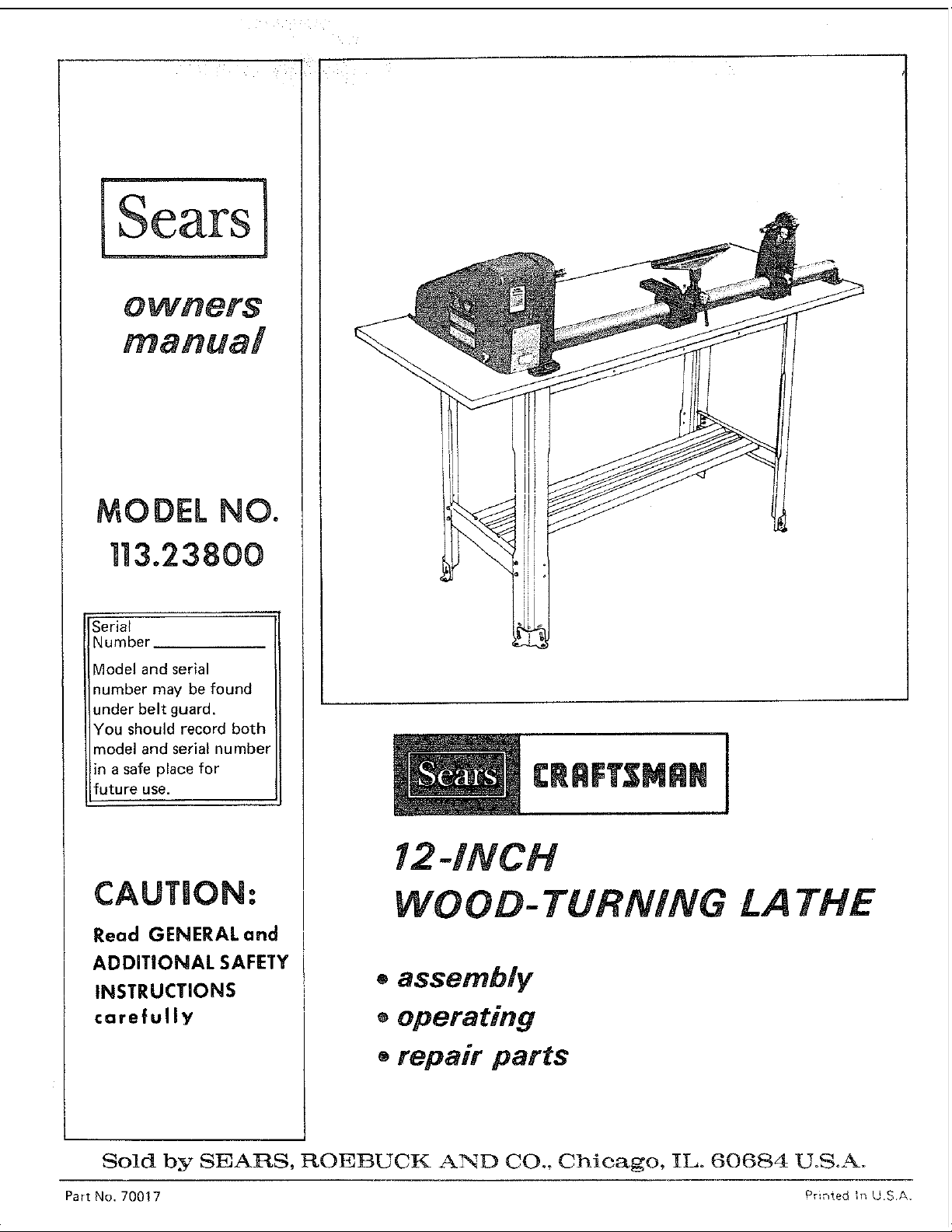

Craftsman 113.23800 Owner's Manual

Serial

Number

Modelandserial

numbermaybefound

underbeltguard.

Youshouldrecordboth

modelandserialnumber

in asafeplacefor

futureuse.

CAUTION:

Read GENERAL and

ADDITIONAL SAFETY

INSTRUCTIONS

carefully

_ CRRFTSMRN

12-iNCH

WOOD-TURNING LA THE

o assembly

®operating

• repair parts

Sold by SEARS, ROEBUCK AND CO., Chicago, IL. 60684 UoS.A.

Part No. 70017 Printed h'_ U.SA.

CRAFTSMAN WOOD TURNING LATHE ]

i

f within one year from the date of purchase, th s Craftsman Wood Turning Lathe fa Is due to a defect in ]

material or workmanship, SearsWill repair it,free of charge,

Warranty service is available by simply contacting the nearest Sears store or Service Center throughout the

United States.

This warranty gives you specific legal rights, an(] you may also have other rights which vary from state to

state.

SEARS, ROEBUCK AND CO.

