Page 1

Owner's Manual

II:RRFTSMRN'I

RAILS AND FENCE SYSTEM

FOR CRAFTSMAN 10 in. TABLE SAWS MODEL NOS.

315.228310, 315.228410, 315.228510, 113.299310, 113.299410, 113.299510

Item No.

_929993

Save this manual for

future reference.

_, CAUTION: Read and follow

all Safety Rules and Operating

Instructions before first use of

this product.

Customer Help Line: 1-800-932-3188

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

Visit the Craftsman web page: www.sears.com/craftsman

TABLE SAWNOTINCLUDED

• SAFETY

• LOOSE PARTS

• PREPARATION

• INSTALLATION

• ALIGNMENT

972000-662

3-99

Page 2

READ ALL INSTRUCTIONS

• READ THESE INSTRUCTIONS AND THE

INSTRUCTIONS FOR YOUR TABLE SAW

THOROUGHLY before using accessories.

• ALWAYS WEAR SAFETY GLASSES. Everyday

eyeglasses have only impact-resistant lenses;

they are NOT safety glasses.

• ALWAYS DISCONNECT SAW FROM POWER

SUPPLY BEFORE MAKING ADJUSTMENTS

KNOW YOUR POWER TOOL. Read the owner's

manual for the Table Saw carefully. Learn the

saw's applications and limitations as well as the

specific potential hazards related to this tool.

KEEP THE WORK AREA CLEAN. Cluttered

work areas and work benches invite accidents.

OR ADDING ACCESSORIES. Make sure the

switch is off when reconnecting to power supply,

• SAVE THESE INSTRUCTIONS. Refer to them

frequently and use to instruct other users. If you

loan someone this tool, loan them these instruc-

tions also.

DO NOT leave tools or pieces of wood on the

saw while it is in operation.

Look for this symbol to point out important safety precautions. It

means attention.q! Your safety is involved.

