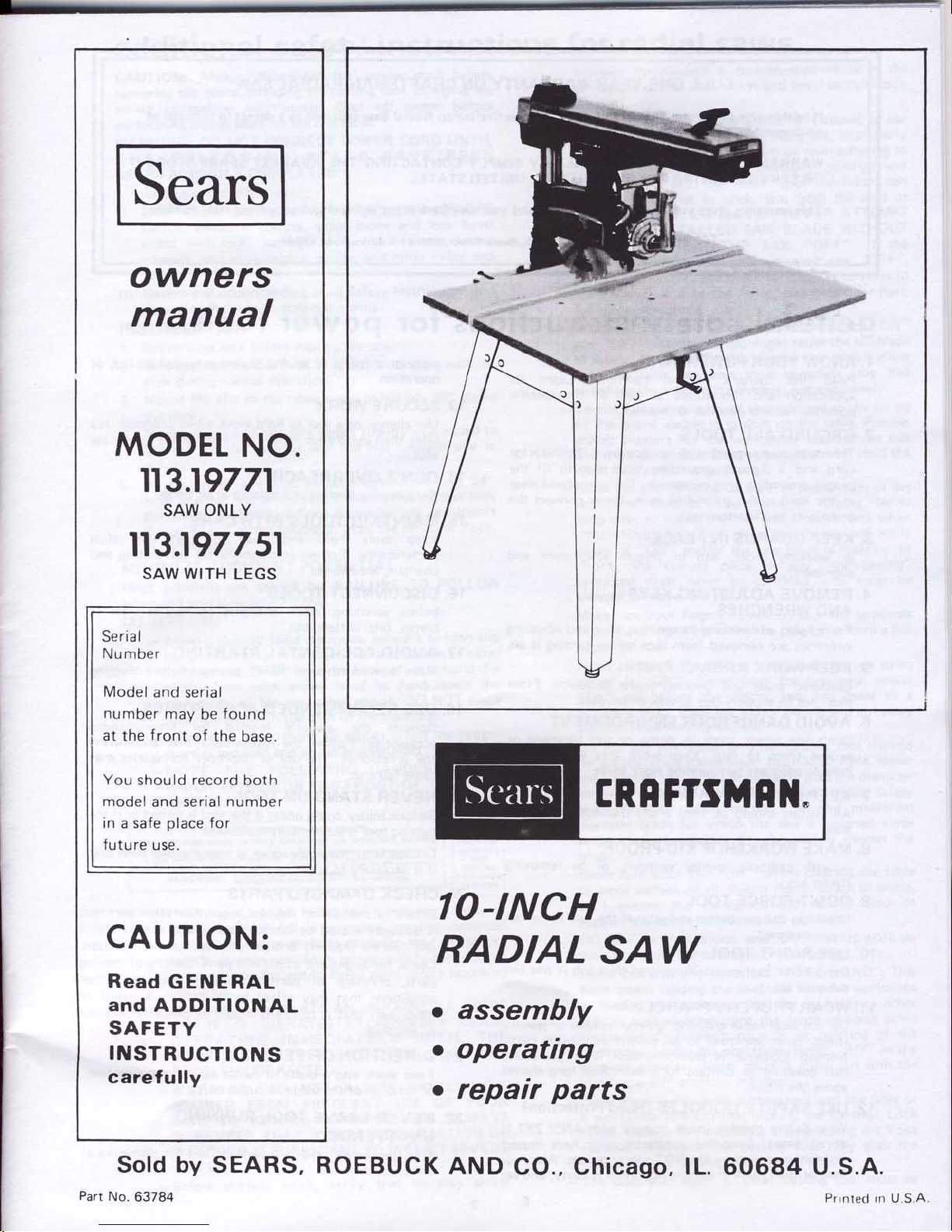

Craftsman 113.19771, 113.197751 Owner's Manual

Sears

owners

manual

MODEL

NO.

ll3 .19771

SAW ONLY

113.1977 5l

SAW

WITH

LEGS

Seri a

I

Number

Model

and

serial

number

may

be

found

at

the

front

of the

base.

You

should record both

model

and serial

number

in

a

safe

place

for

future

use.

CAUTION:

Read

GENERAL

and

ADDITIONAL

SAFETY

INSTRUCTIONS

carefully

IO-INCH

RADIAL

SAW

o

assemblV

o

operating

o

repair

parts

Sold

by

SEARS, ROEBUCK

AND

CO., Chicago,

lL.

60684 U.S.A.

Part

No.

63784

Pnnrecl in U.S.A

g

en

erol

sofetY

instructions

for

Power

tools

1.

KNOW

YOUR

POWER

TOOL

;i;;J

the

owner's

manual

carefullv'

.

Learn

rts

application

anO

rimltaiioni

as

well

as

the

specif

ic

ootential

hazards

peculiar

to

this

tool'

2.

GROUND

ALL

TOOLS

-

This

tool

is

equipped

with

an

approved

3-conductor

cord

and

'

s-p'ong

gtunding

type

plug

to

fit

the

proper

grounding

tyit'""tpttti9

Th:

st-t:i

conductor

in the

cord

i, tnt

ilou"Ollg

wire'

Never

connect

the

green

wire

to

a

live

terminal'

3.

KEEP

GUARDS

IN

PLACE

inworkingorder'andinproperadiustmentano

align

ment'

4 REMOVE

ADJUSTING

KEYS

"

AND

wRENcHES

Formhabitofcheckingtoseethatkeysandadiusting

wrenches

ar"

r"*o-utd"from

tool

before

turning

tt on'

5.

KEEP

WORK

AREA

CLEAN

,.^:

Cluttered

ttt"

unO

Oenches

invite

.accidents'

Floor

t"r.i

".,

be

slippery

due

to

wax

or

sawclusr'

6.

AVOID

DANGEROUS

ENVIRONMENT

Don't

use

po*"'

tools

in

damp

or

wet

locations

or

expose

them

to

oin'

rc"tp

wor'k

area

well

lighted'

Provide

adequate

surrounding

work

space'

7.

KEEP

CHILDREN

AWAY

A||visitorssnoutdbekeptasafedistancefromworx

dt

co.

8.

MAKE

WORKSHOP

KID'PROOF

-

with

padlocts'

master

switches'

or

by

removtng

starter

keys'

9.

DON'T

FORCE

TOOL

It will

do

the

iob-Ot"*l"O

safer

at

the

rate

for

which

it was

designed'

10.

USE

RIGHT

TOOL

Don't

force

too'

i'-*"hment

to

do

a

iob

it

was

not

designed

for'

11.

WEAR

PROPER

APPAREL

DonotwearIoosec|othing,g|oves,necktiesorjewe|ry

(rings,

wrist

*tttnttl

to

ieicaugnt

in

moving

parts'

Nonslip

toot*tti

it

rgcolnmeld-99

o*ttt

protectrve

hair

covering

tJ

"ontain

long

hair'

Roll

long

sleeves

above

the

elbow'

12.

USE

SAFETY

GOGGLES

(Head Protection)

Wear

Safety

goggles

(must

comply

with

ANSI

287'1)

at

all

times.

lGtvOav

ey-eglasses

only

have-

'impact

resistant

r.nstt,

inty

aie

triOi

safety

glasses'

Also"

use

face

or

dust

mask

ii

cutting

operation

is dusty'

and

ear

13.

SECURE

WORK

Use

clamps

o'

a

uii"

to

hold

work

when-practical'

lt's

safer

than

using

your

hand'

frees

both

hands

to

operare

tool.

14.

DON'T

OVERREACH

'-'

I*o

otoper

footing

and

balance

at

all

times'

15.

MAINTAIN

TOOLS

WITH

CARE

Keep

tools

sna'f

ano

clean

for

best

and

safest

oerformance.

f

orroui

instructions

for

lubricating

and

changing

accessories'

16.

DIscoNNECT

TOOLs

before

servicing;

when

changing

accessories

such

as

blades,

bits,

cutters'

etc'

17.

AVOID

ACCIDENTAL

STARTING

Make

sure

switcn

's

in

"OFF"

position

before

plugging

In.

18.

USE

RECOMMENDED

ACCESSORIES

Consult

the

*tt;t

manual-

for

.

recommended

tJitt.ii.t.

rottow

the

instructions

that

accompanY

the

accessortt''

ir''t

use

of

improper

accessories

may

cause

hazards'

19.

NEVER

STAND

ON

TOOL

Serious

intu'v

toJO

ottur

if

the

tool

is

tipped

or

if

the

"u,ring

tool

is accidentally

contacted'

Do

not

store

materials

above

or

near

the

tool

such

that

it

is

necessary

to stand

on

the

tool

to

reach

them'

20.

CHECK

DAMAGED

PARTS

Before

f

urther

"tJ

tnt

tool'

a

guard

or

other

part

that

is damaged

'nouti

[t

"tt"iu"u

ciected

to

ensure

that

it

will

operate

p,opi'iv

tnd

p"'iottn

i1s

i1te1!eo

t.'""]l:l:

Check

for

atignr;eni

of

moving

parts'

binding

of

movtng

parts,

breaKage

o{

parts'

mounting'.

and

any

otner

conditions

tnt'

'it':tttect

its

operation'

A

guard

or

other

part

tnut

it Outtged

should

be

properly

repaired

or

rePlaced'

2l.DIRECTION

OF

FEED

Feed

work

into

a

blade

or

cutter^aga.rnst

the

direction

oiiotation

o{

the

blade

or

cutter

onry'

22.

NEVER

LEAVE

TOOL

RUNNING

UNATTENDED

Turn

power

oti

Oon't

leave

tool

until

it

comes

to

a

comPlete

stoP'

2

protectors

(Plugs

or

muffs)

operation.

during

extended

Periods

of

addltional

safety

instructions

for

radial

saws

CAUTION:

Always

disconnect

the

power

cord before

removing

the

guard,

changing

the

cutting

tool,

changing

the

set-up

or

making

adjustments.

Shut

off

motor

before

performing

layout

work

on

the saw

table.

WARNING:

DO

NOT

CONNECT

POWER

CORD

UNTTL

THE

FOLLOWING

STEPS

HAVE

BEEN

SATISFACTORI

LY COMPLETED:

l.

Assembly

and

alignment.

ll. Examination

and

operating familiarity

with

ON-OFF

switch,

elevation

control,

yoke

index

and

lock

bevel

index

and lock,

carriage

lock,

guard

clamp

screw,

spreader

and antikickback

device,

and miter

index

and

lock.

I

ll. Review

and

understanding

of all

Safety Instructions

and

Operating Procedures

thru-out

manual.

INSTALLATION

1.

Set carriage

lock

before moving

the saw.

