Page 1

f

:Save This Manual

For Future Reference

,SE,AR8

owner's

manuaR

NODEL NO.

113.225941

Belt and Disc Sander with

Motor and Legs

._.-- ......................... t

Serial

Number

Model and serial numbers may

be found on the right hand side

of the base.

You should record both model

and serial number in a safe

place for future use.

FOR YO

SAFETY

READ ALL

INSTRUCTIONS

CAREFULLY

LT AND DiSC

, assembly

- operating

• repair parts

J

Sears Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Part No. SP5582 Printed in U.S.A.

Page 2

f i FULLONE YEAR WARRAN ON CRAFTSMAN STATUONARY TOOL

B_ _!: if this stationa_:tool fails due to a_defect in material or workmanship within one year from the date

I!ii!iof pUrChase;:C()NTACT THE NEAREST SEARS SERVICE CENTER IN THE UNITED STATES and

I:_Sears will repair it free of charge.

Iill This Warranty applies only while this product is in the United States.

I_iil; If this sander!s used for commercial or rental purposes, this warranty will apply for ninety days

_ii: from the dateof purchase.

Iiii::This warranty gives you specific legal rights, and you may also have other rights which vary from

i!ii_ state to state.

Sears, Roebuck and Co., D/817 WA Hoffman Estates, IL. 60179

Safety instructions For Belt and Disc Sander ........

Safety is a combination of common sense, staying alert

andknowing how your belt and disc sander works. Read

this manual to understand this sander.

Safety Signal Words

DANGER: means ifthe safety information is not followed

someone will be seriously injured or killed.

WARNING: means if the safety intormation is not fol-

lowed someone could be seriously injured or killed.

CAUTION: means if the safety information is not followed

someone may be injured.

Before Using the Sander

mistakes could

serious, permanent injury, do not plug the sander

I WARNING: To avoid that cause

in until thefollowing steps are completed,

• Completely assemble sander. See "Assembly"section.

- Learn the use and:function of the ON-OFF switch. See

"Getting to Know:You r Sander"section.

• Review and understanding of all safety instructions

and operating procedures in this manual.

- Review of the maintenance methods for this sander.

See "Maintenance" section.

Read the following WARNING label found on the front of

the sander:

When Installing Or Moving the Sander

Avoid dangerous environment. Use the sander in a

dry, indoor place protected from rain. Keep work area

well lighted.

Place the sander so neither the user or bystanders are

forced to stand in line with the abrasive belt or disc.

To avoid burns or other tire damage, never use the

sander near flammable liquids, vapors or gasses.

To avoid injury or death from electrical shock:

• Ground the sander. This sander has an approved 3-

conductor cord and a 3-prong grounding type plug.

Use only 3-wire, grounded outlets rated 120 volts, 15

amperes (amps)_ The green conductor in the cord is

the grounding wire. To avoid electrocution, never con-

nect the green wire to a live terminal

Make sure your fingers do not touch the plug's metal

prongs when plugging or unplugging the sander,

Never use this or any power sander for wet sanding.

Doing so could cause electrocution, serious injury or

worse.

To avoid injury from unexpected sander movement:

• Always unplug the sander before moving it.

• Put the sander on a firm level surface where there is

plenty of room for handling and properly supporting the

workpiece.

• Support the sander so it does not rock.

• Bolt the sander to its work surface, Use the fasteners

and method shown in "Assembly" section.

• Never stand on tool. Serious injury could occur if the

tool tips. Do not store anything above or near the too!

where anyone might stand on the tool to reach it,

To Avoid Back Injury

• Get help or use recommended casters when you need

to move the sander

• Always get help if you need to liftthe sander.

•• •, i i¸.... i¸¸

Page 3

Before Each Use: i

Inspect your sander. Check for:

oalignment of moving parts,

_obinding of moving parts,

• broken or damaged parts,

• fixtures that cause a gap larger than 1/16" between

work support and sanding surface,

° sanding belt narrower than 4 inches. Narrower belts

uncover parts that could trap your fingers.

° worn or damaged electric cords,

• stable mounting

• any other condition that may affect the way the sander

works.

If any part is missing, bent, or broken in any way, or any

electrical parts don't work properly, turn the sander off

and unplug the sander. Replace damaged, missing, or

failed parts before using the sander again.

Disconnect the sander to avoid injury from accidental

starting. Pdrn the switch off, unplug the sander and

remove the switch key before changing the setup, sand-

ingdisc or belt or adjusting anything.

Maintain tools with care. Keep the sander clean for best

and safest performance, Follow instructions for lubricat-

ing.

Remove wrenches from tool before turning on.

To avoid injury from jams, slips or thrown pieces:

° Use only recommended accessories. Consult this

owner's manual for recommended accessories. The

use of improper accessories may cause injury, See

"Accessory" section..

° Adjust any work support to clear the sanding surface

by no more than 1/16 of an inch. When checking clear-

ance between the belt and work support, press the belt

flat against the metal beneath it.

• Make sure all clamps and locks are tight and no

parts have excessive play.

• Keep work area clean. Cluttered areas and benches

invite accidents. Floor must not be slippery.

Plan Ahead To Protect Your Eyes, Hands,

Face and Ears:

Know your sander. Read and understand the owner's

manual and labels affixed to the tool. Learn its application

and limitations as well as the specific potential hazards

peculiar to this tool.

To avoid injury from accidental contact with moving

parts:

° Keep guards in place and in working order.

• Don't do layout, assembly, or setup work on the sander

while any parts are moving.

Avoid accidental starting. Make sure switch is "OFF"

before plugging sander into a power outlet.

Dress for Safety:

° Wear nonslip footwear.

o

Tie back long hair.

°

Roll tong sleeves above the elbow.

o

Noise levels vary widely. To avoid possible hearing

damage, wear ear plugs or muffs when using sander

for hours at a time.

Sanding operations are usually dusty. Wear a dust

mask along with the safety goggles.

°

Do not wear loose clothing, gloves, neckties or jewelry

(rings, wrist watches). They can get caught and draw

into moving pads.

you

WEAR YOUR

• Wear safety goggles. Any power sander can throw

foreign objects into the eyes_ This can cause perma-

nent eye damage. Wear safety goggles (not glasses)

that comply with ANSI Z87.1 (shown on package).

Everyday eyeglasses have only impact resistant

lenses. They are not safety glasses. Safety goggles

are available at area stores. Glasses or goggles not in

compliance with ANSI Z87.1 could seriously hurt you

when they break.

Plan your work. Think through how you will hold and

maneuver the workpiece from start to finish.

Use the right tool. Don't force toot or attachment to do a

ob it was not designed to do.

CAUTION: This machine is not designed for heavy!

deburring operations. When finishing metals,

sparks or hot fragments could cause a fire. To

avoid this:

• Disconnect any dust collecting hose from the

sander.

• Remove all traces of wood dust from inside the

sander, i

• Remove all traces of metal dust from inside the

sander before sanding wood again, i

Inspect your workpiece. Make sure there are no nails

or foreign objects in the part of the workpiece to be

sanded.

Plan the way you will hold the workpiece from start to

finish. Avoid awkward operations and hand positions

where a sudden slip could cause finger or hand to move

into a sanding surface. Keep fingers away from where the

belt goes intothe dust trap.

Don't overreach. Keep good footing and balance.

Keep your face and body to one side. Stay out of tine

with a possible throwback.

I

Page 4

and Disc Sander (continued)

workpieces.

• Never use thistool to finish pieces too small to hold by hand.

• Use extra supports (tables, saw horses, blocks, etc.)

for any workpieces large enough to tip when not held

down to the table top.

=Never use another person as a substitute for a table

extension, or as additionalsupport for a workpiece that

is longer or wider that the basic sander table, or to help

feed, support orpuU the workpiece.

• When finishing on the disc, always press the workpiece

against the "Down" side of the disc. Sanding against the

side coming up from under the table could damage the

work by making it "chatter", or tear the work from your

hands and throw it,

• Sand 0nly one workpiece at a time.

° Clear everything except the workpiece and related sup-

port devices off thetable before turning the sander on.

wARNING: Don't let familiarity (gained from fre- I

quent use of your belt and disc sander) cause a

careless mistake. A careless fraction of asecond is

enough to cause a severe injury.

sander and workpiece.

Don't force tool. It will do the job better and safer at its

designed rate. Press the workpiece against the sanding

material only hard enough to let it sand without bogging

down or binding.

Before freeing any jammed material:

° Turn switch "OFF"

• Wait for all moving parts to stop.

° Unplug the sander.

Before Leaving the Sander:

Turn power off. Don't leave tool until it comes to a com-

plete stop.

Never leave tool running unattended,

Make workshop child-proof. Disconnect master

switches Remove the yellow switch key. Store it away

from children and others not qualified to use the tool.

Lock the shop.

I

Precautions to Take When Sanding Metals ......

When finishing metals, sparks or hot fragments Could 2. Remove all traces of wood dust from inside the sander

cause a fire, To avoid this: beforesanding metals.

1_Disconnect any dustCollecting hose from the sander, 3. Remove all traces of metal dust from inside the sander

before sanding wood again.

Precautions to Take When Sanding Paint

Sanding of lead based paint is not recommended. It is

very difficult to control the contaminated dust that could

cause lead poisoning.

It is also difficult to identify if paint contains lead. There-

fore, we recommend the following precautions when

sanding all paints:

1. Protect your lungs. Always wear a dust mask or respi-

rator at all times. Wear only dust masks that are suit-

able for working in lead paint sanding environments.

Ordinary painting masks do not offer this protection.

2. Do not allow children or pregnant women to enter the work

area Untlpaint_ sanding job is finished and al! clean up

ii 3::To particles_ Do

" not eat; drink; or :smoke in w6rk area where paint is

4_

5. Thoroughly clean the work area upon completion of

4

being sanded. After sanding paint, wash and clean up

before eating, drinking or smoking. Do not leave food,

drinks, or tobacco products in the work area where

dust can settle on them.

