Page 1

Save This Manual For

Future Reference

OWBeTS

manual

MODEL NO'S.

113,298721

113.298761

SAW WITH LEGS

TWO CAST IRON

TABLE EXTENSIONS

MOTOR AND

QUICK RELEASE

RIP FENCE

Serial

Number

Model and serial number may be found

at the left-hand side of the base

You should record both model and

serial number in a safe place for future

use,

FOR

YOUR

SAFETY:

Read ALL

INSTRUCTIONS

CAREFULLY.

Sold by SEARS, ROEBUCK AND CO., Chicago, IL. 60684 U.S.A.

Part No. SP5396

SE/ RS/C RR FTSM RN

10-INCH _BLE SAW

oassembly

. operating

orepair parts

Printed in U.S.A.

Page 2

FULL ONE YEAR WARRANTY ON CRAFTSMAN TABLE SAW

if within one year from the date of purchase,this CraftsmanTable Saw fail= due to a defect In

material orworkmanship,Searswillrepairit, freeo! charge. This warranty applies only while this

product is In use Inthe United States.

WARRANTY SERVICEISAVAILABLEBYSIMPLYCONTACTINGTHE NEAREST SEARSSERVICE

CENTER/DEPARTMENTTHROUGHOUTTHE UNITEDSTATES.

THIS WARRANTYAPPUES ONLY WHILE THIS PRODUCTIS USEDIN THE UNITED STATES.

This warrantygives you specific legal righte,and you mayalso have other rights which vary from

state tostate.

SEARS, ROEBUCKAND CO., D/817WA HoffmanEstates, IL 60195

safety instructions for table saw

Safety isa combination of common sense, staying alert 4, GROUND THE SAW- This saw has an approved 3-

and knowing how your table saw works. Read this

manual to understand this saw.

BEFORE USING THE SAW

WARNING: To avoid mistakes that could cause

serious, permanent Injury, do not plug the saw in

until the following steps have been satisfactorily

completed.

1. Assembly and Alignment (See pages 10- 24).

2. Learn the use and function ofthe ON-OFF Switch,

Guard, Spreader, Anti-Kickbackdevice, MiterGauge,

Fence, Table Insert and Blade Elevation and Bevel

Controls. (See page 25)

3. Review and understanding of all safety instructions

and operating procedures in this manual.

4. Review of the maintenance methods for this saw.

(See page 43)

Read thefollowing DANGER label found on the front of

the saw:

WHEN INSTALLING OR MOVING THE SAW

1. AVOID DANGEROUS ENVIRONMENT. Use the

saw in a dry place protected from rain. Keep work

area well lighted.

2. To avoid injuryfrom unexpected saw movement: anything.

A. Put the saw on afirm level surface where there is B. Check for alignment of moving parts, binding of

conductor cord and a 3-prong grounding type plug.

The plug fitsgrounding type outletsdesigned for 120

volt 15 amp circuits. The greenconductorinthe cord

lethe grounding wire. To avoidelectrocution. NEVER

connect the green wire to a live terminal.

5. To avoid injuryfrom electrical shock, make sure your

fingers do not touch the plug's metal prongs when

plugging in or unplugging the saw.

6. To avoid back injury, get help or use recommended

casterswhen you needto move the saw. Always get

helpifyou need to lilt the saw. Hold the saw close to

yourbody. Bend yourknees soyou can liftwithyour

legs, not your back.

7. NEVER STAND ON TOOL. Serious injury could

occurit the tool tips or you accidentallyhit the cutting

tool. Do not store anything above or near the tool

where anyone might stand on the toolto reach them.

BEFORE EACH USE:

4. Inspect your saw.

A. To avoid injuryfrom accidental starting, unplugthe

saw, turnthe switchoff and remove theswitch key

before raising or removing the Guard, changing

the cutting tool, changing the setup or adjusting

B. Suppod the saw so thetable is level and the saw

does not rock.

C. Bolt the sawto the floorifit tends to slip walk,or

slide during normal use.

D. When using table extensionsover 24 incheswide using the saw again.

on any side of the saw, boltthe saw to the flooror D Use the Sawblade Guard, Spreader, and Anti-

PrOPup the outer end of the extension from the KickbackPawlsforany thru-sawing(wheneverthe

floor to keep the saw from tipping, blade comes though the top of the workpiece).

3. Put the saw where neither operators nor bystanders Spreader is n line withthe sawblade.

must stand in line with the saw blade.

1 PaeBd_ tzeroee 4. ' ' and_

_j . _ 5. DG not do freehand cuts. , tdade, I_ween _2 and 2 _ from _rv_mg

3._reach_ouridofovefsaw 6, Kee_hat_dsoutctfp_-th_ttsaw _.Knowhowto_edw¢_f_eriskof _ade.Oonotrtlakeripcutsblade, kicld0ack. S_e i_ for ri_, nam_wer titan _2 in¢_l.

_DANGER

2

works. Ifany part is missing, bent, or broken inany

way, or any electrical parts don't work properly,

turn the saw off and unplug the saw.

C. Replace damaged, n_ssing, or failed parts before

Make surethe Pawls work properly. Make surethe

!

Page 3

E, REMOVE ADJUSTING KEYS AND WRENCHES.

Form habit of checking for and removing keys and

adjusting wrenches from tool before turning it on.

F. To avoid injury from jams, slips or thrown pieces

(kickback and throwback):

1. USE ONLY "RECOMMENDED ACCESSO-

RIES" (See page 43). Follow the instructions

that come with the accessories. Using other ac-

cessories may be dangerous.

2. Choose the right blade or cutting accessory for

the material and the type of cutting you plan to

do.

3. Never use gdnding wheels, abrasive cut-off

wheels, friction wheels (metal slitting blades)

wire wheels or buffingwheeL They canfly apart

explosively.

4. Choose and inspect your cutting tool carefully.

a. To avoid cutting tool failure and thrown shrap-

nel (broken pieces of blade), use only 10" or

Smaller blades or other cutting tools marked

for speeds of 3450 rpm or higher.

b. Always use unbroken, balanced blades

designed to fit this saw's 5/8 inch arbor.

c. When thru-sawing (making cuts where the

blade comes through the workpiece top),

always use a 10 inch diameter blade. This

keeps the spreader in closest to the blade.

d. Do not overtighten arbor nut. Use arbor

wrenches to "snug" it securely.

e. Use only sharp blades with properly set teeth.

Consult a professional blade sharpenerwhen

in doubt.

f. Keep blades clean of gum and resin.

5..Adjust table inserts flush with the table top.

NEVER use the saw without the proper insert.

6. Make sure all clamps and locks are tight and no

parts have any excessive play.

_.Keep work area clean

A Cluttered areas and benches invite accidents.

Floor must not be slippery from wax or sawdust.

B. To avoid burnsor other firedamage, never usethe

saw near flammable liquids, vapors or gases.

C. To avoidinjury,don'tdo layout, assembly, or setup

work on the table while the blade is spinning. It

could cut or throw anything hittingthe blade.

Plan ahead to protectyour eyes, hands, face, ears.

AVOID ACCIDENTAL STARTING - Make sure

switch is "OFF" before plugging saw in.

L Plan your work

A. USE THE RIGHT TOOL - Don't force tool or

attachment to do a job itwas not designed for.

B. Dress for safety:

1. Do not wear loose clothing, gloves, neckties or

jewelry (rings, wristwatches). They can get

caught and draw you into moving parts.

2. Wear nonslip footwear.

3. Tie back long hair.

4. Roll long sleeves above the elbow.

5. Noise levels vary widely. To avoid possible

hearing damage, wear ear plugs or muffs when

using saw for long periods of time.

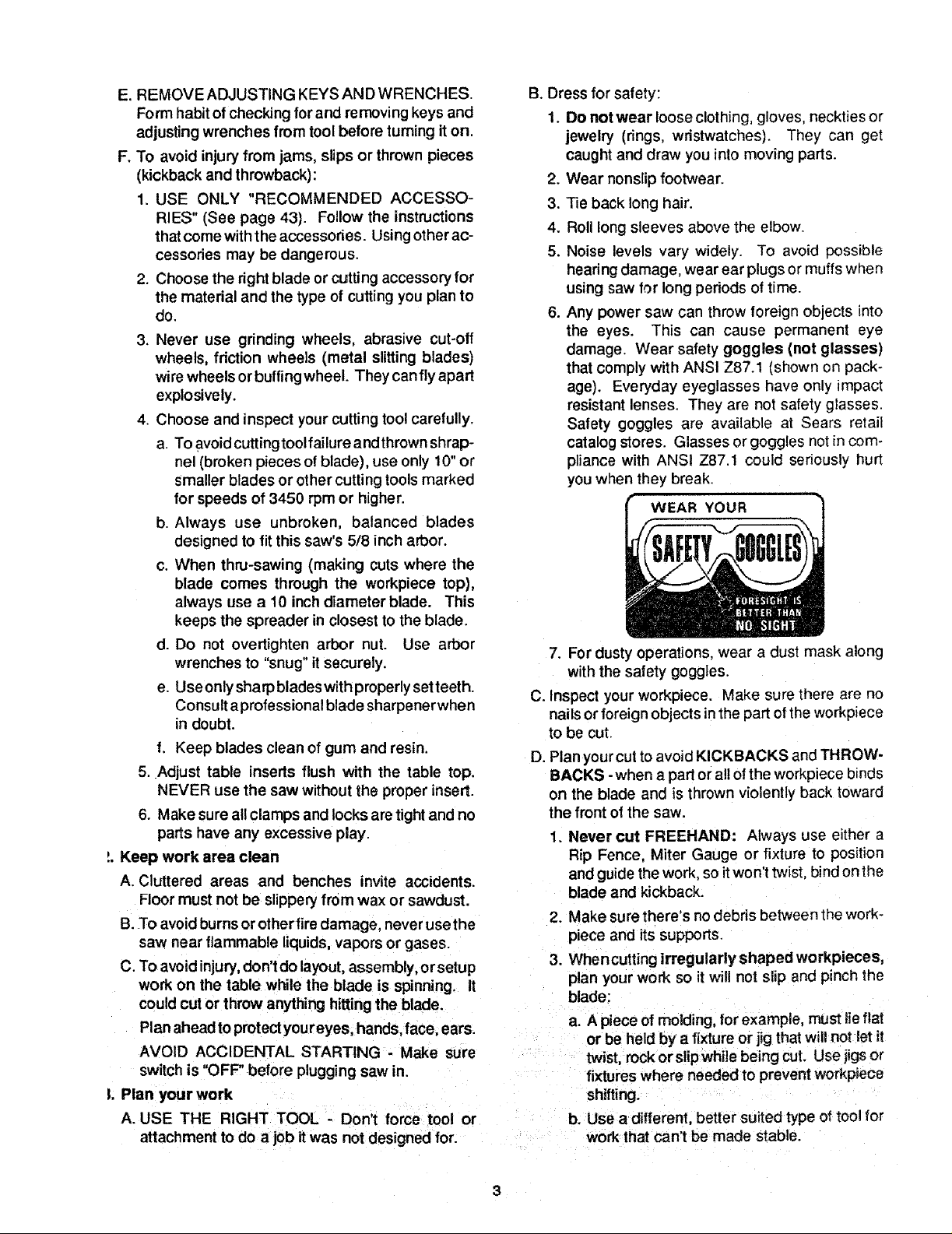

6. Any power saw can throw foreign objects into

the eyes. This can cause permanent eye

damage. Wear safety goggles (not glasses)

that comply with ANSI Z87.1 (shown on pack-

age). Everyday eyeglasses have only impact

resistant lenses. They are not safety glasses.

Safety goggles are available at Sears retail

catalog stores. Glasses or goggles not in com-

pliance with ANSI Z87.1 could seriously hurt

you when they break.

WEAR YOUR

7. For dusty operations, wear a dust mask along

with the safety goggles.

C. Inspect your workpiece. Make sure there are no

nails or foreign objects in the part of the workpiece

to be cut.

D. Plan your cut to avoid KICKBACKS and THROW-

BACKS -when a part or al! of the workpiece binds

on the blade and is thrown violently back toward

the front of the saw.

1. Never cut FREEHAND: Always use either a

Rip Fence, Miter Gauge or fixture to position

and guide the work, so it won't twist, bind on the

blade and kickback.

2. Make sure there's no debris between the work-

piece and its supports.

3. When cutting irregularly shaped workpieces,

plan your work so it will not slip and pinch the

blade:

a. A piece of molding, for example, must tieflat

or be held by a fixture or jig that will not let it

twist, rock or slip while being cut. Use jigs or

fixtures where needed to prevent workpiece

shifting.

b. Use a different, better suited type of tool for

work that can't be made stable.

Page 4

4. Use extra caution with large, very small or

awkward workpieces:

a. Use extra supports (tables, saw horses,

b!ocks,etc.) for anyworkpieces large enough

totip when not held down to the table top.

NEVER use another personas a substitute

for atable extension, or as additional support

for a workpiece that is longer or wider than

the basic saw table, or to help feed, support

or pull the workpiece.

b. Nevercontinethepiecebeingcutoff. Thatis,

the piece NOTagainstthe fence, mitergauge

or fixture. Never hold it, clamp it, touch it, or

use length stopsagainst it. Itmust be free to

move. Ifconfined, itcouldget wedged against

the blade and cause a kickback or throw-

back.

c. Never cut more than oneworkpiece at atime.

d. Never turn your table saw "ON" before clear-

ing everything except the workpiece and

related support devices off the table.

4. Plan the way youwill pushthe workplecethrough.

A. NEVER pull the workplece through. Start and

finish the cut from the front of the table saw.

B. NEVER put your fingers or hands in the path of

the sawblade orother cutting tool.

C. NEVER reach in back ofthe cuttingtoolwith either

hand to hold down or support the workpiece,

remove wood scraps, orfor any other reason.

D. AvoU hand positions where a sudden sl;p could

cause fingers or hand to move into a sawblade or

other cutting tool.

E. DON'T OVERREACH. Always keep good footing

and balance.

F. Push the workpiece against the rotation of the

blade. NEVER feed material into the cutting tool

from the rear of the saw.

G.Always push the workpiece all the way past the

sawblade.

H. As much as possible, keep your face and body to

one side ofthe sawblade,out of linewith apossible

kickback or throwback.

L NEVERtumthesaw"ON"beforeclearingthetable

of all tools, wood scraps, etc., except the work-

piece and related feed or support devices for the

cut planned.

WHENEVER SAW BLADE IS SPINNING

second is enough to cause a severe Injury.

1. Before actually cutting with the saw, watch itwhile it

runsfor ashort while. If itmakes anunfamiliar noise

or vibrates a lot,stop immediately. Turn the saw off.

Unplug the saw. Do notrestart untilfinding andfixing

the problem.

2. Make sL=rethe top of the arbor or cutting toolturns

toward the front of the saw.

3. Set the cutting tool as low as possible for the cut

you're planning.

4. KEEP CHILDREN AWAY, Allvisitorsshouldbe kept

asafedistancefrornwork. Make surebystanders are

clear ofthe saw andworkpiece.

5. Let the blade reach full speed before cutting.

6. DON'T FORCE TOOL. It will do the job better and

saferat itsdesigned rate. Feed theworkpiece intothe

blade only fast enough to let it cut without bogging

down or binding.