2- Bolt

the saw

to

the

floor

if

it

tends

to slip,

walk, or

slide

during normal

operation.

3. Mount

the

saw

so

the table

is

approximately

39,, above

the

floor.

4. Mount

the saw

so the

arm

slopes

slightly

downward

to

the

rear

so the

carriage

will

not roll forward

due

to

gravity.

5.

lf

you

attach

any

kind

of table

extensions

over

24,,

wide

to

either

end

of the saw,

make sure

you

either

bolt

the saw

to the bench

or floor

as appropriate,

or

support

the outer

end of

the extension from

the bench

or

floor,

as

appropriate.

MI

NI M!ZE

ACCIDENT POTENTIAL

Most

accidents

are

caused

by

FAILURE

TO FOLLOW

setup

and

operating instructions:

(A)

GENERAL

-Avoid

awkward

hand

positions,

where

a sudden slip

could

cause

a hand

to move into

a sawblade

or other

cutting

tool.

Never reach

in

back of or

around

the

cutting

tool with

either

hand

to hold

down the

workpiece,

or

for

any

other reason;

DO

NOT

place

fingers

or hands

in

the

path

of the sawblade.

-

Never saw,

dado, mold.

or rabbet

unless

the

proper

guard

is

installed

and

set up

as

instructed-

_

NOTE

TH E FOLLOWING

DANGER

LABELS

WHICH APPEAR

ON THE

FRONT

OF THE YOKE

AND

GUARD:

OANGER

DAIUGEF: FoP Youn

owil

SAF€TY

READ AI{O

UI{O€RSIAND

OWIIER'S MAI{UAL

AEFONE

OPERATING MACHIr{E.

r.waisaFCfrc6clEs.

a.usE"pusHsncr-roFuihowwonx,

2.

tEEp xdDs

our oF

patB

gF

sltluoE. s. N€vai

iuca

^rouio

rxE

s^wtLioE_

3. XiOW XOf TO IVOIO

.i|CXAACXS,"

6. AIIOW IOOL rO

SrOp OEFonE AbJUSTTNG_

wABtll I luG:

llail,oJi

T*?"'af#9335:iioi.l?

l1'j"u.l'^?,.31

-

lf

any

part

of

this

radial

saw is missing

or should

break,

bend

or

fail

in

any way,

or any

electrical

component

fail

to

perform

properly.

shut

off

power

switch,

remove

cord

from

power

supply

and

replace

damaged,

missing

andlor failed

parts

before

resuming

operation.

_

IF

YOUR

SAW MAKES

AN

UNFAMILIAR

NOISE

O R IF

IT

VIBRATES

EXCESSIVELY

CEASE

OPERATING

IMMEDIATELY

UNTIL

THE

SOURCE

HAS

BEEN

LOCATED

AND THE

PROBLEM

CORRECTED.

-WARNING:

DO

NOT

ALLOW

FAMILIARITY

(GAINED

FROM

FREOUENT

USE

OF

YOUR

SAW) TO

BECOME

COMMONPLACE.

ALWAYS

REMEMBER

THAT A

CARELESS

FRACTION

OF

A SECOND

IS

SUFFICIENT

TO INFLICT

SEVERE

INJURY.

-

Before

starting work,

verify

that no

play

exists

between

the column

& column

support, or

in

the

carriage,

and

that arm.

yoke,

and

bevel

locks,/clamps

are

tight.

-

A large

proportion

of

saw

accidents

is

caused by use

of

the wrong

type

blade,

dull, badly set,

improperly

sharpened

cutting

tools,

by

gum

or

resin

adhering to

cutting

tools,

and by

sawblade

misalignment

out-of-parallel

with

the fence.

Such conditions

can

cause

the

material

to stick,

jam

(stall

the saw)

or

"KICKBACK"

at the

operator.

NEVER ATTEMPT

TO

FREE

A

STALLED

SAW

BLADE WITHOUT

FIRST

TURNING

THE

SAW

"OFF".

If

thE

sawblade

is

stalled

or

jammed,

shut saw

,,OFF,,,

remove

workpiece,

and

check

sawblade

squareness

to

table

surface

and

to

the fence,

and check

for

heel.

Adjust

as

indicated.

-

CAUTION:

DO

NOT

cycle the

motor

switch

,,ON"

and

"OFF"

rapidly,

as

this

might

cause

the

sawblade

to

loosen.

In

the

event

this shoutd

ever

occur,

allow

the

saw

blade

to

come

to

a

complete stop and

re-tighten

the

arbor

nut

normally,

not

excessively.

-

D_o

1ot

leave

a

long

board

unsupported

so

the

spring

of

the

board

causes

it

to shift

on

the table.

provide

proper

support

for

the

workpiece,

based

on

its size

and

the

tyBe

of

operation

to

be

performed.

Hold

the

work firmly

against

the

fence.

-

Never

use

a

length

stop

on

the

free

end or edge of

the

workpiece

whether

crosscutting

or

ripping.

Never

hang

onto

or

touch

the free

enJ

of

woikpiece

when

crosscutting,

or

a free

piece

that

is

cui off while

power

is

"ON"

and/or

the

saw

blade is

rotating.

In

s h o rt,

the

cut-off piece

in

anv

,,thru_sawinq"

operation

must

never

be

conf

ined

-

it must

6e

allowed

to move

laterally.

-

Make

sure

your

fingers

do

not

contact

the

terminals

when installing

or removing

the

plug

to or

from

a

live

power

source.

-

Never

climb

on

the saw,

or

climb

near

the saw when

power

is

"ON".

Never

leave

the

saw

with

power

"ON",

or

before

the

cutting

tool

has

come to

a

complete

stop.

Lock

the

motor

switch

and

pur

away

the key

when

leaving

the

saw.

-

Do not

use

any

blade

or

other

cutting

tool marked

for

an operating

speed

lower

than

345b

RpM. Never

use

a cutting

tool

larger

in

diameter

than

the

diameter

for

which

the

saw

was

designed.

For greatest

safety

and eff iciency

when ripping,

use

the

maximum

diameter

blade

for

which

the

saw

is

designed,

since

under

these

conditions

the spreader

is

nearest

the

blade.

-

Never

turn

your

saw

"ON"

before

clearing

the table

or

work surface

of

all

objects

(tools,

scraps

of wood,

etc.)

except

the

workpiece

and related feed

or

support

devices for

the operation

planned.

-

DO NOT

perform

layout.

assembly.

or

setup

work

on

the

table

while

the cutting

tool is rotating.

-Never

perform

any

operation

"FREE

HAND,'. This

term means feeding

the sawblade

into

the workpiece

or

feeding

the

workpiece

into

the

sawblade

or other

cutting

tool

without

using

the

fence

or some

other

device

which

prevents

rotation

or

twistinq

of

the

workpiece

during

the operation.

Never

,,Rti,,

in

the

crosscut

position.

Never

make

a miter

cut with

the

arm

in

the

90o crosscut

position.

*

Never

lower

a

revolving

cutting

tool

into

the

table

or

a workpiece

without first

locking

the

Carriage

Lock

Knob.

Release

the knob

only

after

grasping

the

yoke

Handle.

Otherwise

the cutting

tool may

grab

the

workpiece

and

be

propelled

toward

you.

-

The

sawblade,

dado, or

other cutting

tool must

be

ro ^vorD

I

liJuiY

oo

NO' FECD

]

]

uet:nrt

]

I

riro

I

,

currttc

i

I

TOO!

rnor

I

rHts

Eio

;

i

I

I

additional

safety

instructions

for

radial

saws

removed from

the

saw arbor

before using

the

accessory shaft

(rear

end of the

saw motor). NEVER

operate the

saw

with cutting

tools

(including

sanding

accessories) installed on both ends of the

saw

arbor.

(B)

RIPPING

'l

.

Never

apply

the

feed force

to

the

section

of the

workpiece

that will become the

cut-off

(free)

piece.

Feed

force

when

ripping

must

always

be applied

between

the

saw

blade and

the

fence

.

. . use

a

"PUSH

STICK"

(see

pg.

261

for

narrow or short

worK.

Whenever

possible,

use

the

in-rip

position

-

this

provides

minimum

obstruction

for

feeding

by hand

or

push

stick

as appropriate.

Do not release

the workpiece

before

operation

is

complete

-

push

the workpiece

all

the way

past

the

rear

(outfeed

or exit)

of

the sawblade.

Make

sure

by trial

before

starting

the

cut that the

antikickback

pawls

will stop

a kickback

once

it

has

started.

Keep

points

of

pawls

SHARPI

Use

a

push

stick

when

ripping

short

(under

12

inches)

or

narrow

(under

6

inches

wide)

workpieces.

CAUTION:

Never reposition

the Guard

or

antikickback

with

power

"ON".

A

"KICKBACK"

occurs

during a

rip-type

operation

when

a

part

or

all

of

the workpiece is

thrown back

violently

toward

the operator. lt

can

occur when

the

workpiece

closes

in

on

the

rear

(outfeed

side)

of

the

sawblade

(pinching),

binds between the

fence

and the

sawblade

(heel),

or is

grabbed

by the

sawblade

teeth

(wrong-way

feed)

at

the

outfeed

side.

"PlNCHlNG"

is

generally

avoided

by

utilization

of the

spreader,

and a sharp sawblade

of

the correct

type for

the

workpiece

being cut.

' 'H

E

E L" can

be avoided

by maintaining

the

sawblade

exactly

parallel

to

the

fence.

Grabbing

by

the

sawblade

teeth can

be caused by heel

or

by

feeding

from

the wrong

direction

(see

"DANGER"

wa

rning

on

guard)

it

can

be avoided

by

maintaining

parallelism

of sawblade

to

fence,

feeding

into

the sawblade

from

the nose of

the

guard

only, and

by

positioning

the

spreader

and

antikickback

property,

and keeping

the

workpiece

down on

the table

and against the

fence.

Position

the

nose

of

the

guard

to

just

clear

the

workpiece,

and

position/ad

just

the antikickback

and spreader

devices as instructed.

NEVER

cut more

than one

piece

at a time

by

stacking

workpieces vertical

ly.

10.

NEVER

feed

a

workpiece

thru the

saw with

another

piece

(butting

second

piece

against trailing edge of

piece

being cut), even if

of the

same

thickness.

Feed

each workpiece individually

thru the sawblade,

and

completely beyong

the sawblade,

before

ripping

the

next workpiece.

Use

push

stick

if

the

rip

cut

is less

than

6" wide.

1 1 .

DO NOT

pull

the workpiece

th ru

the sawblade

-

position your

bod1, at

the

nose

(in-feed)

side

of

the

guard:

start

and

complete

the

cut

from

that

same

side. This

will

require

added table

support

for

long

pieces.

