Page 1

Save This №nuai

For Future Reference

owners

manual

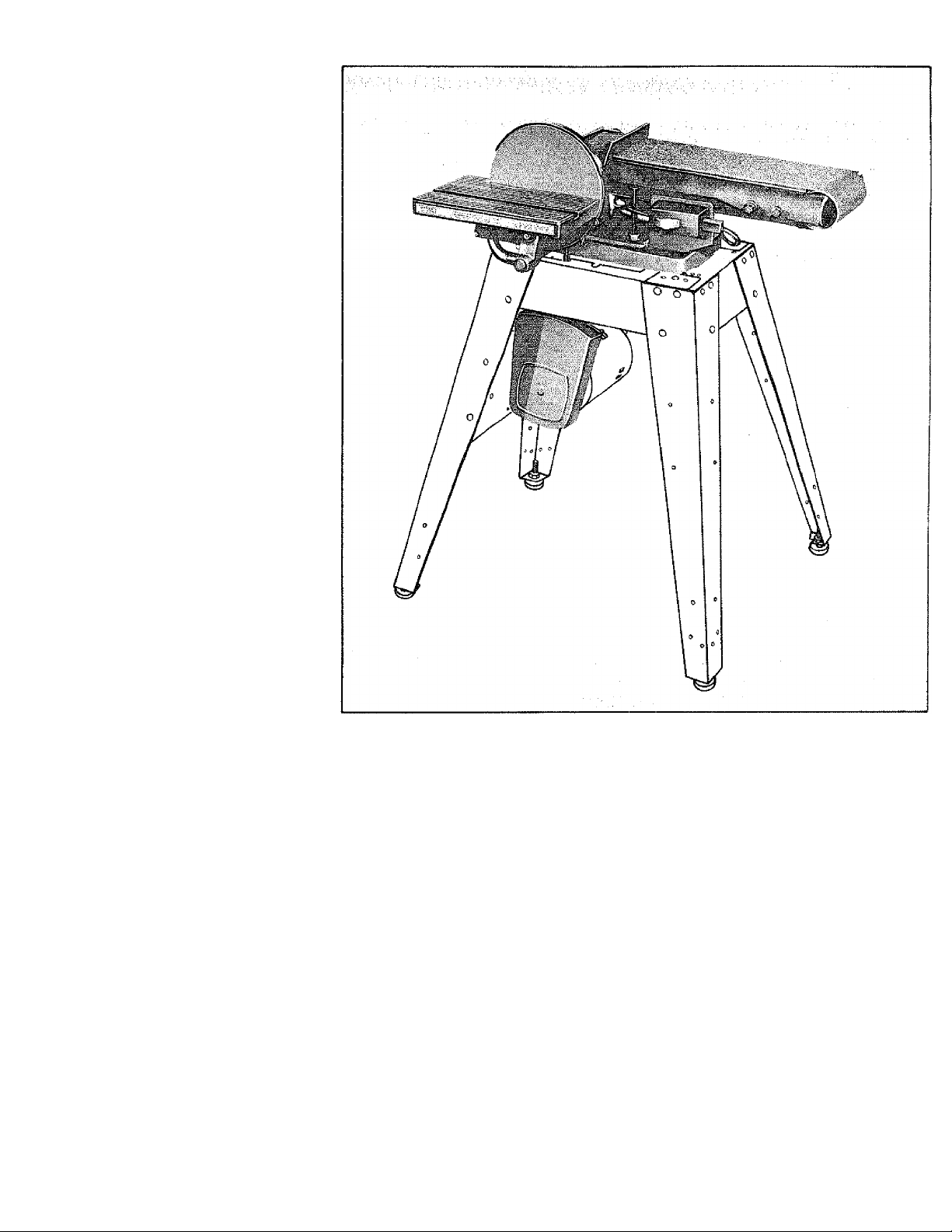

MODEL NO.

113.225900

BELT AND DISC

SANDER ONLY

MODEL NO.

113.225931

BELT AND DISC

SANDER/WITH

LEGS AND MOTOR

Serial

Number

Model and serial

number may be found

at the right-hand side

of the base.

You should record both

model and serial number

in a safe place for

future use.

CAUTION

Read SAFETY

INSTRUCTIONS

carefully

CRRFTSMRN

BELT AND DISC SANDER

• assembly

® operating

® repair parts

Sold by SEARS, ROEBUCK AND CO., Chicago, IL. 60684 U.S.A.

Part No. 68073 Printed m U.S.A,

Page 2

FULL ONE YEAR WARRANTY ON CRAFTSMAN BELT AND DISC SANDER

If within drie year from the date of purchase^ this Craftsman Belt and Disc Sander fails due to a defect in

material or workmanship. Sears will repair it, free of qharge.^ ^ ^ ^

WARRANTY SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS STORE

OR SERVICE CENTER THROUGHOUT THE UNITED STATES. ; ^ ^

This warrarrty gives you specific legal rights, and you may also have other rights which vary from state to

state,

SEARS, ROEBUCK AND CO., Dept. 698/731A, Sears Tower, Chicago, IL 60684

gehéral safe instructions for power fools

1. KNOW YOUR PÓWER TOOL ^ ^ ^

Read and : understand the owner's manual and labels

affixed to thè tool. Learn its application and limitations as

' well as the specific potential hazards peculiar tp this tòoi:-

2 GROUND ALL TOOLS

^ with an approved 3 conductor

grounding type plug to fit the proper

grounding type receptacle. The gieen conductor in the

cord is the.Vgrourrding Wire, Never connect the green wire

to a live terminal. ■

3. KEEP GUARDS IN PLACE

■ tn; vvóric íng. order, and rn proper adjustment and align

4 REMOVE ADJUSTING KEYS AND WRENCHES

^ Trsrm : habit : of checkirig. to see that keys and adjusting

vvrenches are-rernoveri trorn tool,before turning .it on.

5. KEEP WORK AREA CLEAN

. Cluttered, áréés and benches: invite accidents. Floor

must not be slippery due to wax or sawdust.

6. AVOID DANGEROUS ENVIRONMENT

Don't use power tools n damps or wet locations ot ex .

;i'v,e them to tarn. Keep work aica well lighter!. Provide

. : ;a<iepu3te surrounding work space : ;r .;

7. KEEP CHILDREN AWAY

Ali visitors 5hóü(d}be:kepti-d:sated'staricellrdm.jWork area,,

8. MAKE WORKSHOP CHILD-PROOF

With pacifocks. masi(?i swilcfies, or t>y: rerriovinq starter

keys . • . ■ ■ '■ ■: ' • • ■. ■" •

9. DON'T FORCE TOOL

:: " it will do. the. job.:better and safer at the rate for Which .

it was designed : .. : .

10. USE RIGHT TOOL

Don't foice tool oi attachment to do a job. it was not

ciesigned for, ...

It. WEAR PROPER APPAREL

Do not wear loose clothing, gltsves, neckties or jewelry

(rings, wristwatches) to get caught .in moving, parts, j

NONSLIP footwear is recommended. Wear protective,

hair covering to contain Song hair.. Roil long sleeves

above the elbow.

12. USE SAFETY GOGGLES (Head Protection)

Wear safety goggles (must cotrtply with ANSI Z87.Ì) at all

times; Everyday eyeglasses only have impact resistant

lenses, they are NOT safety glasses. Also, use face or dust

mask if cutting operation is dusty, and ear protectors

(plugs or muffs) during extended periods of operation.

13. SECURE WORK

Use clamps or a vise to hold work when practical. It's

safer than using your hand, frees both hands to operate

: tool.

14. DON'T OVERREACH

Keep proper footing and balance at all times.

15 MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for best and safest perform

ance. Follow instructions for lubricating and changing

accessories.

16. DISGONNECT TOOLS

before servicing, when changing accessories such as

blades, bits, cutters, etc.

17. AVOID ACCIDENTAL STARTING

Make sure switch is |n "OFF" position before plugging

in.

18. USE RECOMMENDED ACCESSORIES

: ; Cohsull the owner's manual for recommended accessories.

Follow the instructions that accompany the accessories.

" The use of improper accessories may cause hazards.

19. NEVER STAND ON TOOL

injury could occur if the too! is tipped or if the

cutting tool IS accidentally contacted.

Do not store materials above or near the tool such that

: It IS necessary to stand on the tool to reach them.

20. CHECK DAMAGED PARTS

Before further use of the tool, a guard or other part that

IS damaged should be carefully checked to ensure that it

will operate property and perform rts intended function.

Check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other conditioiis that may affect ns operation. A guard or other

part that IS damaged should be properly repaired or

replaced. .

21. DIRECTION OF FEED

Feed work into a blade or cutter against the direction of

rotation of the blade or cutter only.

22 NEVER LEAVE TOOL RUNNING

UNATTENDED

Turn power off. Don't leave tool until it comes to a

complete stop

Page 3

sofety insfryctlohs f©r belt oiid: di^c soiicler

Safetyis a cprntJination of common sense, staying alert and

knowing how your belt and disc sander works. Read this

manual to understand this sander.

BEFORE USING THE SANDER:

WARNING: To avoid mistakes that could cause serious, per

manent injury, do not plug the sander in until the following

steps are completed.

• Assembly, (See pages 7-16.)

® Learn the use and function of the ON-OFF swilch,

backstop lock screw, belt adjusting screws, belt lock

ing screws, work table and work table tilt lock screw.

(See pages 16-18.)

• Review and understanding of ail safety instructions and

operating procedures in this manual.

• Review of the maintenance methods for this sander.

(See page 22.)

Read the following DANGER label found on the front of the

sander:

fl A R BEfORE OPERATiNO MAC«'Ni

FOB YOUR 3 lAAINlAIK ''16 uvCr'WAKlWUMCI.EAeANCE

OWN SAF£TY stit un

1 HtAO AND UNOEHSTAND OWNiaS

^ 2 WEAR SAFgty iiOddLeS ASP SU5T MASH

i AVO'O-ArCKBACH'fWORKPlECt THUCrWEi

AI VOLJI - DO NOT USE RIGHT HAt.r OT’ DISC

S ACWATSSuPPOftT WOn><.P^EG5 WITH 'iiAC.«!-

STpl- Oft -vVOfiXr45ig •

S N SHOF'VAC’OD'SC

M0US:>«G WM5N 5ANDIKQ iftOH OR STEEL l»

WHEN INSTALLING OR MOVING THE SANDER.

AVOID DANGEROUS ENVIRONMENT. Use the sander in a

dry, indoor place protected from rain. Keep work area weii

lighted.

Place the sander so neither the user or bystanders are forced

to stand in line with the abrasive belt or disc.

To avoid injury from unexpected sander movement:

• Put the sander on a firm level surface where there is

plenty of room for handling and properly supporting the

workpiece.

» Support the sander so it does not rock.

» Bolt the sander to the floor or work surface if it tends

to slip, walk, or slide during normal use.

To avoid injury or death from electrical shock;

» GROUND THE SANDER. This sander has an approved

3-conductor cord and a 3-prong grounding type plug.

Use only 3-wire, grounded outlets rated 120 volts, 15

amperes (amps). The green conductor in the cord is the

grounding wire. To avoid eiectrociitioh, NEVER connect

the green wire to a live terminal.

