Craftsman 113.206891, 113.206932 User Manual

Save This Manual :

For Future Reference

owners

rnanua!

MODEL NO.

113.206932

JOINTER/PLANER WITH

LEGS AND MOTOR

113.206891

JOINTERiPLANER WITH

LEGS AND MOTOR

Serial

Number

Model and serial

number may be found

on a plate attached

to your base.

You should record both

model and serial number

in a safe place for

future use,

CAUTION:

Read ALL

iNSTRUCTiONS

carefully

6-1/8-iNCH JOINTER-PLANER

® assembly

® operating

• repair parts

Sold by SEARS, ROEBUCK AND CO., Chicago, _L. 60684 U,S.A.

Part No. 67095 Primed iN US A

eneraisafety instructions for

power tooas

1. KNOW YOUR POWER TOOL

Read and understand the owner's manual and

fabels affixed to the tool Learn its application

and limitations as well as the specific potential

hazards peculiar to this tool. 13.

2. GROUND ALL TOOLS

This tool is equipped with an approved

3-conductor cord and a 3-prong grounding type

plug to fit the proper grounding type receptacle. 14.

The green conductor inthe cord isthe g rounding

wire. Never connect the green wire to a live 15,

.... .....terminal.

• 3. KEEP GUARDS IN PLACE,

: in working order, and in proper adjustment and

alignment. 16.

4. REMOVE ADJUSTING KEYS AND WRENCHES

Form habit of checking to see that keys and

adjusting wrenches are removed from tool before 17.

turning it on.

.

KEEP WORK AREA CLEAN

Cluttered areas and benches invite accidents. 18.

Floor must not be slippery due to wax or sawdust,

AVOID DANGEROUS ENVIRONMENT

Don't use power tools indamp or wet locations or: party the accessories. The use of improper acces-

....... expose them to rain. Keepw0rkamawel!lighted:. i:::: sories may cause hazards.

Provide adequate surrounding workspace 19_ NEVER STAND ON TOOL

:i : 7, KEEP CHILDREN AWAY ........ Serious injury could occur if the tool is tipped or

: All visitors should be kept a safe distance from _ if the cutting tool is accidentally contacted. Do

work area. _ not store materials above or near the tool such

8, MAKE WORKSHOP CHILD,PROOF that it is necessary to stand on the tool to reach

with padlocks, master switches, or by removing _ i them.

: starter keys. ::i_:_ii:ii 20iCHECK DAMAGED PARTS

9. DON'T FORCE TOOL ::Before further use of the tool, a guard or other

It will do the job better and safer atthe rate for partthat is damaged should becarefully checked

which it was designed, to ensure that it will operate properly and perform

10.

USE RIGHT TOOL

Don't force tool or attachment to do a job it was

not designed for.

11.

WEAR PROPER APPAREL

Do not wear loose clothing, gloves, neckties Or

jewelry (rings, wrist watches) to get caught in

moving parts Nonslip footwear is recommended.

Wear protective hair covering to contain long

hair. Roll long sleeves above the elbow.

12.

USE SAFETY GOGGLES (Head Protection)

Wear Safety goggles (must comply with ANSI

Z87.1) at all times. Everyday eyeglasses only

have impact resistant lenses, they are NOT

safety glasses. Also, use face or dust mask if

cutting operation is dusty, and ear protectors

(plugs or muffs) during extended periods of

operation.

SECURE WORK

Useclamps ora vise to hold work when practical.

It's safer than using your hand, frees both hands

to operate tool.

DON'T OVERREACH

Keep proper footing and balance at all times.

MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for best and safest

performances. Follow instructions for lubricating

and changing accessories.

DISCONNECT TOOLS

before servicing; when changing accessories

such as blades, bits, cutters, etc.

AVOID ACCIDENTAL STARTING

Make sure switch is in "OFF" position before

plugging in

USE RECOMMENDED ACCESSORIES.

Consult the owner's manual for recommended

accessories. Follow the instructions that accom-

its intended function. Check for alignment of

moving parts, binding of moving parts, breakage

of parts, mounting, and any other conditions that

may effect its operation. A guard or other part

that is damaged should be properly repaired or

replaced.

21.

DIRECTION OF FEED

Feed work into a blade or cutter against the

direction of rotation of the blade or cutter only.

22.

NEVER LEAVETOOL RUNNING UNATTENDED :

Turn power off. Don't leave tool until it comes toi:

a complete stop.