12. Plastic

and

composition

(like

hardboard)

materials

may

be cut

on

your

saw.

However, since

these are

usually

quite

hard and

slippery.

the antikickback

pawls

may not stop

a

kickback.

Therefore,

rip

with

the

finished

side

down

(next

to

the table)

and

be especially

attentive

to

following

proper

set-up

and

cutting

procedures.

Do not stand,

or

permit

anyone else to

stand, in line

with a

potential

kickback.

13. When

sawing 1/4"

or thinner

materials,

follow

all

normal ripping

procedures

except

set

sawblade into

table

top at

least 1/8".

DO NOT

let

go

of or

stop

feeding

the workpiece between the blade

and

fence

until

you

have

pushed

it completely

past

the

antikickback

pawls.

Otherwise the workpiece

could

get

into

the back of the sawblade

and be thrown

violently from

the

saw

in

the direction opposite

to

the

feed

direction.

This

is

the

same

action

that

would

occur if the instructions

of

the

DANGER

warning

on

the

guard

is

aborted. Do not stand,

or

permit

anyone else to stand,

in

line with

the

path

of

a

workpiece

that

may

be thrown from

the

saw

in

this manner.

14.

Position

the

saw

so

neither

you,

a

helper,

or

a casual

observer is

forced

to

stand

in

line with

the

sawblade.

15.

Use extra

care when ripping

wood that has a twisted

grain

or

is

twisted or bowed - it may rock

on

the

table and/or

pinch

the

sawblade.

(C)CROSSCUTTING

1. ALWAYS

RETURN THE

CABRIAGE

TO THE

FULL

REARWARD POSITION

AT CONCLUSION

OF EACH

CROSSCUT

TYPE

OPERATION.

Never

remove

your

hand from

the

Yoke

Handle

unless the

carriage is

in

this

position.

Otherwise the cutting

tool

may

climb up

on the

workpiece

and

be

propelled

toward

you.

2.

Place guard

in horizontal

position

and adjust

antikickback

pawls

to

just

clear

the top of the

fence

or workpiece, whichever is

higher.

3. NEVER

gang

crosscut - lining

up more than one

workpiece in front

of

the

fence - stacked vertically,

or

horizontally

outward

on

the table - and

then

pulling

saw

thru:

the blade could

pick

up one or

more

pieces

and

cause a binding or loss

of control

and

possible

injury.'

4. Do

not

position

the

Arm

so

the

operation

you

are

perf

orming

permits

the cutting

tool to

extend

beyond

the edges of

the

Table.

(D)

ACCESSORTES

1. Use only recommended

accessories as

listed

on

page

34.

Never

operate

this saw

when equipped with a

dado

head or molding

head unless

the

molding

head

guard

is installed

-

see

listing

of recommended

accessories. The

only

exception

is

when

"top-side"

dadoing

or molding,

when the sawblade

guard

must

be used.

See

detailed

instructions

that accompany

the

dado

head, molding head, and

molding

head

guard.

The

use

of abrasive

or cut-off

wheels, or

wire

wheels,

can

be

dangerous and

is not

recommended.

(Abrasive

or cut-off wheels

are

used

to

saw

many

different materials including

metals,

stone,

and

glass.

)

Drill

Chuck:

Do

not install

or use

any

twist

drill

f

arger

than 1|2-inch in

dia.,

or

ionger

than 7 incnes

in

length

or extending

more than 6 inches

beyond

the chuck

jaws.

Do

not

install

or

use

any reduced

shank

drill except of the

spade

type

(1

inch

dia. or

smaller).

"Use

for

drilling

WOOD

and

PLASTIC

onlv."

2.

?

4.

6.

8.

9.

2.

4.

WEAR

YOUR

The

operation

of any

power

tool

can result

in

foreign

objects

being

thrown

into

the

eyes,

which

can

result

in

se.vgre

9y9

damage.

Always

wear

safety goggles

complying

with

ANSI

287.1

(shown

on

packaget

OJtore

commencing

power

tool

operation.

Safety

Goggles are

available

at

Seari

retail

or

catalog

stores.

GROUNDING

LUG

ADAPTER

I

3-PRONG

PLUG

MAKE

SURE

THIS

tS

CONNECTED

TO

A

KNOWN

GROUND

RECE

PTACLE

-

-i--'-2-PR.NG

This

power

tool is

equipped

with

a

3-conductor

cord

and grounding

type

plug

which

has a grounding prong,

Listed

by

Underwriters'

Laboratories.

The - ground

conductor

has a green

jacket

and is

attached

to the

tool

NOTE:

The adapter

illustrated

is

for

use

only if

you

already

have

a

properly

grounded

2-prong

receptacle.

ELECTRICAL

CONNECTIONS

WARNING:

CHANGES

tN

ELECTRTCAL

CONNECTIONS

SHOULD

BE

MADE

BY

A

OUALI

FI

ED

ELECTRICIAN.

Changing

Motor

Connections

a.

Under

normal

home

workshop

usage,

and if

proper

(full)

vell3gq

is

supplied

to

the motor,

your

saw

will

operate

efficiently

on

120V,

as connected

at the

factory.

However,

if

any

of the following

conditions

exists,

it

will be

advisable

for

you

to reconnect

the

.

motor

for

24OY

operation

-

to

obtain

the

efficiency

and

performance

for

which

your

saw

is

designed:

(1

)

Heavy-duty

operations.

(2)

Either

an

undersized

or an

overloaded

branch

circuit

serving

the

saw

motor.

(3)

Low

voltage

supplied

by

the

power

source,

which

the

power

company

cannot

correct.

b.

Motor

wiring

connections

for

120V

(as

made

at the

factory)

are described

below.

Necessary

reconnections

for

240V

operation

are

also described

following.

Whenever

changing

connections

frorh

120V

to 24OY

or vice-versa,

make

certain

thatall

necessary

steps

(including

proper

fusing

of the

branch

circuit)

are

completed.

electrical

connections

POWER

SUPPLY

1.

Motorspecifications

The

A-C motor

used in

this

saw is

a capacitor-start.

non-reversible

type

having

the following

specifications:

Voftage

eO/24O

Amperes

11l1.s

Hertz(cycles)

....

.......60

Phase

. .

Sinqle

RPM

.

...

3460

Rotation

as viewed

from

saw

blade

end . .

. . Clockwise

CAUTION:

Your

saw

is

wired

for 12Ov

operation.

Connect

to

a 120V,

l$Amp.

branch

circuit

and

use

a

15-Amp.

time-delay

fuse

or

circuit

breaker.

lf

the

motor

is

used

tor

24OY

operation,

connect

to

a

15-Amp.

branch

circuit

and

use

a 1S-Amp.

time-delay

fuse

or circuit

breaker.

This

machine

must

be

grounded

while

in

use to

protect

the

operator

from

electric

shock.

IF

YOU

ARE

NOT

SURE

THAT

YOUR

OUTLET IS

PROPERLY

GROUNDED,

HAVE

IT

CHECKED

BY

A

OUALI FI

ED

ELECTRICIAN.

WARNING:

DO

NOT PERMTT

FTNGERS

TO TOUCH

THE

TERMINALS

OF PLUGS

WHEN INSTALLING

OR

REMOVING

THE PLUG

TO

OR

FROM THE

OUTLET.

WARNING:

IF

NOT

PROPERLY

GROUNDED THIS

POWER

TOOL

CAN INCUR

THE POTENTIAL

HAZARD

OF

ELECTRICAL

SHOCK.

PARTICU

LAR

LY

WHEN

USED

IN

DAMP

LOCATIONS

IN

PROXIMITY

TO PLUMBING.

IF

AN

ELECTRICAL

SHOCK

OCCURS

THERE

IS

THE

POTENTIAL

OF

A

SECONDARY

HAZARD

SUCH

AS

YOUR

HANDS

CONTACTING

THE

SAWBLADE.

IF POWER

CORD

IS

WORN

OR CUT,

OR DAMAGED

IN

ANY

WAY,

HAVE

IT

REPLACED

I.

IMMEDIATELY.

lf

your

unit is

for

use on

less

than 150

volts it

has

a

plug

that

looks

like

below.

PROPERLY

GROUNDED

OUILET

housing

at

one

end and

to

the ground

prong

in

the

attachment

plug

at the

other

end.

This

plug

requires

a mating

3-conductor

grounded

type

outlet as

shown.

lf

the

outlet

you

are

planning

to

use for

this

power

tool

is

of the two

prong

type

DO

NOT REMOVE

OR

ALTER

THE

GROUNDING

PRONG

IN

ANY

MANNER.

Use an

adapter

as shown

and

always connecr

the

grounding

lug

to known ground.

It

it recommended

that

you

have

a

qualified

electrician

rypF9e

the

TWO

prong

outlet with

a

properly

grounded

THREE

prong

outlet.

An adapter

as shown

below

is

available

for

connectinq

plugs

to 2-prong

receptacles.

The green

grounding

lu!

extending

from

the adapter

must

be

connected

to

i

permanent

ground

such

as

to a

properly

grounded

outlet

box.

ff-r]t

tot

o

fil

\"'

3-PRONG

PLUG

GROUNDING

PRONG

IOR

UsE

ON

r 20v I

240v

5unc:

rero

oru

EROWN

LEAD

ON

o

18

5l

electrical

connections

Connections

for

120V

A'C'

a.-

Ratou"

nameplate

cover

from

motor

to

expose

terminal

boarcl'

u.

ii.

*ir.,

inside

of

the

motor

must

be

connected

as

shown:

(1)

The

orange-colored

wire

on

number

6

terminal'

(2)

The

b'o*n-coto"d

wire

on

number

5

terminal'

c.Usethel20Vpower.cordp|ugfurnishedwithyour

saw'

Connections

for

240V

A'C'

a.

The

wires

inside

the

motor

terminal

box

must

be

connected

as

follows:

(1)

The

orange-colored

wire

on

number

8

terminal'

(2)

The

brown-colored

wire

on

number

7

terminal'

b.

Replace

the

120V

power-cord

plug

with

a

(3-blade)

240V

plug,

"onn"Jting'tnt

po*ti-"ord..white

and

black

leads,

"'ptiiiuJrv'

to

the

two

"hot"

plug

blades

-

,no

"onnJttlnj

irtt

po*tt-cord

grounding

wire

to

the

Plug

ground

Prong'

d.