• Make sure your fingers do not touch the plug's metai

prongs when plugging or unplugging the sander.

To avoid back injury, get help or use recommended casters

when you need to move the sander. Always get help if you

need to lift the sander.

NEVER STAND ON TOOL. Serious injury could occur if the

tool tips or you accidentally hit the cutting tool. Do not store

anything above or near the tool where anyone might stand

on the tool to reach them.

..........................

BEFORE EACH USE:

inspect your sander.

DISCONNECT THE SANDER. Toavoid injury from accidental

starting, unplug the sander, turn the switch off and remove

the switch key before changing the setup, sanding disc or

belt or adjusting anything.

CHECK DAMAGED PARTS. Check for:

« alignment of moving parts,

o binding of moving parts.

® broken parts,

* stable mounting, and

e any other conditions that may affect the way the sander

works.

WARNING; The 2-1/2" machine pulley and the 2" motor

pulley furnished will run the disc at about 2700 RPWI and the

belt at about 2100 FPW! (Feet Per Minute) when used with a

3450 RPM motor. To avoid throwing of work or broken

sander fragments, never substitute or interchange these

pulleys to increase this speed.

If any part is missing, bent, or broken in any way, or any elec

trical parts don't work properly, turn the sander off and

unplug the sander. REPLACE damaged, missing, or failed

parts before using the sander again. .

MAINTAIN TOOLS WITH CARE. Keep the sander clean for

best and safest performance. Follow instructions for lubri

cating.

REMOVE ADJUSTING KEYS AND WRENCHES from tool

before turning it on.

To avoid injury from jams, slips or thrown pieces:

• USE ONLY RECOMMENDED ACCESSORIES, (See

page 22.) Consult this Owner's manual for recom

mended accessories. Follow the instructions that

come with the accessories. The use of improper ac

cessories may cause risk of injury to persons.

* Adjust table to clear the sanding surface by no more

than 1/16 of an inch.

■ Make sure all clamps and locks are tight and no parts

have excessive play.

• KEEPWORK AREA CLEAN, Cluttered areas and benches

invite accidents. Floor must not be slippery.

To avoid burns or other fire damage, never use the sander

near flammable liquids, vapors or gases.

Plan ahead to protect your eyes, hands, face, ears.

KNOW YOUR SANDER. Read and understand the owner's

manual and labels affixed to the tool. Learn its application

and limitations as well as the specific potential hazards pecu

liar to this tool.

To avoid injury from accidental contact with moving parts,

don't do layout, assembly, or setup work on the sander while

any parts are moving,

AVOID ACCIDENTAL STARTING, Make sure switch is "OFF"

before plugging sander into a power outlet.

Page 4

solely instructions for belt ond disc sctnder

Plan your work.

USETHERIGHTTOOU. Don't force toot or attachment to doa

job it was not designed to do. :

CAUTION: This machine is notdesigned for heavy deburring

operations. When finishing metals, sparks or hot fragments

could cause a fire. To avoid this, disconnect any dust col

lecting hose from the sander. Also, remove al! traces of wood

diist from inside dust traps in the Sander.

Dress for safety.

s- This

cán cause permanent eye damage. Wear safety goggles {not

gláséés) that cbrnpl^^ Z87.1. Everyday eyeglasses

have only itripact resistant lenses. They are not safety glasses.

Safety goggles are available at Sears retail cataiog stores.

Glasses or goggles not in compliance with ANSÍ Z87.1 could

seriously hurl you when they break. ^

* Do not wear loose clothing, gloves, neckties or jewelry

(rings, wrist watches}, they can get caught and draw

you into moving parts.

* Wear nonslip footwear, /

.■ Tie backfong hair, . : ■ .

; • Roll long sleeves above the elbow. ;

* Noise levéis vary widely To a void possible hearing dant-

® Sanding operatioris áre usually dusty. Wear a dust mask

along with the safety goggles. . ^ .

inspect your workpiece,

Make sure there are ríoháils or foreign objects ih the part of

the workpiece to be sanded. ■

Plan your work to avoid THRÓWÉACKS—when the work

piece catches on the sanding belt or disc and is torn from

your hands. ■ ■ '.- V, ; ■ ■ -

• Make sure there's no debris between the workpiece and

its supports. . ■ V .

• When sanding irregularly shaped workpieces, plan your

work support so it witi not slip and be pulled from your

hands.

• Use extra caution with large, very small or awkward

. pieces: • : . . .

« Never use this tool to finish pieces too small to hold by

hand. : ^ .

• Use extra supports (tables, saw horses, blocks, etc.) for

: any workpieces large enough to tip when not held down

to the table top. ,

• NEVER use another person as a substitute for a table

extension, or as additional support for a workpiece that

is longer or wider than the basic sander table, or to help

feed, support or pull the workpiece,

• When finishing onthe Disc, always press the wbrkpiece

against the "Down" side of the disc. Sanding against the

side coming up from under the table could damage the

work by making it "chatter," or tear the work from your

hands and throw it.

• Sand only one workpiece at a time.

• Clear everything except the workpiece and related sup

port devices off the table before turning the sander on.

Plan the way you will hold the workpiece from start to finish.

Avoid awkward operations and hand positions where a sud

den slip could cause fingers or hand to move into a sanding

surface. Keep fingers away from where the belt goes into the

dust trap.

DON'T OVERREACH, Keep good footing and balance.

Keep your face and body to one side, out of line with a pos

sible throwback.

WHENEVER SANDER IS RUNNING.

WARNING: Don't let familiarity (gained from frequent use of

your belt and disc sander) cause a careless mistake. A care

less fraction of a second is enough to cause a severe injury.

Before starting your cut, watch the sander while it runs. If it

makes an unfamiliar noise or vibrates a lot, stop immediately.

Turn the sander off. Unplug the sander. Do not restart until

finding and correcting the problem.

Make sure the sanding disc turns counterclockwise before

using the sander.

KEEPC HIED REN AWAY. Keepallvisitorsasafedistancefrom

the sander. Make sure bystanders are clearof the sander and

vvprkpiece. :

DON'T FORCE TOOL. It will do the job better and safer at its

designated rate. Press the workpiece against the sanding

rriaterial only hard enough to let it sand without bogging

down or binding.

Before freeing any jammed material:

: «Turn switch "OFF."

; • Unplug the sander.

• Wait for ail moving parts to stop.

To avoid throwback of the workpiece, use workpiece supports

for all flat surface sanding.

BEFORE LEAVING THE SANDER:

Wait for al! moving parts to stop.

Make workshop child-proof. Lock the shop. Disconnect

rhaster svvitches. Remove the yellow switch key Store it

avVay frorn children and others not qualified to use the tool.

Page 5

electrical requiremerits

CONNECTING TO POWER SOURCE OUTLET

This machine must be grounded white in use to protect

the ofjerator from electric shock.

Plug power cord into a 120V properly grounded type outlet

protected by a 15-amp. dual element time delay or CircuitSaver fuse or circuit breaker.

If you are not sure that your outlet is properly grounded,

have it checked by a qualified electrician.

WARNING: DO NOT PERMIT FINGERS TO TOUCH THE

TERMINALS OF PLUGS WHEN INSTALLING OR RE

MOVING THE PLUG TO OR FROM THE OUTLET.

WARNING: IF NOT PROPERLY GROUNDED THIS

POWER TOOL CAN INCUR THE POTENTIAL HAZARD

OF ELECTRICAL SHOCK. PARTICULARLY WHEN USED

IN DAMP LOCATIONS IN PROXIMITY TO PLUMBING.

IF AN ELECTRICAL SHOCK OCCURS THERE IS THE

POTENTIAL OF A SECONDARY HAZARD SUCH AS

YOUR HANDS CONTACTING THE ABRASIVE BELT

OR DISC.

If power cord is worn or cut, or damaged in any way, have

it replaced immediately.

Your unit is wired for 120 volts and has a plug that looks like

the one shown below.

If the outlet you are planning to use for this power tool is

of the two prong type DO NOT REMOVE OR ALTER

THE GROUNDING PRONG IN ANY MANNER, Use an

adapter as shown and always connect the grounding lug to

known ground.

It is recommended that you have a qualified electrician

replace the TWO prong outlet with a properly grounded

THREE prong outlet,

A temporary adapter as shown below is available for

connecting plugs to 2-prong receptacles. The green ground

ing lug extending from the adapter must be connected to a

permanent ground such as to a properly grounded outlet

box.

Atemporary adapter asillustrated is available for connecting

plugs to 2-prong receptacles. The temporary adapter should

be used only until a properly grounded outlet can be

installed by a qualified electrician.

NOTE: The adapter illustrated is for use only if you already

have a properly grounded 2-prong receptacle.

The use of any extension cord will cause some loss of

power. To keep this to a minimum and to prevent over

heating and motor burn-out, use the table below to deter

mine the minimum wire size (A.W.G.) extension cord. Use

only 3 wire extension cords which have 3-prong grounding

type plugs and 3-poie receptacles which accept the tools

plug.

GROUNDING LUG

3-PRONG

PLUG

I

GROUNDING

PRONG

This power tool is equipped with a 3-conductor cord and

grounding type plug, approved by Underwriters' Labora

tories and the Canadian Standards Association. The ground

conductor has a green jacket and is attached to the tool hous

ing at one end and totheground prong inthe attachment plug

at the other end.

This plug requires a mating 3-conducior grounded type out

let as shown.

3-PRONG

PLUG

ADAPTER

Extension Cord Length Wire Size A.W.G.

0-25 Ft

...........................................

26-50Ft

...............................................

51-100Ft.............................................12

MAKE SURE THIS IS

CONNECTED TO A

KNOWN GROUND

2-PRONG

RECEPTACLE

- 16

14

CHECK MOTOR ROTATION

Place the motor on your workbench or on the floor.

Standing clear of the motor shaft, plug the motor cord into a

properly grounded outlet. Notice the rotation of the shaft.

As you look directly at the motor shaft it should be turning in

the counterclockwise direction Ss v . If the motor shaft is

turning counterclockwise, remove the plug from the power

outlet and continue the assembly procedures. If the motor is

turning clockwise, remove the plug from the power outlet

and contact your Sears Store immediately.

Page 6

CONTENTS

safety INSTRUCTIONS FOR POWER TOOLS 2

ADDITIONAL SAFETY INSTRUCTIONS FOR BELT AND

Belt Locking Screws..................................................17

Work Table Tilt Lock Screw

Backstop Lock Screw

ELECTRICAL REQUIREMENTS

.........................

.::,,.............5

Belt Table Locking Boils

Belt Table Stop......................................................... 18

UNPACKING AND dNECKlNG CONTENTS6

ASSEMBLY ...........,:.,.....„.„.,7

: : ; ; Assembling Steel: Legs..:.;...,..,,8

Mounting Belt and Disc Sander on Steel Leg Set...... 8

: installing Sanding Disc and Dust Trap .

....

9

Installing Motor, V-BeitTensioning and Tracking .... 11

Óri-Otf Switch.:.:.,.,............................................... 12

Installing Work Table ...14

installing Abrasive Beit Tensioning and Tracking ....14

Installing Belt Dust Trap.........

.........................

........15

Installing Backstop 16

GETTING TO KNOW YOUR SANDER

........................

