Craftsman 137212890 Owner’s Manual

Operator's Manual

ICRRFTSMR

14 in. ABRASIVE CHOP SAW

WITH LASER TRAC ®

Model No. 137.212890

CAUTION:

Before using this Chop Saw,

read this manual and follow

all its Safety Rules and

Operating Instructions

Customer Help Line

For Technical Support

1-800-843-1682

Sears Brands Management Corporation Hoffman Estates, IL 60179 USA

See the full line of Craftsman ®products at craftsman.com

Click on the Craftsman Club® link and join today!

Part No. 137212890001

• Safety Instructions

• Installation

• Operation

• Maintenance

• Parts List

Sears Parts &

Repair Center

1-800-488-1222

Printed inChina

SECTION PAGE SECTION PAGE

Warranty ........................................ 2

Product Specifications ...................... 2

Power Tool Safety ............................ 3

Chop Saw Safety ................................. 4

Electrical Requirements and Safety ...... 7

Carton Contents .................................. 8

Know Your Chop Saw............................... 9

Assembly and Adjustments ..................... 10

Operation ........................................... 13

Maintenance ...................................... 14

Troubleshooting Guide ........................... 15

Parts List .............................................. 16

CRAFTSMAN FULL WARRANTY

If thisCraftsman product fails due to a manufacturer's defect in material or workmanshipwith one year from the date

of purchase, return itto any Sears store, Sears Parts & RepairService Center, or other Craftsman outlet inthe United

States for free free repair ( or replacement ifrepair proves impossible).Thiswarranty does not include expendable

parts such as saw blades which can wear out from normaluse withinthe warranty period. This warrantyappliesfor

only 90 days from the date of purchase ifthisproduct isever used for commercial or rental purposes. This warranty

gives you special legal rights,and you may also have other rightswhich vary from state tostate.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

],A, WARNING I

Some dust created by using power tools contains chemicals known to the state of California to cause cancer

and birth defects or other reproductive harm. Some examples of these chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks, cement and other masonry products

• Arsenic and chromium from chemically treated lumber

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well ventilated area and work with approved safety equipment such as

dust masks that are specially designed to filter out microscopic particles.

MOTOR

HP (Maximum developed) .......................... 3.5

Type ........................................................... Universal

Amps .......................................................... 15

Blade arbor size .......................................... 1 in.

Voltage ....................................................... 120

Hz ............................................................... 60

RPM (no load) ............................................ 3300

Wheel size .................................................. 14 in.

Extension wing ...................................... Yes

Laser guide ........................................... Yes

Maximum cutting height ........................ 5 in. @ 2 in. wide

Maximum cuttingwidth .......................... 7 in. @ 3 in. tall

Vise clamp angle ................................... 0° - 45°

I_, WARNING I

To avoid electrical hazards, fire hazards or damage to the chop saw, use proper circuit protection.

This chop saw is wired at the factory for 110-120 Volt operation. It must be connected to a 110-120 Volt /

15 Ampere time delay fuse or circuit breaker. To avoid shock or fire, replace power cord immediately if it is

worn, cut or damaged in any way.

Before using your chop saw, it is critical that you read and understand these safety rules. Failure to follow

these rules could result in serious injury to you or damage to the chop saw.

2011/07

[_k, WARNING I

Before using your chop saw, it is critical that you read and understand these safety rules. Failure to follow

these rules could result in serious injury or damage to the power tool,

Good safety practices are a combination of common

sense, staying alert and understanding how to use your

power tool. To avoid mistakes that could cause serious

15. NEVER LEAVE TOOL RUNNING UNATTENDED.

•TURN THE POWER "OFF". Do not leave the tool

before it comes to a complete stop.

injury, do not plug in your power tool until you have read

and understood the following safety rules:

16. NEVER STAND ON TOOL. Serious injury could

occur if the tool is tipped or if the cutting tool is

1. READ and become familiar with the entire Operator's

unintentionally contacted.

Manual. LEARN the tool's application, limitations and

possible hazards.

17. DO NOT OVERREACH. Keep proper footing and

balance at all times.

2" [_.WARNING I

Look for this symbol that identities important

safety precautions. It means CAUTION!

BECOME ALERT! YOUR SAFETY IS INVOLVED!

.

DO NOT USE IN DANGEROUS ENVIRONMENTS

such as damp or wet locations or exposure to rain.

Keep work area well lighted.

18.

MAINTAIN TOOLS WITH CARE. Keep tools sharp

and clean for most efficient and safest performance.

Follow instructionsfor lubricating and changing

accessories.

19.

CHECK FOR DAMAGED OR LOOSE PARTS.

Before further use of the tool, a guard or other

part that is damaged should be carefully checked

to ensure it will operate properly and perform its

.

DO NOT use power tools in the presence of

flammable liquids or gases.

intended function. Check for alignment of moving

parts, binding of moving parts, loose mounting

and any other conditions that may affect itssafe

.

L

KEEP WORK AREA CLEAN. Cluttered areas and

benches invite accidents.

.

KEEP CHILDREN AWAY. All visitors should be kept

at a safe distance from the work area.

operation. A guard or other part that isloose or

damaged should be properly adjusted repaired or

replaced.

20.

MAKE WORKSHOP CHILD PROOF with padlocks,

master switches or by removing starter keys.

.

DO NOT FORCE THE TOOL. It will do the job better

and safer at the rate for which it was designed•

21.

DO NOT operate the tool if you are under the

influence of any drugs, alcohol or medication that

.

USE THE RIGHT TOOL. Don't force the tool or

could impair your ability to use the tool safely.

attachment to do a job for which it is not designed.

22.

.

WEAR PROPER APPAREL. DO NOT wear loose

clothing, gloves, neckties, rings, bracelets or other

jewelry that may get caught in moving parts. Non-

slip footwear is recommended. Wear protective hair

covering to contain long hair.

10.

WEAR A FACE MASK OR DUST MASK. Sawing,

cutting and sanding operations produce dust.

ALWAYS WEAR EYE PROTECTION. Any power

tool can throw foreign objects into your eyes that

could cause permanent eye damage. ALWAYS

wear safety goggles (not glasses) that comply with

ANSI safety standard Z87.1. Everyday glasses have

only impact resistant lenses. They ARE NOT safety

asses.

OTE: Glasses or goggles not in compliance with

ANSI Z87.1 could cause serious injurywhen they

break.

11.

DISCONNECT TOOLS before servicing and when

changing accessories such as blades, cutters, etc.

12.

REDUCE THE RISK OF UNINTENTIONAL

STARTING. Make sure the switch is in the OFF

position before plugging into the power supply.

USE ONLY RECOMMENDED ACCESSORIES.

13.