Make

certain

the

receptacle

is

co-nnected

to a

240V

A-c

power

t'ppl;;;;Gh

a

2a0v

!1nctr

circuit

having

at

least

t,i'S-ttp'

itpacitv'

a1d-1;'otected

bv

a

1S-amp'

trme-oelay

fuse

or

circuit

breaker'

MOTOR

SAFETY

PROTECTION

NOTE:

This

motor

should

be

blown

out'

or

"vacuumed"'

freouently

to

prevent

;;ilil

interference

with

normal

motor

ventilation.

Your

saw

motor

is

equipped , yitl^i.manual-reset'

thermal

-overl

oad

protecto-rTtli

lntO

tt

99:l llt

power-l

i ne

circuit

when

the

rnoror

a'.'.p.raiure

exceeds

a

safe

value'

I

2.

3.

1.

lf

the

protector

opens

the

line

and'stops

the

saw

motor'

immediately

p""

'ittt'-iaw

switch

to

the

"OFF"

p"titf

"",

and

allow

the

motor

to

cool'

2.Aftercoolingtoasafeoperatingtemperature,the

overload

protector

"tn

U"

"iot"A

manually

by

pushing

in

the

red

button

Jn

ar,.

,op

of

the

motor.

lf the

red

button

will

not

tntf

into

place

immediately'

the

motor

is

still

too

hot

and

Lutt

U"

allowed-t^o

cool

for

a

while

lonqer.

In

some

".r.,

aii,

,ry

take20-30

minutes.

(An

r"ril[:'I,

"ii"[

*irr

l"oicate

protector

is closed')

3.

As

soon

as

the

red

button

will

snap

into

running

position.

the

tt*-

tty

-Ue

start-ed^'and

operated

normally,

by

pulling

o"'tft"

saw

switch

to the

"ON"

position

'

4.

Frequent

opening

of

fuses

or

circuit

lrealers

may

result

if motor

is

overlo]deJ'

or

if

the

motor

circuit

is

fused

differently

tr.ot

-""ot-endations'

Overloading

can

occur

if

you

feed

;itpiJtv

or

if

Your

sa;v

is

misaligned

so

that

the

blade

heels'

Do

not

use

.u

1-t-t-,:,f^:t"tttt

"apicitv

without

consulting

a

qualified

electrlclan'

5.

Although

the

motor

is

designed

for

operation

on

the

voltage

anO

t'equl-ncv

tpu"iiitO

9n,

t::ot

nameplate'

normal

toads

wiri

Ue

handled

sa.fely

on

voltages

not

more

than

tO'U"

atove

or

below

the

nameplate

voltage'

Heavy

loads,

no*u"tt'

require

.lltl

,u-oltust

at

motor

terminals

.q"r'

trtl-*itage'specified

on

nameplate'

6.Mostmotortroub|esmaybe.tracedtolooseor

incorrect

tonntii'ont'

overloading'

reduced

input

voltage

(such

as

tt"ritiit

*ites

in

thJ

supplv

circuit)

or

to

an

overly-'""n'-t"ooit'-liicuit'

,Always

check

the

connections,

tnt

ioJ

tnd

the

supply.

circuit'

whenever

the

motor

tairt

il""p#ott.ttliiltclorilv'

Check

wire

iit".

.nO

lengths

with

the

table

followrng'

WIRE

SIZES

The

use

of

any

extension

cord-will

cause

some

loss

of

power.

To

t""p

ii"it-'io

i

minimum

and

to

prevent

6

GROUNDING

BLADE

15

LONGEST

OF

3

BLADES

NO

ADAPTER

IS

AVAILABLE

FOR

THIS

TYPE

PLUG

PROTECTOR

(RED BUTTON)

FOR USE

ON

I 20V

240V

ORANGE

LEAD

ON

6

8

gRowl

rtlo

ON

5

7

24OV

PLUG

&

RECEPTACLE

c.

Plug

your saw

into

a24OY '

3-blade

receptacle'

over-heating

and motor burn-out,

use the table below to

determine

the minimum

wire size

(A.W.G.)

extension

cord.

Use

only 3 wire

extension

cords which have

3

prong

grounding

type

plugs

and

3-pole

receptacles which

accept

the

tools

plug.

NOTE: For circuits

of

greater

length,

the wire

size must

be

increased

proportionately

in

order to

deliver

ample

voltage

to the

saw

motor.

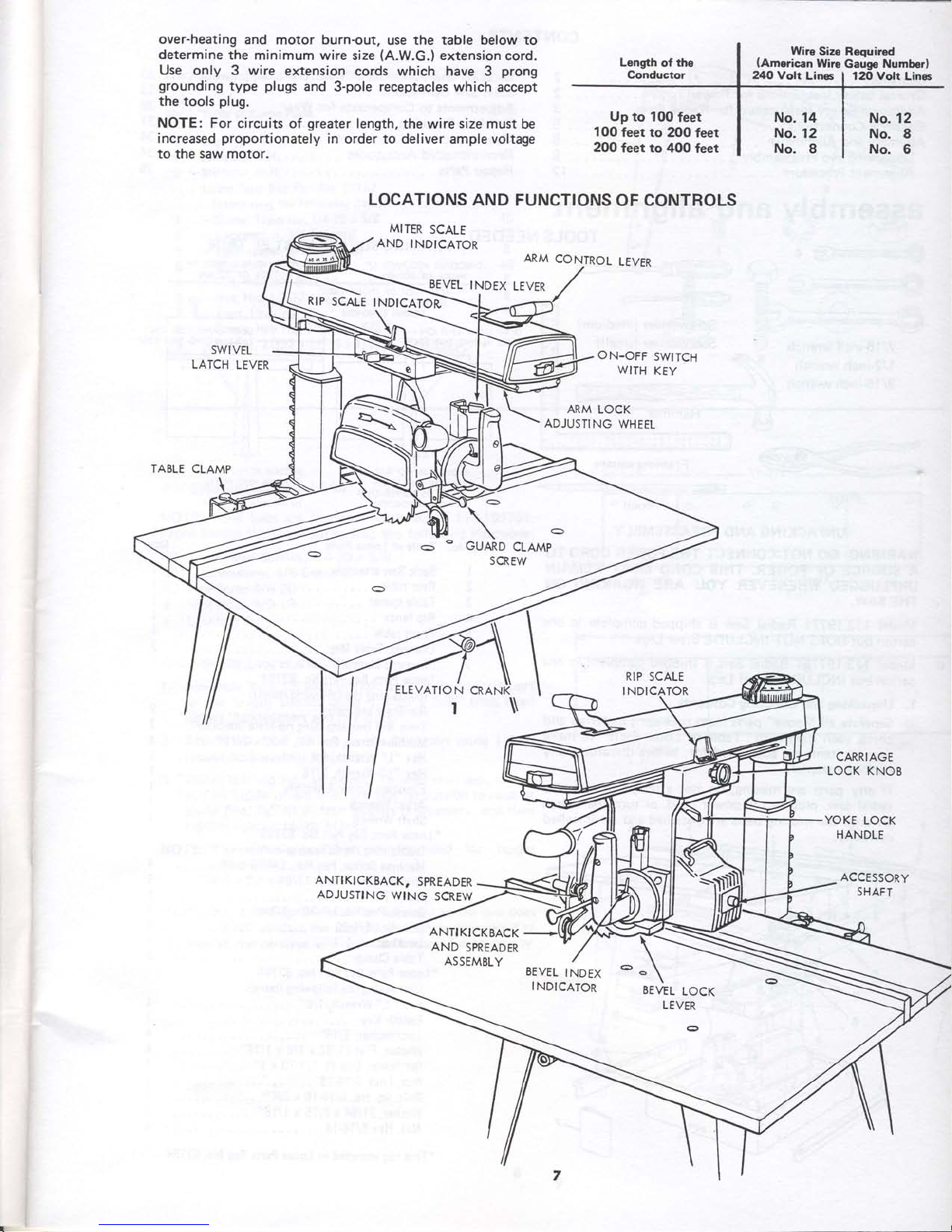

SWIVEL

LATCH

LEVER

LOCATIONS

AND FUNCTIONS

OF CONTROLS

MITER

SCALE

AND

INDIC,ATOR

ARM

CON-TROL

LEVER

BEVEL

INDEX

LEVER

ON-OFF

SWITCH

WITH

KEY

ARM

LOCK

ADJUSTING

WHEEL

RIP

SCALE

INDICATOR

TABLE

CLAMP

CARRIAGE

LOCK

KNOB

YOKE

LOCK

HANDLE

ANTIKICKBACK,

SPREADER

ADJU5TING

W]NG

SCREW

ACCESSORY

SHAFT

.

Wire

Size Required

lAmerican Wire

Gauge

Numberl

240

Volt

Line

|

120

Volt

Lines

Up to

100

feet

1 00

feet to

200 feet

200

feet to 400

feet

RIP

SCALE

INDtCATOi

ANTIKICKEACK

AND

SPREADER

ASSEMBLY

EEVEL

INDEX

INDICATOR

CONTENTS

Guarantee

......2

General

Safety

Instructions

for

Power

Tools

.........

2

Additional

Safety

Instructions

for

Radial

Saws .......

3

ElectricalConnections

........5

AssemblyandAlignment

....

........8

UnpackingandPreassembly...

.:....

g

AlignmentProcedure

.......12

s\_,!l!j:l,-

\d-=$l-]

7/

1

6-inch wrench

'l

/Z-inch

wrench

9/1

6-inch

vvrench

Screwdriver

(medium)

Screwdriver

(small)