16

Belt Adjusting Screws ..,.,.„,...,.17

BASIC OPERATION ..

: Surface Finishing on the Abrasive Belt

: End Finishing on the Abrasive Belt

Finishing Curved Edges on the Abrasive Belt

Finishing Small End Surfaces and Curved Edges

MAINTENANCE

Motor Maintenance and Lubrication........................22

LUBRICATION...................................................................... 22

Recomnnended Accessories

TROUBLESHOOTING

REPAIR PARTS

Motor Connections....................................................29

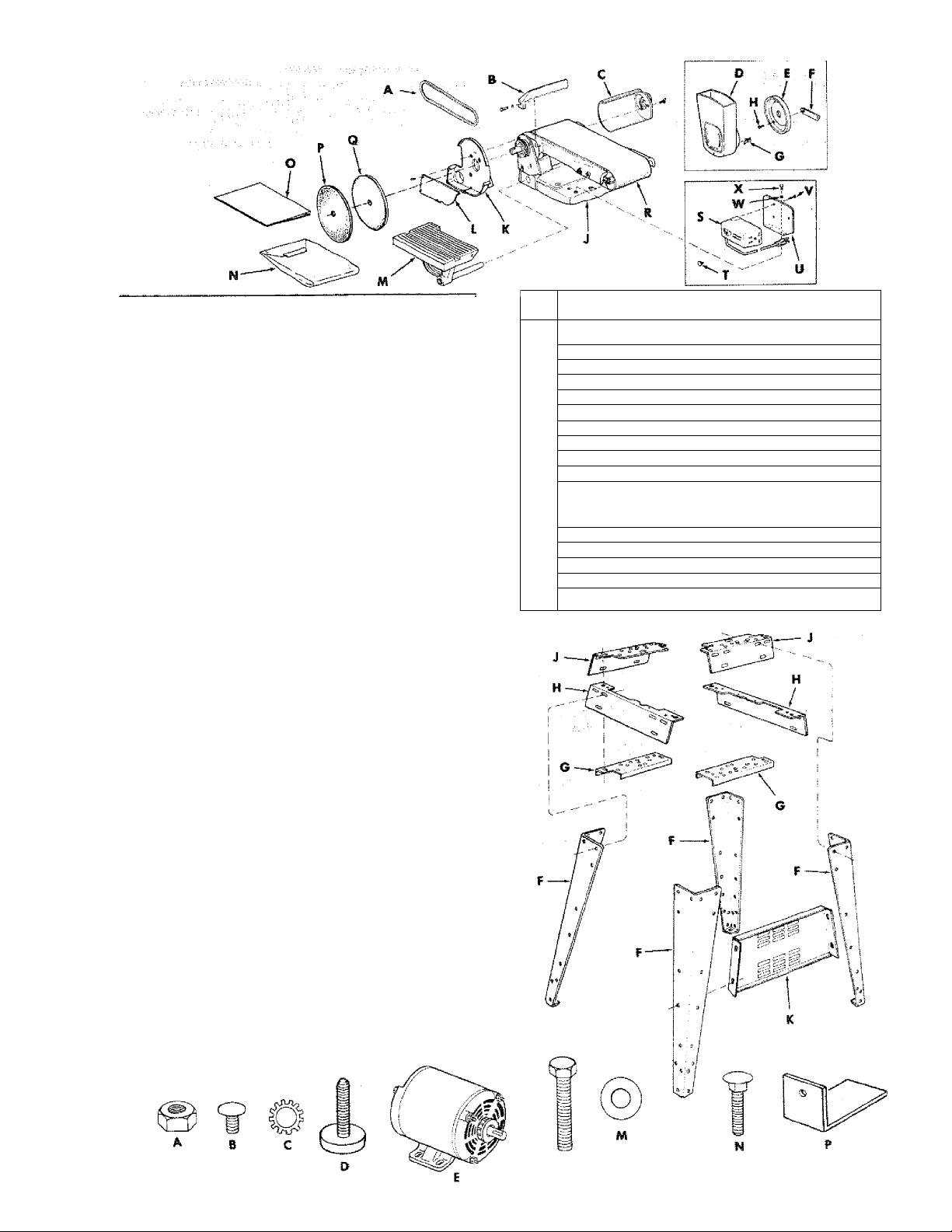

У op a c kiln g checking contents

Model ; 11^ and Disc Sander is shipped

eoniplete in one carton but DOES NOT INCLUDE Steel

Legs or Motor. :

Model 113.225931 Belt and Disc Sander is shipped

complete in one carton and INCLUDES Steel Legs and

Motor.

Separate all parts from packing materials and check each

; : item with iliustration and;'Table of Loose Parts." Make

certain all iterns are 'accounted for, before discarding any

packing material. ^ ^ ^

If any parts are missing, do not attempt to assemble the

Beit and Disc Sander, plug in the power cord, or turn the

. svvitch on Liritil, the missing parts: are . obtained and

■ ; installed correctly. , : ■ ■

Using a 1/2" wrench; remove the plywood attached to

the machine. Save; the nuts and bolts and washers; You

wit! need them for attaching the machine to the base.

1/2" Wrench

7/16" Wrench

3/4" Wrench

3/8" Wrench

DRAW light

LINE 014 ВОДНО

ALONG THIS EDGE

.........

............................

.....

..........i...............................

...........................................18

..........................................................

...................

.........................

.......

21

on Disc...................................................................21

....................................................................

...................................

..........................................................

...................................................................25

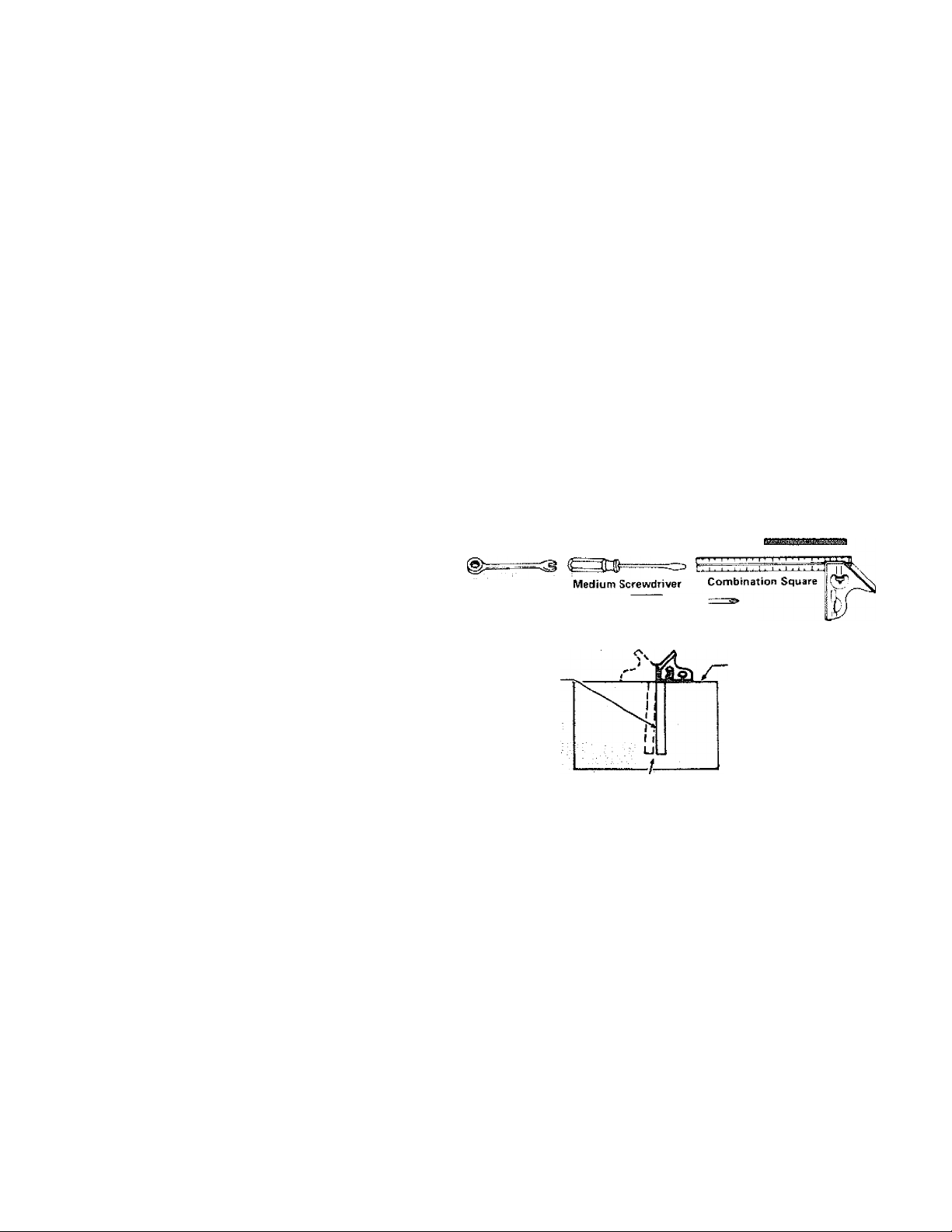

TOOLS NEEDED

#2 Phillips Screwdriver

COMBINATION SQUARE MUST BE TRUE.

STRAIGHT EDGE Of

80AR0 3/4 ' THICK

THIS EDGE MUST BE

PERFECTLY STRAIGHT

SHOULDÔE NO GAP OR OVERLAP HEBE WHEN

SQUARE IS PLIPPEO OVER IN DOTTED POSITION

17

18

19

20

20

22

22

23

Page 7

item

V-Belt, 1/2 X41"

A

Backstop ......................................................... ^

B

Belt, Dust Trap ................................................ ^

C

Motor Pulley Belt Guard .................................. 1

D

Belt Guard Support ......................................... 1

E

Belt Guard Support Bracket ............................ 1

F

"S" Clip ............................................................ 3

G

Pan Head Screw, Type 23,10-32 X 1/2

H

Base and Belt, Table {w/Sanding Belt)

J

Disc Dust Trap ................................................ 1

K

Dust Trap Cover

L

Work Table ...................................................... 1

M

Bag (containing the following loose parts!

N

(Part No. 68035)

Motor Pulley, 2 In. Dia................................... 1

Wrench, 1/2" .................................................... 2

5/32 Setscrew Wrench

Flat Head Machine Screw 10-32 X 1-3/4

Table of Loose Parts

..............................................

.............................................

.................................

..........

............

.....

1

3

1

^

1

4

assembly

The following parts are included with Mode! 113.225931

ONLY.

Item

No. Oty.

‘Loose Parts Bag Part #68062 Containing Following Items;

*A Nut, Hex Head 1/2-13 ................................................ 8

*A Nut Hex 1/4-20.......................................................... 32

*B Screw Truss Hd. 1/4-20 x 5/8

*C Lock washer, 1/4 External

*D Foot, Leveling

E Motor

E Leg ............................................................................. 4

G Channel, Support

H Stiffener, Side ............................................................ 2

J Stiffener, End ........................................................... 2

K Support, Motor ........................................................... 1

P Bracket, Mounting

HARDWARE FOR MOUNTING TOOL & MOTOR

*L Screw, Hex Hd. 5/16-18 x 1-1/2

*C Lockwastier Ext. 5/16

*A Nut, Hex 5/16-18 ...................................................... 6

*M Washer 11/32 ID

*N Bolt, Carriage 5/16-18 x 3/4 .................................... 4

.........................................................................