7. Before freeing any jammed material:

A. Turn switch "OFF",

B. Unplug the saw.

C. Wait for all moving parts to stop.

D. Check blade, Spreader and Fencefor proper align-

rnent before starting, again.

8. To avoid throwback of cut off pieces;

A, Use the Guard assembly.

B To remove loose pieces beneath ortrapped inside

the guard:

1. rum saw "OFF".

2. Remove switch key.

3. Wait for blade tostop before liftingthe Guard.

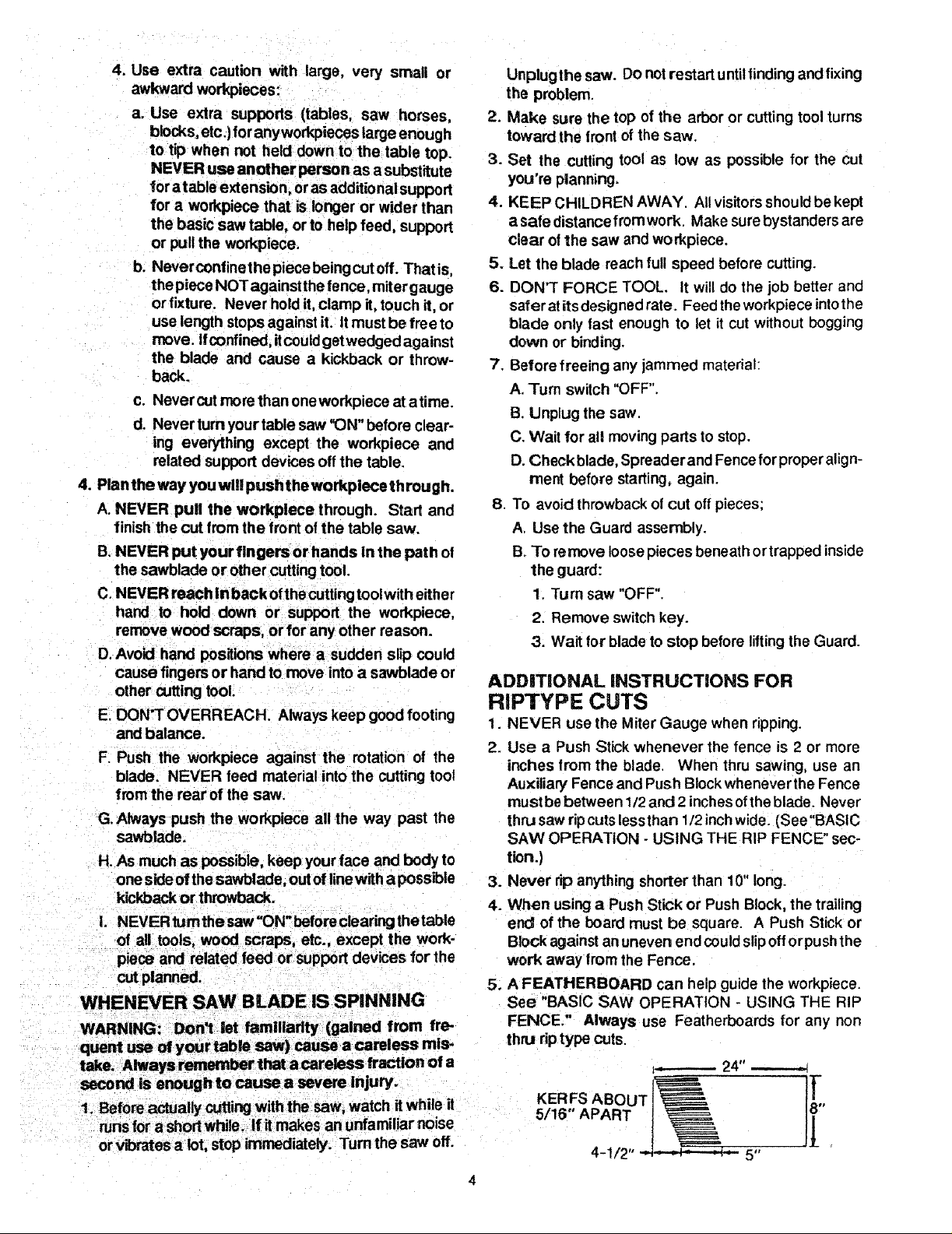

ADDiTiONAL INSTRUCTIONS FOR

RIPTYPE CUTS

1. NEVER use the Miter Gauge when ripping.

2. Use a Push Stick whenever the fence is 2 or more

inches from the blade. When thru sawing, use an

Auxiliary Fence and Push Block whenever the Fence

mustbe between 1/2 and 2 inches oftheblade. Never

thru saw ripcuts lessthan 1/2 inchwide. (See"BASIC

SAW OPERATION - USING THE RIP FENCE" sec-

tion.)

3. Never rip anything shorter than 10"long.

4. When using a Push Stick or Push Block, the trailing

end of the board must be square. A Push Stick or

Blockagainst an uneven end couldslip off orpushthe

work away from the Fence.

5. A FEATHERBOARD can help guide the workpiece.

See "BASIC SAW OPERAT{ON - USING THE RIP

FENCE." Always use Featherboards for any non

thru riptype cuts.

_...-------- 24"

KERFS ABOUT

5/16" APART

Page 5

BEFORE STARTING

1. TO avoid kickbacks and slips into the blade, make

sure the Rip Fence is parallel to the sawblade.

2. Check the anti-kickback pawls. (See "BASIC SAW

OPERATION - USING THE RIP FENCE.") The

Pawls must stop a kickback once it has started.

Replace or sharpen Anti-Kickback Pawls when points

become dull.

3. Plastic and composition (like hardboard) materials

may be cut on your saw. However, since these are

usually quite hard and slippery, the Anti-Kickback

Pawls may not stop a kickback. Therefore, be espe-

cially careful in your set-up and cutting procedures.

WHILE CUTTING

1. To avoid kickbacks and slips into the blade, always

push forward onthe section ofthe workpiece between

the saw blade andthe Rip Fence. Never push forward

on the piece being cut off.

ADDITIONAL iNSTRUCTIONS FOR

CROSSCUT TYPE CUTS

BEFORE STARTING

1. NEVER use the Rip Fence when crosscutting.

2. An auxiliary wood facing attached to the Miter Gauge

can help prevent workpiece twisting and throwbacks.

Attach itto the holes provided. Make the facing long

enough and big enough to support your work. Make

sure, however, it will not interfere with the Sawblade

Guard. (See page 26)

3. Use jigs or fixtures to help hold any piece too small to

extend across the full length of the Miter Gauge face

during the cut. This lets you properly hold the Miter

Gauge and workpiece and helps keep your hands

away from the blade.

WHILE CUTTING

1. To avoid blade contact, always hold the Miter Gauge

as shown in the "BASIC SAW OPERATIONS - US-

ING THE MITER GAUGE."

BEFORE LEAVING THE SAW

1. Turn the saw off.

2. Wait for blade to stop spinning.

3. Make workshop child-proof. Lock the shop. Discon-

nect master switches. Remove the yellow Switch

Key. Store _ away from children and others not

qualified to use the tool.

4. Unplug the saw.

glossary of terms for woodworking

Anti-Kickback Pawls (AKP)

Device which, when properlymaintained, isdesigned to

stopthe workpiece from being kicked back at the opera-

tor during dpping operation.

Arbor

The shaft on which a cutting tool is mounted.

Crosscut

Acutting or shaping operation made acrossthe width of

the workpiece.

Dado

A nonthrough cutwhich produces a square sided notch

or trough in the workpiece.

Featherboard

A device which can help guide workpieces during rip

type operation.

Freehand

Performing a cut without using a Fence, Miter Gauge,

fixture, hold down or other proper device to keep the

workpiece from twisting during the cut.

Gum

A sticky, sap based residue tram wood products.

Heel

Misalignment of the blade.

Kerr

The amount of material removed by the blade in a

through cut or the slot produced by the blade in a non

through or partial cut.

Kickback

An uncontrolled grabbingand throwing ofthe workpiece

back toward the front of the saw.

Leading End

The end of the workpiece which, during a rip type

operation, is pushed intothe cutting tool first.

Molding

A non through cut which produces a special shape inthe

workpiece used for joining or decoration.

Push Stick

A device used to feed the workpiece through the saw

during narrow ripping type operations and helps keep

the operator's hands well away from the blade.

Push Block

A device used for ripping type operations too narrow to

allow use of a Push Stick.

Rabbet

A notch inthe edge of a workpiece.

Resin

A sticky, sap base substance that has hardened.

Ripping

A cutting operation along the length of the workpiece.

Revolutions Per Minute (RPM)

The number of turns completed by a spinning object in

one minute.

Page 6

glossary of terms for woodworking

Sawblade Path

The area ofthe workpiece ortable topdirectly in linewith

the partof the workpiecewhich will be, or has been, cut

bythe blade.

Set

The distancethatthe tip ofthe sawblade tooth isbent (or

set) outward from the face of the blade.

Throw-BaCk

Throwing of pieces in a manner similar to a kickback.

Thru-Sawing

Any cutting operation where the blade extends com-

pletely though the thickness of the workpiece.

Trailing End

The workpiece end last cut by the blade in a ripping

operation.

Workpiece

The item on which the cutting operation is being done.

The surfaces ofa workpiece are commonly referred to

as faces, ends, and edges.

motor specifications and electrical requirements

This saw is designed to use a 3450 RPM motoronly. Do

not use any motor that runs faster than 3450 RPM. It is

wired for operation on 120 volts. 60 Hz., alternating

current. IT MUST NOT BE CONVERTED TO OPER-

ATE ON 230 VOLTS.

CAUTION: Do not use blower or washing machine

motors or any motor with an automatic reset over-

load protector as their use may be hazardous. For

replacement motor, refer to parts list in this manual,

CONNECTING TO POWER SOURCE

OUTLET

This saw must be grounded while in use to protect the

operator from electrical shock.

Itpower cord iswornor cut,of damaged inany way, have

it replaced immediately.

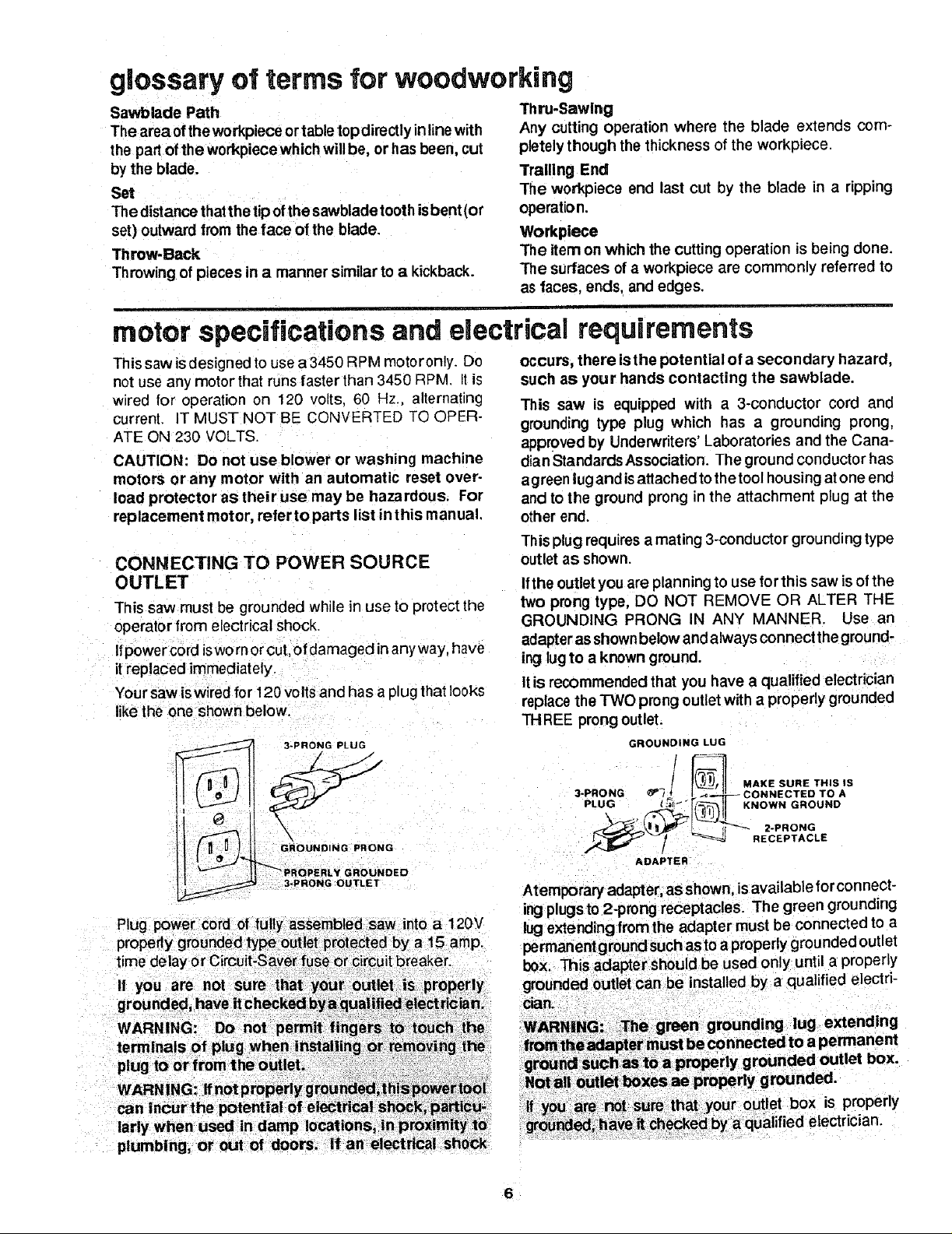

Your saw iswired for 120 volts and has a plug that looks

like the one shown below.

3-PRONG PLUG

occurs, there isthe potential of a secondary hazard,

such as your hands contacting the sawblade.

This saw is equipped with a 3-conductor cord and

grounding type plug which has a grounding prong,

approved by UndenNriters'Laboratories and the Cana-

dian Standards Association. The ground conductor has

agreen lug and isattached to the tool housing atone end

and to the ground prong in the attachment plug at the

other end.

Thisplug requiresa mating 3-conductor grounding type

outlet as shown.

Ifthe outletyou are planningto use for this saw is of the

two prong type, DO NOT REMOVE OR ALTER THE

GROUNDING PRONG IN ANY MANNER. Use an

adapter as shownbelow and always connect the ground-

ing lugto a known ground.

Itis recommended that you have a qualified electrician

replacethe TWO prong outletwith a properly grounded

THREE prongoutlet.

GROUNDING LUG

If you are not sure that

te

plug

can incur the

plumbing,

I_ MAKE SURE THIS IS

3-PRONG _'_ L _ _.-_= CONNECTED TO A

PLUG _:._ "l___ II KNOWN GROUND

/ .EC,.T,C'E

ADAPTER

Atemporary adapter, as shown, is available for connect-

ing plugs to 2-prong receptacles. The green grounding

lug extending from the adapter must be connected to a

perrnanent ground such asto a properlygrounded outlet

box. This adapter should be used only until a properly

Page 7

NOTE: The adapter illustrated is for use only if you

already have a properly grounded 2-prong receptacle.

