Page 1

Sears

MODEL NO,

113.239201

SHAPER ONLY

113.239291

SHAPER WITH STEEL

LEGS AND MOTOR

Serial

Number

Model and serial

number may be found

on the front of

the table.

You should record both

model and serial number

in a safe place for

future use.

CAUTION:

Read GENERAL

and ADDITIONAL

SAFETY

iNSTRUCTiONS

carefui|y

WOOD SHAPER

o assembly

+ operating

o repair parts

Sold by SEARS, ROEBUCK AND CO., Chicago, IL 60684 U.S.A.

Part No. 72033 Pr',_ed in U S,A

Page 2

ON CRAFTSMAN WOOD:SHAPER

this Craftsman: Wood Shaper fails duel to a defect in material or

AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS STORE OR SERVICE

_her rights which vary from state to state,

Sears Tower. Chicago, IL 60684

general safety

-, :i • : rInstructions fo power tools

1. KNOW YOUR POWER TOOL

Read and understand the owner's manual and labels

affixed to the toot. Learn its application and

limitations as wel! as the specific potential hazards

peculiar to this too!,

2. GROUND ALL TOOLS

This tool is equipped w_th an approved 3-conductor

Cord and a 3-prong grounding type plug to fit the

proper grounding type receptacle. The green conductor

in the cord is the grounding wire. Never connect the

green wire to a live terminal.

3. KEEP GUARDS tN PLACE

in working order, and in proper adjustment and

alignment,

4, REMOVE ADJUSTING KEYS

AND WRENCHES

Form habit of checking to see that keys and adjusting

wrenches are removed from tool before turning it on.

5. KEEP WORK AREA CLEAN

Cluttered areas and benches inwte accidents. Floor

must notbe slippery due to wax or sawdust.

6.:AVOID DANGEROUS ENVIRONMENT

Don't-use power:tools in damp or wet locations or

expose them tO Cain. Keepw0(k' area we lighted.

Provide adequate surrounding work space.

7, KEEP CHtLDREN AWAY

All vis=tors sho_J|d be kept-a safedistance from work

area.

8. MAKE WORKSHOP KID-PROOF

with padlocks, master switches, or by removing

starter keys.

9. DON'T FORCE TOOL

It will do the job better and safer at the rate for which

tt was desMgned

10. USE RIGHT TOOL

Don't force tool or attachmem to do a job _t was not

designed for.

11. WEAR PROPER APPAREL

DO not wear loose clothing, gloves, neckties or jewelry

(rings, wrist watches) to get caught in moving parts.

Nonsfip footwear is recommended. Wear protective

hair covering to contain long hair. Roll long sleeves

above the el bow.

12. USE SAFETY GOGGLES (Head Protection)

Wear Safety goggles (must comply with ANSi Z87.1)

-at all times.: Everyday eyeglasses 0nly have impact

resistant _lenSes,;they: are NOT-safety glasses.,Also, use

face or dust mask if cutting operation is dusty, and ear

protectors (plugs or muffs) during extended periods of

operation,

13. SECURE WORK

Use clamps or a vise to hold work when practical, It's

safer than using your hand, frees both hands to operate

tool

14. DON'T OVERREACH

Keep proper footing and balance at all times.

MAINTAIN TOOLS WITH CARE

15.

Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and

changing accessories.

16. DISCONNECT TOOLS

before servicing; when changing accessories such as

blades, bits, cutters, etc.

17. AVOID ACCIDENTAL STARTING

Make sure switch is in "OFF" position before plugging

in,

18. USE RECOMMENDED ACCESSORIES

Consult the owner's manual for recommended

_accessories, Follow the instructions that accompany

i::,!!:i:i;_:!:,i:::!::tfi_:'accessories. The use of improper accessories mav

hazards,

STAND ON TOOL

.... Serious injury could occur if the tool is tipped or if the

: cutting tool is accidentally contacted.

Do not store materials above or near the toot such that

it _snecessary to stand on the tool to reach them.

20. CHECK DAMAGED PARTS

Before further use of the tool, a guard or other part that

is damaged should be carefully checked to ensure that it

will operate properly and perform _ts intended function.

Check for alignment of moving parts, binding of mowng

parts, breakage of parts, mounting, and any other

conditions that may .affect its operation. A guard or

other part that is damaged should be properly repaired

or replaced.

21. DIRECTION OF FEED

Feed work into a blade or cutter against the direction

of rotation of the blade or cutter only,

22. NEVER LEAVE TOOL RUNNING

UNATTENDED

Turn power off. Don't leave tool until it comes to a

complete stop.

Page 3

:ilADDITIONAL SAFETY INSTRUCTIONS

FOR WOOD SHAPER

CAUTION: Turn motor switch "OFF" and disconnect 18, DO NOT perform layout, assembly, or set-Up work on

Power Cord when changing Shaper cutters or making

adjustments.

Safety is a combination of operator common sense and

alertness at all times when the Wood Shaper is being used,

WARNING: FOR YOUR OWN SAFETY, DO NOT

ATTEMPT TO OPERATE YOUR WOOD SHAPER UNTIL

IT IS COMPLETLY ASSEMBLED AND INSTALLED

ACCORDING TO THE INSTRUCTIONS.,. AND UNTIL

YOU HAVE READ AND UNDERSTAND THE

FOLLOWING:

PAGE

1. General Safety Instructions for Power Tools ..... 2

2, Getting to Know your Wood Shaper ............ 11

3. Basic Wood Shaper Operation ................. t4

4. Maintenance .............................. t8

5. Stability of Machine

The Shaper must be bolted securely to a stand or work

bench, in addition, if there is any tendency for the

Shaper to tip over or move during certain operations, it

should be bolted to the floor.

6, Location

The Shaper should be positioned so neither the

operator nor a casual observer is forced to stand in line

with the workpiece when straight line shaping. This

Shaper is intended for indoor use only.

7. Protection: Eyes, Hands, Face, Ears, Body

Wear safety goggles that comply with ANSI Z87.1

1968. Wear ear plugs or muffs during extended periods

of operation, Do not wear gloves .., roll long sleeves

above the elbow,

8, Always feed against rotation of the cutter. NEVER

"back up" the workpiece.

9. Do not take deep cuts or feed the stock too rapidly.

10. Be particularly careful in shaping wood that contains

cross grains or knots, as these may cause the hands to

be thrown into the cutter or cause kickbacks.

11. Before applying power, make sure the keyed washer is

installed immediately under the spindle nut and the

spindle nut is securely fastened, and all guards are in the

proper position, Make sure cutters are sharp,

12. Avoid awkward hand positions, where a sudden slip

could cause a hand to move into the cutt:er. Never reach

in back of or around the cutter with either hand to hold

down the workpiece.

13. Accumulations of stock or of finished work should not

be allowed on the table. Never clear table while cutter is

rotating.

14. Rubbish, shavings, stock, or other objects or material

should not be allowed on the floor where they may be a

tripping hazard.

15. Use working forms, patterns or holders wherever

possible, and keep them maintained, Care should be

taken that the work is securely fastened in these

fixtures, Stock is often of such size or shape that it

must be clamped in a holder before being shaped, The

inside jaws which clamp directly against the stock

should be lined with sand paper, Guards may also be

:mounted on a holder to afford additional protection.

16: When the fence is used, make sure it Ts securely fastened

and will not slip, and is properly adjusted.

17, Do not wear gloves, neckties, loose sleeves, or ragged or

torn clothing of any kind. Wear safety goggles

complying with ANSI Z87,1-t968 to protect your eyes

from dust or flying particles.

the table while the cutting tool is rotating.

19. NEVER perform freehand shaping - Use either the

fence, or a starting pin in the table and a collar on the

spindle, or a pattern.

20. Do not place your fingers or hands near edge of

material being cut.

21. NEVER perform irregular shaping operations with the

cutter guard removed. Be positive it is installed and

adjusted per instructions.

22. NEVER perform internal shaping operations on this

Shaper.

23. Do not use your hands to remove objects or materials

from around cutters; use a brush.

24. Do not tamper with guards nor make them inoperative

in any way.

25. ALWAYS joint or plane edge on surface of workpiece

that will be in contact with fence and/or table.

26. NEVER attempt to shape warped or twisted or bowed

work pieces.

27. Before leaving the machine, make sure the motor switch

is "OFF" the power cord is disconnected from the

power source, and the cutter has stopped revolving.

28. Never operate the Shaper without a protective cover on

the ur_used shaft end of a double ended motor.

29. If any part of this Shaper should break, bend, or fail in

any way or any electrical component fail to perform

properly, or if any is missing, shut off power switch,

remove power supply cord from power supply and

replace damaged missing and/or failed parts before

resuming operation.

WARNING: DO NOT ALLOW FAMILIARITY (GAINED

FROM FREQUENT USE OF YOUR WOOD SHAPER)TO

BECOME COMMONPLACE, ALWAYS REMEMBER

THAT A CARELESS FRACTION OF A SECOND IS

SUFFICIENT TO INFLICT SEVERE INJURY.

30. Note and follow Safety Instructions that appears on the

Shape:r fence.

WAR NIN G

A KEYED WASHER MUST ALWAYS

BE USED UNDER THE SPINDLE NUT

31. Note and follow Safety Instructions that appear on the

Shaper Switch assembly.