...........................................................

.....................................................

.....................................................

......................................................

...................................

.......................................

.............................

..........................................

32

32

4

2

.... 1

.... 1

.... 1

.... 1

___

.... 1

.... 1

.... 1

.... 1

.... 1

.... 3

.... 2

.... 2

Qty.

.... 5

. 1

1

. 1

Item

Pan Head Screw, Type 23 8-32 x 3/8

Flat Washer, 21/64x7/3x1/8

Hex, Head Machine Screw 5/16-18x1 ,, ,.

Screw, M Pan Hd. 10-32x9/16

Lockwasher No, 10 Int. Tooth

Hanger, Cable .........................................

Owner's Manual

0

9" Abrasive Disc .........................................

P

Sanding Disc (w/Set Screw)

Q

Belt,Sanding..............................................

R

Bag Assembly, Outlet (Part No. 68064)

—

(Containing the f ollowing loose parts);

Outlet, on/off Power

S

Switch Key

T

Bracket, Switch Mounting

u

Screw, Pan Hd. 8x3/8 ........................

V

Lockwasher, 1/4"

w

Screw; Pan Hd. Machine 1/4-20 x 1/2 ....

X

1

1

2

6

6

Table of Loose Parts

.....

....................

................

.................

.........................................

......................

...............................

............................................

......................

..................................

Page 8

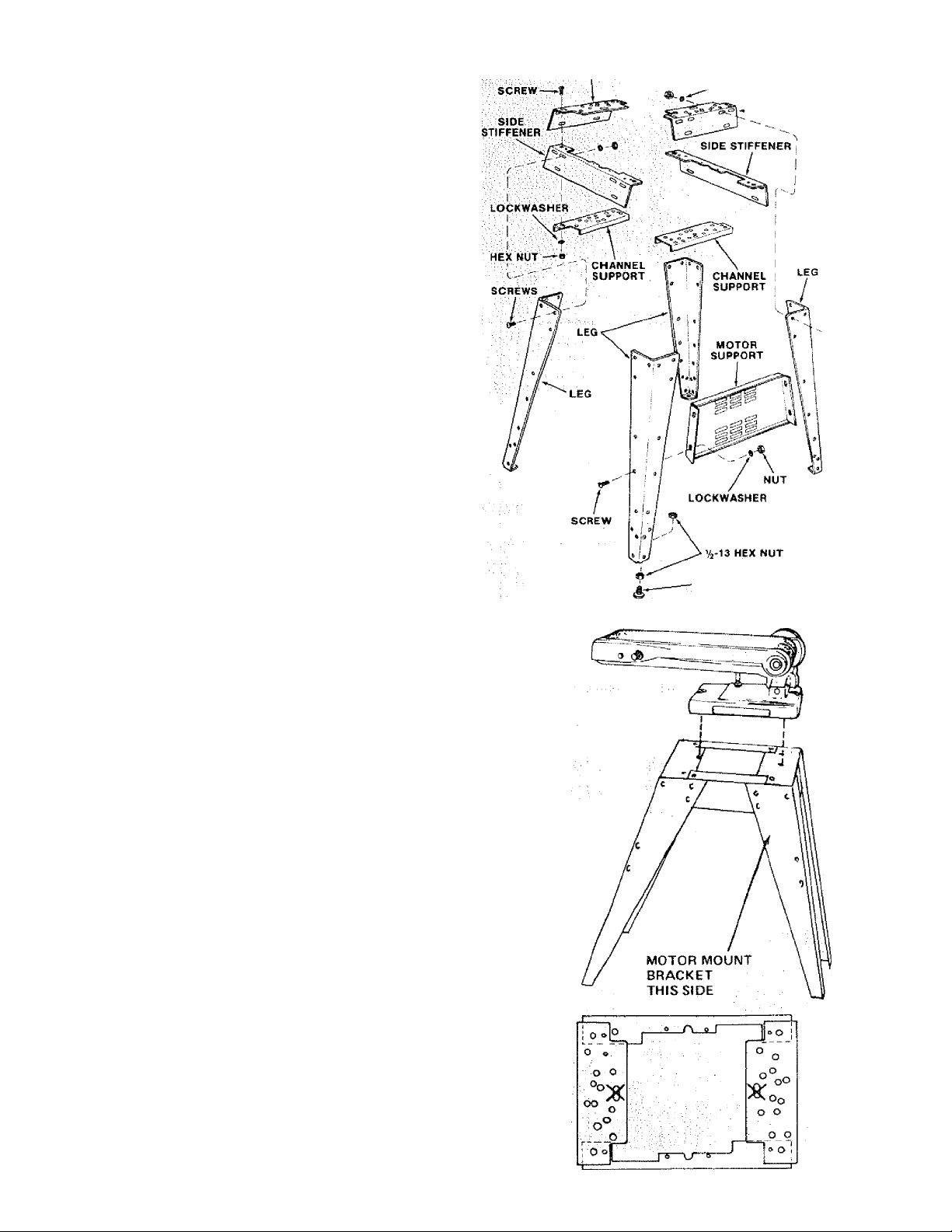

Î^ObiËL 113iZ2S^

i . AssertIbtS; the: tw^ the two (2)

Side Stiffeners using four (4) 1/4-20 Truss head

screwsi The EndiStiffeners are piaced on top of each

Side Stiffener as shbyyn. insert screws through the

; ,9/3Z: inch dianieter holes and finger tighten 1/4-20

END STIFFENER HEX NUT

i ^LOCKWASHER

STIFFENER

END

2, Attach the four (4) legs to the side and End Stiffener

using 1/4-20 screws, lockwashers and nuts as shown.

3: Rerhove!the four (4) Truss head screws which were

assembled: in Paragraph No, One. Place the two (2)

; Support Channels as shown, in position, align holes in

supports with holes in the :Stiffeners, replace

ipckwashers and nuts. Tighten all nuts using 7/16"

//;wrenchv:::,: ' . .

4. Assemble the motor support tosteel legs with 1/4-20

screws and nuts. Motor support can bemounted to

5i Install leveling feet as shown. To level Leg Set, loosen

nut on: inside of leg and turn nut on outside to raise

Adjust all: four ievelers, if necessary,

and then tighten nuts on inside of leg.

: :: NOTE: These levels are not intended for height

adjustment. .....................: i:-, .■

WHEN Installing OR moving the sander.

Avoid DANGEROUS environment. Use the sender in a

drVf indoor placé protected from rairi. Keep work area well

lighted. ■. .. ■ ' : ;■ ■■ ■ ^ \ :: , V

Place the sander so neither the user nor bystanders are

forced to stand iii tine with the abrasive belt or disc:

To aWid injury from unexpected sander movement:

*: Put the sander oh a firm level surface where there is plenty

of room for handling and properly supporting thé

workpiece, .. . : , : : :

• Supportthe sander so it does not rock.

• Bolt the sander to the floor or work surface if it tends to slip,

walk, or slide during normal use. :

To avoid back injury, get help or use recommended casters

when you need to move the sander. Always get help if you

need to lift the sander.

NEVER STAND ON TOOL. Serious injury could occur if the

tool tips or you accidentally hit the cutting toot. Do not store

anything above or near the tool where anyone might stand on

the tool to reach them.

LEVELING

FEET

SCREW

MOUNTfNG BELT AND DISC SANDER ON

CRAFTSMAN STEEL LEG SET.

catalog NO. 9-22236

NOTE; Forillusfrativepui'posesj the Belt and Disc Sander is

shown mounted on the Craftsman Cataiog No. 9^22236

Steel Leg Set. This Leg Set is included with Model No.

113.22593r. :■ ;: v " ■ ■■

Page 9

1. Place the Belt and Disc Sander on the Steel Legs,

position as shown, and align the mounting holes in

the feet of the Belt and Disc Sander with those in the

END STIFFENERS (marked with an X in the

illustration)!

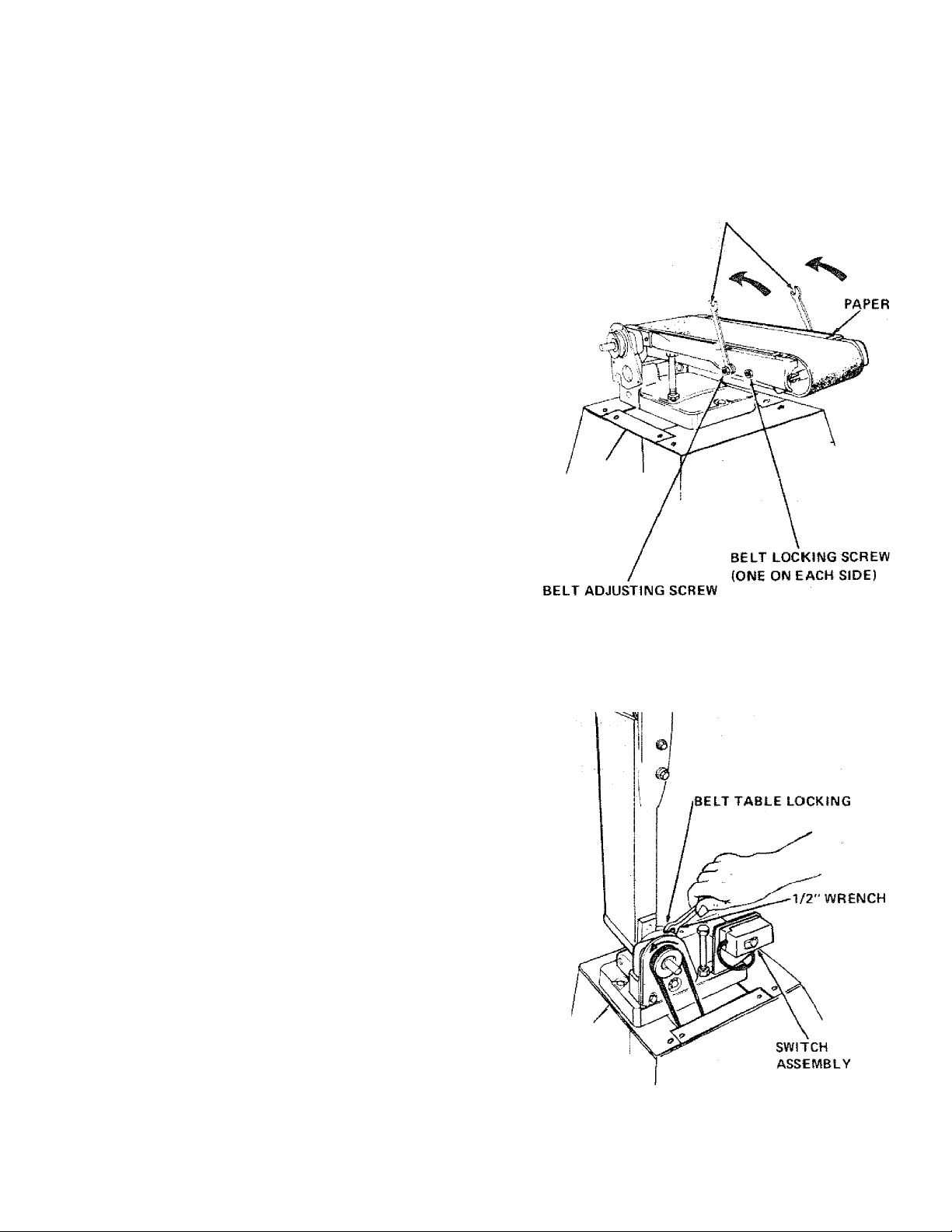

NOTE: The abrasive belt is shipped detached. To

install the belt on the machine:

1. Loosen both belt LOCKING screws, using the 1/2"

wrench furnished with the machine.

