Page 1

Owner's Manual

SCROLLING SABRE SAW

Model No. 135.17243 __

Caution:

Before using this product,

read this manual and follow

all its Safety Rules and

Operating Instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

Safety

Operation

Maintenance

Parts

EspaSol, R 18

Page 2

Page

Warranty ..................................................... 2

Power Tool Safety Rules ...................................... 3-5

Symbols ..................................................... 6

Functional Description and Specifications ........................... 7

Assembly .................................................... 8

Operating Instructions ........................................ 8-11

Tool Tips ................................................. 11-14

Maintenance ................................................. 15

Service Parts .............................................. 16-17

EspaSol .................................................. 18-32

FULL ONE YEAR WARRANTY ON CRAFTSMAN

SCROLLING SABRE SAW

If this CRAFTSMAN Scrolling Sabre Saw fails to give complete satisfaction

within one year from the date of purchase, RETURN IT TO THE

NEAREST SEARS STORE IN THE UNITED STATES, and Sears will

replace it,free of charge.

If this CRAFTSMAN Scrolling Sabre Saw is used for commercial or rental

purposes, this warranty applies for only 90 days from the date of purchase.

This warranty gives you specific legal rights, and you may also have other

rights which vary from slate to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

-2-

Page 3

Read and understand all instructions. Failure to follow all instructions

listed below, may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

Work Area

Keep your work area clean and well lit.

Cluttered benches and dark areas invite

accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power

tools create sparks which may ignite the dust

orfumes.

Keep by-standers, children, and visitors

away while operating a power tool.

Distractions can cause you to lose control.

Electrical Safety

Double Insulated tools are equipped with a

polarized plug (one blade is wider than the

other.) This plug will fit in a polarized outlet

only one way. If the plug does not fit fully

in the outlet, reverse the plug. If it still does

not fit, contact a qualified electrician to

install a polarized outlet. Do not change

the plug in any way. Double Insulation []

eliminates the need for the three wire

grounded power cord and grounded power

supply system. Before plugging in the tool, be

certain the outlet voltage supplied is within the

voltage marked on the nameplate. Do not use

'_4C only" rated tools with a DC power supply,

Avoid body contact with grounded

surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased risk

of electric shock if your body is grounded. If

operating the power too! in damp locations is

unavoidable, a Ground Fault Circuit Interrupter

must be used to supply the power to your tool.

Electrician's rubber gloves and footwear will

further enhance your personal safety.

Don't expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord

tocarry the tools or pull the plug from an

outlet. Keep cord away from heat, oil, sharp

edges or moving parts. Replace damaged

cords immediately. Damaged cords increase

the risk of electric shock.

When operating a power tool outside, use

an outdoor extension cord marked "W-A"

or "W." These cords are rated for outdoor use

and reduce the risk of electric shock. Refer to

"Recommended sizes of Extension Cords" in

the Accessory section of this manual.

Personal Safety

Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or

medication. A moment of inattention while

operating power tools may result in serious

personal injury.

Dress properly. Do not wear loose clothing

or jewelry. Contain long hair. Keep your

hair, clothing, and gloves away from

moving parts. Loose clothes, jewelry, or long

hair can be caught in moving parts. Keep

handles dry, clean and free from oil and

grease.

Avoid accidental starting. Be sure switch

is "OFF" before plugging in. Carrying tools

with your finger on the switch or plugging in

tools that have the switch "ON" invites

accidents.

Remove adjusting keys or wrenches before

turning the tool "ON". A wrench or a key

that is left attached to a rotating part of the tool

may result in personal injury,

Do not overreach. Keep proper footing and

balance at all times. Proper footing and

balance enables better control of the tool in

unexpected situations.

Use safety equipment, Always wear eye

protection. Dust mask, non-skid safety

shoes, hard hat, or hearing protection must be

used for appropriate conditions.

Tool Use and Care

Use clamps or other practical way to

secure and support the workpiece to a

stable platform. Holdingthe work by hand or

against your body is unstable and may lead to

loss of control.

-3-

Page 4

Do not force tool. Use the correct tool for

your application. The correct tool will do the

job better and safer at the rate for which it is

designed.

Do not use tool if switch does not turn it

"ON" or "OFF". Any tool that cannot be

controlled with the switch is dangerous and

must be repaired.

Disconnect the plug from the power

source before making any adjustments,

changing accessories, or storing the tool.

Such preventive safety measures reduce the

risk of starting the tool accidentally.

Store idle tools out of reach of children

and other untrained persons, Tools are

dangerous in the hands of untrained users.

Maintain tools with care. Keep cutting

tools sharp and clean. Properly maintained

tools, with sharp cutting edges are less likely

to bind and are easier to control. Any

alteration or modification is a misuse and

may result in a dangerous condition.

Check for misalignment or binding of

moving parts, breakage of parts, and any

other condition that may affect the tools

operation. If damaged, have the tool

serviced before using. Many accidents are

caused by poorly maintained tools. Develop

a periodic maintenance schedule for your

tool,

Use only accessories that are

recommended by the manufacturer for

your model. Accessories that may be

suitable for one tool, may become hazardous

when used on another tool.

Service

Tool service must be performed only by

qualified repair personnel. Service or

maintenance performed by unqualified

personnel could result in a risk of injury. For

example: internal wires may be misplaced or

pinched, safety guard return springs may be

improperly mounted.

When servicing a tool, use only identical

replacement parts, Follow instructions in

the Maintenance section of this manual.

Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk

of electric shock or injury. Certain cleaning

agents such as gasoline, carbon

tetrachloride, ammonia, etc. may damage

plastic parts.

Hold tool by insulated gripping surfaces

when performing an operation where the

cutting tool may contact hidden wiring or

its own cord. Contact with a "live" wire will

make exposed metal parts of the tool "live"

and shock the operator. Do not drill, fasten

or break into existing walls or other blind

areas where electrical wiring may exist. If

this situation is unavoidable, disconnect all

fuses or circuit breakers feeding this

worksite.

Never leave the trigger locked "ON".

Before plugging the tool in, check that the

trigger lock is "OFF". Accidental start-ups

could cause injury.

Be aware of the location and setting of

the switch "Lock-ON" button. If the switch

is locked "ON" during the use, be ready for

emergency situations to switch it "OFF", by

first pulling the trigger then immediately

releasing it without pressing the "Lock-ON"

button,

Keep hands away from cutting area. Do

not reach under the material being cut.

The proximity of the blade to your hand is

hidden from your sight.

Keep hands from between the gear

housing and saw blade holder, The

reciprocating blade holder can pinch your

fingers.

Do not use dull or damaged blades. Bent

blade can break easily or cause kickback.

Before starting to cut, turn tool "ON" and

allow the blade to come to full speed.

Tool can chatter or vibrate if blade speed is

too slow at beginning of cut and possibly

kickback.

-4-

Page 5

Always wear safety goggles or eye

protection when using this tool. Use a

dust mask or respirator for applications

which generate dust.

Secure material before cutting. Never

hold it in your hand or across legs. Small

or thin material may flex or vibrate with the

blade, causing loss of control.

Make certain all adjusting screws and the

blade holder are tight before making a

cut, Loose adjusting screws and holders

can cause the tool or blade to slip and lose of

control may result.

When removing the blade from the tool

avoid contact with skin and use proper

protective gloves when grasping the

blade or accessory. Accessories may be

hot after prolonged use.

Use only accessories that are sold by

Sears for your model. Accessories that may

be suitable for one tool may become

hazardous when used on another tool.

_Some dust created by

power sanding, sawing,

grinding, drilling, and other construction

activities contains chemicals known to

cause cancer, birth defects or other

reproductive harm. Some examples of

these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement

and other masonry products, and

• Arsenic and chromium from chemically-

treated lumber.

Your risk from these exposures varies,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals: work in a well ventilated area, and

work with approved safety equipment, such

as those dust masks that are specially

designed to filter out microscopic particles.

-5-

Page 6

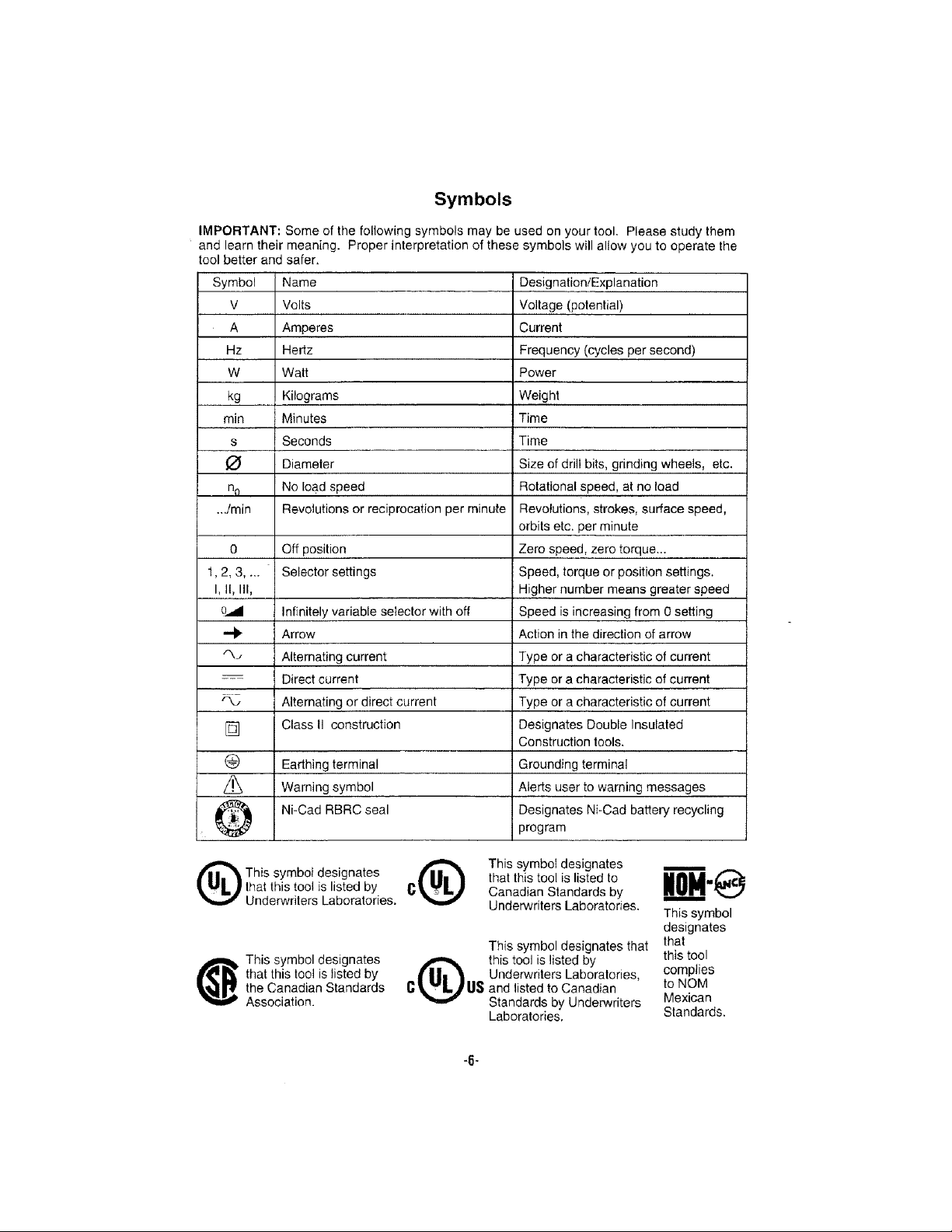

Symbols

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

Symbol Name

V Volts

A Amperes

Hz Hertz

W Watt

kg Kilograms

rain Minutes

s Seconds

_l Diameter

% No load speed

.../min

0

1,2,3 ....