DANGER

FOR YOUR OWN SAFETY:

_EAO AND UNDERSTANO OWN£R S

MANUAL BEFORE OPERATING MACH_N£

1 W£AR S_FET¥ GOGGLES PStq AN$!2'87 t

AT ALL TIME&t

2 BE POStTIVE KEYED _,_,q-_,_._ _S DER_CTLY

LINDE_ gPIN_LE NU? A_ SPJNDL£" NLET IS

TtGHT _E_OR_. T'ORNtN{_ S_4*_.P_R "ON

3 ALWAYS cEED WO_KPIEC£ AGA!N_T

ROTATION OF CUTTER MOTOR AND

CUTTER _OTATE tN SAME QIRECTIO_

4 AVOId" AWK_A_ F,[_._ _OSJ'TIONS

5 _EEP F_NGE_S AWAY _ROM REVOLVING

C{JTTER _ US_ FI×TURE_ WHEN

N_CESSA_tY

6 tJSE OVERHEAD GUARD WH_4 ADJUS1-

ABL_. F_NC£ _S NOT JN PLACE

WARNING: THE 4-3/8" FLAT PULLEY AND THE 2"

MOTOR PULLEY FURNISHED, WILL RUN THE

CUTTER APPROXIMATELY 9000 R,P,M. WHEN

USED WITH A 3450 MOTOR, NEVER SUBSTITUTE

THESE PULLEYS TO INCREASE THIS SPEED

BECAUSE IT COULD BE DANGEROUS.

Page 4

objectsbeingthrownintothe,eyes;whichcanresultin

ilseve:re:eyedamageiAlWayswearsafetyg0gglescomplying

;i:_i;_hANSI:Z87_1(shoWnOnPackage)beforecommencing

powe_tooloperation.SafetyGogglesare available at Sears

retaiFbr catalog stores.

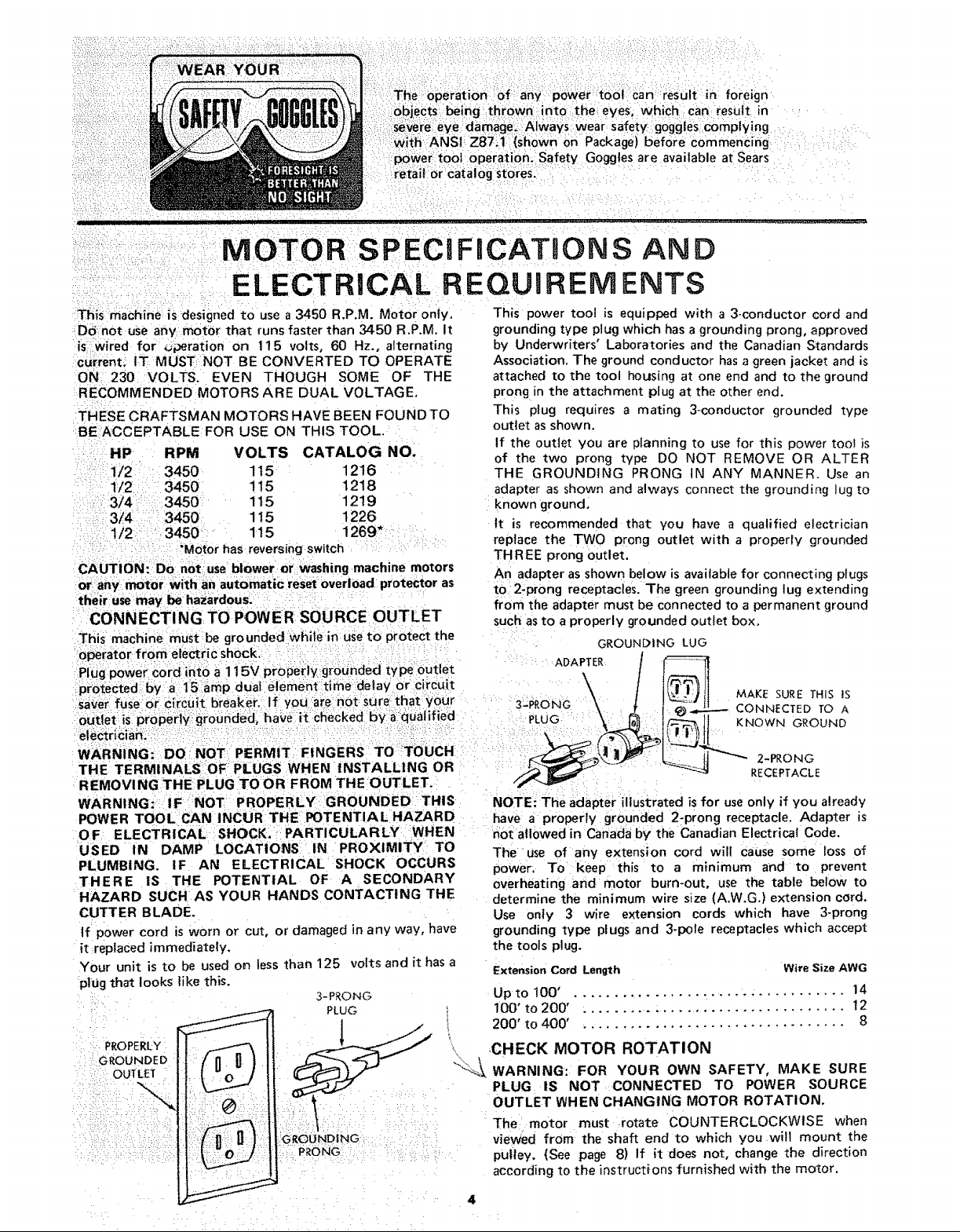

MOTOR SPECUFRCATIONS AND

ELECTRICAL REQUIREMENTS

TtiiS rnachine is designed to use a 3450 R.P.M. Motor only.

DOnot use any motor that runs faster than 3450 R.P.M. It

is: wired for _peration on 115 volts, 60 Hz., alternating

current; IT MUST NOT BE CONVERTED TO OPERATE

ON 230 VOLTS, EVEN THOUGH SOME OF THE

RECOMMENDED MOTORS ARE DUAL VOLTAGE.

THESE CRAFTSMAN MOTORS HAVE BEEN FOUND TO

BE ACCEPTABLE FOR USE ON THIS TOOL.

HP RPM VOLTS CATALOG NO.

1/2 3450 115 12!6

1/2 3450 115 1218

_:3/4 3450 115 1219

115 1226

1/2, _ 3450 115 1269"

"MOtor has reversing switch

CAUTION: Do notuse blower or washing machi ne motors

or any motor with an automatic reset overload protector as

their use may be hazardous.

CONNECTING TO POWER SOURCE OUTLET

This machine must be grounded While in use to protect the

resultin foreign

This power tool is equipped with a 3-conductor cord and

grounding type plug which has a grounding prong, approved

by Underwriters' Laboratories and the Canadian Standards

Association. The ground conductor has a green jacket and is

attached to the toot housing at one end and to the ground

prong in the attachment plug at the other end.

This plug requires a mating 3-conductor grounded type

outlet as shown.

If the outlet you are planning to use for this power tool is

of the two prong type DO NOT REMOVE OR ALTER

THE GROUNDING PRONG IN ANY MANNER. Use an

adapter as shown and always connect the grounding lug to

known ground,

It is recommended that you have a qualified electrician

replace the TWO prong outlet with a properly grounded

THREE prong outlet,

An adapter as shown below is available for connecting plugs

to 2-prong receptacles. The green grounding lug extending

from the adapter must be connected to a permanent ground

such as to a properly grounded outlet box.

GROUNb|NG LUG

Plug power _ord idto a i 15v properly :grounded type outlet ADAPTER .........

sa;_er fUse:o[: ch:cuit breaker. If you:are not: sure that _0Qr S-PRoNG \_ _ t CONNECTED TO A

WARNING: DO NOT PERMIT FINGERS TO TOUCH 2-PRONG

THE TERMINALS OF PLUGS WHEN INSTALLING OR RECEPTACLE

REMOVING THE PLUG TO OR FROM THE OUTLET.

WARNING:: IF NOT PROPERLY GROUNDED THIS

POWER TOOL CAN INCUR THE POTENTIAL HAZARD

OF ELECTRICAL SHOCK. PARTICULARLY WHEN

USED IN DAMP LOCATIONS IN PROXIMITY TO

PLUMBING. IF AN ELECTRICAL SHOCK OCCURS

THERE iS THE POTENTIAL OF A SECONDARY

HAZARD SUCH AS YOUR HANDS CONTACTING THE

CUTTER BLADE.

If power cord is worn or cut, or damaged in any way, have

it replaced immediately.

Your unit is to be used on less than 125 volts and it has a

plttg that looks like this.

3-PRONG

NOTE: The adapter illustrated is for useonly if you already

have a properly grounded 2-prong receptacle. Adapter is

not allowed in Canada by the Canadian Electrica! Code,

The use of any extension cord will cause some loss of

power, To keep this to a minimum and to prevent

overheating and motor burn-out, use the table below to

determine the minimum wire stze (A.W.G.) extension cord.

Use only 3 wire extension cords which have 3-prong

grounding type plugs and 3-pote receptacles which accept

the tools plug.

Extension Cord Length

Wire Size AWG

Up to100' . ................................. 14

100' to 200' . .................................. 12

200' to 400' . ................................ 8

PLUG ,

RouND oII-Fn Ui

PROPERLY___ _ _:

i OUT GROUNDING

_ PRONG

CHECK MOTOR ROTATION

i

WARNING: FOR YOUR OWN SAFETY, MAKE SURE

PLUG IS NOT CONNECTED TO POWER SOURCE

OUTLET WHEN CHANGING MOTOR ROTATION.

The motor must rotate COUNTERCLOCKWISE when

viewed from the shaft end to which you will mount the

pulley. (See page 8) If it does not, change the direction

according to the instructions furnished with the motor.

Page 5

UNPACKmNG: AND

CONTENTS

WARRANTY ................................

General Safety Instruction for Power Tools .........

Additional Safety Instructions for Wood Shaper .....

Motor Specifications and Electrical Requirements ....

UNPACKING AND CHECKING CONTENTS .......

List of Loose Parts ..........................

ASSEMBLY .................................

Tools Needed ..............................

Installing Elevating Rod and Table Support .......

Mounting Belt Guard and Motor to Motor Mount +.

Checking Motor Rotation .....................

Installing Motor Pulley .......................

Mounting Motor Support Assembly to Shaper .....

Mounting Switch Assembly ...................

