Craftsman 113.24261 Instruction Manual

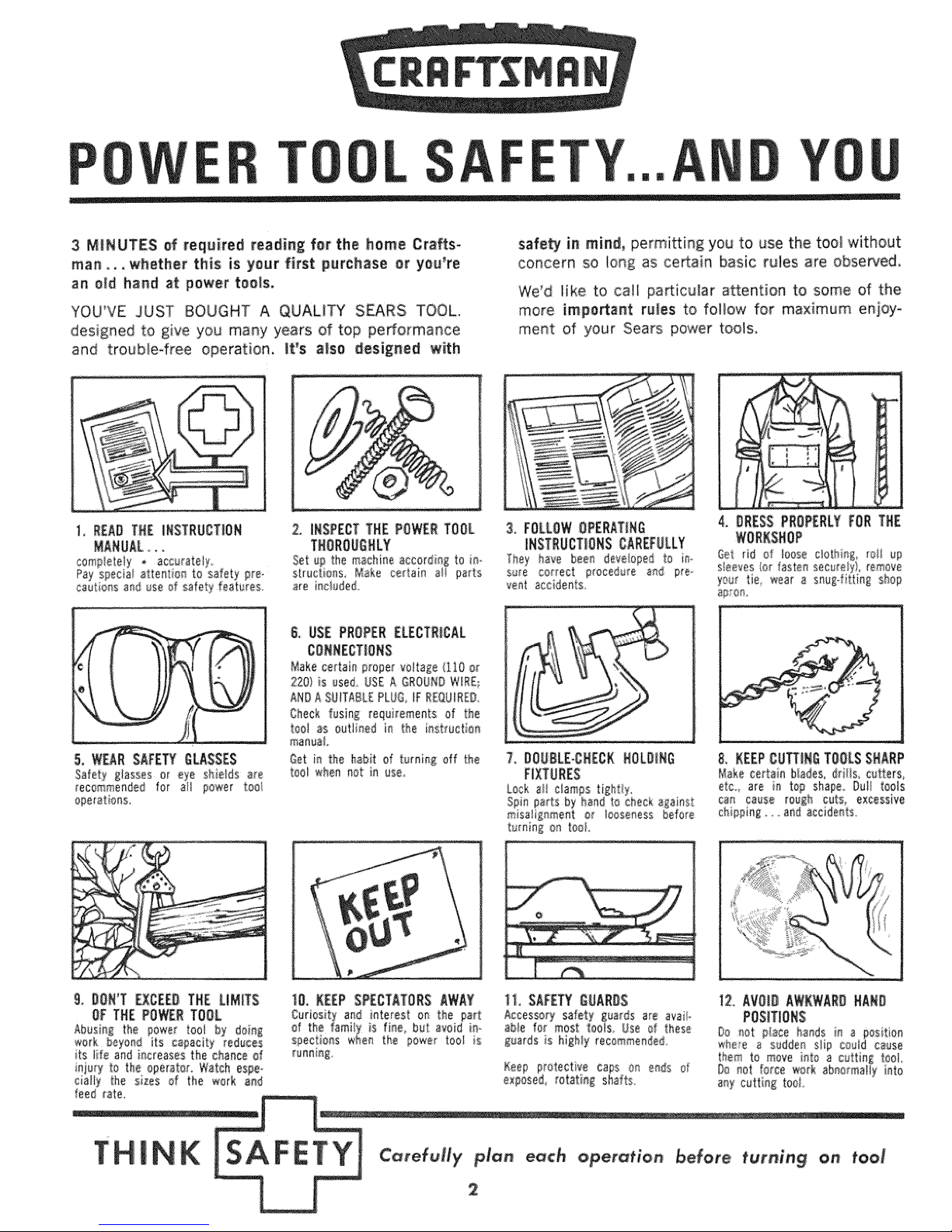

P T L A TY...A Y

3 MINUTES of required reading for the home Crafts_

man ..... whether this is your first purchase or you're

an old hand=at power tools,

YOU'VE JUST BOUGHT A QUALITY SEARS TOOL,

designed to give yOU many years of top performance

and trouble4ree operation, It's also designed with

safe_ in mind, pertaining you to use the too_ without

concern so long as ceRain basic rules are obseP<ed.