I, It, III,

-.€,

I

[]

@

&

Revolutions or reciprocation per minute

Off position

Selector settings

Infinitely variable selector with off

Arrow

Alternating current

Direct current

Alternating or direct current

Class II construction

Earthing terminal

Warning symbol

Ni-Cad RBRC seal

@

Designation/Explanation

Voltage (potential)

Current

Frequency (cycles per second)

Power

Weight

Time

Time

Size of drill bits, grinding wheels, etc.

Rotational speed, at no load

Revolutions, strokes, surface speed,

orbits etc. per minute

Zero speed, zero torque...

Speed, torque or position settings.

Higher number means greater speed

Speed is increasing from 0 setting

Action in the direction of arrow

Type or a characteristic of current

Type or a characteristic of current

Type or a characteristic of current

Designates Double Insulated

Construction tools.

Grounding terminal

Alerts user to warning messages

Designates Ni-Cad battery recycling

program

This symbol designates

lhat this tool is listed by

Underwriters Laboratories.

that this tool is listed by

!_ This symbol designates

the Canadian Standards

Association.

0®

-6-

This symbol designates

that this tool is listed to

Canadian Slandards by

Underwriters Laboratories.

This symbol designates that

this tool is listed by

Underwriters Laboratories,

and listed to Canadian

Standards by Underwriters

Laboratories.

This symbol

designates

that

this tool

complies

to NOM

Mexican

Standards.

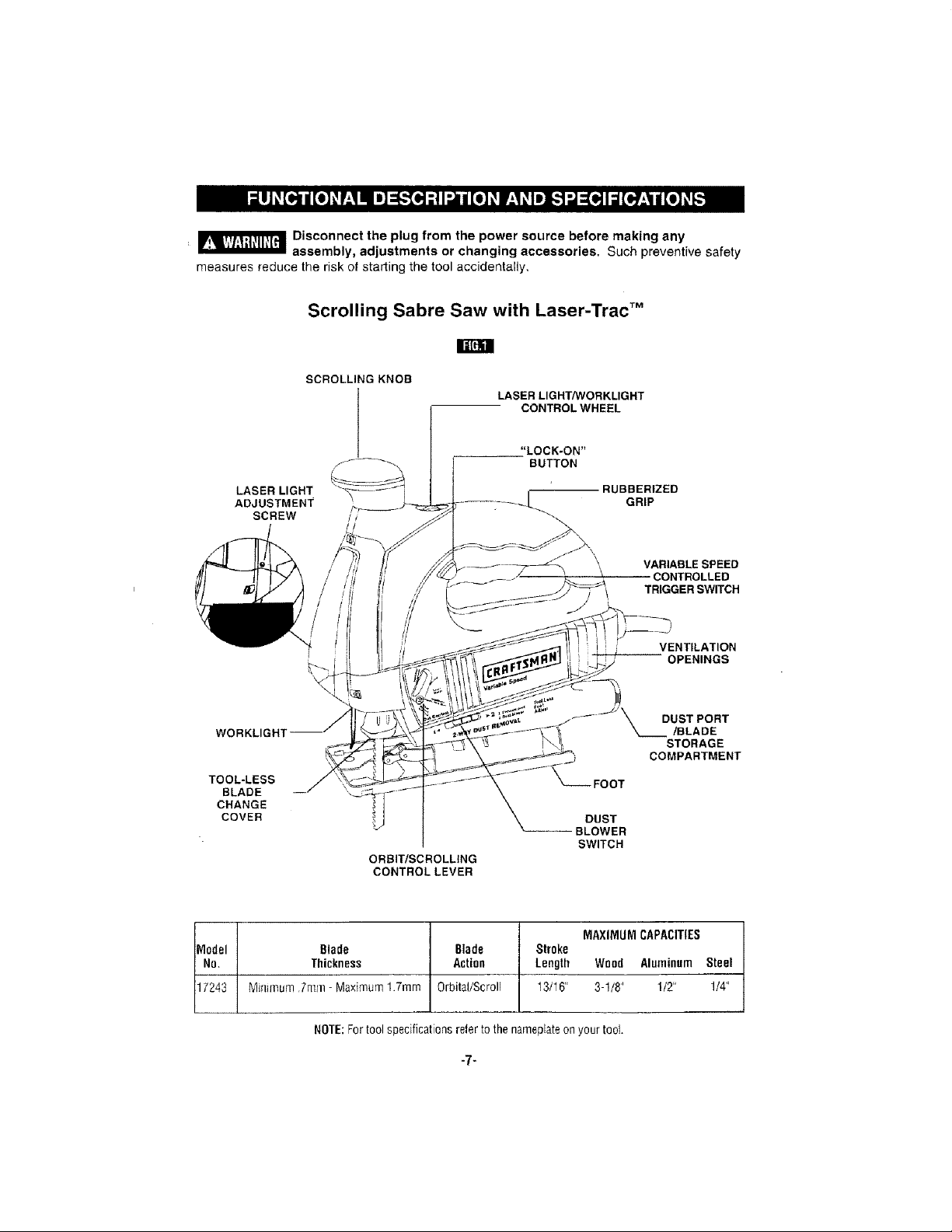

Page 7

F_i_I Disconnect the plug from the power source before making any

assembly, adjustments or changing accessories. Such preventive safety

measures reduce the risk of starting the tool accidentally,

Scrolling Sabre Saw with Laser-Trac TM

SCROLLING KNOB

CONTROL WHEEL

LASER LIGHT

ADJUSTMENT

WORKLIGHT

TOOL-LESS

BLADE

CHANGE

COVER

/_f--_-. BUTTON

SCREW /

I LASER LIGHT/WORKLIGHT

ORBIT/SCROLLING

CONTROL LEVER

"LOCK-ON"

RUBBERIZED

FOOT

DUST

BLOWER

SWITCH

GRIP

VARIABLE SPEED

CONTROLLED

TRIGGER SWITCH

i VENTILATION

OPENINGS

DUST PORT

/BLADE

STORAGE

COMPARTMENT

Model Blade Blade Stroke

MAXIMUM CAPACITIES

No, Thickness Action Length Wood Aluminum Steel

17243 N1inmlum.7m111- Maximum 1.7ram Orbital/Scroll 13/16" 3-!/8" 1/2" 1/4"

NOTE:Fortool specifications refer to the nameplateon your tool.

-7=

Page 8

+a_ i6!9X0<427 9-G4 9/23/04 9 ;04 _i,__ P 8

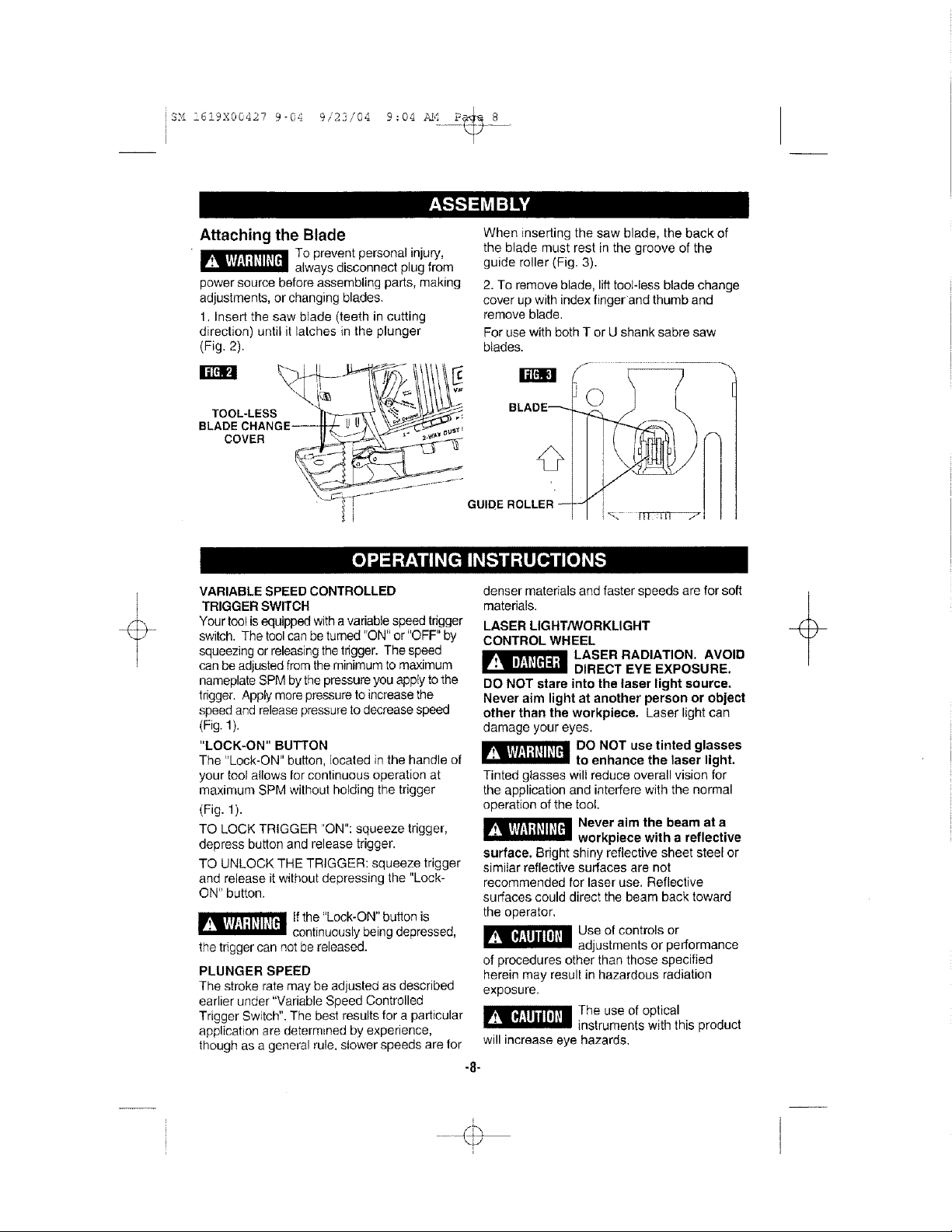

Attaching the Blade

To prevent personal injury,

always disconnect plug from

power source before assembling parts, making

adjustments, or changing blades.

1, Insert the saw blade (teeth in cutting

direction) until it latches in the plunger

(Fig. 2).

TOOL-LESS

COVER

VARIABLE SPEED CONTROLLED

TRIGGER SWITCH

Your tool is equipped with a variable speed trigger

switch, The tool can be turned 'rON" or "OFF" by

squeezing or releasing the trigger. The speed

can be adjusted from the minimum to maximum

nameplate SPM by the pressure you apply to the

trigger. Apply more pressure to increase the

speed and release pressure to decrease speed

(Fig. 1).

"LOCK-ON" BUTTON

The "Lock-ON" button, located in the handle of

your tool allows Ior continuous operation at

maximum SPM without holding the trigger

(Fig. 1).

TO LOCK TRIGGER "ON": squeeze trigger,

depress button and release trigger.

TO UNLOCK THE TRIGGER: squeeze trigger

and release it without depressing the "Lock-

ON" button.

lf the "Lock-ON" button is

continuously being depressed,

the trigger can not be released.

