Page 1

ENERGIZE6

Service Manual

Release Date: August 3, 2012

Publication Number: 621058457SER

Revision Date: August 8, 2013

Revision: A10

Visit the IMI Cornelius web site at www.cornelius.com for all your Literature needs.

Page 2

The products, technical information, and instructions contained in this manual are subject to change without notice.

These instructions are not intended to cover all details or variations of the equipment, nor to provide for every possible contingency in the installation, operation or maintenance of this equipment. This manual assumes that the person(s) working on the equipment have been trained and are skilled in working with electrical, plumbing, pneumatic,

and mechanical equipment. It is assumed that appropriate safety precautions are taken and that all local safety and

construction requirements are being met, in addition to the information contained in this manual.

This Product is warranted only as provided in Cornelius’ Commercial Warrant applicable to this Product and is subject to all of the restrictions and limitations contained in the Commercial Warranty.

Cornelius will not be responsible for any repair, replacement or other service required by or loss or damage resulting

from any of the following occurrences, including but not limited to, (1) other than normal and proper use and normal

service conditions with respect to the Product, (2) improper voltage, (3) inadequate wiring, (4) abuse, (5) accident,

(6) alteration, (7) misuse, (8) neglect, (9) unauthorized repair or the failure to utilize suitably qualified and trained persons to perform service and/or repair of the Product, (10) improper cleaning, (11) failure to follow installation, operating, cleaning or maintenance instructions, (12) use of “non-authorized” parts (i.e., parts that are not 100%

compatible with the Product) which use voids the entire warranty, (13) Product parts in contact with water or the

product dispensed which are adversely impacted by changes in liquid scale or chemical composition.

Contact Information:

To inquire about current revisions of this and other documentation or for assistance with any Cornelius product contact:

www.cornelius.com

38-3600

800-2

Trademarks and Copyrights:

This document contains proprietary information and it may not be reproduced in any way without permission from

Cornelius.

This document contains the original instructions for the unit described.

IMI CORNELIUS INC

Dr

101 Regency

Glendale Heights, IL

Tel: + 1 800-238-3600

Printed in U.S.A.

ive

Page 3

Safety Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Read and Follow ALL Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Recognition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Different Types of Alerts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Qualified Service Personnel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Shipping And Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

CO2 (Carbon Dioxide) Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Description of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Energy Efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Starting the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Ending Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Cleaning and Sanitizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Changing to a Different Flavor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Daily . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Daily Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Weekly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Cleaning and Sanitizing the Quick Disconnect Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Quarterly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Beverage Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Water Filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Syrup Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

CO2 Gas Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Annually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Water Bath . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Service Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Removing the Unit Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cleaning and Sanitizing the Syrup System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Cleaning/Sanitizing the BIB Backroom Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Cleaning and Sanitizing the Quick Disconnect Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Cleaning and Sanitizing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Page 4

Thawing the Ice Bank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Component Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Service Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Main Service Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Replacing Recirculating Pump Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Replacing a Recirculating Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Replacing a Recirculating Pump Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Replacing Carbonator Pump Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Replacing a Carbonator Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Replacing a Carbonator Pump Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Replacing Carbonator Pump Pressure Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Replacing the Agitator Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Replacing the Electronic Ice Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Replacing the Carbonators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Replacing the CO2 Pressure Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Replacing the Expansion Valve Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

High Pressure Switch Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Replacing the Solenoid Coil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Replacing the Solenoid Valve Body. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Replacing the Head Master . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Replacing the Mesh Strainer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Replacing the Check Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Replacing the Controller Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Flow Charts and Circuit Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Plumbing Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Page 5

Energize6 Service Manual

!

DANGER:

!

WARNING:

CAUTION:

!

!

SAFETY INSTRUCTIONS

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

Safety Overview • Read and follow ALL SAFETY INSTRUCTIONS in this manual and any warning/

caution labels on the unit (decals, labels or laminated cards).

• Read and understand ALL applicable OSHA (Occupational Safety and Health

Administration) safety regulations before operating this unit.

Recognition

Recognize Safety Alerts

This is the safety alert symbol. When you see it in this manual or on the unit, be alert

to the potential of personal injury or damage to the unit.

Different Types of Alerts

SAFETY TIPS

Indicates an immediate hazardous situation which, if not avoided, WILL result in

serious injury, death or equipment damage.

Indicates a potentially hazardous situation which, if not avoided, COULD result in

serious injury, death, or equipment damage.

Indicates a potentially hazardous situation which, if not avoided, MAY result in minor

or moderate injury or equipment damage.

