it

frees both hands to operate tool.

DISCONNECT TOOLS before servicing, and when

changing accessories, such as blades, bits, cutters,

and the like.

16.

REDUCE THE RISK OF UNINTENTIONAL STARTING,

Make sure the switch is in OFF position before

plugging in.

17.

USE RECOMMENDED ACCESSORIES. Consult the

owner's manual for the recommended accessories.

The use of improper accessories may cause risk of

injury to persons.

18.

NEVER STAND ON TOOL, Serious injury could occur

if the tool is tipped or if the cutting tool is unintentionally

contacted.

I9.

CHECK FOR DAMAGED PARTS. Before further use of

the tool, a guard or other part that is damaged should

be carefully checked to determine that it will operate

properly and perform _tsintended function. Check for

alignment of moving parts, binding of moving parts,

breakage of parts, mounting, and any other conditions

that may affect its operation. A guard or other part that

is damaged siqould be properly repaired or replaced.

20.

NEVER LEAVE TOOL RUNNING UNATTENDED.

TURN THE POWER OFF, Don't leave the too! until

it comes to a complete stop,

2t.

DON'T OVERREACH. Keep proper footing and

balance at all times.

22.

MAINTAIN TOOLS WITH CARE. Keep tools sharp

and clean for best and safest performance. Follow

instructions for lubricating and changing accessories.

23.

DIRECTION OF FEED. Feed work into blade or cutter

against the direction of the rotation of the blade or

cutter only,

NSTRUCT ONS

PROTECTION. Any mitre

saw can throw foreign

objects into the eyes which

could cause permanent eye

damage. ALWAYS wear

Safety Goggles (not glasses)

24. DO NOT operate the tool if you are under the influence

of any drugs, alcohol or medication that could affect

your ability to use the tool properly.

25. Dust generated from certain materials can be

hazardous to your health. Always operate tile mitre saw

in a well-ventilated area and provide for proper dust

removal Use dust collechon systems whenever

possible.

SPECIFIC SAFETY mNSTRUCTBONS

FOR SLIDtNG MBTRE SAWS

1. READ AND UNDERSTAND all safety instructions

and operating procedures throughout the manual.

2. DO NOT operate the mitre saw until it is completely

assembled and ,lstalled according to the instructions.

3. SHOULD any part of your mitre saw be missing.

damaged, or fail in any way, or any electrical

component fall to perforrn properly, shut off the switch

and remove the plug from tile power supply outtel

Replace missing, darnaged, or failed parts before

resuming operation

4. IF YOU ARE NOT thoroughly famdlar with the

operation of mitre saws, obtain adwce Irom your

supervisor, instructor, or other qualified person.

5. NEVER CARRY the tool by the cord or the cutting

head handle. Damage to the insulation could cause

electric shock. Damage to the w_reconnections could

cause a fire.

6. SERIOUS INJURY could occur if the tool tips over or

you accidentally hit the cutting tool. Do not store

anything above or near the tool.

7. AVOID INJURY from unexpected saw movement.

Place the saw on a firm level surface where the saw

does not rock, and bolt or clamp the saw to its support.

8. BEFORE MOVING the saw. lock the mitre, bevel, and

cutting head positions.

9. CHOOSE the right 8-1/2" diameter blade for the

material and the type of cutting you plan to do. Never

use blades larger or smaller in diameter than

recommended.

10. USE ONLY CROSSCUTTING SAW BLADES. Do not

use blades with deep gullets as they can deflect to

the side and contact the guard.

11. USE only blade collars specified for your saw. The

recessed sides must face the blade.

12. USING THE HEX BLADE WRENCH supplied, make

sure the arbor screw is firmly tightened.

t3. NEVER USE the saw without the cover plate securely

in place, tt keeps the arbor screw from fa!ling out if !t

accidentally loosens, and prevents the spinning blade

from coming off the machine.

14. KEEP HANDS out of the path of the saw blade. If the

workpiece you are cutting would cause your hand to

be within 6-1/2 inches of the saw blade, the workplece

should be clamped in place before makHlg the cut.

15. MAKE SURE the blade and collars are clean and

properly arranged. After installing a new blade, make

sure the blade clears the table slot at the 0° and 45°

bevel positions. Lower the blade tnto [he table slot and

check for any contact with the base or turn table

structure, tf the blade contacts tile table, see the

TROUBLESHOOTING GUIDE for "depth stop

adjustment" or contact the Sears Service Centre.