2. Turn both of the abrasive belt AJUSTING screws as

shown until they stop. Retighten the two belt LOCK

ING screws so that the idler pulley does not come out

3. Remove the piece of paper.

4. Remove the protective coating, that is applied at the

factory, from the belt table. Use any ordinary house

hold type grease and spot remover.

2. Mount to legs using two 5/16-18 x 2-1/2" hex head

screws, flat washers, external lockwashers, and hex

nuts.

1/2" WRENCH

WARNING: Never use gasoline, naptha, or similar

highly volatile solvents.

NOTE: Do not apply wax to the belt table.

INSTALLING SANDING DISC AND DUST

TRAP

1. Loosen the belt table locking bolts behind the mount

ing bracket using one of the 1/2" wrenches supplied

with your machine.

2. Position belt table vertically and tighten only one of

the bolts.

3. Place the V-Belt over the pulley.

4. Attach the switch assembly to the base using the two

screws and washers packed with the switch.

5. Loosen the bolt that you tightened in step 2. Position

the belt table horizontally, and tighten both bolts.

(ONE ON EACH SIDE)

Page 10

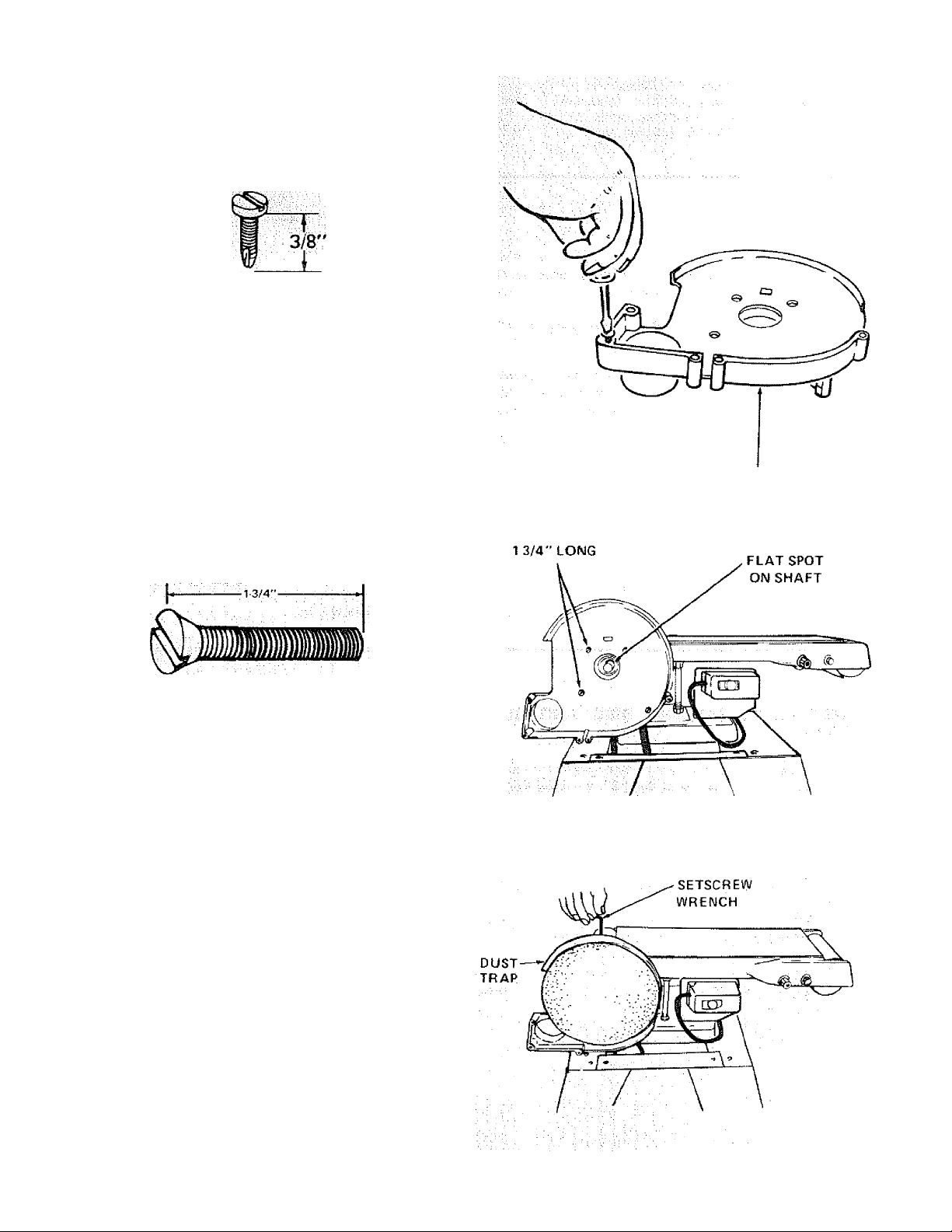

6. Fiind five; 3/Ö'' Pan Head iSelf-Trcàdtng screws from

'W/îamorigitHeddoi^ y :.. ■^ :^;y

7. Place Disc Dust Trap on your workbench and screw in

five Pan Head "Thread Gutting Screws," 3/8" long.

Screw them in all the way.

NOTE: The holes in theTrap are not threaded but the

screws are "Thre^ Cutting Screws" and will cut a

thread as they arc tightened.

DISC DUST TRAP

8. Find four Flat Head Machine Screws 1-%"lohg from

among the loose parts

9; Attach thé Disc Dust Trap with four flat head screws

10. There is a flat spot on the shaft near the end. Rotate

the shaft so that the flat spot is facing up.

11. Place the disc on the shaft so that the set screw is

facing up. Position the disc SO that it is approx. 1/16

inch outward from the edge of the dust trap. :

12. Insert the long end of the 5/32" setscrew wrench

through the hole in the disc housing and into the

. setscrew in the disc. Make sure setscrew is aligned

/with "Flat" on shaft. ■ .

FLAT HEAD SCREWS

5/32 INCH

NOTE: After several hours of operation, check for

i; ■ y . looseness of setscrew and retighten. .

13: Make certain that the metal disc is free of oil and

grease then peel the backing from the 9" abrasive disc

and affix to the sanding disc, ; y

10

Page 11

14, Remove the top right hand screw which you installed in

step 6 and loosen the other three screws.

15. Install the Dust Trap cover and replace the top right

hand screw. Tighten all five screws.

INSTALLING

MOTOR, V-BELT, AND

BELT GUARD

1. Locate the following parts:

QTY. Description

1 Motor

1 "L" Bracket

1 Pulley (approx. 2" Dia.)

1 V-Belt

4 Carriage Bolt 5/16-18 X 3/4

4 Fiat Washer 5/16 i.D.

4 Lockwasher 5/16 I.D.

4 Hex Nut 5/16-18

1 Guard Assembly including a guard support,

guard support bracket, self-threading screws,

and clips.

2. Place motor against the motor mounting bracket and

insert bolts through holes in motor base and then

through holes marked "X" in motor mounting bracket.

DO NOT TIGHTEN BOLTS AT THIS TIME. The "L"

bracket which holds the guard support must be slid

between the motor base and the motor mounting

bracket so motor must be loosely assembled to bracket

at this time.

.........

Slide long leg of "L" bracket between motor base and

motor mounting bracket. Then sandwich the "L" bracket

between the guard support bracket and the guard

support and fasten together with self-threading screws

as shown. Install clips onto belt guard support.

Install the 2" pulley onto the motor shaft flush with the

end of the shaft and tighten the set screw in the pulley

hub against the flat part of the motor shaft.

11

Page 12

5' Riacebèltovër machiné puile^^^ bell into

thé open, end of the guard anci oiit the round openi ng.

MAKE SURE BELtHÀS NOT SLIPPED OFF OF

MACHINE PULLEY FROM STEP 3> DISC AND

DUST TRAP INStALLAtlON.

6 Place the belt onto the motor pulley by rotating the

pulley.

7. Move the motor sideways so that the belt is in the

center of the opening in the top of the base. Visually

tine up the pulleys and V-belt.

8. PUSH dovvrivya rd on motor to apply tensi o n to belt a nd;

tighten motor bolt huts. ^

9. Check guard support before tightening guard support

screws. Guardsupportmustbecenteredaroundmotor

shaft. Tighten screws.

10. Push guard into position on guard support.

ON-OFF SWITCH

WARNIIMG: DON'T CONNECT POWER CORD TO

SURE MOTOR ROTAtlON IS CORRECT. SEE PAGE 5,

The On-Off Switch has a locking feature. THIS FEATURE IS

INTENDED TO PREVENT UNAUTHORIZED AND POSSIBLE

HAZARDOUS USE BY CHILDREN AND OTHERS.

1, Insert key into switch.

NOTE: Key is made of yellow plastic

12

Page 13

2. Tp turn machine on, insert finger under switch lever

and pLill end of switch out.

3. To turn machine OFF . , . PUSH lever in.

Never leave the machine unattended until it has come

to a complete stop.

4. To lock switch in OFF position . . . hold switch IN

with one hand . . . REMOVE key with other hand.

WARNING: FOR YOUR OWN SAFETY, AL

WAYS LOCK THE SWITCH "OFF" WHEN

MACHINE IS NOT IN USE . .. REMOVE KEY

AND KEEP IT IN A SAFE PLACE . . . ALSO

... IN THE EVENT OF A POWER FAILURE

(ALL OF YOUR LIGHTS GO OUT) TURN

SWITCH OFF ... LOCK IT AND REMOVE THE

KEY. THIS WILL PREVENT THE MACHINE

FROM STARTING UP AGAIN WHEN THE

POWER COMES BACK ON.

5. Find plastic cable hanger from among the loose parts.

6. Route the motor cord behind the motor mount,

across the top of the base and plug it into the

receptacle in the side of the switch box,

7. Bring the power cord alongside the motor cord . . .

wrap the plastic cable hanger around the cords and

attach the hanger to the top of the base by pushing

it into a %" diameter hole.

CABLE

HANGER

MOTOR

Page 14

assembly

INSTALLING WORK TABLE

NÖTE; Apply cisat bf paste wax to the work table.

This will make it a little easier to feed.the work; ^

1. Loosen the table positioning screw,

2. Iiisert the table support rod in the hole in the base

until the edge of the table is approximately 1/16"

from the abrasive disc. Tighten the screw.

NOTE: There is a second mounting hole in the base. This

is for mounting the table when the belt is used in a ver

tical position. ; ;

WARNING: To avoid trapping the work or fingers be

tween the babie and sanding surface, the table edge

shbuid be a maximum 1 /16 inch from the sanding

surface, the table should be completely engaged on

the rod.

