Page 1

MODEL NO.

113.213702

DRILL PRESS ONLY

113,21378(}

DRILL PRESS WITH

1/2 HP MOTOR

Serial

Number ...........................

Model and serial

number may be found

at the rear of the head.

You should record both

model and serial number

in a safe place for

future use.

CRRFTSMRNo

i

75-I/2 INCH

CAUTION-

Read GENERAL

and ADDITIONAL

SAFETY

INSTRUCTIONS

carefully

Sold by SEARS, ROEBUCK AND CO., Chicago, iL. 60684 U.S.A.

Part No. 71190 ..P_i,_,_,,4.iq. U.S.A

o

DRILL PRESS

• assembly

, operating

• repair parts

Page 2

FULL ONE YEAR WARRANTY ON CRAFTSMAN DRILL PRESS

If within one year from the date of purchase, this Craftsman Drill Press fails due to a defect in material or

workmanshi p, Sears will repair it, free of charge.

WARRANTY SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS STORE

OR SERVICE CENTER THROUGHOUT THE UNITED STATES.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to

state.

SEARS. ROEBUCK AND CO., SearsTower, BSC 41-3, Chicago, IL 60684

eneral safety instructions for power fools

g

1.

KNOW YOUR POWER TOOL

Read the owner's manual carefully. Learn its

application and limitations as well as the specific

potential hazards peculiar to this tool.

.

GROUND ALL TOOLS

This tool is equipped with an approved 3-conductor

cord and a 3-prong grounding type plug to fit the

proper grounding type receptacle, The green conductor

in the cord is the grounding wire. Never connect the

green wire to a live terminal.

3. KEEP GUARDS IN PLACE

in working order, and in proper adjustment and

alignment.

4. REMOVE ADJUSTING KEYS

AND WRENCHES

Form habit of checking to see that keys and adjusting

wrenches are removed from tool before turning it on.

5. KEEP WORK AREA CLEAN

Cluttered areas and benches invite accidents. Floor

must not be slippery due to wax or sawdust.

6. AVOID DANGEROUS ENVIRONMENT

Don't use power tools in damp or wet locations or

expose them to rain, Keep work area well lighted.

Provide adequate surrounding work space.

. KEEP CHILDREN AWAY

All visitors should be kept a safe distance from work

area.

8. MAKE WOR KSHOP KID-PROOF

with padlocks, master switches, or by removing

starter keys.

9. DON'T FORCE TOOL

It will do the job better and safer at the rate for which

it was designed.

10. USE RIGHT TOOL

Don't force too! or attachment to do a job it was not

designed for.

11. WEAR PROPER APPAREL

Do not wear loose clothing, gloves, neckties or jewelry

(rings, wrist watches) to get caught in moving parts.

Nonslip footwear is recommended. Wear protective

hair covering to contain long hair. Roll long sleeves

above the el bow.

12. USE SAFETY GOGGLES (Head Protection)

Wear Safety goggles (must comply with ANS Z87.1) at

a!l times. Everyday eyeglasses only have impact

resistant lenses, they are NOT safety glasses. Also, use

face or dust mask if cutting operation is dusty, and ear

protectors (plugs or muffs) during extended periods of

operation,

13. SECURE WORK

Use clamps or a vise to hold work when practical. It's

safer than using your hand, frees both hands to operate

tool.

14. DON'T OVERREACH

Keep proper footing and balance at all times.

15.

MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and

changi ng accessories.

16.

DISCONNECT TOOLS

before servicing; when changing accessories such as

blades, bits, cutters, etc.

17.

AVOID ACCIDENTAL STARTRNG

Make sure switch is in "OFF" position before plugging

in.

18.

USE RECOMMENDED ACCESSORIES

Consult the owner's manual for recommended

accessories. Follow the instructions that accompany

the accessories. The use of improper accessories may

cause hazards.

19, NEVER STAND ON TOOL

Serious injury could occur if the tool is tipped or if the

cutting tool is accidentally contacted.

Do not store materials above or near the tool such that

it is necessary to stand on the tool to reach them.

20. CHECK DAMAGED PARTS

Before further use of the too!, aguard or other part that

is damaged should be carefully checked to ensure that it

will operate properly and perform its intended function.

Check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other

conditi0r_s that may ,affect its operation. A guard or

other part that is damaged should be properly repaired

or replaced.

21. DIRECTION OF FEED

Feed work into a blade or cutter against the direction

of rotation of the blade or cutter only.

22. NEVER LEAVE TOOL RUNNING

UNATTENDED

Turn power off. Don't leave tool until it comes to a

complete stop.

Page 3

additional safety instructions for drill presses

WARNING: FOR YOUR OWN SAFETY, DO NOT

ATTEMPT TO OPERATE YOUR DRILL PRESS UNTIL

8T IS COMPLETELY ASSEMBLED AND nNSTALLED

ACCORDING TO THE RNSTRUCTIONS . .. AND UNTIL

YOU HAVE READ AND UNDERSTAND THE

FOLLOWING:

1,

GeneraR Safety instructions for Power Tools . Page 2

2.

Getting to Know Your Drill Press .......... Page 13

3.

Basic Drill Press Operation ............... Page 16

4.

Adjustments .......................... Page 17

5.

Maintenance .......................... Page 18

6.

Stability of Drill Press

If there is any tendency for the drill press to tip over or

move during certain operations such as shaping, the drill

press should be bolted to the floor.

If the workpiece is too large to support with one hand,

provide an auxiliary support.

7,

Location

The drill press should be positioned so neither the

operator nor a casual observer is forced to stand in line

with a potential Kickback.

8.

Kickback

A kickback occurs when the workpiece is suddenly

thrown in the OPPOSITE direction to the DIRECTION

OF FEED; WHICH CAN CAUSE SERIOUS INJURY.

Kickbacks are most commonly caused by:

a. Relaxing your grip of the workpiece while

shaping or routing.

b. Taking too heavy a cut while shaping or routing.

c. Ignoring the instructions for shaping or routing.

9.

Protection: Eyes, Hands, Face, Ears, Body

WARNING: FOR YOUR OWN SAFETY DON'T

WEAR GLOVES WHEN OPERATING A DRILL

PRESS

a. If any part of your drill press is malfunctioning,

has been damaged or broken ... such as the

motor switch, or other operating control, a

safety device or the power cord ... cease

operating immediately until the particular part

is properly repaired or replaced.

b. Wear safety goggles that comply with ANS

Z87.1, and a face shield if operation is dusty.

Wear ear plugs or muffs during extended periods

of operation.

c. Never place your fingers in a position where

they could contact the drill or other cutting

tool (router bit, shaper cutter, etc.) if the

workpiece should unexpectedly shift. (For

instance, hold-down/push blocks must be used

when shaping on the drill press to keep hands

remote from the cutter if a kickback should

Occur.)

d. Never operate drill press with protective cover

on the unused shaft end of the motor removed.

e. Position workpiece to butt against the column

whenever possible - if it is too short, clamp

solidly to the Table - this is to prevent the drill

bit from grabbing the work from your hands,

which could result in personal injury. A drill

press vise must be fastened to the table.

f. Never perform any operation "free-hand"

(hand-holding workpiece rather than support it

on the Table), except wire brushing and

polishing - Wear Safety Goggles!

g- Never perform internal or curved shaping

operations. Perform straight line shaping ONLY

(with the Shaper Fence Accessory).

h. Never perform any operation by moving the

Head or Table with respect to one another. Do

not pull the motor switch "ON" or start any

operation before checking that Head and Table

Lock Handles are clamped tight to Column, and

Head and Table Support Collars are correctly

positioned.

i. Before pulling the rnotor switch "ON", be

positive the belt guard is down, the Chuck is

installed properly, and the drill or other cutting

tool is securely clamped in the chuck.

j. Before starting the operation, jog the motor

switch to be sure the drill or other cutting tool

does not have excessive runout or cause

vibration.

k. Do not operate the Drill Press unless the Depth

Stop and Stop Nut are installed and the Depth

Stop clamped to the Depth Stop Rod.

I. Never pull out on the hub of the quill Hub

Assembly unless you first grasp and support the

Quill, otherwise the Quill will drop and damage

may result.

m. Use the spindle speed recommended for the

specific operation and workpiece material -

refer to panel on right side of the Head for

drilling information, and for accessories, to the

instruction sheets that accompany the

accessories.

n. If workpiece overhangs the Table such that it

will fall to floor if unsupported, clamp it to the

Table or provide auxiliary support.

o. Use fixtures for. unusual operations to

adequately hold, guide and position workpiece

for best quality and minimum hazard.

p. Be sure to lock Quill securely for all routing,

sanding, surfacing, shaping, and dovetailing

operations.

q. Never climb on the drill press Table.

r. Lock the motor Switch and put away the Key

when leaving the drill press.

s. DO NOT perform layout, assembly, or setup

work on the table while the cutting toot is

rotating.

10. Use only accessories designed for this drill press.

a. Holesaws must NEVER be operated on this drill

press at a speed greater than 380 RPM.

b. Drum sanders must NEVER be operated on this

drill press at a speed greater than 720 RPM.

c. Do not exceed the speed recommended for the

drill size in wood when using the mortising bit

and chisel.