Assembling Steel Legs ....................... 10

Mounting Wood Shaper on Floor Stand ............ 10

Plugging in Motor ........................... 1 1

Installing Shaper Fence + For Straight Edge

Shaping only .............................. 1 t

Installing Shaper Cutter Guard - For Curved

or Irregular Shaping only .................... 11

GETTING TO KNOW YOUR WOOD SHAPER ...... 13

On-Off Switch ............................. !3

Elevating Control Lever ...................... 14

Spindle Lock Knob ......................... 14

Spindle ................................... 14

Spacers .................................... 14

Keyed Washer ............................. 14

Fence Adjusting Knob ....................... 14

Fence Lock Knob .......................... 14

Fence Faces ............................... 14

Cutter Guard .............................. 14

Starting Pin ............................... 14

Removing and Installing Cutter ................ 14

ADJUSTMENTS .............................. 15

Shaper Fence .............................. 1 5

Fence Faces ............................... 1 5

BASIC SHAPING OPERATIONS ................. 16

Use of Cutter Spacers ........................ t 6

Straight Edge Shaping ....................... 1 7

Shaping With Use of Miter Gauge and

Hold+Down Clamp (Optional Accessory) ......... 1 7

Irregular or curved Shaping ................... 18

MAINTENANCE ............................. 20

LUBRICATION .............................. 20

RECOMMENDED ACCESSORIES ................

TROUBLE SHOOTING ........................ 21

REPAIR PARTS .............................. 22

CHECKING CONTENTS

Model 113.239291 Wood ShaPer is shipped Complete in

one carton and includes steel legs and motor.

Model 113.239201 Wood Shaper is shipped complete in

2

2 Separate all parts from packing materials and check each

3 one with the illustration and the list of Loose Parts to make

4 certain all items are accounted for, before discarding any

5 packing material.

5 tf any parts are missing, do not attempt to assemble the

6 Shaper, plug in the power cord or turn the switch on until

6 the missing parts are obtained and are installed correctly.

7 Remove the protective oil that is applied to the table top

7 and edges of the table. Use any ordinary household type

8 grease and spot remover.

8 CAUTION: Never use gasoline, naptha or similar highly

9 volatile solvents.

9 Apply a coat of automobile wax to the table.

one carton but DOES NOT INCLUDE Steel Legs or Motor.

Wipe all parts thoroughly with a clean, dry cloth.

WARNING: FOR YOUR OWN SAFETY, NEVER

CONNECT PLUG TO POWER SOURCE OUTLET UNTIL

ALL ASSEMBLY STEPS ARE COMPLETE, AND YOU

HAVE READ AND UNDERSTAND THE SAFETY AND

OPERATIONAL INSTRUCTIONS.

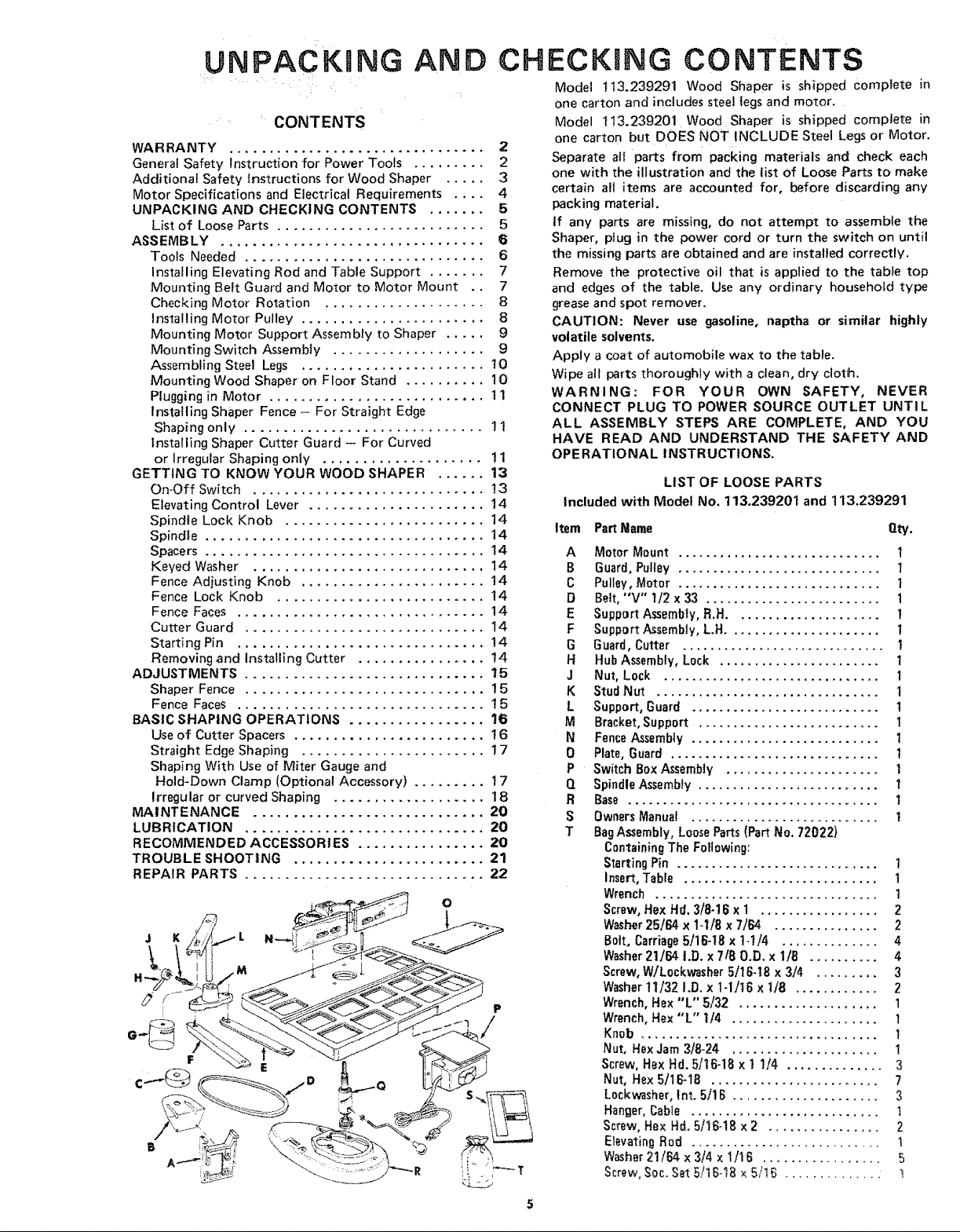

LIST OF LOOSE PARTS

Included with Model No, 113.239201 and 113.239291

Item PartName Qty.

A

Motor Mount ............................. I

B

Guard, Pulley ............................. 1

C

Pulley, Motor ............................. 1

D

Belt, "'V'" 1/2 x 33 ......................... 1

E

Support Assembly, R.H ..................... !

F

Support Assembly,LH ...................... I

G

Guard,Cutter ............................. +

H

Hub Assembly,Lock ....................... I

J

Nut,Lock ............................... I

K

StudNut ................................ I

L

Support, Guard ........................... 1

M

Bracket, Support .......................... 1

N

Fence Assembly ........................... 1

0

Plate, Guard .............................. 1

P

Switch Box Assembly ...................... I

Q

Spindle Assembly .......................... 1

R

Base .................................... 1

S

Owners Manua{ ........................... 1

T

Bag Assembly, Loose Parts (Part No. 72022)

Containing The Following:

Starting Pin ............................. 1

Insert, Table ............................ 1

Wrench ................................ 1

Screw, Hex Hd. 3/8-1B x 1 ................. 2

Washer25164x 1-118x 7164 ............... 2

B01t+ Carriage 5/16-18 x 1-114 .............. 4

Washer 21]64 I.D. x 7 tB 0.D. x lib .......... 4

Screw, W/L0ckwasher 5]16-t8 x 3/4 ......... 3

Washer11/321.D. x1+1116 x1/8 ............ 2

Wrench, Hex "L" 5]32 .................... 1

Wrench, Hex "L" I/4 ..................... 1

Knob .................................. 1

Nut, Hex Jam 3/8-24 ..................... !