Protect the environment when sanding paint. Use a

dust collection system if possible. Seal the work area

with plastic if necessary. Do not track paint dust out-

side the work area.

paint sanding project. If project lasts for an extended

amount of time, clean work area often. Items such a_

sanding dust, vacuum filter bags, plastic drop cloths, etc

should be placed in a sealed container and disposed o'

properly. Clean all items exposed to sanding dust.

Page 5

Motor Specifications and Electrical Requirements

This machine is designed to use, and is equipped with, a

3450 RPM motor. It iswired for operation on 120 volts, 60

!Hz, alternating current.

t WARNBNG: To avoid electrocution or fire, tool must

not be converted to operate on 240 volts.

For replacement motor, refer to parts list in this manual.

Connecting to Power Supply Outlet

This machine must be grounded while in use to protect

the operator from electric shock.

In the event of a malfunction or breakdown, grounding

provides a path of least resistance for electric current to

reduce the risk of electric shock.

Plug power cord into a properly grounded 120V outlet

_rotected by a 15 amp fuse or circuit breaker.

WARNING: To avoid electrocution: Do not let fin-

gers touch the terminams of plugs when installing

jorremoving the plug to or from the outlet.

WARNING: tf not properly grounded, this power

tool can cause an electrical shock, particularly

when used in damp locations close to plumbing, ff

an electrical shock occurs there is the potential of

a secondary hazard, such as your hands contact-

ing the sanding surface.

WARNING: To avoid electrocution or fire, if power

cord is torn or cut, or damaged in any way, have it

replaced immediately.

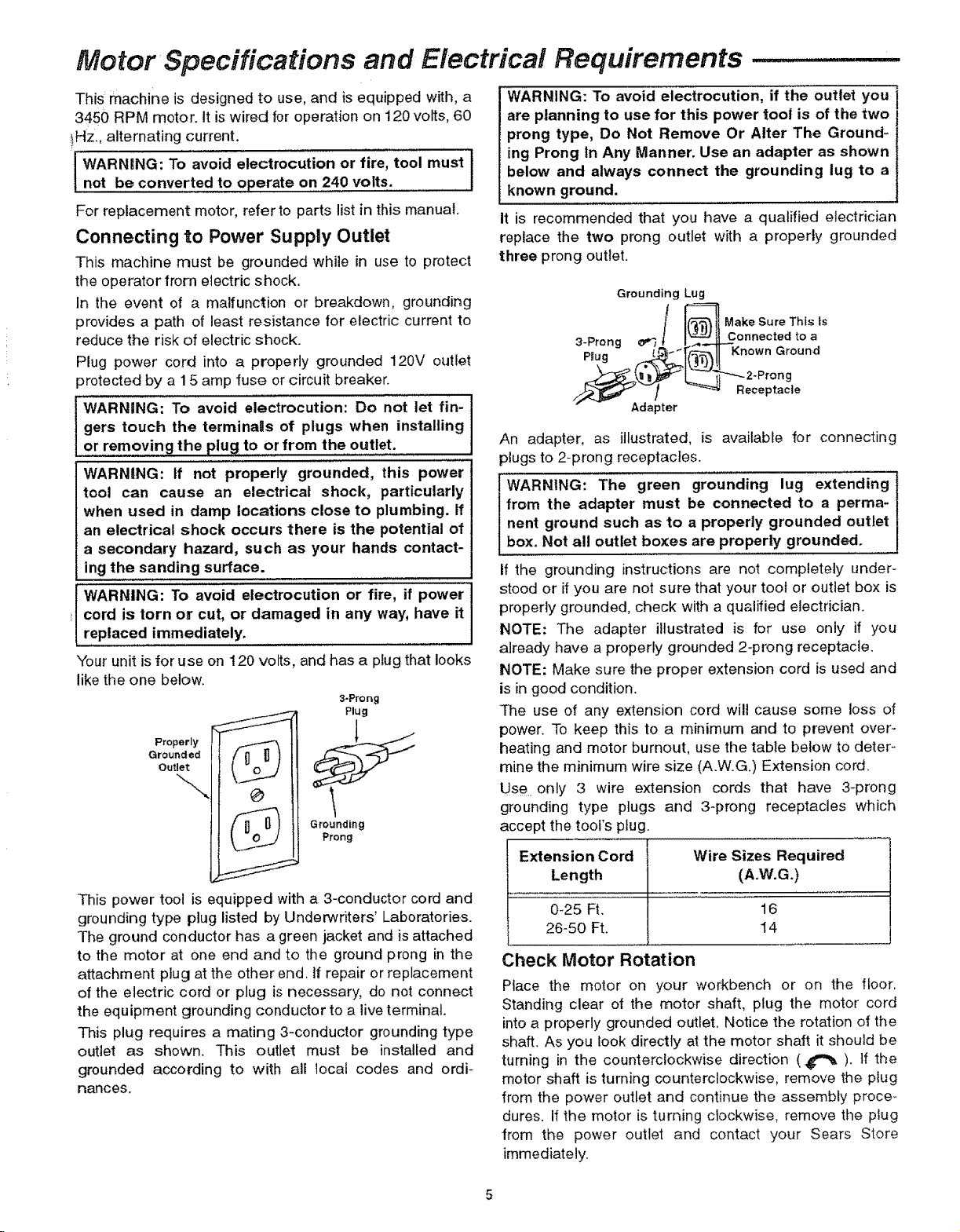

'four unit is for use on 120 volts, and has a plug that looks

like the one below.

3-Prong

Plug

WARNING: To avoid electrocution, if the outlet you

are planning to use for this power tool is of the two

prong type, Do Not Remove Or Alter The Ground-

ing Prong In Any Manner. Use an adapter as shown

below and always connect the grounding lug to a

known ground.

It is recommended that you have a qualified electrician

replace the two prong outlet with a properly grounded

three prong outlet.

Grounding Lug

/ _MakeSureThisls

3-Prong _ t_ I'-_-_11t Connected to a

Adapter

An adapter, as illustrated, is available for connecting

plugs to 2-prong receptacles.

WARNING: The green grounding lug extending

from the adapter must be connected to a perma-

nent ground such as to a properly grounded outlet

box, Not all outlet boxes are properly grounded.

If the grounding instructions are not completely under-

stood or if you are not sure that your toot or outlet box is

properly grounded, check with a qualified electrician.

NOTE: The adapter illustrated is for use only if you

already have aproperly grounded 2-prong receptacle.

NOTE: Make sure the proper extension cord is used and

is in good condition.

The use of any extension cord will cause some loss of

power. To keep this to a minimum and to prevent over-

heating and motor burnout, use the table below to deter-

mine the minimum wire size (A.W.G.) Extension cord.

Use only :3 wire extension cords that have 3-prong

grounding type plugs and a-prong receptacles which

accept the tool's plug.

This power too! is equipped with a a-conductor cord and

grounding type plug listed by Underwriters' Laboratories.

The ground conductor has a green jacket and is attached

to the motor at one end and to the ground prong in the

attachment plug at the other end. If repair or replacement

of the electric cord or plug is necessary, do not connect

the equipment grounding conductor to a live terminal,

This plug requires a mating 3-conductor grounding type

outlet as shown. This outlet must be installed and

grounded according to with all local codes and ordi-

nances,

Extensio n Cord

Length

0-25 Ft.

26-50 Ft.

Wire Sizes Required

(A.W.G.)

16

14

Check Motor Rotation

Place the motor on your workbench or on the floor.

Standing clear of the motor shaft, plug the motor cord

into a properly grounded outlet. Notice the rotation of the

shaft. As you look directly at the motor shaft it should be

turning in the counterclockwise direction (_'_). tf the

motor shaft is turning counterclockwise, remove the plug

from the power outlet and continue the assembly proce_

dures. Ifthe motor is turning clockwise, remove the ptug

from the power outlet and contact your Sears Store

immediately.

Page 6

: .......... ::i:i:/i ¸¸ :: : ;: i :/::::i:i,i_ jl _: ! : i,:i_i::::i :: :? : :, : • • •: • -•

i_:..... -::i_i_i.i.ii installing the Abrasive Belt-. ...................................... 4

Tensioning and Tracking.: .......................................... 14

._:!:i__:_:_:_.i;_::__,,:.::.:.. 2: Installing Belt Dust Trap ............................................ 15

i':':i:iiii:::i:::i!i:_'!:::,". :: Installing Backstop:.. .....:........................................... 16

i !:: Hands, ....

Getting to Know Your Belt and Disc Sander ................. 16

Safety: Instructions for Belt and Disc Sander ................ 19

Before Using the Sander: .......................................... 19

i:: 3: : When 'Installing OrMoving the Sander: .................... 19

: : :: BeforeEach Use:......................................................19

: Whenever Sander:iisRUnning :_i_i':i'=_i':::_i:'':i_:i_:_::'_''''--:--'4 Plan Ahead to Protect Your Eyes, Hands,

: i Face and Ears: ....................................................... 19

Precauti0ns t0 Take When Sanding Metais;,. i.i ..,.i .i.... i._4 Basic Sander Operation ............................................... 20

Precauti0nsto Take:when Sanding Whenever Sander is Running: .................................. 20

Motor Specifications and Electrical Requirements ......... 5

Connecting to Power Supply Outlet. ............................ 5

Table of Contents .............. i.i.._.,i..................................... 6

Unpacking and Checking Contents ............................. 6

ToolsNeeded ....::.........._.............................:_...............6

Loose Parts...:.......ii....................................................6

U npacking ...................................................................6

TableofLoose Parts.......................................................7

Assembly........................................................................7