PLUNGER SPEED

The stroke rate may be adjusted as described

earlier under "Variable Speed Controlled

Trigger Switch". The best results for a particular

application are determined by experience,

though as a general rule, slower speeds are for

When inserting the saw blade, the back of

the blade must rest in the groove of the

guide roller (Fig, 3).

2. To remove blade, lift tool-less blade change

cover up with index finger and thumb and

remove blade.

For use with both T or U shank sabre saw

blades.

f ...........................

BLADE---+

GU DE ROLLER --

denser materials and faster speeds are for soft

materials.

LASER LIGHT/WORKLIGHT

CONTROL WHEEL

_ ASER RADIATION, AVOID

DO NOT stare into the laser light source.

Never aim light at another person or object

other than the workpiece. Laser light can

damage your eyes.

Tinted glasses will reduce overall vision for

the application and interfere with the normal

operation of the tool.

_ Never aim the beam at a

surface. Bright shiny reflective sheet steel or

similar reflective surfaces are not

recommended for laser use. Reflective

surfaces could direct the beam back toward

the operator,

of procedures other than those specified

herein may result in hazardous radiation

exposure.

will increase eye hazards.

DIRECT EYE EXPOSURE.

DO NOT use tinted glasses

to enhance the laser light,

workpiece with a reflective

Use of controls or

adjustments or performance

The use of optical

instruments with this product

-8-

÷

÷

Page 9

SM !6i9X00427 9-04 9/23/04 9:04 AM P_ 9

The 4 position control wheel allows you to

control the function of the lights. Below, lists

the function of each setting (Fig. 1).

Setting 1: Turns OFF all lights.

Setting 2: Turns ON only the laser light.

Setting 3: Turns ON both the laser light and

the worklight.

Setting 4: Turns ON only the worklight

The laser line guide is a class Ilia laser with a

maximum output power of 5.0m Watts and

conforms to 21 CFR 1040.10 and 1040.11.

LASER-TRAC TM LASER LINE GUIDE

The Laser-Trac line guide help you to follow

your cutting line with greater ease and

precision when making a cut.

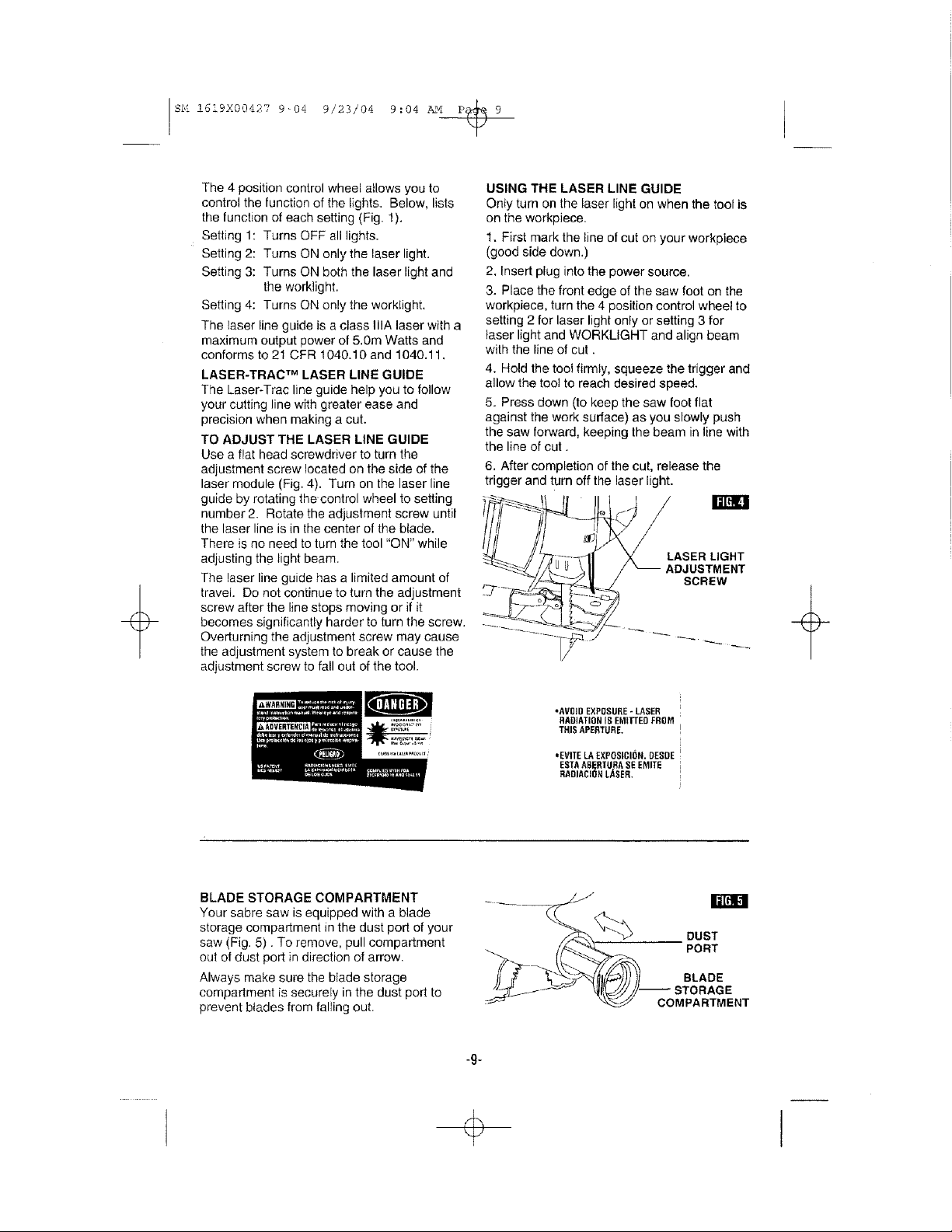

TO ADJUST THE LASER LINE GUIDE

Use a flat head screwdriver to turn the

adjustment screw located on the side of the

laser module (Fig. 4). Turn on the laser line

guide by rotating the control wheel to setting

number 2. Rotate the adjustment screw until

the laser line is in the center of the blade.

There is no need to turn the tool "ON" while

adjusting the light beam.

The laser line guide has a limited amount of

travel. Do not continue to turn the adjustment

screw after the line stops moving or if it

becomes significantly harder to turn the screw.

Overturning the adjustment screw may cause

the adjustment system to break or cause the

adjustment screw to fall out of the tool.

USING THE LASER LINE GUIDE

Onty turn on the laser light on when the tool is

on the workpiece.

1. First mark the line of cut on your workpiece

(good side down.)

2. Insert plug into the power source.

3. Place the front edge of the saw foot on the

workpiece, turn the 4 position control wheel to

setting 2 for laser light only or setting 3 for

laser light and WORKLIGHT and align beam

with the line of cut.

4. Hold the tool firmly, squeeze the trigger and

allow the tool to reach desired speed.

5. Press down (to keep the saw foot flat

against the work surface) as you slowly push

the saw forward, keeping the beam in line with

the line of cut.

6. After completion of the cut, release the

trigger and turn off the laser light.

I/

BLADE STORAGE COMPARTMENT

Your sabre saw is equipped with a blade

storage compartment in the dust port of your

saw (Fig. 5). To remove, pull compartment

out of dust port in direction of arrow,

Always make sure the bIade storage

compartment is securely in the dust port to

prevent blades from falling out.

-9-

•AVOID EXPOSURE- LASER

RADIATION IS EMITTEO FROM

THIS APERTURE. I

,,EVITELAEXPOSICII_N. DESDE I

ESTAABERTU.RASEEMITE

RADIACIOHLASER. I

COMPARTMENT

i"[i_1

DUST

PORT

BLADE

Page 10

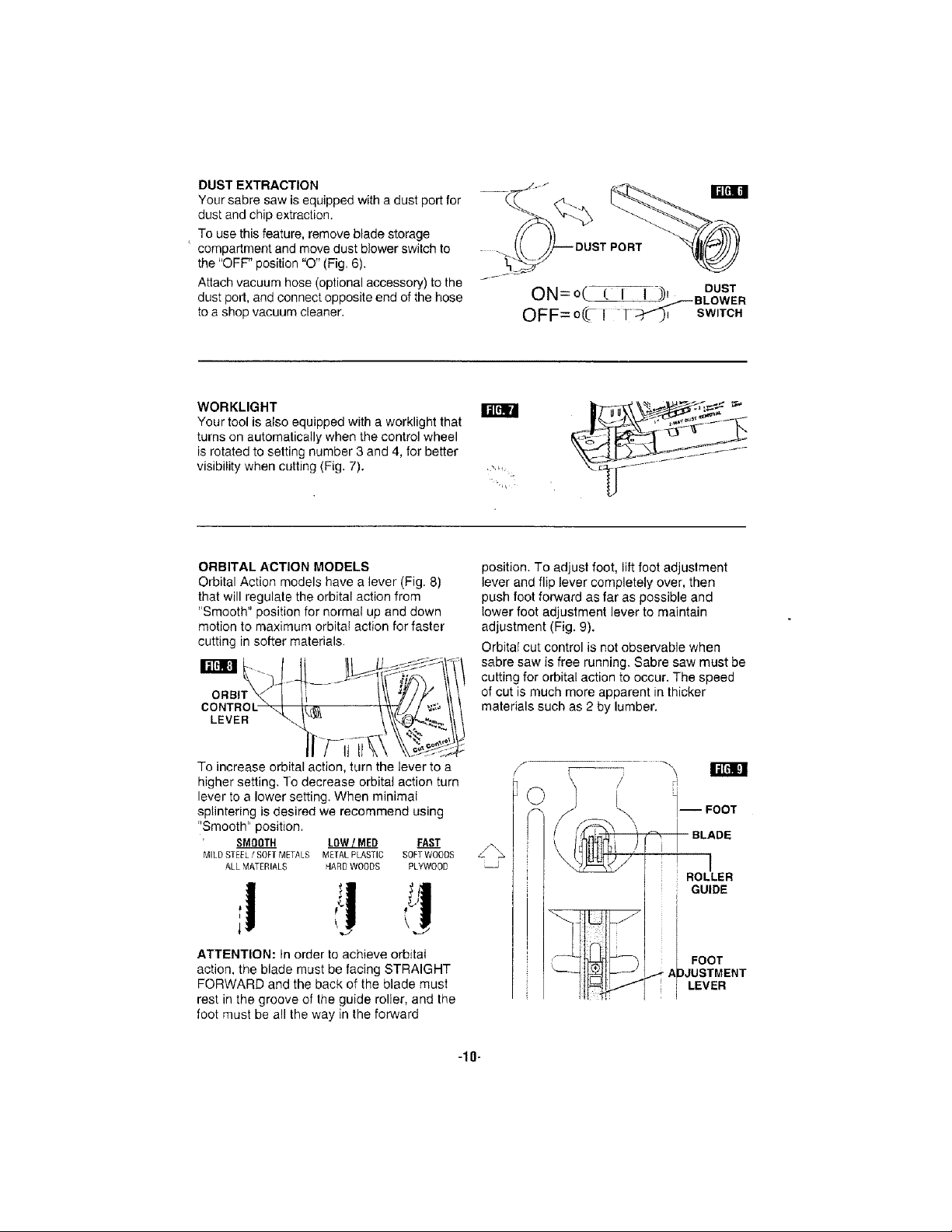

DUST EXTRACTION

Your sabre saw is equipped with a dust port for

dust and chip extraction,

To use this feature, remove blade storage

compartment and move dust blower switch to

the "OFF" position "O" (Fig, 6).

