Operator's Manual

CRIIFTSM

CompuCarve TM System

Model Number: 133.217540

Please save this manual for future reference.

CAUTION: Read and follow all Safety

Rules and Operating Instructions before

using this product.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

• Warranty

• Safety

• Setup

• Features

• Operation

• Maintenance

• Troubleshooting

The CompuCarve TM System, with its computer-controlled 3D carving and

general woodworking capabilities, is a revolutionary breakthrough in

bench-top power tool design. This manual will explain the many features

of the CompuCarve machine to help make creative carving operations

pleasant and rewarding.

Safety, performance, and dependability have been given top priority in the

design of the CompuCarve System. Read carefully through this entire

operator's manual before using the new CompuCarve System. Pay close

attention to the Rules For Safe Operation and all Safety Alert Symbols. If

the CompuCarve System is used properly and only for what it is intended,

it will provide many hours of safe, reliable service.

For access to online information about the CarveWright Design Software

visit http://www.carvewriqht.com.

WARNING or CAUTION:

Look for this symbol to point out important safety precautions.

It means attention -- Personal safety is involved!

Look for this symbol to point out helpful information and hints

that will allow maximum efficiency and enjoyment of the

CompuCarve system.

CRAFTSMAN ONE-YEAR LIMITED WARRANTY

If this tool fails due to a defect in material or workmanship within one year or 200 hours of

use (whichever comes first) from the date of purchase, call 1-800-4-MY-HOME ® to

arrange for repair.

Consumable materials are not subject to warranty, and include, but are not limited to the

flex shaft, cutting/routing bits, grit surface drive belts, and lubricants.

Using the machine with unapproved cutting bits will void the warranty.

This warranty gives you specific legal rights, and you may also have other rights, which

vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

Please keep the box and packaging from the CompuCarve machine. This

box will be used for shipping in the event that the unit needs servicing.

Sears, Roebuck and Co. CompuCarve TM System (Rev 1.13) 01/06/07 i

INTRODUCTION .................................................................................................. I

TABLE OF CONTENTS .................................................................................... II

SPECIFICATIONS ............................................................................................... 3

SAFETY ................................................................................................................. 4

ELECTRICAL CONNECTIONS ....................................................................... 7

STORING THE MACHINE ................................................................................ 7

GLOSSARY ........................................................................................................... 8

UNPACKING THE COMPUCARVE MACHINE ........................................... 9

ITEMS INCLUDED WITH THE COMPUCARVE SYSTEM ........................................... 9

HARDWARE FEATURES ................................................................................ 12

OPERATION ...................................................................................................... 15

USING THE COMPUCARVE SYSTEM .................................................................... 15

CREATING PROJECTS WITH THE CARVEWRIGHT TM SOFTWARE .......................... 15

NAVIGATING THE MENUS VIA THE KEYPAD AND LCD ...................................... 16

Keypad Data Entl T ....................................................................................... 17

BUILT-IN FUNCTIONS ......................................................................................... 17

Rip or Cross (_lt ........................................................................................... 18

Jointing and Squaring ................................................................................... ] 8

Bevel and Miter Cuts .................................................................................... 19

Routing an Edge ............................................................................................ 19

Measuring a Board ....................................................................................... 20

CARVING A PROJECT .......................................................................................... 20

Inserting a Board .......................................................................................... 20

Workpiece Preparation ................................................................................. 23

Jogging the Cutting Truck ............................................................................ 25

Auto Jigging Function ................................................................................... 25

Workpiece Size Limitations ........................................................................... 26

CUTTING BITS .................................................................................................... 26

Bit Adapter Assembly .................................................................................... 27

PROPER BIT INSTALLATION ................................................................................ 28

Approved Bits ................................................................................................ 28

Cocking the Quick Release Chuck ................................................................ 29

Bit Assembly Installation .............................................................................. 29

Bit Assembly Removal ................................................................................... 30

CARE AND MAINTENANCE .......................................................................... 31

GENERAL TIPS AND HELPFUL REMINDERS .......................................... 33

TROUBLESHOOTING ..................................................................................... 36

Sears, Roebuck and Co. CompuCarve TM System (Rev 1.13) 01/06/07 ii

Package Size ................................................. 28.5" Long x 20.25" Wide x 18" Deep

Package Weight ............................................................................ 78 Ibs (35.4 kg)

Machine Weight ............................................................................. 70 Ibs (31.8 kg)

Cut Motor Speed (No Load) ................................................................. 20,000 rpm

Cut Motor Horsepower (Peak) ..................................................................... 1.0Hp

Electrical Rating .................................................................. 110VAC at 8 A, 60 HZ

Power Cord Length .................................................................................... 6 feet

Movement Velocity:

Length Axis .......................................................................... 2" per second

Width Axis .......................................................................... 12" per second

Up/down Axis ...................................................................... 12" per second

Workpiece Size (Min):

Length ..................................................................................... 7.0 inches

Width ....................................................................................... 1.5 inches

Height ...................................................................................... 0.5 inches

Workpiece Size (Max):

Length ..................................................................... 12' (Limited by weight)

Width ..................................................................................... 14.5 inches

Height ...................................................................................... 5.0 inches

Sears, Roebuck and Co. CompuCarve TM System (Rev 1.13) 01/06/07 3

General Safety Rules For Power Tools

ALWAYS WEAR EYE PROTECTION. The operation

of any power tool can result in foreign objects being

thrown into the eyes, which can result in severe injury.