• Carefully read and follow all safety messages in this manual and safety signs on the

unit.

• Keep safety signs in good condition and replace missing or damaged items.

• Learn how to operate the unit and how to use the controls properly.

• Do not let anyone operate the unit without proper training. This appliance is not

intended for use by very young children or infirm persons without supervision. Young

children should be supervised to ensure that they do not play with the appliance.

© 2012, IMI Cornelius Inc. - 1 - Publication Number: 621058457SER

Page 6

Energize6 Service Manual

!

WARNING:

!

WARNING:

CAUTION:

!

CAUTION:

!

!

DANGER:

• Keep your unit in proper working condition and do not allow unauthorized

modifications to the unit.

QUALIFIED SERVICE PERSONNEL

Only trained and certified electrical, plumbing and refrigeration technicians should

service this unit. ALL WIRING AND PLUMBING MUST CONFORM TO

NATIONAL AND LOCAL CODES. FAILURE TO COMPLY COULD RESULT IN

SERIOUS INJURY, DEATH OR EQUIPMENT DAMAGE.

SAFETY PRECAUTIONS

This unit has been specifically designed to provide protection against personal

injury. To ensure continued protection, observe the following:

Disconnect power to the unit before servicing following all lock out/tag out

procedures established by the user. Verify all of the power is off to the unit before

any work is performed.

Failure to disconnect the power could result in serious injury, death or equipment

damage.

Always be sure to keep area around the unit clean and free of clutter. Failure to keep

this area clean may result in injury or equipment damage.

SHIPPING AND STORAGE

Before shipping, storing, or relocating the unit, the unit must be sanitized and all

sanitizing solution must be drained from the system. A freezing ambient

environment will cause residual sanitizing solution or water remaining inside the unit

to freeze resulting in damage to internal components.

CO2 (CARBON DIOXIDE) WARNING

CO2 displaces oxygen. Strict attention MUST be observed in the prevention of CO2

gas leaks in the entire CO

Publication Number: 621058457SER - 2 - © 2012, IMI Cornelius Inc.

2 and soft drink system. If a CO2 gas leak is suspected, par-

Page 7

Energize6 Service Manual

ticularly in a small area, IMMEDIATELY ventilate the contaminated area before

attempting to repair the leak. Personnel exposed to high concentrations of CO

2 gas

experience tremors which are followed rapidly by loss of consciousness and DEATH.

© 2012, IMI Cornelius Inc. - 3 - Publication Number: 621058457SER

Page 8

Energize6 Service Manual

SYSTEM OVERVIEW

DESCRIPTION OF OPERATION

Energize is a backroom soda chiller package that increases the energy efficiency

of an installation by separating the syrup lines from the chiller and python circuits

and using a heat exchanger at the dispenser location to chill the syrup. The Energize unit varies the speed of the circulating pump motors based on the system

demand.

The system consists of the backroom package, the cooler carbonator unit and the

interconnect pythons. These are arranged in a manner similar to Figure 1. Layout

details may vary according to the system location.

Figure 1.

FEATURES

• Environmentally friendly refrigerant - R404a

• Intelligent variable speed recirculation

• Syrup conditioning at the point of dispensing

• Improved water bath insulation for more unit efficiency

• Individual supply shutoffs

• SMART Capable

• Snooze mode

Publication Number: 621058457SER - 4 - © 2012, IMI Cornelius Inc.

Page 9

ENERGY EFFICIENCY

SPECIFICATIONS

Energize6 Service Manual

The cooling liquid in a beverage system takes a significant amount of energy to

maintain, usually using electrical power for this purpose. To keep the need for

energy as low as possible and save costs, the Energize unit decides between dispense times and operational readiness. During operational readiness, for example

overnight, Energize runs in standby mode. All functions are reduced to a minimum

and therefore power consumption is also at a minimum. The Energize system

identifies when drinks are dispensed, automatically switching to maximum power

to supply the required amount of ice. After dispensing, Energize switches back to

standby mode automatically.