INSTALLING ABRASIVE BELT-TENSlONlNG

AND TRACKING

WARNING: FOR YOUR OWN SAFETY, TURN

SWITCH "OFF" AND REMOVE PLUG FROM

POWER SOURCE OUTLET BEFORE REMOV

ING OR INSTALLING ABRASIVE BELT.

On the smooth side of the abrasive belt you will find a

"directional arrow." The; abrasive beh must run in the

direction of this arrow so that the splice does not coihe

apart. ■; ■ ■ ■ ' ■ ■ . ■ ■ ■ ■

1. Loosen the two abrasive belt LOCKING screws.

2. Place the abrasive belt over die pulleys with the direcv

; tional arrow pointing as shown. Make siire the abra

sive belt is centered on both pulleys.

Turning the abrasive belt ADJUSTING screws will cause

the idler pulley to move in or out. When the idler pulley

is moved outward, it puts TENSION on the belt.

3, Place both of the Vi" wrenches on the ADJUSTING

screws and puli the wrenches toward you. This will

stretch the abrasive belt. Move the wrenches back and

forth a few times so that you "get the fee!" of the

abrasive belt while it is stretching (TENSIONING),

PULL WRENCHES IN THIS

DIRECTION TO APPLY

TENSION

DIRECTIONAL ARROW

BELT ADJUSTING SCREWS

BELT LOCKING SCREW

Apply a small amount of TENSION to the abrasive

belt by pulling the wrenches toward you, so that the

TENSION feels the sarhe on both wrenches.

14

Page 15

4. Hold the abrasive disc with your left hand to keep it

from turning while pushing the belt in the direction

■ of the arrow. If the abrasive belt slips over the

pulleys, turn both ADJUSTING screws

simultaneously a small amount to apply a little more

tension to the abrasive belt.

6. Adjust the tension so that the abrasive belt does not

slip very easily when pushing it, while you are holding

the disc.

6. Tighten the locking screws,

7. Plug in the power cord. Turn the switch "ON", and

immediately "OFF", noting if the belt moved to the

right or to the left.

H it did not move to the right or left, it is

TRACKING properly.

8. IF THE ABRASIVE BELT MOVES TO THE

RIGHT:

a. Loosen the LOCKING SCREW on the RIGHT.

b. Place wrench on the ADJUSTING SCREW on the

right,

c. Push abrasive belt so it is moving while pulling the

wrench toward you. This will move the abrasive

belt to the left. PUSHING the wrench will move

the belt to the right

d. The abrasive belt is tracking properly when it is

centered on the DRIVE pulley.

IMPORTANT: If you have difficulty tracking the

abrasive belt, apply more tension.

PUSH BELT IN DIRECTION

OF ARROW

BELT

LEFT

MOVING

9. IF THE ABRASIVE BELT MOVES TO THE LEFT:

a. Loosen the LOCKING SCREW on the LEFT.

b. Place wrench on the ADJUSTING SCREW on the

left.

c. Push abrasive belt so it is moving while pulling the

wrench toward you. This will move the abrasive

belt to the right. PUSHING the wrench will move

the abrasive belt to the left.

d. The abrasive belt is tracking properly when it is

centered on the DRIVE pulley.

IMPORTANT: If you have difficulty tracking the

abrasive belt, apply more tension.

INSTALLING BELT DUST TRAP

1. Find one 10 • 32 X 9/16" Pan Head screw and a lockwasher among the loose parts.

15

Page 16

:.-:'i.:-'ÈélòWLtKe;suriacé^W

top. ■

BACKSTOP

IMSTALLtNG BACKSTOP

1, Find one 5/16" X 1" Hex. Head bolt and one flat

washer among the loose parts.

2. Place the washer on the bolt, and screw it halfway

into the mounting hole. Place the backstop into pos

tion and tighten the bolt. When removing the backstoh, loosen the bolt bMt do not remove it.

9eft!ng to know yoiir bèlt and disc sander

WARNING; FOR YOUR OWN Safety TURN

SWITCH "OFF" AND REMOVE PLUG FROM

POWER SOURCE OUTLETBEFORE MAKING

ANY ADJUSTMENTS.

ABRASIVE DISC

4 BACKSTOP

LOCK SCREW

BACKSTOP

1 BELT ADJUSTING

SCREW

(ONE ON EACH SIDE)

BACKSTOP

BACK OF SANDER

WORK

TABLE

3 WORK TABLE 0 BELT

TILT LOCK SCREW STOP SCREW ^

; , : ; i (ONE ON EACH SIDE)

front OF SANDER /

TABLE 2 BELT LOCKING

.........................

16

IDLER

PULLEY

Page 17

1. ABRASIVE BELT ADJUSTING SCREWS

cause the idler pulley to move irt or out for applying

tension to the abrasive iaelt or for tracking it. They

are adjusted using the 1/2" wrenches.

See "Assembly" section ,. . "Installing Abrasive Belt".

2. ABRASIVE BELT LOCKING SCREWS lock

the adjustment mechanism after the abrasive belt is

tensioned and tracking properly. They are locked

using the 1/2" wrench.

BELT ADJUSTING

See "assembly" section . ,

, "Installing Abrasive

Belt".

3. WORK TABLE TILT LOCK SCREW locks

the table. It is locked using the 1/2" wrench.

a. Using a combination square, check the angle of

the table widi the disc.

NOTE; The combirration square must be '"true"—

See start of assembly section on Pg. 6 for checking

method.

b. If the table is not 90® with the disc . . . loosen

tilt lock screw and tilt table.

c. Loosen the lock nut using a 7/16" wrench,

SCREW

(ONE ON EACH SIDE!

d. Strew the stop screw in or out, using a 3/8"

vwrench so that when ithe table touches the stop

screw, the table is 90° to thé disc.

e. Tighten the lock nut.

17

Page 18

getting to know

f. Loosen the tabie positioning lock screw.. . ppsi-

tion the table approximately 1/16" ayyav ffP't’

the abrasive disc. ^ ^ ^ _

g. Tilt the table downward but don't tighten the lock

screw, and position it as close to the disc as ppssible. Using the head of a combination square,

check the angle of the table with the disc.

h. If the table is not 45° with the disc:

i. Raise the table and loosen the lock nut using a

7/16" wrench.

j. : Screw the stop screw in or out, using a 3/8'

wrench so that when the table touches it,: it is 45

with the disc. ■; '

k. Tighten the lock nut.

WARNING: To avoid trapping thé work or fingers

between the tabie and sanding surface; the table must

be repositioned on the rod to maintain a maximum

1/16 inch space between the table and sanding

surface.

on

ISC sonder

4 BACKSTOP LOCK locks the backstop in

place. It is locked using the 1/2" wrench.

5. BELT TABLE LOCKING BOLTS ... lock the

belt table in position. /

To adjust to vertical position; :

a. Remove the backstop,

b. Loosen the two beit table locking bolts using the

1/2" wrench sullied with your machine.

c. Position belt table vertically and tighten the two

bolts.

6. ABRASIVE BELT TABLE STOP can be adj

usted so that the abrasive belt table is level with

the floor w4ien in ahorirontai position.

a. Loosen the lock nut using a 3/4" wrench.

........ ...............

BACKSTOP

BACKSTOP

b, PI ace a level on the abrasive bel t table and using a

3/4-' wrench, screw the stop bolt in or but until

theTableis;ieyel.':\ ■■■' . - ■

18

Page 19

asic ©perofion

BEFORE USING THE SANDER: ^ ^ ^

WARNING: To avoid mistakes that could cause serious, per

manent injury, do not plug the sander in until the following

steps are completed.

• Assembly, (See pages 7-16.)

• Learn the use and function of the ON-OFF switch,

backstop lock screw, bell adjusting screws, belt tocking

screws, work table and work table tilt lock screw. {See

pages 16-18.)

• Review and understanding of all safety instructions and

operating procedures in this manual.

« Review of the maintenance methods for this sander.

(See page 22.)

BEFORE EACH USE;

Inspect your sander.

DISCONNECT THESANDER, To avoid injury from accidental

starting, unplug the sander, turn the switch off and remove

the switch key before changing the setup, sanding disc or

belt or adjusting anything.

CHECK DAMAGED PARTS. Check for;

® alignment of moving parts,

• binding of moving parts,

• broken parts,

• stable mounting, and

9 any other conditions that may affect the way the sander

works.

If any part is missing, bent, or broken in any way, or any

electrical parts don't work properly, turn the sander off and

unplug the sander. REPLACE damaged, missing, or failed

parts before using the sander again,

MAINTAIN TOOLS WITH CARE. Keep the sander clean for

best and safest performance. Follow instructions for lubri

cating.

REMOVE ADJUSTING KEYS AND WRENCHES from tool

before turning it on.

To avoid injury from jams, slips or thrown pieces:

• USE ONLY RECOMMENDED ACCESSORIES. (See

page 22.) Consult this Owner's manual for recommended

accessories. Follow the instructions that come with the

accessories. The use of improper accessories may

cause risk of injury to persons.

• Adjust table to dear the sanding surface by no more than

1/16bf an inch.

» Make sure alt clamps and locks are tight and no parts have

excessive play.

• KEEP WORK AREA CLEAN. Cluttered areas and benches

invite accidents. Floor must not be slippery.

To avoid burns or other fire damage, never use the sander

near flammable liquids, vapors or gases.

Plan ahead to protect your eyes, hands, face, ears.

KNOW YOUR SANDER. Read and understand the owner's

manual and labels affixed to the tool. Learn its application

and limitationsas well as the specific potènti al hazards pecu

liar to this tool.

To avoid injury from accidental contact with moving parts,

don't do layout, assembly, or setup work on the sander while

any parts are moving.

AVOID ACCIDENTALSTARTING. Make sure switchis "OFF"

before plugging sander into a power outlet.

Plan your work.

USETHERiGHTTOOL.Don'tforcetoolorattachmenttodoa

job it was not designed to do.

CAUTION: This machine is not designed for heavy deburring

operations. When finishing metals, sparks or hot fragments

could cause a fire. To avoid this, disconnect any dust col

lecting hose from the sander. Also, remove alt traces of wood

dust from inside dust traps in the sander.

Dress for safety.

Any power sander can throw foreign objects into the eyes. This

can cause permanent eye damage. Wear safety goggles (not

glasses) that comply with ANSI Z87.1. Everyday eyeglasses

have only impact resistant lenses. They are not safety glasses.

Safety goggles are available at Sears retail catalog stores.

Glasses or goggles not in compliance with ANSI Z87,1 could

seriously hurt you when they break.

• Do not wear loose clothing, gloves, neckties or jewelry

(rings, wrist watches). They can get caught and draw you

into moving parts.

9 Wear nonslip footwear.

9 Tie back long hair,

9 Roil long sleeves above the elbow.

• Noise levels vary widely. To avoid possible hearing dam

age, wear ear plugs or muffs when using sander for hours at

a time.

9 Sanding operations are usually dusty. Wear a dust mask

along with the safety goggles.

Inspect your workpiece.

Make sure there are no nails or foreign objects in the part of

the workpiece to be sanded.

Plan your work to avoid THROWBACKS—when the work

piece catches on the sanding beit or disc and is torn from you r

hands.