BSC41-3

SEARS TOWER

CHICAGO, IL, 60684

GENERAL SAFETY INSTRUCTIONS FOR POWER TOOLS

1. KNOW YOUR POWER TOOL

Read the owner's manual careful V. Learn tsapphcatlon

and lim=tations as well as the specifc potential hazards

pecul=ar to this tool.

13. SECURE WORK

use clamp5 or a vise [o _o_o .vof_ wneP, o_actical Jt's

safer than using your nan_q t_ees _om llanos [c ooe_dte

too

2, GROUND ALL TOOLS

This tool is equipped with an approved 3-conductor

cord and a 3-prong grounpm3 type plug to fit the prooer

grounding type receptacle. The green conductor in the

cord is the grounding wire. Never connect tne green wire

to a live terminal.

3. KEEP GUARDS IN PLACE

n worKing oroer, and in proper adj Jstment and align.

ment.

4. REMOVE ADJUSTING KEYS AND WRENCHES

Form habit of checkmg to see mat keys and aejustmg

wrenches are removed from tool before turning it on.

5. KEEP WO RK AREA CLEAN

Cluttered areas and benches =nvlte accidents Floor

must not be shppery due to wax or sawdust.

6. AVOID DANGEROUS ENVIRONMENT

Don t use power tools in damp or wet locations or ex-

pose them to rain. Keep work area well lighted_ Provide

adequate surrounding work sp_ce.

7, KEEP CHILDREN AWAY

All visitors should be kept a safe distance from WOrK area

8. MAKE WORKSHOP KID-PROOF

= Wlttl padlocks, master switches, or bv removing starter

keys.

9. DON'T FORCE TOOL

It wdl do the job better and safer at the rate for which

it was designed

10. USE RIGHT TOOL

Don't force tool or attachment 1o eo a job _t was not

designed for.

11. WEAR PROPER APPAREL

Do not wear loose clothir_J, gloves, neckties or jewelry

(rings, wristwatches) to get caught m moving carts.

NONSLIP footwear is recommended. Wear proteetwe

hair covering to contain long hair Roll long sleeves

above the elbow.

12. USE SAFETY GOGGLES (Head Protection)

14. DON'T OVERREACH

Keepp_oper footing ano balance at a t_mes

15. MAINTAIN TOOLS WITH CARE

Keen tools shard ano c_ean for nest and safest oe_form-

ante. Follow mstructlo[ls for lubricating ano changing

accessories.

16. DISCONNECT TOOLS

before serv;cmg; when changing accessories such as

blades, o_ts. cutters, etc.

17. AVOID ACCIDENTAL STARTING

Make sure switch s 7 "OFF" oosition before mugging

in.

18. USE RECOMMENDED ACCESSORIES

Consult the owner's manure for recommended accessories.

Follow toe nstruct=ons that accomoanv the accessories.

The use of improper accessor=es may cause hazards.

19. NEVER STAND ON TOOL

Serious injury COUlO occur if tne too[ is tipped or if the

cutting tool is accidentally contacted.

Do not store matenals above or near me tOOl such mat

t is necessary to stand on the tool to reach them.

20. CHECK DAMAGED PARTS

Before further use of the tool. a guaro or other cart mat

s damaged should be carefully checked to ensure that it

will ooerate properly and perform _ts ntendep function.

Check for ahgnment of moving parts, Oinolng of moving

parts, breakage of parts, mounting, ano any otner con-

ditions that may affect ts ooerat_on. ,_ guata or other

Dart That _s damageo should be orooerly reoalreG or

replaced

21. DIRECTION OF FEED

Feed work into a blade or cutter against the dl_ection of

rotation of the blade or cutter omv_

22. NEVER LEAVE TOOL RUNNING

UNATTENDED

Turn power off. Don't leave tOOl until !t comes to ._

complete stop.

Wear safety goggles (must comply with ANS Z87.1)

at all times. Also, use face or dust mask if cutting oper

ation is dusty, and ear protectors (plugs or muffs) durin_

extended periods of operation. 2

Safety is a Combination of operator common senseand

alertness at all times when the Lathe is being used.

WARNING: FOR YOUR OWN SAFETY, DO

NOT ATTEMPT TO OPERATE YOUR LATHE

UNTIL IT IS COMPLETELY ASSEMBLED AND

INSTALLED ACCORDING TO THE INSTRUC-

TIONS . .. AND UNTIL YOU HAVE READ

AND UNDERSTAND THE FOLLOWING:

PAGE

1. General Safety Instructions for Power Tools . . 2

2. Getting to Know Your Lathe ............ 13

3. Basic Lathe Operation ................. 15

4. Maintenance ....................... 19

5. The Lathe and motor must be bolted down to a stand

or workbench for stability.

6. Protection: Eyes, Hands, Face, Ears, Body

a, Wear safety gogglesthat comply with ANS Z87.1-

t968, and a face shield if operation is dusty.