Attach vacuum hose (optional accessory) to the

dust port, and connect opposite end of the hose

to a shop vacuum cleaner.

ON=o( ( I 1 3)1 DUST

,-.--"-BLOWER

OFF=o(C ! 1:_" SWITCH

WORKLIGHT

Your tool is also equipped with a worklight that

turns on automatically when the control wheel

is rotated to setting number 3 and 4, for better

visibility when cutting (Fig. 7).

ORBITAL ACTION MODELS

Orbital Action models have a lever (Fig. 8)

that will regulate the orbital action from

"Smooth" position for normal up and down

motion to maximum orbital action for faster

cutting in softer materials.

To increase orbital action, turn the lever to a

higher setting. To decrease orbital action turn

lever to a lower setting. When minimal

splintering is desired we recommend using

"Smooth" position.

SMOOTH LOW!MED FAST

MILD STEEL/ SOFT METALS METAL PLASTIC SOFT WOODS

ALL MATERIALS "lARD WOODS PLYWOOD

I_[dlM

position. To adjust foot, lift foot adjustment

lever and flip lever completely over, then

push foot forward as far as possible and

lower foot adjustment lever to maintain

adjustment (Fig. 9).

OrbitaI cut control is not observable when

sabre saw is free running. Sabre saw must be

cutting for orbital action to occur. The speed

of cut is much more apparent in thicker

materials such as 2 by lumber.

I

ROLLER

GUIDE

ATTENTION: In order to achieve orbital

action, the blade must be facing STRAIGHT

FORWARD and the back of the blade must

rest in the groove of the guide roller, and the

foot must be all the way in the forward

FOOT

tpJUSTMENT

LEVER

-10-

Page 11

SCROLL MODELS

Scrolling saws permit 360 °rotation of the saw

blade without turning the saw, so intricate

designs may be cut with minimum effort. To

permit rotation of plunger turn lever, (Fig. 10)

to scrolling. The plunger of your scrolling saw

can also be locked in (4) positions, 90" apart.

ATTENTION: When scroll cutting the blade

must be moved away from the guide rollers

(aIways move foot completely back). To

adjust foot, lift foot adjustment lever and flip

lever completely over, then push foot

backwards as far as possible to engage

locking tab, then lower the foot adjustment

lever to maintain ac ustment (Fig. 11).

Note: It may be necessary to turn scrolling

knob slightly back and forth to be sure the

plunger is locked in the desired position.

J

SCROLLING

KNOB

When manually scroll cutting, operate saw by

holding the handle with one hand and rotating

the scrolling knob manually with your free

hand.

_ xcessive side pressure to

broken blades and/or damage to the material

being cut.

Note: When scroll cutting intricate designs,

we recort/mend using a scroll cutting blade.

However, a standard blade can be used.

Face the good side of the material down and

secure it in a bench vise or clamp it down.

Draw cutting lines or designs on the side of

the material facing up towards you. Then

place the front edge of the saw foot on the

work and line up the blade with the line to be

cut. Hold the sabre saw firmly, turn it on, and

press down (to keep the saw foot flat against

the work) as you slowly push the saw in the

direction of the cut.

Build up cutting rate gradually, cutting close to

the line (unless you want to leave stock for

finish sanding). As you cut you may have to

the blade could result in

\

I_[liH

©

I'JC

I

ROLLER

GUIDE

adjust or relocate the vise or clamps to keep

the work stable. Do not force the saw or the

blade teeth may rub and wear without cutting

and the blade may break. Let the saw do most

of the work. When following curves, cut slowly

so the blade can cut through cross grain. This

will give you an accurate cut and will prevent

the blade from wandering.

CUTTING WITH A STRAIGHTEDGE

Always use a rough cut blade when possible,

Clamp a straightedge on the work parallel to

the line of cut and flush with the side of the

saw foot, (Either first mark the line of cut and

-11-

Page 12

then position the straightedge parallel and at

the same distance as between the blade and

the side edge of the foot or first mark the side

edge of the foot and then clamp the

straightedge on the mark and parallel to the

cut line Fig. 12).

On models with the scroll feature, it is advised

to lock scroller knob.

As you cut, keep the saw foot edge flush

against the straightedge and fiat on the

workpiece (Fig. 12).

PLUNGE CUTTING

Plunge cutting is useful and time-saving in

making rough openings in softer materials. It

is not necessary to drill a hole for an inside or

pocket cut. Draw lines for the opening, hold

the saw firmly, tilt it forward so that the toe of

the saw foot rests on the work, but with the

blade well clear of the work. Start the motor,

and then very gradually lower the blade.

When it touches, continue pressing down on

the toe of the saw foot slowly pivoting the saw

like a hinge until the blade cuts through and

the foot rests flat on the work. Then saw

ahead on the line of cut line. We do not

recommend plunge cutting with a scroll blade

(Fig. 13).

To make sharp corners, cut up to the corner,

then back up slightly before rounding the

BEVEL OR ANGLE CUTTING

To prevent damage to the

tool when bevel or angle

cutting, the scroll mechanism must be locked

in place with the cutting edge of the blade

facing the front of the tool.

Disconnect the cord from the power source.

The foot can be adjusted to cut any angle

lrom 0 ° to 45," and is equipped with quick

reference detent stops at 0°, 15°, 30 °, and 45 °.

TO ADJUST: Lift foot adjustment lever in the

bottom of foot as shown, move foot slightly

backward to disengage the locking tab

(Fig. 14).

Position foot to desired angle, then push

forward to engage locking tab and lower

adjustment lever to maintain adjustment. After

adjusting foot make a sample cut to check the

angle (Fig. 14).

corner. After the opening is complete, go back

to each corner and cut it from the opposite

direction to square it off. Do not try to plunge

cut into hard materials such as steel.

J

Note: If the foot becomes loose you can use a

screwdriver to tighten screw located on the

foot adjustment lever, then re-adjust the loot

adjustment lever.

FOOT

ADJUSTMENT

SCREW-_ LEVER

TAB

-12-

Page 13

METAL CUTTING

When cutting metal clamp material down. Be

extra certain that you move the saw along

slowly. Use lower speeds. Do not twist, bend,

or force the blade. If the saw jumps or

bounces, use a blade with finer teeth, if the

blade seems clogged when cutting soft metal,

use a blade with coarser teeth.

For easier cutting, lubricate the blade with a

stick of cutting wax, if available, or cutting oil

when cutting steel. Thin metal should be

sandwiched between two pieces of wood or

tightly clamped on a single piece of wood

(wood on top of the metal). Draw the cut lines

or design on the top piece of wood.

When cutting aluminum extrusion or angle

iron, clamp the work in a bench vise and saw

close to the vise jaws.

When sawing tubing and the diameter is

larger than the blade is deep, cut through the

wail of the tubing and then insert the blade

into the cut rotating the tube as you saw.

RIP FENCE AND CIRCLE CUTTING GUIDE

This accessory is available at an extra cost. It

is used for fast and accurate straight and

circle cutting (Fig. 15).

CLAMp..--.---._

ATTACHING RIP FENCE

1. Insert bar of rip fence through the slots

provided in foot, from either side of loot with

the edge guide facing down (Fig. 15).

CLAMP _

SCREW

2. Thread the clamp screw from under the foot

through the threaded hole in the clamp on left

side of foot, and securely tighten clamp screw I

with a screwdriver, to clamp the rip fence bar

in place,

EDGE GUIDE DOWN

SLOT

I

I

STRAIGHT CUTTING CLAMP ,

Once the rip fence is attached, measure from , _

SCREW /

the edge of work to the line of cut, and set edge

guide of rip fence to the same distance and

then securely tighten clamp screw

(Fig. 16).

LINE OF CUT

-13-

DESIRED___

WIDTH

Page 14

CIRCLE CUTTING

1. Before attaching the rip fence, draw a circle

and drive a finishing nail in the center of circle.

2. Drill or plunge cut near the circles edge,

turn saw off and disconnect the plug from

power source (Fig. 17).

3. Attach rip fence to saw with the edge guide

facing UP.

4. Place the metal center point on the edge

guide into the hole in the center of the circle.

In order for the edge guide to cut a circle, the

metal center point MUST BE in alignment with

saw blade (see Fig. 18).

5. Measure the distance from the selected

hole to the bIade to be equal to the circle

radius.

6. Insert plug into power source, hold the saw

firmly, squeeze trigger and slowly push the

saw forward. To make a hole, cut from inside

the circle; To make wheels or discs, cut from

the outside.

Cutting Tip: Cut slowly so the blade will stay

straight in the cut. Place small wedges in the

cut as shown in Fig. 17, to keep the inner

circle from spreading when near the end of

the cut.

(

\ J

EDGE "WEDGE

GUIDE UP

BLADE MUST BE IN ALIGNMENT

WITH METAL CENTER POINT

-14-

Page 15

Service

_ reventive maintenance

orized personnel may result in misplacing

of internal wires and components which

could cause serious hazard. We

recommend that all tool service, including

service of laser, be performed by a Sears

Service Parts and Repair Center.

Tool Lubrication

Your tool has been properly lubricated and is

ready to use. It is recommended that tools

with gears be regreased with a special gear

lubricant at every brush change.

Carbon Brushes

The brushes and commutator in your toot have

been engineered for many hours of dependable

service. To maintain peak efficiency of the

motor, we recommend every two to six months

the brushes be examined. Only genuine Sears

replacement brushes specially designed for

your tool shouid be used.

Bearings

After about 300-400 hours of operation, or at

every second brush change, the bearings

performed by unauth-

should be replaced at an Authorized Service

Center. Bearings which become noisy (due to

heavy load or very abrasive material cutting)

should be replaced at once to avoid

overheating or motor failure.

Cleaning

I__1 To avoid accidents always

the power supply before cleaning or

performing any maintenance. The tool may

be cleaned most effectively with compressed

dry air. Always wear safety goggles when

cleaning tools with compressed air.

Ventilation openings and switch levers must

be kept clean and free of foreign matter. Do

not attempt to clean by inserting pointed

objects through openings.

_ ertain cleaning agents

plastic parts. Some of these are: gasoline,

carbon tetrachloride, chlorinated cleaning

solvents, ammonia and household

detergents that contain ammonia.

disconnect the tool from

and solvents damage

_lf an extension cord is necessary, a cord with adequate size conductors

that is capable of carrying the current necessary for your tool must be

used. This will prevent excessive voltage drop, loss of power or overheating. Grounded tools

must use 3-wire extension cords that have 3-prong plugs and receptacles.

RECOMMENDED SIZES OF EXTENSION CORDS

120 VOLT ALTERNATING CURRENT TOOLS

Tool's

Ampere

Rating

3-6

68

8-10

10-12

12-16

NOTE: The smaller the gauge number, the heavier the cord.

Cord Size in A.W.G.

Cord Length in Feel

25 50 100 150

18 16 16 14

18 16 14 12

18 16 14 12

16 16 14 !2

14 12

Wire Sizes in mm2

Cord Length in Meters

15 30 60 120

0.75 0,75 1.5 2.5

0.75 1,0 2.5 4.0

0.75 1.0 2.5 4.0

1.0 2.5 40 --

-15-

Page 16

CRAFTSMANSCROLLINGSABRESAWMODEL

NUMBER135.17243

2

13

.810

/

19

I

28

65"

832

34

t

,=

35

29

42

61

14

850

67

30

75

70

71

74

SIERRADEVAIVE:NPARAHACERCONTORNOSCRAFTSMAN

NUMERODEMODELO135.17243

Page 17

KEY PART

NO. NO.