(See chart on R.H. trim panel of the drill press.)

d. Do not instatl or use any drill that exceeds 7" in

iength or extends 6" below the chuck jaws.

11. Note and Follow the Safety Rules that Appear on the

Panel on the Left Side of the Head:

DANGER: FOR YOUR OWN SAFETY: 1, READ AND UNDER-

STAND OWNERS MANUAL BEFORE OPERATING MACHINE.

2. WEAR SAFETY GOGGLES. 3, DO NOT WEAR GLOVES,

NECKTIE OR LOOSE CLOTHING- 4. SECURELY CLAMP WORK

TO TABLE IF tT iS TOO SHORT TO CONTACT THE COLUMN

WHEN iN OPERATING POSITION. 5. USE RECO_MENDED SPEED

FOR DRILL, ACCESSORY AND WORKPtECE MATERIAL

12. Think Safety. Safety is a combination of operator

common sense and alertness at atl times when the dr{(I

press is being used.

WARNING: DO NOT ALLOW FAMILOARITY (GAINED

FROM FREQUENT USE OF YOUR DRILL PRESS) TO

BECOME COMMONPLACE. ALWAYS REMEMBER

THAT A CARELESS FRACTION OF A SECOND IS

SUFF_CIENT TO _NFL_CT SEVERE INJURY.

Page 4

additional safety instructions for driJJpresses

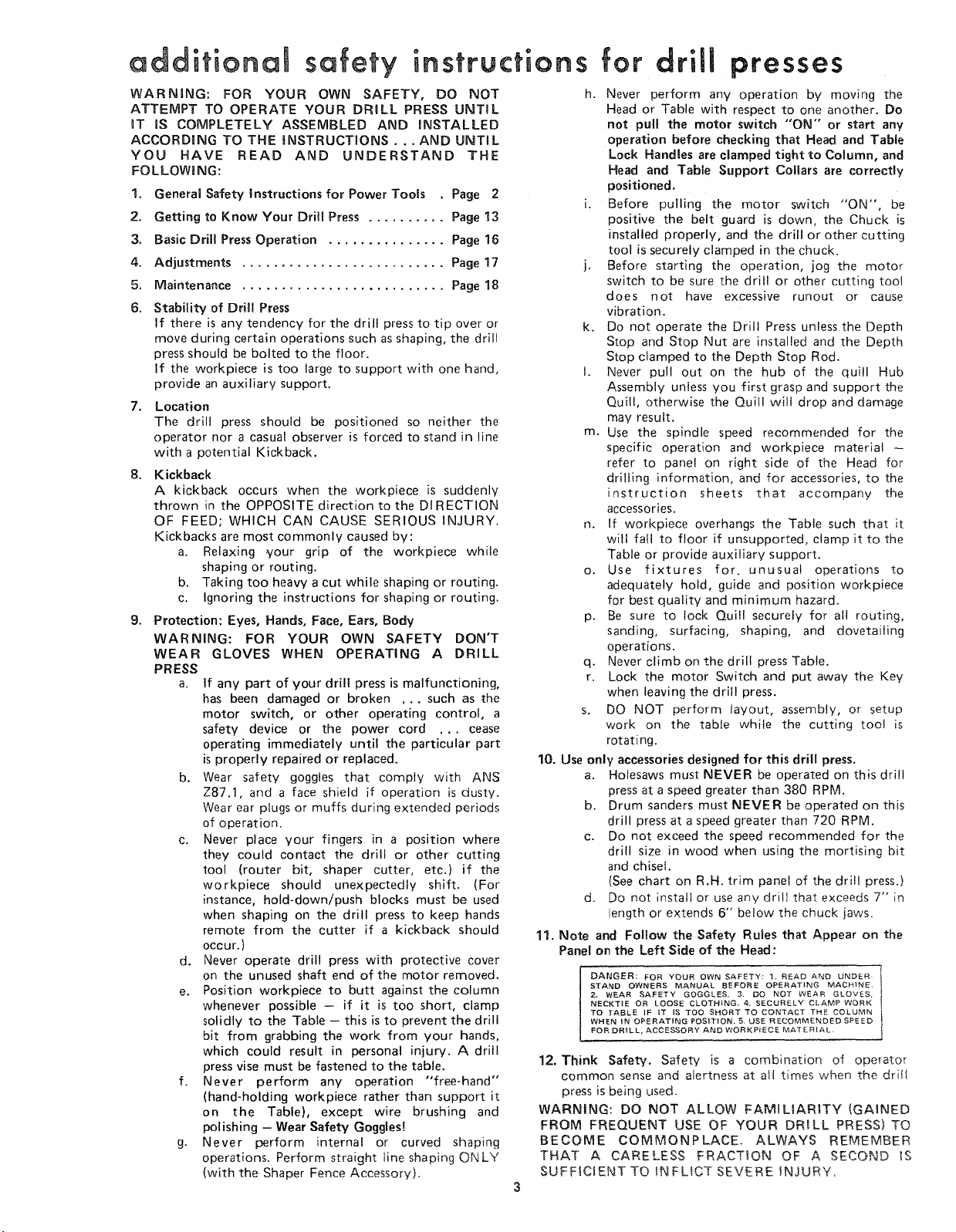

WEAR YOUR

The operation of any power tool can result in foreign

objects being thrown into the eyes, which can result in

severe eye damage. Always wear safety goggles complying

with ANSI Z87.1 (shown on Package) before commencing

power tool operation. Safety Goggles are available at Sears

retail or catalog stores.