Consult the Operator's Manual for recommended

accessories. The use of improper accessories may

cause injuryto you or damage to the tool.

14. REMOVE ADJUSTING KEYS AND WRENCHES.

Form the habit of checking to see that keys and

adjustingwrenches are removed from the tool before

turning ON.

BEFORE USING THE CHOP SAW, IT IS CRITICAL

THAT YOU READ AND UNDERSTAND THESE

SAFETY RULES.

I_, WARNING I

TO AVOID MISTAKES THAT COULD CAUSE SERIOUS

OR PERMANENT INJURY, DO NOT PLUG IN THE

CHOP SAW UNTIL THE FOLLOWING INSTRUCTIONS

HAVE BEEN READ AND UNDERSTOOD.

1. Learn to use the function of the ON/OFF switch,

cutting handle and wheel guard.

2. Review and understand all safety instructionsand

operating procedures in this operator's manual.

3. Review the maintenance methods for this chop saw.

4. Find and read all the warning labels found on the

chop saw:

• Read manual before using the chop saw.

• Wear safety goggles.

• Never perform cutting operations with wheel

guard removed.

• Turn power OFF, wait for abrasive wheel to stop

and remove power cord from power source before

adjusting or servicing.

5. The arbor bolt and all clamps have to be tightened

before cutting.

6. Make sure the workpiece and the abrasive wheel do

not contact before operating the chop saw.

WHEN INSTALLING OR MOVING YOUR CHOP SAW:

I. AVOID A DANGEROUS ENVIRONMENT:

• Use the chop saw in a dry, indoorlocation

protected from rain and moisture.

• Keep work area well-lit.

. TO AVOID INJURY FROM UNEXPECTED CHOP

SAW MOVEMENT:

• Bolt or clamp the chop saw to a firm level surface

where there is plenty of room to move the

workpiece through the entire cut.

• Positionthe chop saw so the feet are level and

the chop saw does not rock.

• Position the chop saw where operators and

bystanders stand a safe distance away from the

saw and are not in direct line with the saw blade.

• To avoid injuryfrom electrical shock, make sure

_- '......... _ 4

your fingers do not touch the plug's metal prongs

when plugging inor unpluggingthe chop saw.

• Turn OFF and unplug the chop saw before

moving it to a new area. To avoid back injury, get

help when transporting.

• Bolt the chop saw to the floor if it tends to move

when cutting long, heavy workpieces.

• DO NOT STAND ON the chop saw. Do not store

materials above or near it. Standing on the tool

could result in serious injury.

BEFORE EACH USE

1. INSPECT YOUR CHOP SAW:

• If any part is missing, bent or broken in any way,

or any electrical part does not work properly, turn

the chop saw OFF and unplug the tool.

• Replace damaged or missing parts before using

the chop saw.

.

AVOID INJURY FROM JAMS, SLIPS OR

THROWN PIECES (KICKBACKS):

• Use this chop saw to cut ferrous material only.

• Avoid injury from thrown pieces. Make sure the

abrasive wheel is properly installed and the

arbor bolt is tight.

• Use the right tool. Do not force the tool todo a

job it is not intended to do.

. INSPECT YOUR WORK AREA:

• Keep the work area clean.

• Cluttered areas and benches invite accidents.

The floor must not be slippery from wax or

sawdust.

• Avoid burns or other fire damage. Do not use the

chop saw near flammable liquids,vapours or

gases.

• Before using the chop saw, clear the table of all

objects not needed to feed the workpiece.

• Avoid injury. Do not perform layout, assembly, or

setup work on the chop saw.

• Never hold a workpiece. Workpiece will become

very hot while being cut.

4. PLAN YOUR WORK:

• Before trying a new or not often used operation,

carefully plan your hand placement. Make sure

you have proper fixtures, stops, and other items

ready to use. Avoid injury form unsafe

accessories. Use only recommended

accessories.

r

"DRESS FOR SAFETY:

,

• Plan ahead to protect your eyes, hands, face and

ears.

• Do not wear loose clothing, gloves, neckties or

jewellery (rings, wrist watches). They can get

caught and draw you into moving parts.

• Wear nonslip footwear.

• Tie back long hair.

• Roll long sleeves above the elbow.

• Noise levels vary widely. To avoid possible

hearing damage, wear ear plugs or muffs when

using the chop saw each time.

• The chop saw can throw foreign objects into your

eyes which can result in permanent eye damage.

Wear safety goggles (not glasses) that comply

with CSA Standards. Regular eyeglasses have

only impact-resistant lenses. They are not safety

glasses.

• Wear a dust mask along with safety goggles

during each operation.

,

INSPECT YOUR WORKPIECE:

• Make sure there are no nails or foreign objects in

the part of the workpiece to be cut.

PLAN YOUR CUT:

,

• Do not cut freehand. Guide yourworkpiece

solidlyagainst the fence and table top. Make

sure there is no debris between the workpiece

and itssupports.

• Use extra caution with large, small or awkward

workpieces.

• Use extra support (tables, sawhorses, blocks) if

your workpiece is hard to hold down to the table.

Do not use another person as additional support

or to help feed, support or pull the workpiece.

• Do not cut more than one workpiece at a time.

• Do not turn your chop saw ON before clearing

everything except the workpiece and related

support devices off the table.

AVOID ACCIDENTAL STARTING:

,

Make sure the switch is OFF before plugging the

abrasive chop saw into a power source.

WHEN THE CHOP SAW IS RUNNING

I_l_ WARNING I

DO NOT ALLOW FAMILIARITY GAINED FROM

FREQUENT USE OF YOUR CHOP SAW TO CAUSE

A CARELESS MISTAKE. REMEMBER THAT A

CARELESS FRACTION OF A SECOND IS ENOUGH

TO CAUSE A SEVERE INJURY.

_:__- .............. ! J' III Jill

. KEEP CHILDREN AWAY:

• Make sure all bystanders are clear of the power

tool before and during use.

• Before using the power tool, test the saw by

turning it on and letting it run for a few seconds. If

itmakes an unfamiliar noise or vibrates, stop

immediately. Turn the chop saw OFF and unplug.

Do not restart the tool untilthe problem has been

corrected.

2. DO NOT FORCE THE TOOL:

• Only cut one piece per cutting operation,

. BEFORE FREEING JAMMED MATERIAL:

• Release the trigger switch.

• Wait for all moving parts to stop.

• Unplug the chop saw.

, BEFORE LEAVING THE CHOP SAW:

• Release the trigger switch.

• Unplug the chop saw.

• Make the workshop childproof. Lock the shop.

Disconnect master switches.

I,A WARNING I

A 14 in. (356 ram) wheel is the maximum wheel capacity

of your chop saw. Never use a wheel that is too thick

to allow outer flange to engage with the flats on the

spindle. Larger wheels will come in contact with the

wheel guards, while thicker wheels willprevent the bolt

from securing the wheel on the spindle. Either of these

situations could result in a serious accident and can

cause serious personal injury.