We'd like to ca!l paRiculer attention to some of the

more impotent rules to re!low for maximum enioy-

ment of your Sears power tools,

1, REAB THE INSTRUCTION

MANUAL.....

co_pletely, accura_e[y

Pay specie;i:a_entien to safety pre_

cautioes ao:duse d safely features

5. WEARSAFETYOLASSES

Safety g!asses _r eye shields are

recemmeoded for a/_ power reel

o_e_ations,

& DON'TEXGEEOTHE LIMITS

OFTHEPOWER TOOL

A_usi_;_ the power tooi by doing

ejury to the operator, Watch espe_

cially _he sizes of the work and

feed ra_e.

2: INSPECTTHE POWER TOOL

THOROUGHLY

Set up the machine accordiog to in

s_ructions Make certain all parts

a_e inciuded.

& USE PROPERELECTRICAL

CONNECTIONS

M_ke certainproperre!rage_110 o_

220} isused.USE k GROUND WIRE;

ANB A SU!TABLEPLUG,IFREQUIRED

Check fusng requirements of the

too_ ,aseutli_edin f;heinstruction

manu_l

Ge_ i_ the habit of tumi_g off the

tool 'when _oL inuse

10, KEEP SPECTATORSAWAY

Curiosity and ioterest oR the par_

of the family is fi_e,, _u_ avoid in,

specfions when the power tool is

runnin_

3. FOLLOWOPERATING

INSTRUCTIONSCAREFULLY

[hey have beee developed _e i;m

sure correct procedure and pro

uen! accideots

7_OOUBLE-CHEOKNOLO[NO

FIXTURES

Lock all c!amps _ght[y,

Spi_ pa_ts by ha_d to Checkaoa!os_

miaatigs_ent or touse_ess before

l_r_ing e_ !Joel

4. ORESS;PROPERLYFOR THE:

WORKSHOP

Ge_ fi;d of loose cloth%, roii up

sleeves {or fasten securely}, remove

your tie, wear a s_gofitI[eg shop

apron,

8, KEEPCO_!NGTOOLSSHARP

Make certain blades, @ilia, c_tte_&

etc are i_ top shape, Ouii _oo!s

can cause _eugh cats_ excessive

chppi_g, .a_d ac:cideets

M. SAFETYGUAROS

Accessory safety guarda are avak_.