Framing

square

:.-

Pencil

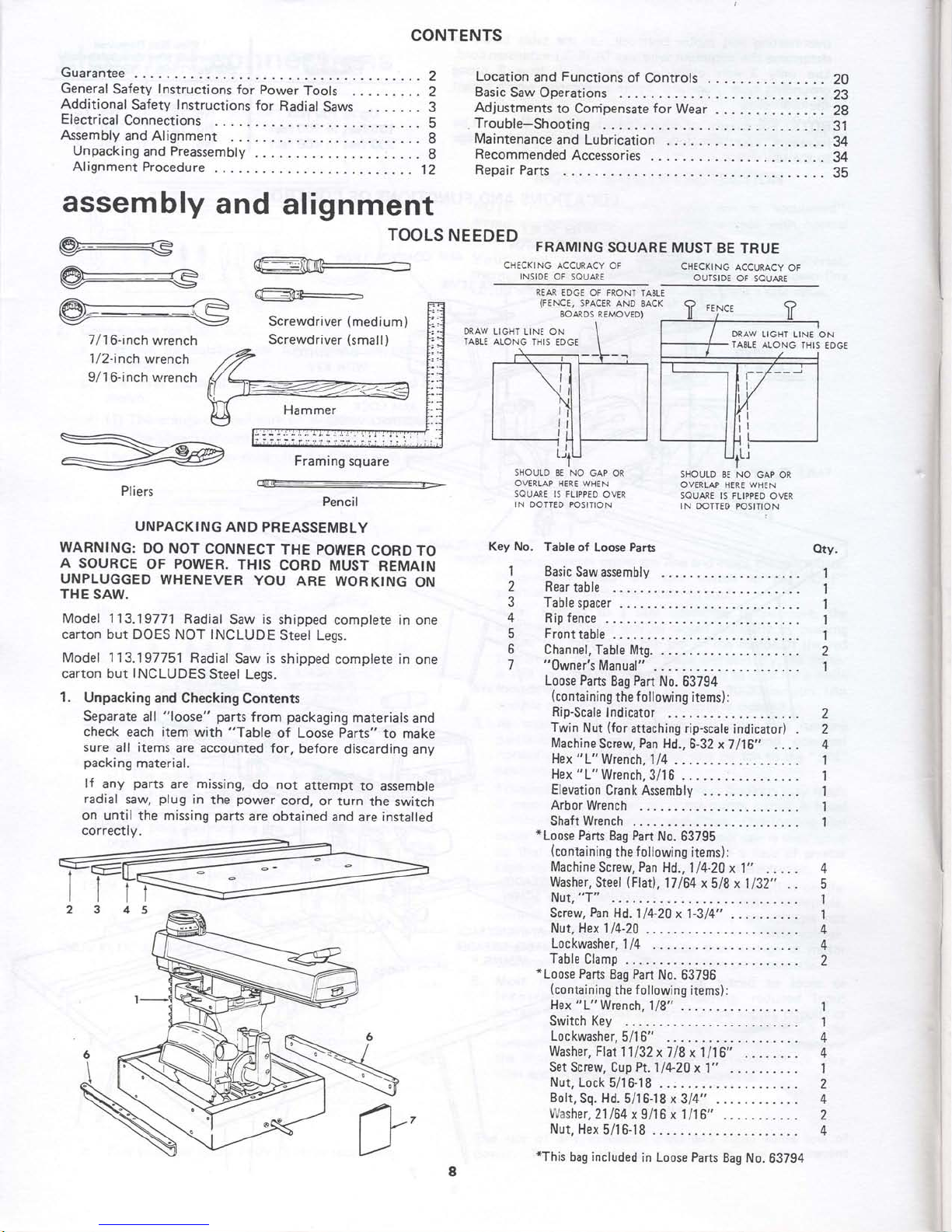

UNPACKING

AND PREASSEMBLY

WARNING:

DO NOT

CONNECT

THE

POWER

CORDTO

A

SOURCE

OF

POWER.

THIS

CORD

MUST

REMAIN

UNPLUGGED

WHENEVER

YOU

ARE

WORKING

ON

THE

SAW.

Model

113.19771

Radial

Saw

is

shipped

complete in one

carton but DOES

NOT

INCLUDE

Steel

Legs.

Model 1 13.197751

Radial

Saw is shipped

complete in

one

carton but

INCLUDES

Steel

Legs.

1.

Unpacking

and Checking

Contents

Separate

all

"loose"

parts

from packaging

materials

and

check

each item

with

"Table

of Loose Parts" to

make

sure

all

items

are accounted for,

before

discarding

any

packing

material.

lf

any

parts

are missing,

do not

attempt

to

assemble

radial

saw,

plug

in

the

power

cord,

or turn

the

switch

on until the missing

parts

are obtained

and are installed

correctlv.

Location

and

Functions

of

Controls

Basic

Saw Operations

Adjustments

to Conipensate

for

Wear

Trouble-Shooting

Maintenance

and Lubrication

. .

Recommended

Accessories

Repair

Parts

20

23

28

31

34

34

?tr

assembly

@::=€

@F-=-S

and

alignment

TooLs

NEEDED

FRAMTNG

souARE

MUsr BE

TRUE

CH€CKING ACCURACY

OF

INSIDE

OF SQUARE

CHECKING

ACCURACY

OF

OUTSIDE

OF

SQUARE

DRAW

TABLE

REAR

EDGE OF FRONT

TABLE

(FENCE,

SPACER

AND BACK

BOARDS

REMOVED)

SHOULD 8E NO

GAP OR

OVERLAP

HER€ WHEN

SQUARE IS FLIPPED

OVER

IN

DOTTED

POSITION

Key No.

Table

of Loose Parts

DRAW

LIGHT

LINE ON

TABL€

ALONG

THIS

EDGE

>

Pliers

SHOULD

BE NO

GAP OR

OVERLAP

HERE

WHEN

SAUARE

IS

FLIPPED

OVER

IN

DOTTEO POSITION

I

I

?

4

E

o

7

Basic

Saw assembly

Rear

table

Table

spacer

Rip fence

Front

table

Channel,

Table

Mtg.

"Owner's

Manual"

Loose Parts

Bag

Part

No. 63794

(containing

the

f

ollowing

items):

Rip-Scale

Indicator

Twin

Nut

(for

attaching rip-scale

indicator)

Machine

Screw,

Pan

Hd.,

6-32

x7116"

Hex

"

1"

Wrench, I

/4

Hex

"1"

Wrench,

3/1 6

Elevation

CrankAssembly

....

Arbor

Wrench

Shaft

Wrench

*

Loose

Parts

Bag Part

No. 63795

{containing the

following

items):

Machine

Screw,

Pan

Hd.,'l

l4-20

x 1"

Washer, Steel

(Flat),

17

164

x 518

x 1132" .

.

Nut,

"T"

Screw,

Pan

Hd. 114-20

x 1-314"

Nut, Hex

114-20

.

Lockwasher.114

...

Table

Clamp

*Loose

Parts

Bag

Part

No. 63796

(containing

the

following

items):

Hex

"1"

Wrench,

118"

. .

Switch Key

Lockwasher,5/16"

Washer, Flat

11/32

x718x1116"

Set

Screw, Cup

Pt.

1

/4-20

x 1" - -

Nut,

Lock 5/16-18

Bolt,

Sq. Hd.

5/16-18 x 314"

.

rYasher.21lE4

x

9i16 x 1/16"

Nut, Hex

5/16-18

*This

bag

included

in Loose Parts

Bag

No.

63794

€lty.

1

1

+

1

2

2

L

z

4

5

I

I

A

2

LIGHT

LINE ON

ALONG

THIS EDGE

(?,

LI

I

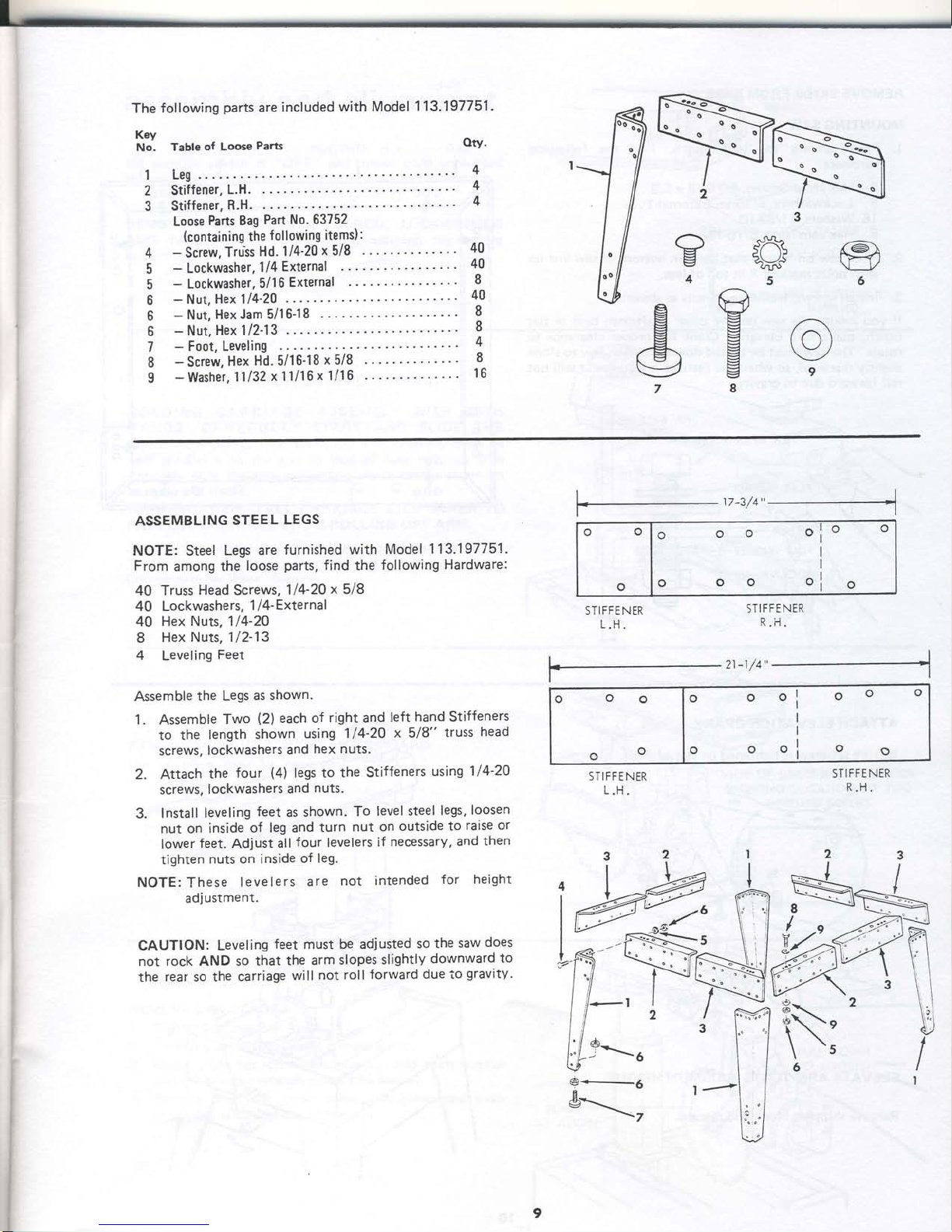

The

fof f owing

parts

are

included

with

Model

113'197751 .

,$a

Ue

g

7

Key

No.

'|

2

3

Table

of

Loose

Parts

Leg

...

Stiffener,

L.H.

..

Stiffener,

R.H.

. .

Loose

Parts

Bag

Part no. o'si'S'Z'

(containing

the

following items):

-

Screw.

Truis

Hd.

114'20

x5l8

- . .

-

Lockwasher,

l/4

External

-

Lockwasher.

5/16

External

-

Nut,

Hex 114'20

.

-

Nut,

HexJam

5/16{8

-

Nut,

Hex 112-13

.

-

Foot. Leveling

-

Screw,

Hex

Hd. 5/16-18

x 5/8

.