L,_ WARNING J

Do not attempt to cut wood or masonry with this chop

saw. Never cut magnesium or magnesium alloy with

this machine. Failure to comply could result in serious

personal injury.

To prevent the chop saw movement or tipping during

cutting procedure, secure the chop saw in place to a

workbench or work surface that is also secure.

1,_ WARNING I

Always use the vise on the chop saw to prevent

accidents that could result in possible serious personal

injury.

[,A WARNING J

Never stand or have any part of your body in line with

the path of the wheel. Doing so may cause an accident

resulting inpossible serious personal injury.

5 .......... I l lll

t_, WARNING J

Large, circular, or irregularly shaped material may

require additional means of clamping to be secured in

place adequately for cutting. Use "C" clamps that can

be mounted along the left and front side of the machine

base. Also use blocks to hold material securely. Failure

to comply could result in serious personal injury.

_,WARNING I

To avoid accident start up of your chop saw, always

make sure switch isoff and "lock-on"feature is

disengaged before connecting to power source. Failure

to heed thisWarning could result in serious personal

injury.

• USE ONLY CORRECT WHEELS. Do not use

wheels with incorrect size holes. Never use wheel

washers or wheel screws that are defective or

incorrect. The maximum wheel capacity of your chop

saw is 14 in. (356mm).

• DO NOT REMOVE THE CHOP SAW'S WHEEL

GUARDS. Never operate the chop saw with any

guard or cover removed. Make sure all guards are

operating properly before each use.

• KEEP HANDS AWAY FROM CU'I-rlNG AREA.

Keep hands away from wheel. Do not reach

underneath work or around or under the wheel while

the wheel is rotating. Do not attempt to remove cut

material while wheel is moving.

• NEVER USE IN AN EXPLOSIVE ATMOSPHERE.

Normal sparking of the motor or sparking from

cutting metal could ignite fumes.

• DO NOT USE TOOL IF SWITCH DOES NOT TURN

IT ON AND OFF. Have defective switches replaced

by an authorized service center.

• KEEP TOOL DRY, CLEAN, AND FREE FROM OIL

AND GREASE. Always use a clean cloth when

cleaning. Never use brake fluids, gasoline,

petroleum-based products, or any solvents to clean

tool.

• ALWAYS SUPPORT LONG WORKPIECES.

To minimize risk of tipping machine, always support

long workpieces.

• BEFORE MAKING A CUT, BE SURE ALL

ADJUSTMENTS ARE SECURE.

• ALWAYS USE THE VISE CLAMP to secure the

workpiece.

• NEVER TOUCH WHEEL or other moving parts

during use.

• NEVER START THE CHOP SAW WHEN THE

WHEEL IS IN CONTACT WITH THE WORKPIECE.

• NEVER cut more than one workpiece at a time.

DO NOT STACK more than one workpiece on the

machine base at a time.

• NEVER PERFORM ANY OPERATION"FREE-

HAND". Always secure the workpiece to be cut in

the vise.

• NEVER hand hold a workpiece. Workpiece will

become very hot while being cut.

• NEVER reach behind, under, or within three inches

of the wheel and itscutting path with your hands and

fingers for any reason.

• NEVER reach to pick up a workpiece, a piece of

scrap, or anything else that is in or near the cutting

path of the wheel.

• MAKE SURE THE WHEEL IS SECURELY

MOUNTED as described in the operating

instructionsbefore connecting the tool to a power

supply. Do not tighten wheel excessively, since this

can cause cracks.

• CHECK THE WHEEL FOR FISSURES AND

CRACKS, and test for normal operation prior to use.

• ALWAYS EASE THE ABRASIVE WHEEL

AGAINST THE WORKPIECE when starting to cut.

A harsh impact can break the wheel.

• ONLY USE A CHOP SAW WHEEL RATED

FOR 3300 RPM OR GRATER and manufactured in

compliance with ANSI B 7.1. Always store wheels in

a dry place with little temperature variation.

• BEFORE CUTTING, press the triggerswitch and

allow the wheel to reach full speed before

cutting.

t_, WARNING J

This chop saw has been designed for cutting metals,

using reinforced abrasive chop saw wheels only. Do not

remove the wheel, install a steel blade, and attempt to

cut other types of materials such as wood, masonry, etc.

Attempting to cut these other types of materials could

cause an accident resulting in possible serious personal

injury.

I_, WARNING I

Do not attempt to modify this tool or create accessories

not recommended for use with this tool. Any such

alteration or modification ismisuse and could result

in a hazardous condition leading to possible serious

personal injury.

GROUNDING INSTRUCTIONS

IN THE EVENT OF A MALFUNCTION OR

BREAKDOWN, grounding provides a path of least

resistance for electdc currents and reduces the risk of

electric shock. This tool is equipped with an electrical

cordthat has an equipment-grounding conductor

and a grounding plug. The plug must be plugged

into a matching receptacle that is properly installed

and grounded in accordance with all local codes and

ordinances.

DO NOT MODIFY THE PLUG PROVIDED. If it will not

fit the receptacle, have the proper receptacle installed

by a qualified electrician.

IMPROPER CONNECTION of the equipment grounding

conductor can result in risk of electric shock. The

conductor with the green insulation (with or without

yellow stripes) is the equipment grounding conductor.

If repair or replacement of the electrical cord or plug is

necessary, do not connect the equipment grounding

conductor to a live terminal.