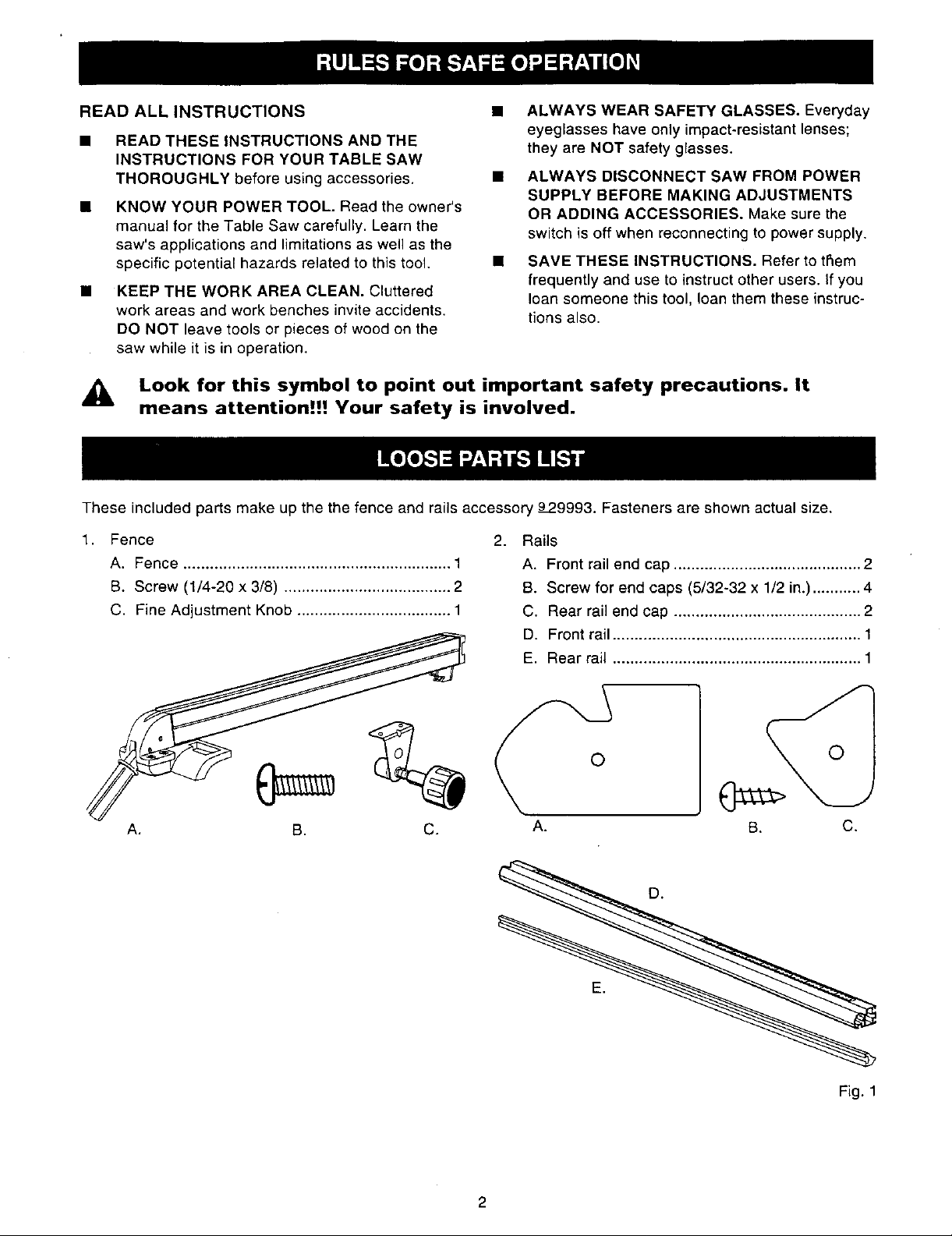

These included parts make up the the fence and rails accessory 9P9993. Fasteners are shown actual size.

1. Fence

A, Fence ............................................................. 1

B. Screw (1/4-20 x 3/8) ...................................... 2

C. Fine Adjustment Knob ................................... 1

A. B. C.

2.

Rails

A. Front rail end cap ........................................... 2

B. Screw for end caps (5/32-32 x 1/2 in.) ........... 4

C, Rear rail end cap ........................................... 2

D. Front rail ......................................................... 1

E. Rear rail ......................................................... 1

O

A. C.

B.