Broken saw parts could injure you or others.

16. ALWAYS check the blade for cracks or damage

before operation. Replace a cracked or damaged

blade irnmediately.

17. USE blades recommended at 5000 RPM or greater.

18. ALWAYS keep the blade guards in place.

19. TO KEEP the nut from working its way off as you use

the saw. at teast one thread of the pivot bolt must

always shck out past the nut. Always keep the nut at

least that tight.

20. FAILURE TO TIGHTEN the jam nut could let the depth

stop slip and let the blade strike the saw table.

Broken saw parts could injure you or others.

21. CLEAR EVERYTHING except the workpiece and

related support devices off the table before turning

the mitre saw on.

22. MAKE SURE all clamps and locks are tight and

there is no excessive play in any part.

23. ALWAYS MAKE SURE all handles are tight before

cutting, even if the table is positioned in one of the

positive stops.

24. MAKE SURE there are no nails or foreign objects in

the part of the workpiece to be cut.

25. MAKE SURE the blade is not contacting the workpiece

before the switch is turned on.

26.

ALWAYS hold the work firmly against the fence and

table. DO NOT perform any operation freehand.

27.

DO NOTTRY TO CUT SHORT PIECES. You cannot

properly support the workpiece and keep your

hold-down hand the required distance from the blade.

28.

ALWAYSTIGHTEN THE CLAMP so that the workpiece

is secured between the clamp and fence or base. No

visible gap should be present between saw and wood.

29. NEVER cut metals or masonry. Because of the

sliding action of the saw, this machine is not designed

for cutting metals. Use this mitre saw to cut only wood

and woodlike products. Other materials may shatter,

bind on the blade, start fires or create other dangers.

30. NEVER reach around the saw blade.

31. TO AVOID POSSIBLE PERSONAL INJURY of

damage to the miter saw due to tipping, do not

operate the saw without the support bracket

securely in position.

32. NEVER PULLTHE SAW toward you during a cut.

The blade can suddenly climb Lip on top of the

workpiece and force itself toward you.

33. ALLOW the motor to come up to full speed before

starhng CLIt.

34.

KEEP the motor air slots clean and free of chips.

35.

NEVER apply lubricants to the blade when it is

running.

36.

MAKE SURE the blade has come to a complete stop

before removing or securing the workpiece, changing

the workpiece angle, or changing the angle of the

blade.

37. NEVER use the mitre saw in an area with flammable

liquids or gases.

38. NEVER use solvents to clean plastic parts. Solvents

could possibly dissolve or otherwise damage the

material.

39. ALWAYS PERFORM DRY RUNS. Make sure the saw

Jsunplugged. Completely set up your saw. Pull the

blade and cutting head through the full range of motion

to check for interference. The clamp can be used in

a left or right configuration. Make sure that your blade,

saw guard or motor does not interfere with the clamp.

Correct any interference before use.

40. PLAN HOW YOU WILL MAKE THE CUT:

MAKE SURE the blade is not spinning.

RAISE the blade.

• SLIDE the saw out above the front edge of the

workpiece before starting the saw.

• PUSH the saw blade down on top of the wood and

back toward the rear of the saw to make the cut_

BE

FORE EACH USE

41.

INSPECT YOUR MITRE SAW.

42.

D!SCONNECTTHE MITRE SAW. To avoid injury from

accidental starting, unplug the saw before changing

the setup, changing the blade, or adjusting anything.

Compare the direction of the rotation arrow on the

guard to the direchon arrow on the blade. The blade

teeth should always point downward at the front of the

saw. Tighten the arbor screw. Tighten the cover plate

stop screw.

43.

CHECK FOR DAMAGED PARTS. Check for:

PROPER alignment of moving parts

DAMAGED electric cords

-_ BINDING of moving parts

o BROKEN parts

, STABLE mounting

FUNCTION of arm return spring and lower guard:

Push the arrn all iEheway down, then let it rise

up until it stops by itself. Check the lower guard

to see it it closed fully_ If it did not, follow the

insiEructionsin the TROUBLESHOOTING GUIDE.

o SMOOTH, solid movement ot:sliding assembly.

o OTHER conditions that may affect the way the

mitre saw works. II any part of the m_tre _s

rniss_ng, bent, or broken in any way, or any

electrical parts don't work, turn the saw o1:1and

unplug it. REPLACE damaged, missing, or faded

parts before using the saw again.