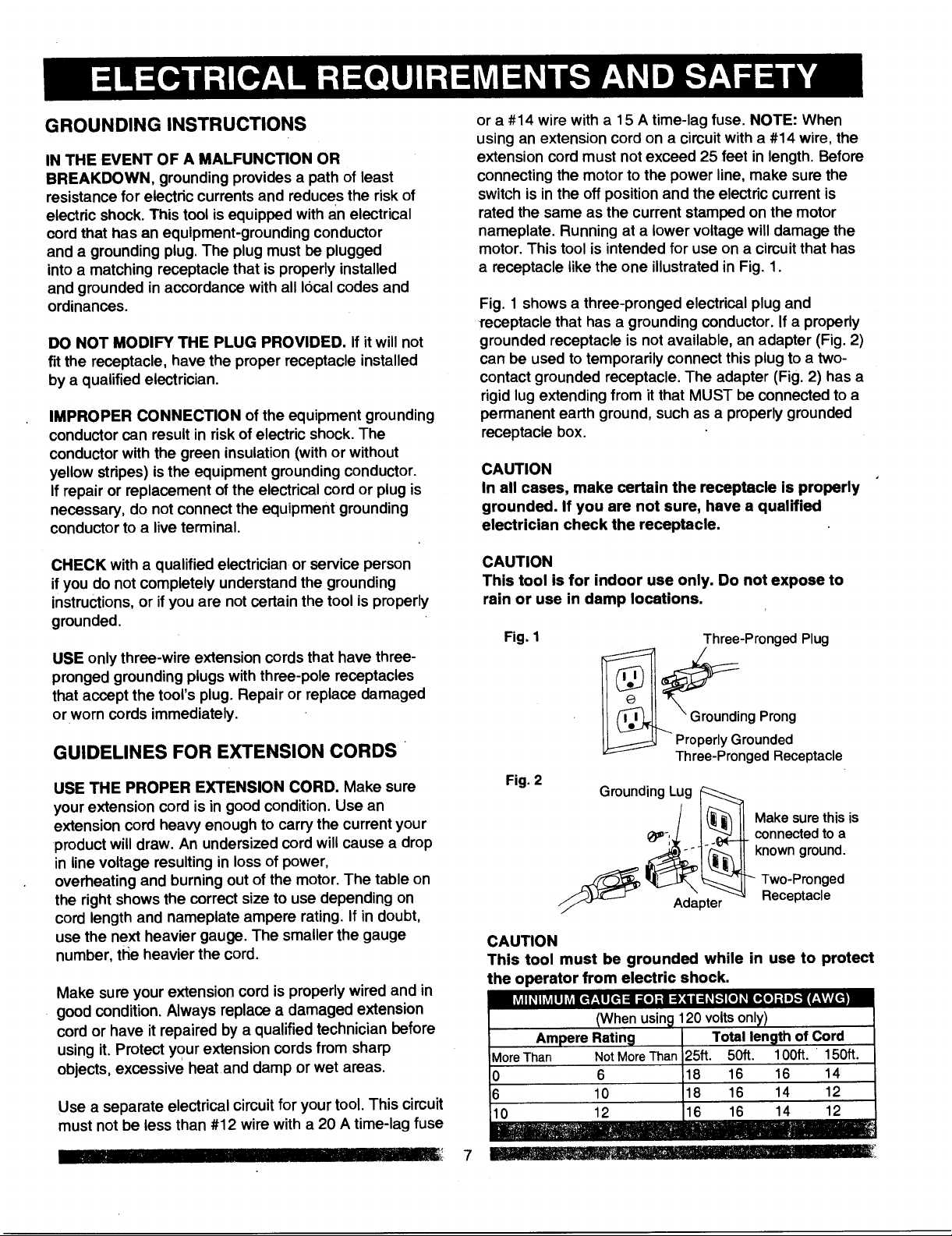

or a #14 wire with a 15A time-lag fuse. NOTE: When

using an extension cord on a circuitwith a #14 wire, the

extension cord must not exceed 25 feet inlength. Before

connecting the motor to the power line, make sure the

switch is in the off position and the electric current is

rated the same as the current stamped on the motor

nameplate. Running at a lower voltage will damage the

motor. This tool is intended for use on a circuit that has

a receptacle like the one illustrated in Fig. 1.

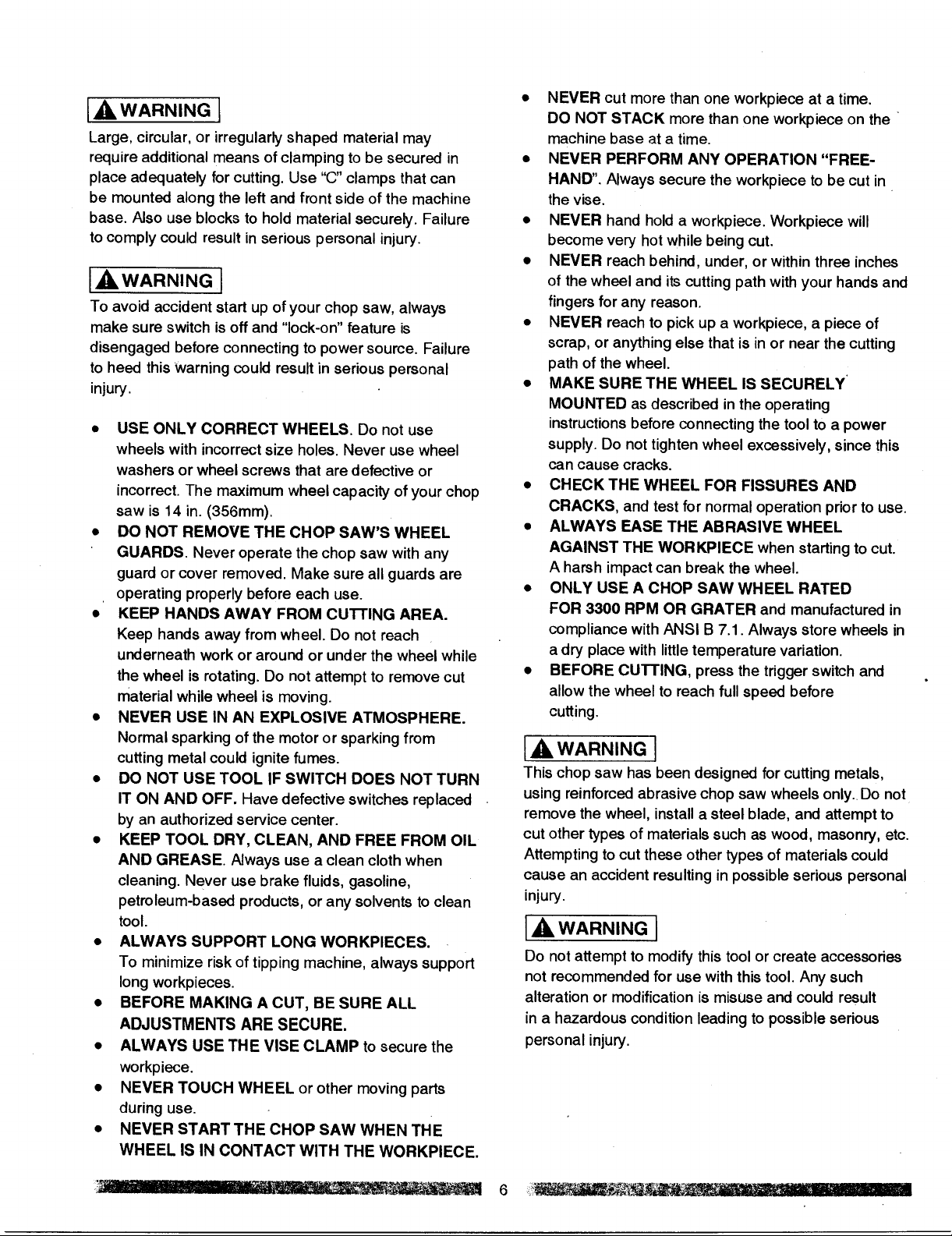

Fig. 1 shows a three-pronged electrical plug and

receptacle that has a grounding conductor. If a properly

grounded receptacle is not available, an adapter (Fig. 2)

can be used to temporarily connect this plug to a two-

contact grounded receptacle. The adapter (Fig. 2) has a

rigid lugextending from it that MUST be connected to a

permanent earth ground, such as a properly grounded

receptacle box.