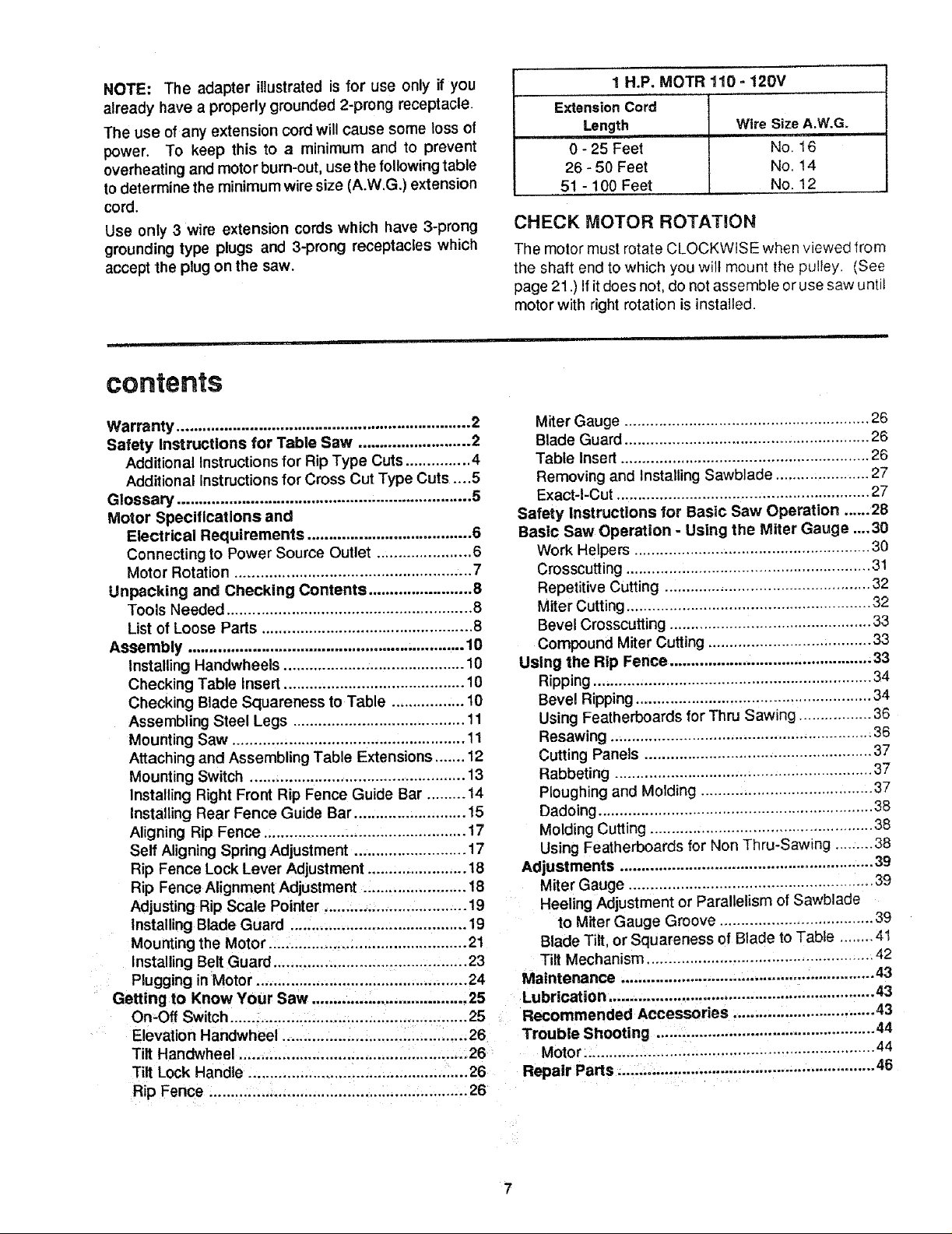

The use of any extension cord will cause some loss of

power. To keep this to a minimum and to prevent

overheating and motorbum-out, use the following table

todetermine the minimum wire size (A.W.G.) extension

cord.

Use only 3 wire extension cords which have 3-prong

grounding type plugs and 3-prong receptacles which

accept the plugon the saw.

contents

1 H.P. MOTR 110 - 120V

Extension Cord

Length Wire Size A.W.G.

0 - 25 Feet No. 16

26 - 50 Feet No. 14

51 - 100 Feet No. 12

CHECK MOTOR ROTATION

The motor must rotate CLOCKWISE when viewed from

the shaft end to which you wilt mount the pulley. (See

page 21 .) If it does not, do not assemble or use saw until

motor with right rotation is installed.

Warranty .................................................................... 2

Safety instructions for Table Saw .......................... 2

Additional Instructionsfor Rip Type Cuts ............... 4

Additional Instructionsfor Cross Cut Type Cuts .... 5

Glossary .................................................................... 5

Motor Specifications and

Electrical Requirements ...................................... 6

Connecting to Power Source Outlet ...................... 6

Motor Rotation ....................................................... 7

Unpacking and Checking Contents ........................ 8

Tools Needed ......................................................... 8

List of Loose Parts ................................................. 8

Assembly ................................................................ 10

Installing Handwheels .......................................... 10

Checking Table insert .......................................... 10

Checking Blade Squareness to Table ................. 10

Assembling Steel Legs ........................................ 11

Mounting Saw ...................................................... 11

Attaching and Assembling Table Extensions ....... 12

Mounting Switch .................................................. 13

Installing Right Front Rip Fence Guide Bar ......... 14

Installing Rear Fence Guide Bar .......................... 15

Aligning Rip Fence ............................................... 17

Self Aligning Spring Adjustment .......................... 17

Rip Fence Lock Lever Adjustment ....................... 18

Rip Fence Alignment Adjustment ........................ !8

Adjusting Rip Scale Pointer ................................. 19

installing Blade Guard ......................................... 19

Mounting the Motor .............................................. 21

Installing Belt Guard ............................................. 23

Plugging in Motor ................................................. 24

Getting to Know Your Saw .................................... 25

On.Off Switch ....................................................... 25

Elevation Handwheel ........................................... 26

Tilt Handwheel ..................................................... 26

Tilt Lock Handle ................................................... 26

Rip Fence ............................................................. 26

Miter Gauge ......................................................... 26

Blade Guard ......................................................... 26

Table Insert .......................................................... 26

Removing and Installing Sawblade ...................... 27

Exact-I-Cut ........................................................... 27

Safety instructions for Basic Saw Operation ...... 28

Basic Saw Operation - Using the Miter Gauge .... 30

Work Helpers ....................................................... 30

Crosscutting ......................................................... 31

Repetitive Cutting ................................................ 32

Miter Cutting ......................................................... 32

Bevel Crosscutting ............................................... 33

Compound Miter Cutting ...................................... 33

Using the Rip Fence ............................................... 33

Ripping ................................................................ 34

Bevel Ripping ....................................................... 34

Using Featherboards for Thru Sawing ................. 36

Resawing ............................................................. 36

Cutting Panels ..................................................... 37

Rabbeting ............................................................ 37

Ploughing and Molding ........................................ 37

Dadoing ................................................................ 38

Molding Cutting .................................................... 38

Using Featherboards for Non Thru-Sawing ......... 38

Adjustments ........................................................... 39

Miter Gauge ......................................................... 39

Heeling Adjustment or Parallelism of Sawblade

to Miter Gauge Groove .................................... 39

Blade Tilt, or Squareness of Blade to Table ........ 41

Tilt Mechanism ..................................................... 42

Maintenance ........................................................... 43

Lubrication .............................................................. 43

Recommended Accessories ................................. 43

Trouble Shooting ................................................... 44

Motor .................................................................... 44

Repair Parts ............................................................ 46

7

Page 8

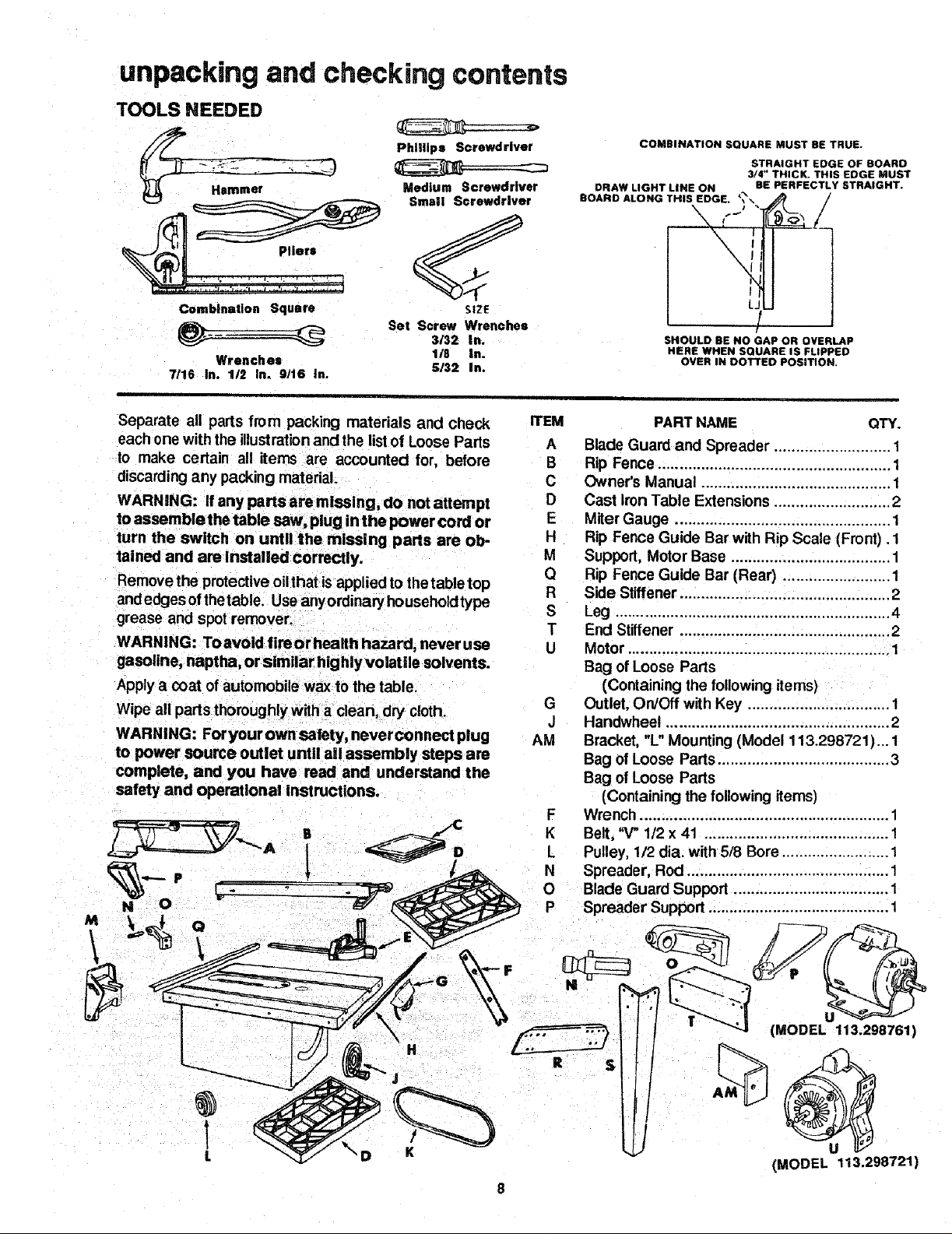

unpacking and checking contents

TOOLS NEEDED

Phillips Screwdriver

Medium Screwdriver

Small Screwdriver

Combination Square

Sot Screw Wrenches

Wrenches

7116 in. 112 In. 9/16 In.

Separate all parts from packing materials and check

eachone withthe illustratbn and the listof Loose Parts

to make certain all items are accounted for, before

discardingany packing material.

WARNING: If any parts are missing, do not attempt

to assemblethe table saw, plug in the power cord or

turn the switch or= until the missing parts are ob-

tained and are Installed correctly.

Remove the protective oilthat isapplied to the table top

andedgesof thetable. Useanyordinary household type

grease and spot remover.

WARNING: Toavoidfireor health hazard, never use

gasoline, naptha, or similar highly volatile solvents.

Apply a coat of automobile wax to the table.

Wipe all parts thoroughlywith a clean, dry cloth.

WARNING: Foryour own safety, neverconnect plug

to power source outlet until a, assembly steps are

complete, and you have read and understand the

safety and operational Instructions.

M

SIZE

3/32 In.

118 in.

5/32 in.

COMBINATION SQUARE MUST BE TRUE.

STRAIGHT EDGE OF BOARD

3/4" THICK. THIS EDGE MUST

DRAW LIGHT LINE ON

BOARD ALONG THIS EDGE, *_-,

SHOULD BE NO GAP OR OVERLAP

HERE WHEN SQUARE IS FLIPPED

OVER IN DOTTED POSITION,

BE PERFECTLY STRAIGHT.

I

ffEM PARTNAME QTY.