Wear ear plugs or muffs during extended periods

of operation.

b, When turning between centers or on the face plate,

always rough-out "out of round" workpieces at

slow speed. Running the Lathe too fast, so that it

vibrates, could cause the workpiece to be thrown

from the Lathe . . . or the turning tool to be

jerked from your hands.

C.

Always revolve the workplace by hand before

turning on the motor, tf the workplece strikes the

tool rest, it could split and be thrown out of the

Lathe.

d. Do not allow the turning tool to "bite" into the

workpiece which could result in splitting of the

workpiece or the workpiece being thrown from

the Lathe. Always position the tool rest above the

centedine of the Lathe for spindle turning, Do not

apply the turning tool to the workpiece below the

level of the tool rest.

e.

Do not run the Lathe in the wrong direction, This

could cause the turning tool to be thrown from

your hands. The Lathe must run in a direction so

that the workpiece turns toward you.

Before attaching a workpiece to the face plate

always "rough it out" to as "true round" as pos-

sible. This will minimize vibration while turning.

Always fasten the workpiece securely to the face

plate,

Failure to perform these set-up operations could

cause the workpiece to be thrown from the Lathe.

g. Avoid awkward hand positions, where a sudden

slip could cause a hand to move into the work-

piece.

7.

8,

9,

10.

11,

h. Remove all loose knots before installing work-

piece between centers or on the face plate.

i. Never leave the Lathe work area with the power

on before the Lathe has come to a complete stop,

or without removing and storing the switch key.

j. Never operate the Lathe with protective cover on

the unused shaft end of the motor removed,

Hang your turning tools on the wall toward the tail-

stock end of the Lathe. Do not lay them on the bench

so that you must reach over the revolving workpiece

to select them,

Keep firm hold and control of the turning tool at all

times. Special caution must be exercised when knots

or voids are exposed to the turning tool.

Note the following DANGER label which appears on

the front of the belt _J_rd.

DANGER

FOR YOUR OWN SAFETY:

I REAO AND UNDERSTAND "_HE

OWNER'S ft'ANUAL BEFORE O_ER

ATING THIS MACHINE

2 %15AR FACE SHIELD AND OR SAF E

TY GOGGLES

3 DO NOT WEAR GLOVES NECK

TIES OR LOOSE CLOTHING

4 BE POSIT}VE ALL LOCKS ARE

TIGHT BEFORE OPERATING ,MAC

HINE

5 TURN WORKPIECE BY HAND BE

FORE APPLYING POWER TO DE

TERMINE IT CLEARS THE TOOL

REST OR OTNERMACHIN£ PARTS

6 ROUGH OUT FACEPLATE WORK

PIECES BEFORE INSTALLING ON

FACEPLATETOAVOIDEXCESSIVE

VIBRATION AND POSSIBLE IN

JURY

7 ALWAYSUSE LOWESTSPEEDWHEN

STARTING A NEW WORKPIECE,

FACEPLA_'E OR BETWEEN CEN

TERS. TO M_Ntt2_ZE POTENTIAL

INJURY

Think Safety

Complete hand sending of between-centers or face

plate mounted workpieces BEFORE removing from

the lathe, NEVER attempt to remount a face plate

turning to the face plate for any reason. NEVER

attempt to remount a between-centers turning if the

original centers in the turning have been a{tered or

removed, Be Positive the lathe is set at the lowest

speed if remounting a between-centers turning with

non-altered original centers.

12. Use extra caution in mounting a between-centers

turning to the faceplate or a faceplate turning to be-

tween-centers for subsequent operations. BE POSI-

TIVE the lathe is set at the lowest speed before turn-

ing ON.

13. NEVER attempt to turn on the facep!ate or be._,_een -

centers a workpiece which contains any cracks or

loose knots,

3

• • • •

addlhonai safety mstruchons for wood turning lathes

WARNING: DO NOT ALLOW FAMILIARITY

(GAINED FROM FREQUENT USE OF YOUR

MACHINE) TO BECOME COMMONPLACE.

ALWAYS REMEMBER THAT A CARELESS

FRACTION OF A SECOND IS SUFFICIENT TO

INFLICT SEVER INJURY.

WARNING: THE FOUR STEP LATHE AND

MOTOR PULLEYS FURNISHED ARE DE-

SIGNED TO RUN THE LATHE AT THE COR-

RECT SPEEDS WHEN USED WITH A 1725

R.P.M. MOTOR. DO NOT USE A 3450 R.P.M.

MOTOR TO INCREASE THE SPEED BECAUSE

IT COULD BE DANGEROUS.

gVEAR YOUR

The operation of anv power tool can result in foreign

objects being thrown into the eves, which can result in

severe eve damage. Always wear safety goggles complying

with ANSI Z87.1 (shown on Package) before commencing

power too_ operation. Safetv Goggles are available at Sears

retail or catalog stores,

4

This Lathe is designed to use a 1725 RPM motor only. Do

not use any motor that runs faster than 1725 RPM, It is

wired for operation on 110-120 volts, 60 Hz., alternating

current. IT MUST NOT BE CONVERTED TO OPERATE

ON 230 VOLTS. EVEN THOUGH SOME OF THE RE-

COMMENDED MOTORSARE DUAL VOLTAGE.