• Make sure there's no debris between the workpiece and its

supports.

• When sanding irregularly shaped workpieces, plan your

work support so it will not slip and be pulled from your

hands.

Use extra caution with large, very small or awkward work

pieces:

• Never use this tool to finish pieces too small to hold by

hand.

• Use extra supports (tables, saw horses, blocks, etc.) for

any workpieces large enough to tip when not held down to

the tabletop.

• NEVER use another person as a substitute for a table exten

sion, or as additional support for a workpiece that is longer

or wider than the basic sander table, or to help feed, sup

port or pull the workpiece.

• When finishing on the Disc, always press the workpiece

against the "Down" side of the disc. Sanding against the

side coming up from under the table could damage the

work by making it "chatter," or tear the work from your

hands and throw it,

• Sand only one workpiece at a time.

• Cleareverythingexceptthe workpieceandrelated support

devices off the table before turning the sander on.

19

Page 20

bosic operation

Plan the way you will hold the workpiece from start to finish.

Avoid awkward operatibns and hand positions yvhere a sud

den slip could cause fingers or hand to move into a sanding

surface. Keep fingers away from wherethebeitgoesintothe

dust trap,

DON'T OVERREAC H, Keep good footing and balance.

Keep your face and: body to one sjde, out of tine with a pos

sible throw/back. ;

WHENEVER SANDER IS RUNNING.

WARNING: Don't let familiarity (gained from frequent use of

yoUr belt and disc sander) cause a careless inistake. A care

less fraction of a second is enough to cause a severe injury.

Before starting your Cut, watch the sander While it runs. If it

rhak^s ah unfamiliar noise or vibratesa lot. Stop immediately,

■Turn the sander off. Unplug the sander. Do not restart until

finding arid correcting the problem..

Make sure the sanding disc turns counterclockwise before

. using the sander. . : ■ ■ : : ; ; . :

SURFACE FINISHING ON THE

■;ABFtAsiVE:'BELT.

KEEPGHILDREN AWAY, Keepall visitors asafedistance from

the sander. Make sure bystanders are clear of the sander and

workpiece. ^

DON'T FORCE TOOL, it will do the job better and safer at its

designated rate. Press the workpiece against the sanding

material only hard enough to let it sand without bogging

down or binding. :

Before freeing any jammed material;

• Turn switch "OFF."

• Unplug the sander.

• Wait for all moving parts to stop.

To avoid throwback of the workpiece, use workpiece supports

for ail flat surface sanding.

BEFORE LEAVING THE SANDER;

Waitfor all moving parts to stop.

Make workshop child-proof. Lock the shop. Disconnect

master switches. Remove the yellow switch key. Store it

away from children and others not qualified to use the tool.

f.FLATSUBFAdES. .'tv .

Ftold the work piece firmly with both hands, keeping

fingers away from riie abrasive belt.

Keep the end bu^ed against the backrtop and move the

work evenly across the abrasive belt. Use extra caution

when finishing very thin pieces.

For finishing long pieces* remove the backstop.

Apply only enough pressure to etiow thè abrasive belt

to remove material, if the abrasive belt stalls and the

belt pUtteys slip ; while ¡applying irioderate pressure

the workpiece, the abrasive belt requires more tension.

END FINISHING ON THE

ABRASIVE BELT.

It is more convient to finish the ends of long work

pieces with the abrasive belt in a vertical position.

Move ihe work eveniy across *e abrasive belt. For

accuracy, use a miter guage. ;

The table may be tilted for beveled work.

Getting To Know Your Finishing Machine section

for adjusting thé abrasive belt table and the work table.

20

Page 21

FINISHING CURVED EDGES ON THE

ABRASIVE BELT

CURVED EDGES

Finish outside curves on the abrasive belt and inside

curves on the idier pulley.

FINISHING SMALL END SURFACES AND

CURVED EDGES ON THE ABRASIVE DISC

Move the work across the "Down Side" of the face of

the abrasive disc. For accuracy, use a miter gauge.

NOTE; Use a combination square to square the miter

gauge to the face of the disc, if it is not square, pull out

the index pin, loosen the miter gauge knob and move the

miter gauge slightly until it is square. Without moving

the miter gauge, tighten the knob securely-

Applying the workpiece to the "Up Side” could cause it

to fly up (kickback) which could be hazardous.

The table may be tilted for beveled work.

Page 22

riMiifeiiarîcé

WARNING: FOR YOUR OWN SAFETY> TURN

SWITCH "OFF'' AND REMOVE PLUG FROW

POWER SOURCE OUTLET BE FORE ADJUST

ING, MAINTAINING, OR LUBRICATING

YOUR FINISHING MACHiNE.

Keep your machine and your workshop clean. The dust

traps around the abrasive disc and the abrasive belt are

designed to deflect most of the fine dust. They should be

connected to a Vac for most efficient dust removal.

WARNING: DO NOT ATTACH A VACWHEN FINISHING

IRON OR STEEL. THE SPARKS COULD IGNITE THE

DEBRIS AND CAUSE A FIRE.

tf power cord is worn or cut, or damaged in any way,

have it replaced immediately.

Frequently Wow out any dust that may accumulate

inside the motor.

A coat of automobile-type wax applied to the work

table will make it a little easier to feed the work while

finishing.

Do not apply wax to the abrasive belt table because the

belt could pick up the wax and deposit it on the pulleys,

causing the’belt to slip.

MOTOR MAINTEMAWCE AMD

LUBRICATiOM

1. The bearings, in both end shields of the motor, have been

lubricated at the factory with correct lubricant. No other

part of the motor requires lubrication.

2. Re-lubricate motor bearings in accordance with the

instructions on the nameplate. Be sure to wipe oil dirt or

grit if present around oil hole caps to prevent any possibility

of foreign material contaminating the oil wicks that supply

the bearings with oil. Use a good grade of medium weight

mineral oil. such as automobile engine oil, SAE 20.

3. If disassembly of the motor is necessary, it should be

returned to your nearest Sears retail or mail-order store in

order to prevent voiding the guarantee.

NOTE: The speed of this rnotor cannot be regulated or

changed.

4. Every effort should be made to prevent foreign material

from entering the motor. When operated under conditions

likely to permit accumulations of dust, dirt, or waste within

the motor, a visual inspection should be made at Irequent

intervals. Accumulations of dry dust can usually be blown

out successfully.

NOTE: Motors usedon wood working tools are particularly

susceptible to the accumulation of sawdust and wood chips

and should be blown out or "vacuumed" frequently to

prevent interference with normal motor ventilation and

proper operation of the centrifugaliy-operated starting

switch.

iiibricafiori

The BEARINGS in this machine are packed with grease at

the factory. They require no further lubrication.

Periodically 1 ubricate the cams and shafts in the idler pulley

mechanism with Silicon Spray;

.................

,

SEARS RECOMMENDS THE

FOLLOWING ACCESSORIES

ITEM CAT. NO.

Steel Stand

Caster Set . .............................................

Niiter Gauge .............................................................. 9-29929

Pressure-Sensitive cement

Abrasive Belts and Disc

Steel Legs

Power Tool Know How Handbooks

Radial Saw .............................................................

Table Saw .................................................................9-2918

Sears may recommend other accessories not listed in the

manual. See your nearest Sears store or catalog department

for other accessories. Do not use any accessory unless you

have received and read complete instructions for its use.

...

..............................................................9-22213

..........................................

..............................

................................................................

9-22222, 9-22221

SEE CATALOG

9-22236

9-2917

9-2220

22

Page 23

trouble shooting

WABWING: FOR YOUR OWN SAFETY, TURN

SWITCH "OFF" AND REMOVE PLUG FROM

POWER SOURCE OUTLET BEFORE TROUBLE

SHOOTING YOUR SANDER,

TROUBLE SHOOTING CHART

TROUBLE

Motor wit! not run.

Machine slows down

when finishing.

Abrasive Belt Slips

Abrasive Belt runs

off pulleys.

Wood burns while

finishing.

PROBABLE CAUSE

1. Defective On-Off switch.

Defective switch cord.

Defective switch box receptacle,

2. Motor protector open, (only if

your motor is equipped with an

overload protector),

3. B u rn ed ou t mo to r.

1. V-Belt too loose.

2. Applying too much pressure to

workpiece.

3. Too much tension on abrasive

belt.

1. Not enou^ tension.

1. Not tracking properly ,

2. Not enou^ tension.

. . .

1. Abra&ive disc or belt is glaz^ with

sap.

REMEDY

1. R e pla ce d ef ec tiv e pa rts b ef ore u sin g be lt disc

Sander aga in .

2. Res e t p rot ec to r a fte r mo to r h a s c oo le d.

3. C on su lt Se a's S e ivic e . A ny a tte m pt to re pa ir thi s

mo tor m ay c re ate a H AZ A RD u n les s firp a ir i s

don e by a qu al ifie d se rv ice t ec hn ici ar ,. R e pa ir

ser vic e is av ail ab le at yo ur n ea re st Se a rs St ore .

1. Increase belt tension, see Assernbly Section,

"Motor Pulley Belt Guard and Motor

Installation."

2. Ease up on pressure.

3. Adjust tension, see Assembly Section, "Installing

and Adjusting Abrasive Beit."

1. Adjust tension, see Assembly Section, "Installing

and Adjusting Abrasive Belt."

1, Adjust tracking, see Assembly Section, "Instaliirrg

and Adjusting Abrasive Belt."

2. Adjust tension, see Assembly Section, "installing

and Adjusting Abrasive Beit."

1, Replace disc or belt.

23

Page 24

TROUBLE SHOOTING - MOTOR

NOTE: Motors used oti wopd'Wbrking tools are particularly susceptible to the accumulation

of saviidust ànd Wdod chips and should be blown out or “vacuunied” frequently to prevent

Ititérferericé with, noritial motor: ventilation and proper operation of the centrifugally-

,;dperated'startirig;switch:/ ^ / .

TROUBLE

EKcesslve hofse.

Motor fails to develop

lull power. NOTE;

LOW VOLTAGE: (Power

output of motor

.decreases rapidly with . ;

decrease.iii voltage at .

motor terminals. For

exarhple, a reduction of

. 10% iri voltage causes : .

a reductiori of 19% in

rnaxtmum power butpüt

. of'Which the fn otor is

capable, and a reduction

of 20% in voltage causes

a reduction of 36% in ■

maximum power output.)

Motor starts slowly

òr fails to cóme up

to full speed.

PROBABLE CAUSE

1. Motor. 1. Have rpotor checked by qualified service

1. Circuit overloaded with

lights, appliances and

other motors.

2. Undersize wires or circuit

too long. ;

,3. General overloading of

power company

facilities. .

IV Low voltage Will not

trip relay: :

2. Windings burned out

Of open ;

3. Starting relay not

operating, .

technician. Repair service is available at

your nearest Sears store,

1. Do not use other appliances or motors on

same circuit when using the saw.

2. Increase wire sizes, or reduce length of wiring.

See. "Motor Specifications and Electrical

. : Requirements" section.

3. Request a voltage check from the power

company.

1: Request voltage check from the power company,

2. Have motor repaired or replaced.

3. Have relay replaced- ..........................

REMEDY

Motor overheats.