A Blade Guard and Spreader ........................... 1

B Rip Fence ...................................................... 1

C Owner's Manual ............................................ 1

D Cast Iron Table Extensions ........................... 2

E Miter Gauge .................................................. 1

H Rip Fence Guide Bar with Rip Scale (Front). 1

M Support, Motor Base ..................................... 1

Q Rip Fence Guide Bar (Rear) ......................... 1

R Side Stiffener ................................................. 2

S Leg ................................................................ 4

T End Stiffener ................................................. 2

U Motor ............................................................. 1

Bag of Loose Parts

(Containing the following items)

G Outlet, On/Off with Key ................................. 1

J Handwheel .................................................... 2

AM Bracket, "L" Mounting (Model 113298721)... 1

Bag of Loose Parts........................................ 3

Bag of Loose Parts

(Containing the following items)

F Wrench .......................................................... 1

K Belt, "V" 1/2 x 41 ........................................... 1

L Pulley, 1/2 dia. with 5/8 Bore ......................... 1

N Spreader, Rod ............................................... 1

0 Blade Guard Support .................................... 1

P Spreader Support .......................................... 1

u

(MODEL 113.298761)

S

(MODEL 113.298721)

Page 9

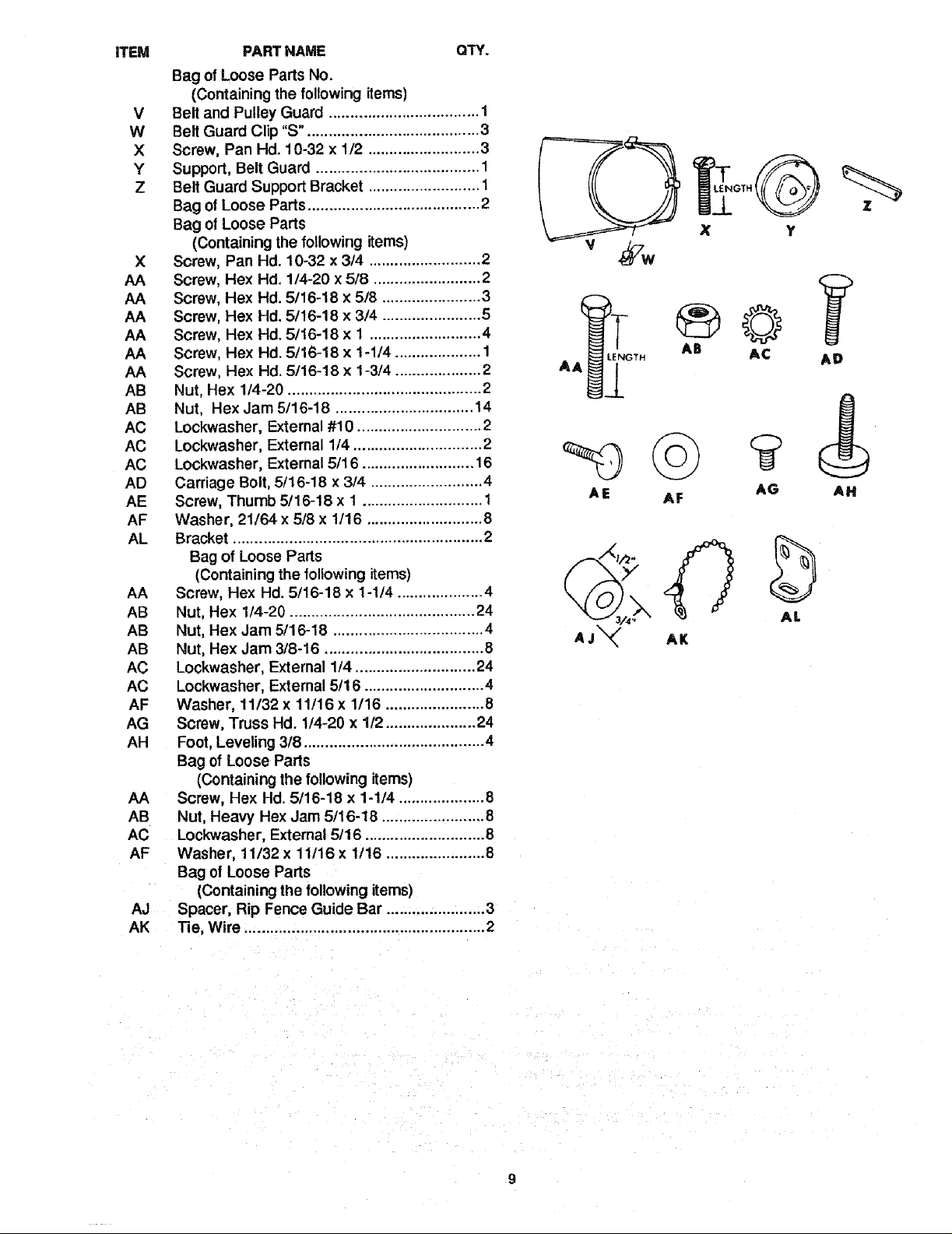

ITEM

Bag of Loose Parts No.

(Containing the following items}

V Belt and Pulley Guard ................................... 1

W Belt Guard Clip "S". ....................................... 3

X Screw, Pan Hd. 10-32 x 1/2 .......................... 3

Y Support, Belt Guard ...................................... 1

Z Belt Guard Support Bracket .......................... 1

Bag of Loose Parts........................................ 2

Bag of Loose Parts

(Containing the following items)

X Screw, Pan Hd. 10-32 x 3/4 .......................... 2

AA Screw, Hex Hd. 1/4-20 x 5/8 ......................... 2

AA Screw, Hex Hd. 5/16-18 x 5/8 ....................... 3

AA Screw, Hex Hd. 5/16-18 x 3/4 ....................... 5

AA Screw, Hex Hd. 5/16-18 x 1 .......................... 4

AA Screw, Hex Hd. 5/16-18 x 1-1/4 .................... 1

AA Screw, Hex Hd. 5/16-18 x 1-3/4 .................... 2

AB Nut, Hex 1/4-20 ............................................. 2

AB Nut, Hex Jam 5/16-18 ................................ 14

AC Lockwasher, External #10 ............................. 2

AC Lockwasher, External 1/4 .............................. 2

AC Lockwasher, External 5/16 .......................... 16

AD Carriage Bolt, 5/16-18 x 3/4 .......................... 4

AE Screw, Thumb 5/16-18 x 1 ............................ 1

AF Washer, 21164 x 5/8 x 1/16 ........................... 8

AL Bracket .......................................................... 2

Bag of Loose Parts

(Containing the following items)

AA Screw, Hex Hd. 5/16-18 x 1-1/4 .................... 4

AB Nut, Hex 1/4-20 ........................................... 24

AB Nut, Hex Jam 5/16-18 ................................... 4

AB Nut, Hex Jam 3/8-16 ..................................... 8

AC Lockwasher, External 1!4 ............................ 24

AC Lockwasher, External 5/16 ............................ 4

AF Washer, 11/32 x 11/16 x 1/16 ....................... 8

AG Screw, Truss Hd. 1/4-20 x 1/2 ..................... 24

AH Foot, Leveling 318.......................................... 4

Bag of Loose Parts

(Containing the following items)

AA Screw, Hex Hd. 5/16-18 x 1-1/4 .................... 8

AB Nut, Heavy Hex Jam 5/16-18 ........................ 8

AC Lockwasher, External 5/16 ............................ 8

AF Washer, 11t32 x 11/16 x 1/16 ....................... 8

Bag of Loose Parts

(Containing the following items)

AJ Spacer, Rip Fence Guide Bar ....................... 3

AK Tie, Wire ........................................................ 2

PART NAME QTY.

AE AF

0

AJ_ AK

AB AC AD

AG AH

Page 10

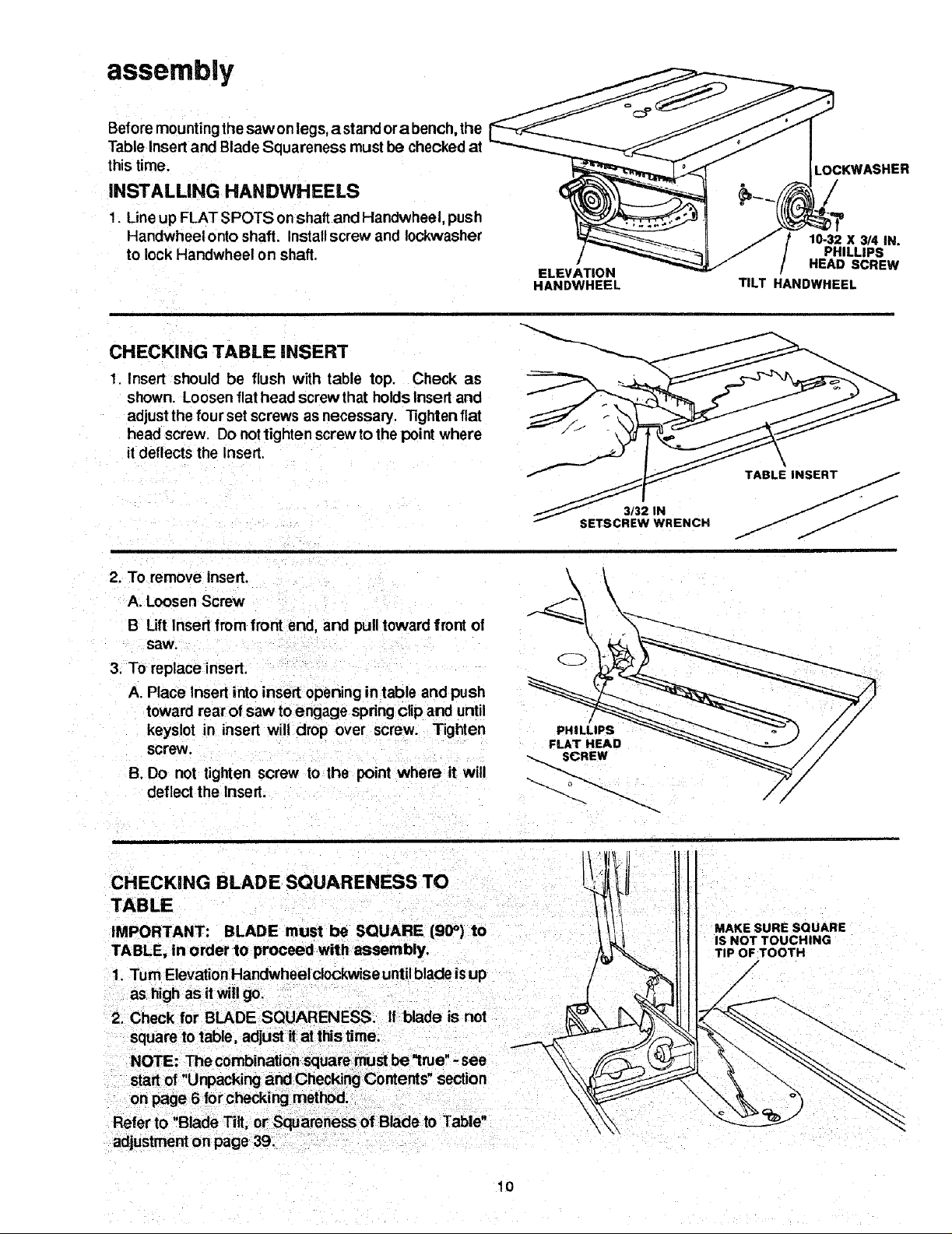

assembly

Before mountingthe saw on legs,a stand ora bench, the

Table Insert and Blade Squareness must be checked at

this time.

INSTALLING HANDWHEELS

1. Line up FLAT SPOTS onshaft and Handwheel, push

Handwheel onto shaft. Installscrew and Iockwasher

to lock Handwheel on shaft.

CHECKING TABLE INSERT

1. Insert should be flush with table top, Check as

shown. Loosen flat head screw that holds Insert and

adjust thefour set screws as necessary. -tighten flat

head screw. Do nottighten screw to the pointwhere

it deflects the Insert.

ELEVATION

HANDWHEEL

SETSCREW WRENCH

LOCKWASHER

10-32 X 314 IN.

PHILLIPS

HEAD SCREW

TILT HANDWHEEL

3/32 IN

2. To remove Insert.

A. Loosen Screw

B Lift Insert from front end, and pulltoward front of

saw,

3, To replaceinsert.

A. Place Insert into insert opening in table and push

toward rear of saw to engage spring clip and until

keyslot in insert will drop over screw. Tighten

screw.

B. Do not tighten screw to the point where it will

deflect the Insert.

CHECKING BLADE SQUARENESS TO

TABLE

IMPORTANT: BLADE must be SQUARE (90°) to

TABLE, in order to proceed with assembly.

1. "rum Elevation Handwheelclockwise untilblade isup

2. Check for BLADE SQUARENESS. If blade is not

square to table, adjust itat this time,

MAKESURESQUARE

ISNOTTOUCHING

TIPOFTOOTH

/

/

Contents" section

Refer to "Blade Tilt, or Squareness of Blade to Table"

adjustment on page 39.

10

Page 11

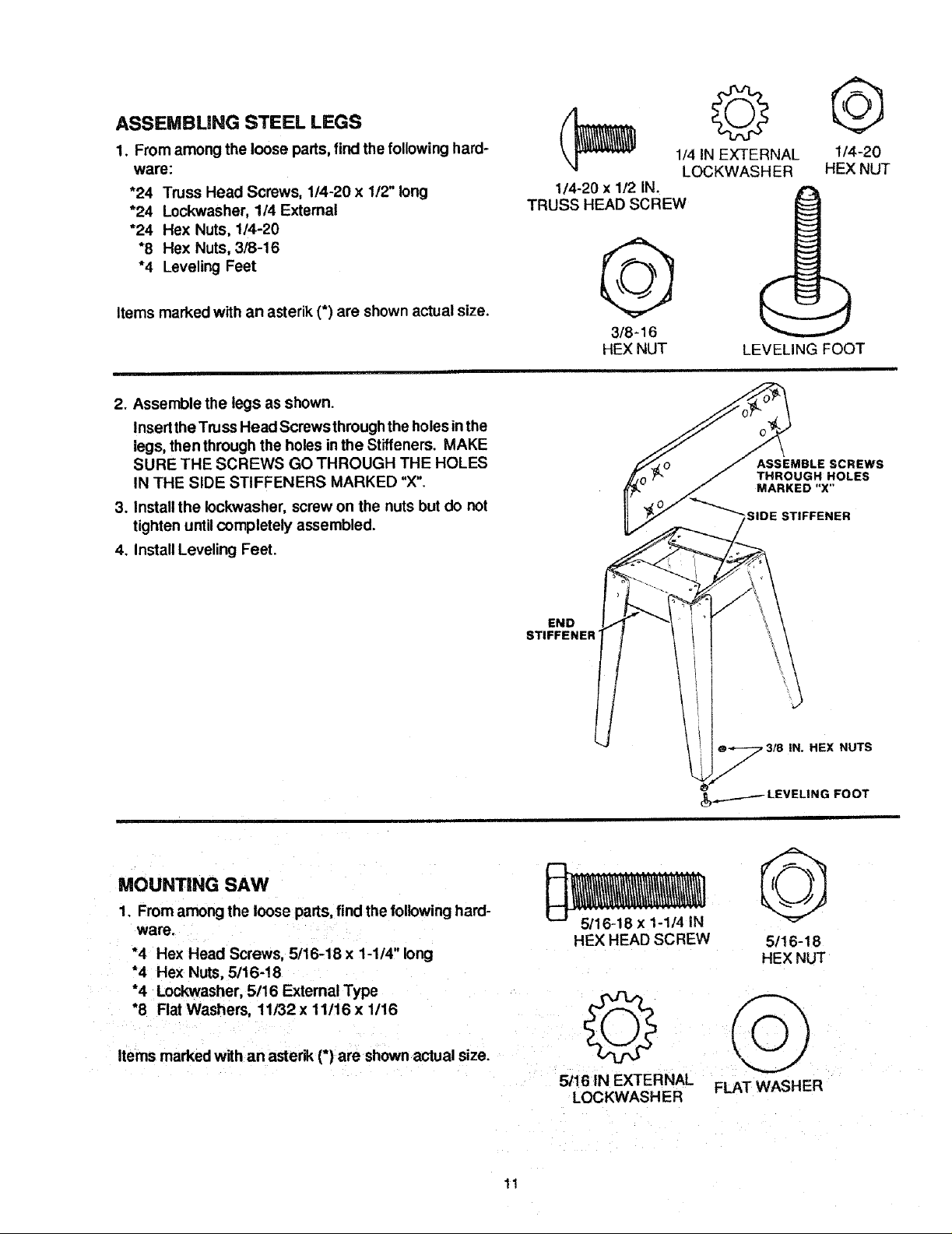

ASSEMBUNG STEEL LEGS

1. From among the loose parts, find the following hard-

ware:

*24 Truss Head Screws, 1/4-20 x 1/2" long

*24 Lockwasher, 1/4 External

*24 Hex Nuts, 1/4-20

*8 Hex Nuts,318-16

*4 Leveling Feet

Items marked with an asterik (*) are shown actual size.

2. Assemble the legs as shown.

Insert the Truss Head Screws throughthe holes inthe

legs, then through the holes inthe Stiffeners. MAKE

SURE THE SCREWS GO THROUGH THE HOLES

IN THE SIDE STIFFENERS MARKED "X".