THESE MOTORS HAVE BEEN FOUND TO RE

ACCEPTABLE FOR USE ON THIS TOOL,

HP RPM VOLTS CATALOG NO.

1/3 1725 110-120 1250

1/2 1725 110-120 1254

1/2 1725 110-120 1255

CAUTION: Do not use blower or washing machine motors

or any motor with an automatic reset overload protector

as their use may be hazardous.

CONNECTING TO POWER SOURCE OUTLET

This machine must be grounded while in use to protect

the operator from electric shock.

Plug power cord into a 110-120V properly grounded type

outlet protected by a 15-amp. time delay or Circuit-Saver

fuse or circuit breaker.

If VOU are not usre that your outlet is properly grounded,

have it check by a qualified electrician.

WARNING: DO NOT PERMIT FINGERSTO TOUCH THE

TERMINALS OF PLUGS WHEN INSTALLING OR RE-

MOVING THE PLUG TO OR FROM THE OUTLET.

WARNING: IF NOT PROPERLY GROUNDED THIS

POWER TOOL CAN INCUR THE POTENTIAL HAZARD

OF ELECTRICAL SHOCK. PARTICULARLY WHEN USED

IN DAMP LOCATIONS IN PROXIMITY TO PLUMBING.

IF AN ELECTRICAL SHOCK OCCURS THERE IS THE

POTENTIAL OF A SECONDARY HAZARD SUCH AS

YOUR HANDS CONTACTING THE CUTTING TOOL.

If power cord is worn or cut, or damaged in any way, have

it replaced immediately.

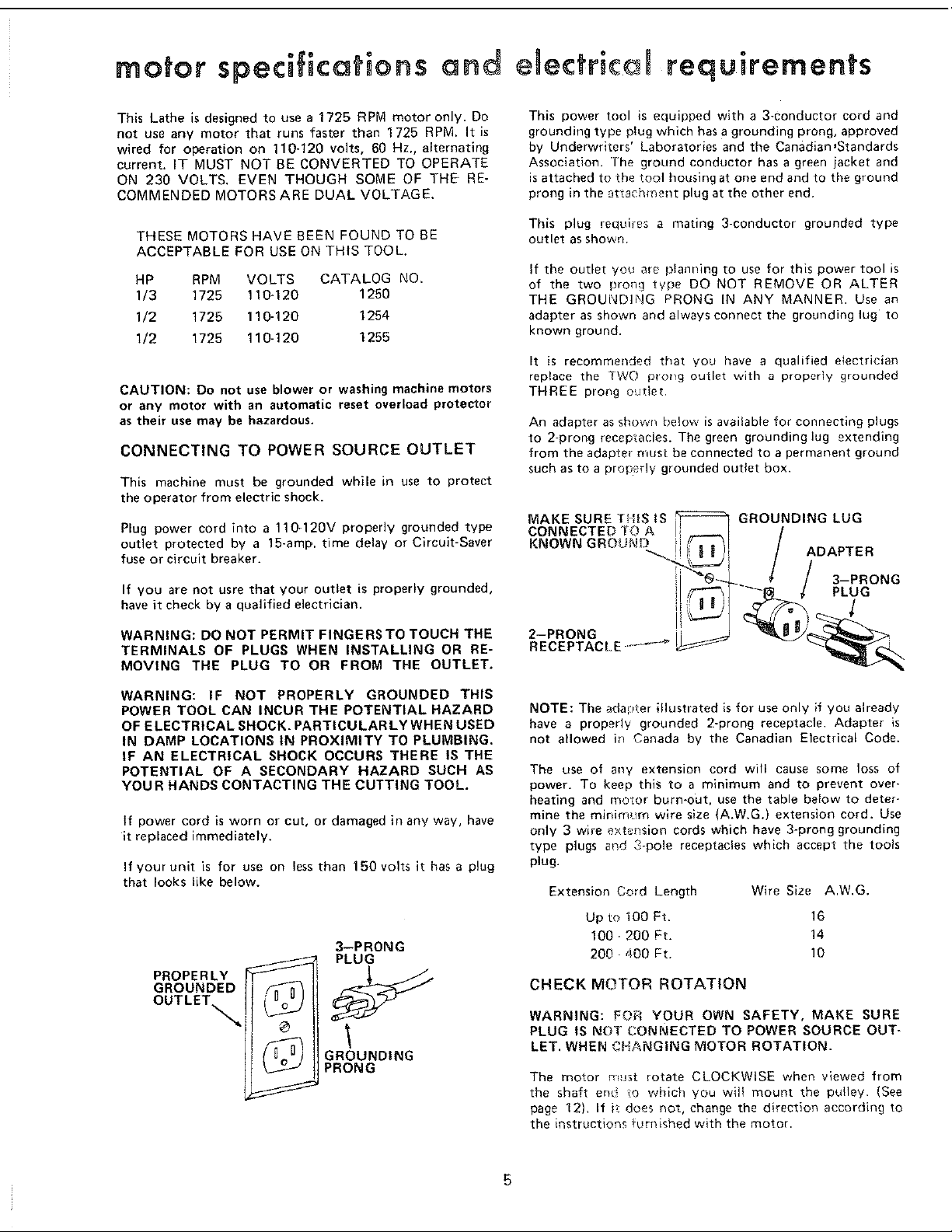

If your unit is for use on less than 150 volts it has a plug

that looks like below.