Before beginning tool operation, always wear safety

goggles or safety glasses with side shields and a full-

face shield when needed. A Wide Vision Safety Mask is

recommended for use over eyeglasses or standard

safety glasses with side shields. Always wear eye

protection that is marked to comply with ANSI Z87.1.

ACAUTION

ALWAYS WEAR EAR PROTECTION. Power tools

can generate high levels of noise that will cause

permanent hearing loss. Before beginning tool

operation, always don hearing protection to minimize

the risk of damaging hearing.

A CAU_ON

ALWAYS BE ALERT. Operating electrically powered

machinery poses a risk of serious physical injury to

hands and fingers. Always operate machinery with

ALL guards in place and in good working order. DO

NOT attempt to defeat safety guards!

• KNOW THE POWER TOOL. Read the operator's manual carefully. Learn the

machine's applications and limitations as well as any specific potential hazards related

to this tool.

• MAINTAIN TOOLS WITH CARE. Keep cutting tools sharp and clean for better and

safer performance. Follow instructions for lubricating and changing accessories.

• USE THE RIGHT TOOL FOR THE JOB. Do not force the tool or attachment to do a

job for which it was not designed. Use it only the way it was intended.

• DO NOT OVERREACH. Keep proper footing and balance at all times.

• KEEP WORK AREA CLEAN. Cluttered work areas and workbenches invite

accidents. Keep floors clean and free of accumulated dust. DO NOT leave tools or

pieces of wood on top of the machine or on support extensions while it is in operation.

• KEEP WORK AREA WELL LIGHTED. Good lighting promotes safety and good

output.

• DO NOT USE IN DANGEROUS ENVIRONMENT. Do not use power tools near

gasoline or other flammable liquids or explosive fumes. Do not use in damp or wet

conditions.

• WEAR A DUST MASK to keep from inhaling fine particles. Use wood dust collection

systems whenever possible.

Sears, Roebuck and Co. CompuCarve TM System (Rev 1.13) 01/06/07 4

• NEVER LEAVE A RUNNING TOOL UNATTENDED. Turn the power off and do not

leave the tool until it comes to a complete stop.

• USE THE PROPER EXTENSION CORD. Make sure the extension cord is in good

condition. Use only a cord heavy enough to carry the current the product will draw

(see under Electrical Connections the proper gauges and lengths to use.)

• DISCONNECT TOOL from the outlet when not in use or before servicing.

• DRESS PROPERLY. Do not wear loose clothing, gloves, neckties, rings, bracelets,

or other jewelry near a running machine. They can get caught and draw the user into

moving parts. Wear protective hair covering to contain long hair. Non-slip footwear is

recommended.

• GUARD AGAINST ELECTRICAL SHOCK by preventing body contact with grounded

surfaces such as pipes, radiators, or appliances while using the tool.

• GROUND ALL TOOLS. (See Electrical Connections)

• DO NOT ABUSE POWER CORD. Never yank the cord to disconnect it from

receptacle. Keep the cord from heat, oil, and sharp edges. Inspect power cords

regularly and repair or replace if damaged.

• PROTECT VISITORS AND CHILDREN. All visitors should wear safety glasses,

hearing protection, and be kept a safe distance from work area. Do not let visitors

contact the tool or extension cord while it is operating.

• MAKE WORKSHOP CHILDPROOF. Use padlocks and master switches, and remove

switch keys

• AVOID ACCIDENTAL STARTING. Be sure switch is offwhen plugging in the tool.

• DO NOT OPERATE ANY POWER TOOL WHILE UNDER THE INFLUENCE OF

DRUGS, ALCOHOL, OR ANY MEDICATION AFFECTING ALERTNESS.

• STAY ALERT AND EXERCISE CONTROL. Stay alert and use common sense. Do

not operate the tool when tired. Do not rush.

Specific Safety Rules & Precautions For The CompuCarve.

• READ THIS ENTIRE MANUAL CAREFULLY

WARNING: Look for this symbol throughout this manual. It

points out important safety precautions. It means attention --

Personal safety is involved!

