Craftsman 113.29501 Assembly, Operating Instructions And Parts List

--A

i4---.

i

ii------,

I?.-j.

:....;-

?

t'

..

<*

.,:!

*>.

.ka

/

,j

$;:

i-:.....

;.

...

*:,;-

>:

,$

ASSEMBLY,

OPERATING

INSTRUCTIONS

,

,,:.

..

,i

...

.

.

.,,:.,

...

2.

;-

.:

/

AND

PARTS

LIST

FOR

L-.

--

,.-..

-...

__

.

CRAFTSMAN

.I2

INCH

RADIAL

SAW

I

MODEL

NUMBER

1

13.29501

p

I

I

The Model Number will be found on a plate attached to your saw,

at the left side of the base.

Always mention the Model Number in

all correspondence regarding the CRAFTSMAN RADIAL SAW or when

ordering repair parts.

Carefully read the instructions provided, observe the simple

safety precautions

and

you

will have many hours

of

satisfactory

use

from

your

new Craftsman

tool.

1

HOW

TO

ORDER REPAIR PARTS---,

All

parts listed herein may be ordered through SEARS, ROEBUCK AND

I

CO.

or SIMPSONS-SEARS LIMITED. When ordering parts

by

mail from

the

catalog order house which serves the territory in which you live,

selling prices will be furnished on request or parts

will be shipped at

prevailing prices and you will be billed accordingly.

I

/

WHEN

ORDERING

REPAIR PARTS, ALWAYS

GlVE

THE FOLLOWlNG

I

INFORMATION AS SHOWN

IN

TH!S LIST:

1.

The PART NUMBER

3.

The

MODEL

NUMBER

1

13.29501

2.

The PART NAME

4.

The

NAME

of item - RADIAL SAW

COAST

TO

COAST NATION-WIDE

SERVICE

FROM

SEARS

FOR

YOUR

CRAFTSMAN RADIAL SAW

SEARS, ROEBUCK

AND

CO.

and

SIMPSONS-SEARS LIMITED in Canada

back up your investment with quick,

expert mechanical service and genu

-

ine CRAFTSMAN replacement parts.

If

and when you need repairs or serv

-

ice, call on us to protect your invest

-

ment

in

this fine piece

of

equipment.

I

J

SEARS,

ROEBUCK

AND

C0.-

U.

S.

A.

IN

CANADA,

SIMPSONS-SEARS

LIMITED

1

Ptinted

in

U.

S.A.

Part

No.

63161

PObVER

TOOL

SAFETY

...

APdD

YOU

3

MINUTES

of required reading for the home Crafts-

safety

in

mind, permitting you to use the tool without

man..

.

whether this

is

your first purchase or you're

concern

so long

as

certain basic rules are observed.

an old hand

at

power tools.

We'd

like

to call particular attention to some of the

YOU'VE

JUST BOUGHT A QUALITY

SEARS

TOOL.

more important rules to follow for maximum enjoy-

designed

to

give

you many years of top performance

rnent of your Sears power tools.

and trouble

-

free operation.

It's

also

designed with'

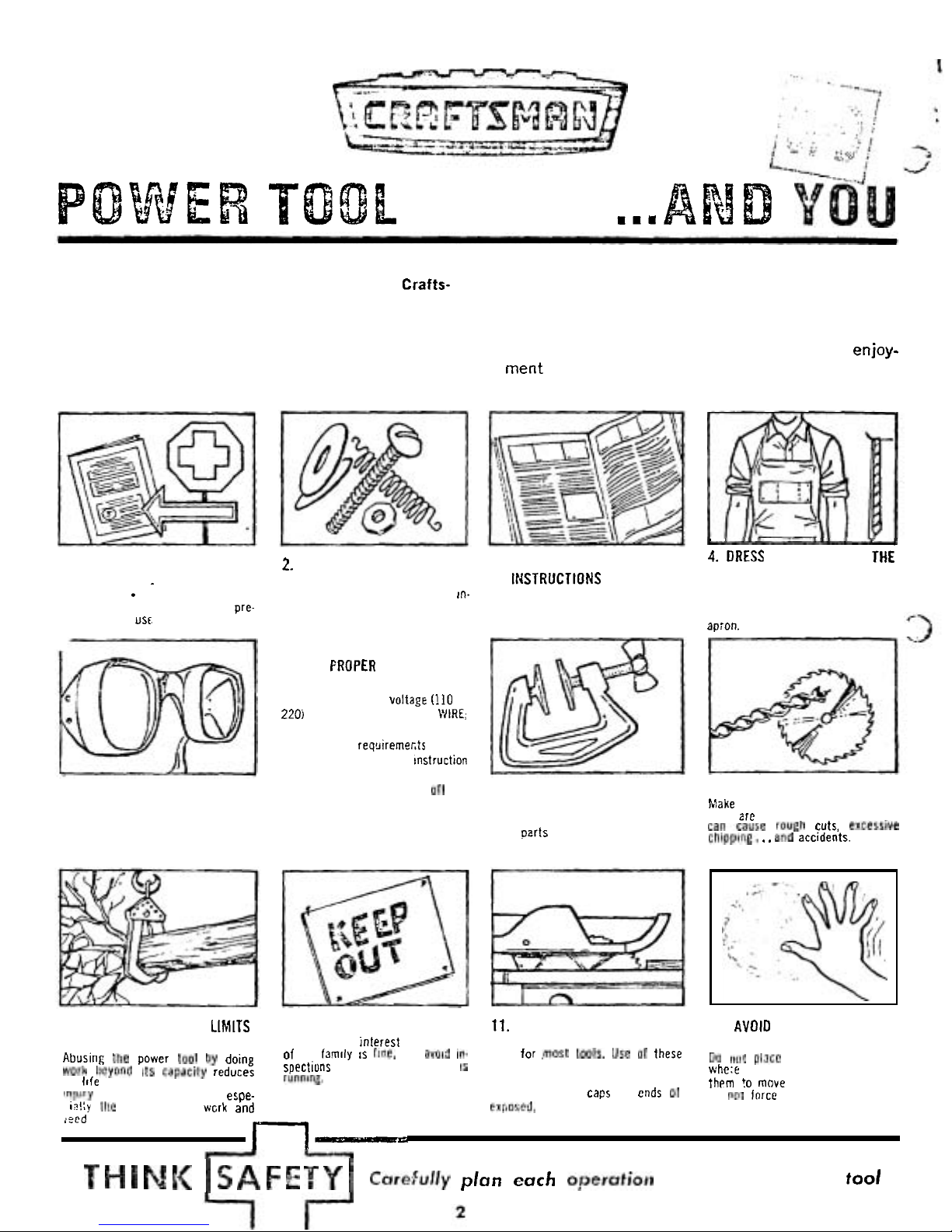

1.

READ THE INSTRUCTION

MANUAL.

.

.

completely accurately.

Pay

special attention to safety pre-

cations and usc of safety features.

5.

WEAR

SAFETY GLASSES

Safety glasses or eye shields are

recommended for all power tool

operations.

2.

INSPECT THE POWER TOOL

THOROUGHLY

Set

up

Ihe machine according to rn-

structions. Make certain all parts

are included.

6.

USE PROPER ELECTRICAL

CONNECTIONS

Make

certain proper voltag~

(110

or

220)

is used. USE

A

GROUND

\'/IRE;

AND

A

SUITABLE

PLUG. IF REQUIRED.

Check fusing

reqclireme~ts of the

tool as outlined in the

instruction

manual.

Get in the habit

of

turning of! the

tool when not in use.

3.

FOLLOW OPERATING

It4STRUCTIONS CAREFULLY

They have been developed to in

-

sure correct procedure and pre

-

vent accidents.

4.

DRESS

P

R

O

P

E

R

L

Y

FOR

THE

WORKSHOP

Gel rid of loose clothing, roll up

sleeves (or fasten securely). remove

your tie, wear a snug

-

fitting shop

apion.

7.

DOUBLE-CHECK HOLDING

8.

KEEP CUTTING TOOLS SHARP

FIXTURES

Make certain blades, drills. cutters,

Lock all clamps tightly.

etc..

zre in top shape. Dull tools

Spin

pzrts by hand

to

check against

cancause rough cuts, excessive

misalignment or looseness before

chip~lng.