1 2610916229

2 2610913978

3 2610913979

4 2610924106

5 2610916910

13 2610967219

14 2610917489

15 2610018632

16 2610320548

19 2914201705

21 2610329898

22 2610968496

23 2610329896

28 2610914014

29 2610913999

30 2610914016

34 2610914010

35 2610914007

42 2610914011

52 2610914015

54 2610916883

55 2610914018

56 2610914884

57 2610913996

58 2610914020

59 2610914019

60 2610914022

61 2610913993

62 2610913994

PART NAME

Housing

Field

Armature

Switch

Cord

Bushing

Ball Bearing

Retaining Ring

Brush Holder

Screw

Spring

Cable

Terminal Clip

Pusher

Counterweight

Shaft

Bushing

Bushing

Spring Clip

Arm

Foot

Bracket

Roller

Pin

Spring Clip

Holder

Pin

Yoke

Bolt

KEY

NO.

1

63

1

64

I

65

1

66

1

67

1

68

1

69

1

70

2

71

12

73

2

74

2

75

2

76

1

78

t

79

t

8O

1

81

1

84

1

85

1

86

1

87

1

88

1

810

1

826

2

832

1

836

1

844

1

85O

1

PART

NO.

2610913995

2610913992

2610917358

2610924134

2610916536

2610390329

2610912487

2610916094

2914201672

261O922316

2610924140

2914201664

261O916537

2610018199

2918150120

2610916541

2610917102

2610922519

2610922520

2610923594

2610924145

2610924146

2610917266

2610917218

261O917219

2610917220

2610917221

2610917222

261O924135

PART NAME

Nut

Lever

Locking Tang

Board Assembly

Lock Botton

Spring

Guard

Lever

Screw

Lens

Metal Front End

Screw

Lever

Spring

Set Screw

Blade Storage

Cap

Sled

Sled Holder

Cable Assembly

Cover

Insulation

Brush Set

Bearing Plate Assembly

Gear Assembly

Plunger Assembly

Blade Holder Assembly

Knob Assembly

Owner's Manual (not shown)

1

1

1

1

1

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Page 18

Indice Pdgina

Garantia .................................................... 18

Normas de seguridad para herramientas mec_.nicas ............... 19-21

Simbolos ................................................... 22

Descripci6n funcional y especificaciones ........................... 23

Ensamblaje ................................................. 24

Instrucciones de funcionamiento .............................. 24-27

Consejos para la herramienta ................................. 27-30

Mantenimiento ............................................... 31

Piezas de repuesto ......................................... 16-17

GARANTIA COMPLETA DE UN AI_IO DE LA SIERRA DE VAIVEN

PARA HACER CONTORNOS CRAFTSMAN

Siesta Sierra de Vaiven para hacer Contomos CRAFTSMAN no le

proporciona comp[eta satisfacci6n a partir de un afro desde la fecha de

compra, DEVUELVALA AL ALMACEN SEARS MAS CERCANO EN

LOS ESTADOS UNIDOS y Sears la reemplazara_gratuitamente.

Si esta Sierra de Vaiven para hacer Contornos CRAFTSMAN se usa

para propSsitos comerciales o de a[quiler, esta garantfa es valida

durante 90 dfas desde [a fecha de compra.

Esta garantfa le otorga derechos legales especfficos y usted puede,

adema.s, terler otros derechos que va6an de un estado a otro.

Soars, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

-18-

Page 19

Leay entiendatodas las instrocciones.El incumplimiento detodas las instrucciones

personalesgraves.

indicadasa continuaoi6npuede darlugara sacudidaselectricas,incendiosy/o ]esienes

CONSERVEESTASINSTRUCCIONES

Areade trahajo

Mantengael_readetrabajolimpiay hieniluminada.

Lasmesasdesordenadasylas_reasoscurasinvitana

quaseproduzcanaccidentes.

Noutiliceherramientasmecdnicas en almbsferas

explesivas,tales come lasexistentesenpresencia de

I[quidos,gaseso pelvesintlamables. Las

herramientasmecanicasgeneranchispasy _stas

puedendar lugara la ignici6n del polvo o Insvapores.

Mantengaa las personasquese encuentren

preseetes,a losnii'ios y a losvisitantesalejadosal

utilizar nnaherramientamecdnica. Las distracciones

puedenhacer qua ustedpierdael control.

Seguridadel_clrica

Las herramientasconaislamientodoble est_n

eqaipadasconanenchufepolarizado (un terminales

m_isanchaqueel otro). Esteenchufeentrar_ en un

tomacorrientepolarizadosolamentede una manera.

Si el enchufenoentrapercompleteenel

tomacorriente,d_lela vuelta. Si siguesin entrar,

p6ngaseen contactoconun electricistacompetente

parainstalarantomacorrientepolarizado.No haga

ninglintipodecambio enel enchufe.Elaislamiento

deble[] elimina la necesidadde] sisternade cerd6n de

energiade treshiles conectadoa tierra y la fuentede

energiaconectadaa tierra.Antesde enchufarfa

herramienta,asegdlresede qua la tensidn dot

tomacnmente suministrada se encuentredentrodot

margende la tensJ6nespecilicadaen ta placadel

fabricante.No ufilice herranfientascon capacidad

nominal "ACsolamente" ('.4Coniy') conuna fuentede

energiaDC

Eviteel contactodel cuerpoconlas superficies

conectadasatierra tales cometuberfas, radiadores,

estafasdecocinay refrigeradores.Haymayerriesgo

deque se produzcansacudidaseleetricassi su cuerpo

estaconectadoa tierra, Sila utilizaciM deia

herramienta mecJnicaenlugares17_medoses

inevitable,se debe usarun interrupter de circuito para

ratiosa tierraparasuministrar la energiaa la

herramienta.Losguantes de goma para electricistay el

_aizadoantideslizanteaumentaranm,_slaseguridad

personal

Noexpongalasherramientasmecanieasa la Iluvia ni

asituacionesh_medas. La entradadeaguaen una

herramientamec_.nicaaumentarael riesgo de quase

produzcansacudidas electricas.

Noabusedel eord6n. Nunca useel eord6n para gevar

lasherramientasni parasacarelenchufe de un

tomaeorriente. Mantengael cord6n alejadede!ealor, el

aceite,los bordesalilados o las piezasm6viles. Cambie

los cordones daRadosinmediatamente.Loscerdones

daSadosaumentanel riesgo de qua se produzcan

sacudidas el_ctricas.

AI utilizarunaherramlentamec_nicaa lainlemperie,

utilJceuncordbndeextensi6npara intemperie

marcado"W-A"o"W". Estoseordonestienen

capacidadnominaIparause ala intemperiey reducen el

fiesgo de quase produzcaesacudidas eldctricas.

CensulLe"Tamales recomendadosde loscordonesde

extensi6n"en la seco!6nAccesoriosdeeste manual,

seguridadpersonal

Mant_ngasealerfa, fljese en Io queest_ hacienday

useel sentidocomz_ncuandoutilice unaherramienla

mec_nica.Nousela herramientacuandoest_

cansadoose encuentrebajola influenciadedrogas,

alcoholomedicamenlos, Un memento de distraccion

al utilizarherramientas mec_nicas puededar lugara

]esienespersonalesgraves.

Vistaseadecuadamente.Nose ponga ropaholgada ni

joyas. Suj6teseel pelo. Mantengael pelo, la ropay

losguantesalejadosde las plazasm6viles. Laropa

holgada,lasjoyas o elpolo largo puedenquedar

atrapadosen laspiezasm6viles. Mantengalosmangos

secos,iimpios y libres de aceitey grasa.

Eviteel arranqae accidental.Aseg_resedeque et

interrupterest_en laposicibn"OFF" (apagado)antes

de enchufarla herramienta.E]Ilevarlasherramientas

con el dedo en elinterrupter oel enehufarherramientas

quetengan el interrupter en la posici6n "ON"

(encendido)invitaa quase produzcanaocidentes.

Quitelas Ilaves de ajaste o de tuercaantesde

encenderla herramJenta,Unaliars deaiuste o de

tuerca qua sedeje puesta en unapiezagiratoria de la

herramientapuede oeasionarlesionespersonales,

No inlentealcanzardemasiadolejos. Mantenga an

apoyo de los pies y on equilibriaadecnadosentodo

memento.El apoyodelos pies y el equilibria

adecuadospermiten un major control de laherramienta

ensituacienesinesperadas.

Utiliceequipodeseguridad. Usesiempreprotecci_n

de losojos.Se debe eti[izaruna mascaraantipolvo,

zapatosde seguridadantideslizantes,caseoo

protecci6n delos aides segL]nle requieran las

eondieiones.

-19-

Page 20

Utilizaci6n y cuidado de las herramientas

Utiliceabrazaderasn otrornodopr;icticodelijar y

soportarla pieza detrabajoa una plataformaestable.

LasujecJ(Jndela piezade trabajo con la mane o centre

el cuerpo resultainestabley puedeocasionarp_rdida de

control

Nofnerce la herramienta, Use la herramienta

correctapare la aplicaci6nque desea, Laherramienta

correcta har_el trabajo reelery con m_s seguridad ala

capacidadnominal parelaque est_ diseSada.

No utilicela herrarnientasiel interruptornola

enciendeo apaga. Toda herramientaque no se pueda

controlar con e]interrupter es peligrosay debeset

reparada.

Desconecteelenchnfede la fuentedeenergiaantes

de hacercualquierajuste, carnbiaraccesorioso

guardarla herrarnienta.Estasmedidas de seguridad

preventivasreducenelriesgo dearrancar]a herramienta

accidentalmente.

Geardelas herrarnientasquenoestd usandofnera

delaleancedolos niiiosy otraspersonasno

capacitadas. Lasherramientasson peligrosasenlas

manesde los usuariosno capacitados.

Nlantengalasherrarnientasconcuidado.Conserve

Insherrarnientasdocarteafiladasy lirnpias. Lax

herramientasmantenidasadecuadamente,con bordes

decorte afilados, tienen menos probabflidadesde

atascarseyson m_sf_cilesdecontrolar. Toda

alteraci6no modificacionconstituye unuse incorrecto y

puedetenor come resultadounasituacion peligrosa.

Compruebela desalieeacidnoel atascodoIns piezas

mdviles,la rupturedepiezasy cualquierolra

sitnacidnque puedaafectarelfuncionarniento de las

herramientas.Si la herrarnlentaesl(idaflada, haga

que realicenun serviciode ajustesy reparacionesa

la herrarnientaantesde nsarla. Muchosaccidentes

son causadosper herramientasmantenidas

deficientemente.Establezcaun prograrnade

mantenimientoperi6dicc parela herramienIa.

Utilicednicamente accesoriosque est_n

recomendadospotel fabricantede su rnodelo. Los

accesorios que puedenseradecuadosparauna

herramientapuedenvolversepeligrososcuando se

utiiizanenotra herramienta.

Servicio

Elserviciode ajustesy reparacionesdo una

herrarnientadebeser realizado _nicamente par

personaldoreparacionescornpetente.Elservicio o

mantenimientorealizadoper personal nocompetente

podria ocasionarun peligrodequese produzcan

lesiones. Per ejemplo: Los cablesinternes pue(fen

colocarserealo pellizcarse,Ins resertes de retorno de

les.protectoresdeseguridad puedenrnontarse

inadecuadamente.