unpacking and checking

CONTENTS

Page

General Safety Instructions for Power Tools ..... 2

Additional Safety Instructions for Drill Presses .... 3

Unpacking and Checking Contents ............. 4

Table of Loose Parts ........................ 4

Motor Specifications and Electrical Requirements.. 5

Assembly ................................. 6

Installing the Chuck .................... 6

Installing and Tensioning Belt ............. 12

Getting to Know Your Drill Press ............. 13

Belt Tension Rod ...................... 13

Drilling Speed ......................... 13

Drilling to Depth ....................... 14

Removing the Chuck ................... 15

On-Off Switch ........................ 15

Basic Drill Press Operation .................... 16

Installing Drills ........................ 16

Positioning Table and Workpiece .......... 16

Feeding ............................. 17

Adjustments .............................. 17

Depth Scale .......................... 17

Quill Return Spring .................... 17

Table and Head Lock Handles ............ 17

Maintenance .............................. 18

Lubrication .............................. 18

Recommended Accessories ................... 18

Trouble Shooting .......................... 19

Repair Parts ............................... 20

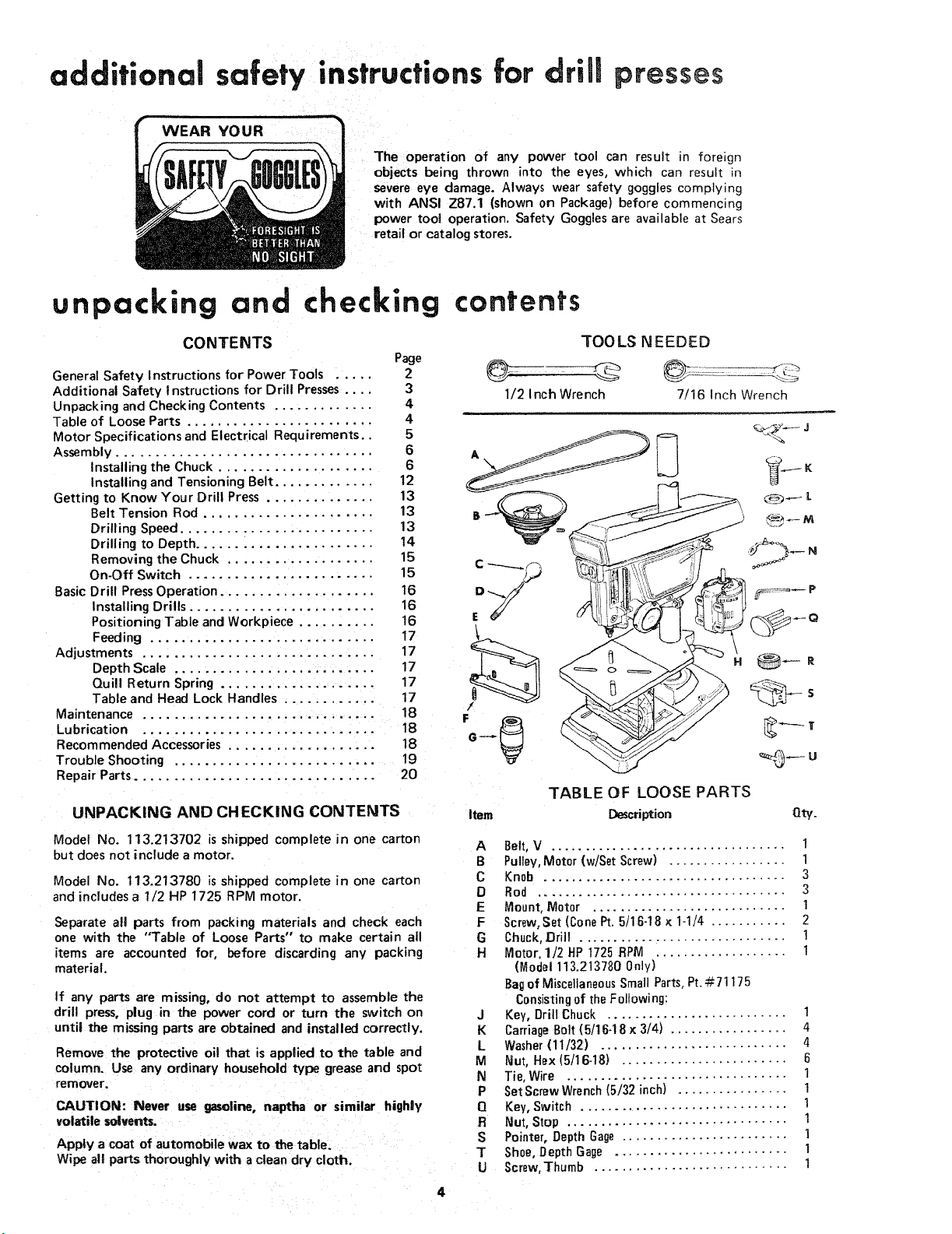

UNPACKING AND CHECKING CONTENTS

Model No. 113.213702 is shipped complete in one carton

but does not include a motor.

Model No. 113.213780 is shipped complete in one carton

and includes a 1/2 HP 1725 RPM motor.

Separate all parts from packing materials and check each

one with the "Table of Loose Parts" to make certain all

items are accounted for, before discarding any packing

material.

If any parts are missing, do not attempt to assemble the

drill press, plug in the power cord or turn the switch on

until the missing parts are obtained and installed correctly.

Remove the protective oil that is applied to the table and

column. Use any ordinary household type greaseand spot

remover.

CAUTION: Never use gasoline, naptha or similar highly

volatile solvents.

ApI_y a coat of automobile wax to the table.

Wipe all parts thoroughly with a clean dry cloth.

contents

TOOLS NEEDED

1/2 Inch Wrench 7/16 Inch Wrench

TABLE OF LOOSE PARTS

Item Description Qty.

A Belt, V .................................. 1

B Pulley,Motor (wiSer Screw) ................. 1

C Knob ................................... 3

D !_od ..................................... 3

E Mount, Motor ............................ 1

F Screw,Set (Cone Pt. 5/16-18 _ 1-1/4 ........... 2

G Chock,Drill .............................. !

H Motor. lj2 HP 1725RPIVI ................... 1

(Model 113.2137800nly)

Bagof Misc_llaneousSn]all Parts,Pt.# 71175

Consistingof theFollowing:

J Key, Drill Chuck .......................... 1

K CarriageBolt(5/16-18 x 3/4) ................. 4

L Washer(11/32) ........................... 4

M Nut, Hex (5/16-18) ........................ 6

N Tie, Wire ................................ 1

P SetScrew Wrench(5/32 inch) ................ 1

Q Key,Switch .............................. 1

R Nut, Stop ................................ 1

S Pointer, DepthGage ........................ 1

T Shoe,Depth Gage ......................... 1

U Screw,Thumb ............................ 1

4

Page 5

motor specifications and

eJectrica| requirements

MOTOR SPECfFICATIONS

This dri!t press is designed to use a _725 RPM rnoto_ orfly.

DO [_ot USeany motor that runs f_iste_ than 17_,:)°r.RPM.

it is wired for operation on 110120 volts, 60 Hz.,

alternating current. 1T MUST NOT BE CONVERTED TO

OPERATE ON 230 VOLTS, EVEN THOUGH THE

RECOMMENDED MOTORS ARE DUAL VOLTAGE.

THESE CRAFTSMAN MOTORS HAVE BEEN

FOUND TO BE ACCEPTABLE FOR USE ON

THIS TOOL.

HP RPM VOLTS CATALOG NO.

1/3 1725 1!0-120 !250

!/2 !725 110-120 1254

1/2 1725 !10-120 1255

1/2 1725 t10-120 1278

1/2 1725 110-120 1279

CAUTION: Do not use blower or washing machme motors

or any motor with an automatic _eset overtoad pTotector as

their use may be hazardous.

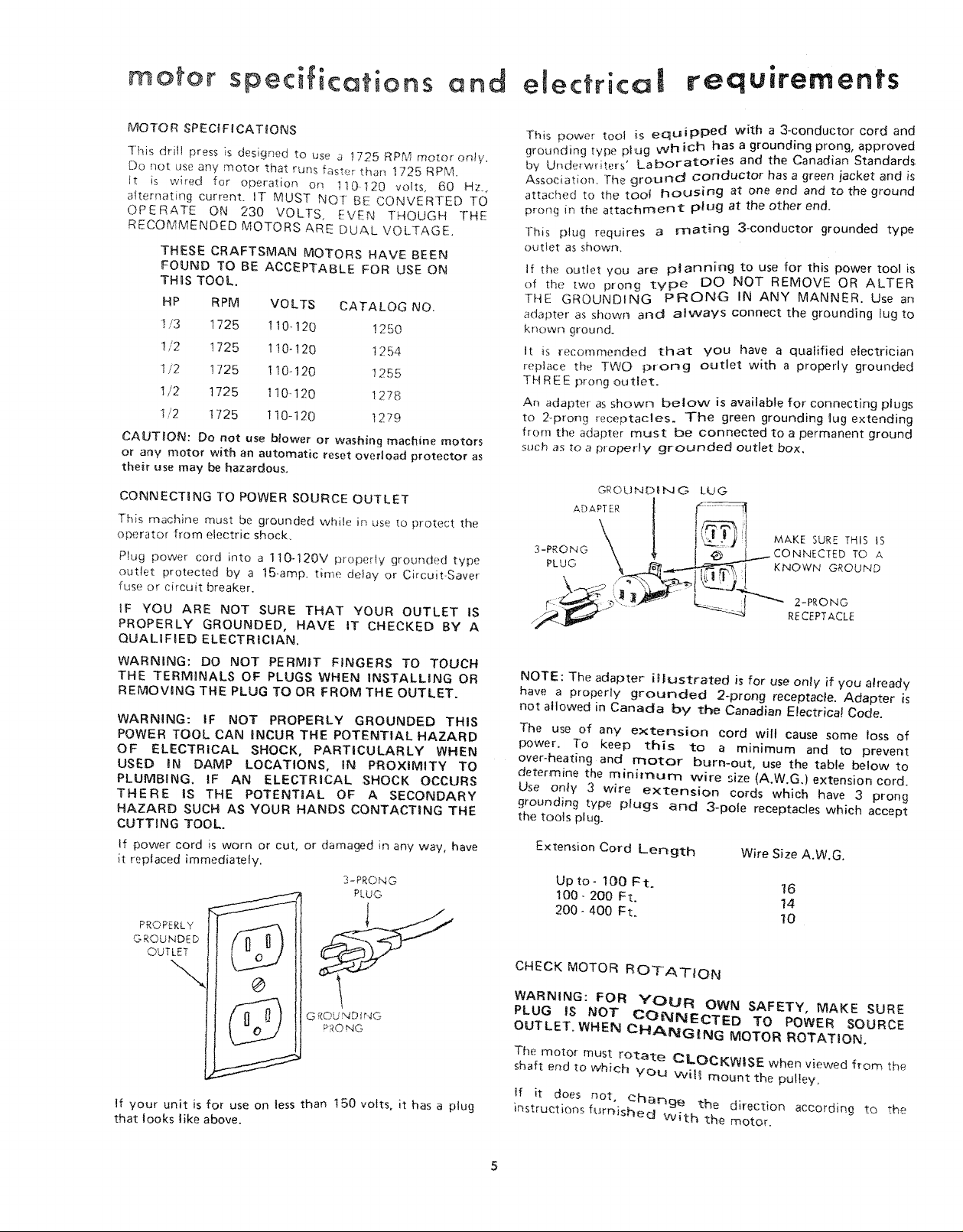

CONNECTING TO POWER SOURCE OUTLET

This machine must be grounded white in use to protect the

operator from electric shock_

P!ug power cord into a 110-120V p-opeHy grounded type

outtet protected by a 15-amp, time delay or Circuit-Saver

fuse or circuit breaker.

_F YOU ARE NOT SURE THAT YOUR OUTLET IS

PROPERLY GROUNDED, HAVE IT CHECKED BY A

QUALIFIED ELECTRICIAN.

WARNING: DO NOT PERMIT FINGERS TO TOUCH

THE TERMINALS OF PLUGS WHEN INSTALLING OR

REMOVING THE PLUG TO OR FROM THE OUTLET.

WARNING: tF NOT PROPERLY GROUNDED THIS

POWER TOOL CAN iNCUR THE POTENTIAL HAZARD

OF ELECTRICAL SHOCK, PARTICULARLY WHEN

USED IN DAMP LOCATIONS, iN PROXIMITY TO

PLUMBING. IF AN ELECTRICAL SHOCK OCCURS

THERE _S THE POTENTIAL OF A SECONDARY

HAZARD SUCH AS YOUR HANDS CONTACTING THE

CUTTING TOOL.