44.

KEEP GUARDS IN PLACE, in working order, and in

proper adjustment. Maintain tools with care.

Keep the mitre saw clean for best and safest

performance. Follow instructions for lubncahng.

DON'T put lubricants on the blade wh!le it's spinning

45.

REMOVE adjushng keys and wrenches from the tool

before turning it on.

46.

TO AVOID INJURY FROM JAMS, SLIPS, OR

THROWN PIECES:

o USE ONLY RECOMMENDED ACCESSORIES.

Consult this Owner's Manuat for recommended

accessories. Follow the instructions that come

with the accessories. The use of improper

accessories may cause risk of injury to persons.

° MAKE SURE the blade is sharp, undamaged,

properly aligned and free of vibration. With the

saw unplugged, push the cutting head all the way

down. Hand spin the blade and check for

clearance. Tilt the cutting head to a 45 degree

bevel and repeat the check. If the blade hits

anything, see the TROUBLESHOOTING GUIDE

for "depth stop adjustment", or contact your

Sears Service Centre.

47. PLAN HOW you will hold the workpiece from start

to finish:

o AVOID awkward operations and hand positions

where a sudden slip could cause fingers or

hand to move into the blade.

o DON'T OVERREACH. Keep good footing and

balance.

KEEP your face and body to one side of the

saw blade, out of line with a possible throwback.

o NEVER CUT FREEHAND:

- BRACE your workpiece solidly against the fence

and table top so it will not rock or twist during

the cut.

- MAKE SURE there is no debris between the

workpiece and its supports,

- MAKE SURE no gaps between the workpiece,

fence and table will let the workpiece sh_ft after

it is cut in two,

"- CUT only one workpiece at a time.

KEEP the cut off piece free to move sideways

after it is cut off. Otherwise it could get wedged

against the blade and be thrown violently.

SAVE THESE

INSTRUCTIONS

4 5

SAVE THESE

iNSTRUCTIONS

CLEAReverythingexcepttheworkpieceand

relatedsupportdevicesofftheworktablebefore

turningthemitresawon.

o SECUREWORK.Useclampsora visetohetp

holdtheworkwhenit_spractical.

48. USE EXTRA CAUTION with large, very small or

awkward workpieces:

o USE extra supports (tables. saw horses, blocks,

etc.) for any workpieces large enough to tip

when not held down to tile table top.

o NEVER use anoiher person as a substitute for a

table extension, or as additional support for a

workpiece that is longer or wider than the basic

m_tre saw table, or io help feecl, support or pull

the workpiece.

o DO NOT USE this saw to cut pieces too small to

let you easily hold the work.

* WHEN CUTTING irregularly shaped workpieces,

plan your work so it will not slip and pinch the

blade and be torn from your hands. A piece of

molding, for example, must lie flat or be held by

a fixture or jig that will not let it twist, rock or slip

while being cut.

o PROPERLY SUPPORT round material such as

dowel rods, or tubing. They have a tendency to

roll while being cut, causing the blade to "bite".

To avoid this, always use a fixture designed to

properly hold your workpiece.

WHEN THE SAW IS RUNNmNG

49. BEFORE STARTmNG your cut, watch the mitre saw

while it runs. If it makes an unfamiliar noise or

vibrates a lot, stop immedJately. Turn the saw OFR

Unplug the saw. Do not restart unbl finding and

correcting the problem.

50. KEEP CHBLDREN AWAY. Keep a!l visitors a safe

distance from the mitre saw. Make sure bystanders

are clear of the mitre saw and workpiece.

51. LETTHE BLADE reach full speed before cutting.

This will help avoid thrown workpieces.

52. DON'T FORCE THE TOOL. tt will do the job better

and safer at its designed rate. Feed the saw into the

workpiece only fast enough to let the blade cut without

bogging down or binding.

53. BEFORE FREEING JAMMED MATERIAL:

, TURN mitre saw OFF by releasing trigger switch.

WAmTfor all moving parts to stop.

• UNPLUG the mitre saw.