A[ realizerserviciode ajuslesyreparacionesde una

herramienta,utilice _nicarnente piezasderepuesto

id_nticas.Sioalas instrnccionesque aparecenen la

secci6nMantenirnientodoeste manual, Eluse de

piezasnoautorizadaso elincumpiimiento de las

instrucciones de Mantenimiento puedeocasionar un

peligro de que se produzcansacudidas el_ctricaso

lesiones.Ciertosagentesde limpieza,tales come

gasolina,tetracloruro de carbeno, amoniaco,etc.,

puedendaSarias piezasde pl_stico.

Sujete la herramienta por las superficiesde agarre

aisladas cuandorealice nnaoperacidn en la que la

berrarnienta de corfepueda entrar on contactocon

cablesocnltos o consu propiocord(_n. Elcontacto

con uncable quetonga corriente har(i que _sta pasea

las partes metalicas descubiertas de la herrarnientay

que el operador reciba sacudidas eldctricas. No

taladre,romp& ni haga trabalo de sujeci6n en

paredes existeetesni en otras areas ciegas donde

pueda haber cables el_ctricos. Siesta situaci6n es

inevitable, desconectetodos los fl]sibtes o

cortacflcuitos quealimentan este sitio de trabajo.

Nunca deje el gatille fije en la pesicidn"ON"

(encendido), Antesdo enchufarla herramienta,

cornpruebeque el cierre del gatillo est_ en la

posici(in "OFF" (apagado). Un arranque accidental

podria causer tesiones.

Sepala nbicaci6n y la posici6ndel bet(in de

"Fijaci(Snon ON"del interrupter. Si el interruptor

esta file en la posici6n "ON"durante el use, este

preparadopara en situaciones de ernergenciaponerlo

en"OFF",tirando primero del gatillo y solt_ndolo

inmediatamente despuessin oprimir el botdn de

"Fijaci6nen ON".

Mantengalas manesalejadas del (irea do corle.

Nopongala rnano debajo del material quese est(i

cortando. Laproximidad de la hoja ala mane queda

ocultaa iavista.

Mantengalasmanesalejadasdelespacioentrela

cajadoengranajesyel soportedela holede

sierra. EIsoportedela hojadevaiv_npuede

peHizcarlelos dedes.

Nontilicehojasdesliladasnidafladas. Unahoja

dobladapuederompersefaciimenteocauser

retroceso.

-20-

Page 21

Antesdecnmenzaretcnrte,enciendala

herramientaydejeque lahnjaalcancetndasu

velncidad.Laherramientapuedechirriaro vibrarsi

lavelocidadde lahnjaesdemasiadolentaal

cnmienzodelcortey posiblementepuede

experimentarretrocese.

Usesiempregalasdeseguridadnprotecci6ndeIns

njnscuandnatiliceestaherramienta.Useuna

mascaraantipnlvoounrespiradnrpara

aplicacinnesquegeneranpolvn.

Fijeelmaterialantesde¢ortar. NuncaInlengaen

la mannnisnbrelaspiernas.EimaterialpequeSoo

delgadopuedecurvarseovibrarconlahnja,

causandoperdidadecontrol.

Aseg_resedequetodnsInstnrnillnsdeajusley el

sopnrtedela hnjaestenapretadnsantesdehacer

ancorte.Si instornillnsde ajustey Inssoportes

est;_nflojos,puedenhacerquela herramientan la

hojaresbale,pudiendoproducirsep_rdidadecontrol,

AIquitarla hojadela herramienta,eviteel

contactoconlaplelyusegnantesprnlectnres

adecuadnsal agarrarla hojanelaccesnrin.Los

accesnrinspuedenestarcaiientesdespu6sdeluso

prolongado

Uses61nIns accesnrinsvendidnspnrSearsparasu

modeln. Los accesoriosquepuedenser adecuadns

paraunaI_erramienta,puedenserpeligrosos si se

utilizanenotra herramienta.

Ciertnpnlvogeneradnpnrel

lijadn, aserradn,amnladoy

laladradomec_nieos, y pnrntrasactividadesde

cnnstrucci6n,cnntieneagentesquimicnsqnese sabe

que causanc_ncer, defectnsdenacimientou otrns

dafiossnbrela reprodocci6n.Algunns ejemplos de

eslosagentesquimicnsson:

• Plomode pinturas a basede plomo,

• Sflicecristalina de ladrillosy cementoy otrns

productnsde mampostefia,y

• Ars_nicn y cromo de maderatratada quimicamente.

Suriesgo pnr causade estasexposiciones varfa,

dependiendode con cu&ntafrecuenciareaticeestetipo

detrabajo. Parareducir suexpnsici6n aestos agentes

quimicos:trabaje en un ;_reabien ventiladay trabaje con

equipodeseguridad aprnbado,como pot ejemplo

mascarasantipolvo queestendise_adasespecialmente

paraimpedir mediante filtracion elpasode partfculas

microsc6picas.

-21-

Page 22

tMPORTANTE: Es posible quealgunos de los sfmbolos siguientes se usen ensu herramienta. Por favor,

estedielos y aprendasu significado, Lainterpretaei6n adeeuadadeestos simbolos Is permitira utilizar la

herramienta meier y con m;_sseguridad.

Simbo!o Nombre Designaci6nlexpiicaci6n

V Vnlt Tensi6n (potencial)

A Ampere Corriente

Hz Hertz Frecuencia(ciclos per segundo)

W Watt Potencia

kg Kitogramo Peso

rain Minute Tiempo

s Segundo Tiempo

0 Diametro Tamafio de las brocas taladradoras,

nO Velocidad sin carga Velocidad rotacional sin carga

...imin Revoluciones o alternacion per minute Revoluciones, golpes, velocidad de

0 Posici6n "off" (apagado) Velocidad eero, par motor cero...

1.2 3.... Graduacionesdel selector Graduacionesde velocidad, par motor o

I, II, III, position. Un n_mero m_s alto significa

o.,.dl

""_ Flecha Acci6n en ladireeci6n de la flecha

"_\/ Corriente alterna Tipo o una caracteristica decorriente

[] Construcci6n de clase I! Designa las herramientas de construction

0 Terminaldetoma de tierra Terminal deconexi6n atierra

Selector infinitamente variable con La velocidad aumenta desde la

apagado graduaci6n de 0

Corriente continua Tipo o una caracteristica decorrienle

Corrientealterna o continua Tipo o unacaracteristica de corriente

muelas, etc

supedicie, 6rbitas, etc., per minute

mayor velocidad

con aislamiento doble.

t_ Simbolo de adverteneia Ateda al usuario sobre mensajesde

_ SelloRBRCTM de Ni-Cd Designa el programa dereciclaje de baterias

herramienta esta catalogada

Eslesimbolo indica que esta Q

per Underwriters C

Laboratories.

j_, herramienta est,1eatalogada per

herramienta esta catalogada

Estesimbolo indiea que esta

par la CanadianS_andards

Association.

I' | |l _ Underwriters Laboratories y que

C _Vll JU_ Underwriters Laboratories la ha

advertencia

de Ni-Cd

Estesimbolo indica que

UnderwritersLaboratories ha

catalogadoesta berramienta

indicandoquecumple las

norrnascanadienses.

Estesimbolo indica que esta

catalogado segun las normas

eanadienses.

Estesimbolo

indica queesta

herramienta

cumplecon la

norma mexicana

oficial (NOM).

-22-

Page 23

DESCRIPCI6N FUNCIONALY ESPECIFICACIONES

_ esconecteel enchufede la luente de energia anles de realizar cualquier ensamblaje

riesgo dearrancar ia herramienta accidentalmente.

o ajuste, o cambiar accesorios. Estasmedidas de segufidad preventivas reducen el

Sierra de vaiv_n para hacer contornos con Laser-TracTM

ll[_il

POM0DEOESPLAZAMIENTO

CONTINUO

BUEOADECONTROLDELALUZ

L/_SERYLALUZOETRABAJO

/_'_, "FIJACIONENON"

TORNILLODE EMPU_ADURA

AJUSTEDELA ,-L CAUCHUTAOA

LUZLASER

BOTONDE

INTERROPTOR

(DEENCENDIDOY

APAGADO)

ABERTURASDE

--VENTILACION

LUZDETRABAJO-/i

CUBIERTA DE

CAMBI0 DE HOJA

SIN HERRAMtENTAS

--DEL SOPLADOR

PALAXCADECONTROL

_RBITAL/DESPLAZAMIENTO

CONTINUO

CAPACIDADESMAXIMAS

No. de Espesorde Accionde Long.de

modelo la hoja a hoja carrera Madera Aluminio Acero

17243 Miriirno .7mm- M_,ximo1,Tram Orb./Desp. cont. 20 mm 80 turn 12 mm 6 mm

NOTA: Paraobtener lasespecificacionesdelaherramienta, consultela placa de]fabricantecolocada en

la herramienta.

BASE

INTERRUPTOR

DEPOLVO

0RIFICIOPARA

POLVO/

COMPARTiMIENTO

PARAGUARDAR

HOJAS

-23-

Page 24

Colocaci6n de la hoja

_ Para prevenir lesiones

el enchufe de la fuente de eoergia antes de montar

piezas,realizarajusteso cambiar hojas.

1. Introduzca la hoia de sierra (con Ins dientes en el

sentido de corte) hasta que se acople en el embele

(Fig 2).

UBIERTADECAMBIO

DEHOJASIN

HERRAMIENTAS

personales, desconecte siempre

, gas1

AI introducir la hoja de sierra, la parte posterior de la

hoja debe descansar en la ranura del rodilio de gufa

(Fig. 3).

2. Para quitar la hoja, levante la cubierta de cambio de

hoja sin herramientascon Ins dedos indice y pulgar y

quite la hoja.

Parautilizarse con hejasde sierra caladoracon cuerpo

tantoen T como enU.

HOJA

RODILLODEGuJA--

INTERRUPTORGATILLODEVELOCIDADVARIABLE

Laherramientaest,,equipadacon un inlerruptor gatfllo

develocidadvariable.Laherramientase puedeeneender

(posici6n "ON')o apagar(posici6n"OFF')apretandoe

sottandoel gatillo. Lavelocidadsepuedeajustardesde

lasCPM minimas hastalasCPMm_ximasindicadasen

taplacadel fabbcante por medio dela presi6nqueusted

ejercesobreel gatillo. Eierzam_spresionparaaumentar

taveIocidady disminuyata presi6n parareducir la

velocidad(Fig.1).

BOTONDE"FIJACIONENON"

El bot6n de"Fijaci6nenON".ubicado enel mangode la

herramienta,permiteun funcionamientocontinuo a CPM

m_ximassin tenorque mantenerapretadoelgatillo

(Fig.1).

PARAFIJARELGATILLOENLA POStCION"ON":apriete

eJgatillo,optima el bot6ny suelteel gatillo.

PARADESBLOQUEAREL GATILLO:aprieteelgaIiltoy

su_ite]osin oprimir el bot6nde"FijacionenON"

Si seoprime continuamenteel

bot6n de "Fijacionen ON", no se

puedesoltar elgatil]o.

VELOCIDABDELEIVIBOLO

Lavelocidad de carrera puede aiustarse tal como se

describio anleriormente en "lnterruptor gatillo de

velocidadvariable". La seieccion de la posici6n optima

a fin de obtener Ins meiores resultados para una

aplicaci6n especiflca se basaen laexperiencia,

aunque como norma general, las velocidades mas

,JtUIL J

bajasson para materiales mas densos y las

velocidades m_s altas son para materiales blandos.