. .

and accidents.

turning on tool.

9.

DON'T EXCEED THE LIMITS

10.

KEEP SPECTATORS AWAY

11.

SAFETY

GUARDS

12.

AVOID AWKWARD HAND

OF

THE POWER TOOL

Curiosity and Interest on the part Accessory safety guards are avail

-

POSITIONS

Abusing the power tool

by

doing

of

the

family

IS

ffne, but

avad

in-

able for .most tools. Use

of

these

IICI~

pl~ce hands in a position

work lleyond its capacity reduces

spections when the poner tool

IS

guards is highly recommended.

whe:e a sudden slip could cause

its

Itfe and increases the chance

of

runfllne.

th~rn !o move into a cutting tool.

ln~c~fy to the operator. Watch espe-

Keep protective caps on ends of

Do

POI

inrcc

work abnormally into

in!:y

the sizes of the wcrk and er[~osrd, rotating shafts. any cutting tool.

.

15cd rate.

n-

T

H

N

I.(

I

S

A

F

E T Y

I

cart?fdr~

plan

each

operofiotl

before

turning

on

tool

.

.

..

,

. .

...

.

.

.

I

.

.i

:,

..

:;

;;.

;..

J,'

:

'

ASSEMBLING

AND

ADJUSTING

YOUR

SAW

/:::...i;:d::..::j

;

y;,..;

-

:'

'.

,

.+?';

i

,.

.>

1

.

POWER

SMPPLY

&

MOTOR

CONNECTIONS

lead. (The black motor cord lead is al!Zidy-con

nected to the overload protector.)

-

MOTOR

SPECIFiCATt ONS

b.

Connect the

GREEN

and

BROWN

leads to the BLUE

The AC motor used

in

this saw

is

a capacitor start, non-

lead.

reversible type, with the following specifications:

c. Twist bare ends of wires together and install a wire

Horsepower

.........

3

nut on each connection.

Voltage

.............

120 / 240

Amperes

............

13

/

6.5

d.

Push all leads carefully into motor terminal box and

Cycles

..............

60

install terminal box cover.

~l;ase

..............

Single

RPM

................

3450

Rotation (viewed from

.....

saw blade end) Clockwise

CAUTION: The motor

is

wired for 115-120

volt operation. Connect to a 20 amp. branch

circuit and use

a 20 amp., time-delay fuse.

ELECTRICAL

CONNECTiONS

NOTE: This.saw motor

is

wired at the factory

for 120

-

volt,

60

cycle,

AC

service as shown

in figure 1 and described in paragraph

1,

below. Under normal home workshop use

with proper voltage to the motor, the saw

will

operote with adequate efficiency. How

-

ever, if any of the following conditions exist,

it may be necessary to reconnect the sow

for 240 volts AC as described in paragraph

2, below.

1.

Continuous heavy-duty use.

2. Undersize wiring in circuit from motor to

power source, or overloaded circuit.

3.

Low voltage from power source to motor

(which

may be due to overlooded power

source).

The power cord must also be changed from the 120

-

volt type

to the 240

-

volt type, when changing to 240-volt operation.

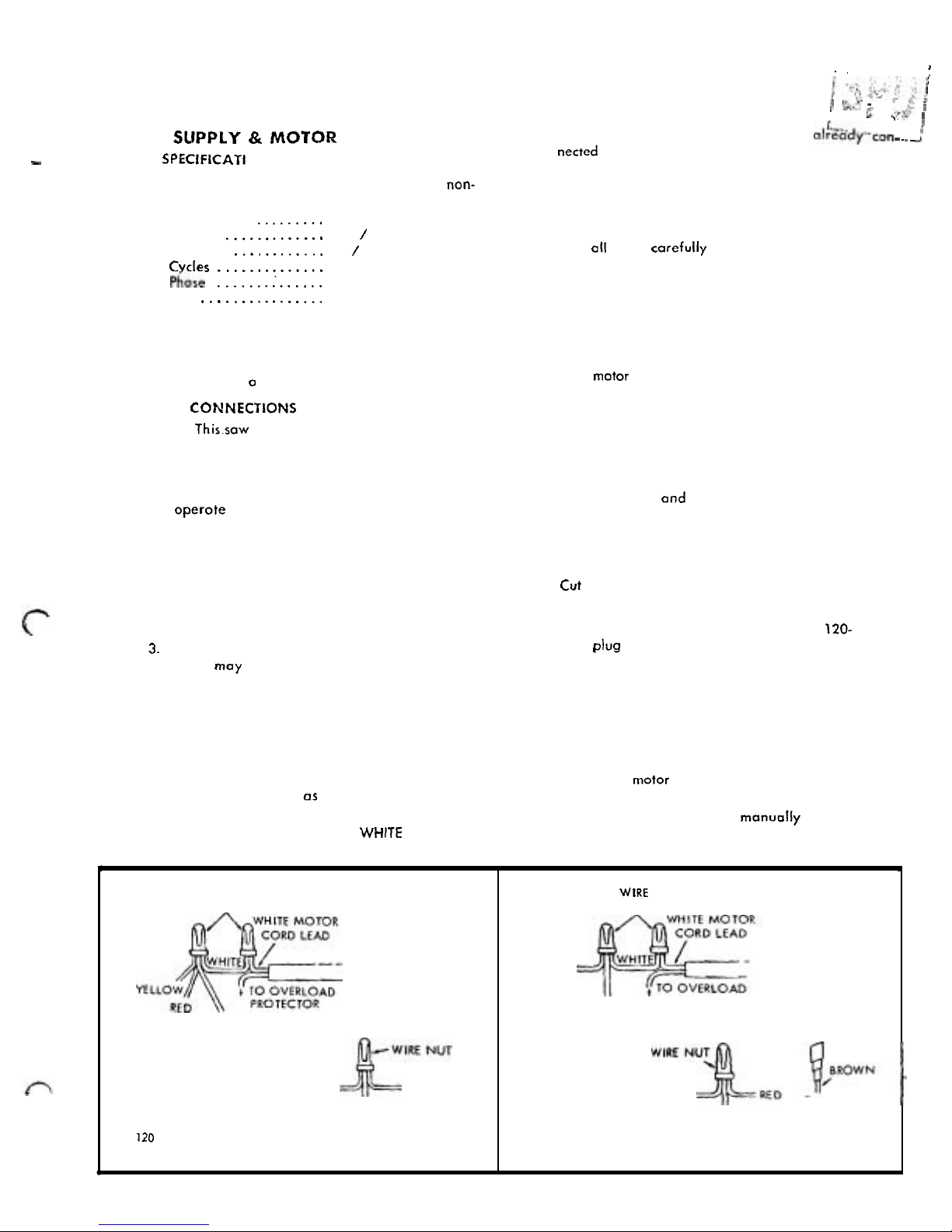

1.

Connections For 120-Volts

AC.

(See figure 1.) When

replacing a motor or connecting the saw to 120

-

volts

for any reason, make sure the wires inside the motor

terminal box are connected

as follows:

a.

Connect the

YELLOW,

WHITE, BLACK and RED leads

from the motor terminal box to the

WHlTE motor cord

2.

Connections For 240-Volts

AC.

(See figure

2.)

When

connecting the motor for 240

-

volt operation, the fol

-

lowing connections must be made inside the motor ter

-

minal

box:

a. Connect the

YELLOW,

WHITE and BLACK leads

from

mator terminal box to the WHITE motor cord

lead. Twist bare ends together and install a wire

nut as shown in figure 2.

b.

Leave the BROWN lead (from overload protector)

disconnected and insulate

it

with tape to prevent

short circuiting inside motor terminal box.

c. Connect the GREEN, RED and BLUE leads together,

twist bare ends

and install a wire nut.

d.

Push all leads carefully into motor terminal box and

install terminal box cover.

3.

Modifying

the

Power Cord.

a.

Cut off the existing molded plug (for 120-volts).

b.

Attach an appropriate 240-volt plug.

CAUTION: Do notconnect the stcndard

120-

volt plug to a 240-volt receptacle.

MOTOR

SAFETY PROTECTION

The saw motor

is

equipped with a manual-reset thermal

overload protector, designed to open the power line circuit

when the motor temperature exceeds a safe value.