:: _: _:i¸¸i¸¸:¸ii: ,: i: :: _;:

additional safety instructions

for jointer-planer

Safety is a combination of operator common sense and

alertness at all times when the Jointer-Planer is being

used.

WARN|NG: FOR YOUR OWN SAFETY, DO NOT AT-

TEMPT TO OPERATE YOUR JOINTER-PLANER UNT_IL

IT iS COMPLETELY ASSEMBLED AND INSTALLED

ACCORDING TO THE INSTRUCTIONS... AND UNT|L

YOU HAVE READ AND UNDERSTOOD THE FOLLOW-

ING.

PAG E

1. GENERAL SAFETY INSTRUCTIONS FOR POWER

TOOLS ..................................... 2

2. GETTING TO KNOW YOUR JOINTER-PLANER 11

3. BASIC MACHINE OPERATION ................ 17

4. USE OF HOLD-DOWN/PUSH BLOCKS ......... 18

5, MAINTENANCE ............................. 19

6. STABILITY OF MACHINE

If there is any tendency for the Jointer-Planer to tip

over or move during certain operations such as when

planing or jointing long heavy boards, the Jointer-

Planer (stand) should be bolted to the floor.

7. LOCATION

The Jointer-Planer should be positioned so neither

the operator nor a casual observer is forced to stand in

line with the wood while it is being planed.

This machine is intended for indoor use only. Provide

adequate lighting.

8. KICKBACKS

Kickbacks can cause serious injury. A kickback occurs

when the operator looses control of the workpiece

causing it to be kicked back toward him.

Kic_kbacks-and possible injury from them can usually

be avoided by:

a. Holding the workpiece firmly against tables and

fence.

b. Not taking too deep a cut at one time. A deep cut

requires more effort to feed the wood while planing

and can cause the wood to kickback. A cut between

t/32 and 1/16 of an inch deep will produce the best

results.

C.

Not jointing, planing, or beveling pieces of wood

smaller than recommended. (See section in this

manual, "Basic Jointer-Planer Operations.")

Smaller pieces of wood can tip over on the tables,

or into the cutter head and can be kicked back

toward you.

d.

Keeping blades sharp. Blades that are dutl or

nicked require more effort while planing and will

tend to pound the wood rather than cut it, which

can cause the wood to kickback. A nicked blade will

cut aridge in your wood and cause the wood to ride

u pon the outfeed table. Make sure the cutter blades

are installed properly, and cutter blade wedge

screws are tight.

9. PROTECTION: EYES; HANDS, FACE, EARS, BODY

a. If any part of your jointer is malfunctioning, has

been damaged or broken . . . such as the motor

switch, or other operating control, a safety device

or the power cord.., cease operating immediately

until the particular part is properly repaired or

replaced.

b, Wear safety goggles that comply with ANSI Z87.1

and a face shield if operation is dusty. Wear ear

plugs or muffs during extended periods of operation.

c. Do not plane, joint, or bevel wood shorter than 12

in. Smaller pieces of wood can tip over on the

tables, or into the cutterhead and be kicked back

toward you.

d. Always use the hold down/push block when jointing

or beveling wood narrower than 3in. but never joint

or bevel wood narrower than 3/4 in., or less than !/4

inch thick.

e. Always use the hold down/push blocks when

planing wood thinner than 3 in. but never plane

wood thinner than !/2 in. under any circumstances.

f. Avoid awkward hand positions, where a sudden

slip could cause a hand to move into the cutters.

g. Neverturn yourJointer-Planer"ON" before clearing

the table(s) of all objects (tools, scraps of wood,

etc.) except for the workpiece and related feed or

support devices for the operation planned.

h. Make sure the cutterhead revolves in the right

direction, (toward the infeed table).

i. KEEP CUTTER GUARD IN PLACE AND OPERAT-

ING PROPERLY AT ALL TIMES. Regularly check

the tension of the cutter guard spring to assure

satisfactory operation. (See Getting To Know Your

Jointer-Planer section.)

j. Always feed the wood completely through the

cutter head and past the cutter guard so that the

guard returns to the rest position against the fence.

When using only one hold down/push block to feed

the wood, do not place your other hand on the

Jointer-Planer.

k. Always maintain complete control of the workpiece

and provide adequate support for long and heavy

workpieces.

10. Warped wood should be surface planed on the concave

side for best results.

11. To avoid a rough planed surface, determine if possible,

which way the grain emerges from the wood and feed

the wood accordingly.