54. AFTER FINISHmNGA CUT:

o KEEP holding the cutting head down.

RELEASE the switch, keeping the cutting head

down, and walt for all moving parts to stop before

moving your hands.

o iF BLADE doesn't stop within 6 seconds, unplug

the saw and foltow ihe instructions in the

TROUBLESHOOTING GUIDE for iixlng the blade

brake before using the saw again.

55. BEFORE LEAVING THE SAW:

NEVER LEAVE the tool runnnlg unattended.

Turn Ihe power OFR WaR for all moving parts

to stop.

o iWAKE WORKSHOP child proof. Lock the shol:_

Disconnect master swdches. Store the tool away

from childron and others not quahfied [o use the

tool.

56. NEVER unplug the saw with the switch in _lle ON

posibon.

57. DISCONNECT the saw from the power source and

clean the machine before leaving if.MAKE SURE [he

work area is clean before leaving the machine.

ELECTRICAL REQU RE[v E .

POWER SUPPLY AND MOTOR

SPECiFiCATiONS

The AC motor used in this saw is a universal, nonreverspble

type. See "MOTOR" in the PRODUCT SPECIFICATIONS

section on page 2.

To avoid electrical hazards, fire hazards, or damage [o lhe

tool, use proper circuit protection. Your saw iswired at the

factory [or 120V operation. Connect to a 120V, 15Amp

circuit and use a 15 Amp time delay fuse or circLntbreaker.

To avoid shock or fire, if power cord is worn or cut, or

damaged in any way, have it replaced immediately.

DOUBLE _NSULATED

The mitre saw is double insulated to provide a double

thickness of insulabon between you and the tool's electncal

system. All exposed metal parts are isolated from the

internal metal motor components with protecbng insulation.

Replacement parts - When servicing use only identical

replacement parts.

Polarized plugs - This saw has a plug that looks like the

one shown below:

To reduce the risk. of electrical shock, _hissaw has a

polarized plug (one blade is wider than the other). _hls

plug will Ii[ m a polarized ouile[ only one way. II the plug

does no! fit [u!ly Jn Ihe outlet, reverse the piug. it Rstill

does not fit, contact a qualified electrician to mslall the

proper outleL Do not chan.ge the plug in any way.

Double insulation does not take the place ol normal safety

precautions when operabng [!_istooi.

To avoid electrocution:

i. Use only identical repiacement parts when serwcmg a

toot with double insulation. Servicing should be

pel!ormecl by a qualit:iedtechnician.

2. Do not use power tools in wet or damp areas or

expose them to rain.

This !ool is intended for indoor use only.

MOTOR SAFETY PROTECTION

IMPORTANT: -Foavoid motor damage, l.his motor

should be blown out or vacLIumed frequently to keel)

sawdust from interfering with normal motor ventilation.

.

CONNECT [his tool to a 120V, 15 Amp branch arcuit

with a 15 Amp [!me delay fuse or cwcuit breaker.

Using the wrong size fuse can damage the motor.

.

tF the motor won't start, release the trigger switch

immediately. UNPLUG TIdETOOL. Check the saw

blade to make sure it turns freely. !i:the blade is free.

try to start the motor again. If the motor still does not

start, refer to the TROUBLESHOOTING GU_'DE.

.

IF [he motor suddenly stalls while cutting wood.

release the [rigger switch, unplug the too!, and free

the blade from [he wood. The saw may now be

restarted and the cut finished.

4.

FUSES may "blow" or circuit breakers may trip

frequen!ly it:

a. MOTOR is overloaded. Overloading can occur il:

you feed [oo rapidly or make [oo many start /

stops in a short brae.

b. LINE VOLTAGE is more than 10% above or

below the nameplate voltage. For heavy loads,

however, the voltage at motor terminals must

equal the voltage specified on the nameplate.

c. iMPROPER or dutl saw blades are used.

5.

MOST motor troubles may be traced to loose or

incorrect connections, overload, iow voltage (such as

small size wire in the supply circuit) or to overly long

supply circuit wire. Always check iEheconnechons, the

load and [he supply clrcufl if the motor doesn't work

well. Check wire sizes and teng[lq with the Extension

Cord Chnr[ below.