AssemblingSteelLegs ................................................8

When InstallingOr Moving the Sander........................8

MountingBeltAnd DiscSander On Legset.................9

InstallingV-Beltand Switch.........................................9

InstallingSanding Disc and Dust Trap....,..................10

InStallingMotor,V-Beltand BeltGuard .....................11

On-OFF Switch................i.........................................12

Before Leaving the Sander: ...................................... 20

Precautions to Take When Sanding Metals .................. 20

Precautions to Take When Sanding Paint .................... 20

Surface Finishing on the Abrasive Belt ..................... 21

End Finishing on the Abrasive Belt ........................... 21

Finishing Curved Edges on the Abrasive Belt ........... 21

Finishing Small End Surfaces and Curved Edges

on the Abrasive Disc ............................................. 22

Maintenance ................................................................. 22

Motor Maintenance and Lubrication .......................... 22

Lubrication................................................................22

Recommended Accessories.........................................23

Troubleshooting............................................................23

RepairParts.................................................................25

MotorConnections.......................................................30

InstallingWork Table.................................................14

Unpacking and Checking Contents

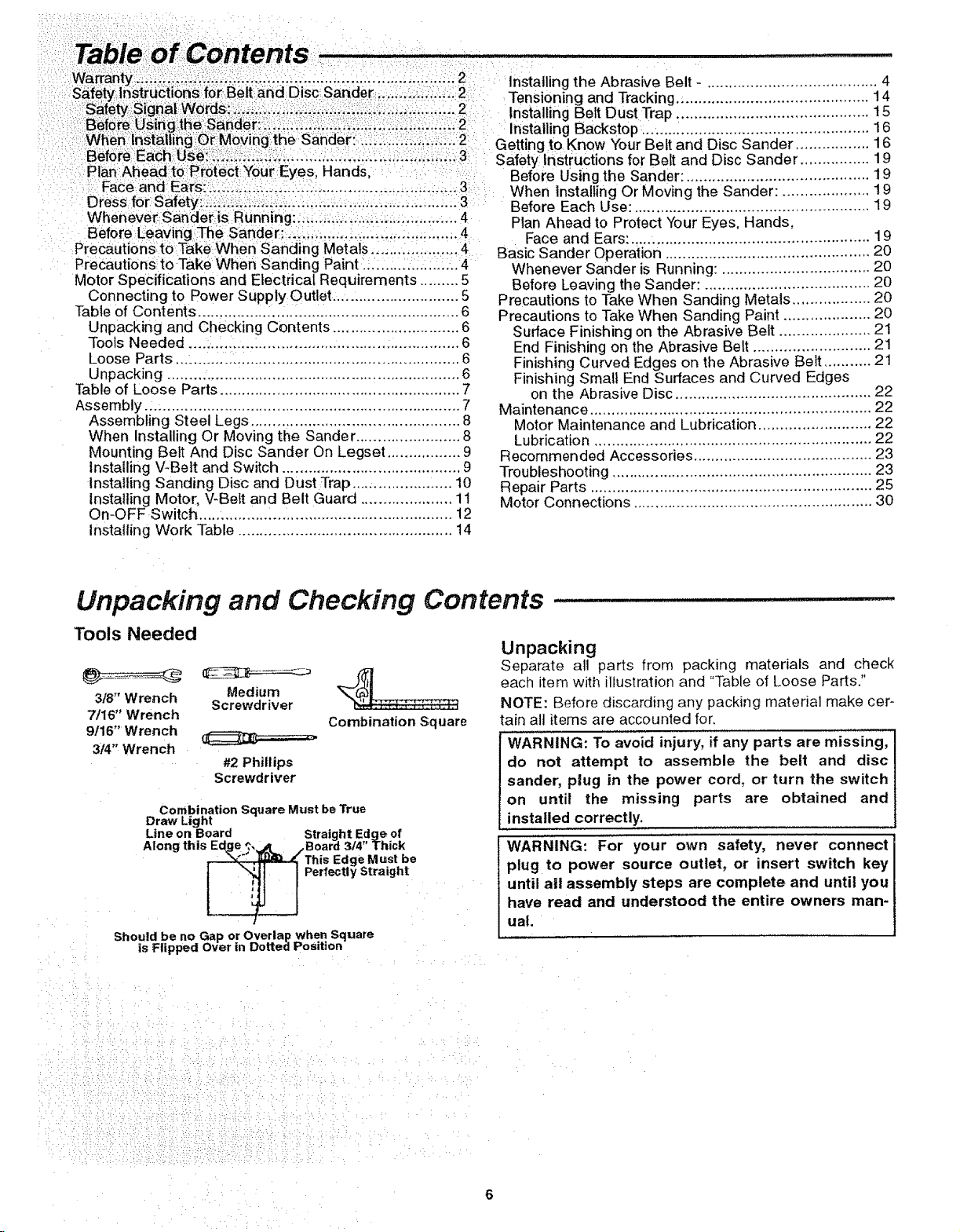

Tools Needed

Unpacking

Separate all parts from packing materials and check

318" Wrench

7116" Wrench

9116" Wrench

3/4" Wrench

Combination Square Must be True

Draw Light

Line on Board Straight Edge of

Along this_ _/Board 314" Thick

Should be no Gap or Overlap when Square

is Flipped Over in Dotted Position

Medium

Screwdriver

#2 Phillips

Screwdriver

"" _I_L_ This Edge Must be

Combination Square

Perfectly Straight

each item with illustration and "Table of Loose Parts."

NOTE: Before discarding any packing material make cer-

tain all items are accounted for.

WARNING: To avoid injury, if any parts are missing,

do not attempt to assemble the belt and disc

sander, plug in the power cord, or turn the switch

on until the missing parts are obtained and

installed correctly,

WARNING: For your own safety, never connect

plug to power source outlet, or insert switch key

until all assembly steps are complete and until you

have read and understood the entire owners man-

ual.

Page 7

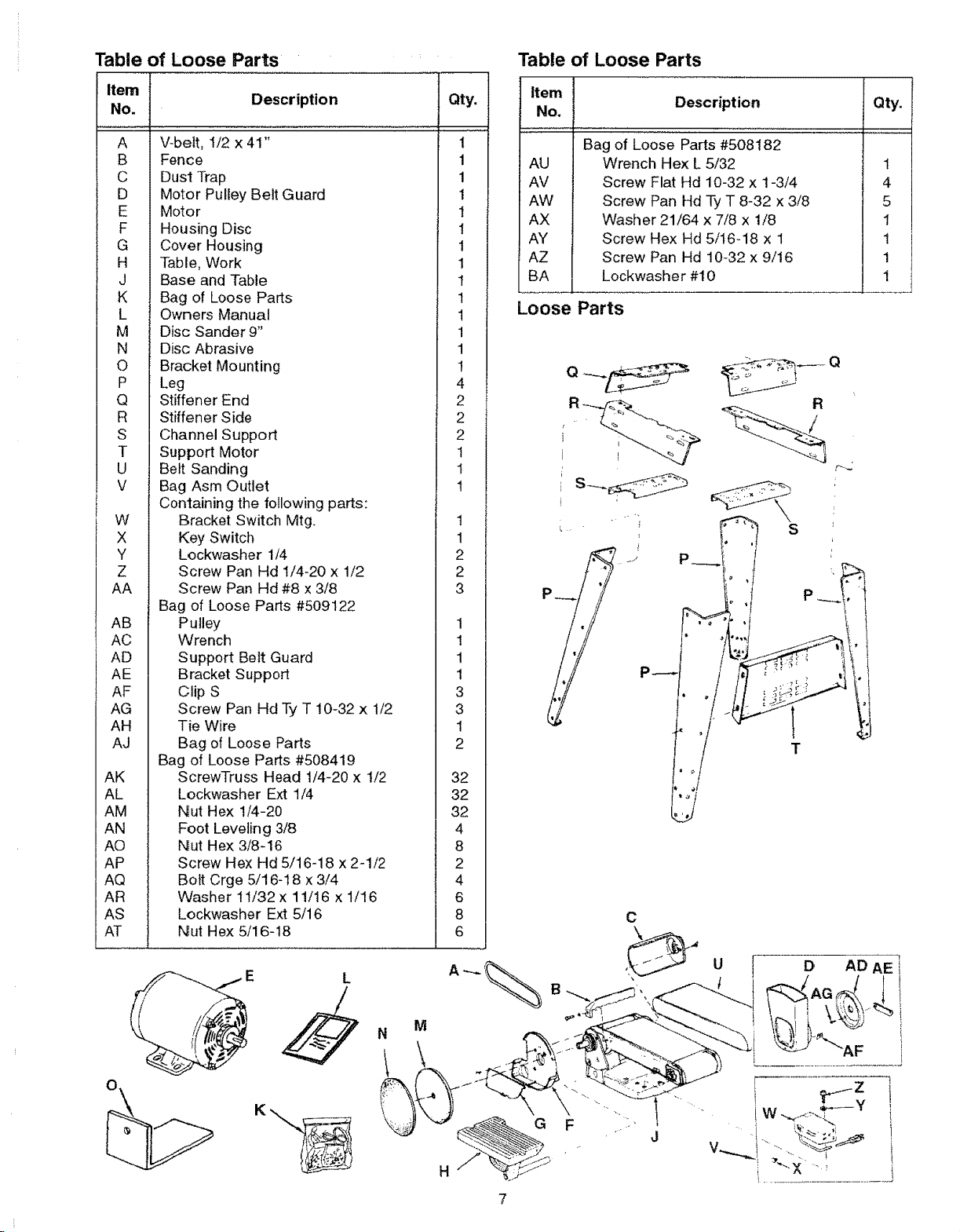

Table of Loose Parts

Table of Loose Parts

Item

No. Description Qty.