• WHILE USING MACHINE, make sure that the power to the machine is kept constant.

Using other high power draw machines on the same power leg may cause the

machine to lose position and damage the workpiece.

• BEFORE MAKING A CUT, be sure that all mechanical adjustments and settings are

secure. Until thoroughly familiar with the operation, it is a good idea to create a checklist to

help ensure all are secure.

• REMOVE WRENCHES AND ADJUSTING KEYS. Get in the habit of checking - before

turning on the tool - that any hex keys or adjusting wrenches are removed from tool.

• CHECK FOR DAMAGE. Before using the tool, routinely check for any damaged parts,

including guards. Look for anything that could interfere with proper operation and

performance, such as any binding or misalignment of moving parts or any sign of

instability in the carving system. A damaged part must be properly repaired or replaced by

a qualified service technician at a repair center to avoid risk of personal injury.

• BE SURE THE BIT CLEARS THE WORKPIECE. Never start the system with the bit

touching the work piece.

• DO NOT HOLD OR STRESS THE FLEX SHAFT DURING OPERATION. Placing stress

on the shaft during operation will accelerate wear and cause premature failure.

• NEVER ATTEMPT TO DEFEAT SAFETY DEVICES OR INTERLOCKS. Guards and

other safety devices protect the user from injury; do not try to bypass or remove them.

• KEEP HANDS AWAY FROM CUTTING AREA. When the machine is running, never

reach underneath the workpiece or into the blade-cutting path for any reason.

Sears, Roebuck and Co. CompuCarve TM System (Rev 1.13) 01/06/07 5

• DO NOT PLACE HANDS ON THE GRIT SURFACE DRIVE BELTS DURING

OPERATION. Belts in motion could drag a hand into the machine and cause injury.

• AVOID AWKWARD OPERATIONS AND HAND POSITIONS where a sudden slip could

cause hands to move into the cutting area.

• NEVER OPERATE THE MACHINE WITHOUT THE MUFFLER BAG IN PLACE. The bag

captures dust and debris from machining operations.

• NEVER LOOK INTO THE VACUUM OUTLET DURING MACHINE OPERATION.

Machining debris could be thrown out at high speed and cause eye injury.

• TURN OFF THE SYSTEM IF A STRANGE NOISE OR HEAVY VIBRATION OCCURS.

Immediately turn off the system. Then locate and correct the source of the problem before

restarting.

• USE A SUPPORT FOR LONG WORKPIECES. To minimize the risk of over stressing the

machine, use a sturdy "outrigger" support when carving long workpieces more than 36

inches in length. Never substitute a person for a proper support.

• USE RECOMMENDED ACCESSORIES. Using improper accessories may risk injury.

Consult the accessories section for recommended accessories.

• USE ONLY APPROVED CUTTING BITS to ensure quality and to avoid equipment

damage or injury.

• KEEP BITS CLEAN AND SHARP. Sharp bits minimize workpiece burning, poor cut

quality, and stress to the system. Keep bits free of rust, grease, and pitch.

• USE GLOVES TO HANDLE HOT CUTTING BITS. Recently used cutting bits are hot,

and all bits have sharp edges; gloves will help prevent cuts and burns.

• USE ONLY ORIGINAL REPLACEMENT PARTS. Repairs using other than original

replacement parts may create a hazard as well as damage to the machine. To ensure

proper repair using original replacement parts, a qualified service technician at a Sears

service center should make all repairs, whether electrical or mechanical.

• DO NOT USE THE TOOL IF THE POWER SWITCH DOES NOT TURN IT ON AND OFF.

Have defective switches replaced by a Sears service center.

• CUT ONLY WOOD, PLASTIC OR WOOD-LIKE MATERIALS. Do not cut metal.

• NEVER cut more than one piece at a time.

• DO NOT STACK more than one workpiece in the CompuCarve at a time.

• BE SURE THE WORKPIECE PATH IS FREE OF NAILS. Inspect for, and remove all

nails, staples, and protruding features from the lumber before cutting.

• KEEP TOOL DRY, CLEAN, AND FREE FROM OIL AND GREASE. Always use a clean

cloth when cleaning. Never use brake fluids, gasoline, petroleum-based products, or any

solvents to clean the system.

• DO NOT STAND ON TOOL. Serious injury can occur if tool is tipped or if the cutting tool

is unintentionally contacted.

WARNING: Operation of this tool should not be attempted until all

instructions, safety rules, etc. contained in this manual have been read thoroughly and

understood completely. Failure to do so can result in accidents involving fire, electric

shock, or serious personal injury. Save the operator's manual and review it frequently for

continuing safe operation and for instructing others who may use this tool.