PROPERLY J

GROUNDED I

OUTLET.,,,,...!

/n ui

\ /

/_ UJ I

3--PRONG

PLUG

GROUNDING

PRONG

This power tool is equipped with a 3*conductor cord and

grounding type plug which has a grounding prong, approved

by Underwriters' Laboratories and the Canadian*Standards

Association. "Tile ground conductor has a green jacket and

is attached to the tool housing at one end and to the ground

prong in the _ttachment plug at the other end.

This plug requires a mating 3-conductor grounded type

outlet as shown.

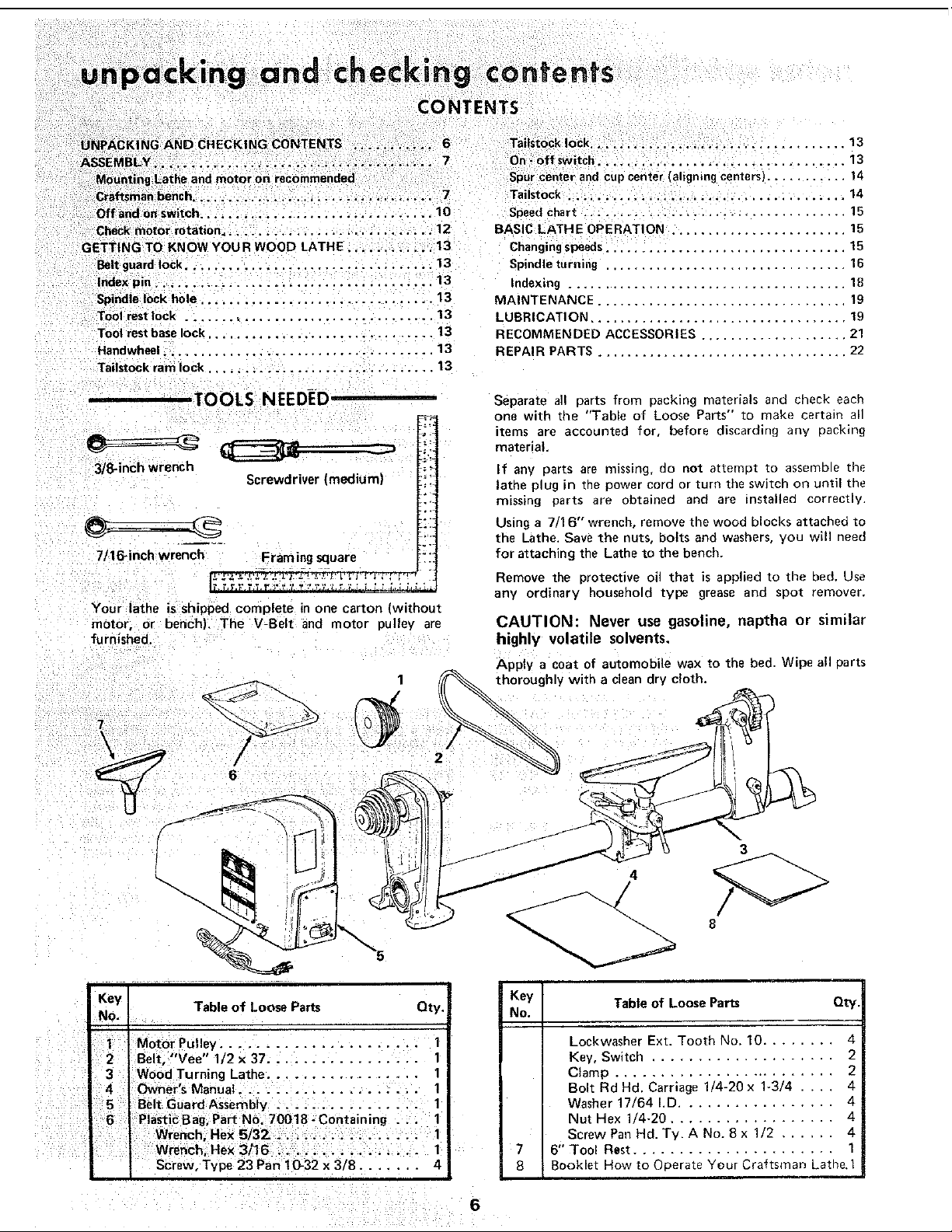

If the outlet you are planning to use for this power tool is

of the two prong b/pe DO NOT REMOVE OR ALTER

THE GROUNDING PRONG IN ANY MANNER. Use an

adapter as shown and always connect the grounding lug to

known ground.