If power cord is worn or cut, or damaged in any way, have

it replaced immediately.

3-PRONG

PLUG

This power tool is equipped with a 3-conductor cord and

groundmg type ptug wh ich has a grounding prong, approved

by Underwriters' Laboratories and the Canadian Standards

Association. The ground conductor has a green jacket and is

attached to the tool housing at one end and to the ground

prong in the attachment p!ug at the other end.

This plug requires a treating 3-conductor grounded type

outlet as shown,

If the outlet you are planning to use for this power tool is

of the:; two prong type DO NOT REMOVE QR ALTER

THE GROUNDING PRONG IN ANY MANNER. Use an

adapter as shown and always connect the grounding lug to

known ground.

It is recommended that you, have a qualified electrician

replace the TWO prong outlet with a properly grounded

THREE prong outlet.

An adapter as shown below is available for connecting plugs

to 2-pror_ 9 receptacles. The green grounding tug extending

from the adapter must be connected to a permanent ground

such as to a properly' grounded outlet box.

GROUNd)! N G LUG

ADAPTER

MAKE SURE THIS tS

3-PRONG CTED TO A

PLUG KNOWN GROUNID

2-PRONG

RECEPTACLE

NOTE: The adapter illustrated is for use only if you already

have a properly grounded 2-prong receptacle. Adapter is

not allowed in Canada by the Canadian Electrica! Code.

The use of any extension cord wilt cause some loss of

power, To keep this to a minimum and to prevent

over-heating and motor burn-out, use the table below to

determine the minimum wire size (A.W.G.)extension cord.

Use only 3 wire extension cords which have 3 prong

grounding type plugs and 3-pole receptacles which accept

the tools plug.

Extension Cord Length Wire Size A.W.G.

Upto- 10OFt. 16

tO0- 200 Ft. 14

200- 400 Ft, 10

GROUNDED

OUTLET

PROPERLY _j

-.,,,

if your unit is for use on less than 150 volts, it has a plug

that looks like above.

@

GROU_Dt_dG

PRONG

CHECK MOTOR ROTATION

WARNING: FOR YOUR OWN SAFETY, MAKE SURE

PLUG IS NOT CONi_IECTED TO POWER SOURCE

OUTLET. WHEN CHANGING MOTOR ROTATION.

The motor must rotate CLOgKW|SE when viewed from the

shaft end to which You will mount the pulley,

if it does not, chef, go the direction according to the

instructions furnished With the motor.

Page 6

assembly

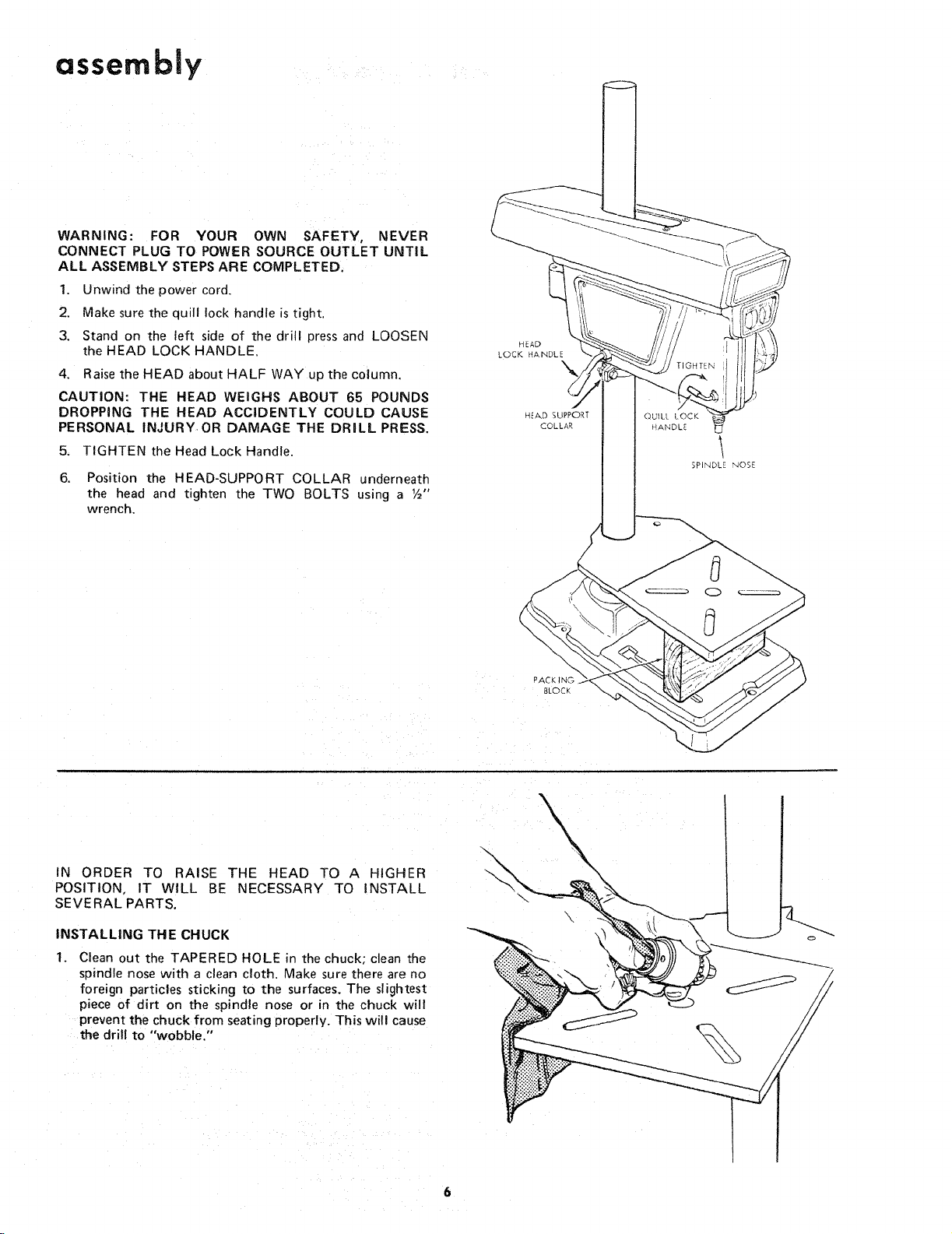

WARNING: FOR YOUR OWN SAFETY, NEVER

CONNECT PLUG TO POWER SOURCE OUTLET UNTIL

ALL ASSEMBLY STEPS ARE COMPLETED,

1. Unwind the power cord.

2. Make surethe quill lock handle is tight.

3. Stand on the left side of the drill press and LOOSEN

the HEAD LOCK HANDLE.

4. Raise the HEAD about HALF WAY up the column.

CAUTION: THE HEAD WEIGHS ABOUT 65 POUNDS

DROPPING THE HEAD ACCIDENTLY COULD CAUSE

PERSONAL INJURY OR DAMAGE THE DRILL PRESS,

5, TIGHTEN the Head Lock Handle.

6. Position the HEAD-SUPPORT COLLAR underneath

the head and tighten the TWO BOLTS using a ½"

wrench.

\

HEAD SUPPORT

COLLAR

SPINDLE NOSE

IN ORDER TO RAISE THE HEAD TO A HIGHER

POSITION, IT WILL BE NECESSARY TO INSTALL

SEVERAL PARTS.

INSTALLING THE CHUCK

Clean out the TAPERED HOLE in the chuck; clean the

spindle nose with a clean cloth. Make sure there are no

foreign particles sticking to the surfaces. The slightest

piece of dirt on the spindle nose or in the chuck will

prevent the chuck from seating properly. This will cause

the drill to "wobble."