WARNING! Some dust created by power sanding, cutting, and drilling

contains chemicals known to cause cancer, birth defects, allergic reactions, or

reproductive damage. Some examples of these chemicals are:

• Lead from lead-based paints

• Arsenic, copper, and chromium from chemically treated lumber

• Wood resin

• Plastic solvents

• Silica Dust

Sears, Roebuck and Co. CompuCarve TM System (Rev 1.13) 01/06/07 6

To reduce exposure to these chemicals:

• Work in a well ventilated area

• Work with approved safety equipment, such as dust masks that are specially

designed to filter out microscopic particles

• Keep the machine and work area clean

IMPORTANT NOTE: Servicing requires much care and specialized

knowledge of the system and should be performed only by a qualified service technician.

For service, return the machine to the nearest repair center in the original packaging.

POWER SUPPLY

The CompuCarve woodworking machine is controlled by precision electronics, tt should

be connected only to a power supply that is 120 volts nominal, 60 Hz, AC (normal

household outlet). It should not be connected to a 240-volt power supply. This tool will

not operate on direct current (DC). If the machine does not operate when plugged into

an outlet, check to see that the fuse or circuit breaker for the outlet is not open and that

the outlet has power available. The plug has polarized terminals so make sure that it is

inserted properly into the outlet.

EXTENSION CORDS

When using a power tool at an extended distance from the power source, use an

extension cord heavy enough to carry the current that the tool will draw. An undersized

extension cord will cause a drop in line voltage, resulting in a loss of power and causing

potential damage to the machine. Use the chart provided below to determine the

minimum wire size required in an extension cord. Only jacketed cords listed by

Underwriter's Laboratories (UL) should be used.

Length of Extension Cord vs. Wire Size (American Wire Gage - AWG)

Up to 10 feet - 18 AWG minimum

10 to 50 feet - 14 AWG minimum

Over 50 feet - not recommended

When working with the tool outdoors, use an extension cord that is designed for outside

use (This is indicated by the letters WA on the power cord's outer jacket). Before using

an extension cord, inspect it for loose or exposed wires and cut or worn insulation.

It is important that the CompuCarve be stored indoors in a low humidity environment.

Never expose the machine to temperatures of over 110 degrees Fahrenheit for any

extended period of time. Make sure that all exposed metal surfaces on the quick release

chuck and bit adapters are well oiled for operation and storage.

Be sure to keep your box and packing foam in case your machine

needs to be returned for service.

Sears, Roebuck and Co. CompuCarve TM System (Rev 1.13) 01/06/07 7

Bevel Cut

A cut made across a workpiece that results in an angle other than 90° to

the table surface.

Cross Cut

A cutting operation across the grain or width of the workpiece.

Head Screw

The threaded shaft on each side of the machine by which the head is

raised and lowered when activated by the head crank.

Joint or Jointing

A trim cut parallel to the grain of the wood on the edges of a board to

create 90-degree angle with the top and bottom surface. A joint will create

a smooth and, most important, straight edge. Often used in preparation

for a glue joint to attach the board to another piece of wood.

LCD

Liquid Crystal Display - The two-line text display found above the keypad.

Miter Cut

A vertical cut made at any angle other than 0° across the workpiece.

Molding

A shaping cut that gives a varied profile to the workpiece.

Pitch

A sticky, sap-based substance found in some woods.

Rip Cut

A cut made parallel to the grain or length of the workpiece.

Rout

To hollow, scoop or carve out.

Snipe

An unwanted depression formed near the end of a workpiece caused by

the uneven transition of the workpiece from one support surface to

another. Snipe can be minimized by ensuring that auxiliary outfeed

supports are even with machine support surfaces. The free end of the

workpiece should also be well supported so that its weight does not place

lifting pressure at the end of the workpiece being carved.

Squaring Cut

A smoothing trim cut across the grain of the wood on the end of a board

to create 90-degree angles with the top, bottom, and side edges.

Vector Cut

A cutting operation that is composed of a group of strokes from one point

to another. These can be lines, circles, splines or any other number of

geometric elements.

Workpiece

The item on which the cutting operation is being performed. The surfaces

of a workpiece are commonly referred to as faces, ends, and edges.