ab!e for most _oels Use of these

g_ards is highly_ecommended

Keepprotectivecaps On ends of

exposedrotating shdts

12.AVOIOAWKWARO HARO

POSITIONS

any cutting to_l

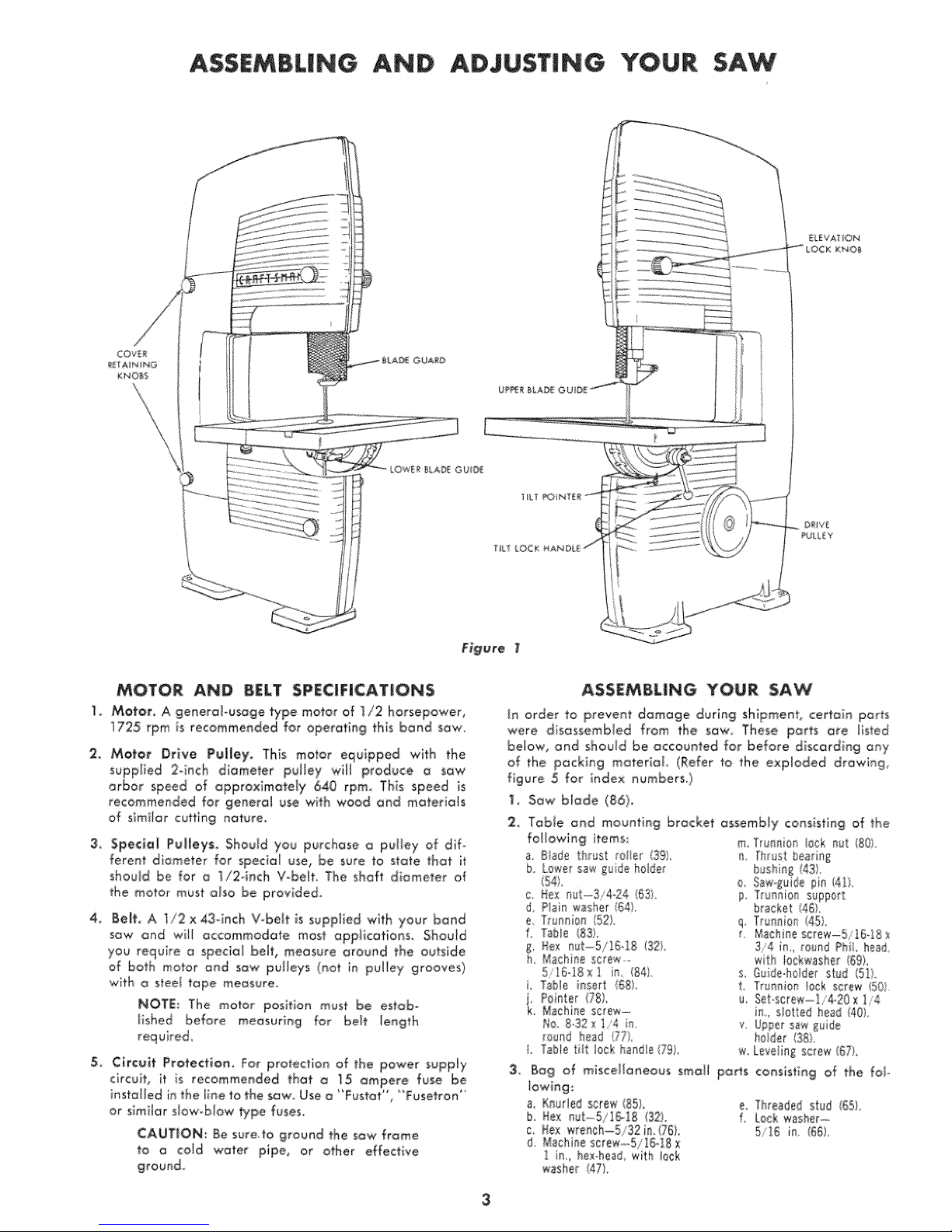

ASSEMBLING AND ADJUSTING YOUR SAW

MOTOR, AND BELT SPECJFiCATi|ONS

] Motor, A generobusoge type motor of }/2 horsepower,

i725 rpm is recommended for operating this bond SOw.

2. Motor DHve PuJJey'_ This motor equipped with the

supp!]ed 2-inch diameter pulley will produce a S_Wi

arbor speed o_ approximately 640 rpm, This speed is

recommended for general use with wood and materials

of simi!ar eutt{ng nature,

3:, Specie| P#i{eys, Should you purchase a pulley of dlf-

ferent diameter for spedat use_.be sure to sto_e that it

shouJd be for a ]/24nch V-belt. The shaft diameter of

the motor must also be provided,

4, Serf, A 1/2 x43dnch V-belt is supplied wlth your band

sow and wi!l accommodate most opplicotions_ Should

you require o special bah, measure around the outside

of both motor and saw puileys (not in policy grooves)

w_th a steel tape measure

NOTE: The motor position must be estab,

tshed before for belt length

5, Circuit £to_ectioa, For proteetioe of the power supply

circuit, it is recommended thorn !5 ampere, fuse be

installed n the iine to the saw Use o "Fustot', 'Tusetran"

or similar slow,-blow _pe fuses

CAUTION: Be sure to ground the saw frame

to a cow water pipe, or other effective

ASSEMBLING YOUR SAW

tn order to prevent damage during shipment, certain RaMs

were disassemb!ed from the saw, These ports o{e listed

below, and shou!d be accounted for before d{scarding any

of the packing material (Refer to the exploded drowlng,

figure 5 for index numbers,}

1_ Sow blade (86),

2 Tobie and mounting bracket assembly consisting of the

following items: m T_unni@_ !0ok n_t 801

3_

a. Blade _h_ust relier {3£) i [hrust bearie£

b. Lewe saw i_ide holle£ busli_g (43).

i54i. 0, Saw=!lida pie (4b,

c Hex 163i. p Trunnion support

d Plain washer (54L b_acka_ 45).