BLOC_

Page 7

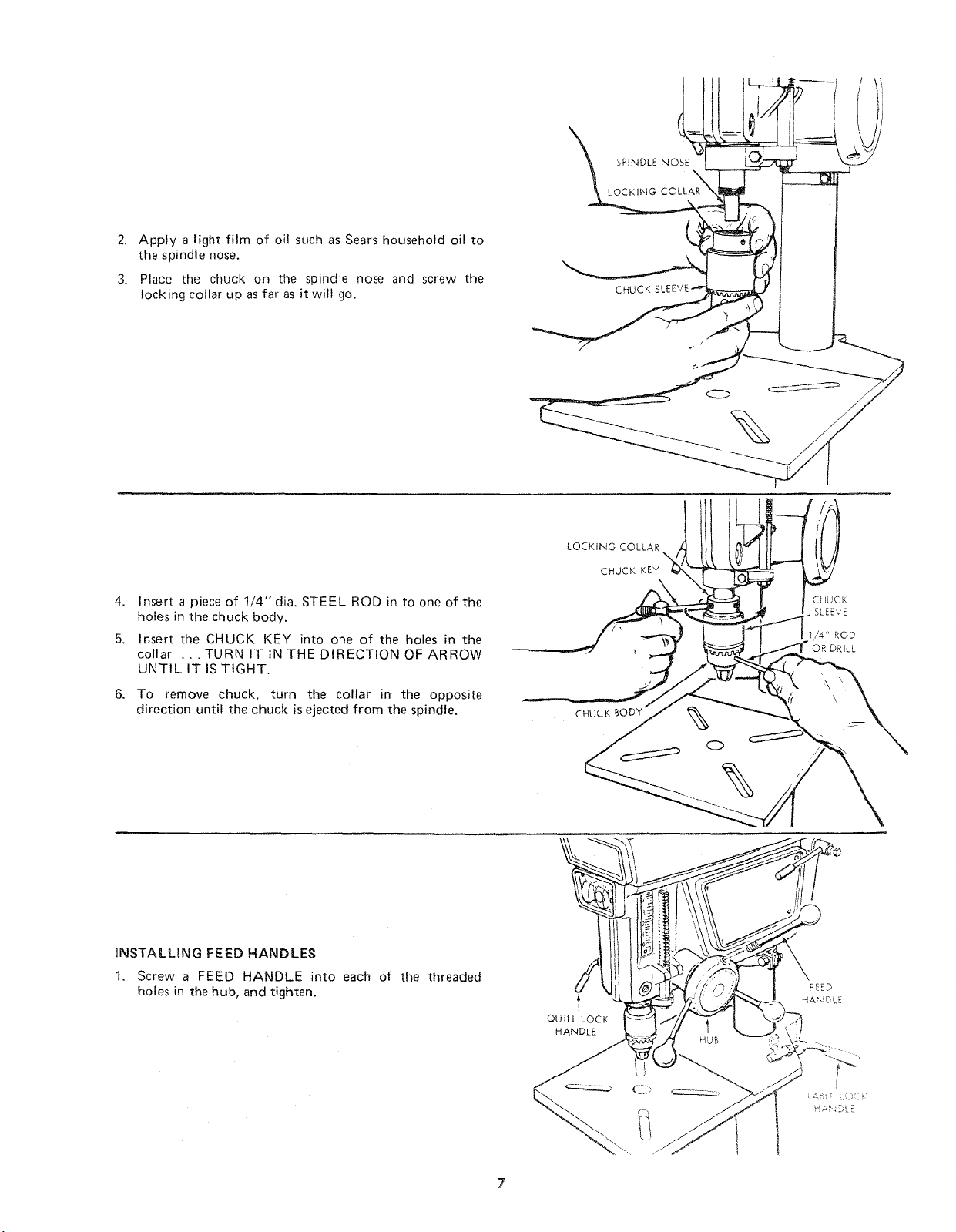

2,

Apply a light film of oil such as Sears household oil to

the spindle nose.

3.

Place the chuck on the spindle nose and screw the

locking collar up as far as it will go.

CHUCK

LOCKING COLLAR

CHUCK KEY

4. Insert a piece of 1/4" dia. STEEL ROD in to one of the

holes in the chuck body.

5. Insert the CHUCK KEY into one of the holes in the

collar ...TURN IT IN THE DIRECTION OF ARROW

UNTIL IT IS TIGHT.

6. To remove chuck, turn the collar in the opposite

direction until the chuck is ejected from the spindle.

nNSTALLING FEED HANDLES

1. Screw a FEED HANDLE into each of the threaded

holes in the hub, and tighten.

CHUCK BODY

t

QUILL LOCK

HANDLE

CHUCK

SLEEVE

ROD

HANDLE

Page 8

assembly

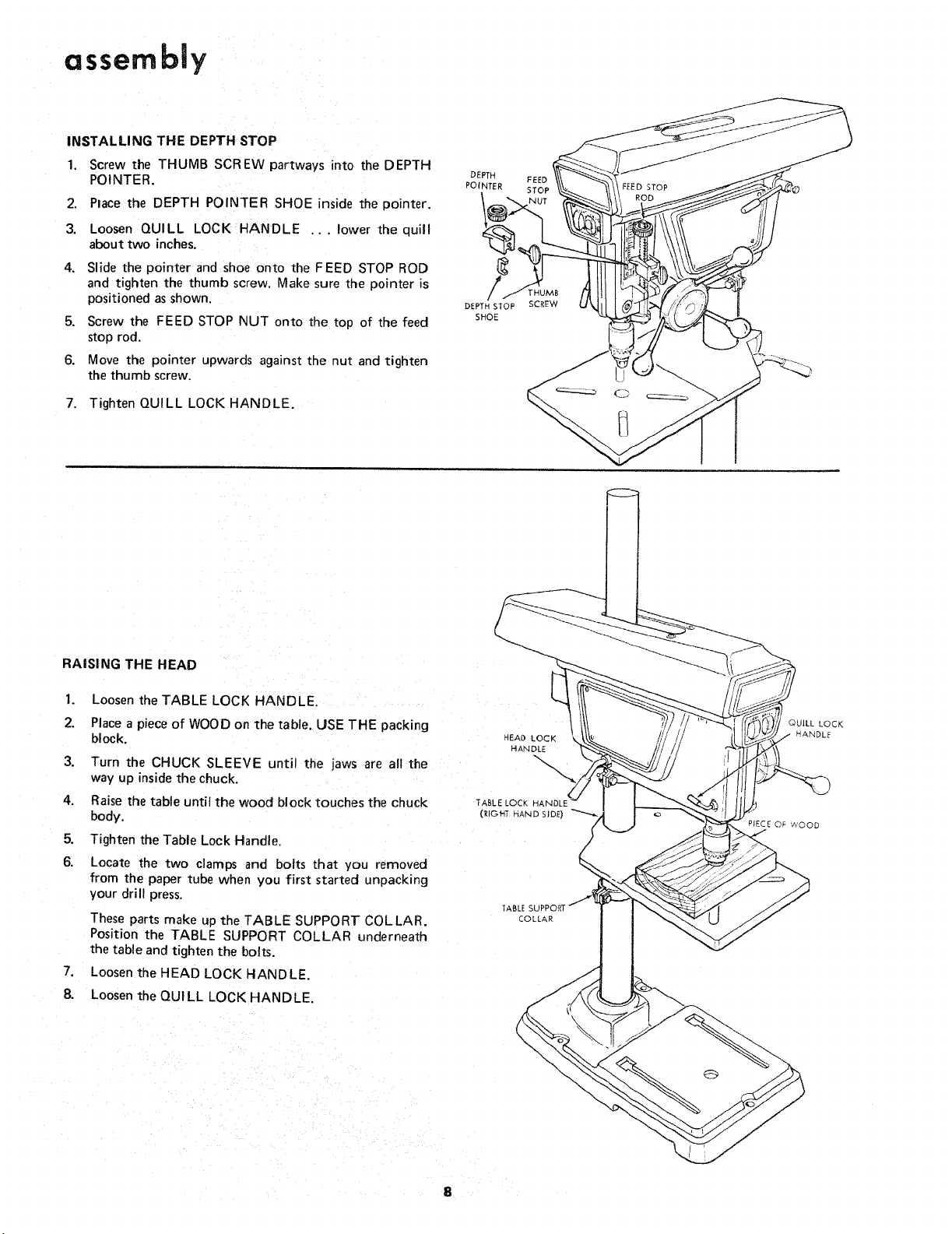

INSTALLING THE DEPTH STOP

1. Screw the THUMB SCREW partways into the DEPTH

POINTER.

2. Place the DEPTH POINTER SHOE inside the pointer.

3. Loosen QUILL LOCK HANDLE ... lower the qui|l

about two inches.

4. Slide the pointer and shoe onto the FEED STOP ROD

and tighten the thumb screw, Make sure the pointer is

positioned as shown.

5. Screw the FEED STOP NUT onto the top of the feed

stop rod.

6. Move the pointer upwards against the nut and tighten

the thumb screw.

7. Tighten QUILL LOCK HANDLE.

DEPTH

POINTER

/

DEPTH STOP

SHOE

FEED

STOP

RAISING THE HEAD

1. Loosen the TABLE LOCK HANDLE,

2. Place a piece of WOOD on the table. USE THE packing

block,

3. Turn the CHUCK SLEEVE until the jaws are all the

way up inside the chuck.

4. Raise the table until the wood block touches the chuck

body.

5. Tighten the Table Lock Handle.

6. Locate the two clamps and bolts that you removed

from the paper tube when you first started unpacking

your drill press.

These parts make up the TABLE SUPPORT COLLAR.

Position the TABLE SUPPORT COLLAR underneath

the table and tighten the bolts.

7. Loosen the HEAD LOCK HANDLE.

8. Loosen the QUILL LOCK HANDLE.

HEAD LOCK

HANDLE

TABLE LOCK

(RIGHT HAND SIDE)

TABLE SUPPORT

COLLAR

QUILL LOCK

HANDLE

PIECE OF WOOD

Page 9

9. Gently push down on the FEED HANDLES until the

head raises upwards as far as it will go.

10, TIGHTEN THE HEAD LOCK HANDLE AND THE

QUILL LOCK HANDLE.

11. HOLD onto the Feed Handle and UNLOCK the quill

lock handle.