1. If the protector opens the line and stops the saw motor,

press the saw switch to the

"

OFF'

position immediately

and allow the

motor to cool.

2.

After cooling to a safe operating temperature, the over

-

load protector can be closed manually

by

pushing in

the red button on the motar capacitor cover.

If

the red

I

WIRE

NUTS

BLACK

GREEN BROWN

BLUE

110

VOLTS

figure

1

I

WIRE

NUTS

YELLOW

BLACK

PROTECTOR

GREEN

TAPE

BLUE

UNCONNECTED

EXPOSED

WlRE

240

VOLTS

Figure

2

button will not snap into place immediately, the motor

is

still

too hot and must be allowed to cool for a while

longer. (An audible click will indicate protector

is

closed.)

3.

As

soori os the red button will snap into running position,

the

saw moy be started and operated normally by press

-

ing the saw switch to the

"ON"

position.

4.

Frequent opening of fuses or circuit breakers may result

if

motor

is

overloaded, or if the motor circuit

is

fused

with a fuse other than those recommended.

Do

not use

a fuse of greater copocity without consulting the power

company.

5.

Although the motor

is

designed for operation on the

voltage and frequency

specified on motor nameplate,

normal loads will be handled safely on voltages not

more than 10% above or below the

narneplote voltage.

Heavy loads, however, require that voltage at motor

terminals be not less than the voltage specified on

nameplate.

6.

Most motor troubles may be traced to loose or incorrect

connections, overloading, reduced input voltage (which

results when small size wires are used in the supply

circui:) or when the supply circuit

is

extremely long.

Always check connections, load and supply circuit when

the motor fails to perform

satisfactorily. Check wire

sizes and lengths with the table in the next poragraph.

WIRE SIZES

The followin

g

table lists recommended wire sizes for con

necting the motor to the power source. These sizes should

be maintained for trouble

-

free operotion of the saw.

Length

of

Wire

Sire

Required

Condurtor

(American Wire Gauge

No.)

120 Volt Lines

240 Volt Lines

50 feet or less No.

12

No. 14

100 feet or less No.

10

No.

12

100 feet to

150

feet No.

8

No. 10

150 feet to 200 feet No.

6

No.

8

200 feet to 400 feet No.

4

No.

6

NOTE: For circuits of greater length, the wire

size must be increased proportionately in or

-

der to deliver ample voltage to the saw motor.

:-..

NOTE: The seven basic "steps" that follow

-'---..

are essential in order to insure correct align-

/

ic:

;:.-;

.,

I.

:.

..

.

ment of the saw.

:.'

.

.

I

C.

2. ..

,

7

>.\,

..~.

..

_

.

..

..

;

&,

'.

3'L.

:'

4

WARNING: Make sure the power cord is

,p

..

t;.

not plugged into an electrical outlet when

2

b?,

working on the saw.

-..__.

---

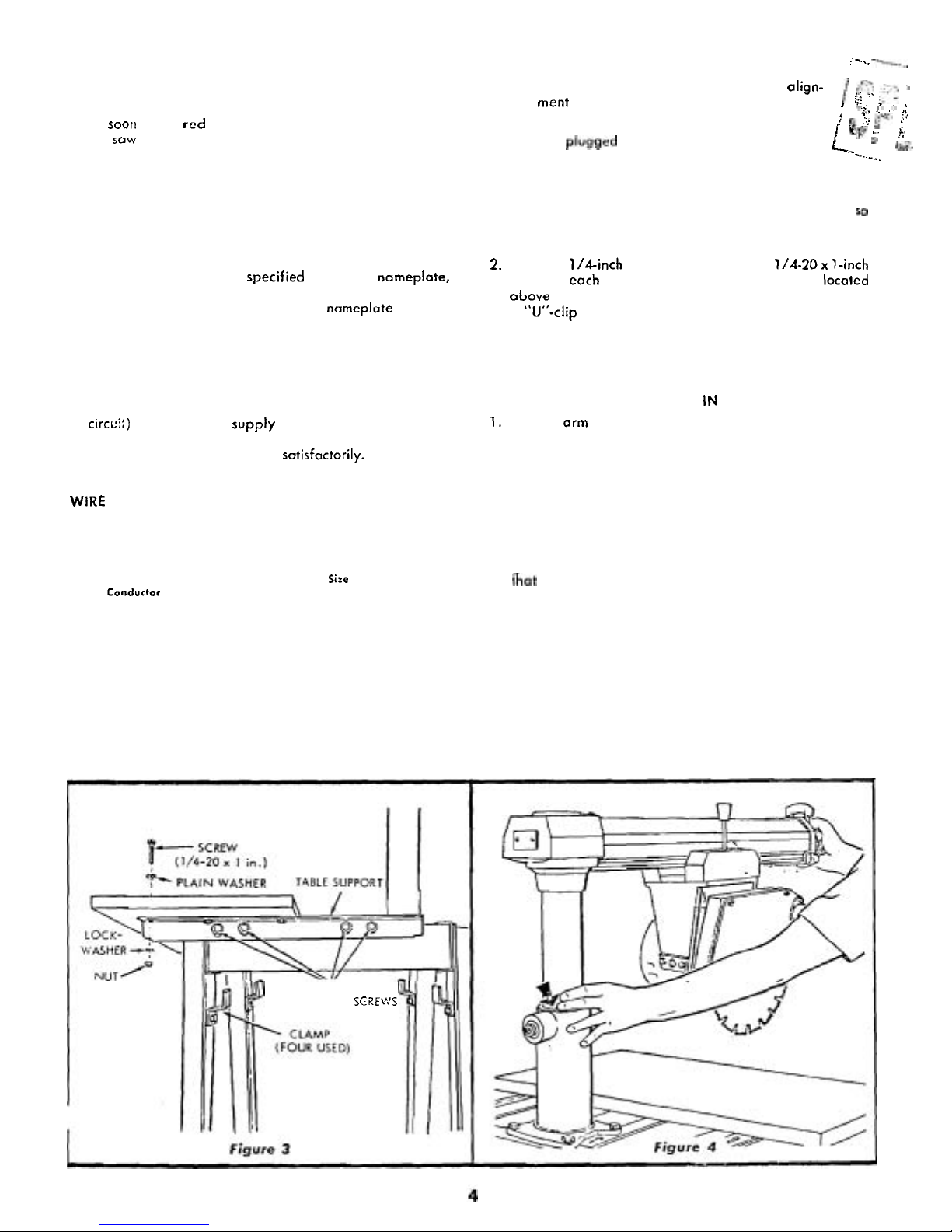

STEP

ONE - INSTALLATION OF FRONT TABLE

1. Place the large front table board on toble supports

so

that holes in board match holes in supports. (See fig

-

ure

3.)

2. Place a l/dinch plain wosher and a l/4-2Ox l-inch

screw

in

eoch of the seven counterbored holes located

above the table supports. One screw

is

threaded into

a

"U"-clip nut mounted on the No. 2 support.

3.

Attach lockwashers and nuts to the six screws in the

table supports. Do not tighten these screws at this time.

STEP

TWO

-

CHECKING

FOR

LOOSENESS

OF

COLUMN

TUBE

IN

COLUMN SUPPORT

1.

Tighten arm latch handle

(22,

figure 20.)

2.

Grasp arm latch handle (22, figure 20) with one hand

and hold fingers of other hand at parting line between

column tube and column support. (See figure 4.)

Apply

gentle side force to the radial arm in opposing directions.

Any looseness between column and column support (in

-

dicated by arrow in figure

4)

can be felt with fingers.

3.