Screw, Hex Hd+ 5/16-18 x 1 1/_, .............. 3

Nut, Hex 5/16-18 ........................ 7

L0ckwasher, Int. 5]! B ..................... 3

Hanger,Cable ........................... 1

Screw, He× Hd. 5/_6-18 x 2 ................ 2

Elevating Rod ........................... 1

Washer 21/84 x 3/4 x 1/16 ................. 5

Screw, Soc. Set 5/1E;..l_ x 5/1_ 1

Page 6

i ii:izzi ¸/:! ! iii ¸¸:,

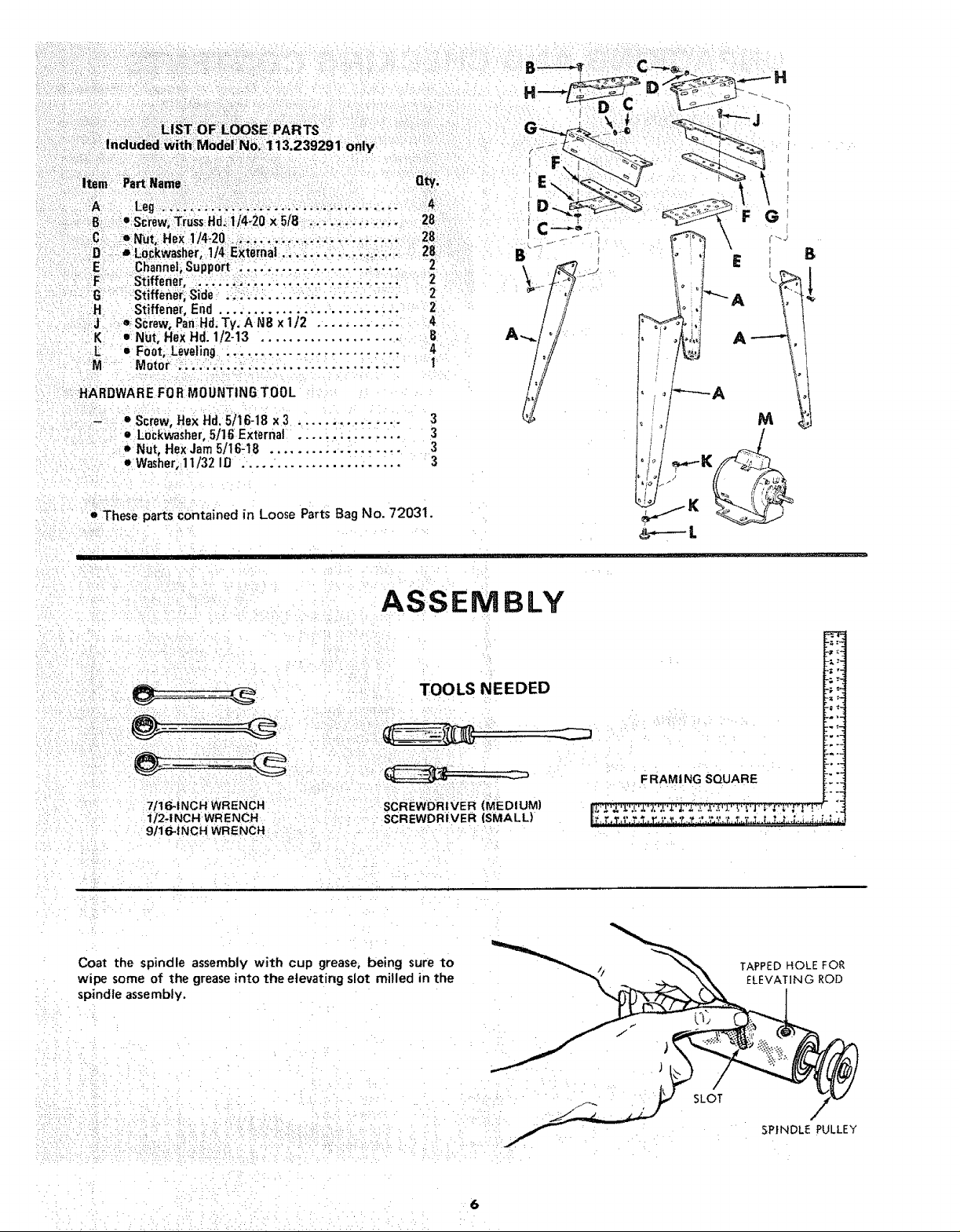

Induded With ModeiNo;: 113.239291 only

¢

nty.

8 _=.Screw,Truss:Hd_Ii4o20x 5/B: ,,,:.............. 28

c:i:D_"Nut,_RexIJ4_2o...:;.........................2B

....i:Loci(washer; 1/4:External. _.;. :.:,. .... _=.,;L,. 28

......E Cl_anneliSuppb_ti.,. .......... .. ,. _,.., 2

F

..... G ::-Stiffener; Side ......................... 2

:HARDWAREFOR MOUNTING TOOL

Stiffener, i....!_.;...,,,,... .... :.i...; 2

.H Stiffener, End .......................... 2

e;Screw,Pan Hd.Ty, A N8 x 1/2 ............ 4

Nut, HeXHd. 1/2-13 .................... B

L • Foot, Leveling .......................... 4

M Motor ......... ; ...................... 1

_ • Screw,Hex Hd,5/16-18 x 3 3

• Lockwasher,5/lBExterna _!_:.ii_i_i_ 3

oNut, Hex Jarn5/16-18 ................... 3

• Washer,11/32 ID ....................... 3

• These parts contained in Loose Parts Bag No. 72031.

' III

ASSEMBLY

i

TOOLS NEEDED

C

B

A

_----L

7/16-INCH WRENCH

1I2-1NCH WR ENCH ......

9/16-_ NCH WRENCH

Coat the spindle assembly with cup grease, being sure to

wipe some of the greaseinto the elevating slot milled in the

spindle assembly.

SCREWDRIVER (MEDIUM}

SCREWDRIVER (SMALL)

F RAMI NG SQUARE

TAPPED HOLE FOR

ELEVATING ROD

SLOT

SPINDLE PULLEY

6

Page 7

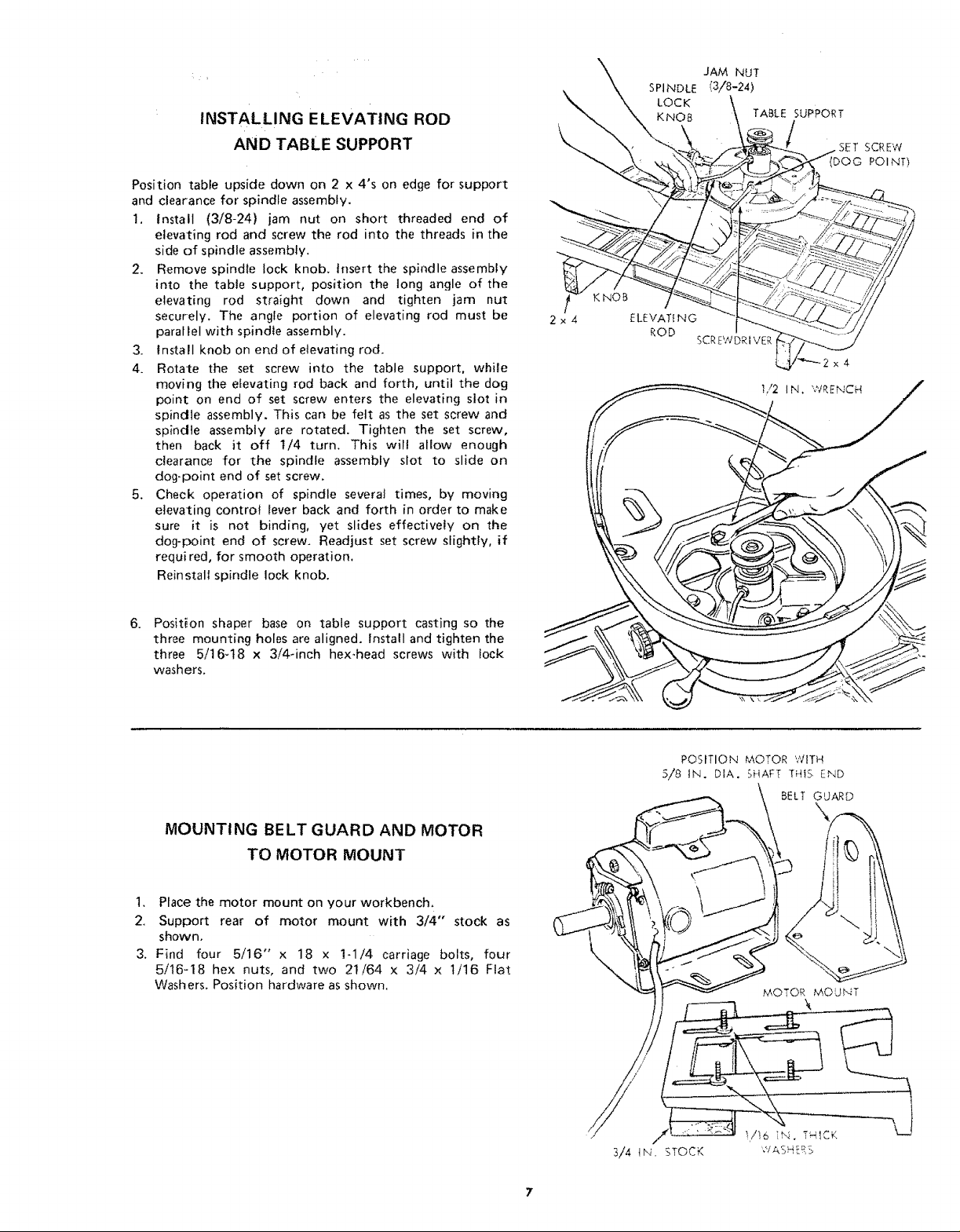

INSTALLING ELEVATING ROD

AND TABLE SUPPORT

Position table upside down on 2 x 4's on edge for support

and clearance for spindle assembly.

1. Install (3/8-24) jam nut on short threaded end of

elevating rod and screw the rod into the threads in the

side of spindle assembly.

2. Remove spindle lock knob. htsert the spindle assembly

into the table support, position the tong angle of the

elevating rod straight down and tighten jam nut

securely. The angle portion of elevating rod must be

parallel with spindle assembly.

3. Install knob on end of elevating rod.

4. Rotate the set screw into the table support, while

moving the elevating rod back and forth, until the dog

point on end of set screw enters the elevating slot in

spindle assembly. This can be felt as the set screw and

spindle assembly are rotated. Tighten the set screw,

then back it off 1/4 turn. This wilt allow enough

clearance for the spindle assembly slot to slide on

dog-point end of set screw,

5. Check operation of spindle several times, by moving

elevating control lever back and forth in order to make

sure it is not binding, yet slides effectively on the

dog-point end of screw. Readjust set screw slightly, if

requi red, for smooth operation.

Reinstall spindle lock knob.

6.

Position shaper base on table support casting so the

three mounting holes are aligned. Install and tighten the

three 5/16-18 x 3i4dnch hex-head screws with fock

washers.

MOUNTING BELT GUARD AND MOTOR

TO MOTOR MOUNT

1. Place the motor mount on your workbench.

2. Support rear of motor mount with 3/4" stock as

shown.

3. Find four 5/16" x 18 x 1-1/4 carriage bolts, four

5/16-18 hex nuts, and two 2t/64 x 3/4 x 1/16 Flat

Washers. Position hardware as shown.