CAUTION

In all cases, make certain the receptacle is properly

grounded. If you are not sure, have a qualified

electrician check the receptacle.

CHECK with a qualified electrician or service person

ifyou do not completely understand the grounding

instructions, or ifyou are not certain the tool is properly

grounded.

USE only three-wire extension cords that have three-

pronged grounding plugs with three-pole receptacles

that accept the tool's plug. Repair or replace damaged

or worn cords immediately.

GUIDELINES FOR EXTENSION CORDS

USE THE PROPER EXTENSION CORD. Make sure

your extension cord is in good condition. Use an

extension cord heavy enough to carry the current your

productwill draw. An undersized cord will cause a drop

in line voltage resulting in loss of power,

overheating and burning out of the motor. The table on

the right shows the correct size to use depending on

cord length and nameplate ampere rating. If in doubt,

use the next heavier gauge. The smaller the gauge

number, tl_eheavier the cord.

Make sure your extension cord is properly wired and in

good condition. Always replace a damaged extension

cord or have it repaired by a qualified technician before

using it. Protect your extension cords from sharp

objects, excessive heat and damp or wet areas.

Use a separate electrical circuit for your tool. This circuit

must not be less than #12 wire with a 20 A time-lag fuse

CAUTION

This tool is for indoor use only. Do not expose to

rain or use in damp locations.

Fig. 1

_ Properly Grounded

Fig. 2

GroundingLug

_':_ I _ connectedtoa

._.1-(_ II known ground.

Three-Pronged Plug

_ng Prong

Three-Pronged Receptacle

/ I L||-_ II Make surethis is

wo-Pron e,

Adapter''--_ Receptacle

CAUTION

This tool must be grounded while in use to protect

the operator from electric shock.

(When usin_ 120 voltsonly)

Ampere Rating

MoreThan NotMoreThan

0 6

6 10

Total len_lthof Cord

25ft. 50ft. 100ft. 150ft.

18 16 16 14

18 16 14 12

16 16 14 12

!_ 7

#2 Phillips screwdriver

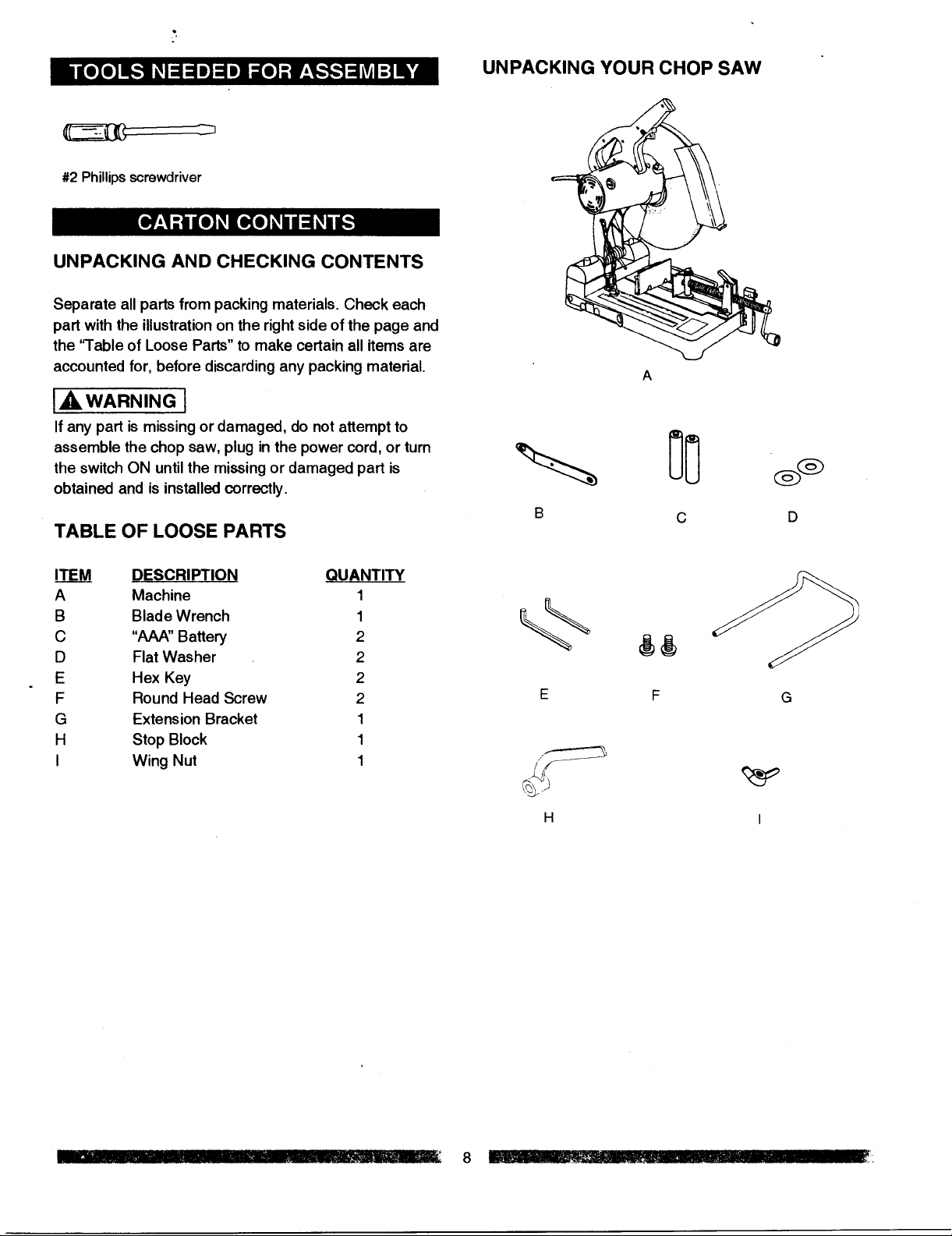

UNPACKING AND CHECKING CONTENTS

Separate all parts from packing materials. Check each

part with the illustrationon the right side of the page and

the 'q'able of Loose Parts" to make certain all items are

accounted for, before discarding any packing material.

I,A WARNING I

If any part is missing or damaged, do not attempt to

assemble the chop saw, plug in the power cord, or turn

the switch ON until the missing or damaged part is

obtained and is installed correctly.