It is recommended that you have a qualified electrician

replace the TWO ploI_g outlet with a proper!y grounded

THREE pro_g o,_iet,

An adapter as shown below is available for connecting plugs

to 2-prong receptacles. The green grounding lug extending

from the adapter must be connected to a permanent ground

such as to a properly grounded outlet box.

MAKE SURE "flits tS

CONNECTED TO A I

KNOWNGROlJ_!_ ii/',,

2-PRONG

RECEPTACLE .........."-_

GROUNDING LUG

ADAPTER

NOTE: The ada!._ter illustrated is for use only if you already

have a properly grounded 2-prong receptacle. Adapter is

not allowed ir_ Canada by the Canadian Electrical Code.

The use of any extension cord will cause some loss of

power. To keep this to a minimum and to prevent over-

heating and motor burn-out, use the table below to deter-

mine the minimum wire size (A.W.G,) extension cord. Use

only 3 wire extet/sion cords which have 3-prong grounding

type plugs aqd 3-pole receptacles which accept the tools

plug.

Extension Cord Length Wire Size A.W.G.

Upto 100 Ft. 16

100-200 Ft. 14

200-400 Ft, 10

CHECK MOTOR ROTATION

WARNING: FOR YOUR OWN SAFETY, MAKE SURE

PLUG IS NOT CONNECTED TO POWER SOURCE OUT-

LET. WHEN CHANGING MOTOR ROTATION.

The motor must rotate CLOCKWISE when viewed from

the shaft enC o which you wilt mount the pulley. (See

page 12}. If b does not, change the direction according to

the instructions furnished with the motor.

5

ontents

Check motor rotation ................ 12

GETTING TO KNOW YOUR WOOD LATHE ......... 13

Belt guard lock .................................. 13

Index pin ..................................... 13

Spindle lock hole ................ 13

Tool rest lock .." .................,., . ............ 13

Tool rest base lock ............................... 13

Handwheel ..................................... 13

Tailstock ram lock ............................... 13

TOOLS NEEDED ='-'=`-'=.'."'.".'-

3/8-inch wrench

Screwdriver (medium)

7/16-inch wrench Framing square

Your lethe is shipped complete in one carton [without

motor, or bench). The V-Belt and motor pulley are

"furnished.

................... 13

On - off switch .................................. 13

Spur center and cup center (aligning centers) ........... 14

Tailstock .................................... 14

Speed chart .................................... 15

BASIC LATHE OPERATIOIk ........................ 15

Changing speeds ................................. 15

Spindle turning ............................... 16

Indexing ...................................... 18

MAINTENANCE ................................. 19

LUBRICATIOI_ ................................... 19

RECOMMENDED ACCESSORIES .................... 21

REPAIR PARTS .................................. 22

Separate all parts from packing materials and check each

one with the "Table ol Loose Parts" to make certain all

_tems are accounted for, before discarding any packin£

material,

If any parts are missing, ao not attempt to assemDle th_

lathe plug in zne power cord or turn the switcn on until tn(

mtssing oarta are obtained and are nstalled correctly

Using a 7 16" wrench, remove the wood blocks attached to

the Lathe. Save the nuts. bolts and washers, you will need

for attaching the Lathe to the bench.

Remove the protective oil that is applied to the bed. Usa

any ordinary household type grease anc spot remover,

CAUTION: Never use gasoline, naptha or similar

highly volatile solvents,

Apply a coat of automobile wax to the bed. Wipe all parts

thoroughly with a clean dry cloth.

Key Table of Loose Parts Qty.

No.

Motor Pulley ...................... 1

Belt, 'Vee 1/2x37 ................. 1 !

3 Wood Turning Lathe ................. 1

4 1Owner a Manual ....................

5 Belt Guard Assembly ................ 1

6 PlasticBag, Part No. 70018-Containing ... 1

Wrench, Hex 5/32. ................ 1Wrench, He× 3/16 ................ 1

Screw, Type 23 Pan 10-32 x 3/8 ....... 4

3

Key Table of Loose Parts Qty,

No.