A V-belt, 1/2 x 41" 1

B Fence 1

C Dust Trap 1

D Motor Pulley Belt Guard 1

E Motor 1

F Housing Disc 1

G Cover Housing 1

H Table, Work 1

J Base and Table 1

K Bag of Loose Parts 1

L Owners Manual 1

M Disc Sander 9" 1

N Disc Abrasive 1

O Bracket Mounting 1

P Leg 4

Q Stiffener End 2

R Stiffener Side 2

S Channel Support 2

T Support Motor 1

U Bett Sanding 1

V Bag Asm Outlet 1

Containing the following parts:

W Bracket Switch Mtg. 1

X Key Switch 1

Y Lockwasher 1/4 2

Z Screw Pan Hd 1/4-20 x 1/2 2

AA Screw Pan Hd #8 x 3/8 3

Bag of Loose Parts #509122

AB Pulley 1

AC Wrench 1

AD Support Belt Guard 1

AE Bracket Support 1

AF Clip S 3

AG Screw Pan Hd Ty T 10-32 x 1/2 3

AH Tie Wire 1

AJ Bag of Loose Parts 2

Bag of Loose Parts #508419

AK ScrewTruss Head 1/4-20 x 1/2 32

AL Lockwasher Ext 1/4 32

AM Nut Hex 1/4-20 32

AN Foot Leveling 3/8 4

AO Nut Hex 3/8-16 8

AP Screw Hex Hd 5/16-18 x 2-1/2 2

AQ Bolt Crge 5/16-18 x 3/4 4

AR Washer 11/32 x 1!/16 x t/16 6

AS Lockwasher Ext 5/16 8

AT Nut Hex 5/16-18 G

item

No, Description Qty.

Bag of L0ose Parts #508182

AU

AV

AW

AX

AY

AZ

BA

Wrench Hex L 5/32

Screw Flat Hd 10-32 x 1-3/4

Screw Pan Hd Ty T 8-32 x 3/8

Washer 21/64 x 7/8 x 1/8

Screw Hex Hd 5/t6-18 x 1

Screw Pan Hd 10-32 x 9/16

Lockwasher #10

Loose Parts

R

T

:/

C

1

4

5

1

1

1

1

L

J

H

D AD AE i

Page 8

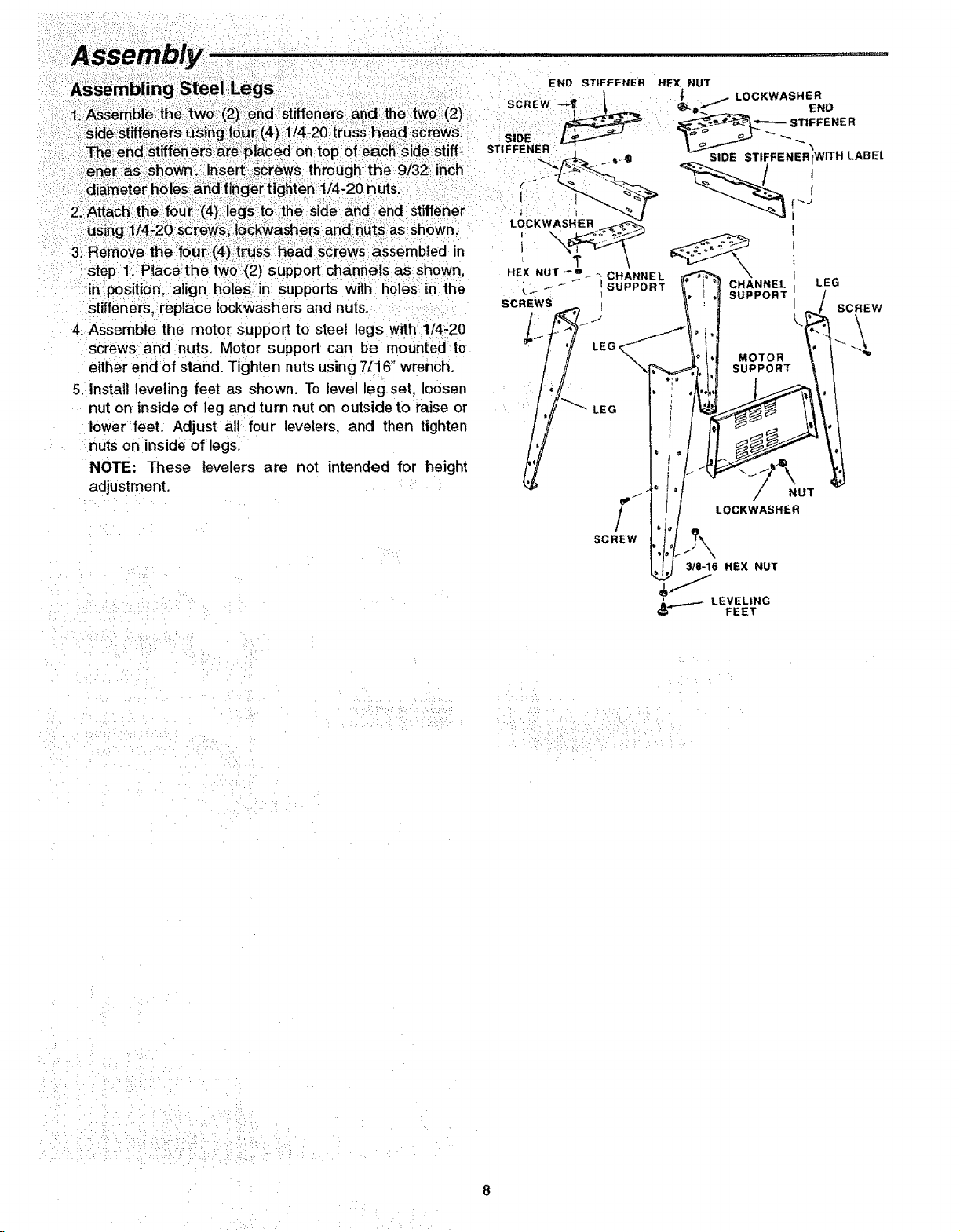

AsSembly. i.

As_mbiing Steei Legs _i

:::_sid_ ;'stiffenersu_i_g |_iUr (4)1!/4 _20ti'uss head screwsl

9/32: i_:ch

::::diamete_iholesaSdfingertight_n 1/4-20 nutsl : :i::::::::

i:using:iL4 2o

3::Renlove the faUr,:::(_ii_:truss:head screws assembled in

step 1: Place the two (2) support channels as:shown,

in position, align h01es in Supports with holes _n the

stiffeners, replace loci(washers and nuts.

4.Assembte the motor support to steel legs with 1/4-20

screws and nuts. Motor support can be mounted to

either end of stand. Tighten nuts using 7/16" wrench.

5. Install leveling feet as shown. To level leg set, loosen

nut on inside of leg and turn nut on outside to raise or

lower feet. Adjust all four levelers, and then tighten

nuts on inside of legs.

NOTE: These levelers are not intended for height

adjustment.

Page 9

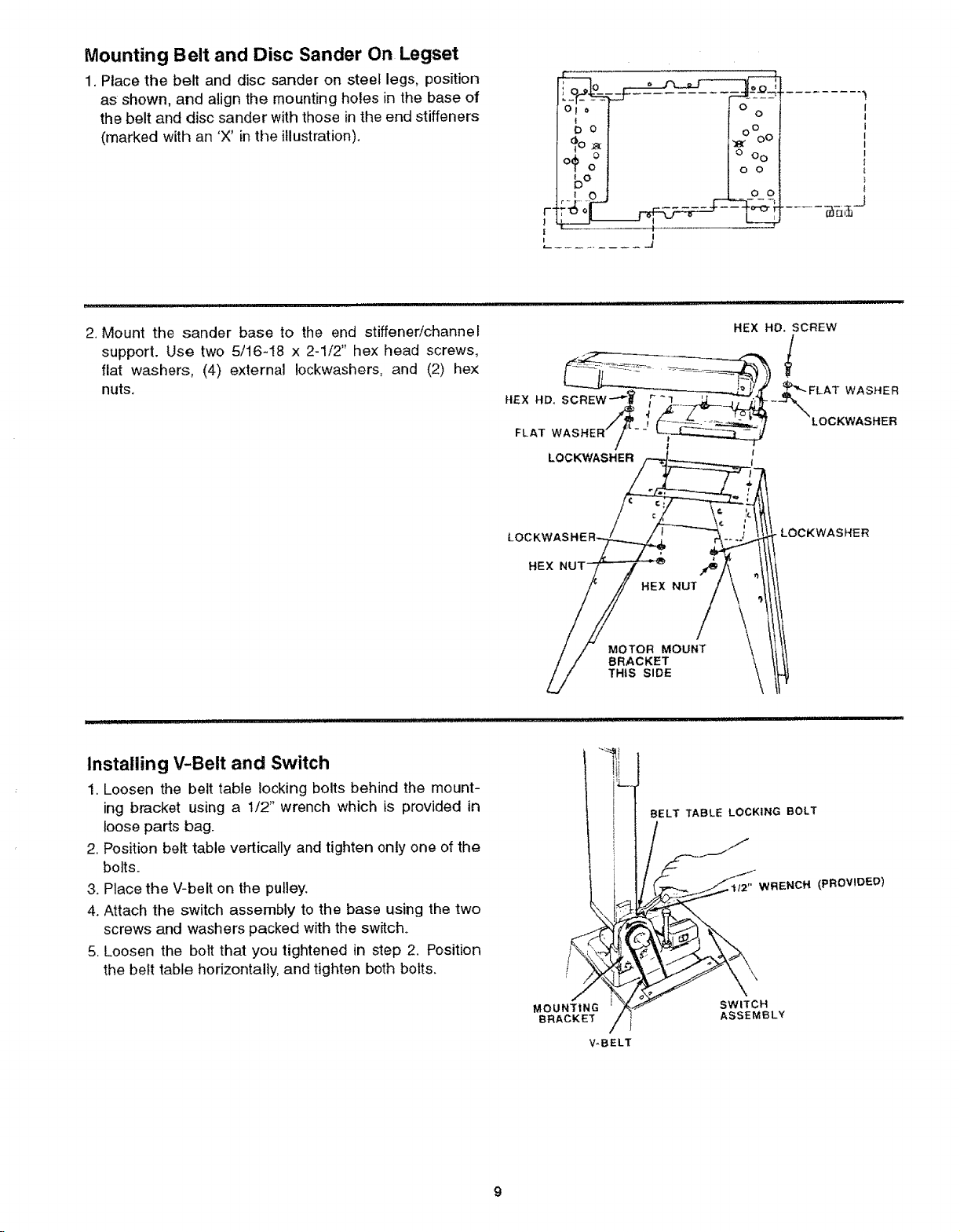

Mounting Belt and Disc Sander On Legset

1. Place the belt and disc sander on steef legs, position

as shown, and align the mounting holes in the base of

the belt and disc sander with those in the end stiffeners

(marked with an 'X' in the illustration).

b°

|

i !