/#_ GRAIN EMERGING

ROTATION

12. Do not plane edges of plywood, composition materials,

or wood that has glue on it or is painted or varnished.

Planing these materials witl dull the blades quickly.

3

additional safety instructions for jointer-pUaner

i,

15: Never leave the Jointer-Planer work area with the

power on; before the Jointer-Planer has come to a

complete stop, or without removing and storing the

switch key.

16. Never operate the Jointer-Planerwith protectivecover

onthe unused shaft end of the motor removed.

17. Do not attempt to perform an abnormal or little-used

operation without study and the use of adequate hold

down/push blocks, jigs, fixtures, stops, etc.

18. DO NOT perform layout, assembly, or setup work on

the table while the cutting toot is rotating:

WARNING: THE 2" JOINTER-PLANER PULLEY AND

THE 2-1/2" MOTOR PULLEY FURNISHED WILL RUN

THE CUTTER HEAD AT APPROXIMATELY 4300 RPM

WEAR YOUR

THAT A CARELESS FRACTION OF A SECOND IS

SUFFICIENT TO INFLICT SEVERE INJURY.

19. Read and follow the instructions appearing on the

danger label on the cutter guard.

DANGER - FOR YOUR OWN SAFETY

READ AND UNDERSTAND OWNER'S

MANUAL BEFORE OPERATING MACHINE

1. WEAR SAFETY GOGGLES PER ANSI Z87.1 AT ALL TIMES.

2. NEVER PERFORM A JOINTING OR PLANING OPERATION WITH CUTTER

HEAD OR DRIVE GUARD REMOVED.

3. NEVER MAKE A JOINTING OR PLANING CUT DEEPER THAN 1/8 INCH.

4. ALWAYS USE HOLD DOWN!PUSH BLOCKS FOR JOINTtNG MATERIAL

NARROWER THAN 3 INCHES, OR PLANING MATERIAL THINNE_ THAN 3

INCHES.

The operation of any power too_ can result in foreign

objects being thrown into the eyes, which can result in

severe eye damage. Always wear safety goggles complying

with ANSl Z87.1 (shown on Package) before commencing

power tool operation. Safety Goggles are available at

Sears retail or catalog stores.

m ' '_'_'

contents

POWER TOOL GUARANTEE ...................... 2

GENERAL: SAFETY INSTRUCTIONS FOR

POWER TOOLS ............................... 2

ADDITIONAL SAFETY INSTRUCTIONS FOR

JOINTER-PLANER ............................. 3

MOTOR SPECIFICATIONS AND ELECTRICAL

REQUIREMENTS .............................. 5

Connecting to Power Source Outlet ............. 5

Check Motor Rotation ........................ 5

UNPACKING AND CHECKING CONTENTS ......... 6

ASSEMBLY .............................. ....... 7

Assembling Steel Legs ........................ 7

Mounting Jointer-Planer On Recommended

Craftsman Leg Set .......................... 8

i Checking Cutterblades and Screws .............. 8

iMounting Switch. _.;, _._. ...... ...... .. :.......9

Insta_i|ng Mot0r, Pulley, V-Belt and Belt Guards ... 9

• installing Siidi'ng Guard_:..... ....... .. :. ...... 10

GETTING TO KNOW YOUR JO1NTER-PLANER _.... 11

DePt h of Cut Handwheel :! .. _.,..., ::. :. .... ,..tl

Fence Locks and Stops ...................... 12

Fence Tilt Scale ............................ 12

Cutter Guard ............................... 13

Infeed Table ................................ 14

On-Off Switch .............................. 16

BASIC JOINTER-PLANER OPERATION ........... 17

Feeding the Workpiece ....................... 17

Using the Hold Down/Push Blocks ............. 18

Beveling ................................... 19

MAINTENANCE ................................ 19

Replacing Cutter Blades ..................... t9

Installing Cutter Guard Spring ................ 21

Sharpening Cutter Blades .................... 23

GENERAL MAINTENANCE ...................... 23

LU BRI CATION ................................. 23

MOTOR MAINTENANCE AND LUBRICATION ...... 24

TR OUBLE-SHOOTI NG .......................... 24

REPAIR PARTS ................................ 26

RECOMMENDED ACCESSORIES ................. 31

4 i

i ,

i

motor specifications and

electrica! requirements

This machine is designed to use a 3450 RPM motor only.