3. Install the lockwasher, screw on the nuts but do not

tighten until completely assembled.

4. Install Leveling Feet.

1/4-20 x 1/2 IN.

TRUSS HEAD SCREW

3/8 -16

HEX NUT

©

1/4 IN EXTERNAL

LOCKWASH ER

LEVELING FOOT

ASSEMBLE SCREWS

THROUGH HOLES

MARKED "X"

SIDE STIFFENER

@

1/4-20

HEX NUT

MOUNTING SAW

1. From among the loose parts,find the following hard-

ware.

*4 Hex Head Screws, 5/16-18 x 1-1/4" long

*4 Hex Nuts, 5/16-18

*4 Lockwasher, 5/16 External Type

*8 Flat Washers, 11/32 x 11/16 x 1/16

Items marked with an astenl_(*) are shown actual size.

END

STIFFENER

HEX HEAD SCREW

5/16 IN EXTERNAL

LOCKWASHER

\

HEX NUTS

_ LEVELING FOOT

5/16-18

HEX NUT

FLAT WASHER

11

Page 12

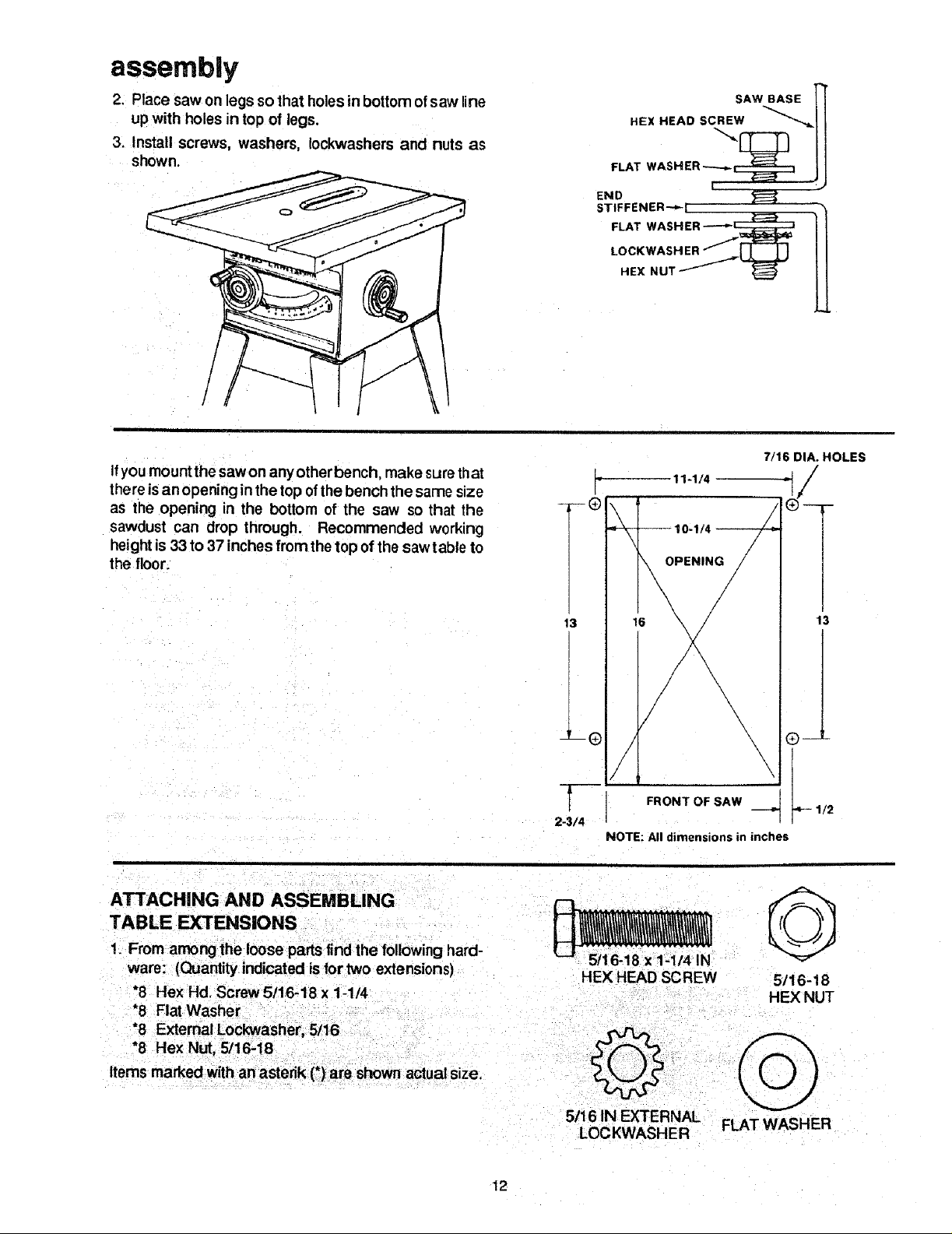

assembly

2. Place saw on legs sothat holes in bottom of saw line

up with holes in top of legs.

3. Install screws, washers, Iockwashers and nuts as

shown.

/

Ifyou mountthe saw on any other bench, make surethat

there isan opening inthe top ofthe bench thesame size

as the opening in the bottom of the saw so that the

sawdust can drop through. Recommended working

heightis 33 to 37 inches from the top of the saw table to

the floor.

FLAT WASHER ..----_ _ I

END

FLAT WASHER -----'_

!

LOCKWASHER

STIFFENER'_ k i

L

F

T®

11-1/4

OPENING_ 7_

SAW BASE !

7/16 DIA. HOLES

ATTACHING AND ASSEMBLING

TABLE EXTENSIONS

1. From among the loose parts findthe following hard-

ware: (Quantity indicated isfor two extensions)

*8 Hex Hd. Screw 5/16-18 x 1-1/4

*8 Flat Washer

*8 External Lockwasher, 5/16

*8 Hex Nut, 5/16;18

Items marked with an asterik (*) are shown actual size.

13 16 \

t \

2-3/4

NOTE: All dimensions in inches

HEX HEAD SCREW

13

/ \

1t2

G

5/16-18

HEX NUT

12

,5/16 IN EXTERNAL

LOCKWASHER FLAT WASHER

Page 13

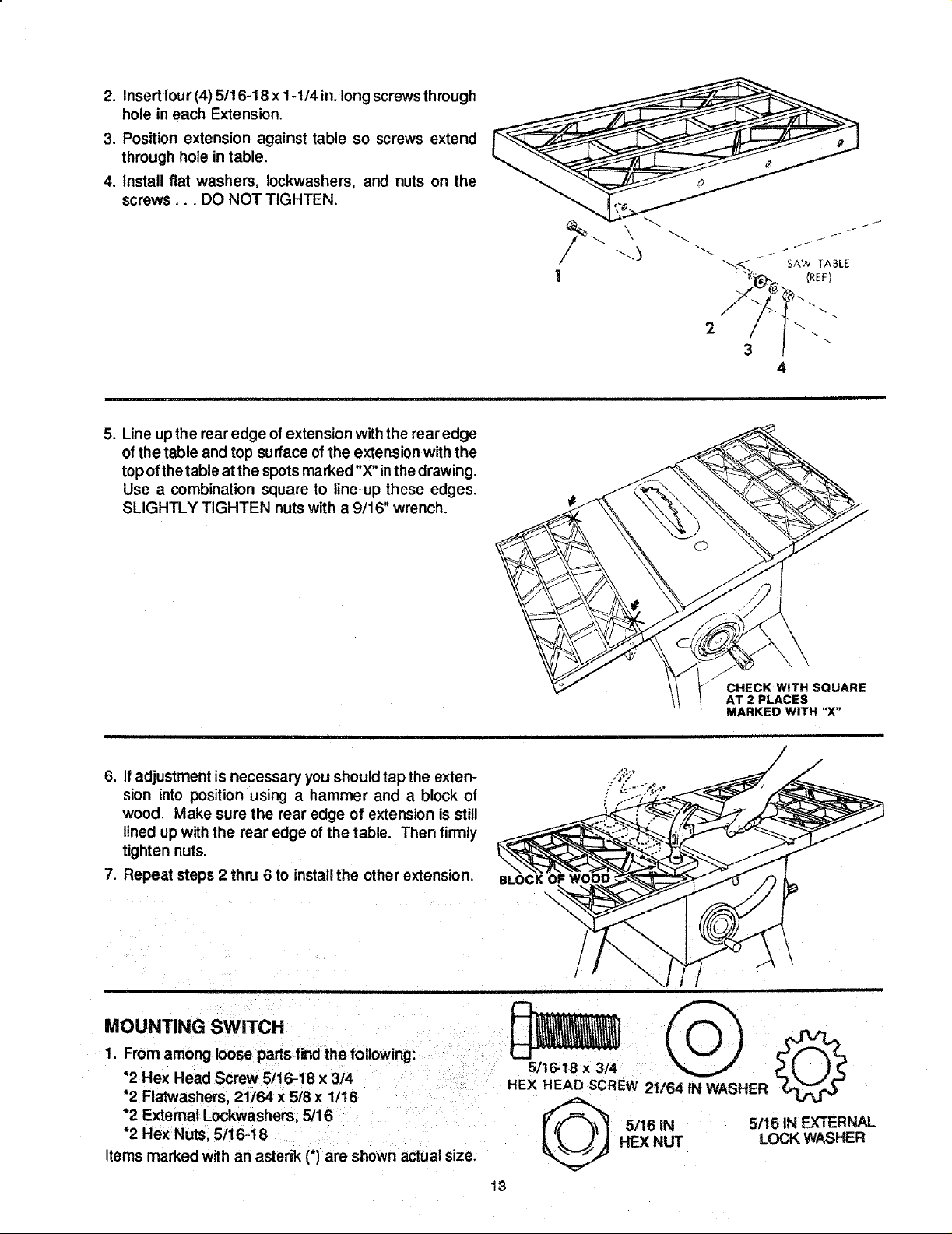

2. Insertfour (4) 5/16-18 x 1-1/4 in. long screws through

hole in each Extension.

3. Position extension against table so screws extend

through hole in fable.

4. Install flat washers, Iockwashers, and nuts on the

screws... DO NOT TIGHTEN.

5. Line up the rear edge ofextension with the rear edge

of the table and top surface of the extension with the

top of the table at the spots marked"X" inthe drawing.

Use a combination square to line-up these edges.

SLIGHTLY TIGHTEN nuts with a 9/16" wrench.

1 (REF)

SAW TABLE

2 \

3

4

CHECK WITH SQUARE

AT 2 PLACES

MARKED WITH "X"

6. If adjustment is necessary you shouldtap the exten-

sion into position using a hammer and a block of

wood. Make sure the rear edge of extension is still

lined up with the rear edge of the table. Then firmly

tighten nuts.

7. Repeat steps 2 thru 6 to install the other extension.

MOUNTING SWITCH

1. From among loose parts find the following:

*2 Hex Head Screw 5/16-18 x 3/4

*2 Flatwashers, 21/64 x 5/8 x 1/16

*2 External Lockwashers, 5/16

*2 Hex Nuts, 5/16-18

Items marked with an asterik (*) are shown actual size.

/

/

5/16-18 x 3/4

HEX HEAD SCREW2t/64 tN WASHER

5/16 IN 5/16 IN EXTERNAL

HEX NUT LOCK WASHER

13

Page 14

assembly

JAM NUT

2. Insert two 3/4 inch screws though two flat washers

then through holes inswitch holes in switch.

3. Insert screws through holes eight and ten in front

fence guide bar as illustrated.

4. Install two Iockwasher and nuts. Tighten nuts. J ".

INSTALUNG RIGHT FRONT RiP FENCE

GUIDE BAR

5/16-18

•.u,_.,, "_,.._ /8TH HOLE

IOTH HOLE

LOCKWASHER

\ GUIDE BAR

%%'--- WASHER

HEX HEAD SCREW

5/16-18 x 3/4 IN.

FRONT FENCE

(UPSIDE DOWN)

t

1. From among the loose parts, find the following hard-

ware;

*2 Hex Head Screws, 5/16-18 x 1-3/4

"1 Hex Head Screws, 5/16-18 x 3/4

*4 Lockwashers, 5/16 External Type

*4 Hex Nuts 5/16-18

*3 Spacers, 3/4 diameter x 1/2 long

"1 Hex Head Screw 5/16-18 x 1-1/4

*2 Flat Washers 5/8 x 1/16

1 Bracket

Items marked with an asterik (*) are shown actual size.

2. Put the bracket against the right edge of the right

extension so the bracket is lined up with the FIRST

hole near the front of the extension. Insert a 3/4 long

screw through a flat washer, through top hole in the

bracket, and through the FIRST hole in the extension.

Install a Iockwasher and nut on the screw. Tighten the

nutonly slightly.

5/16-18 x 1-!/4 iN

HEX HEAD SCREW 5/16 IN EXTERNAL

5/16 IN

LOCK WASHER HEX NUT

HEX HD. SCREW 5/16-18 x 3/4 IN

5/8 X 1/16 IN WASHER 3/4 IN, DIA. X 1/2 IN. .,_/ II

SPACER

BRACKET

HEX NU

EXTERNAL

LOCKWASHER HEX HEAD

SCREW

5116-18 x 3/4 IN

3. Lay Guide Bars on saw table.

NOTE: The various holes inthe Bar allow them to be

positioned on the saw and also makes them adapt-

able to other models.

4. Insert a 1-3t4 inch/ong screwthrough the THIRDhole

5. Place spacers on screws.

14

LEFT SIDE OF

FRONT GUIDE BAR

TTH HOLE TURNED END FOR END

3RD HOLE AFTER SCREWS ARE

(GUIDE BAR I$ TO BE

INSTALLED)

SCREW

S/16-18 x 1-3/4 IN.