O O

go

..... _7i_ -1

I

!

i

I

I

I

I

t

2. Mount the sander base to the end stiffener/channel

support. Use two 5/16-18 x 2-1/2" hex head screws,

flat washers, (4) external Iockwashers, and (2) hex

nuts,

Installing V-Belt and Switch

1. Loosen the belt table locking bolts behind the mount-

ing bracket using a 1/2" wrench which is provided in

loose parts bag.

2. Position belt table vertically and tighten only one of the

bolts.

3. Place the V-belt on the pulley.

4. Attach the switch assembly to the base using the two

screws and washers packed with the switch.

5, Loosen the bolt that you tightened in step 2. Position

the belt table horizontally, and tighten both bolts.

HEX HD

HEX

LOCKWASHER

I

HEX NUT

MOTOR MOUNT

BRACKET

THIS SIDE

BELT TABLE LOCKING BOLT

HEX HD. SCREW

• LOCKWASHER

WRENCH (.PROVIDED)

9

MOUNTtNG '

BRACKET i

V-BELT

SWITCH

ASSEMBLY

Page 10

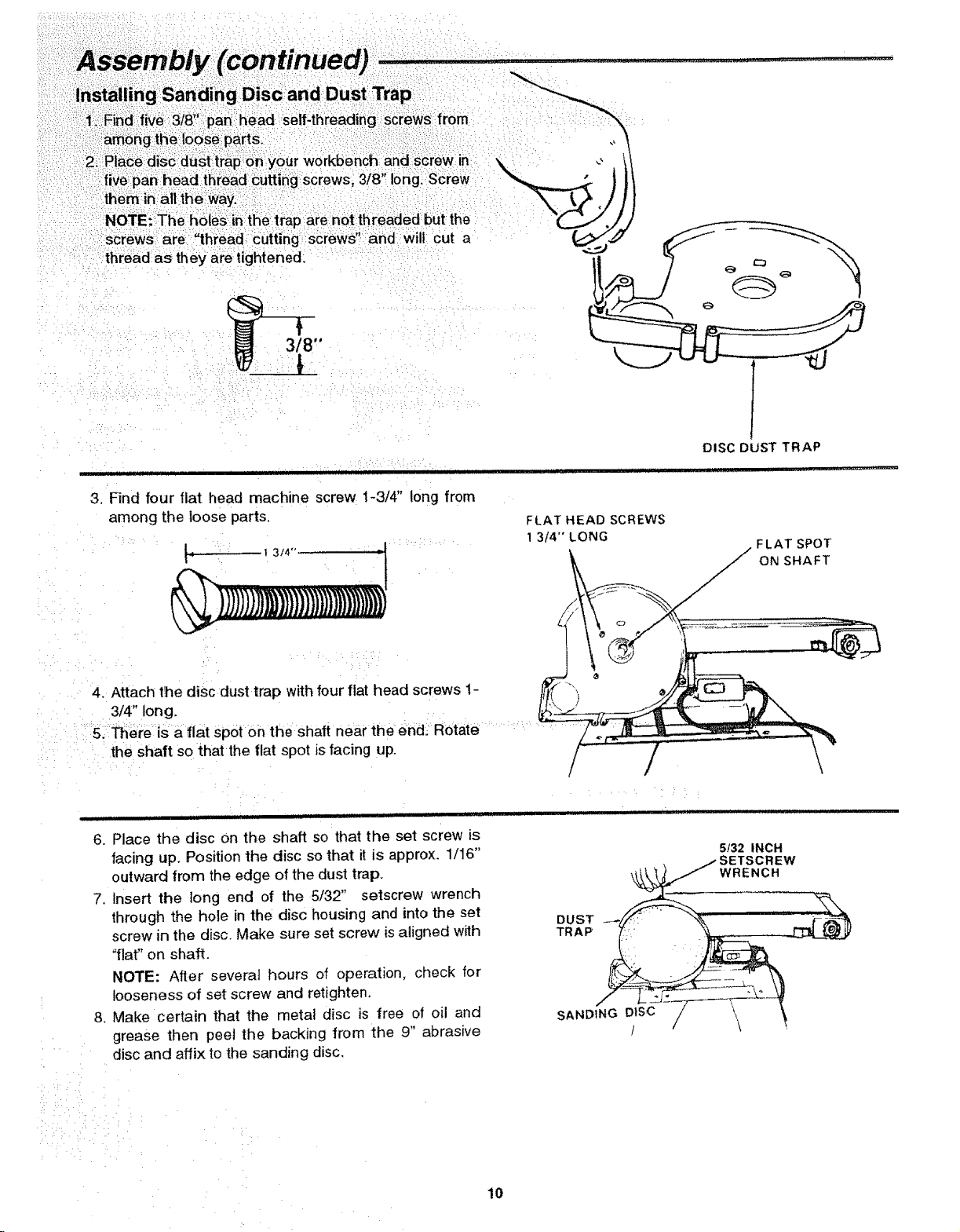

3. Find four flat head machine screw 1-3/4" long from

among the loose parts.

I_ 1 3t4

4. Attach t_hedisc dust trap withfour flat head screws 1-

3/4" long.

5. There is a flat spot on the shaft near the end_ Rotate

the shaft so that the flat spot is facing up.

DISC DUST TRAP

_j ii ii

FLAT HEAD SCREWS

1 3t4" LONG

_:_ i _, '_ • "

i 11 i _l,,i

6. Place the disc on the shaft so that the set screw is

facing up. Position the disc so that it is approx. 1/t6"

outward from the edge of the dust trap.

7. Insert the long end of the 5/32" setscrew wrench

through the hole in the disc housing and into the set

screw in the disc. Make sure set screw isaligned with

"flat" on shaft.

NOTE: After several hours of operation, check for

looseness of set screw and retighten,

8. Make certain that the metal disc is free of oil and

grease then peet the backing from the 9" abrasive

disc and affix to the sanding disc,

10

=_ •

DUST

TRAP

SANDING DISC

/

• . _ = _ _

5132 INCH

WRENCH

Page 11

9.Removethetopleft handscrewthatyouinstalledin

step6andloosentheotherfourscrews.

10.Installthedusttrap coverandreplacethetop left-

handscrew.Tightenallfivescrews.

TOP RIGHT HAND SCREW

DUST TRAP COVER

Installing Motor, V-Belt and Belt Guard

1. Locate the following parts:

Qty. Description

1 Motor

1 "L" Bracket

1 Pulley (approx. 2" dia.)

t V-Belt

4 Carriage bolt, 5/16-18 x 3/4

4 Flat Washer, 5/16 I.D.

4 Lockwasher, 5/16 I.D.

4 Hex Nut, 5/16-18

1 Guard Assembly including

Guard Support

Guard Support Bracket

Self-threading Screws

Clips

2. P]ace motor against the motor mounting bracket and

insert bolts through holes in motor base and then

through holes marked "X" in motor mounting bracket.

Do not tighten bolts at this time, The "L" bracket,

which holds the guard support, must be slid between

the motor base and the motor mounting bracket. The

motor must be loosely assembled to the bracket at

this time.

LOCKWASHER

FLAT WASHER

MOTOR MOUNTING

BRACKET

CARRIAGE BOLT

5f16.18 X 3/4

MOTOR

3. Slide long leg of "L" bracket between motor base and

motor mounting bracket. Then sandwich the "L"

bracket between the guard support bracket and the

guard support and fasten together with self-threading

screws as shown.

4. Install the 2" pulley onto the motor shaft flush with the

end of the shaft and tighten the set screw in the pul-

ley hub with a 5/32" hex "L" wrench. Tighten against

the flat part of the motor shaft.

11

TWO HOLES CLOSES

SET SCREW

\

g

SCREW

I SELF-THREADING

2"PULLEY 1

TOGETHER

MOTOR t

BASE

"'L'"

BELT GUARD

SUPPORT

BELT GUAHD _\

MOTOR MOUNTING

BRACKET

Page 12

Assembly (continued) .... .- .-..

5_ Place V_beltover machine pulley and insert the V-belt

into the _open end of the guard and out the round

.::::opening:i_:

Make_sUr@:belt has not slipped off machine pul!ey from

step 3. ?Disc and: Dust Trap Installation".

6: L0cate and instatlthree clips on the guard as shown.

7. Place the belt onto the motor pulley by rotating the

pu!tey.

8_ Move the motor sideways so that the belt is in the

center of the opening in the top of the base. Visualty

tine up the pulleys and V-belt

9. Wedge "L" bracket under upper leg of motor base

(approximately 1/8_'):while positioning guard support

bracket around the shaft.

10. Push downward on motor to apply tension to belt and

tighten motor bolt nuts.

11 Check guard support before tightening guard support

screws. Guard support must be centered on motor

shaft. Tighten screws

12. Push guard intoposition on guard support.

GUARD

BELT

\

BELT MUST BEON

MACHINE PULLEY

/

/

I

t

LL ' L_ I I I

On-OFF Switch

WARNING: Don't connect power cord to electrical

outlet in your shop until you are sure motor rota-

tion is correct. See "Check Motor Rotation" sec-

tion.

The On-Off switch has a locking feature. This feature is

intended to prevent unauthorized and possible hazard-

ous use by children and others.

1. Insert key into switch. _-_

NOTE: Key is made of yellow plastic.

i¸ : i <: :

••• 12

KEY

Page 13

2. To turn machine on, insert finger under switch lever

and pull end of switch out.

3. To turn machine OFE_PUSH lever in.

Never leave the machine unattended until it has

come to complete step.