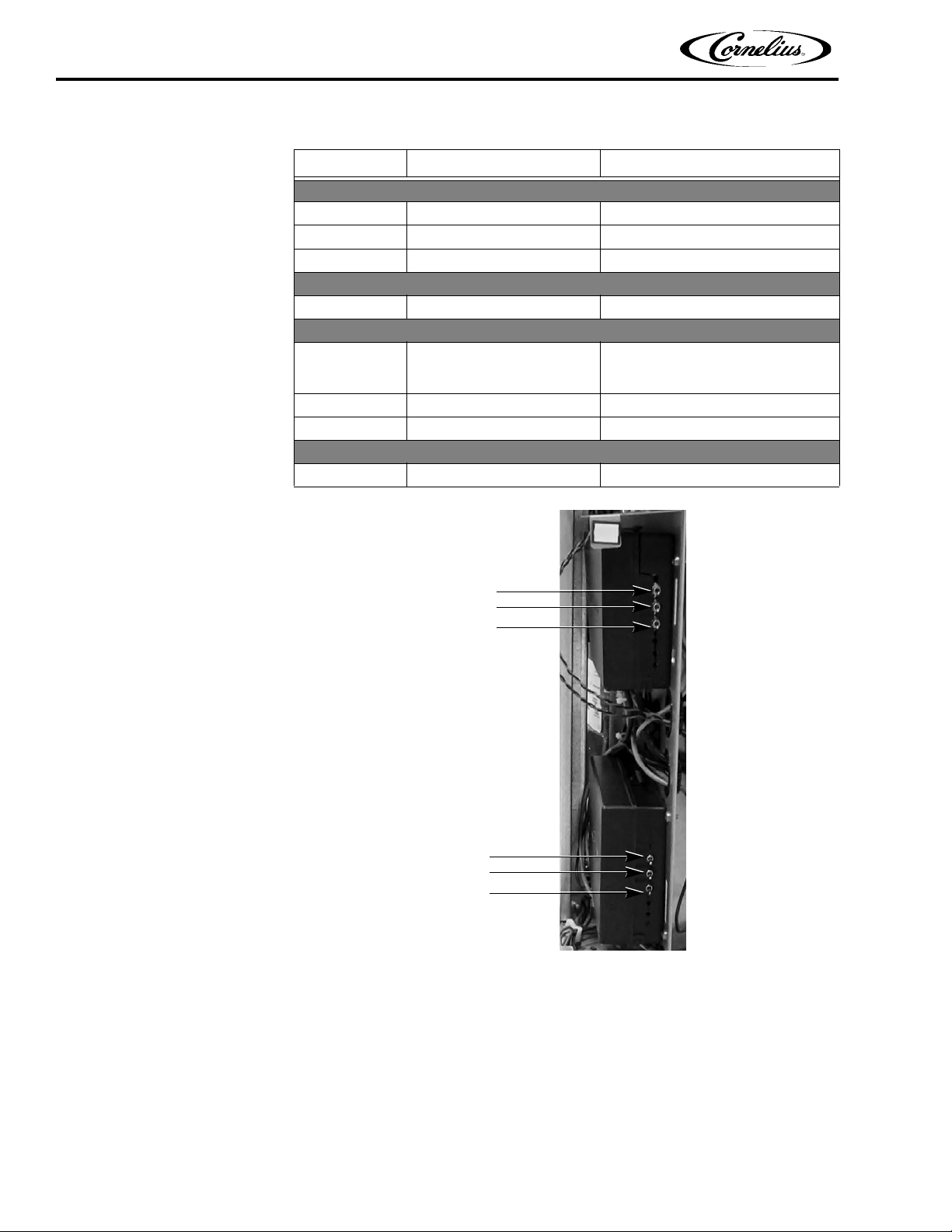

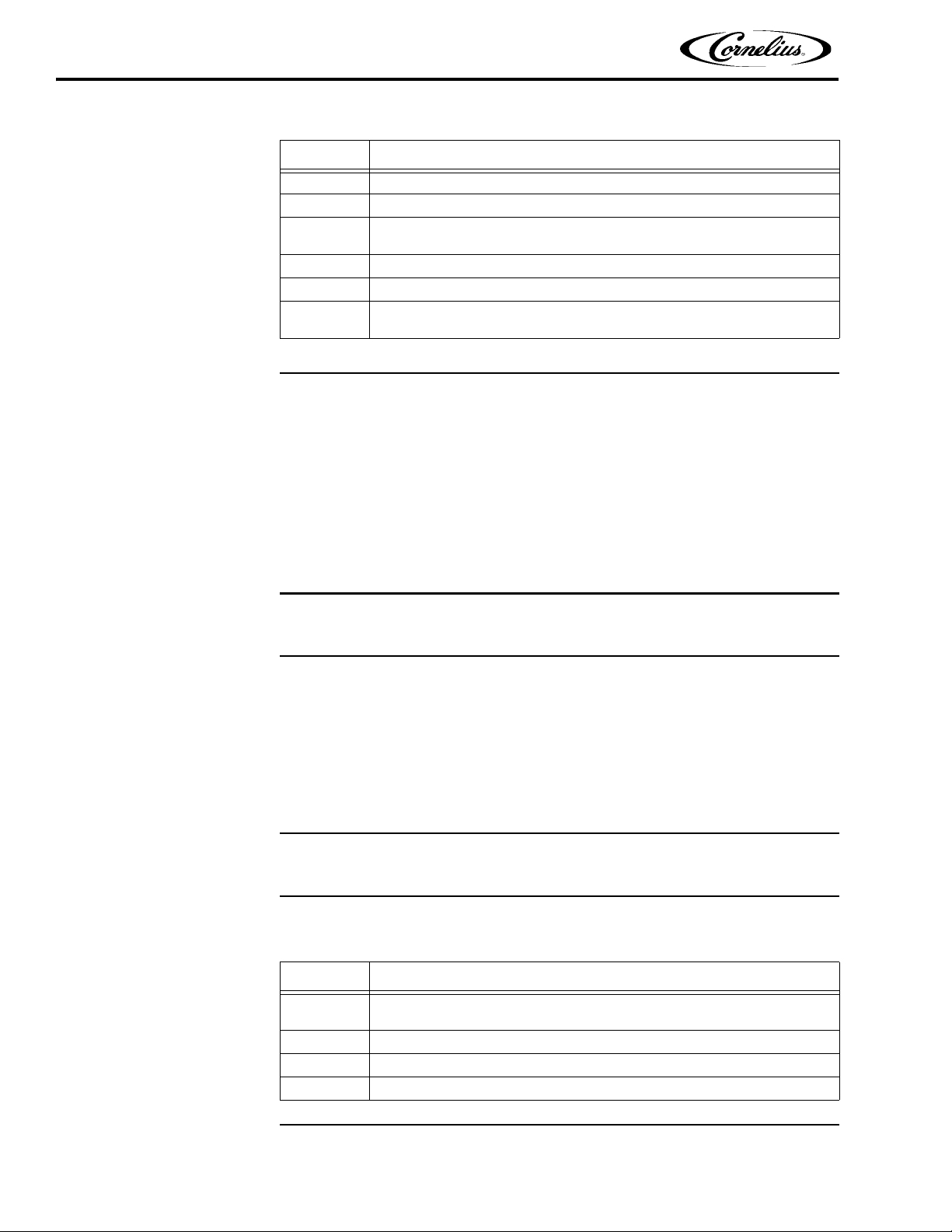

Ta bl e 1 .

Model Energize6 USA 220V 60Hz

Continuous Dispense Rate at 75 °F (24 °C)

ambient

Peak Dispense Rate for 2 hours at 75 °F

(24 °C) ambient

Maximum Ambient Condition

Ice bank Weight 110 lbs. (50 kg)

Compressor size 2 HP 2.65 cu in. (43.5 cc)

Refrigerant R404a

Refrigerant charge 14.5 lbs. (6.6 kg)

Tank fill volume (Water Bath) 39 gal. (148 liters)

Compressor run time Start delay 3 min, min run 5 min.

Carbonator size Dual carb with 2 x 3 liter tanks

Pressure switch water inlet

Pressure switch carbonator pump outlet

Voltage 220V 60Hz 3 phase

Height 31.8 in. (810mm)

Depth 27.2 in. (690mm)

Width 42.5 in. (1080mm)

Shipping Weight approx 441 lbs. (200kg)

7 x 12 oz. (355 ml)

10 x 12 oz. (355 ml)

104 °F (40 °C) Unit / 120 °F (49 °C)

Remote Condenser

on >10 psig (0.689 bar) / off <5 psig

(0.345 bar)

ON >145 psig (10 bar) / OFF <130.5 psig

(9 bar)

© 2012, IMI Cornelius Inc. - 5 - Publication Number: 621058457SER

Page 10

Energize6 Service Manual

STARTING THE UNIT

OPERATION

The water bath must be filled up to the overflow with tap water. Refer to the Specifications on page 5 section of this manual for the amount of water required. To prevent

algae from forming in the water a mild disinfectant may be added to the solution.

To fill the unit, perform the procedure in Table 2.

Ta bl e 2 .

Step Action

1

2 Lift the cover up, as shown in Figure 2 and store it in a safe place.

3

4 Fill the water bath to the top of the drain pipe, as shown in Figure 5.

5

6 The unit will start to build an ice bank. (approx. 2.5 hrs @ 75 °F)

7

8

9

10 Replace the cover on the unit.

To fill the water bath loosen the screw on the left end of the unit and

remove the cover.