Sears, Roebuck and Co. CompuCarve TM System (Rev 1.13) 01/06/07 8

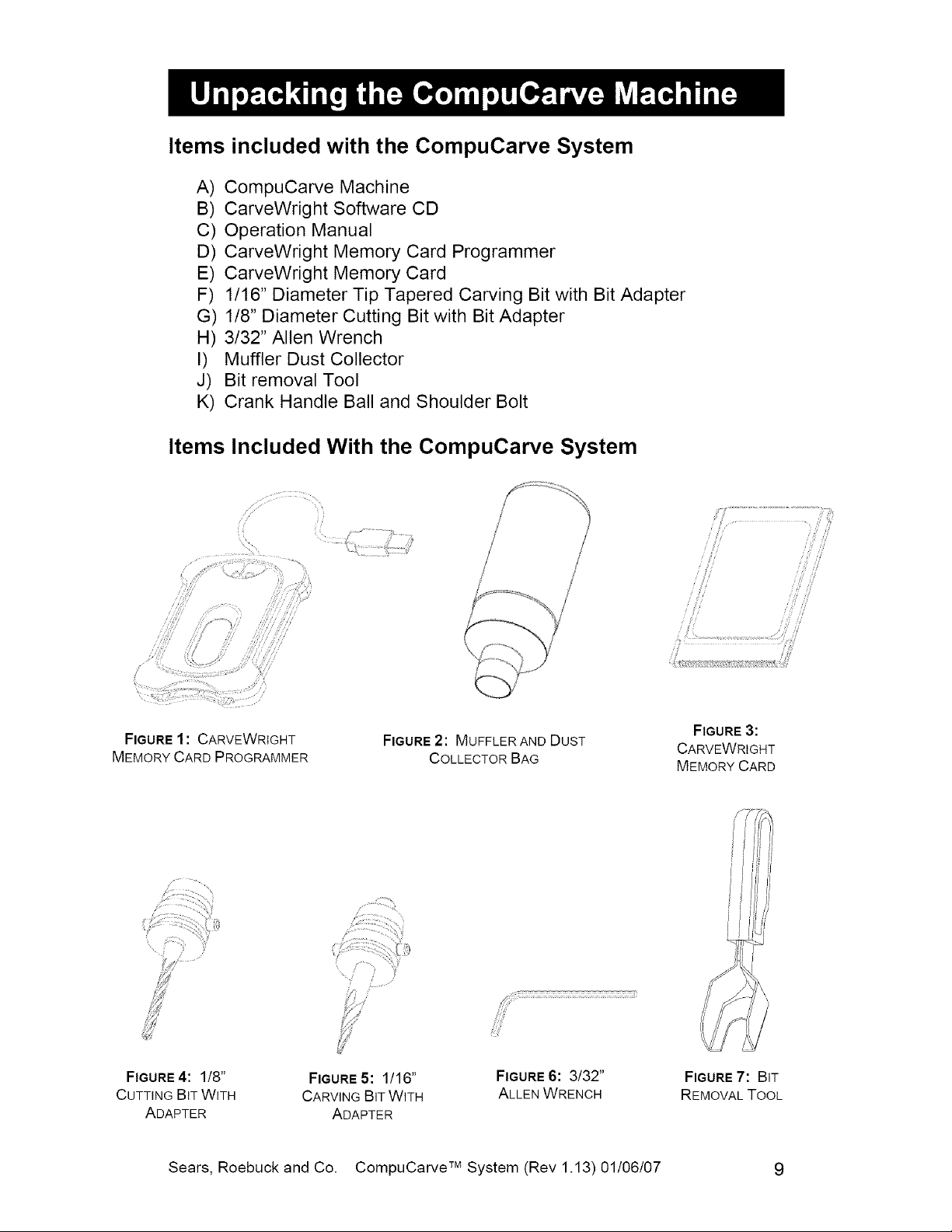

Items included with the CompuCarve System

A) CompuCarve Machine

B) CarveWright Software CD

C) Operation Manual

D) CarveWright Memory Card Programmer

E) CarveWright Memory Card

F) 1/16" Diameter Tip Tapered Carving Bit with Bit Adapter

G) 1/8" Diameter Cutting Bit with Bit Adapter

H) 3/32" Allen Wrench

I) Muffler Dust Collector

J) Bit removal Tool

K) Crank Handle Ball and Shoulder Bolt

Items Included With the CompuCarve System

\,i?,,

//

FIGURE 1: CARVEWRIGHT

MEMORY CARD PROGRAMMER

FIGURE2: MUFFLERAND DUST

COLLECTOR BAG

/

/iY //

FIGURE 3:

CARVEWRIGHT

MEMORY CARD

FIGURE4: 1/8"

CUTTING BIT WITH

ADAPTER

Sears, Roebuck and Co. CompuCarve TM System (Rev 1.13) 01/06/07 9

FIGURE 5" 1/16"

CARVING BIT WITH

ADAPTER

FIGURE 6: 3/32"

ALLEN WRENCH

FIGURE7: BIT

REMOVAL TOOL

Unpacking and Setting Up the CompuCarve System

1. Remove the top packaging foam: After opening the shipping box,

carefully remove the top molded foam packing from the machine.

Located in the top tray are items B through K listed above.

2. Remove the machine from box: With a helper, lift out the machine

and place it on a sturdy table or bench. Fold down the Outfeed Support

Tables. Remove the plastic film covering the top clear safety cover.