a True_fi0n (52L q Truani0_ I45,

f, Table (83) t. Nachnescrew-5i1618x

I, Rex nut........5/15,18(321, 3/4 in,= re,and Phil head

b Math se sc_e,_,,- wth 10ck,washer {69L

5 1548_1 in (84). re, Guidehelder stlt {Ill

i Table insert i58). L Tru_=eie_ 10okscrew 1%1.

j Partier178) u %t scre_'-......]i4_20_1/4

k Machine screw- i_ slotted he_t t40

No 132xi 4 in v @pet sawl_,,lde

[OU_r_I }_e_d {77L haler 1381

I. Table Iill IICI handle I.?£L _, LeveIinl scre_ (57).

Bag of miscellaneous small pots contesting of tle fol-

a. RoaMed screw (85L

b. tax mst_5/!51S (32L

c No× 'wre_eb=-5/32 i1.(76)

I, lacbi_e SCr'eW--,rb/IY,:I[8 X

i_, hex.head, wth leek

_sber 47),

e. Threaded s_ud (551.

5'15 im (85}.

4, ASSEMBLY PROCEDURE.

(See figure 5 for index numbnrsQ

a, Remove 'the four cover retaining knobs (1) and slide

the cover (2) off the studs, (See figure _,,)

CAUTION: Unscrew the leveling screw (67,

figure 5)_ until the end & flesh with the back

slde of trunnion support bracket (46),

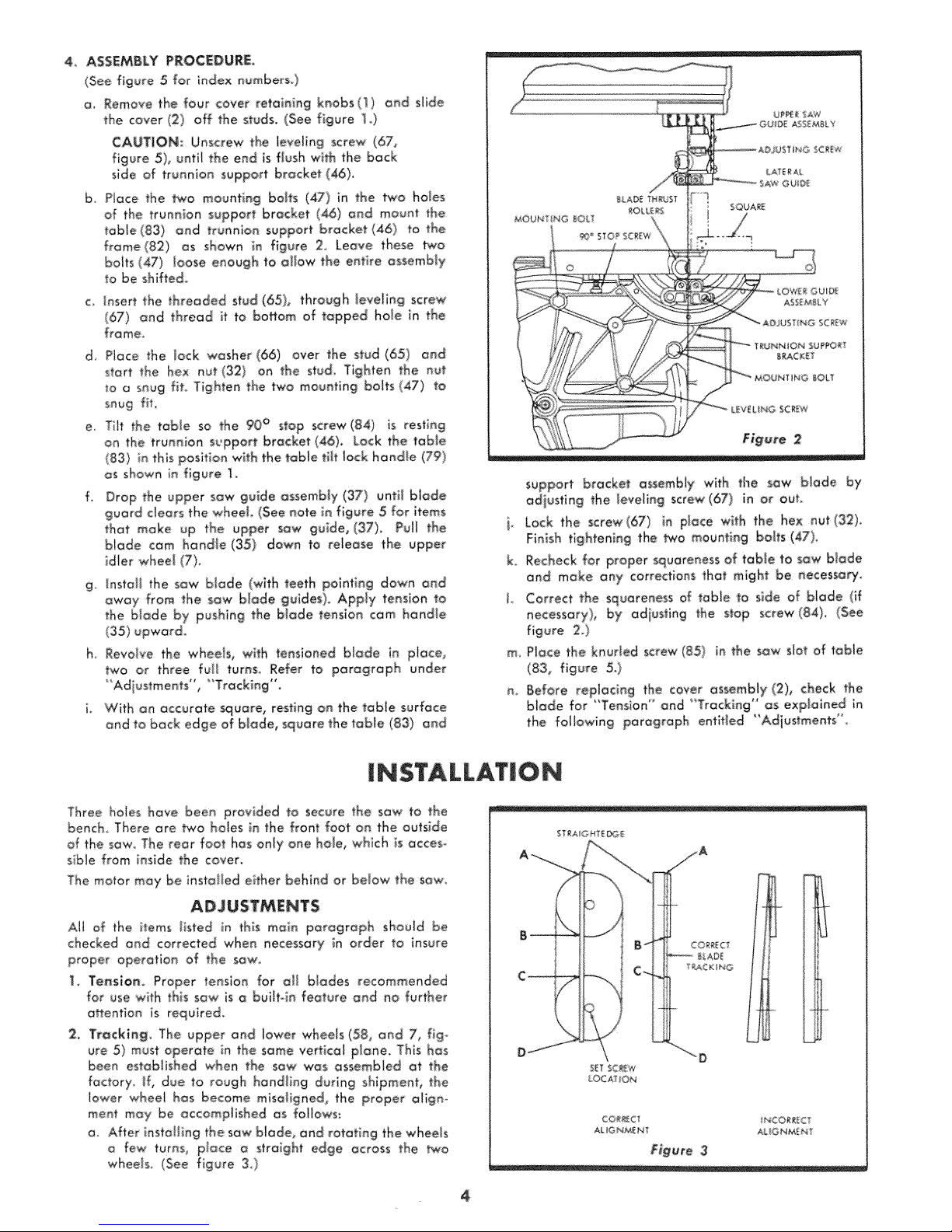

b Piece the _o mountieg brits (47) in the two hales

of the trunnion support bracket (_)oed mount the

table(83) end trunnion support bracket (46) to the

f:rome (82) os shown in: figure 2._Leave: these two

bolts (47) _eose enough to allow the eetbe assembly

to be shifted.

c, _nsert the threaded stud (65), through _eve_in,g screw

(67) _nd thread it to bo_om of tapped hole in the

frame,

d, Piece the lock washer (66), over the _tud (651 and

_tort the hex nut (132) on the stud Tighten the nut

u_ a seug fit, Tighten the two meuetieg bobs (47) to

snug fiL

e, Tit the table so the 90° stop screw(84) is resting

on the truen_on support bracket (46), Lock the table

(83) in this position with the tQb_etiff lock handle (79)

as shown in figure ]

f, Drop the upper sow guide assembly (37') until b_ade

guard clears the whoa!, (See note in figure 5 for items

that make up the upper saw guide, (37), Pull the

blade cam handle (35) down to release the upper

_dler wheel (7},

g install the saw blade (with teeth pointing down and