©

Fig. 1

2

Page 3

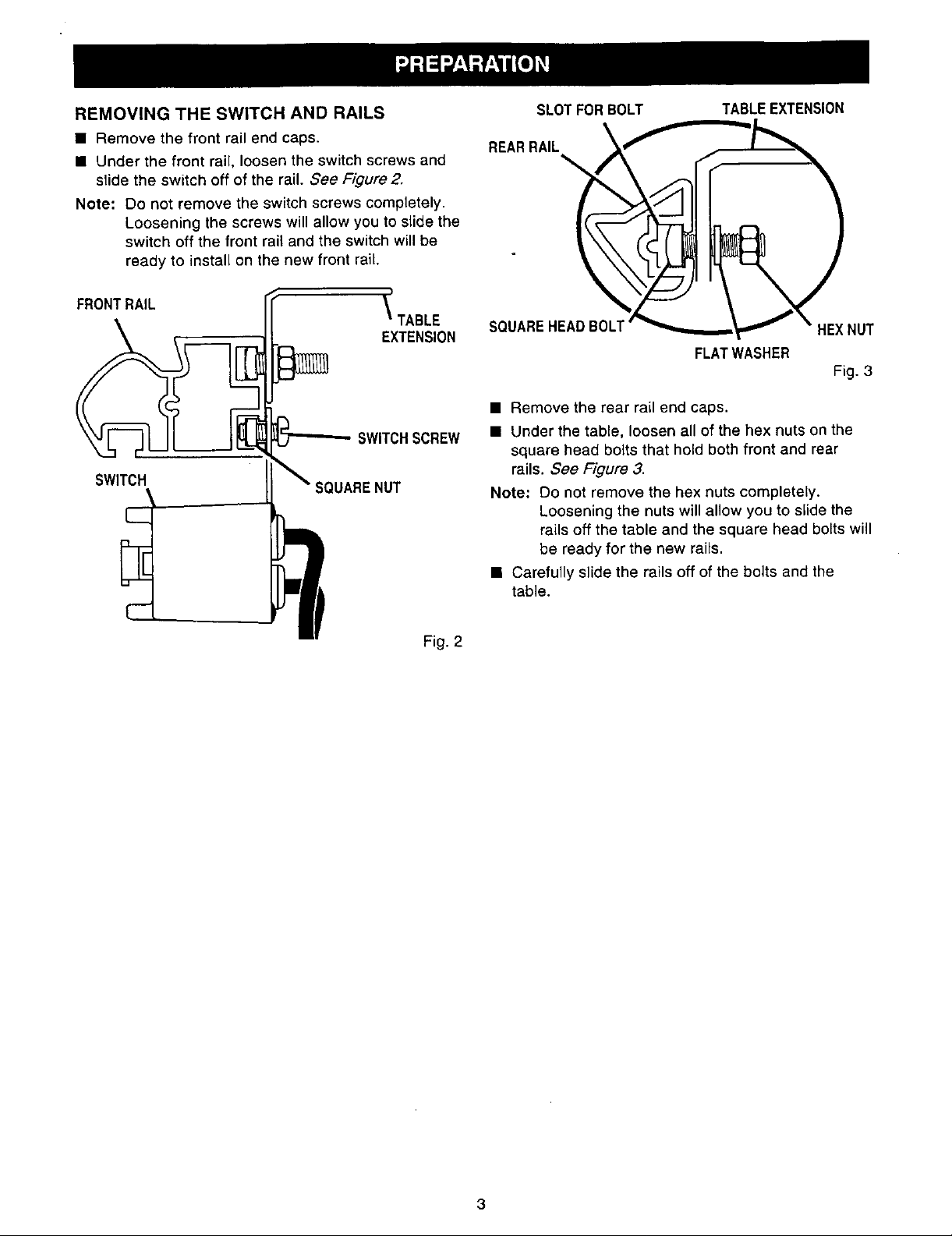

REMOVING THE SWITCH AND RAILS

• Remove the front rail end caps.

• Under the front rail, loosen the switch screws and

slide the switch off of the rail. See Figure 2.

Note: Do not remove the switch screws completely.

Loosening the screws will allow you to slide the

switch off the front rail and the switch will be

ready to install on the new front rail,

SLOTFORBOLT

REARRAIL __

TABLEEXTENSION

FRONTRAIL

SWITCH

L._

_ TABLE

EXTENSION

SWlTCHSCREW

SQUARENUT

Fig. 2

SQUAREHEADBOLT

FLATWASHER

• Remove the rear rail end caps.

• Under the table, loosen all of the hex nuts on the

square head bolts that hold both front and rear

rails. See Figure 3.

Note: Do not remove the hex nuts completely.

Loosening the nuts will allow you to slide the

rails off the table and the square head bolts will

be ready for the new rails.

• Carefully slide the rails off of the bolts and the

table.

HEXNUT

Fig. 3

Page 4

INSTALLING THE REAR RAIL

A'_ WARNING: Front and rear rails must be

carefully aligned to reduce the risk of kickback,

which can cause serious injury.

• From the carton, remove the rear rail and the

following hardware:

Right and left end caps for rear rail

2 screws (5/32-32 x 1/2 in.) for end caps

Note: The square head bolts, washers, and hex nuts

shown at the top of figure 3 should still be on the

table saw. If you mistakenly removed them, put

them back on the table. Do not tighten.

• Carefully slide the rail onto the square head bolts.

SQUAREHEAD

BOLT

• Position rail so that the right hand edge extends

2-1/2 in. beyond the table extension.

Note: Instructions are given from the operator's

position in front of the saw.

• Push the rail against table and tighten each hex

nut with a 12 mm wrench. If the rail jams or does

not slide easily over the bolts, re-align the table

extensions according to the instructions in the table

saw owner's manual.

Note: Make sure there are no gaps between the rail

and edge of table or extensions.

• Put the end caps on the rail ends. Insert the

screws and tighten with a phillips screwdriver.

FLAT WASHER

HEXNUT

SCREW

Fig. 4

4

Page 5

INSTALLING THE FRONT RAIL

• Locate the front rail and the following hardware:

Right and left end caps for front rail

2 screws (5/32-32 x 1/2 in.) for end caps

• Set aside the end caps and two screws until the

switch has been installed.

Note: The square head bolts, washers, and hex nuts

shown at the bottom of figure 6 should still be

on the table saw. If you mistakenly removed

them, put them back on the table. Do not

tighten.

• The back of the rail has two slots. See Figure

Carefully slide the upper slot over the bolts.

(Bottom slot is for switch.)

• Align the rail left to right - Match the 7-1/8 in. mark

on the right scale to the right edge of the saw base

(main table). See Figure 8.