12. Let the quill return to the UP position in the head.

13. TIGHTEN THE OUlLL LOCK HANDLE.

Repeat steps 3 thru 10 until the head is raised to the

desired position. Position HEAD SUPPORT COLLAR

underneath the head and tighten the bolts.

HEAD LOCK

HANDLE

HEAD EVEN

WITH TOP

CAUTION: Do not raise the head above the top of the

column.

gNSTALL|NG MOTOR PULLEY

When using a double shaft motor, remove the KEY from

the 5/8 in. dia, shaft.

1.

Using a 5/32 in, setscrew wrench, UNSCREW the

setscrew in the pulley so that it is clear of the

KEYWAY (GROOVE).

2.

Place the pulley on the shaft. Make sure it slips on

EASILY ... don't FORCEJt. Remove any burrs in the

pulley or on the shaft if any.

3.

Position the pulley so that the KEYWAYS in the shaft

and in the pulley line up; and the small end of the

pulley is about 1/16 of an inch away from the motor.

COLUMN

Page 10

assembly

NOTE: When using motors which have V2" dia. shafts,

place the adapter sleeve (furnished with the motor) on

the shaft so that the slot in the sleeve is over the flat

spot,

4.

Insert the shaft key (furnished with motor) into the

grooves in the shaft and pulley so that the end of the

key is even with the end of the shaft.

5,

Tighten the set screw. Use a pair of pliers on the short

end of the set screw wrench for increased leverage.

MOUNTING THE MOTOR

1. Position the motor mount as shown and place the

motor on top of it.

2. Find four 5/16 in.-18 x 1 in. CARRIAGE BOLTS, flat

washers and hex. nuts. among the loose parts.

I/2 IN. DIA.

MOTOR SHAFT

3/16 × 3/16 KEY

I I

I I

I

FLAT SPOT

EEVE

Insert the bolts as shown ... install washers ... screw

3.

on nuts but DON'T TIGHTEN them,

4.

Using a 5/32 inch set screw wrench unscrew the PIVOT

screws as shown.

CARRIAGE BOLT

10

I._ ",, ..,,,II_/....-piVOTSC,_EW

PIVOT SCREW

Page 11

5. Remove the belt guard by "pushing in" on the two

"links".

6,

Place motor on drill press .., screw the pivot screws

into the holes.

NOTE: DO NOT SCREW THEM IN TOO TIGHT ...

EXCESSIVE TIGHTNESS COULD BEND THE

MOTOR MOUNT.

7,

Find two 5/16 in-18 hex. nuts among the loose parts

... screw them on to the pivot screws .., tighten

them with a '/2 in. wrench while preventing the pivot

screws from turning,

8. Plug motor cord into outlet inside of drill press,

9. Find the plastic CORD TIE among the loose parts ...

insert the pointed end into the hole in the motor

mount.

10. Gather up the slack in the motor cord.., wrap the

CORD TIE around it... insert one end of the TIE into

the hole in the other end. Pull it tightly to secure the

cord to the motor mount.

CAUTION: If you are using a DOUBLE SHAFT motor.

Make sure the SHAFT PROTECTOR is installed. NEVER

USE THE DRILL PRESS WiTH THE UNUSED SHAFT

EXPOSED.

Page 12

assembly

iNSTALLING AND TENSIONING BELT

1. Place a straightedge such as a piece of wood, metal or

framing square across the pulleys.

2. Move the motor UPWARDS until the pulleys are IN

LINE .., tighten the motor mounting nuts with a ½ in.

wrench.

3, Place the belt on the pulleys.

4. Put a dab of grease such as Sears gear case lubricant on

the rubber tip of the BELT TENSIONING ROD.

5. Loosen HEX HEAD SCREW with a 7/16 in. wrench

•.. position BELT TENSIONING ROD as shown.

6. Push the motor to the right with moderate pressure

while pushing THE BELT TENSIONING rod against

the motor mount . . TIGHTEN the HEX SCREW.

7. If belt slips while drilling, readjust belt tension.

8. Replace the belt guard.

INSTALLING LIGHT BULB

1. Install a light bulb (not larger than 60 watt) into the

socket inside the head.

BELT TENSIONIN_

Y MOTOR

f

MOTOR

MOL NT

12

Page 13

getting to know your dri B press

QUILL AND SPINDLE ASSEMBLY

INSIDE OF DRILL PRESS

-_--- SPLINES

(GROOVES)

'-'---- SPINDLE

QU ILL

CHUCK

KEY _ CHUCK

RACK "ON-OFF"

(TEETH) SWITCH

DRILL

DEPTH SCALE

QUILL

HANDLE

CHUCK LOC

COLLAR

SWITCH

KEY

POINTER

DEPTH

TABLE SUPPORT

COLLAR

SUPPORT

CO[iAR

SCRE'¢,:

HANDLE

LOCK

HANDLE

HEAD LOCK HANDLE

ON LEFT SiDE OF HEAD

BE LT TENSION. [ROD... maintains constant tension on the

belt, TO RELEASE belt tension for changing speeds,

push the GRIP of the rod up.

To APPLY belt tension, PUSH the MOTOR to the REAR

while pulling DOWN on the GRIP of the rod. Belt should

only be tight enough so that it does not slip. If belt slips

while drilling, readjust belt tensioning rod

FEED HANDLES . . . are for moving the quill up or down.

One or two may be removed if necessary whenever the

workpiece is of such unusual shape that it interferes with

the handles.

Although there is a rubber cushion between the FEED

STOP COLLAR and the head, NEVER let go of the feed

handles when you have finished drilling a hole.

Hold on to the handle while allowing the quill to return to

the UP position.

SPINDLE SPEED CHART

DRILLING SPEED ...Canbechanged by placing the belt

in any of the STEPS (grooves) in the pulleys. See Spindle

Speed chart on right side of Head.

To determine the approximate drilling speed, refer to the

table on the RIGHT side of the drill press head. For

example to drill a 5/8 inch hole in wood, the belt is placed

in the FOURTH step from the top. The speed wi!l then be

2300 RPM (revolutions per minute).

QUSLL LOCK ... Holds the quill at any desired point,

within its travel.

To lock the quill requires only moderate pressure on the

lock handle.

FEED STOP NUT limits the dowr;ward movement of the

quill at any desired point within its travel and preven_s the

pointer from moving upward,

The DEPTH POINTER is locked in p_ace with the

THUMBSCREW,

t3

Page 14

getting to know your drill press

HEAD LOCK HANDLE ... locks the head to the column.

ALWAYS have it locked in place while operating the drill

press.

HEAD SUPPORT COLLAR ... prevents the head from

dropping when the head lock handle is loosened.

ALWAYS have the collar LOCKED into position against

the UNDERSIDE of the head.

TABLELOCK HANDLE .,. locks the table to the column.

ALWAYS have it locked in place while operating the drill

press,

ALWAYS hold the table while unlocking it.

TABLE SUPPORT COLLAR . .. Prevents the table from

accidently dropping all the way to the bottom when the

table lock handle is loosened.

DRILLING TO DEPTH

To drill a BLIND hole (not all the way through) toa given

depth, can be done two ways,

1. Mark the depth of the hole on the side of the

workpiece.

2. With the switch OFF bring the drill down until the TIP

or lips are even with the MARK ... LOCK the QUILL.

3. Move the POINTER a!l the way down and tighten the

thumb screw.

4, Tighten the STOP NUT against the pointer,

5. Unlock the quill.

6. Feed the drill into the workpiece until it is stopped by

the pointer.

ALWAYS have the collar LOCKED into position

approximate{y 34 in. from the floor for average drilling

operations.

CHUCK KEY ... is used to tighten or loosen the chuck. It

has a spring loaded EJECTOR pin to "pop" it out of the

chuck when you let go of it. This action is designed to

preclude throwing of the chuck key from the chuck when

power is turned "ON". Do not use any other key as a

substitute, order a new one if damaged or lost. When not in

use, ALWAYS store the key in the hole in the table.

CHUCK LOCKING COLLAR .,. draws the chuck onto

the spindle nose.

It prevents the chuck from coming loose during operation,

ALWAYS have the collar tightened.

\

\

ANOTHER WAY-

1. With the switch OFF, bring the drill down until the TiP

touches the TOP of the WORKPIECE ... lock the

quill.

2. Set the POINTER to the desired DEPTH ,.. lock it

and TIGHTEN the STOP NUT against it. For example

,.. if you want to drill a hole one inch deep . .. set

the pointer at the one inch mark in the scale,

14

Page 15

REMOVINGTHECHUCK.

LOCKING COLLAR /

CHUCK KEY

1. Insert apiece of 1/4 in. alia. steel rod in one of the holes

in the chuck body.

2. Insert the CHUCK KEY into one of the holes in the

collar ... turn it in the direction of arrow until

LOOSE. Continue to turn it until the chuck is released.

"ON-OFF" SWITCH for drill has locking feature. THIS

FEATURE IS INTENDED TO PREVENT

UNAUTHORIZED AND POSSIBLE HAZARDOUS USE

BY CHILDREN AND OTHERS.

"ON-OFF" SWITCH for light is independent of the drill

switch. This permits the light to be "on" while making your

setups.