TABLE OF LOOSE PARTS

UNPACKING YOUR CHOP SAW

A

B C D

ITEM DESCRIPTION QUANTITY

A Machine 1

B Blade Wrench 1

C "AAA" Battery 2

D Flat Washer 2

E Hex Key 2

F Round Head Screw 2

G Extension Bracket 1

H Stop Block 1

I Wing Nut 1

F

H

G

.......... ! I ,,p , ,L, 8 IRllgllllBml' .._i,-=i ........... "_"

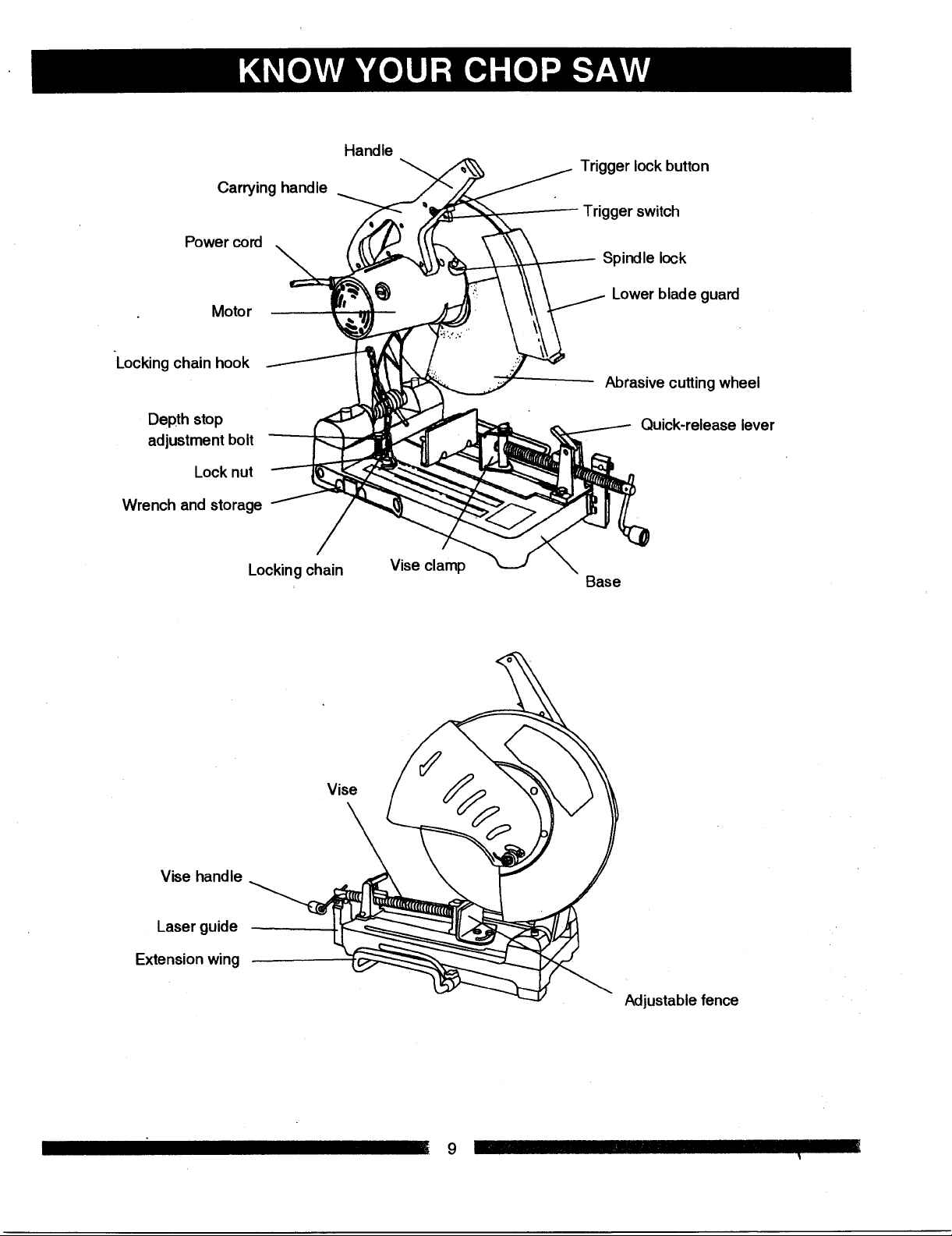

Carrying handle

Power cord

Motor

Locking chain hook

Handle

Trigger lock button

Trigger switch

Spindle lock

Lower blade guard

Abrasive cutting wheel

Depth stop

adjustment bolt

Lock nut

Wrench and storage

Locking chain

Quick-release lever

Vise clamp

Base

Vise

Vise handle

Laser guide

Extension wing

Adjustable fence

9 !111

I,_ WARNING J

Never connect the plug to the power source outlet until

all installations and adjustments are completed and you

have read and understood the safety and operational

instructions.

Fig. B

Fig. C

Fig. D

l_, WARNING ]

Failure to unplug your saw could result in accidental

starting causing possible serious personal injury.