-

Washer.

11132

x l1/16

x 1/16

. .

oty.

4

4

4

4

5

5

6

6

6

7

8

I

40

40

I

40

8

8

4

8

't6

s}{"

a\_-/J

</t'u

5

@

6

a

\E{

FJ

g

v

8

r-))

9

40

40

40

8

4

ASSEMBLING

STEEL

LEGS

NOTE:

Steel

Legs are

furnished

with

Model

113.197751 .

From

among the

loose

parts,

find

the

following

Hardware:

Truss

Head Screws,

114-20x5/8

Lockwashers, 1 /4-External

Hex

Nuts, 1/4-2O

Hex

Nuts, 1/2-13

Leveling

Feet

Assemble

the

Legs

as shown.

1.

Assemble

Two

(2)

each

of

right

and

left

hand Stiffeners

to

the

length

shown

using 1/4-20

x

518"

truss

head

screws,

lockwashers

and

hex nuts.

2.

Attach

the

four

{4)

legs to the Stiffeners

using 1/4-20

screws,

lockwashers

and

nuts.

3.

Install leveling

feet

as

shown.

To

level steel

legs,

loosen

nut on

inside

of leg and

turn

nut on

outside to

raise

or

lower

feet.

Adjust

all

four

levelers

if

necessary,

and

then

tighten

nuts

on inside

of

leg.

NOTE:

These

levelers

are

not

intended

for

height

adiustment.

CAUTION: Leveling

feet must be adjusted

so

the

saw

does

not rock AND so

that

the arm

slopes

slightly

downward

to

the

rear so the

carriage

will

not

roll

forward due to

gravity.

o

o

lo

olo

""1:

" "

o

STIFFENER

L.H.

STI

FFE NER

R.H.

STI

FFE NER

e.-5

&\,

9

21-1/4"+

STIFF E NER

tlJ

o

o

o

lo

o

o

ooo

o

o

oo

o

o

REMOVE

SKTDS

FROM

BASE

MOUNTING

SAW

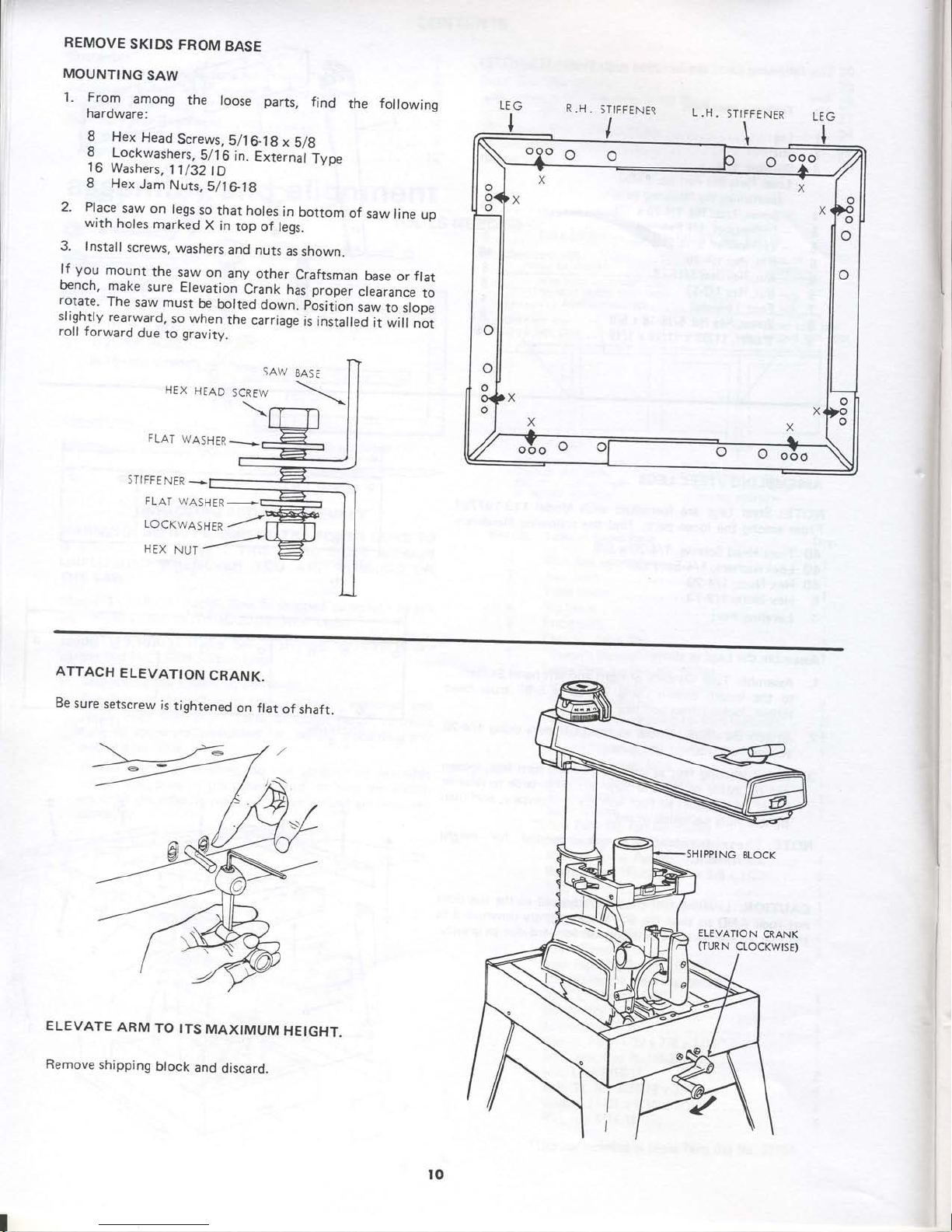

1.

.FroT

among

the

loose parts,

find

the

following

hardware:

8

Hex

Head

Screws,5/16_1g

x

5/g

8^

.Lockwashers,

5/.l6

in.

exierna'tlype

16

Washers,

11/32tD

8 Hex

Jam

Nuts,5/lGlg

2. Place

saw

on

legs

so

that holes

in

bottom

of

saw line

up

with

holes

marked

X

in

top

of

legs.

3. lnstall

screws,

washers

and nuts

as

shown.

lf

you

mount

the

saw

on

any

other

Craftsman

base

or

flat

bench,

make

sure

Elevation

Crank

has

propei

clearance

to

rotate.

The

saw

must

be

bolted

down.

position

saw

to slope

sligh-tly

rearward,

so when

the

carriage

is

instailed

it

wiil

not

roll

forward

due

to

gravity.

R.H.

STIFFENER

SAW

BASE

HEX

HEAD

SCREW

FLAT

WASHER-

STIFFE

NER

FLAT

WASHER

loc<wassen

/

HEX

NUT

ATTACH

ELEVATION

CRANK.

Be

sure

setscrew

is

tightened

on

flat

of shaft.

ELEVATE

ARM

TO

ITS

MAXIMUM

HEIGHT.

Remove

shipping

block

and

discard.

ro

assembly

and alignment

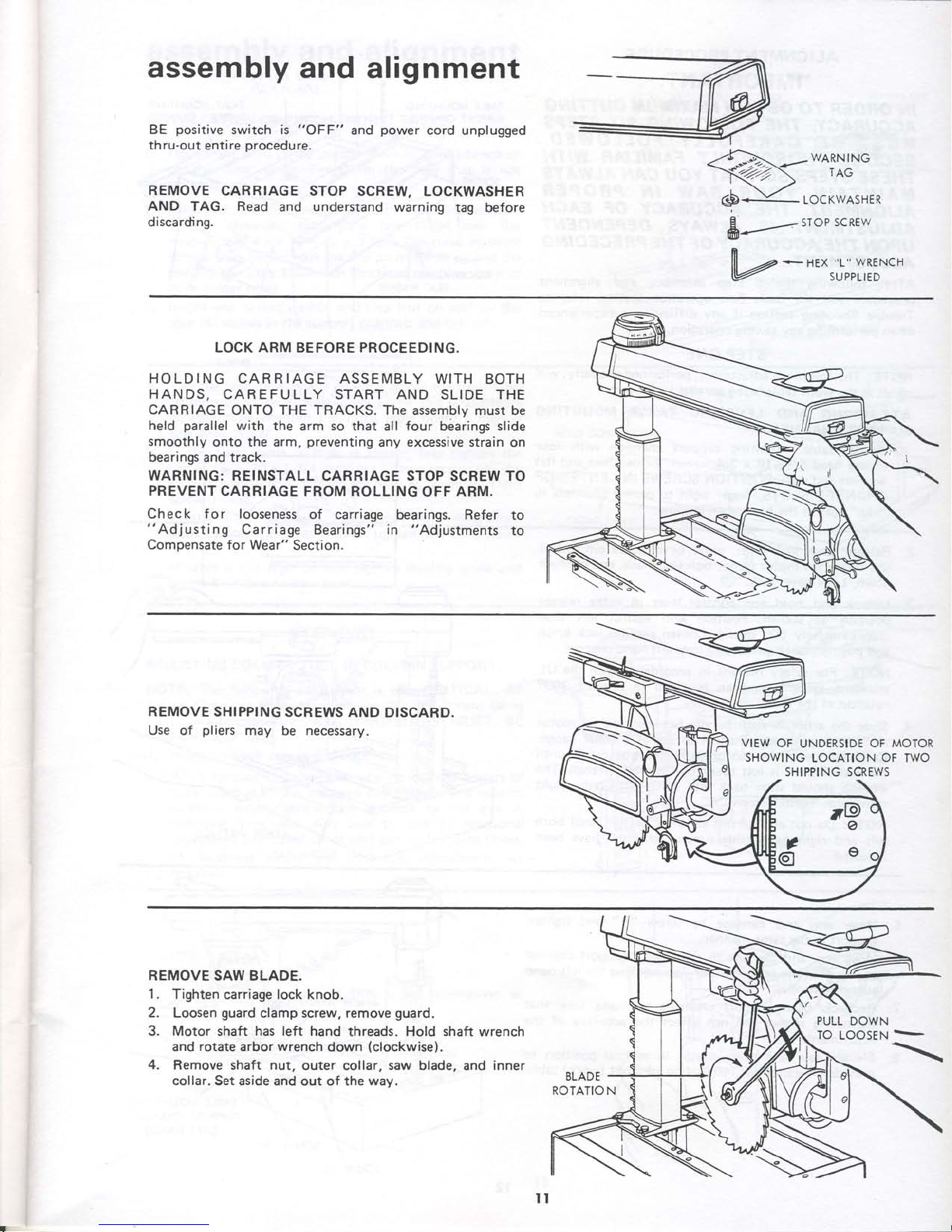

BE

positive

switch is

"OFF"

and

power

cord unplugged

thru-out

entire

procedure.