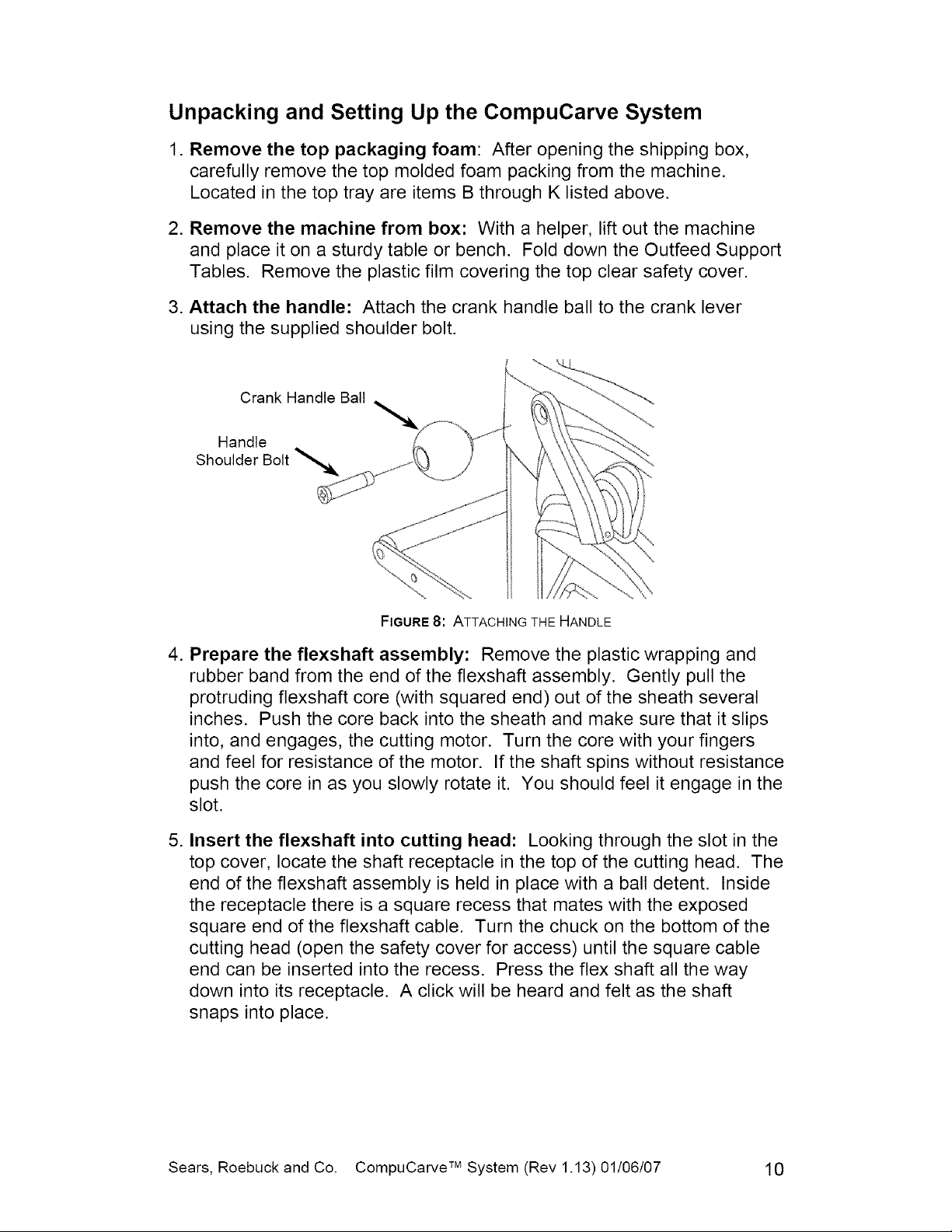

3. Attach the handle: Attach the crank handle ball to the crank lever

using the supplied shoulder bolt.

Crank Handle Ball

Handle

Shoulder Bolt

FIGURE 8: ATTACHING THE HANDLE

4. Prepare the flexshaft assembly: Remove the plastic wrapping and

rubber band from the end of the flexshaft assembly. Gently pull the

protruding flexshaft core (with squared end) out of the sheath several

inches. Push the core back into the sheath and make sure that it slips

into, and engages, the cutting motor. Turn the core with your fingers

and feel for resistance of the motor. If the shaft spins without resistance

push the core in as you slowly rotate it. You should feel it engage in the

slot.