7

8

Lockwasher Ext. Tooth No. 10 ........ 4

Key, Switch .................... 2

Clamp ......................... 2

Bolt Rd Hd. Carriage 1/4-20 x 1-3/4 .... 4

Washer 17/64 LD ................. 4

Nut Hex 1/4-20 .................. 4

Screw Pan Hd. Ty. A No. 8 x 1/2 ...... 4

6" Tool Rest ...................... 1

Booklet How to Operate Yeur Craftsman Lathe, 1

6

assembly

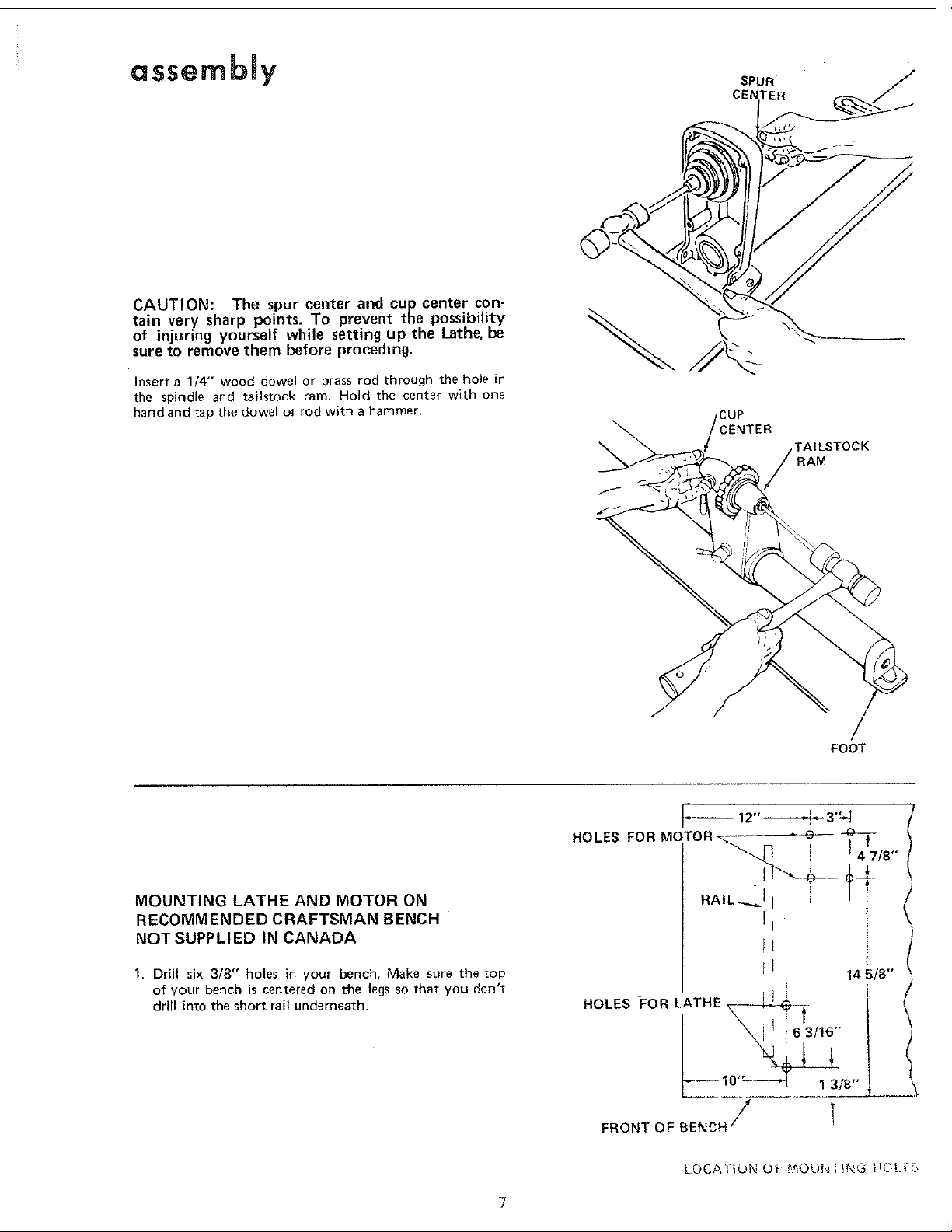

CAUTION: The spur center and cup center con-

tain very sharp points. To prevent the possibility

of injuring yourself while setting up the Lathe, be

sure to remove them before proceding.

Insert a 1/4" wood dowel or brass rod through the hole in

the spindle and tailstock ram. Hold the center with one

hand and tap the dowel or rod with a hammer.

,CUP

MTER

TAILSTOCK

FOOT

MOUNTING LATHE AND MOTOR ON

RECOMMENDED CRAFTSMAN BENCH

NOT SUPPLIED IN CANADA

1. Drill six 3/8" holes in your bench. Make sure the top

of vour bench is centered on the tegsso that you don't

drill into the short rail underneath,

J

14 5/8"