Do not use any motor that runs faster than 3450 RPM. It is

wired for operation on 110-120 volts; 60 Hz., alternating

current. IT MUST NOT BE CONVERTED TO OPERATE

ON 230 VOLTS. EVEN THOUGH SOME OF THE RECOM-

MENDED MOTORS ARE DUAL VOLTAGE.

THESE CRAFTSMAN MOTORS HAVE BEEN

FOUND TO BE ACCEPTABLE FOR USE ON

THIS TOOL.

HP RPM VOLTS CATALOG NO.

t/2 3450 110-120 1216

1/2 3450 110-220 12!8

3/4 3450 110-120 t219

3/4 3450 110-120 1226

CAUTION: Do not use blower or washing machine motors

or any motor with an automatic reset overload protector as

their use may be hazardous,

CONNECTING TO POWER SOURCE OUTLET

This machine must be grounded while in useto protect the

operator from electric shock.

Plug power cord into a 110-120V properly grounded type

outlet protected by a 15-amp, dual element time delay or

Circuit-Saver fuse or circuit breaker.

If you are not sure that your outlet is properly grounded,

have it checked by a qualified electrician.

WARNING: DO NOT PERMIT FINGERS TO TOUCH THE

TERMINALS OF PLUGS WHEN INSTALLING OR

REMOVING THE PLUG TO OR FROM THE OUTLET.

WARNING: IF NOT PROPERLY GROUNDED THIS

POWER TOOL CAN INCUR THE POTENTIAL HAZARD

OF ELECTRICAL SHOCK. PARTICULARLY WHEN USED

IN DAMP LOCATIONS IN PROXIMITY TO PLUMBING, IF

AN ELECTRICAL SHOCK OCCURS THERE IS THE

POTENTIAL OF A SECONDARY HAZARD SUCH AS

YOUR HANDS CONTACTING THE CUTTING BLADE.

tf power cord isworn or cut, or damaged in any way, have

it replaced immediately.

3-_RONG

PLUG

PROPE R LY

GROUNDED

GROUNDING

PRONG

ifthe outlet you are planning touse for this power tool isof

the two prong type DO NOT REMOVE OR ALTER THE

GROUNDING PRONG IN ANY MANNER. Use an adapter

asshown and always connect the grounding lug to known

ground.

It is recommended that you have a qualified electrician

replace the TWO prong outlet with a properly grounded

THREE prong outlet.

A temporary adapter as shown below is available for

connecting plugs to 2-prong receptacles. The green

grounding lug extending from the adapter must be con-

nected to a permanent ground such as to a properly

grounded outlet box.

A temporary adapter as illustrated is available for con-

necting plugs to 2-prong receptacles. The temporary

adapter should be used only until a properly grounded

outlet can be installed by a qualified electrician.

GROUNDING LUG

_' "_,,_,_.,,,.._' LIJ 2-PRONG

/ _ RECEPTACLE

ADAPTER

WARNING: THE GREEN GROUNDING LUG EXTENDING

FROM THE ADAPTER MUST BE CONNECTED TO A

PERMANENT GROUND SUCH AS TO A PROPERLY

GROUNDED OUTLET BOX. NOT ALL OUTLET BOXES

ARE PROPERLY GROUNDED.

If you are not sure that your outlet is properly grounded,

have it checked by a qualified electrician.

NOTE: The adapter illustrated is for tJseonly if you already

have a properly grounded 2-prong _eceptacle.

The use of any extension cord wilt cause some loss of

power. To keep this to a minimum and to prevent over-

heating and motor burn-out, use the table below to

determine the minimum wire size (A.WG.) extension

cord. Use only 3 wire extension cords which have 3 prong

grounding type plugs and 3-pole receptacles which will

accept the plug on the saw.

Wire Size Required

(American Wire Gauge No.)

Extension Cord Length

0-25 Ft. 16

26-50 Ft. 14

51-100 Ft. 12

120 V. Lines

This power toot is equipped with a 3-conductor cord and

grounding type plug listed by Underwriters' Laboratories

Association. The ground conductor has a green jacket

and is attached to the tool housing at one end and to the

ground prong in the attachment plug at the other end.

This plug requires a mating 3-conductor grounded type

outlet as shown.

CHECK MOTOR ROTATION

Place the motor on your workbench or on the floor.