Starting switch iri

motor will not

operate.

Motor stalls

(resulting in blown

fuses or tripped

circuit breakers).

Frequent opening of

fuses or circuit

breakers.

t: Motor overloaded-

2. Improper^cooling: (Air

. circulafipn restricted:

: through motor due to

sawdust, accumulating.

1, Burned switch contacts :

(due to extended .

hold-in periods caused

by low line voltage, etc )

2, Shorted capacitor

3, Loose or broken

connections.

1. Starting switch not

operating.

2. Voltage loo low to permit

motor to reach operating

speed.

3. Fuses or circuit breakers

do not have sufficient

capacity.

1. Motor overloaded.

2. Fuses or circuit, breakers

do not have sufficient

: capacity, .■ ;

3. Starting svvitch not

, operating. (motor does

not reach speed).

1. Feed work slower into belt or disc.

•2- Clean out sawdust to provide normal air

circulation through rnotor.

■ See "Maintenance and Lubrication" section.

1. Have switch replacedand request a voltage check

: from the power company.

2. Have capacitor tested and replace if defective.

3. Have wiring checked and repaired.

1. Have switch replaced.

2. Request voltage check from the power company.

3. Install proper size fuses or circuit breakers.

1, Feed work slower into belt or disc.

2, Install proper size fuses or circuit breakers.

3, Have switch replaced.

24

Page 25

repair parts

CRAFTSMAN BELT AND DISC SANDER MODEL NO. 113.225900 & 113.225931

J

FIGURE 1 PARTS LIST

SUPPLIED WITH MODEL 113.225931 ONLY

Key

No.

10

Part

No.

62 SI 4

1

60314

2

STD541Q25

3

STD551225

4

68060

5

68059

6

62615

7

68061

8

STI1541050

9

803835

68062

tTheSB items all contained in Loose Parts Bag, Part No. 68062.

Leg

t Screw, Truss Hd. 1/4-20 x 5/8

t*Nut, Hex 1/4-20

T* Lockwasher, 1/4 External

Channel, Support

Stiffener, Side _

Stiffener, End

Support, Motor

t*Nut, Hex 1/2-13

t Foot, Leveling

t Bag of Loose Parts (Not illustrated)

Description

Key

No.

HARDWARE FOR MOUNTING TOOL & MOTOR

—

Part

No.

STD523125

STD551131

STD541231

STD551031

STD532507

^Standard Hardware Item - f^ay be Purchased Locally.

t*Screw, Hex Hd. 5/16-18x2-1/2

t*Lockwasher, External 5/16

t*Nut, Hex Jam 5/16 x 18

t’Washer, 11/32 x 11/16 x 1/16

t*Bolt, Carriage 5/16-18 x 3/4

25

Description

Page 26

m

CRAFTSMAN BEIT AND DISC

SANDER MODEL NO. 113.225900 8.113.225931

Q

-22

17 2.3 17 T

I >_ -Ls

trt

FIGURE 2

Page 27

CRAFTSMAN SELT AND DISC SANDER MODEL NO. 113.225900 & 113.225931

FIGURE 2 PARTS LIST

N)

Key

rjü.

1

2 68033

STD503103

3

4

Part

No.

38834

tDisc, 9 inch Abrasive

Description

Disc, Sanding (w/Set Screwl

‘Screw, Socket Head Set, 5/16-18 x 5/16

30646 tPuMey (w/Set Screw) 2 1/2 dia. x 1/2,

Key

No.

36 47813

37 60254 Bracket. Support

38

39

STD601105

"V" Groove 5/8 bore. Keyed

5 STD600803

'Screw, Type 23, Pan No. 8-32 x 3/8

6 68003 Cover, Housing

7

133656

'Screw, Machine Flat Head No. 10-32

X 1-3/4

8

9 68069

68004 Housing, Disc

Shaft, Drive

10 STD580025 Key, Woodruff, No. 9

11 38812

12

STD523115

ST0551131 'Lockwasher, 5/16 48 68015

13

14

68005 Bracket, Mounting 49

15 STD551031

Key, Woodruff

*Screw. Hex Head 5/16-18 x M/2

'Washer, 21/64 X 7/8 X 1/8

16 68068 Bracket, Tabie Support

17

18 60434

19 STD523110

20 47222

21

22

37158 Ring, Retaining 5/8

Bearing, Bal!

'Screw, Machine Hex Head 5/16-18 x 1

Backstop

47190 Puliey, Drive {w/Set Screw)

STD502502 'Screw, Socket Head Set, 1/4-20

X 5/16

23

24

25

350 9

68006 Trap, Dust

STD5S1210 'Lockwasher No. 10 Ini. Tooth

26 STD511105

27

28

29

30

680 70 Table. Belt 63

STD551037

68007

STD510605

Bearing Balt

'Screw Mach. Pan Hd. 10-32 x 9/16

'Washer, 3/8 x 3/4 x 1/16

Nut, Cam

'Screw, Machine Pan Slotted

No. 6-32 X 7/16

31

32

33

68008

47815

68009

34 68010

ST0510803

36

L__

' Siunildfci HhuJwüre lien'^ May l-Se P^uri:ha’',íXÍ LocaMy.

1 Stock tteoi May IJti ‘fOCunx! through the* Hardware Department oí íthjsI Sear? or Catalog Of<iei Ho;.

Cam, Left Hand

Spring

Cam, Right Hand

Guard, Idler

'Screw, Machine Pan Head

No. 8-32 X 3/8

40 60255 "S" Clip

41

42 STD304410

43

44 47622

ST0571807

45

46

47

50

51

52

53 STD512505

54

55

STD541250

56

STD523107

57

STD523122

58

59

ST0541026

60

STD522512

61

62

64 ST D 57 18 12 ■pi n. Ro il 3/1 6 X 1-1 /4

65

66

87 68072

68

Part

No.

Description

t8eh. Sanding

60253

Support, BeSt Guard

'Screw, Type 23 Pan Head

No, 10-32 X 1/2

60252 Guard, Belt

iV-8elt, 1/2x41"

62023

tPulley, (w/Set Screw) 2" Dia. x 1/2

"V" Groove 5/8 Bore

Shaft, Control

Pin, R-oll 3/16 X 5/8

38538 Ririg, Retaining 5/8

38536 Bearing, Ball

Base

47621

60096

47414

68017

Shaft, Idler

'Wrench Hex,, 5/32

Pulley, Idler

Wrench

'Screw, Machine Pan Head 1/4-20 x 1/2

ST0551125

'Lockwasher, 1/4

100167 'Bolt, Hex. Head. 1/2-13 x 4-1/2

'Nut, Hex., 1/2-13

8o!t, High Strength, 5/16-18 x 3/4

Bolt, High Strength, 5/16-18 x 2-1/4

68016

Support Assembty, Base

'Nut, Hex,, 1./4-20

'Screw, Mac h ine H ex . He ad , 1/4-20 x 1 -1 /4

38738

941 61 87

6B055

680 36 Han ge r, C ab le

Bracket, Table Lock

'Sc rew , T y -'T " 5/ 16 -1 8 X 3,'4

Hex . He ad

Tab ie , W o rk

Motor (Model 113-225931 j ONLY

69184

68073

68035

Bracket, Mounting

Ow ne r's M an u ai ÍNot illu st ra ted )

Bag o f L oo se P a rts (N o ! il ius trs io d!

68064 fiaq of Lo os e Pa rt s ( No t Hkistraied]

Page 28

CRAFTSIVIAN BELT AND DISC SANDER MODEL 113,225931

NOTE:

Key

No,

1

2

■ .3

Part

No.

60306 Screw, 8-32 x 3/8, Thread

64088

64258 ;

Cutting, Slotted, Serrated

■ ■ Hd;, . /■- ■

Cover, Terminal

Cord with Plug

Description

2B

Page 29

MOTOR CONNECTIONS

WARNING: FOR YOUR OWN SAFETY, TURN SWITCH

"OFF" AND REMOVE PLUG FROM POWER SOURCE

OUTLET BEFORE PROCEEDING.

1. Open motor connector box cover located on left end of

motor (viewed from rear of saw) using a flat blade

screwdriver.

2. Remove GREEN SCREW and lockwasher and insert

screw through round metal terminal on the end of the

GREEN wire of power cord with lockwasher between

terminal and motor frame. (See iilus.)

3. Reinsert GREEN SCREW in the threaded hole. Tighten

securely.

4, insert terminal end of WHITE wire on spade terminal

marked T4 on the motor. Push terminal firmly until

seated.

5. Insert terminal end of BLACK wire on spade terminal

marked T1 on the motor. Push terminal firmly until

seated.

6, Close motor connector box being sure that power cord is

seated in the largest strain relief groove, and tighten box

cover screws.

TERMINAL

29

Page 30

Cf?AFTSMAN BELT AND DISC SANDER MODEL NO. 113.225900 & 113.225931

FIGURE 4 PARTS LIST

ON\OFF POWER OUTLET 60382 AND

MOUNTING BRACKET

Key

No.

__ ■ ■

1

2

3

4 60374

5 60376

6

7

8

*Standard Hardware tten^ - May be Purchased LocaiSy.

» Does Not Include Key No. 3,

Order Separately If Required.

tStockllem—May be secured through the Hardware Deparlment Of

' . ; ^ most Sears Retail Stores or Catalog Order Houses.

NOTE; Shipping arrd handling charges for standard hardware items (identified by *) such as nuts, screws, washers, etc., make

: boy trig these ¡terns by mail uneconom ¡cat To avoid shipping and handling charges, you may obtain most of these

locaity. \ V, 'O' ' .. . ; . : . . , '

Part

No.

60382

60375

60378 Housing, Switch

9-22255

448007 Screw, Pan Hd. No. 6 x 3/4

68066

STD600803 *Screw, Pan Hd. Plastite No. 8 x 3/8

• On/Off Power Outlet

Cord, Molded

tKey, Switch

Switch, Locking

Cover, Switch

Bracket, Switch Mounting

Description

30

Page 31

HOTES

31

Page 32

owners

manual

BEL T AND DISC SANDER

SERVICE

MODEL NO.

113.225900

BELT AMD DISC

SANDER ONLY

MODEL NO.

113.225931

BELT AND DISC

SANDER/WITH

LEGS AND MOTOR

HOW TO ORDER

REPAIR PARTS

Now that you have purchased your Belt & Disc Sander should a

need ever exist for repair parts or service, simply contact any

Sears Service Center and most Sears, Roebuck and Co. stores.

Be sure to provide all pertinent facts when you call or visit.

The model number of your Belt and Disc Sander will be found

on a plate attached to your sander at the right-hand side of the

base.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE

FOLLOWING INFORMATION:

PART NUMBER

MODEL NUMBER

113.225900 OR

113.225931

Alt parts listed may be ordered from any Sears Service Center

and most Sears stores. If the parts you need are not stocked

locally, your order will be electronically transmitted to a Sears

Repair Parts Distribution Center for handling.

PART DESCRIPTION

NAME OF ITEM

Belt And Disc Sander

Sold by SEARS, ROEBUCK AND CO., Chicago, IL. 60684 U.S.A.

Part No. 66073 Form No. SP4928-2 Printed in U.S A

Loading...

Loading...