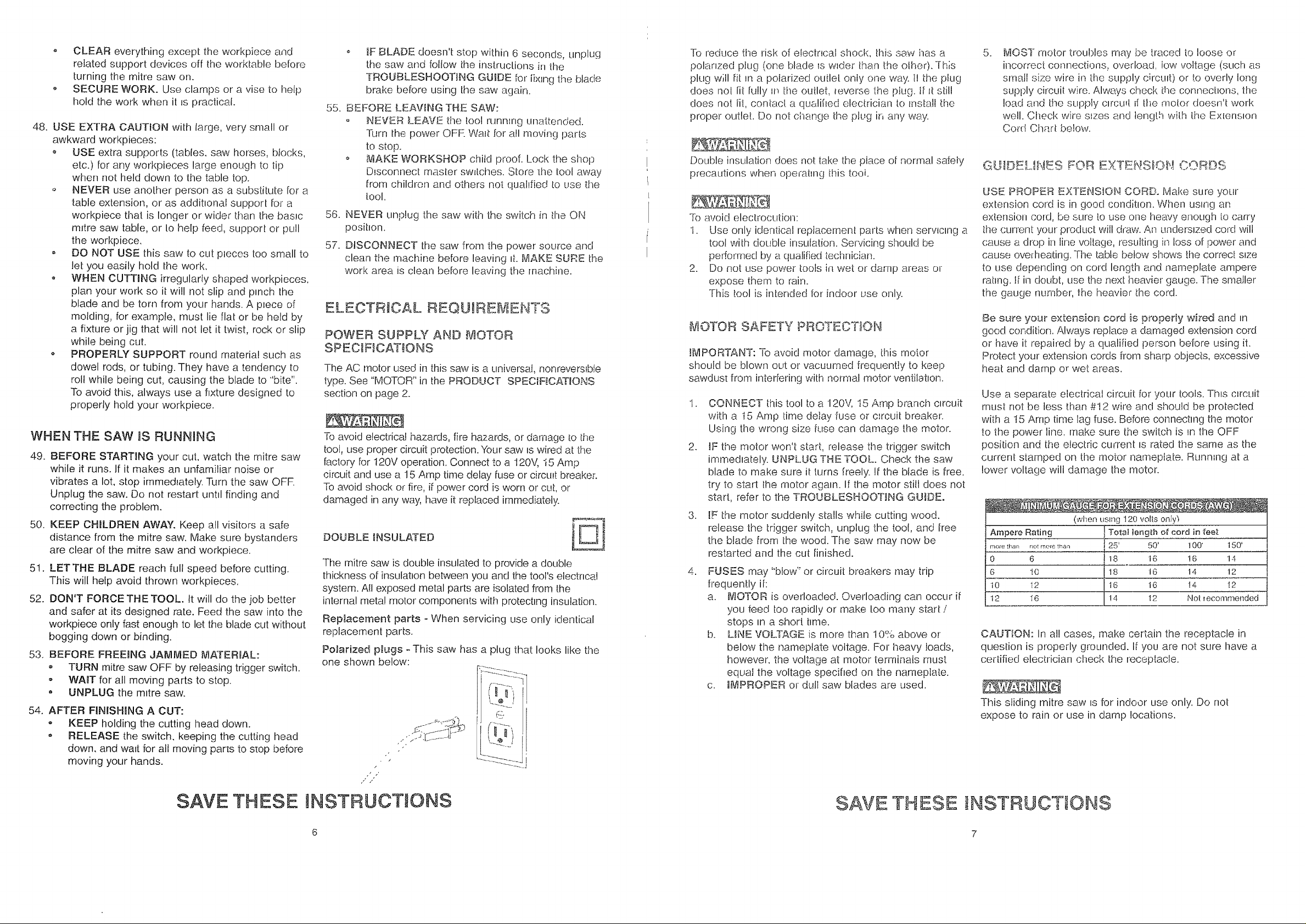

GUIDELINES FOR EXTENS_OI1 CORDS

USE PROPER EXi'E_\_S_ON CORDL Make sure yOLW

extension cord is in good condibon. When using an

extension cord, be sure [o use one heavy enough to carry

the current your procluc[ will draw. An undersized cord will

cause a drop in !ine voltage, resulting in loss of power and

cause ovedqeating. The table below shows the correci size

to use depending on cord length end nameplate ampere

rahng. I1:in cloubt, use tlqe next heavier gauge. The smaller

the gauge number, the heavier _he cord.