............... i

,u,,,,,,,,,, _ ,i i lll_ i,,Ni i i ,i,l,,!,l

4. To lock switch in OFF position.,,hold switch in with

one hand...Remove key with other hand.

WARr, ilNG: For your own safety, always lock the

switch, "OFF" when machine is not in use, remove

key and keep it in a safe place, also in the event of

a power failure (all of your lights go out) turn

switch off, lock it and remove the key. This will pre-

vent the machine from starting up again when the

power comes back on,

5, Find plastic wire tie from among loose parts,

iiiiiiiiiI ! i ii I ll!!!l llqlW I llllplll!l_l pi 11111 II[L,IIIIIIIIIIIIIIIII

6. Route the motor cord through the leg set and plug it

into the receptacle inthe side of the switch box.

7. Bring the power cord under the switch box and attach

to leg set with wire tie as shown.

8. Attach wire tie to power cord and motor cord as

shown.

,, ii,!ll,,ll_l ,i ,ll,i , , m i !ll J,

PULL

i i, i ! iiiiiiiii

, iiiii,iiiiii ii lUll I I'I II

POWER

MOTOR

CORD

13

MOTOR CORD

1

Page 14

ASSembly (continued)

Installing WorkTable

NoTE_:Appiyl aCoatof paste iwax to:the work table: This

wiii:make _iia :little easier to feed the wotk_

:;t_ Loosen thetabl'e positioning screw.

21Insert the table :support rod:in the hole in the ba:se

untilthe edge of ti_etable is approximately 1/i6" from

the abrasive disC: Tighten the screw.

NOTE:There is a second mounting hole in the base. This

is for mounting tl_e:tabie When the belt is used in a verti-

cal position,

WARNING: To avoid trapping the work on fingers

between the table and sanding surface, the table

edge should be a maximum 1116 inch from the

sanding surface, the table should be completely

engaged on the rod.

Installing the Abrasive Belt -

Tensioning andTrack!ng

turn, switch _OFF_,: remove key!:and remove plug

from power sour€el outlet before removing or

I WARNING: To avoid Injury from accidental start,

installing abrasive belt_

NOTE: Two types of belts may be used,

On the smooth side of the abrasive belt you will see a

!'direCtional arrow."

Lap Splice: The abrasive belt must run in direction of this

arrow so that the splice does not come apart:

Butt Splice: The arrow points in both directions or identi-

fies no arrows, this indicates the user may position the

belt in either direction.

1:::Pdshtension |eVerto rear position:

2. Turn bett adjustment knob counterclockwise.

3. Appty light pressure to the idler pulley so the pulley

moves to rigfit_ :_:

4. Place the abrasive belt over the idler and drive pul-

leys with the-directional arrow pointing as shown.

Make sure the abrasive belt is centered on both pul_

teys.

5. Position tension lever in forward position. When the

idler pulley is moved outward, it puts tension on the

belt.

6. Standing to the side of the machine, push the belt by

hand to check if belt is moving either left or right.

/

/

SECOND

MOUNTING

HOLE

ABRASIVE BELT

DRIVE

J SUPPORT

TABLE ROD

POSiTiONING

SCREW

, i p ,i ,,

DIRECTIONAL ARROW

TABLE

IDLER PULLEY

ABRASIVE

DISC

BELT ADJUS_tENT

IN REAR

POSITION

WORK

TABLE

KNOB

.EVER

14

Page 15

7, If the abrasive belt moves to the right:

a. Turn the belt adjustment knob clockwise slightly,

until the belt recenters itself.

b. The abrasive belt is tracking properly when it is

centered on the drive pulley.

8. If the abrasive belt moves to the left:

a. Turn the belt adjustment knob counterclockwise

slightly until the belt recenters itself,

b. The abrasive belt is tracking properly when it is

centered on the drive pulley.

9, Turn machine on and off several times to observe

tracking. Repeat steps 7 and 8 as needed.

10. Turn machine on and adjust tracking, if needed, by

turning the belt adjusting knob slightly.

ABRASIVE

DISC

PUSH BELT IN

DIRECTION OF DISC

DRIVE MOVING

PULLEY TO RIGHT

BELT

BELT ADJUSTING

KNOB

RIGHT

installing Belt Dust Trap

1. Find one 10-32 x 9/16" pan head screw and a lock-

washer among the loose parts.

2. Attach the dust trap. Make sure the top edge is below

the surface of the abrasive belt.

Installing Backstop

1. Find one 5/16 x 1" hex head bolt and one flat washer

among the loose parts,

2. Place the washer on the bolt, and screw it halfway

into the mounting hole. Place the backstop into posi-

tion and tighten the bolt. When removing the back-

stop, loosen the bolt but do not remove it.

PAN HEAD SCREW

AND LOCKWASHER

BACKSTOP

LOCK SCREW

LEFT

i i i ii iiii iiiiiiiiiii

BELT DUST TRAP

BACKSTOP

15

Page 16

_Getting to Know Your Belt and Disc Sander

start, turn switch "OFF" and remove plug from

power source outlet before making any adjust-

WARNING:: To avoid Injury from accidentalJi

ments-

ABRASIVE DISC 4 BACKSTOP BACKSTOP 1

LOCK SCREW KNOB

\

WORK

TAB LE

WORK TABLE BELTTABLE

TILT LOCK SCREW STOP

[ i ii ii i , •

1. Abrasive Belt Adjustment Knob, Causes the idler

pulley to move in or o ut for tracking adjustment.

2. Abrasive Belt Tension Lever. Causes the idler pulley

to move backward and fox,yard for adjustm ent of the

belt tension.

See"Assembly"section- "Installing Abrasive Belt"

6

BELT TENSION

LEVER

BELT ADJUSTMENT

IDLER

PULLEY

BELT ADJUSTMENT KNOB

16

\

Page 17

3.Work Table Tilt Lock Screw. Locks the table, it is

locked using the 1/2' wrench supplied.

a. Using a combination square, check the angle of

the table with the disc.

NOTE: The combination square must be "true".

See start of "Assembly" section on for check

method.

b. tf the table is not 90° to the disc...toosen tilt lock

screw and tilt table.

c. Loosen the lock nut using a 7/16" wrench.

d. Screw the stop screw in or out, using a 3/8"

wrench so that when the table touches the top

screw, the table is 90° to the disc.

e. Tighten the lock nut. TABLE POSITIONING

LOCK SCREW

\

TABLE 1/!6"

FROM DISC

UI_ I I'11111 IIIII

to Know Your Belt and: Disc Sander (continued)

4. Backstop:Lock scre_w.Locks the backstop in place, tt

is:iocked using:the ii/2, wrench:Supplied: BACKSTOP

LOCKSCREW

5. Belt Table Locking Bolts. Lock the belt table in posi-

tion.

To adjust to vertical position:

a. Remove the backstop.

b. Loosen the two belt table locking bolts using the

1/2" wrench, supplied with your machine.

c. Position belt table vertically and tighten the two

bolts:

6. AbrasiveBeit Table Stop. Can be adjusted so that

the abrasive belt table is level when in a horizontal

position:.

a. Loosen the lock nut using a 3/4'! wrench.

b.Place a level on tl_e abrasive belt table and using

a 3/4" wrench, screw the stop bolt inorout until the

table is level,

BELT TABLE

LOCKING

BACKSTOP

\

\

STOP BOLT

LOCK NUT

Safety Instructions for Belt and Disc Sander

Before Using the Sander:

serious, permanent injury, do not plug the sander

I WARNING: To avoid mistakes that could cause !

in until the following steps are completed.

• Completely assemble the sander. See "Assembly" section.

• Learn the use and function of the ON-OFF switch. See

"Getting to Know Your Belt and Disc Sander" section.

° Review and understanding of all safety instructions

and operating procedures in this manual.

• Review of the maintenance methods for this sander.

See "Maintenance" section.

When Installing Or Moving the Sander:

Avoid dangerous environment. Use the sander in a dry,

indoor place protectedfrom rain. Keep work area well lighted.

Place the sander so neither the user or bystanders are

forced to stand in line with the abrasive belt or disc.

To avoid burns or other fire damage, never use the

sander near flammable liquids, vapors or gasses.

To avoid injury or death from electrical shock:

'GrOund the sander. This sander has an approved 3-

conductor cord and a 3-prong grounding type plug.

Use only 3-wire, grounded outlets rated 120 volts, 15

amperes (amps). The green conductor in the cord is

the grounding wire. To avoid electrocution, Never con-

nect the green wire to a live terminal.

° Make sure your fingers do not touch the plug's metal

prongs when plugging or unplugging the sander.

o Never use this or any power sander for wet sanding. Doing

so could cause electrocution, serious injury or worse.

To avoid injury from unexpected sander movement:

° Always unplug the sander before moving it.

• Put the sander on a firm level surface where there is

plenty of room for handling and properly supporting

the workpiece.

oSupport the sander so it does not rock.

o Bolt the sander to its work surface. Use the fasteners

and method shown in "Assembly" section,

• Never stand on tool, Serious injury could occur if the

tool tips. Do not store anything above or near the tool

where anyone might stand on the tool to reach them.

18

Page 19

To Avoid Back Injury

oGet help or use recommended casters when you need

to move the sander

o Always get help if you need to lift the sander.

Before Each Use:

Inspect your sander. Check for:

o alignment of moving parts,

• binding of moving parts,

o broken or damaged pads,

o worn or damaged electric cords,

stable mounting

• any other condition that may affect the way the sander

works,

If any part is missing, bent, or broken in any way, or any

electrical parts don't work properly, turn the sander off

and unplug the sander. Replace damaged, missing, or

failed parts before using the sander again.

Disconnect the sander to avoid injury from accidental

starting, Turn the switch off, unplug the sander and

remove the switch key before changing the setup or

sanding belt and disc.

Maintain tools with care. Keep the sander clean for the

best and safest performance.

Remove wrenches from tool before turning on.