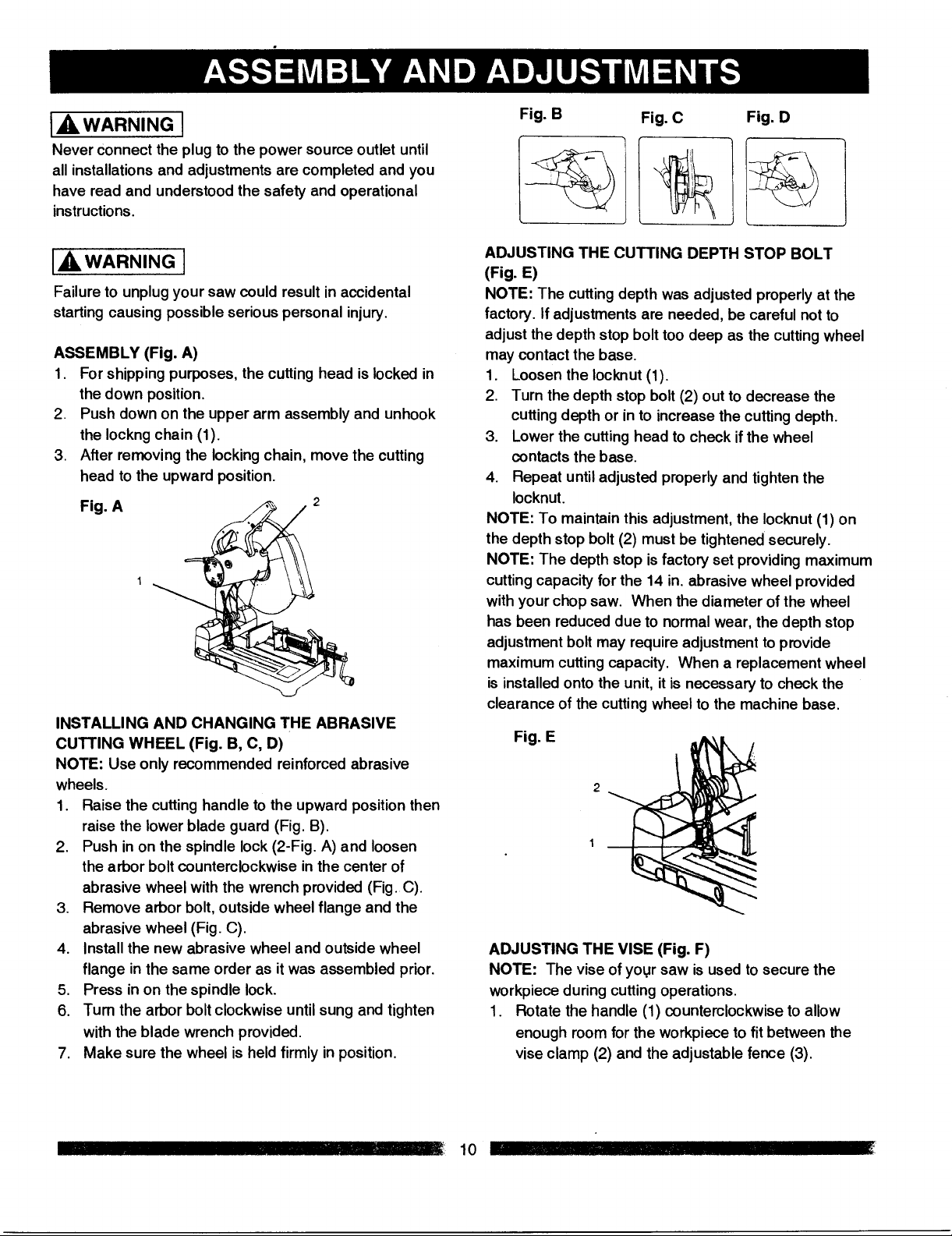

ASSEMBLY (Fig. A)

1. For shipping purposes, the cutting head is locked in

the down position,

2. Push down on the upper arm assembly and unhook

the Iockng chain (1).

3. After removing the lockingchain, move the cutting

head to the upward position.

Fig. A

INSTALLING AND CHANGING THE ABRASIVE

CUTTING WHEEL (Fig. B, C, D)

NOTE: Use only recommended reinforced abrasive

wheels.

1. Raise the cutting handle to the upward position then

raise the lower blade guard (Fig. B),

2, Push in on the spindle lock (2-Fig. A) and loosen

the arbor bolt counterclockwise inthe center of

abrasive wheel with the wrench provided (Fig. C).

3. Remove arbor bolt, outside wheel flange and the

abrasive wheel (Fig. C).

4. Install the new abrasive wheel and outside wheel

flange in the same order as it was assembled prior.

5. Press in on the spindle lock.

6. Turn the arbor bolt clockwise untilsung and tighten

with the blade wrench provided,

7. Make sure the wheel is held firmly in position.

ADJUSTING THE CUTTING DEPTH STOP BOLT

(Fig. E)

NOTE: The cutting depth was adjusted properly at the

factory. If adjustments are needed, be careful not to

adjust the depth stop bolt too deep as the cutting wheel

may contact the base.

1. Loosen the Iocknut (1),

2. Turn the depth stop bolt (2) out to decrease the

cutting depth or in to increase the cutting depth.

3. Lower the cutting head to check if the wheel

contacts the base.

4. Repeat until adjusted properly and tighten the

Iocknut.

NOTE: To maintain this adjustment, the Iocknut (1) on

the depth stop bolt (2) must be tightened securely.

NOTE: The depth stop is factory set providing maximum

cuttingcapacity for the 14 in. abrasive wheel provided

with your chop saw. When the diameter of the wheel

has been reduced due to normal wear, the depth stop

adjustment bolt may require adjustment toprovide

maximum cutting capacity. When a replacement wheel

is installed onto the unit, itis necessary to check the

clearance of the cutting wheel to the machine base,

Fig. E

ADJUSTING THE VISE (Fig. F)

NOTE: The vise of your saw is used to secure the

workpiece during cutting operations.

1. Rotate the handle (1) counterclockwise to allow

enough room for the workpiece to fit between the

vise clamp (2) and the adjustable fence (3),

10

2. Position the workpiece between the vise clamp and

the adjustable fence. Turn the handle (1) clockwise

to clamp the workpiece securely.

3. The vise incorporates a quick release locking lever

(4). To use the quick release vise feature, lift up on

the quick release locking lever (4) and slide in or out

the vise to the desired position.

4. When the desired location for the vise clamp is

achieved, flip the quick release locking lever (4)

forward to engage the threads with the threads of

the vise. Beginto turnthe lever (1) clockwise to

secure the workpiece within the vise.

Fig. F

ADJUSTING FOR ANGLE CUTTING (Fig. G )

1. Loosen the vise handle and back away the vise.

2. Loosen the two bolts (1) of the adjustable fence with

a 17 mm wrench.

3. Adjust the adjustable fence (2) to the desired angle.

4. Tighten the two bolts (1).

5. The vise clamp (3) will align itself automatically with

the angle of the workpiece when clamping a

workpiece in position.

Fig. G

1

loosening the wing nut (3), slidingthe stop block to

the desired position and locking in place.