Standing clear of the motor shaft, plug the motor cord into

a properiy grounded outlet. Notice the rotation of the

shaft. As you took directly at the motor shaft it shoufd be

turning in the counterclockwise direction,_J_"_--, tf the

motor shaft is turning counterclockwise, remove the ptuc

from the power outlet and continue the assembly pro-

cedures. If the motor isturning clockwise, remove the pluc.

from the power outlet and foi!ow the instructions on th{

motor labet to reverse the rotation of the motor shaft.

unpaCkingand checking contents :

.... , TA.LEO LOOSEPARTS

No. :, Description .... Qty.:

i: :: : Combination Square A Jointer-Ptaner ............... ...........

.... B V-Belt, 1/2 x 52" .. ........................ ;_l

i / i•i ii i

1/2" Wrench : ::

7116_ Wrench

: l Wrench

3i8' Wrench Medium Screwdriver

Models t13.206932 and 113.20689t Jointer-Planer are

shipped complete in one carton and INCLU DE Steel Legs

and Motor.

Model 113.206801 Jointer/Planer is shipped complete in

one carton but DOES NOT INCLUDE steel legs or motor.

Separate all parts from packing materials and check each

one with the illustration and the list of Loose Parts to make

certain all items are accounted for, before discarding any

packing material.

If any parts are missing, do not attempt to assemble the

jointer/planer, plug in the power cord or turn the switch on

until the missing parts are obtained and are installed

correctly.i. .....

Remove the protective oil that is applied to atl unpainted

metal surfaces. Use any ordinary household type grease

and spot remover.

WARNING: Never use gasoline, naptha or similar highly

volatile solvents.

Apply a Coat of paste wax to the table .... :

Wipe all parts thoroughly with a clean, dry cloth.

WARNING.': FOR YOUR OWN SAFETY ;:NEVER CONNECT

PLUG TO POWER SOURCE OUTLET UNTIL ALL

ASSEMBLY STEPS ARE COMPLETE, AI_D YOU HAVE

READ AND UNDERSTAND THE SAFETY AND OPERA-

*C 5/32 Setscrew Wrench ....................... i

*D 1/8 Setscrew Wrench ........................ 1

*E Motor Pulley, 2-1/2" Dia ...................... 1

*F Sliding Guard Knob ......................... 1

*G Concave Plastic Washer ..................... 2

H Sliding Guard .............................. 1

*J Sliding Guard Rod .......................... 1

*K Nut, 1/2-13 ................................. 1

*L Lockwasher, 1/2 ............................ 1

*M Lockwasher, No. 10 ......................... 2

*N Screw, Pan Hd., 10-32 x 1/4 ................... 2

O Owners Manual ............................. 1

*P Depth of Cut Handwheel ..................... 1

*Q Screw, Sems, 1/4-20 x 1-1/4 .................. 1

R On/Off Power Outlet ........................ 1

*S Washer, 17/64 x 1/2 x 1/32 .................... 2

*T Lockwasher, External 1/4 .................... 2

*U Screw, Pan Hd. 1/4-20 x 1/2 .................. 2

V Jointer-Planer Belt Guard .................... 1

*W Attaching Hardware (2 Nuts, 2 Bolts)

X Belt Guard Clips ............................ 3

Y Bracket, Mounting .......................... 1

Z Belt Guard Support Bracket .................. 1

AA Belt Guard Support ......................... 1

AB Screw Pan Hd. 10-32 x 1/2 .................... 2

ACMotor Pulley Belt Guard ...................... 1

AD Switch Key ................................ 1

AE Hold Down!Push Block ...................... 2

"Supplied in Loose Parts Bag #67092

i

!

61: • ..... :

• • ; :i¸ i;¸ i ¸ ; : • •

unpacking and checking contents

TABLE OF LOOSE PARTS

The Following Parts Are Included With

Models 113.206891 and 113,206932

Item

No. Description Qty.

A Leg ....................................... 4

B End Stiffener ............................... 2

C Side Stiffener .............................. 4

D Motor Support .............................. 1

E Motor ..................................... 1

Package of Miscellaneous Small Parts,

No, 67035, Consisting of the Following:

F Cord Clip .................................. 2

G Hex Nut, 1/4 in. -- 20

(approx. dia. of hole 1/4 in.) ................ 40

G HexNut, 5/16in.-- 18

(approx. dia. of hole 5116 in.) ................ 7

G Hex Nut, 1/2 in. -- 13

(approx. dia. of hole 1/2 in.) ................. 8

H Truss Hd. Screw, 1/4 in. -- 20 x 5/8 In.

long. (Top of screw is rounded) ............. 40

J Flat Washer (dia. of hole 11/32 in.) ............. 7

K Lockwasher, 1/4 in. External Type

(approx. dia. of hole 1/4 in.) ................ 40

K Lockwasher, 5/16 in+ External Type

(approx. dia. of hole 5/16 in.) ................ 7

L Carriage Bolt, 5/16 in. -- 18 x 3/4 long .......... 3

M Leveling Foot .............................. 4

N Hex Hd. Screw, 5/16 in. -- 18x 2 in............. 3

G

H

©

K

L M N

assembly

ASSEMBLING STEEL LEGS

NOTE: Steel legs are furnished with Model 113,206932

and 113.20689t.