REMOVE

CARRIAGE STOP SCREW,

LOCKWASHER

AND TAG. Read

and

understand

warning tag

before

discarding.

@t*ofi:fo

6p

-

LocKwAsHER

&

,

sToP scREw

V*n'*rrt

rillto*tt

LOCK

ARM

BEFORE PROCEEDING.

HOLDING

CARRIAGE ASSEMBLY WITH

BOTH

HANDS,

CAREFULLY START AND

SLIDE

THE

CARRIAGE

ONTO THE TRACKS. The assembly

must

be

held

parallel

with

the arm so that

all

four

bearings

slide

smoothly

onto the arm,

preventing

any

excessive

strain on

bearings

and

track.

WARNING:

REINSTALL CARRIAGE STOP SCREW TO

PREVENT

CARRIAGE

FROM ROLLING

OFF

ARM.

Check for looseness

of

carriage

bearings.

Refer

to

"Adjusting

Carriage Bearings" in

"Adjustments

to

Compensate

for Wear"

Section.

REMOVE SHIPPING

SCREWS

AND

DISCARD.

Use of

pliers

may

be

necessary.

VIEW

OF

UNDERSIDE

OF MOTOR

SHOWING

LOCATION OF TWO

SHIPPING SCREWS

REMOVE SAW BLADE.

1.

Tighten

carriage

lock

knob.

2.

Loosen

guard

clamp screw, remove

guard.

3. Motor shaft has left hand

threads. Hold shaft wrench

and

rotate

arbor

wrench

down

(clockwise).

4,

Remove shaft nut,

outer collar, saw blade,

and

inner

collar. Set aside

and out of the

way.

PULL

DOWN

TO

LOOSEN

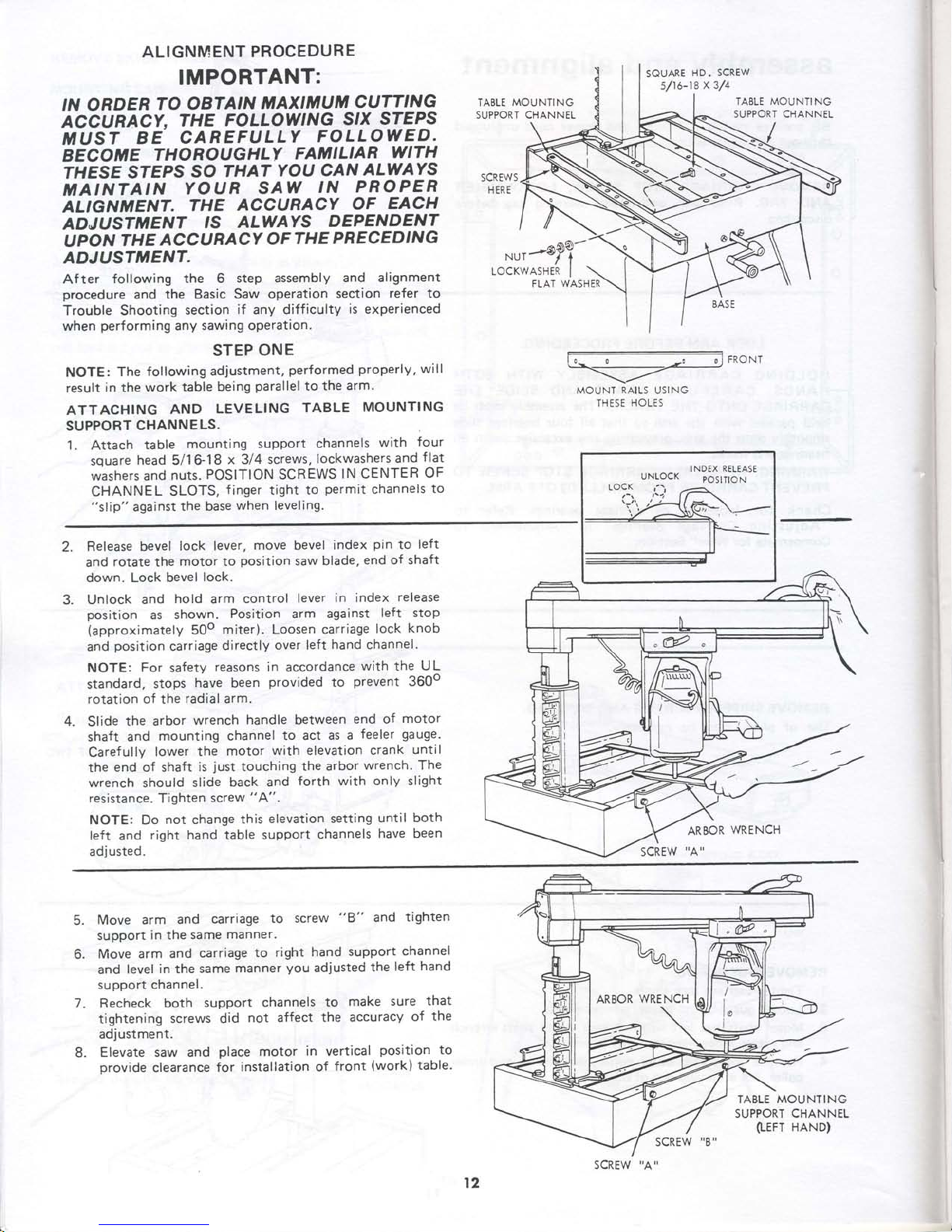

ALIGNMENT

PROCEDURE

IMPORTANT:

IN ORDER

TO

OBTAIN

MAX'MUM

CUTT'NG

ACCURACY,

THE FOLLOWI'VG

S'X

STEPS

MUST

BE

CAREFULLY

FOLLOWED.

BECOME

THOROUGHLY

FAMILIAR

WITH

THESE

STEPS

SO

THAT

YOU CAN

ALWAYS

MAINTAIN

YOUR

SAW

'N

PROPER

ALIGNMENT.

THE

ACCIJRACY

OF

EACH

ADJUSTMENT

'S

ALWAYS

DEPENDENT

UPON

THE

ACCIJRACY

OF

THE

PRECEDING

ADJUSTMENT.

After

following the

6 step

assembly

and alignment

procedure

and the Basic

Saw operation

section

refer to

Trouble Shooting

section

if any difficulty

is

experienced

when

performing

any

sawing operation.

STEP

ONE

NOTE:

The

following

adjustment,

performed

properly,

will

result

in

the

work

table

being

parallel

to

the arm.

ATTACHING

AND

LEVELING

TABLE

MOUNTING

SUPPORT

CHANNELS.

1

. Attach

table

mounting

support

channels

with

four

souare

head

5/16-18

x 3/4 screws,

lockwashers

and

flat

washers and

nuts.

POSITION SCREWS

lN CENTER

OF

CHANNEL

SLOTS,

f

inger tight

to

permit

channels

to

"slip"

against

the base

when leveling.

FRO

NT

MOUNT RAILS

U5ING

I NI)E hULE)

2.

Release bevel

lock lever,

move

bevel

index

pin

to

left

and

rotate

the

motor

to

position

saw blade,

end

of

shaft

down. Lock bevel

lock.

Unlock and

hold arm

control

lever

in index

release

position

as

shown.

Position arm

against

left stop

(approximately

50o

miter). Loosen

carriage

lock

knob

and

position

carriage

directly

over left

hand

channel'

NOTE:

For

safety

reasons in

accordance

with

the

UL

standard,

stops

have

been

provided

to

prevent

3600

rotation of the

radial

arm.

Slide

the arbor

wrench

handle between

end

of

motor

shaft

and

mounting channel

to act

as a

feeler

gauge.

Carefully

lower the

motor

with elevation crank

until

the

end of shaft

is

just

touching

the

arbor

wrench. The

wrench should

slide

back and

forth with

only

slight

resistance. Tighten

screw

"A".

NOTE:

Do

not

change

this

elevation setting

until both

left

and

right

hand table support

channels

have been

ad i usted

.

4.

SQUARE

HD. SCREW

s/16-18

x

3/4

TABLE MOUNTING

SUPPORT CHANNEL

FLAT

WASHER

INDEX

RELEAsT

POSlTtO N

UNLOCK

LOCK

'i'\

5.

Move

arm

and

carriage

to

screw

"8"

and

tighten

support

in the

same

manner.

Move

arm and

carriage

to

right

hand

support

channel

and level

in

the

same

manner

you

adjusted

the

left

hand

support channel.

Recheck

both

support

channels

to

make sure

that

tightening

screws did

not affect

the accuracy

of

the

adjustment.

Elevate saw and

place

motor

in vertical

position

to

provide

clearance for

installation of

front

(work)

table.

TABLE

MOUNTING

SUPPORT CHANNEL

(LEFT

HAND)

SCREW

"8"

ARBOR

WRENCH

8.