Fig. H

Fig. H-1

3 2

1

6

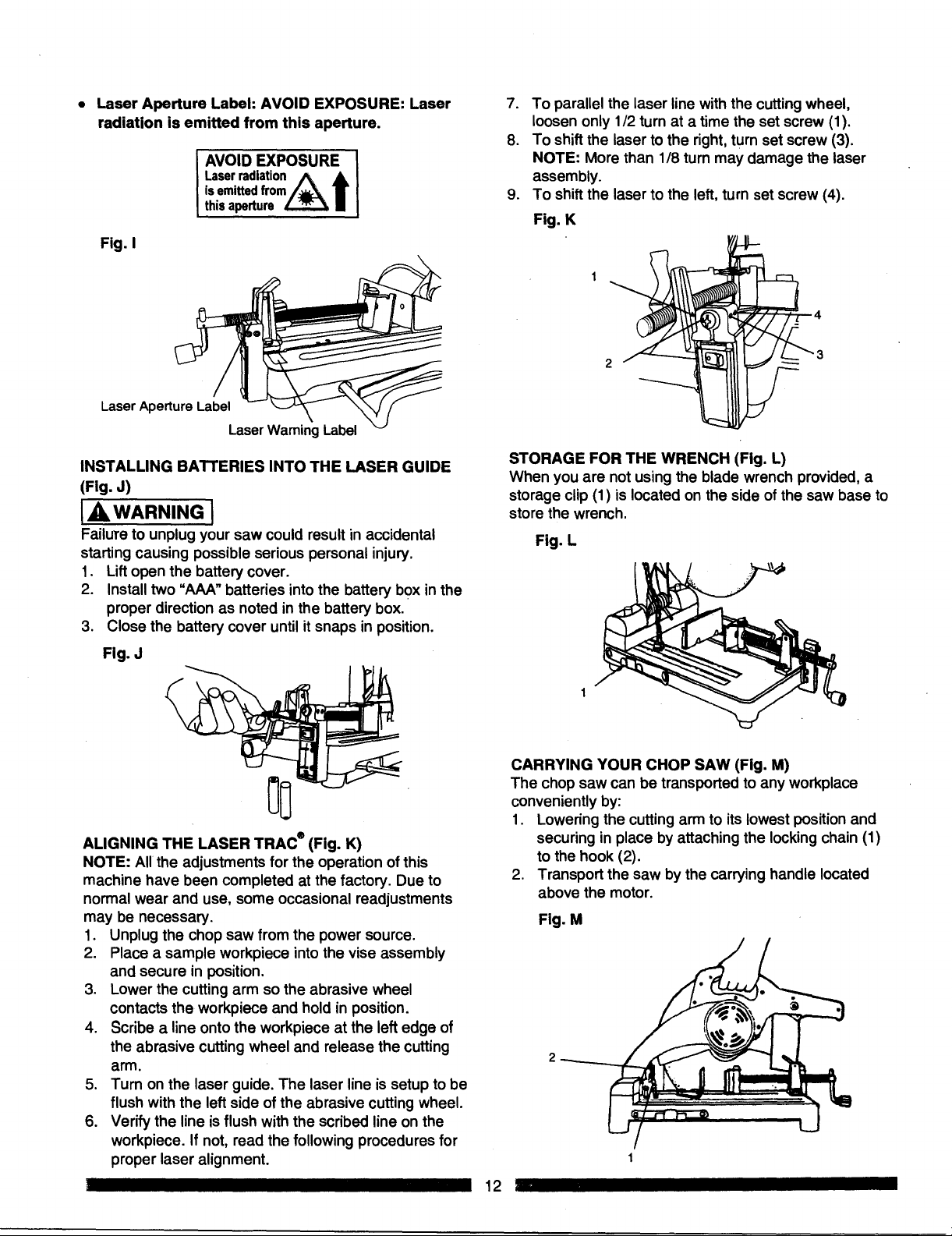

THE LASER GUIDE

Your tool is equipped with the Laser Trac_ cutting guide,

a battery powered device using Class Ilia laser beams.

The laser beams will enable you to preview the abrasive

wheel path on the workpiece to be cut before you begin

your operation.

I,_ WARNING I

• Do not stare into beam or view directly with

optical instruments. Do not remove the warning

label affixed to the wheel guard. Avoid direct eye

contact with light source.

• Laser Warning Label: Max. Output < 5 mW,

Wavelength: 630660 nm, Complies with 21CFR

1040.10 and 1040. 11 Class Ilia laser product.

INSTALLING AND ADJUSTING THE EXTENSION

BRACKET AND STOP BLOCK (FIG. H, H-l):

1. Loosen the locking screw (1) with the 5ram hex

wrench provided (Fig. H).

2. Insert the extension bracket (2) into the mounting

holes located on the right side of the chop saw

base (Fig. H).

3. Thread the stop screw (5) and washer (6) into each

end of the extension bracket (Fig. H-l).

4. Adjust the extension bracket (2) to the desired

position (Fig. H).

5. Tighten the locking screw (1) (Fig. H-l).

6. Adjust the stop block (4) for repetitive cutting by

L I _ ii --_ii ; 11

LASER RADIATION-AVOID

DIRECT EYE EXPOSURE

Max.0utput<5 mWWavelength: 630..660 nm

Complieswith21CFR 1040.10and1040.11

Clau Ilia Laser Product

• CAUTION-Use of controls or adjustments or

performance of procedures other than those

specified herein may result in hazardous

radiation exposure.

• CAUTION-The use of optical instruments with this

product will increase eye hazard.

• Do not attempt to repair or disassemble the

laser. If unqualified persons attempt to repair

this laser product, serious injury may result.

Any repair required on this laser product should

be performed by authorized service center

personnel.

LaserApertureLabel:AVOIDEXPOSURE:Laser

radiationisemittedfromthisaperture.

AVOIDEXPOSURE

Laserradiationh •

is emitted from/:_._ •

thisaperture_L._._ II

Fig. I

Laser Aperture Label

Laser Warning Label

7. To parallel the laser line with the cutting wheel,

loosen only 1/2 turn at a time the set screw (1).

8. To shift the laser to the right, turn set screw (3).

NOTE: More than 1/8 turn may damage the laser

assembly.

9. To shiftthe laser to the left, turn set screw (4).

Fig. K

INSTALLING BATI'ERIES INTO THE LASER GUIDE

(Fig. J)

I,_ WARNING I

Failure to unplug your saw could result inaccidental

starting causing possible serious personal injury.

1. Lift open the battery cover.

2. Installtwo =AAA" batteries into the battery box in the

proper direction as noted in the battery box.

3. Close the battery cover until it snaps in position.

Fig. J

ALIGNING THE LASER TRAC e (Fig. K)

NOTE: All the adjustments for the operation of this

machine have been completed at the factory. Due to

normal wear and use, some occasional readjustments

may be necessary.

1. Unplug the chop saw from the power source.

2. Place a sample workpiece into the vise assembly

and secure in position,

3. Lower the cutting arm so the abrasive wheel

contacts the workpiece and hold in position.

4. Scribe a line onto the workpiece at the left edge of

the abrasive cutting wheel and release the cutting

arm.

5. Turn on the laser guide. The laser line issetup to be

flushwith the leftside of the abrasive cutting wheel.

6. Verify the line is flush with the scribed line on the

workpiece. If not, read the following procedures for

proper laser alignment.

III I 12

STORAGE FOR THE WRENCH (Fig. L)

When you are not using the blade wrench provided, a

storage clip (1) is located on the side of the saw base to

store the wrench.

Fig. L

CARRYING YOUR CHOP SAW (Fig. M)

The chop saw can be transported to any workplace

conveniently by:

1. Lowering the cutting arm to its lowest position and

securing in place by attaching the lockingchain (1)

to the hook (2).

2. Transport the saw by the carrying handle located

above the motor.

Fig. M

1

IIIII

Loading...

Loading...