From among the loose parts, find the following Hardware:

40 Truss Head Screws, 1/4-20 x 518

40 Lockwashers, !!4-External

40 Hex Nuts, 114-20

8 Hex Nuts, t/2-13

4 Leveling Feet

1. Assemble two (2) Side Stiffeners together using four

(4) 1/4-20 Truss head screws, Iockwasher and nuts.

Make two (2) Side Stiffener assemblies.

The End Stiffeners are placed on top and at each end

of Side Stiffener assemblies as shown. Align holes,

letter coded "B" (see page 8) in Side Stiffeners and

End Stiffeners and then insert 1/4-20 Truss head

screws through the 9/32 diameter holes and install

Iockwashers and nuts and then tighten.

2. Assemble the four (4) Legs to the Side and End

Stiffeners us/ng 1/4-20 screws, lockwashers and nuts

as shown.

3. Assemble the Motor Support to the Legs with 1/4-20

screws, Iockwashers and nuts. Motor Support can be

assembled to either end of Leg set.

4. Install leveling feet as shown. To level Leg Set, loosen

nut on inside of leg and turn nut on the outside to raise

or lower feet. Adjust all four leveling feet, if necessary,

and then tighten nuts on the inside of leg.

NOTE: These levelers are not intended for height

adjustment.

TRUSS HD. SCREW

1/4-20 x 5/8

END ST|FFENER

7

assembly

MOUNTING JOINTER-PLANER

i:. From among the loose parts, find the following hard-

ware:

4 Carriage Bolts, 5/16-18 x 3/4

3 Hex Head Screws; 5/16-18 x 2

7 Lockwashers, 5/16 in. External Type

7 Washers, 11/32 ID

7 Hex Jam Nuts, 5/16-18

2 Cord Clips

2. Loosen FENCE LOCK KNOB. Tilt fence upward and

slide it toward the pulley.

3; Position machine on Leg Setand align mounting hole._

in machine with holes in Leg Set letter coded "A".

Mount with three (3) 5/16-18 x 2" Long Hex Head

Screws.

4. Place a flat washer, a lock washer and a nut on each

screw from underneath the stand and tighten.

5: Place handwheef on shaft aligning ftat surfaces on

shaft with flat surfaces on handwheel.., attach with

1-1/4 in. screw.

1f4-20 TRUSS

HEAD SCREW S_DE STIFFENER

/ /\

l

DEPTH OF CUT

HANDWHEEL

A EN TIFFENE

-- MOTOR SUPPORT AT THIS END

IIL_ J JJJJl I I i

FLAT WASHER

CHECKING CUTTER BLADES AND SCREWS

TOOLS NEEDED

: 5i32" and 118" Setscrew Wrenches (furnished with 5/32 IN. SETSCREW

OUTFEED TABLE WRENCHi J°inter).

Lead Pencii /

Short straight edge (or head of Combination square)i :i ____....._ WEDGE

i 1, Insert penci;! in space at end of cutterhead to hold , L"k. I! ! __

cutterhead guard open. _ _______ _--

2. Lower the infeed table wilth the Depth of Cut Hand-

wheel

%

3. Rest the straight edge on edge on the surface of

outfeed table so itextends across the open ing between -_'-_ _

the tables, at three positions: neareach endand atthe _ .__

middle of the cutter b_ade. ""--..,.__ _Y_-_

4. Rotate the cutterhead by grasping the 2" die. driven __

pulley and make sure each knife nicks (touches) the PENCt L

straight edge at all three positions. If not, follow CUTTER GUARD

procedure under "REPLACING CUTTER BLADES"

on pgs. 19 thru 21.