\

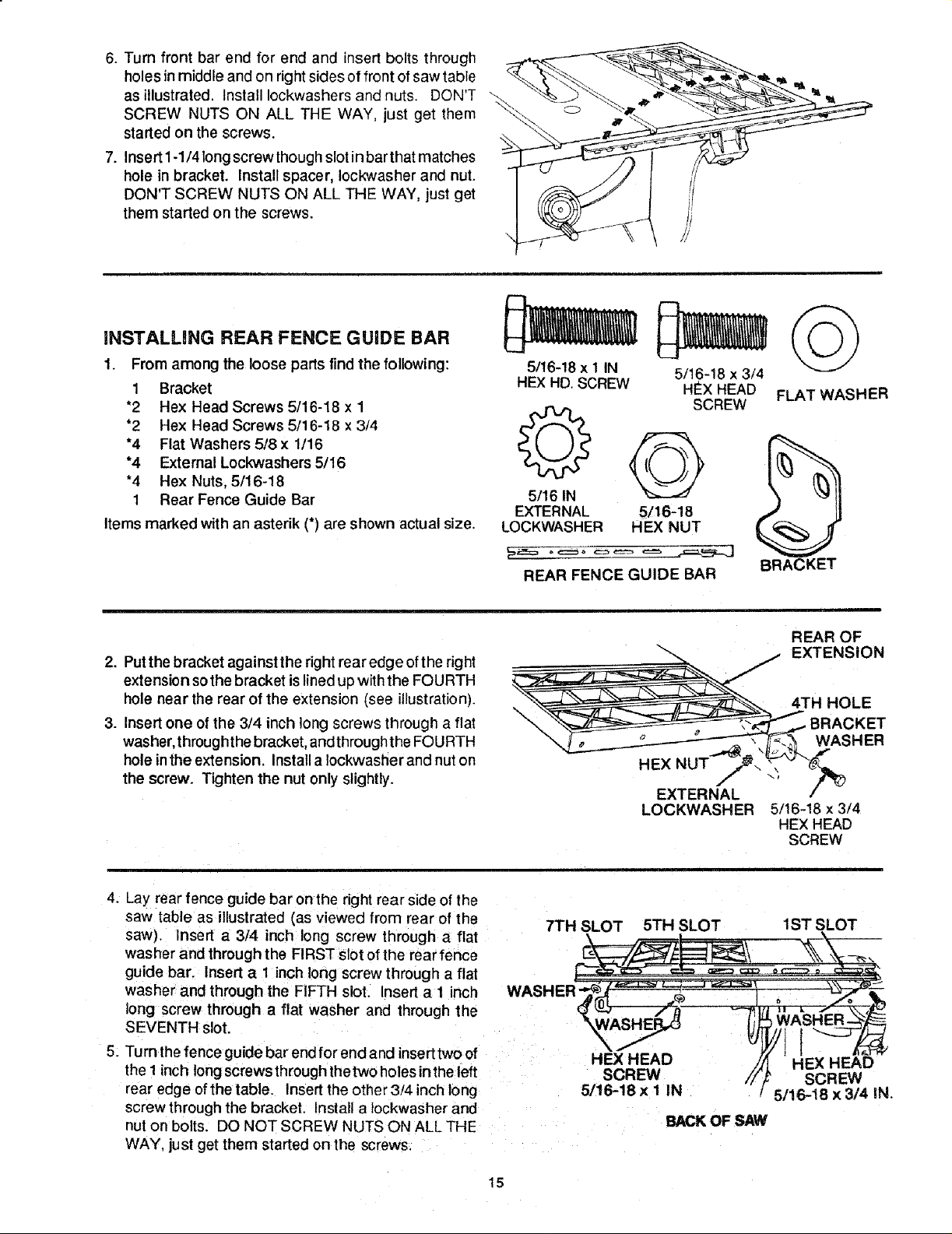

Page 15

6. Turn front bar end for end and insert bolts through

holes in middle and on right sides of front of saw table

as illustrated. Install Iockwashers and nuts. DON'T

SCREW NUTS ON ALL THE WAY, just get them

started on the screws.

7. Insert 1-1/4 long screwthough slot in bar that matches

hole in bracket. Install spacer, Iockwasher and nut.

DON'T SCREW NUTS ON ALL THE WAY, just get

them started on the screws.

iNSTALLING REAR FENCE GUIDE BAR

1. From among the loose parts find the following:

1 Bracket

*2 Hex Head Screws 5/16-18 x 1

*2 Hex Head Screws 5/16-18 x 3/4

*4 Flat Washers 5/8 x 1116

*4 External Lockwashers 5/16

*4 Hex Nuts, 5/16-18

1 Rear Fence Guide Bar

Items marked with an asterik (*) are shown actual size.

2. Putthe bracket against the right rear edge of the right

extension sothe bracket is lined up with the FOURTH

hole near the rear of the extension (see illustration).

3. Insert one of the 3/4 inch long screws through a flat

washer, through the bracket, andthrough the FOU RTH

hole inthe extension. Install a Iockwashe rand nut on

the screw. Tighten the nut only slightly.

5/16-18 x 1 IN

HEX HD.SCREW

5/16 IN

EXTERNAL 5/16-18

LOCKWASHER HEX NUT

REAR FENCE GUIDE BAR

5/16-18 x 3/4

HEx HEAD

\

HEX NUT

EXTERNAL

LOCKWASH ER

SCREW

FLAT WASHER

BRACKET

REAR OF

EXTENSION

4TH HOLE

IKET

WASHER

5/16-18 x 3/4

HEX HEAD

SCREW

4. Lay rear fence guide bar on the right rear side of the

saw table as illustrated (as viewed from rear of the

saw). Insert a 3/4 inch long screw through a flat

washer and through the FIRST slot of the rear fence

guide bar. Insert a I inch long screw through a flat

washer and through the FIFTH slot. Insert a I inch

long screw through a flat washer and through the

SEVENTH slot.

5. Turn the fence guide bar end for end and inserttwo of

the 1 inch long screwsthrough thetwo holes inthe left

rear edge ofthe table. Insert the other3/4 inch long

screw through the bracket. Instal] a tockwasher and

nut on bolts. DO NOT SCREW NUTS ON ALL THE

WAY. just get them started on the screws.

7TH SLOT 5TH SLOT

1ST SLOT

I

HEX HEAD

SCREW

5/16-18 x 1 IN

BACK OF SAW

15

HEX HEAD

SCREW

5/16-18 x 3/4 IN,

Page 16

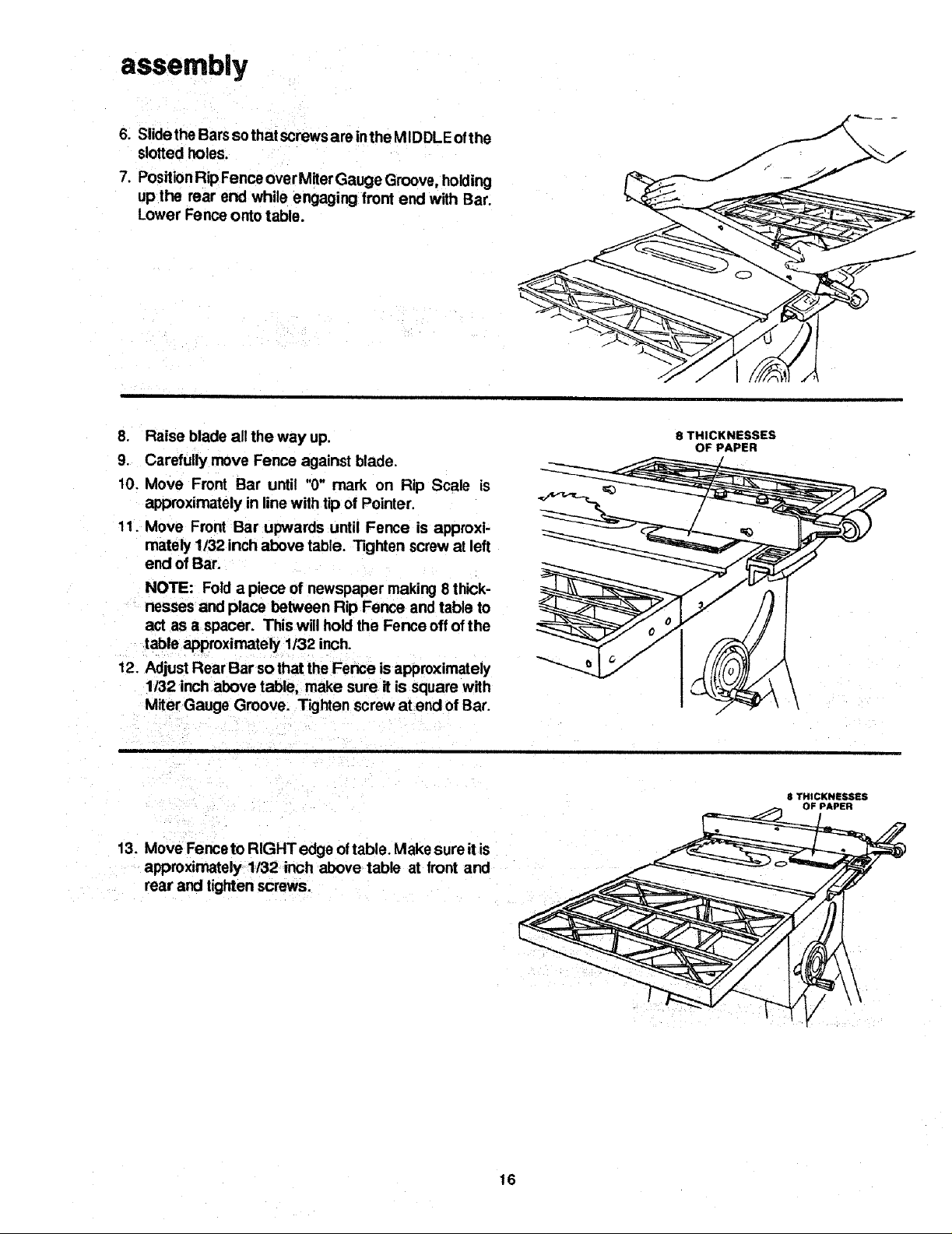

assembly

6. Slide the Barssothat screwsare inthe MIDDLE ofthe

slotted holes.

7. PositionRipFenceoverMiterGaugeGroove, holding

up the rear end while engaging front end with Bar.

Lower Fence onto table.

8. Raise blade all the way up.

9. Carefully move Fence against blade.

10. Move Front Bar until "0" mark on Rip Scale is

approximately in line with tip of Pointer.

11. Move Front Bar upwards until Fence is approxi-

mately 1/32 inch above table. l-_Jhten screw at left

end of Bar.

NOTE: Fold a piece of newspaper making 8 thick-

nesses and place between Rip Fence and table to

act as a spacer. This will hold the Fence off of the

table approximately 1/32 inch.

12. Adjust Rear Bar so that the Fence is approximately

1/32 inch above table, make sure it is square with

Miter Gauge Groove. Tighten screw at end of Bar.

13. Move Fenceto RIGHTedge oftable. Make sure itis

approximately 1/32 inch above table at front and

rear and tighten screws.

8THICKNESSES

OF PAPER

8 THICKNESSES

16

Page 17

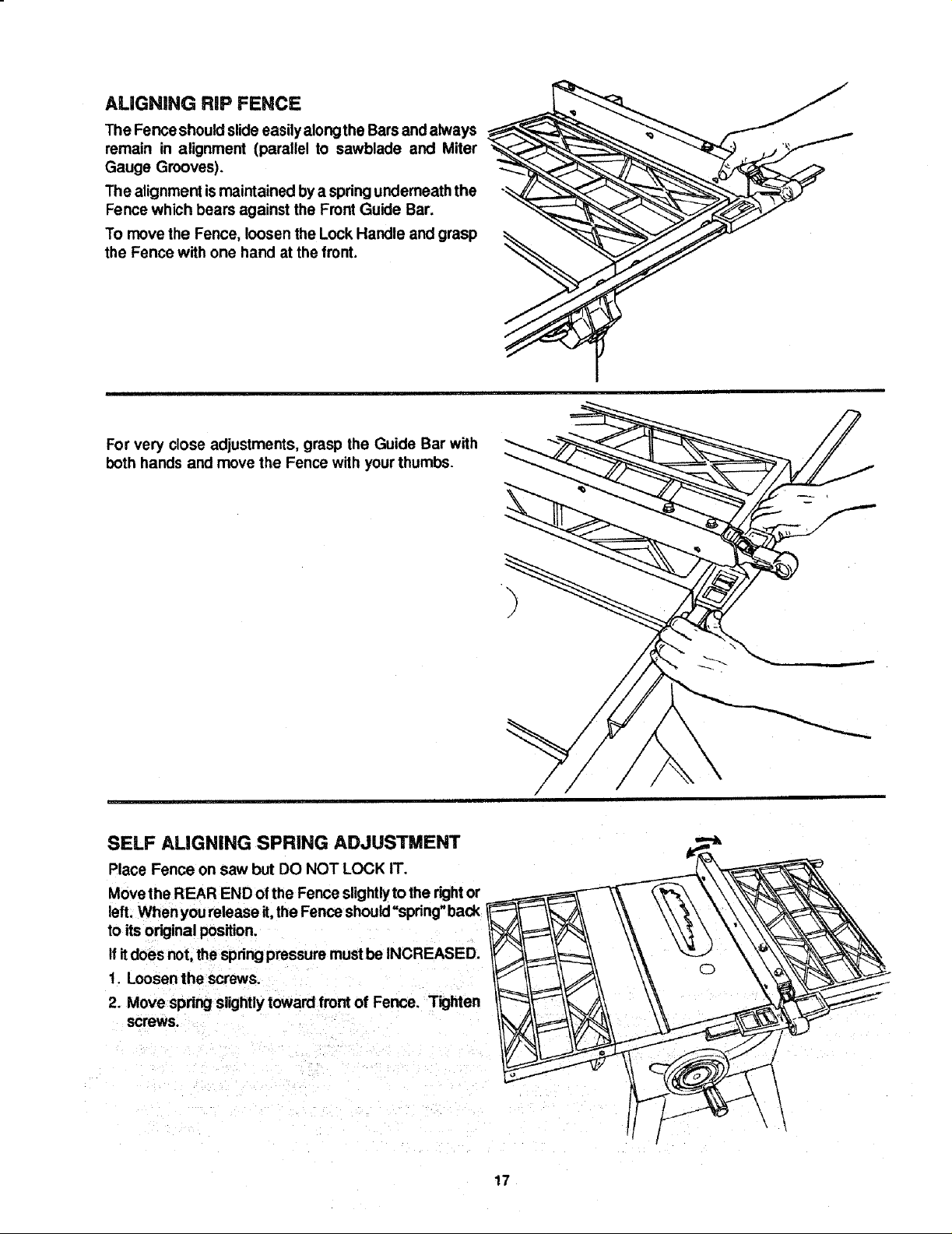

ALIGNING RiP FENCE

The Fence should slideeasilyalongthe Bareand always

remain in alignment (parallel to sawblade and Miter

Gauge Grooves).

The alignment ismaintained by a spring underneath the

Fence which bears against the FrontGuide Bar.

To move the Fence, loosen the Lock Handle and grasp

the Fence with one hand at the trent.

For very close adjustments, grasp the Guide Bar with

both hands and move the Fence with your thumbs. "_"

SELF ALIGNING SPRING ADJUSTMENT

Place Fence on saw but DO NOT LOCK IT.

Move the REAR END of the Fence slightlyto the rightor

left. When you release it,the Fence should=spring" back

to its original position.

If itdoes not,the spring pressure must be INCREASED.

1. Loosen the screws.

2. Move spring slightlytoward front of Fence. Tighten

screws.

/

\

17

Page 18

assembly

Ifthe Fence does not slide easily along the Bars, the

pressure of the spring can be REDUCED.

1. Loosen the screws.

2. Move spring slightly toward rear of Fence. Tighten

screws.

WARNING: Toavoid Injury from jarnsorklckbacks,

be sure to push properly adjusted Lock Lever all the

way down until the lever rests on the stop before

using the Rip Fence.

RiP FENCE LOCK LEVER ADJUSTMENT

The Rip Fence Lock Lever, when locked down, should

holdthe Rip Fence securely, it should not be difficultto

pushdown and lock.

If Lock Lever does not lock fence securely:

1. Raise Lock Lever.

2. Tighten the adjusting nut using a small screwdriver

until the lever, when locked, holds the Rip Fence

securely.