POSITION MOTOR WITH

.5/8 IN. DIA, SHAFT THiS END

BELT GUARD

MOTOR MOUNT

3/4 IN. STOCK

Page 8

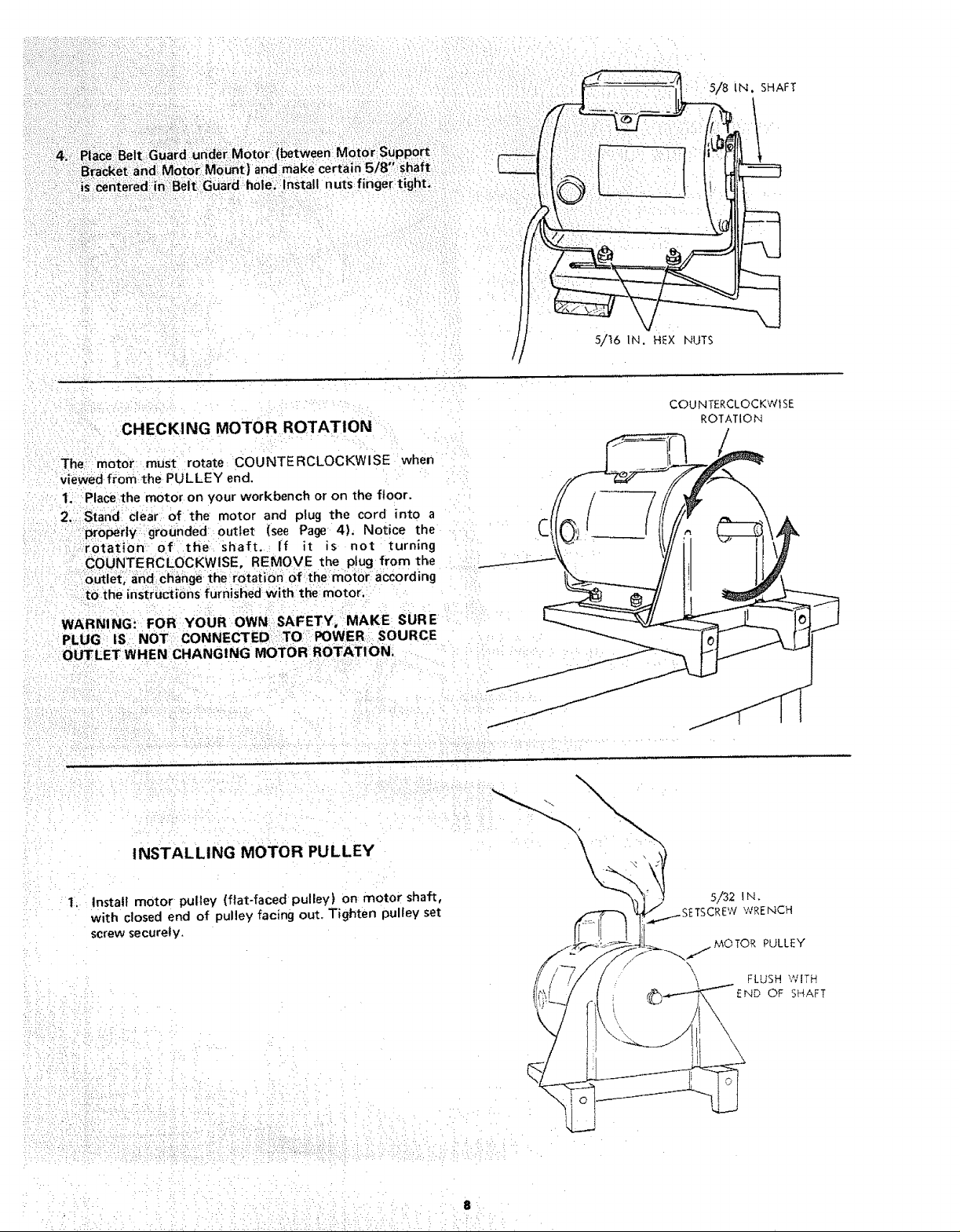

{ u ::

5/8 IN. SHAFT

:::4.;!:::Place:':Belti::G_ard iunde_iMotor (between; Motor Support

' i:iB_a_ket and M0torll Mount )and makd certaln 518' shaft

: :is Centeied in •Bblt Guard hoie. :inStall nuts finger tight,

?i!!

CHECKING MOTOR ROTATION

The motor must rotate COUNTERCLOCKWISE when

viewed from the PULLEY end.

1. Place the motor on your workbench or on the floor.

2. Stand clear of the motor and plug the cord into a

properly,grounded outlet (see Page 4). Notice the

rotation of the shaft, If it is not turning

COUNTERCLOCKWISE, REMOVE the plug from the

Outlet and change the:irotation of the motor according

tO the instructions furnished with the: motor,

i1t,

5/t6 IN. HEX NUTS

COU NTERCLOCKW]SE

ROTATION

WARNING_ FOR YOUR OWN SAFETY, MAKE SURE

PLUG IS NOT CONNECTEDi:TO POWER SOURCE

OUTLET WHEN CHANGING MOTOR ROTATION.

INSTALLING MOTOR PULLEY

Install motor pulley (flat-faced pulley) on motor shah,

1.

with closed end of pulley facing out. Tighten pulley set

screw securely.

\

5/32 lN.

TSCREWWRENCH

MOTOR PULLEY

\

FLUSH WITH

END OF SHAFT

k• ••/, : • .

Page 9

MOTOR MOUNT PLATE

.

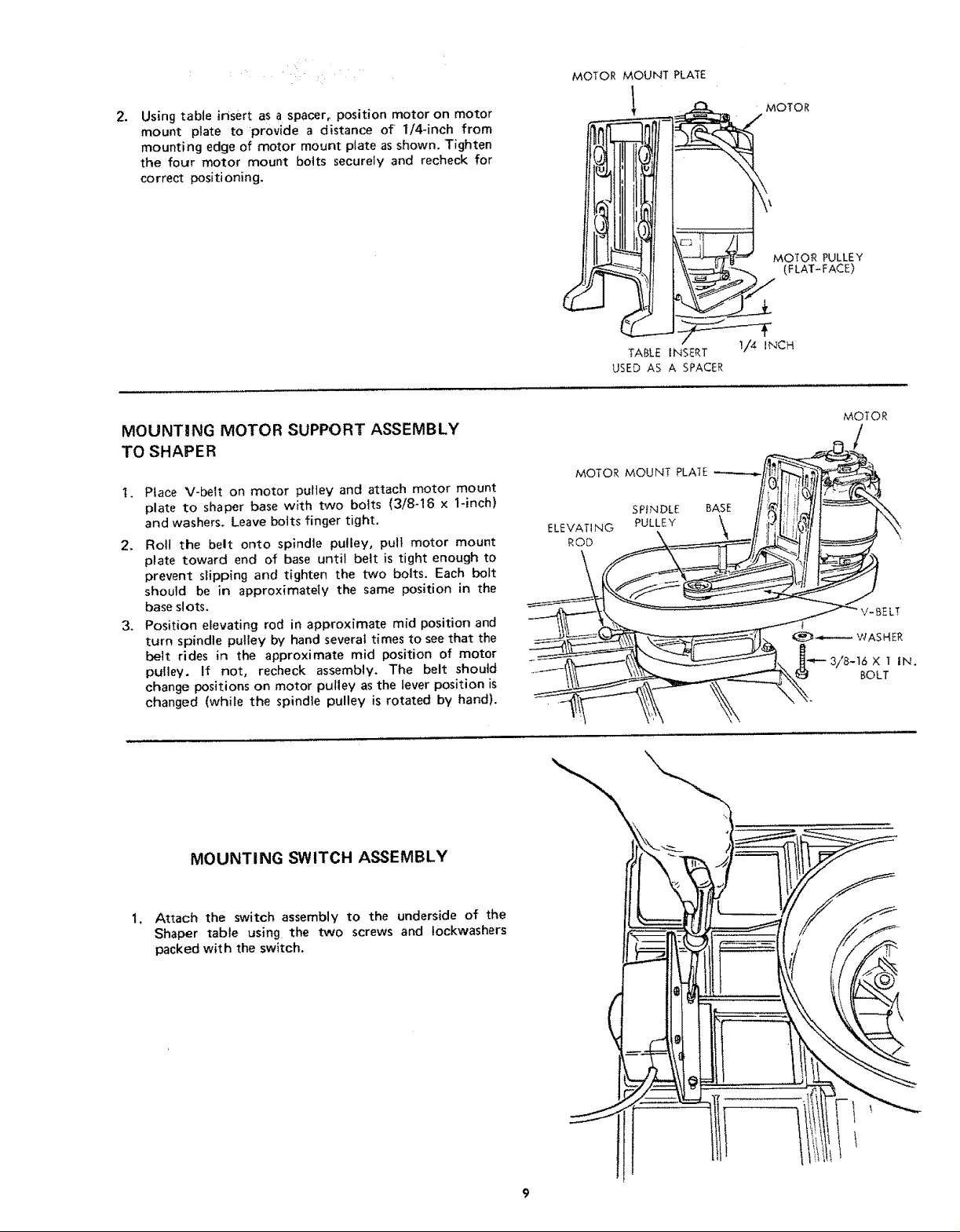

Using table insert as a spacer, position motor on motor

mount plate to provide a distance of 1/4-inch from

mounting edge of motor mount plate as shown. Tighten

the four motor mount bolts securely and recheck for

correct positioning.

MOUNTING MOTOR SUPPORT ASSEMBLY

TO SHAPER

t. PLace V-belt on motor pulley and attach motor mount

plate to shaper base with two bolts (3/8-16 x 1-inch)

and washers. Leave bolts finger tight.

2. Roll the belt onto spindle pulley, pull motor mount

plate toward end of base until belt is tight enough to

prevent slipping and tighten the two bolts. Each bolt

should be in approximately the same position in the

base slots.