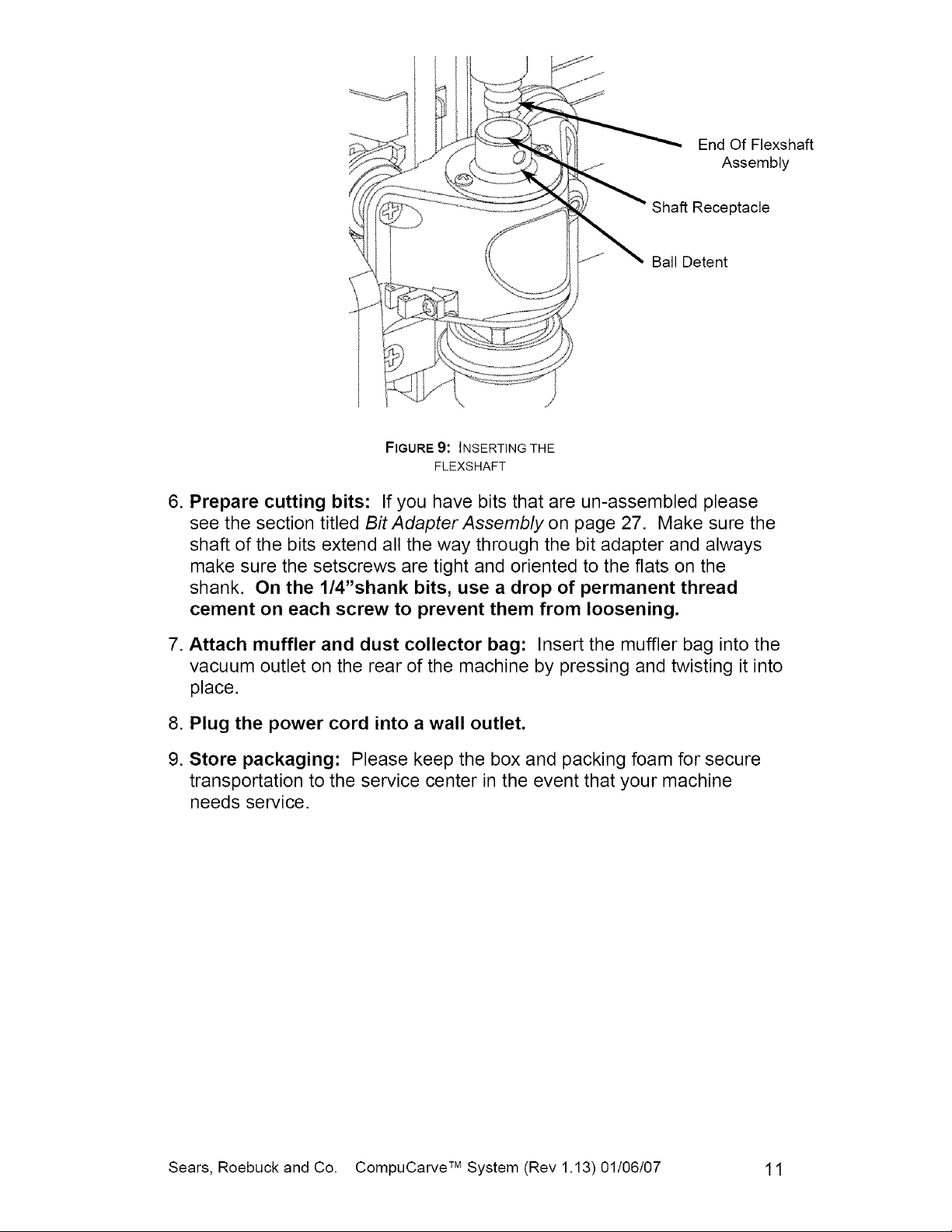

5. Insert the flexshaft into cutting head: Looking through the slot in the

top cover, locate the shaft receptacle in the top of the cutting head. The

end of the flexshaft assembly is held in place with a ball detent. Inside

the receptacle there is a square recess that mates with the exposed

square end of the flexshaft cable. Turn the chuck on the bottom of the

cutting head (open the safety cover for access) until the square cable

end can be inserted into the recess. Press the flex shaft all the way

down into its receptacle. A click will be heard and felt as the shaft

snaps into place.

Sears, Roebuck and Co. CompuCarve TM System (Rev 1.13) 01/06/07 10

End Of Flexshaft

Assembly

Shaft Receptacle

Ball Detent

FIGURE 9" INSERTING THE

FLEXSHAFT

6. Prepare cutting bits: If you have bits that are un-assembled please

see the section titled Bit Adapter Assembly on page 27. Make sure the

shaft of the bits extend all the way through the bit adapter and always

make sure the setscrews are tight and oriented to the flats on the

shank. On the 1/4"shank bits, use a drop of permanent thread

cement on each screw to prevent them from loosening.

7. Attach muffler and dust collector bag: Insert the muffler bag into the

vacuum outlet on the rear of the machine by pressing and twisting it into

place.

8. Plug the power cord into a wall outlet.

9. Store packaging: Please keep the box and packing foam for secure

transportation to the service center in the event that your machine

needs service.