Be s_._reyour extension cord is properly wired and m

good condition. Always replace a damaged extension cord

or have it repaired by a qualified person before using it.

Protect your extension cords from sharp objects, excessive

tqea[ and damp or wet areas.

Use a separate electrical circuit for your tools. This cwcuit

must not be less than #12 wire and should be protected

with a !5 Amp time lag fuse. Before connechng the motor

to the power line, make sure the switch is m the OFF

position and the electric current is rated the same as the

current stamped on the motor nameptaie. Running at a

lower voltage will damage the motor.

(when using 120 volts onfy_

Ampere Rating ! Tota_ ienglh of cord in fee__

mo_e than not mare than T 25' 50' ] 00' 150'

0 6 ! _8 i6 !6 14

6 10 I 18 16 14 12

10 I2 I 16 16 14 1212 16 14 12 Not _ecommended

CAUTION: In all cases, make certain the receptacle in

question is properly groLmcled. If you are not sure have a

certified electrician check the receptacle.

Tt_is sliding mitre saw is for indoor use only. Do not

expose to rain or use in damp locations.

4-

SAVE THESE

SAVE THESE _NSTRUC0iONS

6 7

UNPACKNNG YOUR COMPOUND SLIDING MITRE SAW

PROHJBBTED ACCESSORIES

Use only accessories recommended for this sliding mitre

saw. Follow Instructions that accompany accessories.

Use of improper accessories may cause hazards_

Tile use of any cutttng tool except 8-1/2 inch saw blades

which meet the reqLHrements under recommended

accessories is prohibited. Do not use accessories such as

shaper cutters or dado sets. Ferrous metal cuthng and the

To avoid injury Irom unexpected starting or electrical

shock, do not plug the power cord into a power source

receptacle dunng unpacking and assembly. This cord nqusL

remain unplugged whenever you are working on the saw.

Carefully unpack the slidH_gmitre saw and all its parts,

and compare against the illustration on page 9.

t. Before removing the saw from the shipping carton,

use of abrasive wheels is prohibited.

2. DO NOT LIFT the sliding mitre saw by the cutting

Do not attempt to modify this tool or create accessories

not recommended for use with this tool. Any such alteration

or modification is misuse and could result in a hazardous

condition leading to possible serious injury.

3. Place the saw on a secure, stationary work surface

RECOMMENDED ACCESSORIES

Visit your Sears Hardware Department or see the Sears

Power and Hand Toot Catalogue for the following

accessories:

Although compact, this saw is heavy. To avoid back injury,

get help whenever you have to lift the saw.

ITEM

Blades: 8-1/2" Diameter, 5000 RPM, 5/8" Arbor

Dust bag

Safety goggles, hearing protection, dust respirators

Power tool manuals

If any part is missing or damaged, do not plug the sliding

mitre saw in until the missing or damaged part is replaced,

and assembly is complete. To avoid electric shock, use

only identical replacement parts when servicing double

BASIC BLADES RECOMMENDED FOR MITRE SAWS

insulated tools.