RUEDADE CONTROLDELALUZL_,SER

Y LALUZ DETRABAJO

_ RADIACIONLASER.EVITELA

OJOS.No mire a lafuente deluz Idser. No apunte

nuncala luzhasiaotra personao haciaotroobjeto

queno sea la piezade trabajo. LaluzI_serpuede

da_arins ojos.

lentestintados reduciranla visi6n total pararealizarta

aplicaci6ne interferiran con el funeinnamientonormal

dela herramienta.

ariasuperficie reflectora, Lachapade acorn reflectora

brillante y resplandecienleo las superficies reflectoras

similaresno se recomiendan parausar un 19ser.Las

superficies refleetoraspodrian dirigir el rayode vuelta

haciael operador.

no sean Ins quese especificanen este manual, podria

causarunaexposici6n peligrosa a la radiaci6n.

peligros para insojos.

EXPOSICI(]NDIRECTADELOS

Nouse lentestintadospare

inlensificarla luz laser. Los

No apantenuncaelrayo hacla

una pieza detrabajo quelenga

Ei uso de eontroles o ajustes, o la

realizacionde proeedimientos que

Ei uso de instrumentos 6prices

con este producto aumentara Ins

-24-

Page 25

Laruedade control de4 posiciones permite al operador

controlar la funci6n de losluces.A continuaci6n se

indica la funci6n de cadaposisi6n(Fig,1).

Posici6n 1: Apagatodas las luces.

Posicion 2: Enciendesolamente la tuz I_ser,

Posici6n 3: Enciendetanto ia luz I;_sercome la luz

Site-Ligth,

Posici6n 4: Enciendesdamente ta luzde trabajo.

La guiade la fineadel I;_seres un laserde claseIliA con

unapotencia desalida m_iximade 5.0 mW y cumpie

con las normas 21 CFR1040.10y 1040.11.

GUiADE LALiNEADELLASERLASER-TRACTM

Laguia de ia IfneaLaser-Tracle ayuda a seguir la linea

deeorte con mayor facilidad y precisi6n al realizarun

code,

PAFIAAJUSTARLAGUIADELALiNEADELLASEI_

Utilice undestomillador de sabezaplanapara girar el

tomillo deajuste ubicado en el lads del m6dulo del

laser(Fig. 4). Enciendala guia de ia I[neadel I&ser

girando la rueda de control hastalaposici6o nQmero2,

Gireeltornillo de ajuste ,haslaquelaIfnea delI_.serest_

en el centre de la hoja,No hay necesidadde encender

la herramientamientras se esteajustando el rays de

luz.

Laguia dela If_leadel laser tieneuna cantidad limitada

de recorrido, Nocontim]e girando e{ tornillo dealuste

despues de que la Ifneadeje demoverseo si Ilegaa set

signiticativamente masdiffcil girar el tornillo, Si se gira

excesivanrenteeltornilto deajuste, el resultado podrfa

ser que el sistema deajuste se rompa o qne el tornilin

de ajuste se caigade laherramienta.

UTILIZACI(}NDELA GUiADE LALiNEADELLASER

Enciendagu2adela linea del I_sersolamentecuando ia

herramienta estesobre lapiezadetrabajo.

1, Marque primers lalineade code en la piezade

trabajo (con el lads buenohacia abajo)+

2. Introduzca el eochule en la fuente de energia.

3, Cdoque el borde delanterode la basede la sierra

sobre la pieza de trabajo, gire larueda de control de 4

posiciones hastala posici6n 2 paraseleccionar la tuz

l_sersolamente ohasta laposici6n 3 paraseleccionar

la luz I;_sery ta luzdetrabajo, y alineeel rays con la

ifneadecode.

4.Sujetefirmemente la herramienta,apriete el gatillo y

dejeque la herramierltaalcancelaveiocidad deseada.

5. Presionehaciaabajo (paramantenerla basedela

sierra pianocontra lasuperficie de trabajo)a medida

queempuja lentamentela sierra hacia delante,

manteniendod rays en Ifneacon la Ifneadecode.

6, Despues decompletar el corte suelteel gatillo y

apague la luz I_ser,

li[_ _]

TORNILLODE

AJUSTEDELA

LUZLASER

COMPARTIMIENT0PARAGUARDARHOJAS

Lasierra devaiv6nesta equipadacon un

compartimiento para guardarhojas enel orilicio para

polvo de lasierra (Fig, 5). Para quJtardiche

compartimiento, tire de61enet sentido de laflecha

Ilastasepararlo del orilicio parapolvo.

Aseguresesiempre deque el compartimiento para

guardar hojasestefirmemente sujeto enel orificio para

polvo para evitar que/as hojas se caigan.

-25-

• A_OIDEXPOSURE-LASER

RADIATIONIS EMITTEO FROM

THIS APEeTURE.

• EVITELA EXPOSICIONr DESDE

ESTAABEFITU_ASE EMIle

RADIACION LASER.

ORIFICIO

PARAPOLVO

HOJAS

Page 26

EXTRACCIONDEPOLVO

Lasierradevaiv_nest_equipadaconun orificio para

polvoafin de extraerelpolvo y lasvirutas.

Parautilizarestedispositivo,quite ei eompartimiento

paraguardar hojasy muevael interruptor del soplador

depolvo hastala posici6n de apagado"0"(Fig,6).

Coloqueunamangueradeaspiraci6n(accesorio

opcionai) en el orificio parapolvoy conecteel otro lado

de ia mangueraa unaaspiradorade taller.

PARAPOLVO

INTERRUPTOR

ENCENDIDO=o( _ _DELSOPLAOOR

APAGADO--.o_-I--F _ )l DEPOLVO

LUZ DE TRABAJO

La herramientatambi_n est;i equipadacon una luz que

se eociendeautoroaticamentecuando se activael

interruptor, para tener mejor visibiiidad al cortar

(Fig.7).

MODELOSDEACCI(]NORBITAL

Los modelos de acci6n orbital tienen una palanca

(Fig. 8) que regula ia acci6n orbital desde la posicf6n

'suave' para movimiento normal haciaarriba y hacia

abajo hasta la acci6n orbital m_xima para corte m_s

r_pido enmateriales mas blandos.

I_[_!_]

PALANCP

CONTROL

ORBITAL

Paraaumentar la acci6r] orbital, gire la palanca hasta

unaposici6n mJ.salta. Para reducir la accic_norbital,

gire la palanca hasta una pesici6n mas baja. Cuando

se deseequeel astiliado seaminimo, recomeodamos

utilizar ia posiciOn"suave".

SUAVE BAJA/IHTERMEDIA RAPIDA

ACE_O SUAVE _ METAL__S MET&L PLASTICO MAOERAS BLANDAS

BL ANDOS MADERAS DURAS MADERA CONTRACHAPADA

TODOS LOS MAT_ Rill ES

ATENCI()N:Conelfin de Iograracci6norbital, la hoia

debeestarobentadaRECTAHACIADELANTE,la parte

traseradela hojadebedescansaren laranuradel rodiNo

deguia y la basedebeestaren iaposici6n

IIIPlll

completamentebaciadelante. Paraajustarlabase,suba

tapalancadeajustedela base,basclJlela

completamente,luegoempujela basehaciadelante

tantocomo seaposibley bale lapalancadeajustede la

baseparamantenerelajuste(Fig.9).

Elcontrol decorte orbital noes observablecuandola

sierrade vaivenestafuncionadolibremente. Lasierra de

vaiv6ndebeestar cortandoparaque se produzcala

acci6norbital. Lavetocidadde cortees muchomAs

evidenteee materialesmas gruesos,como maderade 2

pulgadasde grosor.

_\ !--BASE

it,..J PALANCADE

"._,,.__/_I;._,_.-,,_•

i ,,I A

i RODILLO

DEGU]A

-26-

Page 27

MODELOS DE DESPLAZAMIENTO CONTINUO

Lassierrasdedesplazamientocontinue permiten una

rotaciCnde360° dela hojade sierraa fin de quelos

dise_os complicadosse puedancortar con un esfuerzo

minima. Parapermitir la rotaciCndeJ_mbolo, gire ta

palanca,(Fig. 10),a fin dedesplazamiento.El _mbolo

dela sierra de desplazamientocontinue se puedelijar

en(4) posicionesseparadas90°.

ATENCION:AI I]acer cortes de despiazamiento

continue, la hoja debemoverse alej#,ndosede los

rodillos de guia. (Mueva siempre la base

completamentehaeiaatr_ts.)Paraajustar labase,suba

tapalancade ajuste dela base,basct_lela

completamente,luego empujeia base haciaatRis tanto

come sea posible paraacopiar la lengiJetade fijaniCny

iuego bajelapalancade aluste dela base para

mantenerel ajuste (Fig. 11).

Nota: Puedeque seanecesariogirar el paine de

desplazamientocontinue ligeramente haciaarras y

haciaadelanteparaasegurarsede que el 6mbolo est;_

fijo en laposicion deseada.

POMODEJ _ _j Y_X.____

DESPLAZAMIENTO/ _'_ _--

CONTINUO I _ v'__

PALANCA'--'-_] ]1 __

A]coriar con desplazamientecontinue manualmente.

hagafuncionar la sierra agarrandoel mango con una

maney girando et paine de desptazamientocontinue

rnanualmentecon famane libre.

UnapresiCnlateralexcesivasabre

la hola podrfa dar lugar a holas

rotasy/o dagosal materialque se est_icortando.

Nota: AI eortarcon despiazamientocontinue disefios

complicados,recomendamos la utilizaciCndeuna hoja

decarte paradespiazamientocontinue. Sin embargo, se

puede utilizaruna hojaest_ndar.

Coloqueet]adobuenadel materialhaciaabajoy fijelo en

un tornillo de earpinterodebancoo sujetelocon

abrazaderas.Tracelineaso dise_osdecarteen el lade

del material queestaorienladohaciaarriba, haciausted.

Lueg& coloqaeelhordedelanterode la basede la sierra

sabre la piezade trabatey alineelahoja con la linea que

seva a cortar.Agarrelasierrafirmemente, enci_ndalay

ejerzapresi6n haciaabajo(paramantenerla basedefa

sierra en posicionhorizontaltocandola piezadetrabajo)

amedidaqueempuia lentamentelasierra enel sentido

decode.

Aumente lavelocidaddecarte gradualmente,cortando

cercadela lfnea(amenosque quieradejar material para

tijadode acabado).Arnedidaqueustedvayacortan(lo,

puedeque tongaque ajustarocambiarde sitio el tornillo

f

li_, 1 HOJA

decarpinteroolas abrazaderasparamanlenerla pieza

detrabajoestabie.Nofuerce la sierra,si no los dientes

dela hojapuedenrozar y desgastarsesin cedar y la hoja

se puederomper,Dejeque la sierra hagala mayor parle

deItrabafo, AI seguirlascui_as,corie lentamente para

quela hojapuedacedar endirecei6ntransversala la

vet& Estoproporcionara un carteprecise y evitar;_que la

sierrase desvie.

CORTECONREGLARECTA

Siempre que sea posible, utilice unahoja de carte

bast& Fijecon abrazaderassabrelapiezadetrabajouna

reglarecta paralelaa la lineadecarte y parejaconel lade

de la basedela sierra. (Marqueprimero lalineade eerie

y luegoeoiaquelareglarectaparalelamentey a ia

rnisma distaaciaque existeentrela heray el borde

-27-

Page 28

lateraldela baseo marqueprimero el hordelateraldela

basey luegofiie con abrazaderaslareglarecta sobre esa

marca y paralelamentea lalineade corte (Fig. 12).

Enlos modelos con el dispositivo de desplazamiento

continuo, se recomienda bloquear el pomo de

desplazamiento continuo.