IfLock Lever isdifficultto push down:

1. Raise Lock Lever.

2. Loosen the adjusting nut using a small screwdriver

untilthe lever is easy to push down and holdsthe Rip

Fence securely.

SPRING

SLIDE SPRING TO

ADJUST PRESSURE

ADJUSTING NUT

FENCE HEAD

RiP FENCE ALIGNMENT ADJUSTMENT

1. The Rip Fence must be PARALLEL with the

sawblade and Miter Gauge Grooves. Move Fence

until it is along side of Groove. DO NOT LOCK IT. It

should be parallel to Groove. ff it is not;

A. Loosen the two Hex Hd. Screws.

B. Hold Fence head tightlyagainst Bar. Move end of

Fence so that it is parallel with Groove.

C. Alternately tighten the screws.

D. Recheck alignment.

E. Repeat steps as needed.

WARNING: A misallgned fence can cause kick-

backs and jams. To avoid Injury, follow these irv

structlons until the fence is properly aligned.

HEXSCREWS

FENCE HEAD

18

Page 19

ADJUSTING RiP SCALE POINTER

1. Turn Elevation Handwheel clockwise untilblade is up

as high as it will go.

IMPORTANT: BLADE must be SQUARE (90°) to

TABLE, in order to ALIGN Rip Scale.

2. Position Fence on right side of sawblade so that it

touches the sides of the teeth, tighten Lock Handle.

3. Loosen screw holding the Pointer, adjust so that it

pointsto "0"on the Rip Scale, tighten screw.

NOTE: If you cannot adjust Pointer so that itpoints to

"0", loosen the screws holding the Front Guide Bar

and move the Guide Bar.

INSTALLING BLADE GUARD

1. From among the loose parts, find:

*2 Hex Head Screws, 1/4-20 x 5/8

*3 Hex Head Screws, 5/16-18 x 5!8

*2 Hex Head Screws, 5/16-18 x 1

*2 Hex Nuts, 1/4-20

*2 Lockwashers, 1/4 Extemal Type

*2 Lockwashers, 5/16 ExternalType

"1 Thumbscrew

1 Blade Guard Support

1 Spreader Support

1 Spreader Rod

Items marked with an astedk (*) are shown actual size.

@

1/4-20

HEX NUT

Q

_161N.

EXTERNAL

LOCKWASHER

©

1/4 IN.

EXTERNAL

LOCKWASH ER

BLADE GUARD

SUPPPORT

LOCK HANDLE

THUMBSCREW

1/4-20 X 5/8 IN.

HEX HD. SCREW 5/16-18 X 5/8 IN.

2. Before installingthe Blade Guard, you must check

the heeling adjustment (parallelism of sawblade to

Miter Gauge Groove). The procedure for making this

check and adjusting it are found in the "ADJUST-

MENTS" secion of this manual. Refer to "HEELING

ADJUSTMENTOR PARALLELISM OF SAW BLADE

TO MITER GAUGE GROOVE."

3. Lower the blade.

4. Screw the Motor Base Clamp Screws part way into

cradle. Screw the 5/16-18 x 5/8 inch Hex Hd. screw

into the Blade Guard Support.

5. Attach Blade Guard Support. DO NOT TIGHTEN

SCREWS.

HEX HD. SCREW

5/16-18 X 1 IN.

, HEX HD. SCREW

BLADE (

SUPPORT

5/16-18 X

5/8 IN.

HEX HD.

SCREW

5/16.18X1 IN. ]

HEX HD. SCREWS

19

SPREADER ROD

SPREADER SUPPORT

\

5116-18 X 5/8 IN

HEX HD. SCREWS

Page 20

assemb|y

6. Insert Spreader Rod intoSpreader Supportuntil pin

fits into notch. Insert Thumbscrew and tighten it.

7. Slide Spreader Rod into Blade Guard Support until

end of Rod is even with edge of Support. Tighten

Hex Head Screw in Support.

8. Attach Spreader to Spreader Support so that the

edge of the Spreader is ever_with the edge of the

Spreader Support. Tighten screws.

9. Raise Anti-Kickback Pawls (hold in place with a set-

screwwrench -see below). AlignSpreader SQUARE

to table,

Tighten both 5/16-18 x 1 inch Hex Head Screws.

THUMB SCREW

\

\

SPREADER

ROD

\

\

FLAT

SURFACE

\ (INTO SUPPORT)

SPREADER

SUPPORT

17 "

U

1/-2ONE\ I II II _L-""-.-.._

HD. SCREW ___\ I_'__

114 IN. LOCKWASHER _ II I.j'_Trr'" \ /l_";) _J/.i/"

,,,-,O.EX.UT '/I I t

SPREADER EDGE f I II "_.%'_ ,_t_J \\ v_l I

EVEN WITH SPREADER I U _h_'_ \/_--II \\ \\ _1 I

10. Raise blade all the way up, make sure itis square

with table.

11.Raise Blade Guard. Lift up both Anti-Kickback

Pawls. Insert one of the Setscrew Wrenches inthe

notches to hold the Pawlsout ofthe way.

13.Loosen Hex Head Screw in Guard Support and

move Spreader so that it touches blade of square.

Tighten screw.

EmDOFROD - _ ,J,/_-'<'-"_---_A\ I I

EVEN WiTH EDGE _ _._=1 _ _.._._ I [

HE\ HD.

SCREW

Page 21

15.IMPORTANT: To work properly, the Spreader

must always be PARALLEL to the sawblade and

adjusted so the cut workplece will pass on either

side at the Spreader without binding or skewing

to the side.

NOTE: The Spreader isthinner than the width of the

cut (KERF) by approximately six thicknesses of

paper.

16. Make two folds ina small piece (6 x 6 inch)ofordinary

NEWSPAPER making three thicknesses.

The folded paper will be used as a "spacing gauge".

17.Place RipFence on table, CAREFULLY move it

against blade so that it is parallel to the blade, and

just TOUCHEStips of sawteeth. Tighten Rip Fence

Lock Lever.

18.Insert folded paper between Spreader and Fence.

19.Using 7/16 wrench loosen the 1/4-20 hex head

screws so the Spreader can slide sideways.

20. Hold Spreader flat against Fence. Tighten screws

using 7/16 inch wrench.

21.To remove Blade Guard and Spreader, loosen 7/16IN. WRENCH

Thumbscrew. DO NOT LOOSEN OTHER SCREWS.

This lets you remove and replace the Guard without

disturbing the Spreader alignment.

SPREADER ..__ -- . ....

KERF WOOD

LOOKING DOWN ON SAW

/

FOLDED PAPER

MOUNTING THE MOTOR

Model 113.298721 & 113.298761

Check Motor Rotation

1. The Motor must rotate CLOCKWISE when viewed

from the 5/8 inch shaft.

2. MAKE SURE "KEY' IS REMOVED FROM SHAFT.

3. Place the Motor on your workbench or on the floor.

4. Plug the cord into a properly grounded outlet (See

"MOTOR SPECIFICATIONS AND ELECTRICAL

REQUIREMENTS" section) Notice the rotation of

the shaft. If it is not turning CLOCKWISE, do not

assemble or attempt to operate saw until motor with

correct rotation is obtained,

KEY

TION

518 IN.

DIA, SHAFT

21

Page 22

assembly

5. From among the loose parts, find the following

hardware:

*4 Carriage Bolts, 5/16-18 x 3/4

*4 Hex Nuts 5t16-18

*4 Lockwashers, 5/16 External Type

1 Motor Pulley

1 Belt Guard "L" Bracket

1 Belt Guard Support Bracket

Items marked with an asterisk (*) are shown actual size.

= == i ,=,,,,,H i , i= ,1=

POSITIONING MOTOR ON MOTOR MOUNTING

BASE

Model 113.298761

1. Put the motormounting base against the flat surface

of a workbench.

2. Positionthe motor so the end with terminal cover is

facing you.

3. Loosen both cradle clamp screws.

4. Put a square against the LEFT side of the motor and

against the top of the workbench.

5. Turn the motor inside the cradle clamps untilthe top

of both capacitors touch the square

6. Tighten bothcradle clamp screwsIo holdthe motor in

this position.

WARNING: Failure to properly Install motor may let

workplece strike capacitor cover during bevel or

compound miter cuts.

=l

MOUNTING MOTOR ON MOTOR BASE

Model 113.298721 & 113.298761

1. Place Motoron MotorBase so that shaft is pointing

to the right. Insert bolts through holes in Base, then

throughtheMotorMountingBase. Installlockwashers

and nuts, DO NOT TIGHTEN AT THIS TIME.

2. PositionMotor so that edge of Motor Foot and Motor

Base are even. Slide Motor allthe way tothe RIGHT.

Slip the long part of the "L" Bracket fully under the

Motor so the short part is just under shaft (Model

113.298721 only). Tighten the fournuts.

_ BELT GUARdeD

BELTGUARD MOTOR SUPPORT BRACKET

"L_BRACKET PULLEY

5/16-18 x 3/4 IN

CARRIAGE BOLT

LOOSEN BOTH CRADLE CLAMP SCREWS

r.---

CAPACITORS"

SQUARE

WELDED MOTOR

MOUNTING BASE

LOCKWASHER

5/16 IN.

5/16-18

5/16-18 5/16 IN EXTERNAL

HEX NUT LOCKWASHER

MOTOR

MOTOR MOUNTING

BASE

WORK BENCH

THESE TWO

EDGES EVEN

CARRIAGE BOLT

5116-18 X 3/4 iN.

away from Motor. DO NOTTIGHTEN SETSCREW.

4. Install 3116 inchsquare key (furnished with Motor) in

groovesin PulleyandMotorshaft. DONOTTIGHTEN

SETSCREW.

, = =

INSTALUNG BELT

Model 113.298721 & 113.298761

1. Lift Motor and insert the TWO PINS on Motor Base

intoHOLES in Cradle. Push Motor in as far as itwill

go.

BELT GUARD SUPPORT "" PULLEY

INSERTED EVEN WITH

MOTOR END HUB

2. Lowerthe blade, installBelt on Saw Pulley and Motor

Pulley.

3. Sight along edges of both pulleys and move Motor

Pulley so that belt is parallel to the edges of bol

Pulleys. Tighten the set screw in the Motor Pulley.

22

Page 23

4. iMPORTANT:Measurethe distance from end of

Motor shaftto Pulley, Mark this dimension down;

you will need it later when reinstalling the Pulley.

5. Make sure blade is 90°totable, raise it allthe way up.

6. Lift Motor untiledge ofwasher isevenwith endof slot

tighten pivotscrew. Inthis position, pullMotortoward

you (pinswillslide out of Cradle) until Belt is TIGHT,

tighten the two Motor Base Clamp Screws.

7. Loosen Pivot Screw slightly.

8. Lower the saw blade all the way down.

9. iMPORTANT: Motor should pivot freely down-

ward as blade is lowered. If it does not, LOOSEN

the Pivot Screw some more.

10.Pivot Screw must be adjusted only tight enough to

allow Motor to pivot FREELY as blade is raised and

lowered. This will maintain constant tension on Belt.

11.Put your hand around the belt half way between the

two Pulleys and squeeze Belt until two sides of Belt

touch, The Motorshould move freely as you squeeze

the Belt. If Motor does not move freely, Belt tension

must be readjusted.

INSTALUNG BELT GUARD

Model 113.298721

=

EDGE OF WASHER

EVEN WITH END

OF SLOT

/

MOTOR PULLEY

SCREW

"L"BRACKET

k MOTOR BASE

CLAMP SCREWS_

1. Remove the Belt and Motor Pulley.

2. Screws furnished with Guard are "Self Threading".

Screwthem into holesin BeltGuard SupportBracket,

then remove them.

3. Position BeltGuard Support Bracket and Belt Guard

Support as shown and installthe screws. Make sure

Motor shaft is in CENTER of hole in Support.

SUPPO.T..ACKET

oEL,oo,°o

BELT GUARD SUPPORT SCREW

BELT GUARD

"L" BRACKET

TWO HOLES CLOSEST

TOGETHER

SELF-THRSADING

INSTALLING BELT GUARD

Model 113.298761

1. Remove the Belt and Motor Pulley.

2. Screws furnished with Guard are Serf Threading."

Screw them intoholesin Belt Guard Support Bracket,

then remove them,

3. Position BeltGuard Support Bracket and Belt Guard

Support as shown and installthe screws. Make sure

Motor Shaft is in CENTER of hole insupport.

BELT GUARD

SUPPORT

BELT GUARD

PIVOT

-SCREW

\

PIVOT

SCREW

BELT GUARD

SUPPORT BRACKET

'1 TWO HOLES CLOSEST

TOGETHER

/

CENTERED

BELT GUARD SUPPORT

Page 24

assembly

iNSTALLiNG BELT GUARD

Model 113.298721 & 113.298761

1. install three Clips (furnished with Guard) 90° apart

starting with one Clip at the end of the Guard as

shown. LONG END of Clip facing AWAY from you.

BELT GUARD

OPENING

_ CLIPS

N

LONG END

2. Reinstall Motor Pulley the same way itwaswhen you

aligned the Belt,

3. Place Belt on Saw Pulley. Insert end ofBell through

opening in END of Guard.

4. Slip Belt over Motor Pulley.

5. Press Guard onto Support sothat bottom of Guard is

approximately 3/4 inch away from Belt.

NOTE: To remove Guard, lift up on LONG TABS of

Clips, pull Guard outward. The Clips should remain

on the Belt guardSupport.

BELT

PLUGGING iN MOTOR

1. From among the loose parts find:

2 Wire Ties

2. Route Motor Cord along dghtside ofcabinet andsnap

ties in 1/4 inchbole in side ofcabinet. Secure cord in

wire ties,

3. Plug Motor cord intooutlet onside of switchbox.

24

3/4 iN.

EXTENSION REMOVED FOR

PICTURE CLARITY

WIRE TIES

Page 25

getting to know your saw

S TABLE INSERT

|0 EXACT-I-CUT ANTIKICKBACK

6 MITER GAUGE

RiP FENCE

LOCK HANDLE

4 TILT LOCK HANDLE

(UNDERNEATH TABLE)

9 SAWBLADE

J 7 BLADE GUARD

PAWLS

RiP FENCE

ATTACHING FACING

HOLES; FOR

2 ELEVATION HANDWHEEL

1 ON-OFF SWITCH

ON-OFF SWITCH

CAUTION: Before turning switch "ON", make

sure the blade guard Is correctly Installed and

operaUng properly.

The On-Off Switch has a locking feature. THIS

FEATURE IS INTENDED TO PREVENT UN-

AUTHORIZEDAND POSSIBLE HAZARDOUS USE

BY CHILDREN AND OTHERS.

A. To turn saw ON, stand to either sideot the blade,

never in line with it, insert finger under switch

lever and pull END of lever out.

Afterturning switchON, always allow the blade to

come up to full speed before cutting.

Do notcycle the Motor Switch on and oft rapidly,

as this may cause the sawblade to loosen. Inthe

event this should ever occur, allow the sawblade

to come to a complete stop and retighten the

arbor nutnormally, not excessively. Never leave

the saw while the power in =ON",

B. Totum saw OFF, PUSH leverin. Never leave the

saw untilthe cutting tool has come to a complete

stop.

C. To lockswitchinOFF position, hold switch IN with

one hand, REMOVE key with other hand.