If looseness can be felt, at point indicated by the arrow

in figure 4, perform operations outlined in instructions

hat follow:

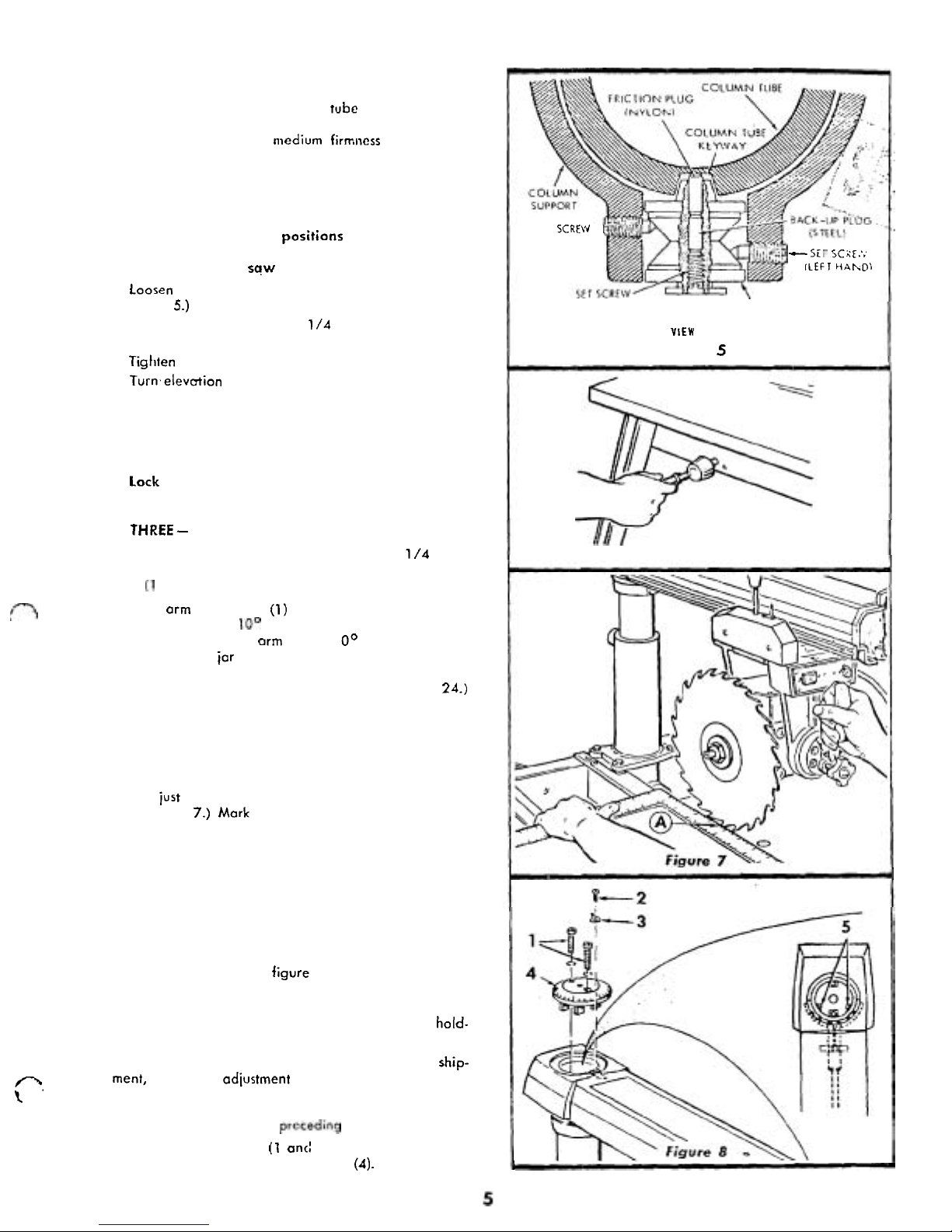

NOTE Before attempting to adjust the col

-

umn tube key, the function of this adjustment

should be understood. Figure 5 shows a sec

-

tional view through the column tube support

(looking downward) at this location. By loos

ening the left-hand set screw and tightening

the right

-

hand set screw the column tube key

will be forced tighter into the column tube

keyway. Conversely, loosening the right

-

hand set screw and tightening the left-hand

TABLE

SUPPORT

MOUNTING SCREtAJS

set screw, the column key will be retracted

out of the column tube keyway. The set

screw in outer end of column

tube key must

be loosened while adjustment

is

being made

and tightened with

medium firm~icss after

adjustment

is

completed. This screw applies

pressure on the Nylon friction plug and pro

-

vides smoother elevation movement of col

-

umn tube. This set screw should be tightened

to provide maximum smoothness of opera

-

tion. Right

and

left positions are given

with operator facing the saw

-

stand

-

ing

in

front of saw table.

a.

Loosen set screw in center of column tube key. (See

figure

5.)

b.

Loosen left-hand set screw

1/4

turn. (See figure

5.)

c. Tighten right-hand set screw. (See figure

5.)

d.

Tighten left-hand set screw. (See figure

5.)

e. Turn.elevution crank to raise and lower radial arm.

(See figure

6.)

If too tight, loosen right-hond set screw

(figure

5)

slightly ond check again for smooth oper

-

ation. When correct, tighten left-hand set screw

f.

Tighten set screw in center of column tube key (figure

5)

until smoothest operation

is

obtained.

g.

Lock the yoke clamp handle

(7,

figure

20)

and

bevel lock knob

(17)

securely.

STEP

THREE-

SQUARING

THE CROSS CUT

1.

Loosen the arm latch handle

(22,

figure

20)

1/4

turn.

Make sure the yoke clamp handle

(7)

and bevel lock

knob

(1

7)

are tight.

rl

2.

Pull the arm latch lever

(1)

outward and move radial

arm approximately

lo0

to the right. Release arm latch

lever and move radial

arm into the

O0

(index) position.

Do not bump or

jar the arm. Push the arm latch handle,

or arm. latch lever solidly with palm of hand in order

to seat arm lock pin

in

the arm latch. (Refer to figure

24.)

3.

Tighten arm latch handle. (Refer to "PRECISION

IN

-

DEXING" for detailed instructions on indexing the radial

arm.)

4.

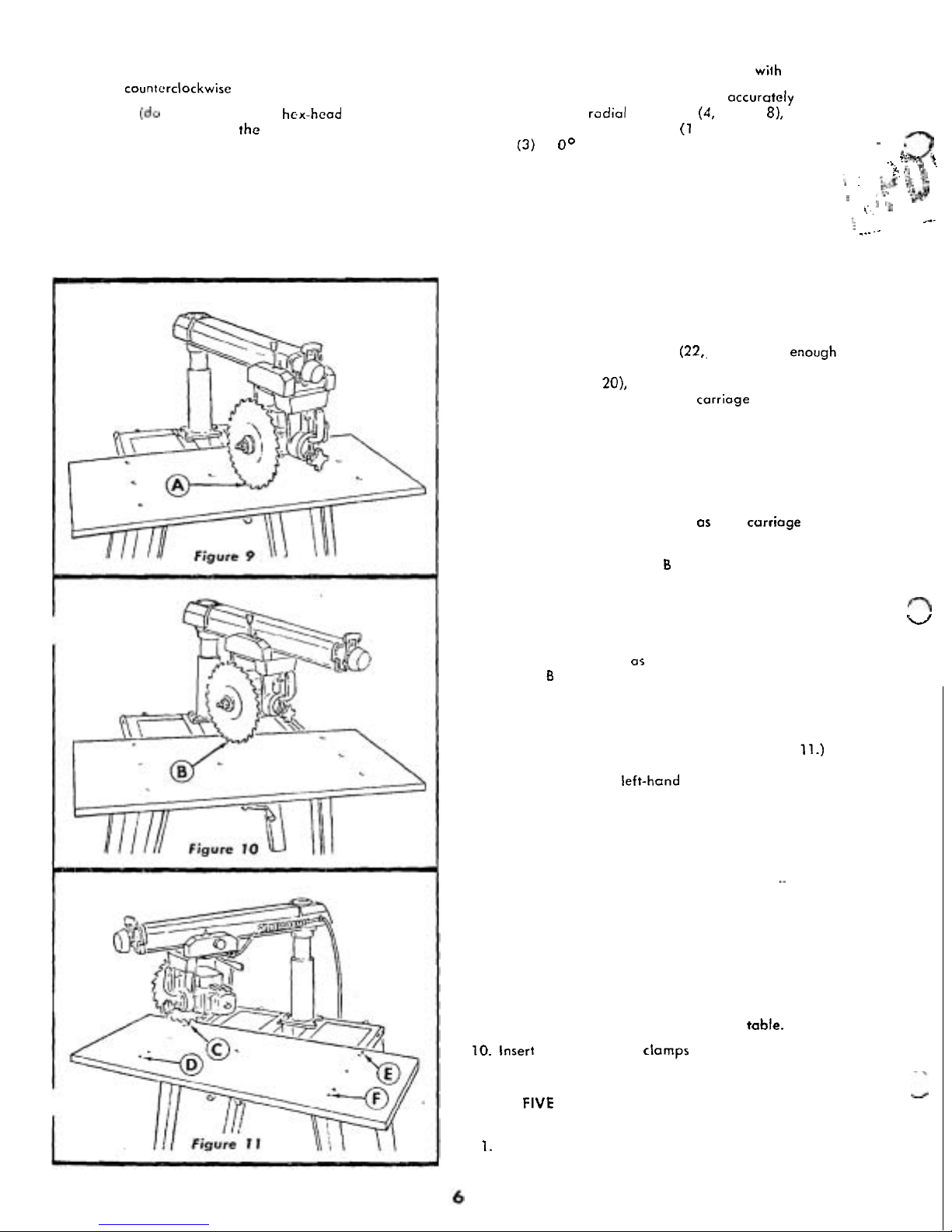

Place a framing square on the table as shown in figure

7

and position the saw and square until the leg of the

square

iust contacts a tooth of the saw blade. (Position

"A"

,

figure

7.)

Mark this tooth with crayon or chalk.

5.

When the carriage

is

moved back and forth on the radial

arm, the saw tooth

"A"

should just touch the square at

all positions. If saw tooth

"A"

does not touch the square

at all points, make the following adjustments:

a. If saw tooth (

"A"

, figure

7)

moves away from the

square when moving the blade from the rear toward

the front of the table, tap the right

-

hand front edge

of the table.

b.

If

the saw tooth ("A", figure

7)

moves into the square

when moving saw from the rear to the front of saw

table, tap the left

-

hand front edge of table.

c.

Recheck

. .

.

and, if correct, tighten all table hold-

down screws. (See figure

3.)

6.

In extreme cases, due to rough handling during ship-

C

ment, the above adiustment procedure may not be suf

-

ficient. Make the following adjustment only after tight

ening the table screws and the cross-cut cannot be

squared accordin

g

to the

preceding

adjustment routine.

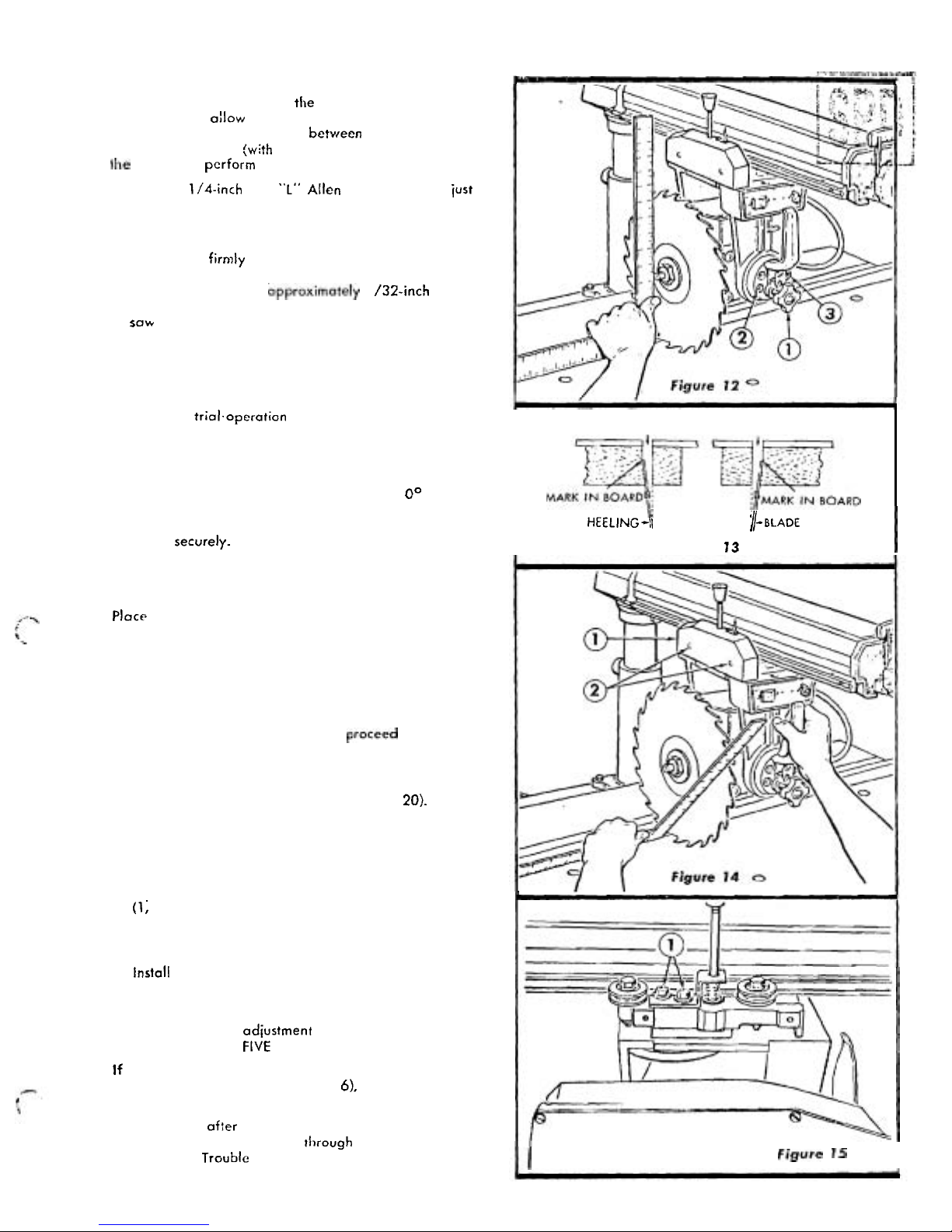

a. Remove three screws

(1

ancl

2,

figure

8),

miter-scale

indicator

(3)

and radial arm cap

(4).

SET

SCREVJ

-

(RIGHT

HAND!

-

Si

1

5C2E

.';

CLEFT

HAhDi

COLUMN

TUBE

KEY

SECTIONAL VIEW LOOKING OOAN

Figure

5

-7'w

Figure

6

b.

Turn the arm latch handle

(22,

figure 20) one-quarter

turn

countcrclockwisc but do not. pull it out.

c.

Loosen (do not remove) two hex-head screws

(5,

fig

-

ure

8)

located inside the column tube.

d. Move radial arm slightly in the proper direction to

make saw tooth

("A",

figure

7)

follow edge of square

when the saw blade

is

moved in and out in a "cross

-

cut" manner.

e. Re

-

tighten the hex-head screws

(5,

figure

8)

and arm

latch handle.

f. Recheck travel of blade tooth

("A")

wilh the square.

g.

After the cross-cut has been

accurately

squared,

install the

radial arm cap

(4,

figure

81,

miter-scale

indicator

(3)

and screws (1 and

2).

Set the indicator

-

(3)

at O0 position.

.

I,.

*3

.

..

i>'

.'

.,.

..

.s

!.

.

$.

!)

8

.

STEP

FOUR

-

ADJUSTING

THE

TABLE

PARALLEL

:

;&!$

$

3

TO RADIAL

ARM

!

.\,

.

.

'@

(,,

5

:i

NOTE:

DO

NOT

USE

A

CARPENTER'S

1

.--

.

...-

.

-

LEVEL.

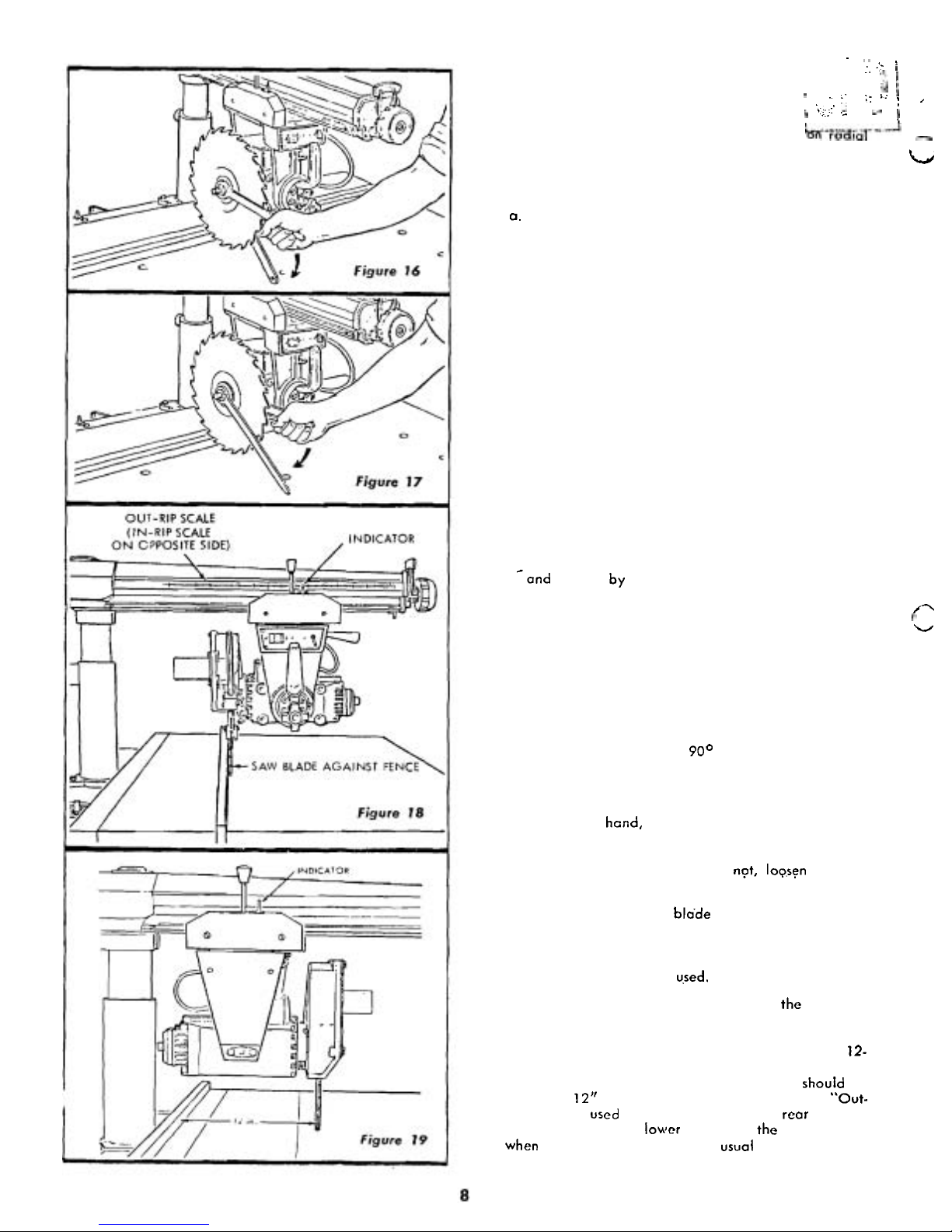

1. Remove the saw guard.

2.

Loosen table support mounting screws (figure

3)

at

both left and right sides of the base. Re

-

tighten to finger

tightness for adjustment of table.

3.

Loosen arm latch handle (22, figure

20)

enough to

obtain free movement of radial arm. Release arm latch

lever (1, figure

20), and loosen carriage lock knob for

easy movement of motor and

carrioge assembly durin

g

this operation. Move the motor and carriage assembly

out to the end of radial arm and lower the saw blade

until it just touches the table at point A, which is the

front central position. (See figure

9.)

NOTE:

Actual contact with table can be deter

-

mined

by

rotating saw blade and listening for

a light

"

pinging" sound as the carriage

is

lowered.

4.

Move the blade to point B near the rear edge of table.

(See figure

10.)

If saw blade starts to ride on table as it

is

moved rearward, loosen the nut near the rear of the

No.

2

table support and tap the table downward until

9

the blade just contacts the table at this point.

If

table

L/

is

too low at the back, tap it upward until a pinging

sound can be heard

os blade

is

rotated. Recheck at both

A

and B locations and correct as required. Tighten nut

at rear of No.

2

table support when correct center height

is

obtained.

5.

Move the blade to the left-rear of table at point C and

tap table up or down as required. (See figure

11.)

Then

move blade to point

D

and adjust table as required.

Tighten screws in

left-hond table support angle when

height

is

correct. (See figure

3.)

6.

Move blade to points E and F and adjust the right-hand

table support in the same manner as described for the

left

-

hand support. Tighten screws in right-hand support

when adjustment

is

correct.

..

.

7.

Move the saw blade to all six positions to recheck for

proper leveling of table. (See figures

9,

10 and 11

.)

Make

slight corrections

if

required, and make sure all support

mounting screws are tight. (See figure

3.)

8.

Place the rip fence in vertical position behind the front

table board.

9.

Place the rear table board behind the rip fence and the

table spacer board behind the rear

table.

10.

Insert -the three table clamps

(9,

figure 20) and tighten

them finger tight to secure

all

table boards.

STEP

FIVE

-

SQUARING

THE

SAW

BLADE

TO

THE TABLE

TOP

1.

Place the edge of o framing square on the table top

and against the saw blade, as shown in figure 12.

2.

When the saw blade

is

square with the table top, no

light will be visible between

the square and face of saw

blode. Do not

a:low the square to rest against o tooth

of the saw.

If

light

is

visible between the square and

face of saw blade

(with square leg

held

firm against

the table top) pcrform the following adjustments:

a. Using a

1/4-inch hex

"L"

Allen wrench, loosen iust

slightly the four socket-head screws

(2,

figure 12).

b.

Tilt the motor until the saw blode is square with the

table top as shown in figure 12. Then, while holding

the square

firmly against the

saw

blade and table

top. apply pressure against lower part of saw blade

with the thumb until

~pproximately 1 /32-inch clear

ance exists between the square and lower edge of

saw blade. This

is

to compensate for the possible

slight shifting of the motor while screws

(2)

ore bein

g

tightened.

c. Tighten the four socket

-

head screws

(2,

figure 12).

.

.

NOTE: It may be necessary to perform more

thon one

trial.opcration before the saw blade

remains perfectly square with table top after

screws have been tightened.

d.

Recheck for blade squoreness with table top.

e. The indicator

(3,

figure 12) should read

O0

on the

bevel index scale. If not, loosen the indicator attach

-

ing screw, adjust indicator to zero

and

tighten the

screw

secure1 y.

STEP SIX-CHECKING THE SAW BLADE

FOR

"

HEEL" (LEFT

AND

RIGHT)

1.

Place a square against the

rip

fence and the saw blade

as shown in figure 14. The long leg of the square must

be held firmly against the rip fence and table top

and the short leg must not touch any of the teeth on

the saw blade.

2.

If a gap exists between the saw blade and the-square,

one of two types of

"

heel" exists. (See figure 13.) To

correct for either type of condition,

proceed as follows:

a.

Remove the left-hand carriage cover

(1,

figure 14)

by removing the two attaching screws

(2).

b.

Loosen the yoke clamp handle

(7,

figure 20).

c. Loosen (slightly) two hex-head screws

(1,

figure

15).

d.

Rotate the yoke until the gap between saw blode

and square

is

eliminated. (See figure

14.)

e. Lock the yake and tighten the two hex-head screws

(1;

figure 15).

f.

Recheck for "heel" after tightening screws, and make

corrections

if

necessary.

g.

Install left-hand carriage cover. (See figure

14.)

STEP

SEVEN

-

DOUBLE

CHECK SQUARING

OF

SAW

1.

Recheck for correct adiustment of the saw by perform

-

ing

"

STEPS THREE, FIVE and SIX".

2.

If

the cross-cut

is

not perfectly squared, proceed with

"

STEP THREE" (paragraphs 5 and

6).

and "STEP SIX",

if a correction

is

required.

NOTE: If

afier making all adjustments out

-

lined in

STEPS

"

ONE" through "SEVEN,

"

refer to Trciublc Shooting Charts for any

existing problems.

BLADE TRAVEL BLADE TRAVEL

I

'1:

BLADE

HEELING-\\

;I-BLADE

H

EE

L

I

N

G

TO LEFT

TO RIGHT

Figure

13

I

LEFT

HAND

SIDE

figure

15

I

.

..

.

-

. ..

.

..

?

:,

-,

3

.?.

i

ATT

A

C

H

I

N

G

AND

DET

A

C

HIN

G

...

,

.

,

:i

I

SAW

BLADE

!

..

:

.-

,:

. ....

..

,

.,.,

-..

._

.

:

'

;

..;:;.

.-

-.*

\

1

1.

Locate the motor carriage assembly midway

k--~idicil--.'-~

.I

arm ond tighten carriage lock knob

(6,

figure 20).

L/

2.

REMOVAL

(See figure 16.)

a. Place the open-end shaft wrench on hex portion

of motor shaft on inside of saw blade. Allow end of

wrench to rest on saw table.

b. Using the box

-

end arbor wrench, loosen the shah nut.

NOTE:

The motor shaft has left-hand

threads.

c. Remove shaft nut, collar, saw blade and second collar.

3.

INSTALLATION

(See figure 17.)

a. Place inside collar on motor shaft, with flange next

to saw blade.

b. Install saw blade, outside collar and nut.

NOTE:

Make sure the larger (flange) face of

each collar

is

next to saw blade.

c. Place box

-

end arbor wrench on shaft nut and let it

rest on saw table.

d. Use open

-

end shaft wrench on hex portion of shaft

-and tighten by pushing downward as shown in fig

-

ure 17.

/--

h

ADJUSTMENT OF

RIP

SCALE INDICATORS

w

NOTE:

The rip scales and pointers are intend

ed to be used for quick settings. For greater

accuracy, toke direct measurement between

blade and fence.

1.

When the fence

is

in its normal position (next to the

front table), index the yoke

90'

from the cross-cut posi

-

tion so that the blade

is

between the motor and the

fence. Lock the yoke.

2. Move the motor along the radial arm until the blade,

when spun by

hond, just touches the front face of the

fence. (See figure

18.)

The indicator on the right-hand

side of radial arm should now reod 0

-

inches on lower

portion of the

"In-

Rip" scale. If not, logsen the

two

screws and shift the indicator to reod 0-inches.

NOTE:

With the saw bldde and fence in the

position shown in figure

18,

the lower portion

of the

"in-

Rip" scale

is

used. If the fence is

moved to the extreme rear position, the upper

portion of the scale

is

u.sed.

3.

The "Out-Rip" scale pointer, located on the left-hand

side of radial arm,

is

adjusted in essentially the same

manner as the

"in-

Rip" scale pointer, except the blade

should be positioned as shown in figure 17. With

12-

inches measured between the fence (when in full rear

position) and face of saw blade, the pointer

should be

set to the

12"

position. The upper portion of the "Out-

Rip" scale

is

used when the fence

is

in the rear position.

(See

figure

19.)

The lower portion of the scale

is

used

when the fence

is

located in the usual position - at the

rear edge of front table board.

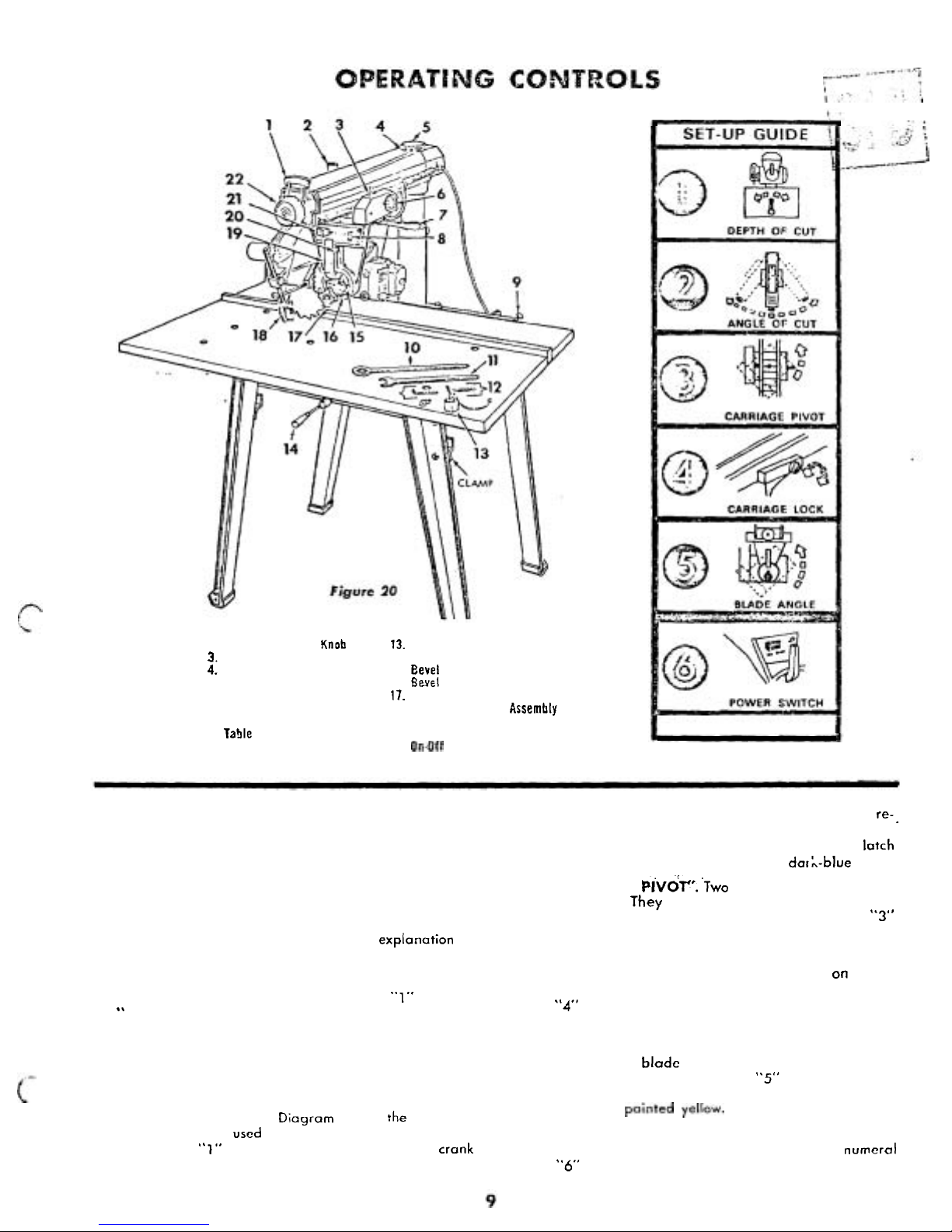

1.

Arm Latch Lever

2.

Swivel

Latch Pin Knoh

3.

Rip Scale lndicator

4.

Radial

Arm Indicator

5.

Radial

Arm Scale

6.

Carriage Lock

Knob

7.

Yoke Clamp Handle

8.

Switch

Lock

and

Key

9.

Table

Clamp

10.

Arbor Wrench

11.

Shaft Wrench

12.

Allen Wrenches

13.

Adapter Plug

14.

Elevation Crank

15.

Eevel lndex Indicator

16.

Bevel

lndex

Scale

17.

Bevel

Lock Knoh

18.

Anti-Kickback

Pawl

Assemhly

19.

Bevel

lndex Handle

20.

Latch

Pin

Handle

21.

On.Cff

Switch

22.

Arm Latch Handle

Figure

21

SET-UP

GUIDE

A

combined number and color code system, designated as

a

"

SET-UP GUIDE", has been applied to the saw in order

to simplify the location

of

tontrols required for a particular

set

-

up operation. The "SET-UP GUIDE

"

is

both a conveni

ence and safety measure, particularly for inexperienced

operators., The operator should become familiar with this

feature before operating the saw.

A

brief explanotion of

the

"

SET-UP GUIDE" is as follows: (See figure

21.)

1.

Notice the radial arm trim strip, the forward end of

which contains six diagrams numbered

"1"

through

..

6".

Each number

is

in a colored circle, and a corres

ponding number in an identical colored circle will be

an the particular operating control member involved.

2.

Locate each control and become familiar with its oper

ation.

a.

"

DEPTH

OF

CUT".

Diagram shows

:he

elevation

crank which

is

used to raise and lower the

blade.

The

numeral

"1"

in a light-blue circle

is

on the crank

handle.

b.

"

ANGLE

OF

CUT".

Two controls 'are involved in re-.

leasing, securing and indexing the angle of the radial

arm. These are: arm latch handle and arm

latch

lever. The handle

is

marked with a dot:-blue circle.

c.

"

CARRIAGE

PIVOT".

'TWO

controls are used in this

operation.

They are: swivel latch knob and yoke

clamp handle, each marked with the numeral

"3"

in an orange circle.

d.

"

CARRIAGE

LOCK".

The carriage lock knob

is

rotated clockwise to secure the carriage on radial

arm, and counterclockwise to release it. The numeral

"4"

in a green circle

is

at the center of the knob.

e.

"

BLADE

ANGLE".

The two controls used in angular

positioning and indexin

g

of the motor to provide the

desired saw

blade angle are: bevel lock knob and

latch pin handle. The numeral

"5"

in a yellow circle

is

attached to the bevel lock knob. The latch pin

handle

is

painted yellow.

f.

"

POWER

SWITCH". This switch

is

located in the

upper left area of the carriage and has the

numeral

"6"

in a red circle directly under it.

USE OF

KEY

AND SWITCH

NOTE: This

savt cannot be operated without

the key, and likewise, the key cannot be re

moved trom the lock while the sow motor is

running. This feature was designed into your

saw for safety and protection.

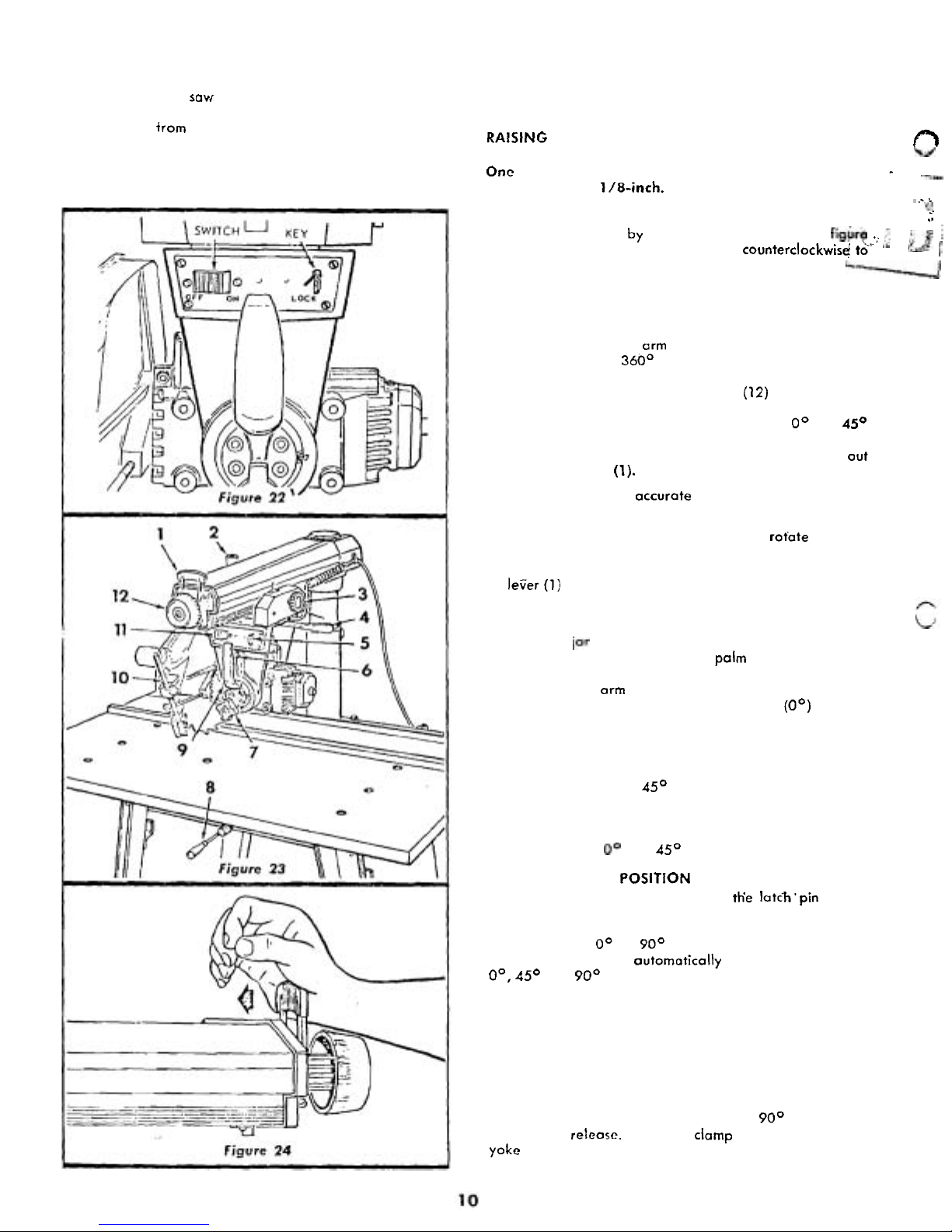

1.

Insert key

in

slot and turn it. (See figure 22.)

2.

Press the right-hand side of toggle switch lever to turn

the saw

ON.

Press left-hand side of switch to turn

saw

OFF.

RAISING

AND

LOWERING

THE

RADIAL ARM

This

is

accomplished by the elevation crank

(8,

figure

23).

r"l

kd

One complete turn of this handle will raise or lower

-

---

the radial arm 1/8-inch.

:

..

i

.

t&

LOCKING THE CARRIAGE TO THE RADIAL

ARM

.

.

.

..

.

.

.

...

.

.

..

This is accomplished by the carriage lock knob

(3,

fig"rb

.;

;-,tf

23). Turn the knob clockwise to lock; counterclockwisq! tb'

''

unlock.

&-I

ANGULAR MOVEMENT AND LOCKING

OF

RADIAL

ARM

These movements are controlled by the arm latch lever

(1,

figure 23) and the arm latch handle (12). The radial

arm can be rotated

360° and locked in any position. The

arm

is

unlocked from any position by a slight counterclock

-

wise rotation of the arm latch handle (12) and is locked

in any position by rotating the arm latch handle clockwise

until tight. The radial arm has positive stops at

O0

and 45O

left and right, and is released from these index positions

by unlocking the arm latch handle (12) and pulling

out

the arm latch lever

(1).

For most positive and accurate settings at the index posi

-

tions, the following

is

recommended:

1. If the radial arm is already indexed,

rotate the arm

latch handle (12, figure 23)

1/4

turn counterclock

wise from the locked position, pull out the arm latch

lever

(1)

and move the radial arm off the index position.

Release the arm latch lever

(1).

2.

Move the radial arm into the index position (do not

bump or

jar it) and push on the handle (12) or arm

latch lever (1) solidl

y

with the palm of the hand. (See

figure

24).

This

is

very important as it insures proper

seating of the

arm lock pin in the arm latch, thus always

returning the arm to the correct cross

-

cut (0°) position.

3.

Lock the radial arm by rotating the arm latch handle

(12, figure 23) clockwise until tight.

CAUTION: When moving the radial arm in any

direction beyond

4S0 left or right, always pull

out the arm latch lever (at end of radial arm)

to prevent damaging the arm lock pin.

If

dam

age occurs, the radial arm will not index

properly at

0'

and 4S0 positions (left to right).

MOVEMENT

AND

POSITION OF MOTOR

IN

YOKE

These movements are controlled by

th'e latch'pin handle

(6,

figure 23) and bevel lock knob (7). The bevel scale

indicates the angular position

of

the motor with respect

to

horizontal from

O0

to 90° in either vertical position. The

latch pin handle

(6)

outornotically indexes the motor at

0°,

45O and 90° up and down. Lift the latch pin handle to

release. At any other position, the latch pin handle

is

not

engaged. The bevel lock knob (7) locks the motor to the

yoke when the motor is in any position. Rotate it clockwise

to lock; counterclockwise to unlock.

MOVEMENT

AND

POSITION

OF

THE YOKE

These are controlled by the swivel latch pin knob

(2,

figure

25)

and the yoke clamp handle (4). The swivel latch pin

automatically indexes the yoke at each

90° position.

Lift

the knob to release. The yoke clamp handle

(4)

locks the

yokc to the carriage in any position. Pull the handle to

release. Push

it

to tighten.

Loading...

Loading...