To avoid injury from jams, slips or thrown pieces:

° Use only recommended accessories. Consult this

owneCs manual for recommended accessories. The

use of improper accessories may cause injury. See

"Accessory" section.

• Adjust any work support to clear the sanding surface

by no more than 1/16 of an inch. When checking clear-

ance between the belt and work support, press the belt

flat against the metal beneath it.

• Make sure all clamps and locks are tight and no

parts have excessive play.

• Keep work area clean. Cluttered areas and benches

invite accidents. Floor must net be slippery.

Plan Ahead to Protect Your Eyes, Hands,

Face and Ears:

Dress for Safety:

• Wear nonslip footwear.

, Tie back long hair.

• Roll long sleeves above the elbow.

o Noise levels vary widely, To avoid possible hearing

damage, wear ear plugs or muffs when using sander

for hours at a time.

• Sanding operations are usually dusty. Wear a dust

mask along with the safety goggles.

• Do not wear loose clothing, gloves, neckties or jewelry

(rings, wrist watches). They can get caught and draw

you into moving parts.

o Wear safety goggles. Any power sander can throw

foreign objects into the eyes. This can cause perma-

nent eye damage. Wear safety goggles (not glasses)

that comply with ANSI Z87.1 (shown on package).

Everyday eyeglasses have only impact resistant

lenses. They are not safety glasses. Safety goggles

are available at area stores. Glasses or goggles not in

compliance with ANSI Z87.1 could seriously hurt you

when they break.

Know your sander. Read and understand the owner's

manual and labels affixed to the tool. Learn its applica-

tion and limitations as well as the specific potential haz-

ards peculiar to this tool.

Toavoid injury from accidental contact with moving parts:

• Keep guards in place and inworking order.

° Don't do layout, assembly, or setup work on the sander

while any parts are moving.

Avoid accidental starting. Make sure switch is "OFF"

before plugging sander into a power outlet.

Plan your work, Think through how you will hold and

maneuver the workpiece from start to finish.

Use the right tool, Don't force tool or attachment to do a

job it was not designed to do.

Inspect your workpiece make sure there are no nails or

foreign objects in the part of the workpiece to be sanded.

Plan the way you wilt hold the workpiece from start

to finish. Avoid awkward operations and hand positions

where a sudden slip could cause finger or hand to move

into a sanding surface. Keep fingers away from where the

bolt goes into the dust trap.

Don't overreach. Keep good tooting and balance.

Keep your face and body to one side, out of line with a

possible throwback.

19

Page 20

+:Makesurethereisno debrisbetweenthe workplace

andits supports.

• When sandir+g irregularly shaped workpieces, plan

your work support So it willnot slip and be pulied from

your hands.

• Use extra caution with large, very small or awkward

workpieces.

• Never useIbis toot to finish pieces too smallto hold by hand.

• Use extra supports (tables, saw horses, blocks, etc.)

for any workpieces large enough to tip when not held

down to the tabletop.

° Never use another person as a substitute for a table

extension, or as additional support for a workpiece that

is longer or wider that the basic sander table, orto help

feed; support or pull the workpiece.

• Clear everything except the workpiece and related sup-

port devices off the table before turning the sander on+

• When finishing on the disc, always press the workpiece

against the "Down'_side of the disc. Sanding against the

side coming up from under the table could damage the

work by making it "chatter". or tear the work from your

hands and throw it.

• Sand only one workpiece at a time.

WARNING: Don't let familiarity (gained from fre-

quent use of your belt and disc sander) cause a

careless mistake. A careless fraction of a second is

enough to cause a severe injury.

iii i i L = _,, , , II .

Whenever Sander is Running:

Before starting your work, watch the sander while it runs.

If it makes an unfamiliar noise or vibrates a lot, stop

immediately. Turn the sander off. Unplug the sander. Do

not restart until finding and correcting the problem,

Make sure the sanding disc turns counterclockwise,

belore using the sander.

Keep children away. Keep all visitors a safe distance

from the sander. Make sure bystanders are clear of the

sander and workpiece.

Don't force tool. It will do the job better and safer at its

designed rate. Press the workpiece against the sanding

material only hard enough to let it sand without bogging

down or binding.

Before freeing any jammed material:

° Turn switch "OFF".

° Wait for al! moving parts to stop.

• Unplug the sander.

Before Leaving the Sander:

Turn power off, Don't leave tool until it comes to a com-

plete stop.

Never leave tool running unattended.

Make workshop child-proof. Lock the shop. Disconnect

master switches. Remove the yellow switch key. Store it

away from children and others not qualified to use the

t0ol.

Precautions to Take When Sanding Metals

When finishing metals, sparks or hot fragments could 2, Remove all traces of wood dust from inside the sander

cause a fire. To avoid this: before sanding metalsl

1. Disconnect any dust collecting hose lrom the sander: 3. Remove all traces of metal dust from inside the sander

before sanding wood again.

Precautions to Take When Sanding Paint ........

Sanding of lead based paint is not recommended. It is

very difficult to control the contaminated dust that could

cause lead poisoning.

It is also difficult to identify whether or not paint contains

lead. Therefore we recommend the following precautions

when sanding all paints:

1. Protect your lungs. Wear a dust mask or respirator at

all times. Wear only dust masks that are suitable for

working in lead paint sanding environments. Ordinary

painting masks do not offer this protection.

2+Do not altlowchildren or pregnant women to enterthe work

area until paint sanding job is finished and all clean up

completed:

3. To prevent ingesting contaminated paint particles: Do

not eat, drink, or smoke in a work area where paint is

being sanded. After sanding paint, wash and clean up

before eating, drinking or smoking. Do not leave food,

drinks, or tobacco products in the work area where

dust can settle on them.

4. Protect the environment when sanding paint. Use a

dust collection system if possible+ Seal the work area

with plastic if necessary, Do not track paint dust out-

side the work area,

5. Thoroughly clean the work area upon completion of

paint sanding project. If project lasts for an extended

amount of time, clean work area often, items such as

sanding dust, vacuum filter bags, plastic drop cloths, etc.

should be placed in a sealed container and disposed ol

properly. Clean all items exposed to sanding dust.

2O

Page 21

,ii

Surface Finishing on the Abrasive Belt

Flat surfaces

Hold the workpiece firmly with both hands, keepir_g fin-

gers away from the abrasive belt.

Keep the end butted against the backstop and move the

work evenly across the abrasive bell Use extra caution

when finishing very thin pieces.

For finishing long pieces, remove the backstop.

Apply only enough pressure to allow the abrasive belt to

remove material. If the abrasive belt stalls and the belt

pulleys slip, too, much pressure is being applied to the

workpiece

End Finishing on the Abrasive Belt

It is more convenient to finish the ends of long work-

pieces with the abrasive belt in a vertical position.

Move the work evenly across the abrasive belt. For accu-

racy, use a miter gauge.

The table may be tilted for beveled work.

See "Getting to Know Your Belt and Disc Sander" section

for adjusting the abrasive belt table and work table.

\

\

lii

t

Finishing Curved Edges on the Abrasive

Belt

Finish outside curves on the abrasive belt and inside

curves on the idler pulley.

21

Page 22

der Operation (continued)

|1 !L J

the Abrasive Disc

Move thework acroSs the "Down Side" of the face of the

abrasive diSc_Foraccuracy; use a miter gauge.

NOTE: Use a combination square to square the miter

•gauge tothe face of the disc: If it is not square, pull out

the index pin, loosen the miter gauge knob and move the

miter gauge, tighten the knob securely.

The table may be tilted for beveled work

I WARNING: Applying the workpiece to the "Up 1

I Side" of the disc first could cause workpiece to fly

I up (kickback) and result in an injury.

I

DOWN SIDE

(LEFT)

/

MITER GAUGE / SQUARE

\

\

Maintenance i i nl,,i, i nn ,i t ill|Hi

Maintenance

IWARNING_ For:your own safety, turn switch "OFF" I

1 and'remove plug from power: source outlet before I

I adjusting, maintaining, or lubricating your belt and i

disc sander, l

Keep _our machineand your workshop clean. The dust

traps around the abrasive disc and the abrasive belt are

designed to deflect most of the fine dust. They should be

connected to a vac for most eflicient dust removal.

{WARNING: To avoid electrocution or fire, any

Jrepairs to electrical systems should be done only

Iby qualified service technicians. Unit must be

I reassembled exactly to factory specifications.

If powercord is worn or cut, or damaged in any way, have

itreplaced immediately.

Frequently blow out or vacuum out any dust that may

accumulate inside the motor.

A coat of automobile-type wax applied to the worktable

will make it easier to feed the work while finishing.

Do not apply wax to the abrasive belt table because the

belt could pick up the wax and deposit it on the pulleys,

causing the bet! to slip.

' uul i ......................._, ii, ii ,, =H,,u,,,,,=,l,

Motor Maintenance and Lubrication

1. The bearings, in both end shields of the motor, have bee/

lubricated at the factory with correct lubricant. No othei

part of the motor required lubrication.

2. Re-lubricate motor bearings following the instructions on

the nameplate. Be sure to wipe oft dirt or grit if present

around oil hole caps to prevent any possibility of foreign

material contaminating the oit wicks that supply the bear-

ings with oi!. Use a good grade of medium weight mineral

oil, such as automobile engine oil SAE 20.

3. If disassembly of the motor is necessary, it should be

returned to your nearest Sears retail store in order to pre-

vent voiding the guarantee.

NOTE: The speed of this motor cannot be regulated or

changed.

4. Every effort should be made to prevent foreign material

from entering the motor. When operated under conditions

likely to permit accumulations of dust, dirt, or waste within

the motor, a visual inspectionshould be made at frequent

intervals. Accumulations of dry dust can usuaIly be blown

out successfully,

NOTE: Motors used on wood-working tools are particu-

larly susceptible to the accumulation of sawdust and

wood chips and should be blown out or "vacuumed" fre-

quently to prevent interference with normal motor ventila-

tion and proper operation of the centrifugally-operate_

starting switch.