Cuandccorte,mantengael bordedela basedela sierra

parejocon la regtarectayapoyado horizontalmente

sobre la piezadetrabajo(Fig.12),

CORTEMEDIANTEDESCENSOVERTICAL

Elcorte mediante deseensovertical es titil y ahorra

[iempo at hacerabeduras bastas en materiales mas

blandos. No esnecesario_acerunagujero parauncorte

interioro de bolsillo.Traceffneasparalaabedur& agarre

Issierra tirmementeeinclinelahaciaadelanteparaque la

punladela basede lasierra estdapoyadasobre la pieza

detrabajo, perocon la hojabienalejadadela piezade

lrabajo.Ar[anque el molor y luegobajelahoia muy

graduaimente.Cuandohagacontacto,continOeejercien-

do presi6n haeiaabajosobre la puntade la basede Ia

sterra,baciendopivotarlasierralentamentecomo una

bisagrailasta quela hojacortey la baseseapoye hori-

zontalmentesebrela piezade trabajo.Luego,aserre

haciaadelantesiguiendola linea decode. No

recomendamoselcorte mediantedescensovedical con

unahoja paradesplazamientocontinuo (Fig,13).

Parahaceresquinasmuypronunciadas,corte hasta]a

esquinay luego retrocedafigeramenteantes derodear la

CORTEINCLINADOOENANGULO

_Para evitardafiosa la herramienta

_,ngu]o,etnrecanismodedesplazamientocontiouo debe

estarlijo en su posicion con el borde decorte de Iahoja

orientadohaciala partedelanterade ia herramienta

Desconecteelcord{_nde la luentede energia.Labase

puedeajustarseparacortarcualquier&ngulodesde0°

basra45° y est,_equipadacontopes de retchde

referenciarapidaa 0°, 15°, 30° y 45°.

PARAREALIZARELAJUSTE:Suba lapalancadeaiuste

dela basequeestaenla parteinlerior de dicha basedela

maneraque semuestraenla iluslracibnymueva labase

ligeramentehaciaarrasparadesacoplarla lengQetade

fijacion(Fig.14).

Posicionelabaseenelangulodeseado,luegoempuje LENGIJETA

haeiaadelanteparaacoplarla leng[ietadefijacion y baje

la palancadeaiustepapamantenerelajuste.Despuesde

aiustarlabase,hagaunccrte demuestrapara

comprobarel angulo(Fig.14).

al realizarcodes inclinadoso en

esquina.Despu_sdeterminartaabedura, vuelvaacada

esquinay cSrteladesdeelsentidocontrario para

completareianguio recto. No intente cortar mediante

descensovertical en materiales duros como pot

ejemplo acero.

Nota:Si la baseseafloja, sepuedeusar undestorniliador

paraapretarel tomi!loubicado eniapalancadeajustede

la basey tuegoreajustarlapalancadeajustedela base.

DEFIJACli)N

-28-

PALANCADEAJUSTE

DELABASE

I

Page 29

CORTEDEMETAL

AIcortar metal,fJjeei materialcen abrazaderas.

AsegOresemuy biende que haceavanzarla sierra

lenlamenle.Utiliee velocidades m_s bajas. No tuerza,

doble,ni luerce lahoja.Si lasierrasaltao rebota,utilice

unahoiacon dientesmas fines. Si parecequela hojase

atascaalcortar metalblando,utilice unaheja con

dientesm_s gruesos.

Paracortar conm_s facilidad,lubrique la hojaconuna

barrade cerade code,si estadisponible,o con

querosenocuandosecoda aluminio oconaceitede

cortecuandose eortaaeero. Elmetaldelgadose debe

colocarentre dos piezasdemadera ose debefijar

TOPE-GUIAPARACORTARAL HILO

YGUIADECORTECIRCULAR

Esteaccesoriose encuentradisponiblea uncosto

adicionaLSeutiliza paracodes rectoy circular r_pidosy

precisos(Fig.15).

COLOCACIONDELTOPE-GUIAPARACORTARAL HItO

1. ]ntroduzcala barradeltope-guiaparacortar al hilo a

tray,s delasranurasde queest_dotadala basedesde

cualquieradelos dos lades de labasecon la guia de

bordeorientadahaciaABAJO(Fig.15).

2.Enrosque el torni!lo defijaci6n desde debajo de la

baseen el aguiero roscado de Iaabrazadera que esta

en el lade izquierdo de la base yapriete lirmemente el

tomillo defijaci6n cen un destorniliador parafijar en

su sitie la barra del tope-gufa para cortar aFhilo.

tuedementecon abrazaderasa una solapiezade madera

(lamaderasobre el metal).Tracelaslineaso el dise5o

decode sobre ]apiezasuperior demadera.

AIcortar aluminio extrudadoo hierroangular,fije la

piezade trabajo en un torniilo decarpinterodebancoy

aserrecercade ias mordazasdel tornillo de earpintero.

Cuandoseaserrantubes y el di_.metroes mayor que la

profundidadhastalacual ]a _oiapuedepenetrar,eorte

atravesandolapareddelostubes y luego introduzcala

hojaenel corte girando eitube a medidaqueva

aserrando.

ASRAZADERA

TORNILLO

DE--_

FIJACION

GUIADEBORDEHACIAABAJO

--' RANURA

CORTERECTO

Unavezque se hayacolocadoel tope-guiaparacedar al

bile, midadesdeel bordede Ispieza detrabajo basrala

lineadeco[re, coloque laguia de be[de del tope-guia

paracortaral bile a la misma distanciay apriete

firmementeeltornillo de fijacion (Fig. 16).

TORNILLODE

FIJACION

ANCHO

DESEADO

LINEADECORTE

-29-

Page 30

CORTECIRCULAR

1. Antesde coIocareltope-gu[a paracor_aralhiIo, trace

undrculo y claveunclavofino enel centrodetcircuIo.

2. Per[ore un corte o realicelo mediantedescenso

vedical cerca del borde de]circulo, apague la sierra y

deaconecfe el enchufe de la fuente de energia

(Fig. 17).

3. Coloqueel tope-guia para cortar al hilo en la sierra

con la gu[ade borde orientada hacia ARRIBA.

4. Pongala punta central del metal,on lagu[a de

borde,en e! orificioen el eentro del cireulo. Afin de

quela guia de borde corte un c[rculo, elpunto de

centro de metal D EBEestaralineado con la hoja de

lasierra (ver Fig.18),

5. Mida la distancia desdeel agujero seleccionado

hasta la hoja Debeser igual al radio de] circuto.

6. Introduzcaelenchufeen la luenle deenergia,sujetela

sierrafirmemente, apfiete el gatiI!oy empujela sierra

lentamentehaciaadelante.Parahacer unagujero,code

desdedentrodelcirculo; para hacerruedas odiscos,

cortedesdefuera.

Consejoparacodar: Cortelentamenteparaquelahoja

permanezcarectaenel corte.Coloquepeque_ascuSas

enelcode, tel como semuestraenla Fig. 17, paraevitar

queel circulo interior se separecuando usted estecerca

dei final del code.

1[ef il'J

CUbA

/

\

\\

GUIADEBORDEHACIAARRIBA

LAHOJADESEESTAR

ALINEADACONLAPUNTA

DECENTRODEMETAL

Punlade

Centrode Metal

l t--b

-30-

Page 31

Servicio

El manlenimiento preventive

realizado per personalno

autorizadopude dar lugar a la colocaci6n incorrecta

de cablesy componentesinternesque podria

constituirun peligro serio, Recomendamosque todo

el servicio delaherramient& incluyendo el servicio de]

laser, searealizadoper un Centrede Piezasde

Repuestoy ReparacionesSears.

Lubricaci6n de las herramienlas

Suherramienla hasido iubdcada adecuadamente y

esta lista parala utflizaci6n. Se recomienda quelas

herramientas con engranajes se vuelvan a engrasar

con un lubricante especial paraengranajes en cada

cambio deescobiilas.

Escobillasdecarb6n

Losescobfllasyel conmutadorde laherramienlahen

sidodisefiadospara muchas horasde servicio fiabie.

Paramantenerun rendimiento6primodel motor,

recomendamosquecadadosa seismesesse examinee

lasescobilla&S{_losedebenusarescobillasderepuesto

Searsgenuinasdise_adasespecificamenteparasu

herramienta.

Rodamientos

Despudsde 300-400 horas deluncionamiento,o

despuesde cadasegundocambiode escobillas, los

rodamientos debencambiarseen un

Centrodeservicio autofizade.Losrodamientosque se

vuelvenruidosos(debidoa la pesadacargaoal corte de

materialesmuy abrasivos)debensersustituidos

inmediatamenteparaevitarel sobreealentamientooel

falledel motor.

Limpieza

_Para evitar accidentes

herramienta dela luentede eeerg[aantesde la

limpiezao de la realizaci6ndecualquier

mantenimiento. Laherramientase puedelimpiarm_s

eficazmentecon airecomprimido seco.Usegafasde

seguridadsiemprequelimpie herramientasconaire

comprimido.

Lasaberturasdeventilaci6ny laspalancasdeirlterruptor

deben mantenerseIimpiasy libres de materiasextra5as.

No intentelimpiar introduciendo objetospuntiagudosa

trav6sde]asaberturas.

_ Cieilosagenlesde limpieza y

plastics,Algunosde estosson: gasolina,tetracloruro de

carbon& disolventesdelimpiezaciorados,amon[aeoy

detergentesdom_sticos queeontienenamoniaeo.

desconectesiempre la

disolventesdoriantaspiezasde

Si es necesario un cord6nde extensi6n, se debe usar un cordbn conconductoresde

herramienta. Esto evitar6,caidas de tensi6n excesivas, perdida de poteneiao recalentamiento. Las

herramientas conectadas a tierra deben usar cordones de extensi6n de 3 hiios quetengan enchufes de3

terminales y reeept_iculospara3 terminales.

tamafio adecuado que sea capaz de transporterla corrienteflecesaria parela

TAMANOSRECOMENDADOSDECORDONESDE EXTENSION

HERRAMIENTASDE 120 V CORRIENTEALTERNA

Capacidad

nominal

enomperissde

laherramienta

3-6

6_8

8-10

10-12

12-16

NOTA: Cuantomas peque_oes el nL]merode calibre, m_s gruesoeselcord6n.

Tamafiode]cordonenA.W.G.

Leogituddelcord6nenpies

25 50 100 150

18 16 16 14

18 16 14 12

18 16 14 12

16 16 14 12

14 12

Tamaflosdelcableenmm2

Longituddelcord6nenmetros

15 30 60 120

0,75 0,75 1,5 2,5

0,75 1,0 2,5 4.0

0,75 1,0 2,5 4.0

1,O 2,5 4,0 --

-31-

Page 32

Get it fixed, at your home or ours!

Your Home

For repair in your home of all major brand appliances,

lawn and garden equipment, or heating and cooling systems,

no matter who made it, no matter who sold it!

For the replacement parts, accessories and

owner's manuals that you need to do-it-yourself.

For Sears professional installation of home appliances

and items like garage door openers and water heaters.

1-800-4-MY-HOME e Anytime, day or nght

(1-800-469-4663) (U.S.A. and Canada)

www.sears.com www,sears,ca

Our Home

For repair of carry-in products like vacuums, lawn equipment,

and electronics, ca] or go on-line for the nearest

Sears Parts and Repair Center.

1-800-488-1222 Anybme, day or night (U,S.A. only)

www,sears.com

To purchase a protection agreement on a product serviced by Sears: