Craftsman 11327521 Owner’s Manual

OPERATING INSTRUCTIONS

AND PARTS LIST FOR

C

|smqE

10-inch Tilting Arbor

, , Model Number

113.27521

The above Model Number will be found on a plate attached to

your saw, at the back, near the bottom of the base. Always men-

tion the Model Number when communicating with us regarding

your saw or when ordering parts.

Instructions for Ordering Parts

All parts listed herein must be ordered through a Sears retail store

or mail order house. Parts are shipped prepaid. When ordering

repair parts, always give the following information:

1. The part number.

2. The part name.

3. The model number,

proper parts service. We suggest you keep it with other valuable

This list is valuable. It will assure your being able to obtain

papers.

........... ii i • i

i i

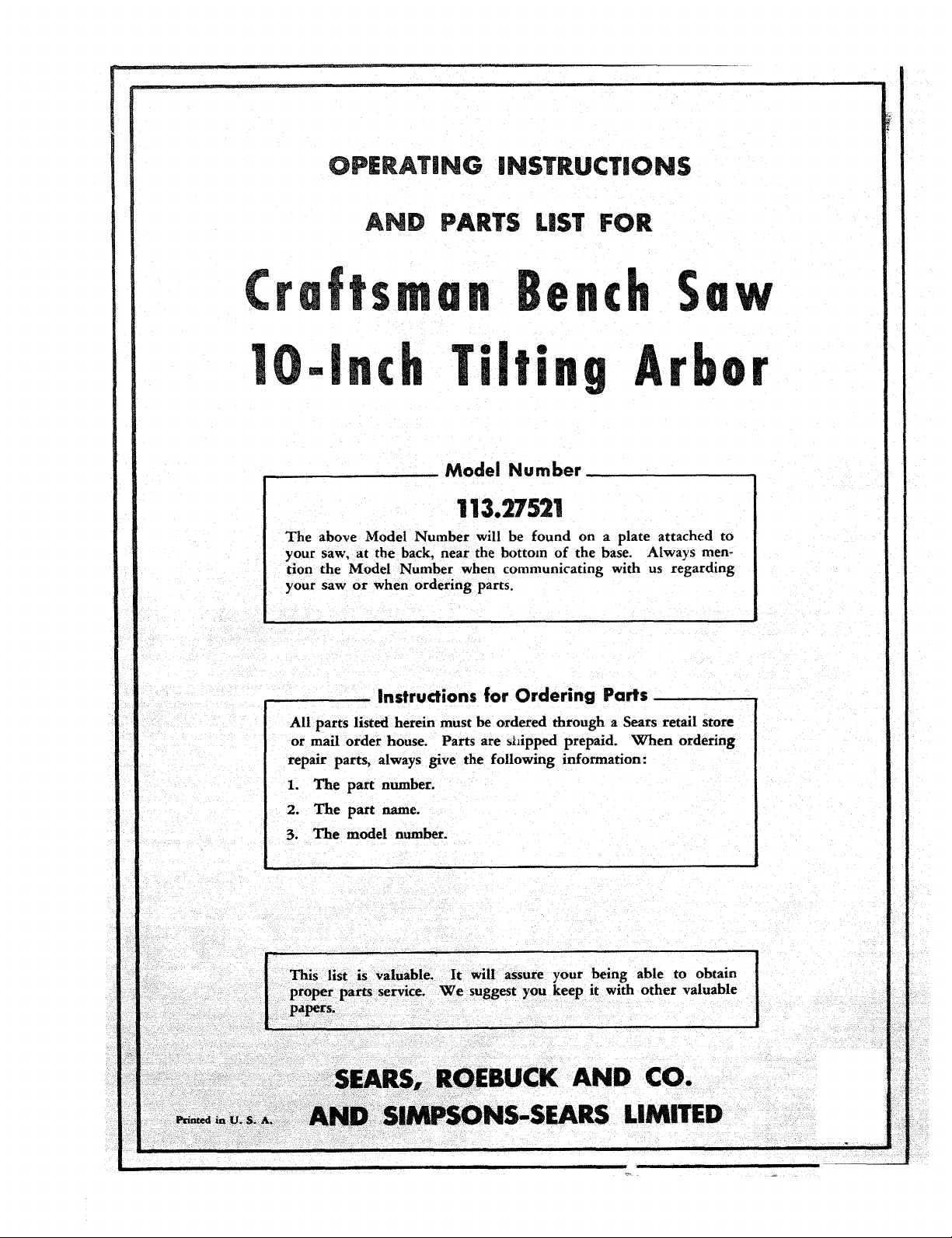

AB LE F

T D J

Figure 1

H O M and lift out the insert (A, fig. 1).

CHECK ARBOR NUT- Remove two screws (B, fig. 1)

[ saw arbor nut (part 6362, fig. 5),

/ using wrench (M, fig. 1). Re- ""--_'I

!

place insert and screws.

ALIGN SAW BLADE WITH

TABLE GROOVES- Using ele-

vation hand wheel (A, fig. 2),

set saw blade for deepest cut.

Make pencil mark on tooth that

is just above table top at front of

blade. Measure distance from this

tooth point to right-hand table

groove (L, fig. 1). Rotate blade by hand to place this

same tooth just above table top at rear then again

g measure distance from tooth point to right-hand groove.

The two measurements must be exactly equal. If not,

loosen the three screws (part S-860, fig. 4) in each trun-

nion which secure the table trunnion (part 13, fig. 4) to

the table. Shift the two trunnions until the two measure-

ments are equal, then retighten the screws. Again check

measurement.

Check tightness of

_our

examine it carefully for loose

NOTICE

INSTALL RIP FENCE- Secure the rack (J, fig. 1) to

rack parallel with the top of table. Pull the rip fence knob

(G, fig 1) out to pera_it the guide of the rip fence (F,

fig. 1 ) to slide over rack ( J, fig. 1 ) then place the. rip

fence on the saw table as shown in figure 2. A shght

pressure must be exerted on the rip fence to cause it to

Slide fence along rack, noting clearance between fence

and table top. If any part of the fence (other than the

sliding pad at the rear) drags on the table top, or if the

clearance between fence and table varies apl_reciably as

fenc( is (j, fig. 1) must then be readjusted.

This again loosening screws (D, fig. 1)

to

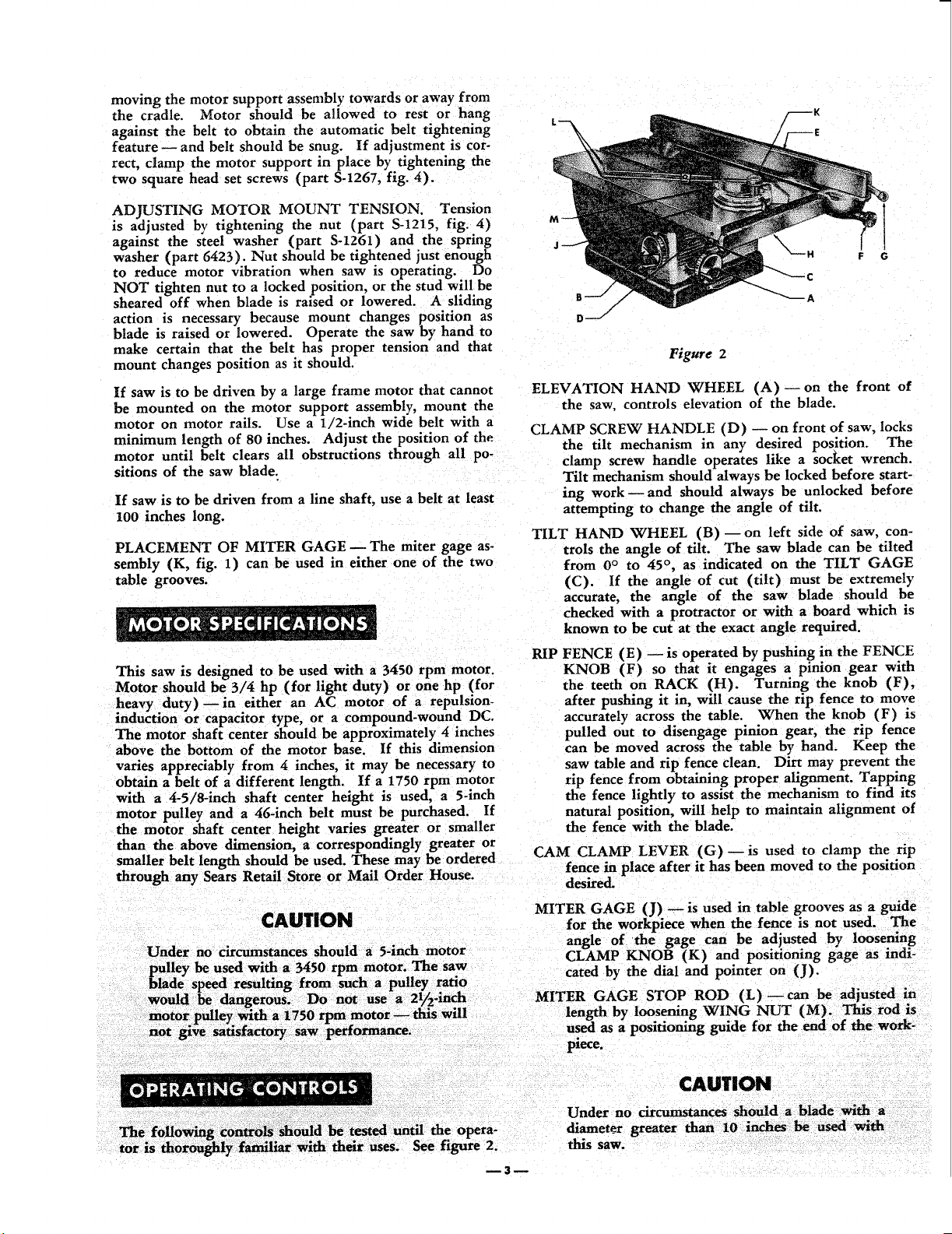

;PARALLEL TO SAW

next to the right-hand

Fence

and

the _

\

moving the motor support assembly towards or away from

the cradle. Motor should be allowed to rest or hang

against the belt to obtain the automatic belt tightening

feature- and belt should be snug. If adjustment is cor-

rect, clamp the motor support in place by tightening the

two square head set screws (part S-1267, fig. 4).

ADJUSTING MOTOR MOUNT TENSION, Tension

is adjusted by tightening the nut (part S-1215, fig. 4)

against the steel washer (part S-1261) and the spring

washer (part 6423). Nut should be tightened just enough

to reduce motor vibration when saw is operating. Do

NOT tighten nut to a locked position, or the stud will be

sheared off when blade is raised or lowered. A sliding

action is necessary because mount changes position as

blade is raised or lowered. Operate the saw by hand to

make certain that the belt has proper tension and that

mount changes position as it should.

If saw is to be driven by a large frame motor that cannot

be mounted on the motor support assembly, mount the

motor on motor rails. Use a 1/2-inch wide belt with a

minimum length of 80 inches. Adjust the position of the

motor until belt clears all obstructions through all po-

sitions of the saw blade.

If saw is to be driven from a line shaft, use a belt at least

100 inches long.

ELEVATION HAND WHEEL (A)- on the front of

the saw, controls elevation of the blade.

CLAMP SCREW HANDLE (D) on front of saw, locks

the tilt mechanism in any desired position. The

clamp screw handle operates like a socket wrench.

Tilt mechanism should always be locked before start-

ing work and should always be unlocked before

attempting to change the angle of tilt.

Figure 2

TILT HAND WHEEL (B) on left side of saw, con-

PLACEMENT OF MITER GAGE- The miter gage as-

sembly (K, fig. 1) can be used in either one of the two

table grooves.

trois the angle of tilt. The saw blade can be tilted

from 0° to 45 °, as indicated on the TILT GAGE

(C). If the angle of cut (tilt) must be extremely_

accurate, the angle of the saw blade should be

checked with a protractor or with a board which is

known to be cut at the exact angle required.

RIP FENCE (E) -- is operated by pushing in the FENCE

This saw is designed to be used with a 3450 rpm motor.

Motor should be 3/4 hp (for light duty) or one hp (for

heavy duty)- in either an AC motor of a repulsion-

induction or capacitor type, or a compound-wound DC.

The motor shaft center siaould be approximately 4 inches

above the bottom of the motor base. If this dimension

varies appreciably from 4 inches, it may be necessary to

obtain a belt of a different length. If a 1750 rpm motor

with a 4-5/8-inch shaft center height is used, a 5-inch

motor pulley and a 46-inch belt must be purchased. If

the motor shaft center height varies greater or smaller

than the above dimension, a correspondingly greater or

smaller belt length should be used. _hese may be ordered

through any Sears Retail Store or Mail Order House.

CAUTION

Under no circumstances should a 5-inch motor

KNOB (F) so that it engages a pinion gear with

the teeth on RACK (H). Turning the knob (F),

after pushing it in, will cause the rip fence to move

accurately across the table. When the knob (F) is

pulled out to disengage pinion gear, the rip fence

can be moved across the table by hand. Keep the

saw table and rip fence clean. Dirt may prevent the

rip fence from obtaining proper alignment. Tapping

the fence lightly to assist the mechanism to find its

natural position, will help to maintain alignment of

the fence with the blade.

CAM CLAMP LEVER (G)m is used to clamp the rip

fence in place after it has been moved to the position

desired.

MITER GAGE (J) w is used in table grooves as a guide

for the workpiece when the fence is not used. The

angle of the gage can be adjusted by loosening

CLAMP KNOB (K) and positioning gage as indi-

pulley be used with a 3450 rpm motor. The saw

blade speed resulting from such a pulley ratio cated by the dial and pointer on (J).

would be dangerous. Do not use a 2fi_-inch MITER GAGE STOP ROD (L)--can be adjusted in

motor pulley _Tith a 1750 rpm motor --_is will length by loosening WING NUT (M). TI_ rod is

not ive satisfactory saw erformance, useci as a positioning guide for the end of the work-

g P

ptece.

The ¸

their uses. See figure 2.

CAUTION

Under no circumstances sh_d a blade with a

diameter greater than 10 inches: be _ with

this saw.

_3_

Loading...

Loading...