Sears, Roebuck and Co. CompuCarve TM System (Rev 1.13) 01/06/07 11

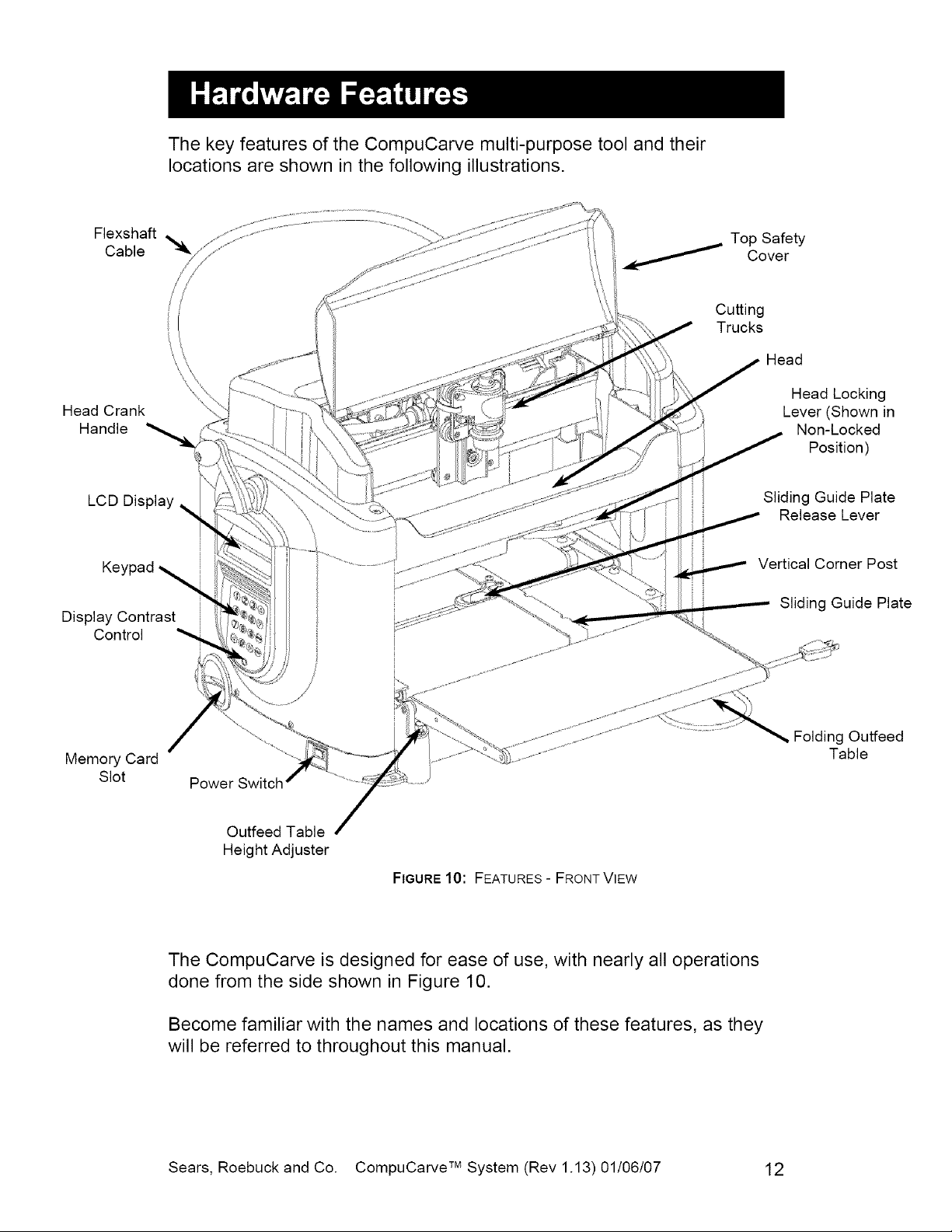

The key features of the CompuCarve multi-purpose tool and their

locations are shown inthe following illustrations.

Flexshaft

Cable

Head Crank

Handle

LCD Display

Keypad

Display Contrast

Control

Top Safety

Cover

" Cutting

Trucks

Head

Head Locking

Lever (Shown in

Non-Locked

Position)

Sliding Guide Plate

Release Lever

Vertical Corner Post

Sliding Guide Plate

Memory Card

Slot

• Folding Outfeed

Table

Outfeed Table

Height Adjuster

FIGURE 10" FEATURES - FRONT VIEW

The CompuCarve is designed for ease of use, with nearly all operations

done from the side shown in Figure 10.

Become familiar with the names and locations of these features, as they

will be referred to throughout this manual.

Sears, Roebuck and Co. CompuCarve TM System (Rev 1.13) 01/06/07 12

Loading...

Loading...