5. If a cutter blade adjustment is not required, check

each locking screw of each wedge (5/32" setscrew

wrench) and tighten if necessary. Hold the pulley

while tightening screws and be careful that your

fingers do not slip off the wrench,

..... /

i •_ : ::: :i, :,i:,i _ ,, • _ ,:

::,: i, _ : ,:

8

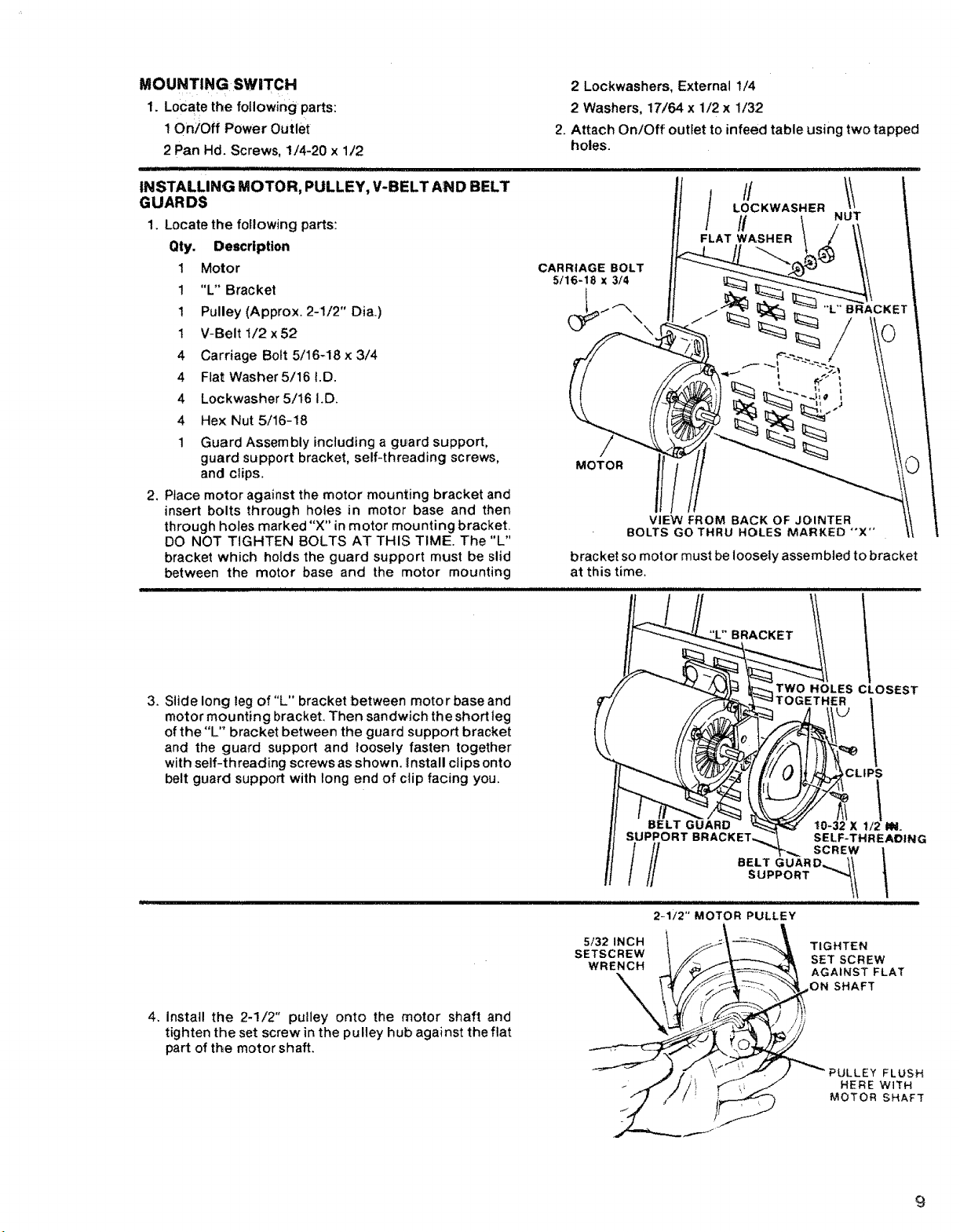

MOUNTING SW|TCH

1. Locate the following parts:

! On/Off Power Outlet

2 Pan Hd. Screws, 1/4-20 x 1/2

IIj!' ILLLjl II JI!l II I

INSTALLING MOTOR, PULLEY, V-BELT AND BELT

GUARDS

1. Locate the following parts:

Qty. Description

1 Motor

1 "L" Bracket

! Pulley (Approx. 2-1/2" Dia.)