8-I/2" Carbide tipped combination blade

8-1/2" Steel combination blade

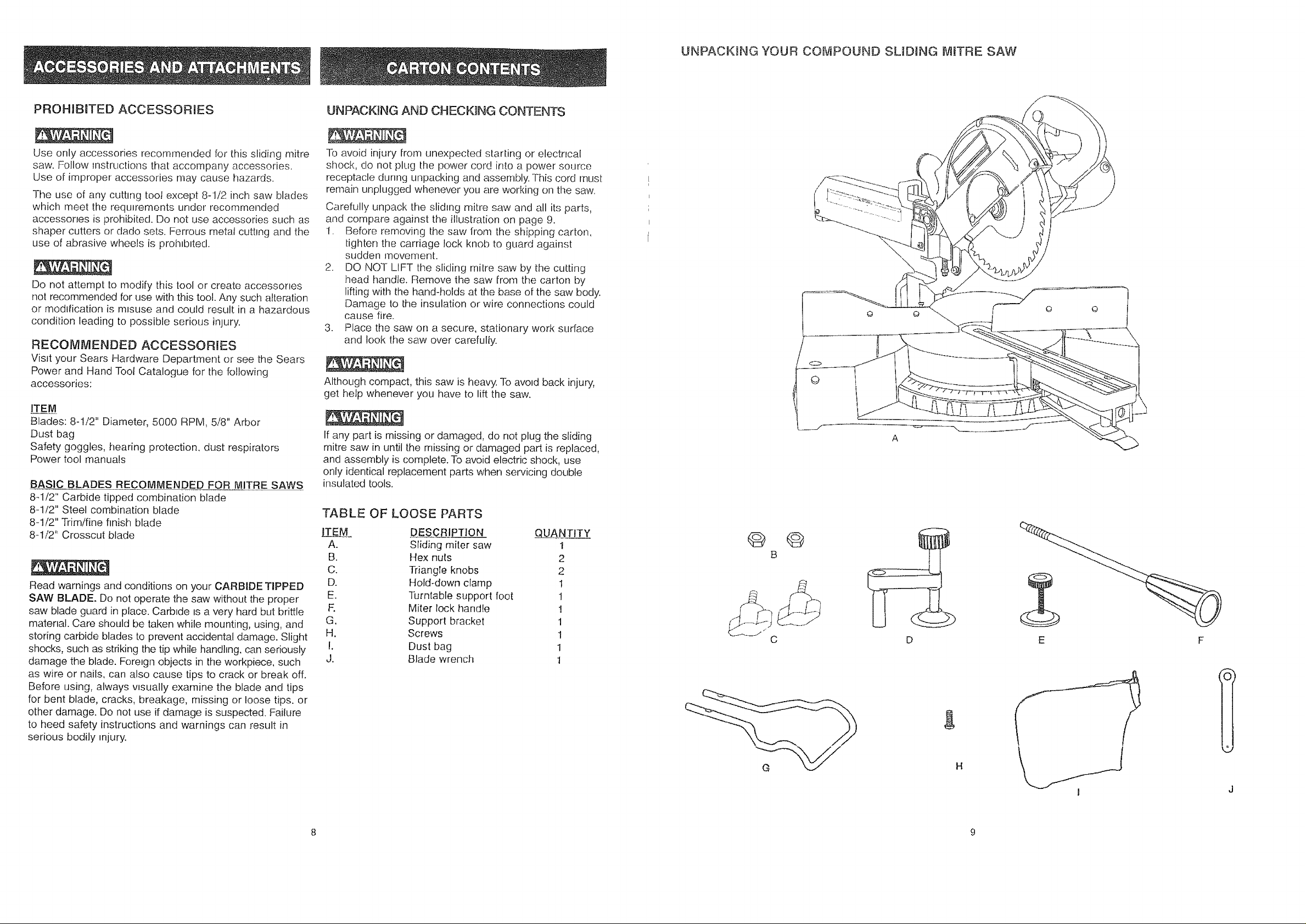

TABLE OF LOOSE PARTS

8-1/2" Trim/fine finish blade

8-I/2" Crosscut blade

Read warnings and conditions on your CARBIDE TIPPED D.

SAW BLADE. Do not operate the saw without the proper

saw blade guard in place. Carbtde is a very hard but brittle F.

material. Care should be taken while mounting, using, and G.

storing carbide blades to prevent accidental damage. Slight H.

shocks, such as striking the tip while handhng, can seriously !.

damage the blade. Foreign objects in the workpiece, such J-

as wire or nails, can also cause tips to crack or break off.

Before using, always visually examine the blade and tips

for bent blade, cracks, breakage, missing or loose tips. or

other damage. Do not use if damage is suspected. Failure

to heed safety instructions and warnings can result in

serious bodily injury.

UNPACKING AND CHECKING CONTENTS

Lighten the carriage lock knob to guard against

sudden movement.

head handle. Remove the saw from the carton by

lifting with the hand-holds at the base of the saw body.

Damage to the insulation or wire connections could

cause fire.

and look the saw over carefully.

DESC_RJPTION _QUANTITY_

A.

B.

c.

Sliding miter saw 1

Hex nuts 2

Triangle knobs 2

Hold-down clamp 1

E.

Turntable support foot 1

Miter lock handle !

Support bracket 1

Screws 1

Dust bag 1

Blade wrench 1

O O

B

C

/

/

O O

\

E F

\

H

8 9

I

Loading...

Loading...