WARNING: For your own safety, lower blade or

other cutting tool below table surface. (If blade

IsUlted. return It to vertical, 90°, position). Always

lock the switch "OFF". When saw Is not in use,

remove key and keep it in a safe place. Also, in

the event of a power failure (all ofyour,ghts go

out) turn switch off, lock It and remove the key.

This will prevent the saw from starting up again

when the power comes back on,

3 TiLT HANDWHEEL

KEY

(YELLOW PLASTIC)

25

Page 26

getting to know your saw

2

ELEVATION HANDWHEEL ... elevates or

Iowersthe blade, Turnclockwiseto elevate, counter-

clockwise to lower.

3

TILT HANDWHEEL...tilts the blade for bevel

cutting. Turn clockwise to tilt toward left,counter-

clockwise to tilt toward dght.

When the blade is tilted to the LEFT as far as itwill

go, it should be at 45" to the table and the bevel

pointer should point 45°.

NOTE: There are LIMIT STOPS inside the saw

which prevent the blade from tilting beyond 45° to

the LEFT and 90° to the RIGHT. ( See "ADJUST-

MENT,<;AND ALIGNMENTS"section"BLADE TILT,

OR SQUARENESS OF BLADE TO TABLE").

4

TILT LOCK HANDLE... locks the blade inthe

desired tilt position. To loosen, turn counterclock-

wise. Push handle in and turn itto anotherposition

ifnecessary in order to tighten or loosen.

5

RIP FENCE... islocked inplace by pushingthe

Lock Lever downuntilthe lever rests onthe stop. To

move the Fence, lift the Lock Lever and grasp the

Fence with one hand at the front.

Holes are provided inthe Rip Fence for attaching a

woodfacing when using theDado Head, or Molding

Head.

Select a piece of smooth straight wood approxi-

mately 3/4 inchthick, and the same size as the Rip

Fence.

Attach it to the Fence with three Round Head #10

Wood Screws, 2 inches long. TOremovethe facing,

loosen the screws, slide the facing forward and pull

the screws through the round holes.

WOOD FACING

t

If necessary, the Miter Gauge head can then be

swiveled slightlyto compensate and then locked.

Slots are provided in the Miter Gauge for attaching

an Auxiliary Facing to make it easier to cut long

pieces. Be positive Facing does not interfere with

the proper operation of the Sawblade Guard.

Select a suitable piece of smooth straight wood, ddll

two holes through it and attach it with screws.

NOTE: When bevel crosscutting, attach Facing so

that it extendsto the dght of the Miter Gauge and use

the Miter Gauge in the groove to the righl of the

blade.

FACING

STb.PI. +s+soT \ I I-

FO.STO..,.

7 BLADEGUARD...must always be in place and

working properlyfor all thru-sawing cuts. That is, all

cuts where the blade cuts completely through the

workpiece.

To remove the Guard for special operations, loosen

the Thumbscrew andslidethe Guard offof the Rod.

DO NOT DISTURB THE SETTING OF THE ROD.

When replacingthe Guard, make sure the PIN inthe

Rod engages with the NOTCH in the Spreader

Support. Make sure Thumbscrew is tightened se-

curely.

8 TABLE INSERT... is removable for removing

or installing blades or other cutting tools.

6 MITER GAUGE .., headislockedin positionfor

crosscuttingorrnitedngby tighteningthe LockKnob.

ALWAYS LOCK IT SECURELY WHEN IN USE.

Gauge to cut miters.

NOTE: The slotsfor the Stop Pin and the gradu-

ations are manufactured to very close tolerances

which provide accuracy for average woodworking.

In some cases where extreme accuracy is required,

when making angle cuts. forexample, make a trial

cut and then recheck it.

\

\

/

SCREW

A, Lower the blade below the table surface.

B. F_aiseBlade Guard.

C. Loosen screw.

D. Lift insert from front end, and pull toward front of

saw.

26

Page 27

NEVER OPERATE THE SAW WITHOUT THE

PROPER INSERT IN PLACE. USE THE SAW-

BLADE INSERT WHEN SAWING. USE THE

COMBINATION DADO MOLDING INSERT WHEN

USING A DADO OR MOLDING HEAD.

REMOVING AND iNSTALLiNG

SAWBLADE

WARNING: For your own safety, turn switch

"OFF"and remove plug from power sourceoutlet

before removing or installing sawblade.

A. Raise Blade Guard, remove Insert.

B;TO REMOVE Blade, place ablockofwood against

front ofBlade, PULL arborwrench toward youto

LOOSEN arbor nut.

C. To TIGHTEN arbor nut, place a block of wood

against rear of Blade, PUSH wrench away from

you.

When installingthe Blade, make sure the teeth are

pointing toward the front of the saw and that the

Blade and Collars are clean, and free from any

burrs.

The HOLLOW side ofthe collarmustbe against the

Blade.

Always tighten the arbor nut securely.

NOTE: When using the Dadoor Molding Head, it is

not necessary to install the loose Collar.

To replace insert.

Place insert intoopening in table and push toward

rear of saw to engage Spring Clip and until keyslot

in insert will drop over screw. Tighten screw.

Do nottighten screw to the point where itwilldeflect

the insert.

WOOD BLOCK

NUT

BLADE GUARD NOT SHOWN

FOR PICTURE CLARITY

BLADE GUARD NOT SHOWN

PICTURE CLARIFY

ICH

OR NUT

LOOSE

COLLAR

ARBOR ._ ,_.._

<3 ._ _' _ :\ ARBORI NUT

TEETH POINTING TO ---._, , _.:?__._

FRONT OF SAW

10 EXACT-I-CUT

The "yellow" Plastic Disc imbedded in the table En

front of the sawblade, is provided for marking the

location of the 'sawcut" on the workpiece.

A. Check Disc. If it is above table surface, place a

piece of hardwood on top of itand tap itdown.

B. Withblade 90° (square totable) crosscuta piece

of wood.

C. Pull Miter Gauge back until wood is over Disc.

Using a sharp pencil, mark a line on Disc.

D. With Miter Gauge in fight hand groove, follow

same procedure and mark another line on Disc.

E. These lines indicate the -path" of the cut (ken')

made by the sawblade.

F. When cutting the workpiece, line up mark on

workpiece with line on Disc.

BLADE GUARD NOT SHOWN

FOR PICTURE CLARITY

27

Page 28

safety instructions for basic saw operations

BEFORE EACH USE:

1. Inspect your saw.

A. To avoid injuryfrom accidental starting, unplugthe

saw, turn the switch offand remove the Switch Key

before raising or removing the Guard, changing

the cutting tool, changing the setup or adjusting

anything.

B. Check for alignment of moving pads, binding of

moving pads, breakage of pads, mounting, and

any other conditions that may affect the way it

works. If any partis missing, bent, or broken inany

way, or any electrical parts don't work properly,

turn the saw off and unplug the saw.

C. Replace damaged, missing,or failed parts before

using the saw again.

D. Use the Sawblade Guard, Spreader, and Anti-

Kickback Pawls forany thin-sawing (whenever the

blade comes through the top of the workpiece).

Make sure the Pawlswork properly. Makesurethe

Spreader isin linewith the sawblade.

E. REMOVE ADJUSTING KEYS AND WRENCH ES.

Form habit of checking forand removing keys and

adjusting wrenches from tool before turning it on.

F. To avoid injury from jams, slips or thrown pieces

(kickback and throwback):

1. USE ONLY RECOMMENDED ACCESSORIES

(See page 44). Follow the instructions that

come withthe accessories. Using other acces-

sories may be dangerous.

2. Choose"the right blade orcutting accessory for

the material and the type of cutting you plan to

do.

3. Never use grinding wheels, abrasive cut-off 6.

wheels, friction wheels (metal slitting blades)

wire wheels orbuffingwheel. Theycan flyapart

explosively.

4. Choose and inspect your cutting tool carefully.

a. To avoid cuttingtoolfailure andthrownshrap-

nel (broken pieces of blade), use only 10" or

smaller blades or other cutting tools marked

for speeds of 3450 rpm or higher.

b. Always use unbroken, balanced blades

designed to fit this saw's 5t8 inch arbor.

c. When thru-sawing (making cuts where the

blade comes through the workpiece top),

always use a t 0 inch diameter blade. This

keeps the Spreader in closest to the bade.

d. Donor overtighten arbor nuL Use arbor

enches to snug itsecurely. 7. For dusty operations, wear a dust mask along

e; Use onlysharp blades with properlyset teeth, with the safety goggles.

Consult aprofessionalblade sharpenerwhen

in doubt, nailsor foreign objects in the part of the workpiece

f. Keep blades clean ofgum and resin, to be cut.

5. Adjust table inserts flush with the table top.

NEVER use the saw without the proper insert.

6. Make sure all clamps and locks are tight and no

parts have any excessive play.

2. Keep work area clean

A. Cluttered areas and benches invite accidents.

Floor must not be slippery from wax or sawdust.

B. To avoid burns orother fire damage, never use the

saw near flammable liquids, vapors or gases.

C. To avoid injury frorn accidental blade contact, don't

do layout, assembly, or setup work on the table

while the blade is spinning. It could cut or throw

anything hitting the blade.

Plan aheadto protect your eyes, hands, face, ears.

AVOID ACCIDENTAL STARTING - Make sure

switch is "OFF" before plugging saw in.

3. Plan your work

A. USE THE RIGHT TOOL - Don't force tool or attach-

ment to do a job it was not designed for.

B. Dress for safety:

1. Do not wear loose clothing, gloves, neckties or

jewelry (rings, wristwatches). They can get

caught and draw you into moving pads.

2. Wear nonslip footwear.

3, Tie back long hair.

4. Roll long sleeves above the elbow.

5. Noise levels vary widely. To avoid possible

head ng damage, wear ear plugs or muffs when

using saw for long periods of time.

Any power saw can throw foreign objects into

the eyes. This can cause permanent eye

damage. Wear safety goggles (not glasses)

that comply with ANSI Z87.1 (shown on pack-

age). Everyday eyeglasses have only impact

resistant lenses. They are not safety glasses.

Safety goggles are available at Sears retail

catalog stores. Glasses or goggles not in com-

pliance with ANSI Z87.1 could seriously hurt

you when they break.

JR

C. Inspect your workpiece. Make sure there are no

28

Page 29

D. Plan your cutto avoid KICKBACKS and THROW-

BACKS -when a partor allofthe workpiece binds

on the blade and is thrown violently back toward

the front of the saw.

f. Never cut FREEHAND: Always use either a

Rip Fence, Miter Gauge or fixture to position

and guide thework, so itwon't twist,bind onthe

blade and kickback.

2. Make sure there's no debris between the work-

piece and its supports.

3. Whencutting irregularlyshapedworkpieces,

plan your work so itwill not slip and pinch the

blade:

a. A piece of molding, for example, must lie flat

or be held by a fixture or jig that will not let it

twist, rock or slip while being cut. Use jigsor

fixtures where needed to prevent workpiece

shifting.

b. Use a different, better suited type of toolfor

work that can't be made stable.

4. Use extra caution with large, very small or

awkward workpieces:

a. Use extra supports (tables, saw horses

blocks,etc.) for anyworkpieces large enough

to tip when not held down to the table top.

NEVER useanother person as a substitute

for a Table Extension, or as additional sup-

port for a workpiece that is longer or wider

than the basic saw table, or to help feed,

support or pull the workpiece.

b. Neverconfinethepiecebeingcutoff. That is,

thepieceNOT againstthe Fence,MiterGauge

or fixture. Never hold it, clamp it, touch it, or

use lengthstops against it. It must be free to

move. Ifconfined, itcouldgetwedged against

the blade and cause a kickback or throw-

back.

c. Never cutmore than oneworkpiece at atime.

d. Never turnyourtable saw "ON" before clear-

ing everything except the workpiece and

related support devices off the table.

4. Planthewayyouwill pushtheworkplecethrough.

A. NEVER pug the workpiece through. Start and

finishthe cut from the front ofthe table saw.

B. NEVER put your fingers or hands in the path of

the sawblade or other cutting tool.

C. NEVER reach in back ofthecuttingtoolwith either

hand to hold-down or support the workpiece,

remove wood scraps, or for any other reason.

D. Avoid awkward operations and hand positions

where a suddenslip couldcause fingers or hand to

move into a sawblade or other cutting tool.

E. DONq" OVERREACH. Always keep good footing

and balance.

F. Push the workpiece against the rotation of the

blade. NEVER feed material into the cutting tool

from the rear of the saw.

G.Always push the workpiece all the way past the

sawblade.

H. As much as possible, keep your face and body to

one sideof the sawblade, out of line with a possible

kickback or throwback.

I. NEVER turn the saw"ON"before clearing the table

of all tools, wood scraps, etc., except the work-

piece and related feed or support devices for the

cut planned.

WHENEVER SAW BLADE IS SPINNING

WARNING: Don't let familiarity (gained from fre-

quent use of your table saw) cause a careless mis-

take. Always remember that a careless fraction of a

second is enough to cause a severe injury.

1. Before actually cutting with the saw, watch it while it

runs for a short while. If it makes an unfamiliar noise

or vibrates a lot, stop immediately. Turn the saw off.

Unplugthe saw. Do not restart untiltinding andfixing

the problem.

2. Make sure the top of the arbor or cutting tool turns

toward the front of the saw.

3. Set the cutting tool as low as possible for the cut

you're planning.

4. KEEP CHILDREN AWAY. All visitors should be kept

a safe distance from work. Make sure bystanders are

clear of the saw and workpiece.

5. Let the blade reach full speed before cutting.

6. DON'T FORCE TOOL. It will do the ._obbetter and

safer atits designed rate. Feed the workpiece intothe

blade only fast enough to let it cut without bogging

down or binding.

7. Before freeing any jammed material:

A. Turn switch "OFF".

B. Unplug the saw.

C. Wait for all moving parts to stop.

D. Checkblade, Spreader and Fence for proper align-

ment before starting, again.

8. To avoid throwback of cut off pieces;

A. Use the Guard Assembly.

B. To remove loose pieces beneath ortrapped inside

the Guard:

1; Turn saw "OFF".

2. Remove Switch Key.

3. Wait for blade to stop before lifting the Guard.

29

Page 30

safety for basic saw operations

BEFORE LEAVING THE SAW

1. Turn the saw off,

2. Wait for blade to stop spinning.

3. Make workshop child-proof. Lock the shop. Discon-

i i,,i

nect master switches. Remove the yellow Switch

Key. Store it away from children and others not

qualified touse the tool.

4. Unplug the saw.

basic saw operation - using the miter gauge

CROSSCUTTING, MITER CUTTING, BEVEL CUT- 2.

TING, COMPOUND MITER CUI-rlNG and when RAB-

BETING across the end of a narrow workpiece, the

MITER GAUGE IS USED.

WARNING: For your own safety, aNvays observe the

following safety precautions in addition to the safety

instructions on pages 2, 3, 4, 5, 28, 29 & 30. 3.

ADDITIONAL SAFETY INSTRUCTIONS FOR

CROSS CUT TYPE CUTS

Before S_rting:

1. Never use the Rip Fence when crosscutting,

WORK HELPERS

Before cutting any wood on your saw, study all of the

"Basic Saw Operations."