HOLES FOR LATHE\ ,I"_----_

\I , [6,3/16

t

LOCA'I'ION 0;* #_OUFFfU'_G HC_L_;.S

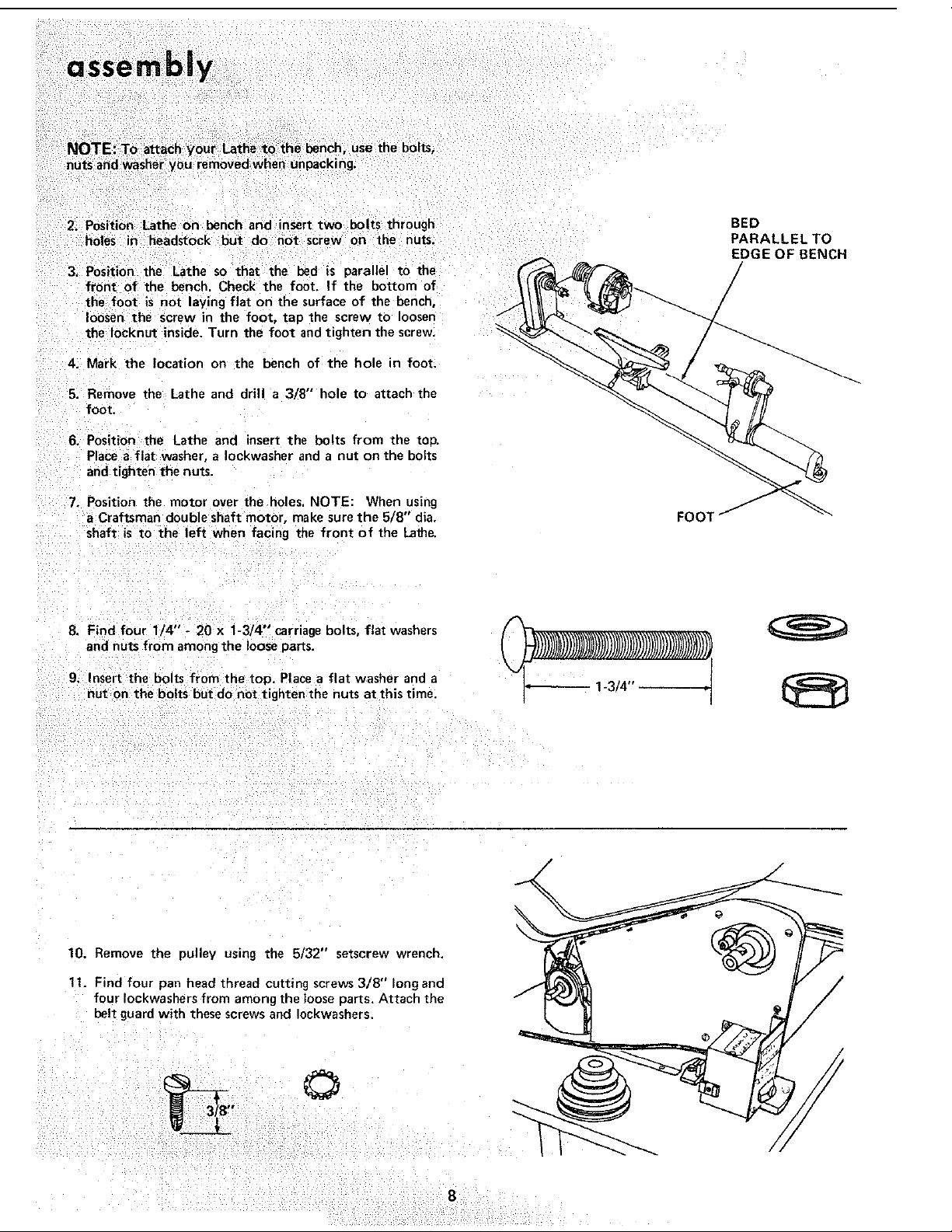

assembly

NOTE: To attach your Lathe to the bench, use the bolts,

nuts and washer you removed when unpacking.

2. Position Lathe on bench and nsert two bolts through

holes in headstock but do not screw on the nuts.

3. Position the Lathe so that the bed is parallel to the

front of the bench. Check the foot. If the bottom of

the foot is not laying flat on the surface of the bench,

loosen the screw in the foot, tap the screw to loosen

the Iocknut inside. Turn the foot and tighten the screw.

4. Mark the location on the bench of the hole in foot,

5. Remove the Lathe and drill a 3/8" hole to attach the

foot.

6. Position the Lathe and insert the bolts from the toP.

Placea flat washer, a Iockwasher and a nut on the bolts

and tighten the nuts.

7. Position the motor over the holes. NOTE: When using

a Craftsman double shaft motor, make sure the 5/8" dia.

shaft is to the left when facing the front of the Lath_

FOOl

BED

PARALLELTO

EDGE OF BENCH

/

8. Find four 1/4" - 20 x 1-3/4"' carriagebolts, flat washers

and nuts from amongthe loose pans.

9. Insert the bolts from the top. Place a flat washer and a

nut on the bolts but do not tighten the nuts at this time,

10. Remove the pulley using the 5/32" setscrew wrench.

11. Find four pan head thread cutting screws 3/8" long and

four Iockwashers from among the loose parts, Attach the

belt guard with these screws and Iockwashers.

©

B"

/

Loading...

Loading...