3. Position elevating rod in approximate mid position and

turn spindle pulley by hand several times to see that the

belt rides in the approximate mid position of motor

pulley. If not, recheck assembly. The belt should

change positions on motor pulley as the lever position is

changed (while the spindte pulley is rotated by hand).

TABLE iNSERT I/4 INCH

USED AS A SPACER

MOTOR MOUNT PLATE

SPINDLE

ELEVATING PULLEY

ROD

MOTOR

MOTOR PULLEY

(FLAT-FACE)

MOTOR

BASE

MOUNTING SWITCH ASSEMBLY

"J,

Attach the switch assembly to the underside of the

Shaper table using the two screws and lockwashers

packed with the switch.

Page 10

ASSEMBLINGSTEELLEGS

: (Si_ppli_ With 113J2392910nly),

£

: :: 'Side::Stiffeners USi_ig::f0ur: (4)i: i14;20 Truss heads_re_;

: Thel EndStiffeners;_are placed cin: itop 0f each Side

::stiffener as:shown.: !lfisert screws:thi0ugh: the 9/32 inch

i: :::di;_meterholes and finger tighten l:/4-20;nutS:

2_ Attach: the four (4) legS;'::tothe Sicle'_nd End Stiffener

{]singl_/4_20 screws, IOckwashers and nuts assh6wn:

3; Remove the four (4) Truss head screws which were

assembled in Paragraph No. Orie. Place the two (2)

Support Channels as Shown, in position, align holes in

supports with holes in the side Stiffeners, replace

|ockw_shers and nuts. Tighten all nuts using 7/!6

wrench;

4: The two (2) Stiffeners, (F)iare fastened to the top side

of each side stiffener using N8 x 1/2 self-threading

screws. The guard plate is mounted as shown using same

screws.

Install leveling feet as shown. To level Leg Set, loosen

nut on inside of leg and turn nut on outside to raise or

lOWer feet, Adjust all four levelers, if necessary, and then

:'tighten nuts on inside of leg.

NOTE_ These levelers ape not: intended for height

adjUstment._ "

•

/

Part Name

Item

A Leg .................................. 4

8 e Screw, Truss Hd, I/4-20 x 5/8 ............. 28

C • Nut, Hex 1/4-20 ........................ 28

D Lockwasher, 1!4 External ................ 28

E Channel, Support ........................ 2

F Stiffener .............................. 2

G Stiffener. Side ........................ 2

H Stiffener, End .......................... 2

j • Screw, Pan Hd, TV- A N8 x 1/2 ............ 4

K • Nut, Hex Hal. 1/2-13 .................... 8

L • Foot, Leveling ......................... 4

• These parrs contained in Loose Parts Bag No, 72031.

Qty.

MOUNTING WOOD SHAPER ON FLOOR STAND

t. Three mounting holes are provided in the base of the

shaper for the purpose of mounting it securely on a

substantial tool stand with screws or bolts.

2. The tool stand should be high enough so the top surface

of the shaper table will be 35 to 37 inches above the

floor. The shaper must be mounted to allow the motor

to overhang rear edge of tool stand.

CAUTION: The shaper must be mounted on a

substantial tool stand and secured so there is no

possibility of tipping. The Shaper must be positioned on

the toot:stand-so that the spindle pulley isguarded from

the bottom.

Place the Shaper on the Steel LEGS. PositiOn as shown,

and align mounting holes; SecUre with 3 ea. 5/16" x 18

x 3" screws;washersand nuts,

.... i= .............. .....

10

GUARD PLATE

t

NO. 8 X I/2 iN.

PAN HD, SCREW

(SUPPL}ED WiTH LEG SET)

Page 11

PLUGGING IN MOTOR

1. Find plastic cable hanger from among the loose parts.

2. Route the motor cord behind the motor mount, across

the top of the Leg Set and plug it into the receptacle in

the side;of the switch box.

3. Bring the power cord alongside the motor

cord ... wrap the plastic cable hanger around the cords

and attach the hanger to the top of the Leg Set.

5/16-18 X 2 IN.

HEX HD. SCREWS

AND WASHERS

RNSTALLING SHAPER FENCE --

FOR STRAIGHT EDGE SHAPING ONLY

1,

Instal_ the fence with two 5/16-18 x 2 inch hex head

screws and two plain washers. These screws thread into

tapped holes in the table. Adjust the fence as outlined

on page 13.

INSTALLING SHAPER CUTTER GUARD -

FOR CURVED OR IRREGULAR SHAPING ONLY

NOTE: Fence must be removed.

1. Assemble Cutter Guard as illustrated.

FENCE

GUARO

HEX HD, SCR,EW

1t

Page 12

ki_:ii:i¸__;¸¸ :

!:!_-_:_i/:_::i:¸¸!,I:I/i_ _ .:_ _;:; :_::: _`:;_;_::_:::_;;j_

...... Aiign the guard _pportl _0 that it is:cer_teredon the shaper

spind e i(It may_ibe necessary to ioosen: the 5/16:18 ScreWs

Which: secure _the ii Support bracket :tO the channeis ito

perform this adjustment):; Af{er the :alignment is achieved

tighten allfour SCrewSsecurely.

InStall Cutter GUard:Assembly to table support using the

two 5/16:18 X:2 inch hex head screws located at rear of

table Support.

GUARD

k

]2

Page 13

GETTING TO

TABLE INSERT

MITER GAUGE

TABLE

\

2

_:LEVATI NG

CONTROL LEVER

KNOW YOUR WOOD SHAPER

8

FENCE

LOCK KNOB

9

FENCE FACE

STARTING PIN

FENCE

ADJUSTING KNOB

FENCE FACE

1

ON-OFF SWITCH

CAUTION: All set-up and operational instructions that

follow (for the Shaper) relate to and require

counterclockwise rotation of the spindle.

1. ON-OFF SWITCH

CAUTION: Before turning switch on, make surethe cutter

is installed properly and the keyed washer is positioned

below the spindle nut,

The On*Off Switch has a locking feature, THIS FEATURE

IS INTENDED TO PREVENT UNAUTHORIZED AND

POSSIBLE HAZARDOUS USE BY CHILDREN AND

OTHE RS.

a. TO turn Shaper ON... insert finger under switch lever

and putl END of lever out.

After turning switch ON, always allow the cutter to

come up to full speed before cutting.

Do not cycle the motor switch on and off rapidly, as

this may cause the cutter to loosen. In the event this

should ever occur; allow the cutter to come to a

complete stop and ret_ghten the spindle nut normally,

not excessively. Never leave the shaper white the power

is "ON".

b. TO turn shaper OFF... PUSH lever in. Never leave the

shaper until the cutting tool has come to a comptete

stop,

c. TO lock switch in OFF position...hold switch 1N

with one hand ,. o REMOVE key with other hand.

ALWAYS LOCK THE SWITCH "OFF" WHEN

SHAPER IS NOT IN USE.,. REMOVE KEY AND

KEEP IT IN A SAFE PLACE,,, ALSO.,, IN THE

EVENT OF A POWER FAILURE (ALL OF YOUR

LIGHTS GO OUT) TURN SWITCH OFF ... LOCK IT

AND REMOVE THE KEY, THIS WILL PREVENT

THE SHAPER FROM STARTING UP AGAIN WHEN

THE POWER COMES BACK ON.

I3

SHAPER BASE

\

MOTOR MOUNT PLATE

KEY

(YELLOW PLASTIC)

3 SPINDLE

LOCK KNOB

MOTOR (NOT

FURNISHED)

Page 14

2; :ELEVATING CONTROL LEVER , i .... 1!, STARTING PIN

The :,Elevating ::i:co_troi Lever:: movesl _he: spindle : :The Starting' Pin must be used as a pivot to support the

:vertically :a di_ait_:of,718:inch to locate:the: cUttei;_;at: : i:iwork unti!:it has been fed into the cutter and against

the desired:vertical_i_Sition_ the collar. The Starting Pin may be located in either of

the two threaded holes near the table insert opening,

depending upon the direction of rotation, but

determined, ALWAYS on the in-feed side.

CAUTION: Always release the quill lock knob before 12. REMOVING AND INSTALLING CUTTERS

attempting to ichattge ithe iposition:of Spindle a. Raise:spind}eto maximum height

tighten the knob Secureiy before startinff operation. : .... b. To REMOVE cutter, hold spindle with the 1/4" hex

4. SPINDLE L_.This::=shaper is designed for use with wrench and loosen nut with wrench provided as

maximum 2Li/2-inch diameter cutters having a l/2:inch

diameter bore.

5_ SPACERS- A total of three spacers are provided, two

7/16inch thick and one 1/4 inch think for positioning

the cutter for desired shapes.

6; KEYED WASHER - Must always be positioned

immediately below the spindle nut;

7. FENCE ADJUSTING KNOB Each fence face may be

moved forward or backward by turning the fence

adjusting knobs.

8. FENCE LOCK KNOB - After the desired fence face

position has been selected, the fence is secured bY

tightening the fence lock knobs.

9. FENCE FACES -- Each fence may be moved forward

or backward by releasing the fence lock knob and

turning the fence adjusting knobs. Each fence face

operates independently of the other, by means of the

adjusting mechanism. After the desired fence position

has been selected, it is secured by tightening the fence

lock knob. The fence faces wilt close in from a

maximum three-inch opening down to one-inch for

Small diameter cutters, by loosening the two screws in

the front of each face and sliding the face to the desired

posiiton. The Screws must be tightened securely after

each setting.

shown- Reverse procedure to TIGHTEN SPINDLE

NUT.

NOTE: TO AVOID POSSIBLE BENDING OF THE

SPINDLE LOOSEN OR TIGHTEN NUT WITH BOTH

WRENCHES POINTING AS NEARLY IN THE SAME

DIRECTION AS POSSIBLE.

CAUTION: Always have the keyed washer directly

under the nut, otherwise the nut may loosen and

seriousinjury could resu|t.