Lubrication

The ball bearings in this machine are packed with grease at

the factory, They require no further lubrication,

22

Page 23

Recommended Accessories ..............

Sears Recommends the following accessories:

item

Caster Set

Miter Gauge

Pressure-Sensitive Cement

Abrasive Belts and Discs

Steel Legs

Power Tool Know How Handbook

Oat, No.

,, '...................;,,, ,,,

9-22222, 9-22221

9-29929

See Catalog

See Catalog

9-22236

9-291 17

Do not use any accessory unless you have received and

read complete instructions for its use.

See your nearest Sears store for other accessories.

WARNING: Use only accessories recommended for ]

this sander. Using other accessories may be dan-

gerous.

h ,._ou...es.oo..nu............ .......

Motor

I WARNING: For your own safety, turn switch "OFF" and remove plug from power source outlet before trou- I

bleshooting your sander.

NOTE: Motors used on wood-working tools are particularly susceptible to the accumulation of sawdust and wood chips

and should be blown out or "vacuumed" frequently to prevent interference with normal motor ventilation and proper

operation of the starting switch.

Trouble Probable Cause

..... , ............... , .... , ............... ,,, ,,i .........................., .......................... ,...... , ..........

Excessive Noise 1. Motor 1.

..... , ...... " ,........... ,,,_

Have motor checked by qualified service technician,

Repair service is available at your nearest Sears

retail store,

Remedy

/

I

Motor failed to

develop full power.

NOTE:

Low Voltage:

(Power output of

motor decreases rap-

idly with decrease in

voltage at motor ter-

minals. For example,

a reduction of 10% in

voltage causes a

reduction of 19% in

maximum power out-

put of which the motor

is capable, and a

reduction of 20% in

voltage causes a

reduction of 36% in

maximum power out-

put,)

Motor starts slowly or

fails to come to full

speed

Motor overheats

1. Circuit overloaded with

lights.

2. Undersize wires or circuit too

long,

3. General overloading of

power company facilities.

1. Low voltage.

2. Windings burned out or open.

3. Starting switch not operating.

1. Motor overloaded,

2. Improper cooling. (Aircircula-

tion restricted through motor

due to sawdust, accumulating.

.

Do not use other appliances or motors on same cir-

cuit when using the saw,

2,

Increase wire sizes, or reduce length of wiring, See

"Electrical Requirements" section.

3.

Request a voltage check from the power company.

1. Request voltage check from power company,

2, Have motor repaired or replaced,

3. Have switch replaced.

1. Feed work slower intobelt or disc.

2. Clean out sawdust to provide normal air circulation

through motor, See "Maintenance" section.

23

Page 24

ootmg (con nued)

:Starting switchJn 1_Burned sWitCh_ontactS(dUel _ 1. Have switch replaced and request a voltage check

motOrwiit'notoper - : :i t0 extendedf_old-in periods =fromthe power company.

ii:ate_ i _::_i :_i: caused by 10wlinevoltagei : ]

:: HH_L II ' =' = r

oo; • o

: tions.

Motor stalts (result- 1. Starting switch not operating. 1. Have switch replaced.

ing in blown fuses or 2. Voltage too low to permit 2. Request voltage check from the power company.

.:tripped circuit break- motor to reach operating

ers) speed.

3. Fuses or circuit breakers do 3. Install proper size fuses or circuit breakers.

not have sufficient capacity.

Frequent opening of 1. Motor overloaded. 1. Feed work slower into belt or disc.

fuses or circuit 2. Fuses or circuit breakers do 2, install proper size fuses or circuit breakers.

not have sufficient capacity.

[ 3. Starting switch not operating 3. Have switch replaced,

L _ (motor does not reach

.... speed)

Motor will not run 1, Defective On-off switch. 1. Replace defective parts before using belt and disc

Defective switch cord. sander again.

Defective switch box. 2. Consult Sears Service. Any attempt to repair this

2. Burned out motor, motor may create a hazard unless repair service is

..... I ..... done by a qualified service technician. Repair ser-

Machine slows down 1. Timing belt too tighL 1. Decrease belt tension, see "Maintenance" section,

when sanding : : : : "Removing Pulley Cover and Installing Timing Belt.

[: .... 2. Applying too much pressure 2. Ease up on pressure.

.... to workpiece

.a::w:. a:::::::::::::::::::,,,o,oc,,vo.

vice is available at your nearest Sears retail store.

..... i .....

Abrasive belt tuns off 1. Not tracking properly, 1. Adjust tracking, See "Assembly" section, "Installing

pulleys _ .... = the abrasive Belt - Tensioning and Tracking".

• . ..... , .. , ,

Wood burns while 1. abrasive disc or belt is 1. Replace disc or belt.

sanding _ glazed with sap.

• • : :• :• _i¸ _• :• •

• ..ii • ' i i_.:_i_ _i/.._ii i _ •

_...._i_i __i,!ii_ _i__ __

24

Page 25

Repair Parts ...........................

Parts List for Craftsman Begt and Disc Sander

Model 113.225941

A]ways order by Part Number--Not by Key Number

Figure 1

3 4 7

LI f

3 je

4 3

f

f

6

2

Key

No. Part No. Description

1 820040

2 60314

3 STD541025

4 STD551225

5 68060

6 68059

7 62615

8 68061

9 STD541237

10 803835-1

11 508419

Leg

J-Screw, Truss Hd. 1/4-20 x 1/2

"1_Nut, Hex 1/4-20

"1- Lockwasher, 1/4 External

Channel, Support

Stiffener, Side

Stiffener, End

Support, Motor

"1- Nut, Hex 3/8-16

t Foot, Leveling

Bag of Loose Parts (Not Ills.)

25

No. I Part No. Description

Hardware for mounting toot & motor

!

-- STD523125 1"1-Screw, Hex Hd. 5/16_2-1/2

STD541231 "1-Nut, Hex Jam 5/16 x 18

-- STD551031 *1-Washer, 11/32xlli16xli16

STD551131 I"1 Lockwasher, External 5/16

STD532507 "I" Bolt, Carriage 5/16q/x 3/4

1-These items all contained in Loose Parts Bag, Part No.

508419

* Standard Hardware Item - May be purchased tocally

Page 26

Page 27

"6

E

o_

, Z

c_

o z

mz_

i

i o

i

i

i

£

dd

_5

I

o

_D

£

S

@

6

z

E

E_

II1 >.

i_ -_

E_

o

_1

11.

o

X

.o

K

,m

O

4--- .

6

Z

co c,,I

o o4

,,r- c,

o (N

DID

i •

27

Page 28

Parts List for Craftsman Belt and Disc Sander - iViodei 113.225941

A_waysorder by Part Number--Not by Key Number

Figure 3 - Motor Part No. 68072

KeyPart I

No. No. i t ....- Description

1 60306 Screwl 8-32 x3/8, Thread Cutting,

Slotted, Serrated Head

2 64088 Cover, Terminal

3 64258 Cord w/Plug

NOTE: Any attempt to repair this motor may create a

hazard unless repair is done by a qualified service tech-

nician. Repair service is available at your nearest Sears

Service Center.

28

Page 29

Parts List for Craftsman Belt and Disc Sander - Model 113.225941

Always order by Part Number--Not by Key Number

6

Figure 4 - On/Off Power Outlet 60382

Key

No.

Part No. Description

60382

1 60375

2 60378

3 9-22255

4 60374

5 60376

6 448007

* On/Off Power Outlet

Cord, Molded

Housing, Switch

1" Key, Switch

Switch, Locking

Cover, Switch

Screw, Pan Hd. No. 6 x 3/4

• Does not include Key No. 3 - order separately if

required.

1 Stock Item - May be secured through the Hardware

Department of most Sears store.

29

Page 30

-::WARNiNG:i.For::your own safety, never connect 1

i;:_eps _ €ompleted_

motor;Using a flat blade screwdriverl

! _WARNING: To iavoid electrocution, never connect I

• : :,,,,, _ :

outlet until all assembly

located on side of

I anything but the ground wire (colored green)to

Ithe green screw.

2. Remove green screw and insert through round metal

terminal on the end of the green wire of motor cord:

3. Reinsert green screw in threaded hole that it was

removed from and tighten securely.

4. Connect terminal end of black wire to terminal #1 on

the motor. Push terminal firmly until seated.

5. Connect terminal end of white wire to terminal #4 on

the motor. Push terminal firmly until seated.

6, Close motor connector box being sure that motor cord

is seated in lower strain relief groove and tighten box

cover screws.

I

Black Motor

Cord Lead On

#1

Green Motor

Cord Lead

Under Green

;crew

Vlotor Cord in

Strain Relief

Groove

"White Motor

Cord Lead On

Terminal #4

Motor Cord Connections

Z

i:iii_•_•ii!z¸_!:i•:i•¸•

30

Page 31

Notes ............................

3_

Page 32

MODEL NO,

• /

ELT AND DISC

SANDER

Forthe repair or replacement parts you need

Call 7 am - 7 pm, 7 days a week

t -800-366=PART

(1-801)-366-7278)

113o225941

The model number of your Belt

and Disc Sander will be found

on a plate attached to the right

hand side of the base.

When requesting service or

ordering parts, always provide

the following information:

- Product Type

•Model Number

• Part Number

• Part Description

Forin-home majorbrandrepair service

Call 24 hours aday, 7 days a week

t -800=4,-REPA|R

(1-800-473-7247)

Forthe location of a

Sears Repair ServiceCenter inyour area

Call 24 hours aday, 7 days a week

t -800-488-1222

Forinformation onpurchasinga Sears

Maintenance Agreementor to inquire

about an existing Agreement

Call 9 am -5 pro, Monday-Saturday

t -800-827-6655

lIIII_

SEARS

America's Repair Specia tis ts

, ii i i i i i i i ill i,,,,,i H H ,,,,,, i

Sears Roebuck and Co., Hoffman Estates, IL. 60179 U.S.A.

Part No. SP5582 SP5582-5 Printed in U.S,A, 4t97

Loading...

Loading...