t2

SCREW

assembfy

and

alignment

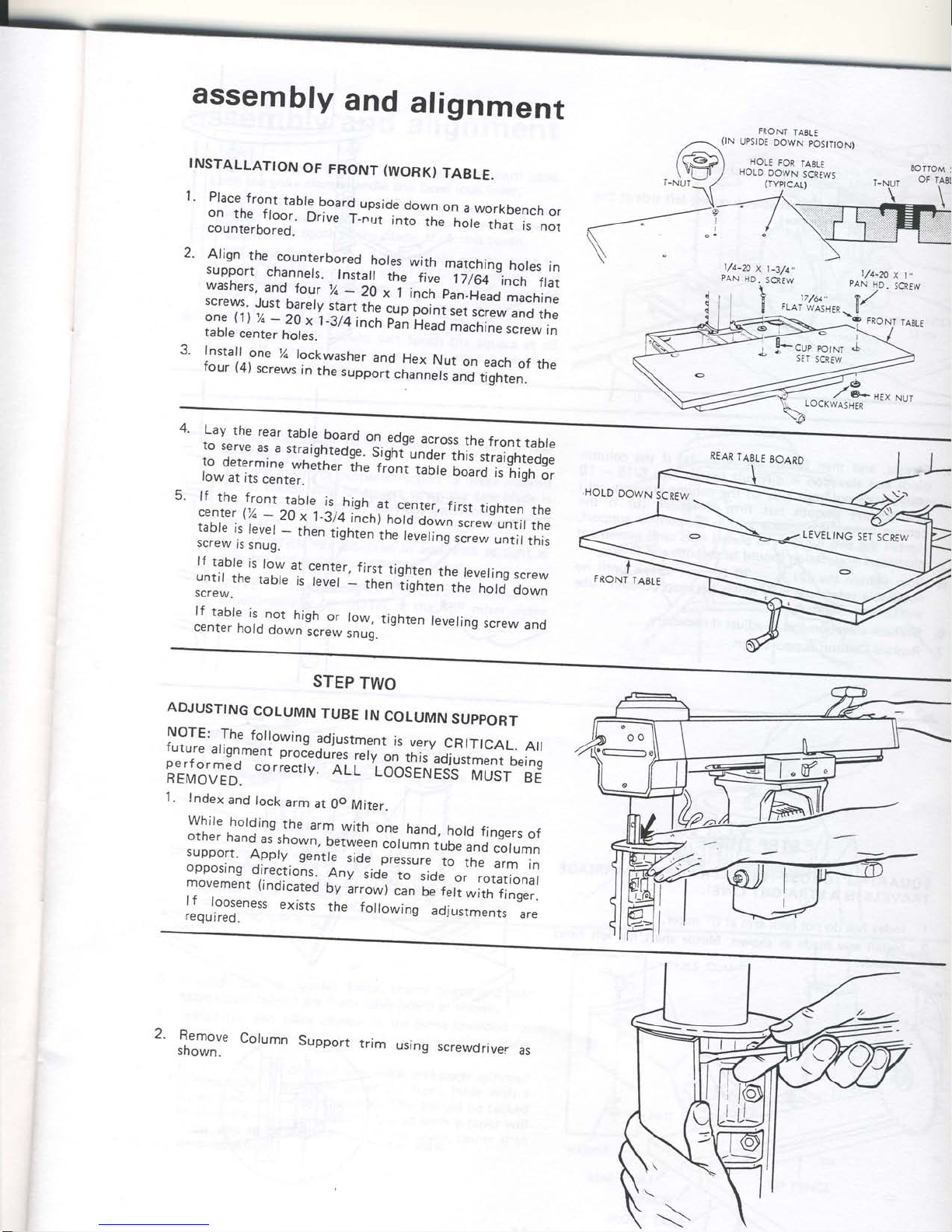

INSTALLATTON

OF

FRONT

(WORK)

TABLE.

1.

Place

front

table

board

upside

down

on

a workbench

or

on

the

f

loor.

Drive

f_"ui

into

-ir,J'iJr.,

that

is

not

counterbored.

FRONT

TABLT

EOITOM

S

OFI

2.

3.

Align

the

counterbored

.holes

with

matching

holes

in

support

channels.

Instail

the

tir:"

l)ifil'"tnch

flat

washers,

and

four

%

_.2g

" ii""i.,-p#-'H?o

macnine

screvvs.

Just

barety

start

the

gup

poin;;;;'r;"ie"w

and

the

one

(1)

%

-

20

x 1-3/4

inch

pii

i;J

il;riJ

screw

,n

table

center

holes-

Install

one

%

lockwasher

and

Hex

Nut

on

each

of

the

four

(4)

screws

in

the

support

channels

and

tighten.

l-

:+cuP

PO|NT

sET

SCREW

4.

,fL::: ::.: ::_b],._.b:.,d

ol

edge

across

the

front

tabre

["J,ffn'

jJi"n?l".ogi^tj-t-iT4;il:':Jffi

;;1'J:

f_ffil::,whether

ir,.

r."t

i.ir;

il'o'i1,il;ii.:;

low

at

its

center.

5.

lf

the front

table

is,trigh.

at

center,

first

tighten

the

center (%

_

20

x 1-3/4

,inch)

notO

Oown

screw

until

the

table

is

tevel

_

then

lishlen

th;i;;;'#w

untitthis

screw

is

snug.

lf

table

is

low

at

center.

first

tighten

the

leveling

screw

untir

the

tabte

is

tevet

_

til

i;e;;;"inJ

noro

oo*n

screw.

it-

taOtg

is.not

high

or

low,

tighten

leveling

screw

anol

center

hold

down

screw

snuq.

LEVETING

SET

SCREW

FRONT

TABLE

STEP

TWO

ADJUSTING

COLUMN

TUBE

IN

COLUMN

SUPPORT

|.9TE: ,The

fo,owing

adjustment

is

very

CRtTICAL.

Atl

l1Y: -1is",t.nt

pro"-"durgl

l.rv

on

th is'adlustment

bei

no

BtilB'rft;1

correctry.

ALL'Looa-irui"dj"

rvrUii";;

1.

Index

and

lock

arm

at

0o

Miter.

While

holding

the

arm

rrvith

one

hand,

hold

fingers

of

other

hand

as

shown,

between

column

iuOe

ano

column

:leeo1

Appty

gentte

side

presi"r.-;;-the

arm

in

opposing

directions.,

.Anv

,io.

1"-rid."",

rotational

movement

(indicated

by

arrow)

;

il;.;'*ith

finger.

lf

looseness

exists

the following

adjusrments

are

req

u

i red.

2.

Remove

Column

S

shown.

tupport

trim

using

screwdriver

as

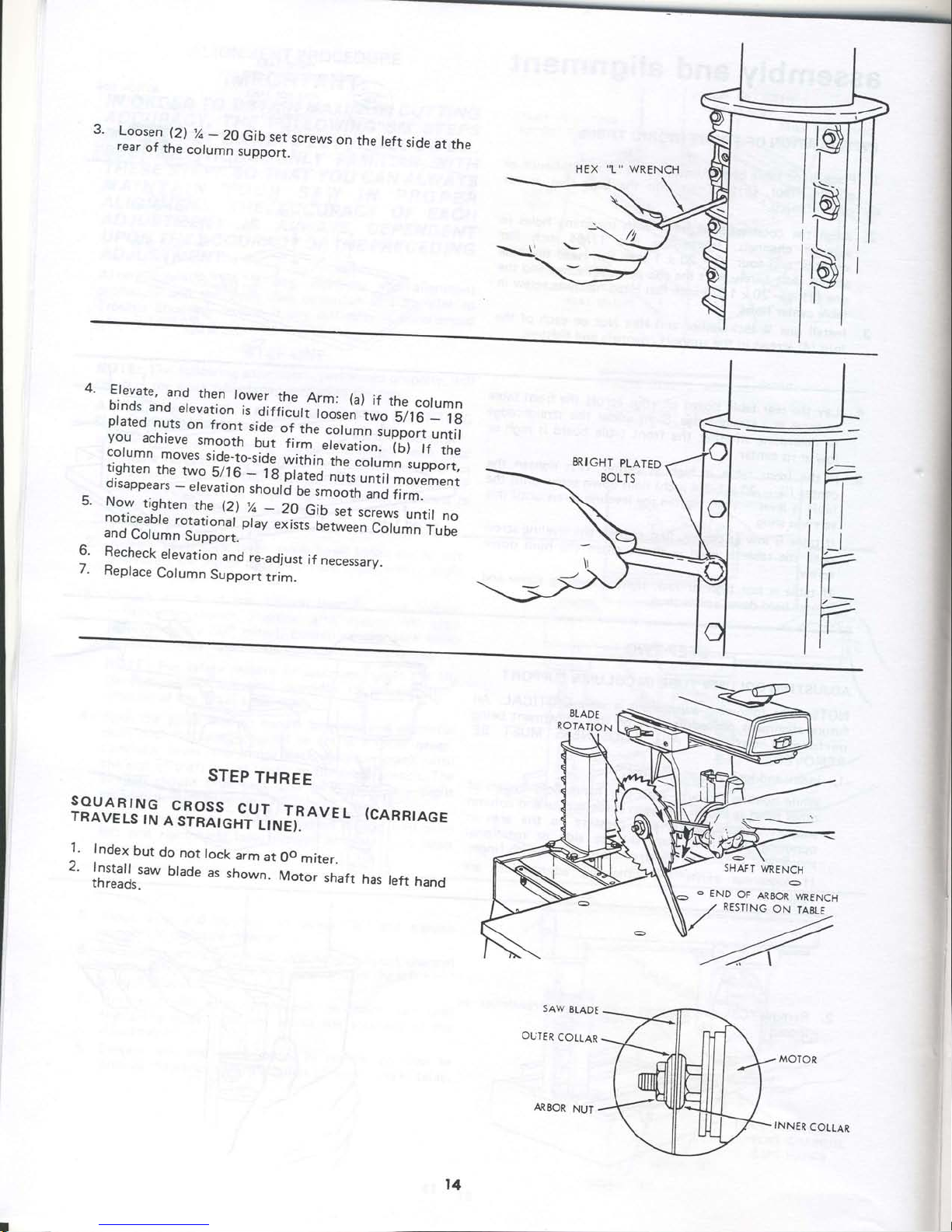

3.

L,oosen

(2')

%

-

20

Gib

set

screws

on

the

left

side

at

the

rear

of

the

column

support.

4.

Elevate,

and

then

bincts :nrr -,-.,-.,^-t?y:,l,lh".Arm:

(a)

if

the

column

binds

and

elevation

l;

_

.,."

^r,,,.

rd,

rr

rne

column

Dtarprr nr,+. ^^ 3_-_^

.diffic-ult

loosen

two

5/16

_

id

3:i1,1^ly::^"1

jl.it,iil.-ii;;";;ilT#

j:,;"1;

I:,i,j:T"::^.rT::,1

but

firm-.r.r.,i"".'i6)

tf

ths

n,r1g,nf:^,:o; :.,iJ"

*iir,

i"

ff

H;,i::ilo",l;

tighten

the

two

s/16

-

--

uurumn

support,

disanne:,. _ ar^.,^r:^_ -,

lg.plated

nuts

until

movement

d i

sappea

rs

-

e I

evat

i

on

rr,.i

r

I'

[.

ili

;:?,#.i

;i#:

5.

Now tinhto- rlr- /rr 1/ ^^ ^..

**":r*::,:f,.^-(^2,) !:

_

2g

Gib

;;;;;;;s

untir

no

::i'""':,?*:""t:l:l3lpr'v""i'ts-f

;;#'ff

Hirffi

and

Column

Support.

9

Recheck

elevation

and

re-adjust

if

necessary.

7.

Replace

Column

Support

trim.

STEP

THREE

SOUARING

CROSS

.C-U-T

TRAVEL

(CARRIAGE

TRAVELS

IN

A

STRAIGHT

LINE'.'-'"

I

i

Index

but

do

not

lock

arm

at

0o

miter.

,

|;:::[.:.w

btade

as

shown.

Moto.

,n"r

has

teft

hand

Saw

314P6

OUTER

COTLAR

e

END

OF

AREoR

wRENcH

RESTING

ON

IAELE

l4

ARBOR

NUT

INNER

COLLAR

Loading...

Loading...