Insert KEY into switch. NOTE: Key is made of yellow

plastic.

To turn drill ON ..

Insert finger under switch lever and pull.

Iris7 RoD

LIGH_T pULLpIRILL

/

TO turn drill OFF . .. Push lever in.

In an emergency; ... the drill bit BINDS ... STALLS ...

STOPS ... or tends to tear the workpiece loose ... you

can QUICKLY turn the drill OFF by hitting the switch

with the palm of your hand,

TO lock switch in OFF position ... hold switch IN with

one hand ... REMOVE key with other hand.

WARNING: FOR YOUR OWN SAFETY, ALWAYS LOCK

THE SWITCH "OFF" WHEN DRILL PRESS IS NOT IN

USE ... REMOVE KEY AND KEEP IT IN A SAFE

PLACE ... ALSO ... IN THE EVENT OF A POWER

FAILURE (ALL OF YOUR LIGHTS GO OUT) TURN

SWITCH OFF ... LOCK IT AND REMOVE THE KEY.

THIS WILL PREVENT THE DRILL PRESS FROM

STARTING UP AGAIN WHEN THE POWER COMES

BACK ON.

_5

Page 16

basic drill press operation

We recommend the following instructions for operating

your drill press so that you get the best results and to

minimize the likelihood of personal injury,

WARNING: FOR YOUR OWN SAFETY, ALWAYS

OBSERVE THE FOLLOWING SAFETY PRECAUTIONS.

1. Check spindle speed

2. Before operating, turn the switch "on" then "'off" to

make sure that the cutting tool is centered in the chuck

iNSTALLiNG DRILLS

Insert drill into chuck far enough to obtain maximum

GRIPPING of the CHUCK JAWS .., the jaws are appox. 1

in. long. When using a small drill do not insert it so far that

the jaws touch the flutes {spiral grooves) of the drill.

Make sure that the drill is CENTERED in the chuck before

tightening the chuck with the key.

Tighten the drill sufficiently, so that it does not SLIP while

drilling.

properly and that the cutting tool is not causing

excessive vibration.

3,

Never perform any operation freehand (hand-holding

workpiece rather than supporting it on table) except

when wire brushing or polishing,

4. Keep your hands clear of the cutting tool (drill, shaper

cutter or router bit).

,5. Make sure quill is locked securely when shaping,

routing, dovetailing, wirebrushing, polishing sanding or

surface planing.

/

POSITIONING TABLE AND WORKPIECE

Lock the table to the column in a position so that the tip of

the drill is just a little above the top of the workpiece. It is

not necessary to reposition the TABLE SUPPORT

COLLAR each time you reposition the table. Always keep

the collar locked about 34 in. from the floor.

Always place a piece of BACK-UP MATERIAL (wood,

plywood ...) on the table underneath the workpiece. This

will prevent "splintering" or making a heavy burr on the

underside of the workpiece as the drill breaks through.

Position workpiece to butt against the column whenever

possible if it is too short, clamp solidly to the Table -

this is to prevent the drill bit from grabbing the work from

your hands, which could result in personal injury. A drill

press vise must be fastened to the table.

CAUTION: To prevent the workpiece or the back-up

material from being torn from your hand while drilling,

position them against the left side of the column. Failure to

do this could result in personal injury.

CAUTION: If the workpiece or the back-up material are

not long enough to reach the column, CLAMP them to the

table. Failure to do this could result in personal injury.

For small pieces that cannot be clamped to the table, use a

dritt press vise (Optional accessory). The vise must oe

clamped or bolted to the table.

QUILL

LOCK

WORKPIECE

N

\

\

V_ORKPIECE

\

16

DRILL PRESS

V ISE

Page 17

HOLE LOCATOON

Make a DENT in the workpiece where you want the hole

. . . using a CENTER PUNCH or a SHARP NAIL.

Before turning the switch ON, bring the drill down to the

workpiece lining it up with the hole location.

FEEDONG

Pull down on the feed handles with only enough effort to

adiustments

WARNING: FOR YOUR OWN SAFETY TURN SWITCH

"OFF" AND REMOVE PLUG FROM POWER SOURCE

OUTLET BEFORE MAKBNG ANY ADJUSTMENTS,

DEPTH SCALE

When the quill is in the UPPERMOST position, the top

SURFACE OF THE FEED STOP POINTER should be in

line with "'0"" graduation on the DEPTH SCALE.

If it is not ... LOOSEN both mounting screws and

reposition the scale.

allow the drill to cut.

Feeding TOO SLOWLY might cause the drill to burn ,.

Feeding TOO RAPIDLY might stop the motor ,.. cause

the belt or drill to SLIP ... tear the workpiece LOOSE

from your hand or BREAK the drill bit.

When drilling metal use Sears Thread-cutting oil

FEED STOP ~

POINTER

MOU NTIN

SCREWS

QUILL RETURN SPRING

If the quill does not return to its UPPERMOST position

when the quill lock is UNLOCKED .,. or if the return

action is SLUGGISH ... the SPRING TENSION must be

increased.

1. Move DEPTH POINTER to uppermost position and

lock it in place.

2.

Lock the quill in the uppermost position.

3.

GRASP the HUB . .. pull it straight out until it is free

to turn.

4.

Rotate hub COUNTERCLOCKWISE about 1/4 turn

and PUSH it back in place. This wilt WIND UP the

spring.

5,

Unlock quill ... check tension ... if more is required,

repeat steps 2, 3, 4, and 5.

TABLE AND HEAD LOCK HANDLES

The lock handles can be adjusted to make them more

convenient to operate.

1. Make sure the support collar is locked in position below

the table or the head.

2. Unscrew the lock handle and push the barrel lock out

of the hole,

3. Rotate the barrel lock 180 ° , replace it in the hole and

screw in the handle.

NOTE: The HEADLOCK HANDLE is located on the LEFT

side of the head.

BELT TENSION

Refer to section "Getting To Know Your Drill Press" ,,.

BELT TENSIONING ROD.

RETURN SPRING

TABLE LOCK HANDLE

HANDLE

BARREL LOCK

_7

Page 18

maintenance

WARNING: FOR YOUR OWN SAFETY, TURN SWITCH

"OFF" AND REMOVE PLUG FROM POWER SOURCE

OUTLET BEFORE MAINTAINING OR LUBRRCATJNG

YOUR DRI LL PRESS.

Frequently blow out any dust that may accumulate inside

the motor.

A coat of automobile-type wax applied to the table and

column will help to keep the surfaces clean.

If the power cord is worn or cut, or damaged in any way,

have it replaced immediately.

For motor maintenance, follow instructions furnished with

motor.

lubrication

All of the BALL BEARINGS are packed with grease at the

factory. They require no further lubrication.

Periodically lubricate the SPLIN ES (grooves) in the spindle

and the RACK (teeth on the quill).

USE Sears Gear Case Lubricant.

1. Lower quill and spindle all the way down ... LOCK

the quill.

2. Use a small stick of wood and apply lubricant around

the inside of the hole in the spindle pulley.

3. Apply lubricant to RACK (teeth) on quill extending

below drill press head.

For motors lubrication, follow instructions furnished with

motor.

recommended accessories

Drills, Shaper Cutters, Router Bits ......... See Catalog

Rotary Planer ............................ 9-2745

Mortising Chisel Housing .................... 9-2465

Hollow Chisels and Mortising Bits .......... See Catalog

Dovetailing Attachment ..................... 9-2462

Shaper Fence Attachment ................... 9-2487

Hold-Down and Guide ...................... 9-2457

Drill Press Vises ....................... See Catalog

Rotary Table ............................. 9-2495

Tilt Table ................................ 9-2439

Shaper Cutter Adapter ..................... 9-24832

The recommended accessories listed here are current and

were available at the time this manual was printed.

18

Sanding Drum ..................... 9-2497 - 9-2498

Hole Saws up to 2½ in. dia ............... See Catalog

Wire Wheels up to 4 in. dia. max ........... See Catalog

Buffing Wheels up to 4 in. dia. max ......... See Catalog

Polishing Wheel, 1½" x 1 In .................. 9-64991

Column Collar ............................ 9-2438

"'V" Belt ................................. 9-1745

Slow Speed Attachment ................... 9-24646

Power Tool Know-how Handbooks

Radial Saw .............................. 9-2917

Table Saw ............................... 9-2918

Page 19

troubRe shooting

WARNING: FOR YOUR OWN SAFETY, TURN SW_TCH "OFF" AND ALWAYS REMOVE PLUG FROM POWER SOURCE

OUTLET BEFORE TROUBLE SHOOTING,

TROUBLE

Noisy Operation

Drilt Burns.

Drill leads off...

ho|e not round.

Wood splinters on 1. No "back-up material"

underside, under workpiece.

PROBABLE CAUSE

!.

Incorrect belt tension

2,

Dry Spindle

3.

Loose spindle pulley

or motor pulley.

1. Incorrect speed

2. Chips not coming out

of hole.

3, Dull Drill

4. Feeding too slow.

5. Not lubricated.

6. Drill running backwards,

1.

Hard grain in wood or

lengths of cutting

lips and/or angles

not equal.