away from the saw blade guides), Apply tension to

the blade by pushing the blade tension cam handl÷

(35) upward_

h, Revalue the whoa!s, with tensioned Made in piece,

two or three fuji turns_ Refer to paragraph under

"Adiustments" , "T_acking '°.

i, With on accurate _uare, resting on the table surface

and to back edge air blade, square the table (83) and

support br'_cke_ assembly with the sow blade by

adjusting the lauding screw (67) in or eu)

i. Lock _he screw(67} in place wlth the h÷× out (32)

Finish tightening the _0 mounting barfs (47),

k. Recheck for propersquareness of table to s_w btade

and make any corrections that might be aeces_Fy

J Correct the squareness af table to side ef blade (if

necessary), by adjus_ieg the stop screw (84), (See

figure 2.}

m_ Place the keurled screw (85_ in the saw slot of tome

(83, figure 5_)

n, Before replacing the cover _ssembJy (2), check the

biade for "Tension" end "TrackMg" as expi_ieed in

the following paragraph entiHed

I $TALLATIO

Three holes have been p_ovided to :secure the saw _o, the

bench There are two holes in the front foot on the ouiside

of the sow The rear foot has only one hole, which is _cces-

sible from inside the cev'er,

The motor may be iest'aI_ed either behind or below the saw

A!l of the i_ems Iisted in this maie paragraph should be

checked and corrected when _ecessary in order to insure

proper operation of the sow,,

1, Te_slom Proper' tensioe for a[[ biades recommended

for use with this sow is o buihoin feature and _0 further

o#eetioe is required,

2, Trecki_g_ The upper and lower wheels (58, end 7, fig°

ure 5) must operate in, the some vertical p!_e, This has

been estob!ished when the sow was assembled _t the

factory, if, due to rough hand_ing during shipment, the

lower wheel has become misoligned, the proper a!igno

meet may be accomplished as fe|iows:

a After installing the sow blade, and rotating the wheels

few turns, place o strolgh_ edge across the two

wheels, (See figure 3)

ST_AiG HTE_E

CORAC iNCORReCT

AIL _G_ME _ t AJ. IG _E N

Figure 3

4

Loading...

Loading...