1 V-Belt 1/2x52

4 Carriage Bolt 5/16-18 x 3/4

4 Flat Washer5/16 I.D.

4 Lockwasher 5/16 I.D.

4 Hex Nut 5/16-18

1 Guard Assembly including a guard support,

guard support bracket, self-threading screws,

and clips,

2, Place motor against the motor mounting bracket and

insert bolts through holes in motor base and then

through holes marked "X" in motor mounting bracket.

DO NOT TIGHTEN BOLTS AT THIS TIME. The "L"

bracket which holds the guard support must be slid

between the motor base and the motor mounting

2 Lockwashers, External 1/4

2 Washers, 17/64 x 1/2 x 1/32

2. Attach On/Off outlet to infeed table using two tapped

holes.

CARRIAGE BOLT

5/16-18 x 3/4

bracket so motor must be loosely assembled to bracket

at this time.

3. Slide long teg of"L" bracket between motor base and

motor mounting brackeL Then sandwich the short leg

of the"L" bracket between the guard support bracket

and the guard support and loosely fasten together

with self-threading screws as shown. _nstall clips onto

belt guard support with long end of clip facing you.

4. Install the 2-1/2" pulley onto the motor shaft and

tighten the set screw in the pulley hub against the flat

part of the motor shaft.

5/32 INCH

SETSCREW

WRENCH

SUPPORT BRA(

///

2-1/2" MOTOR PULLEY

BRACKET

TWO HOLES CLOSEST

TOGETHER

t0-32 X 112 IN.

SELF-THREADING

BELT GUARD_,_ I_

SUPPORT _'_t

SCREW

TIGHTEN

SET SCREW

AGAINST FLAT

ON SHAFT

_CLIPS

FLUSH

HERE WtTH

MOTOR SHAFT

9

6. P0sition btherend Of V:Belt ontoCutter head p_iiey. ........ :

i :

ii1111111 i i ] i i i ii iiii iiii

7. Visually fin tl

eupbothpueys dan until they areV-Belt

perpendicular to the floor by sliding motor sideways

as needed.

8. Press down hard on motor to put tension on theV-Belt

and tighten the motor mounting bolts at this time.

9. Check guard support before tightening motor support

screws to be sure it is centered around motor shaft and

will not rub against shaft when motor is running.

Tighten screws.

10. Push motor pulley belt guard into position onto guard

support.

11. Plug motor cord into outlet on switch box installed

eadier through hole provided in stand.

12, Fasten cord along front side stiffener using the two

cord clips.

' " " I' ' '' ............ ;............ ..............

INSTALLING SLIDING GUARD :

PARTS NEEDED

i .... ::" ....

Sliding Guard

1 Sliding Guard Knob

1 Sliding Guard Rod

2 Sliding Guard Washers(one side of washer is concave)

.2HeX Hd; Screws 1/4-2Ox !/2"

1:::Positionihe sli;ding guaid !:r0d throughthe opening in

the belt guard asillUstratedl :;......

2: Screw i/2" nut all the way onto long end0f rod..:.

place i/2!' !ockwasher next to nut (as illustrated) ....

3. SCrew the sliding guard rod into the jointer as far as it

wil! go with the short end of rod pointing straight up.

4. Tighten the i/2" nutto hold the rod securely in this

position.

II iiiii .lUll II II IH

OPEN END

..I-MUST BE STRAIGHT IN-LINE

__ AT 90° WITH RELATIONSHIP

_-_--__. TO THE FLOOR

1

[ ........ ! GUARDS REMOVED

,----_V-BELT

/ _=___:__.... _ _ FOR PICTURE CLARITY

MOTOR _i_-_r \

/ / i:'_--_ STRAIGHT LINE

/ / .J _, I UP--DOWN

/ / 9o_'m, \ I

// ( I ',',

: 2 Hex Nuts 1/4-20

......... '1 Rex Nut 1/2 in. - 13

1 Split iockwasher 1/2 in,

2 Ext, tooth Iockwashers

2 10-32 x 1/4 Pan Hd. Screws

I Belt Guard

....... Ill I J IJ

1i2, LOCKWAS_R

!:: BELT

/

1/2" X 13 /o/ SLIDING

__ GUARD

HEX NUT )_/ GUARD ROD

y

PULLEYS AND V-BELT

iiii i iiiii i ii iiiJlll

1/2" HEX NUT

GUARD RO0

5. Attach guard to stand with hex hd. screws and nuts.

Make sure belt does not scrape guard.

BELT

Loading...

Loading...