CAUTION; The opening between inner ends of fence faces

ShOuld:never_be large_ than required to just clear the

particular cutter being used. ALWAYS ROTATE THE

SPINDLE BY HAND BEFORE STARTING THE SHAPER

MOTOR TO MAKE SURE CUTTER DOES NOT STRIKE

FENCE FACES,

10. CUTTER GUARD

NOTE: Used for curved or irregular shaping only -

fence must be removed and starting pin must be in

placeon in-feed side.

Provides added protection for irregular shaping. Guard

is adjustable for various thickness of material.

CAUTION; Always rotate the spindle by hand before

starting the shaper motor to make sure cutter does not

strike guard,

• •-•::::i:: • •: •••:• O••::• •• :• •: • :__-•i _•:•i: • :• •

/

WRONG

RIGHI"

:'14. ¸

Page 15

ADJUSTMENTS

WARNING: FOR YOUR OWN SAFETY, TURN SWITCH

"OFF." AND REMOVE PLUG FROM POWER SOURCE

OUTLET BEFORE MAKING ANY ADJUSTMENTS.

ADJUSTABLE SHAPER FENCE

1. Move both fence faces out 3/4" by turning the two

fence adjusting knobs.

FENCE

ADJUSTING

KNOBS

2. Position fence faces in the same plane by using a

framing square or straightedge and adjusting the fence

adjusting knob.

3, Loosen the fence attaching bolts and shift the complete

fence assembly until both fence faces are the same

distance from the miter slot.

Tighten fence attaching bolts after fence has been

correctly positioned.

Check this adjustment after tightening bolts to make

sure it did not change.

Lock all controls securely after desired settings have

been completed.

FENCE FACES

STRAIGHT EDGE

FENCE FACE

1°

Loosen the four (4) screws as shown and slide each

fence face in as close to the cutter as possible, but do

not permit the cutter to strike fence faces.

,

Set the fence faces so the cutter (Not supplied see

Recommended Accessory List) projects far enough

beyond them to produce the desired depth of cut. if

the cutter is set to remove only a portion of the edge of

the work piece, the two fence faces should be set even

with each other.

15

Page 16

BA SiC SHAPING; O PERATION S

cutter would have to be turned over.

2i :Always remember (when mounting the cutter) that the

cutting edge of cutter must lead into the direction of

rotation;

Instructions:_:for : reversing the motor rotation are

normally :foUnd On the motor name plate, or electrical

cover plate. Make sure the plug has been removed from

electrical:outlet before attempting to reverse rotation.

SPINDLE

USE OF CUTTER SPACERS

1; The spacers can be positioned below and above the

cutter,

Notice when the spacer is positioned below the cutter

how the spacer proVides a bearing surface for the uncut

edge of the board, in addition to its use as a spacer in

vertical positioning of the cutter.

2;:This same :cutter can be inverted and mounted to

produce a Shape with the board fed through in the

ooposite direction I F DIRECTION OF- ROTATION OF

THE SPINDLE IS REVERSED,

Notice how the spacer again provides a bearing surface

for the uncut edge of the board.

3. Cut the workpiece to size, so the shaping cut will be as

light aspossible to produce the desired pattern.

CAUTION: Do not attempt to usethe Shaper for sizing

a workpiece (except when using the jointer cutter and

adjustable fence).

4. Feed workpiece against rotation of cutter.

NOTE: It is a very good practice to make a trial cut on

a piece of scrap wood as a double check on the set-up

before usingthe actual workpiece.

CAUTION: Serious injury may result if workpiece is

not always fed into the cutter against the direction of

rotation of the cutter, Use a smooth even pressure.

Experience will:soon reveal the best rate of feed for

producing rite Smoothest cut,

5. If :the :Cut removes materia_ Over the entire ed

reducing the Width 0f_t!_e work

fence ir_ fron_

enough:to provid,

it passesthee:utter: This! mg to

support the workpiece.

" : :i•. • • . • :

•16

SPINDLE f

y DIRECTION

KEYED OF FEED

WASHER

"_CUTTER

__SPACER

k

TABLE INSERT

/

DIRECTION /

OF FEED DIRECTION OF

NOTE: TABLE INSERT

REMOVED

/ SPACER

ROTATI 0 N

Page 17

AUXILIARY FENCE/WORK SUPPORT

WORKPIECE

X

STRAIGHT EDGE SHAPING

I

SLIGHTLY THICKER

THAN WORKPfECE

FENCE

WO_KPI ECE

AUXiLiARY FENCE!

WORK SUPPORT

,\

2,7 IN,

PUSH STICK

(FEEDS UNDER

AUXILIARY _ENCEi

WORK SUPPORT

CAUTION: The Shaper fence must be used in all straight

edge shaping operations.

1. When shaping stock 3 inches wide or tess, an auxiliary

fence/work support must be usedasshown.

2, Make the push stick as shown.

SLIGHTLY THINNER AND

NARROWER THAN WORKPiECE

2O

PUSH STICK

END SHAPING WITH USE OF MITER GAUGE AND

HOLD-DOWN CLAMP (OPTIONAL ACCESSORIES)

1. NEVER use the Miter Gauge on the Shaper without the

Hold-down Clamp installed and the workpiece clamped.

2. Both fence faces MUST be positioned so the workpiece

cannot contact them.

3. Adjust the head of the miter gauge so the end of the

workpiece to be shaped will be exactly parallel to the

miter gauge slot in the table, This holds true for all

angles of the end of the workpiece,

4. The board is positioned in the miter gauge; then hold

the workpiece firmly against the miter gauge head and

down on the table with your left hand, and feed by

gripping the lock handle with vour right hand.

17

Page 18

,."EGUL RORC RVE S. PmG

workpiece; by using various combinations of cutters on

successive passes, and/or by invertlng Cutterand changing

direction of spindie:rotati0n and:feedidirectibn_ Tile table

insert:must be removed if the cutter does not ctearthe hole

in the insert when the cutter is lowered below the table

surface:check clearance before turning switch "ON":

t; To make irregular shaping cuts remove power cable

from electrical source, remove the fence assembly,

select the shaper collar that wit! position the cutter to

obtain the desired pattern, and lock the shaper collar

and Cutter onthe spindle.

NOTE: A shapercollar may be located above or below

a cutter, or between the two cutters selected.

DIRECTION

OF FEED

DIRECTI(

OF

SHAPER COLLAR

(OPTIONAL ACCESSORY)

o

©

2. Mount the cutter guard and adjustas shown.

Position the: Guard verticalli (A) (Guard should just

clear workpiece)

Center the Guard over the cutter. (B)

NOTE: Rotate cutter by hand and check for proper

clearance inside guard.

SHAPER COLLAR SET

(OPTIONAL ACCE SSORY)

/

STARTING(-

._: c•• : •_..• _

/

/

i

Page 19

3. The starting pin must be used as a pivot to support the

work until it has been fed into the st_aper collar. The

Starting Pin may be located in either of the two

threaded holes near the table insert opening, depending

upon the direction of rotation; but always on the

in-feed side.

4. Start the workpiece by pivoting it around the starting

pin slowly into the path of the cutter until the

workpiece contacts the shaper collar.

WARNING: DO NOT ATTEMPT TO SHAPE WARPED

LUMBER.

PIVOT WORKPIECE

AROUND STARTING PIN

Workpiece MUST contact the FRONT of the cutter and

collar - toward the miter gauge slot.

5. in addition, the following operations are some which

can be performed on the shaper - shaping with a

pattern, tongue and groove joints, reading and fluting,

etc. ("Power Toot Know How" Handbooks are

available) See Recommended Accessories list.

NOTE: After a few hours of operation, tighten both pulley

set screws securely with the Hex wrenches provided.

COLLAR

POSITION J

19

Page 20

MAINTENANCE

:i_¸ !j: :i

WARNING: FOR YOUR OWN SAFETY, TURN SWITCH

I?OFF_ AND REMOVE PLUG FROM POWER SOURCE

OUTLET BEFORE:MAINTAINiNG OR LUBRICATING

YOURSAW,I :

NOTE: After a few hours of operation, tighten both pulley

set screws securely withthe Hex wrenches provided.

Frequently clean your cutting tools with Craftsman Gum

and Pitch Remover,

A coat of automobi]e-type wax applied to the table wil!

help to keep the surface clean and allow workpieces to slide

more freely.

If the power cord is worn or cut, or damaged in any way,

have it replaced immediately.

LUBRnCATION

:i ii : i_

The ball bearings used on the cutter spindle have been

packed with lubricant at the factory and require no further

attention,

To maintain smooth and easy operation, occasionally add a

few drops of oil tothe outside of the spindle assembly.

RECOMMENDED ACCESSORIES

IN CANADA, SEE YOUR LOCAL SIMPSONS-SEARS STORE

OR CATALOG FOR ACCESSORY SELECTION AND NUMBERS

ITEM CAT. NO. ITEM

Floor Base ................................. 9-22213

Steel Legs .................................. 9-22236

Casters ............................ 9-22222, 9-22221

Shaper Collar Set ........................... 9-23672

Shaper Cutters ......................... See Catalog

Push Blocks ................................. 9-2299

Motor W/Reversing Switch ................... 9-1269

The above recommended accessories are current and were

available at the time:this manual was _rinted.

Miter Gauge ............................. 9-29929

Miter Gauge Hold Down .................... 9-29928

"Power Tool Know How" handbooks

Table Saw .............................. 9-2918

Radial Saw .............................. 9-2917

Universal Jig .. _........................... 9-3231

CAT. NO.

Page 21

TROUBLE

SHOOTING

TROUBLE

Spindle

Assembly actuates

too hard.

Cutter comes loose

during operation.

Cutter slow down

during operation.

Binding of Fence

Boards when adjusting

in or out,

Shaper produces ragged

or ripple cuts.

Shaper produces a

smooth cut, but does

not hold a straight edge.

Shape varies across

width of board.

PROBABLE CAUSE

Set screw engaging slot

in spindle assembly

too tight,

Keyed washer not

properly installed.