REMEDY

1. Adjust tension. See section "Getting To Know

Your Drill Press"...BELT TENSIONING ROD.

2. Lubricate spindle, See "'Lubrication" section.

3. Tighten setscrews in pulleys.

1.

Change speed. See section "Getting To Know

Your Drill Press"., . DRILLING SPEED.

2.

Retract drill frequently to clear chips.

3.

Reshapen drill.

4.

Feed fast enough...allow drill to cut.

5.

Lubricate drill. See "Basic Drill Press

Operation" section.

6.

Check motor rotation. See "Motor Specifications

and Electrical Requirements" section.

1. Resharpen drill correctly.

1. Use "back-up material"...See Basic Drill

Press Operation" section.

Workpiece torn

loose from hand.

Drill Binds in

workpiece.

Excessive drill

runout or wobble.

1. Not supported or

clamped properly.

1.

Workpiece pinching drill

or excessive feed

pressure.

2. Improper belt tension.

1. Bent drill.

2. Worn spindle bearings.

3. Drill not properly

installed in chuck.

4. Chuck not properly installed.

I. Support workpiece or clamp it...See "Basic

Drill Press Operation" section.

1. Support workpiece or clamp it...See "Basic

Drill Press Operation" section.

2.

Adjust tension...See section "Getting to Know

Your Drill Press"...BELT TENSION ROD.

1, Use a straight drill.

2. Replace bearings.

3, Install drill properly ...See "Basic Drill

Press Operation" section.

4. Instatl chuck properly...refer to "Unpacking

and Assembly Instructions"...INSTALLING THE

CHUCK.

_9

Page 20

PARTSLIST FOR CRAFTSMAN DRILL PRESs MODEL NO. 113.213702 & 113.213780(5E_ FIGURE 2)

I 9,.._

i I,,--'_lO

7

14

Q

2O

15

(SEE FIGURE 2)

"l)

{}

19

36 37 53

38

\

\

\

\

18

J

Figure I

RED RED

MOTOR SWITCH

WIRING DIAGRAM

Page 21

PARTS LIST FOR CRAFTSMAN DRILL PRESS MODEL NO. 113.213702 & 113.213780

Always order by Part Number -- not by Key Number

FIGURE 1 PARTS LIST

Key

No.

1

2

3

4

5

6

7

8

9

10

11

12 _

13

14

15

16

17

18

19

2O

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

Part

No.

71097

STD 541110

71046

;TD 571812

71163

STD 551210

STD 551208

169689

71092

STD 610805

71170

37818

STD 601103

71056

STD 610802

71088

139377

STD 541231

37837

71138

9411963

71065

STD 532507

71164

STD 551031

71165

71151

71153

71152

60226

71166

71167

145372

60307

STD 533115

71050

38626

Description

Pulley Assembly (See Figure 2)

*Nut, Hex 10-32

Connector, Wire 14-18

*Pin, Roll 3/16

Saddle, Wire

*Lockwasher, Internal No. 10

Lockwasher, Int. No. 8

*Screw, Type 23 Pan Hd. 6-32 x 5/8

Plate, Rear Cover

*Screw, Type A Pan SI. No. 8 x 1/2

Bracket

Relief, Strain

*Screw, Type 23 Pan SI. 10-32 x 3/8

Outlet

*Screw, Type A Pan SI.No. 8 x 1/4

Socket, Bulb

*Screw, Set Cone Pt., 5/16-t8 x 1-1/4

*Nut, Hex 5/16-18

Wrench, Hex "L'" 5/32

Guard Assembly (See Figure 2)

Belt, V

*Screw, Set Soc.Cup Pt.5/16-18 x 1/2

Pulley, Motor

*Bolt, Carriage, 5/16-18 x 3/4

Mount, Motor

*Washer, 11/32

Tie, Wire

Clamp, Adjusting Rod

Rod, Adjusting

Tip, Adjusting Rod

Screw, Adjusting Rod

Cord with Plug

Panel, R.H. Trim

_Screw, Drive Rd.Hd.No. 4 x 1/4

Grid

_Bolt, Carriage 5/!6-18 x 1-1/2

Collar

Lock, Barrel

Key

No.

39

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

58

60

61

62

57

59

63

64

65

66

67

68

69

70

75

71

72

73

74

Part

No. Description

71098

60193

71074

38989

27617

71139

38546

60260

60265

38627

71136

38452

38631

71168

100163

71101

71178

38623

71075

71149

60191

71140

71082

71169

71161

38632

318595

71146

60256

133423

71086

71144

71145

71099

132124

70047

71190

71175

Scale, Depth

*Pin, Roll 3/16

Hub Assembly (includes Key Nos. 43 & 44)

Spring

Pin

Rod

Knob

Grip

Handle, Lock

Lock, Barrel

Tube, Column

Washer, Fiber

Lock, Barrel

Table

Bolt, Hex Hd. 1/2-13 x 2-1/2

Base

Key, Drill Chuck

Chuck, Drill

Spindle Ass'y, Stop (See Figure 3)

Shoe, Depth Gage

Screw, Thumb

Pointer, Depth Gage

Nut, Stop

Panel, L.H. Trim

Handle

Lock, Barrel

Lockwasher, Int. C'Sink No. 6

Cover, Switch Plate

Key, Switch

*Screw, Mach.Flat Hd.6-32 x 3/8

Plate, Switch Mounting

Switch

Switch

Head, Drill Press (Includes Key No. 74)

'Screw FiI.Hd. 10-32 x 3/4

tMotor, 1/2 H.P. 1725 RPM

Owners Manual (Not Illustrated)

Bag Assy., Loose Parts (Not l!lustrated)

*Standard Hardware Item -- May be Purchased Locally

t Stock Item - May be secured through the hardware dept.

of most Sears Retail or Catalog Outlets,

Page 22

PARTS LIST FOR CRAFTSMAN DRILL PRESS

3

,

"--4 __2--- s

10_

14 -..--._ _

5

4 MODEL NO. 113.213702 & 113.213780

FIGURE 2 PARTS LIST

Key Part

No. No. Description

1 71173

2 144987

3 71069

4 STD 610807

5 60158

6 71071

7 71070

8 71162

9 71072

10 71097

11 60192

12 71089

13 71090

14 STD 315253

15 71091

16 18414

Pan'el, Front Guard

*Screw, Type B, Flat Hd., No. 10 x 1/2

Guard

*Screw, Type B, Pan Hd., No. 8 x 3/4

*Washer,13/64 x 9/16 x 3/64

Clamp

Link, Rear

Clamp

Link, Front

Pulley Assembly, Spindle

Screw, Nylok Set, 5/16-18 x 1/2

Pulley, Spindle

Insert, Pulley

*Bearing, Ball

Spacer

Ring, Retaining, 15/16

13

O

_e

13

(3

==iP

_n

15 -------_0

14 --'-'__

Figure 2

*Standard Hardware item - May be Purchased Locally.

Page 23

PARTS LIST FOR CRAFTSMAN DRILL PRESS

MODEL NO. 113.213702 & 113.213780

/

/

/

/

/

FIGURE 3 - 71075 SPINDLE ASSEMBLY, STOP

/

Key I Part

/

/

/

/

/

/

7

No. I No. Description

71075

37158

3509

3 I

71147

4 I

27813

5 I

60176

6 I

27812

? ,

STD 551125

8 I

STD 541025

0 I

38422

101

STD 541237

11 I

STD 522512

121

71078

131

71077

*Standard Hardware Item - May be Purchased Locally.

Spindle Assembly, Stop

Ring, Retaining, 5/8

Bearing, Ball

Tube, Quill

Gasket, Quill

Washer, Quill

Ring, Retaining

* Lockwasher, !/4

*Nut, Hex, 1/4-20

Collar, Feed Stop

*Nut, Hex.Jam, 3/8-16

*Screw, Mach., Hex.Hd., 1/4-20 x 1-I/4

Rod, Depth Stop

Spindle Assembly

Figure 3

Page 24

] 5q/2 NCH DRILL PRESS

SERVmCE

MODEL NO.

113.213702

DRILL PRESS ONLY

113,213780

DRILL PRESS WITH

1/2 HP MOTOR

HOW TO ORDER

REPAIR PARTS

Now that you have purchased your 15-1/2 inch drill press

should a need ever exist for repair parts or service, simply

contact any Sears Service Center and most Sears, Roebuck and

Co. stores. Be sure to provide atl pertinent facts when you call

or visit.

The model number of your 15-!/2 inch drill press will be found

on a plate attached to the rear of the head.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE

FOLLOWING INFORMATION:

PART NUMBER

PART DESCRIPTION

MODEL NUMBER

!13.2!3702

113.213780

All parts listed may be ordered from any Sears Service Center

and most Sears stores° tf the parts you need are not stocked

locally, your order will be electronically transmitted to a Sears

Repair Parts Distribution Center for handling.

NAME OF ITEM

15-I/2 INCH DRILL PRESS

Sold by SEARS, ROEBUCK AND CO., Chicago, IL. 60684 U.S.A.

Part No. 71190 Form No. SP4475-6 Printed in U.S.A. I0"83

Loading...

Loading...