• Snug the rail against table. Finger-tighten each nut

on the table and extensions.

RAILSLOT

SAWTABLE

HEXNUT

SWITCHSLOT

Fig. 7

TABLETOPVIEWEDFROMABOVE

TABLE

EXTENSION

SCALE

FRONTRAIL

HEIGHT

HANDWHEEL

SQUAREHEAD

SCALE

\.

FRONTRAIL 7-1/8in,MARKRIGHTSCALE

Fig. 8

FLATWASHER

HEXNUT

Fig. 6

Page 6

• Insert the two remaining pan head screws into

holes in the fine adjustment knob bracket.

• Attach the fine adjustment knob bracket to the

bottom of the fence head on the right or the left

side of the fence handle. Securely tighten the two

screws.

BRACKET

SCREWS _ _

Fig. 9

FRONTRAIL

SWITCH

ASSEMBLY

P

\

TABLE

EXTENSION

SWITCHSCREW

Fig. 10

MOUNTING THE SWITCH

• Locate the switch assembly, The fasteners should

still be attached.

Note: If the fasteners were removed from the switch,

see instructions in your table saw Owner's

Manual for mounting the switch or refer to

Figure 10.

• Holding the switch to the front, insert and slide the

two square nuts into the lower slot of the front rail.

_I, WARNING: Place the switch out of the immedi-

ate work area to avoid accidentally turning it off

during operation.

• Slide the switch assembly to a convenient position,

leaving ample clearance for the handwheel.

Tighten securely with a screwdriver.

• Attach the front rail end caps and screws with a

phillips screw driver. See Figure 11.

ENDCAP

SCREW

Fig. 11

Page 7

ALIGNING THE RIP FENCE AND FRONT RAIL •

The rip fence scale indicator is installed on the right

side of the rip fence but can be removed and rein-

stalled on the left side if needed. If a cutting operation •

requires placing the rip fence on the left side of the

blade, and you find relocating the indicator necessary,

simply unscrew and re-attach it.

• Hook the back of the rip fence over the rear rail. •

See Figure 12. Lowper the front of the rip fence

into the groove on the front rail. See Figure 13.

• Slide the rip fence back and forth. It should move

freely with about 1/16 in. clearance below the rip

fence. If it doesn't, loosen the nuts holding the front

rail and adjust the rail up or down. See Figure 6.

RIPFENCE

HOOKOVER

REARRAIL

HERE

Remove the rip fence and repeat on the other side

of the blade. When the fence rides smoothly,

tighten all rail hex nuts with a 12 mm wrench.

Push in the micro-adjust knob and turn it. The gear

on the shaft assembly will engage the rack teeth

on the rack and will move the fence assembly left

or right.

Push down on the rip fence handle to lock the rip

fence in place.

TOINSTALL

INDICATOR

ONLEFT

SIDE

REARRAIL

Fig. 12

RIP FENCEHANDLE

Fig. 13

Page 8

CHECKING RIP FENCE AND.

BLADE ALIGNMENT

The rip fence is self-aligning but should be checked

before first use.

_. WARNING: Failure to align the rip fence to the

blade can cause jams and kickback, resulting in

serious personal injury.

• Slide the rip fence to the miter gauge groove,

which is parallel to blade. Do not lock the rip fence.

• Place a framing square against the blade, with the

long end under the rip fence at the front. See

Figure 14. Note the distance.

• Move the square to the back and measure the

length from other end of the fence. See Figure 15.

• Ifthe distances are different, loosen the four

screws around the rip fence handle with a 6 mm

hex key. Alternate the order (remove the screw

opposite, not next to the first one). See Figure 16.

• Hold the fence handle against the front rail and

align the rip fence with the blade.

• Retighten the screws in alternating order and

check the alignment.

• Repeat until the rip fence is aligned.

MITERGAUGEGROOVE FRAMING

SQUARE

ADJUSTMENTSCREWS

Fig. 15

RIPFENCE

MITERGAUGEGROOVE

BLADE RIPFENCE

MITERGAUGE

GROOVE

Fig. 14

ADJUSTMENT

SCREWS(4)

RIPFENCE

HANDLE

Fig. 16

Note: To insure proper self alignment when position-

ing rip fence, push sides of scale indicator

housing against front rail before locking rip

fence handle.

8

Loading...

Loading...