1, Work being fed too

rapid I%

2, Insufficient belt

tension.

3. Glazed belt

Bottoms of fence faces

striking table,

1. Work piece not being

held firmly against

fence and/or table.

2. Interrupted feed

past cutter.

3. Dull cutter.

4. Belt slipping - causing

cutter speed to vary.

5. Cutter blades not

concentric. (Blade

segments have uneven

lengths.)

6. Work being fed too

rapidly.

7. Quality of wood not

sufficient to produce

desired results.

1. Fence faces improperly

set.

2. Spindle Assembly lock

knob not tight.

3. Workpieoe not held

snugly against fence,

4. Work piece not held

snugly against table.

5. Work being fed to

rapicJly.

6. Attempting to remove

more material than

required to produce

desired shape,

7. Fence loose on table,

1. Work not held

securely to miter

gauge and/or to

table.

2. End of workpiece

not parallel with

miter gauge slot.

3, End to be shaped

is wavy (not

straight).

REMEDY

Tighten screw then back it off 'i/4 turn, Adjust until

action is smooth without end piay.

The keyed washer must always be used directly under

the nut,

i '.'F'eed work through more slowly to allow cutter to

remove stock smoothly.

2. Loosen motor mount plate bolts and move motor

slightly toward rear of shaper until belt tension is

correct, tighten bolts.

3, Replace belt.

Loosen the two screws through front of face, raise it

slightly and tighten screws.

I, Apply sufficient hand pressure in _c)th

directions or revise Auxiliary Fence/Work

Support (pg. 15) accordingly.

Maintain continuous feed.

,

3.

Sharpen or replace cutter

4.

Adjust belt for proper tension.

5.

Replace or resharpen cutter.

6. Feed work through slow enough to produce

smooth cut,

7. Use a better grade of material.

1.

Adjust fence faces,

2.

Tighten spindle assembly lock knob,

3.

Increase hand pressure or revise Auxiliary

Fence/Work Support (10g. 15),

4,

Increase hand pressure or revise Auxiliary

Fence/Work Support (pg, t 5),

5.

Feed work through more slowly,

Joint workpiece to proper width before shaping edge.

6.

7. Tighten fence.

I. Hold work firmly against miter gauge and down

on the table.

2. Adjust miter gauge.

3. Resaw and/or joint as necessary.

iii ,, ,,, ,,,,,,,

21

Page 22

I 36.__.._ _ |

I |

! |

I g

§ |

I g

! g

I: 40 41 42 H

37 =

I !

I i 44 i

ii 91

I

g

REPAIR:: PARTS

6

II t "'38

g 35

\

(used with 9-22236 Steel Leg Set)

22

Page 23

PARTS LIST FOR CRAFTSMAN WOOD SHAPER

MODEL No. 113.239201 & 113.239291

FIGURE 1

Key Part

No. No, Description

1

3

4

5

J

10

11

12

13

!4

1

17

t8

19

20

21

22

23

24

25

26

72008

60167

STD 623120

39411

39613

39290

39512

STD 551037

STD 54t 137

39629

60437

38799

39628

38546

STD 55! 210

STD 511 t05

39215

72014

STD 304330

STD 533t 12

STD 55t 031

STD 541231

39217

453068

Fence Assembly (See Figure 2)

Washer, .343 x 1.062 x 1/8

*Screw, Hex Hd. 5/16-18 x 2

Insert, Table

Pin, Table Dowel

Table (Includes Nameplate}

Knob, Lock

*Washer, 13/32 x 47/64 x t/16

*Nut, Hex, Jam, 3/8-24

Stud, Lock

*Washer, 2t/64 x 7/8 x 1/8

Screw, Set, 3/8-24 x 3/4 Dog Pt.

Rod, Elevating

Knob

Switch Box Assembly (See Figure 4)

* Lockwasher,.lnternal No. 10

*Screw, Pan Hal. 10-32 x 1/2

Base

Spindle Assembly (See Figure 5)

Plate, Guard

*Belt, V, I/2 x 33

*Bolt, Carriage 5/16-18 x 1-1/4

*Washer 21/64

*Nut, Hex 5/16-18

Mount, Motor

Screw, Mach., 5/16-18 x 3/4,

Hex. Hd. w/Lockwasher

' Part !

Ke!

No

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

No. i Description

72003

STD 503102

39230

STD 551037

STD 523710

39216

72027

72024

72025

STD 551231

STD 523112

72005

60262 I.Grip

STD 541525 Nut, Lock 1/4-28

70007 Hub Asm. Lock

56634 Stud, Nut

72026

72023

68036

37435

37837

38713

72022

72033

Guard, Pultey

*Screw, Set 5/t6-18 x 5/16,

Soc. Hd. Cup Pt.

Pulley, Motor, (w/Set Screw)

Washer, 25/64 x 1-9/64 x 7/64

*Screw, Hex Hd. 3/8-16 x 1

Support Tabre

Guard, Asm. Cutter

Support Assembly, R.H.

Support Assembly, L.Ho

* Lockwasher, tnternat 5/16

Screw, Hex Hd. 5/16 x !8x 1-t/4

Guard, Cutter

i Includes Key No. 39 )

Arm, Guard

Holder, Guard

Hanger, Cable

*Wrench, He×., t/4

*Wrench, Hex., 5/32

Wrench

Bag Asm. Loose Parts

(not illustrated)

Owners Manual (not illustrated)

*Standard Hardware Items- May be Purchased Loca!ly.

23

Page 24

12

11 10

FIGURE 2 -- FENCE ASSEMBLY 72008

: Key

No.

! " : I

: 72008:: Fence

Description

Assembly Complete

7

x 1/2

9

\

3 138612 K_ob, Adjusting

:: 41t:t8451-I Washer, Spring •

: 5::138413 Frame

6 138531 ..... {i Knob

7 _ 381:10 Shoe Assy., Fence

9 38533 .

t0 S'£D 512507

11 STD 551012

t 2 38532

*Standard Hardware Item -- May be Purchased Locally.

Plate, Work Face (Right)

*Screw, Pan Hd., 114-20 x 3/4

*Washer, Plain, 1/4

Plate, Work Face (Left)

24

Page 25

PARTS LIST FOR CRAFTSMAN WOOD SHAPER

MODEL No, 113.239201 & 113.239291

2

L

FIGURE 3- LEGS (Supplied with 113.239291 only)

Key

No.

1

2

3

4

5

6

7

8

9

10

11

12

HARDWARE FOR MOUNTING TOOL

Part

No,

62614

60314

STD541025

STD551225

68060

72030

68059

62615

ST D610805

STD541050

803835

72029

STD523130

STD 551131

ST0541231

STD551031

Description

Leg

OScrew, Truss Hd. 1/4-20 x 5/8

e_ Nut, Hex 1/4-20

o* Lockwasher, 1/4 External

Channel, Support

Stiffener

Stiffener, Side

Stiffener, End

®*Screw, Pan Hd. Ty. A N8 x 1/2

o* Nut, Hex Hdo 1/2-13

• Foot, Leveling

t Motor

• Screw, Hex Hd, 5/16-t8 x 3

e* Lockwasher, 5/16 External

• Nut, Hex Jam 5/16-t8

• Washer, 11/32 ID

i ,i

Standard Hardware Item - May be purchased

!ocatly.

Stock Item - May be secured through the

Hardware Department of most Sears Retail

Stores or Cata;tog Order Houses,

These parts contained in Loose Parts Bag

No. 72031.

25

Page 26

J • •ii :L_;:i/• ;•. ":k

i_/•i•!.i i¸

8

f

J

FIGURE 4-

ON/OFF POWER OUTLET 60382

AND MOUNTING BRACKET

'Key; -Pa,t

No, i_ . No, i Description; ....

I i i = i

60375 _ Cord, Molded .....

211 6037811; i Housing,Switchi_ : i

: 3 _' 60256 :: I • Key;Switch : i

6o374 I SwitchiLocking:

ii: 51 160376 : : SwitCh;i:; ;= • = :

*Standard Hardware Item - May be Purchased Locally.

Does Not Include Key No. 3

Order Separately If Required.

FIGURE 5 - SPINDLE ASSEMBLY

Key Part

No. No.

R

! 39615

2 39711

3 39616

4 39617

5 72007

6 STD 503103

STD 328011

Spindle Assembty Complete

Nut, Spindle

Washer, Keyed

Spacer 1/4

Spacer 7/t6

Spindle Assembly

*Screw, Set 5/16-18 x 3/8,

Soc. Hd. Cup pt.

*Pulley, (w!Set Screw) "V"

2 x 1/2 Bore

Description

r i .

7

*Standard Hardware Item - May be Purchased Locally.

k-

•i::••• ••: •i•••" " •i/•: i••••:: •i •• •• •• :; • . 26

Page 27

NOTES

27

Page 28

WOOD SHAPER

SERVmCE

MODEL NO.

113.239201

SHAPER ONLY

113.239291

SHAPER WITH STEEL

LEGS AND MOTOR

HOW TO ORDER

REPAIR PARTS

Now that you have purchased your wood shaper, should a need

ever exist for repair parts or service, simply contact any Sears

Service Center and most Sears, Roebuck and Co. stores. Be sure

to provide all pertinent facts when you call or visit.

The model number of your wood shaper will be found on a

plate attached to your wood shaper on the front of the table.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE

FOLLOWIN3 INFORMATION:

Sold by SEARS, ROEBUCK AND CO., Chicago, IL. 60684 U.S.A.

PaN No. 72033

PART NUMBER

MODEL NUMBER

113.239201

113.239291

All parts listed may be ordered from any Sears Service Center

and most Sears stores. If the parts you need are not stocked

locally, your order witl be electronically transmitted to a Sears

Repair Parts Distribution Center for handling.

Form No. SP4462-6 Printed in U.S.A, 11/82

PART DESCRIPTION

NAME OF ITEM

WOOD SHAPER

Loading...

Loading...