Open the fill valve, located near the right rear corner (near the tubing

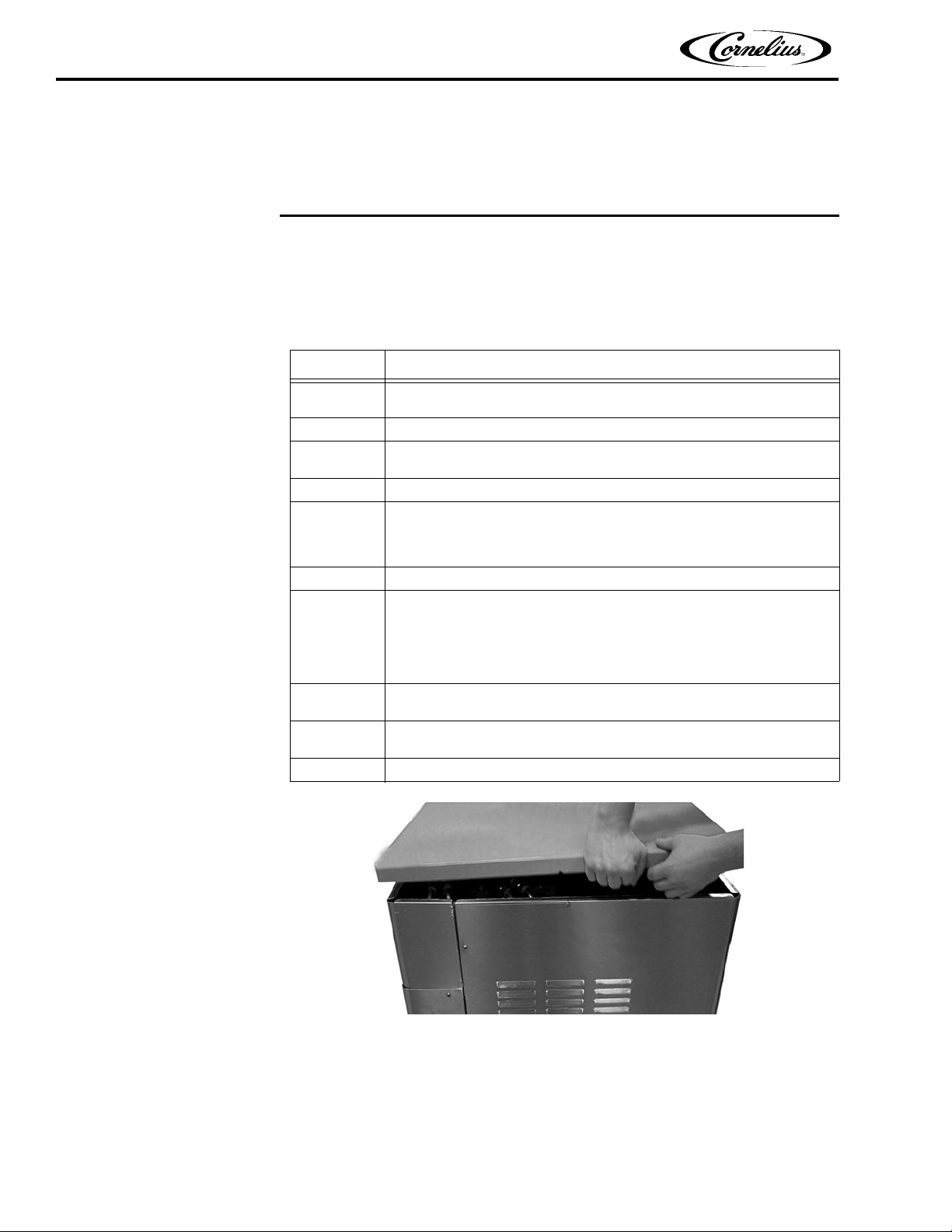

entrance). See Figure 3 and Figure 4.

Remove the front access panel (See Service Access on page 18) and

turn on the compressor by moving the compressor switch on the master

controller to the ON position, as shown in Figure 7. The compressor

should start and begin to cool after a 3 to 5 minute time delay.

Turn on the carbonator pump motors by moving the carbonator pump

switches to the ON position. (see Figure 7.)

If the water inlet pressure is within specifications, the carbonator pump

fills the carbonator and then switches off when the upper fill level is

reached. The carbonator tanks are located inside the water bath, as

shown in Figure 8 and Figure 9 on page 9.

Bleed air out of the carbonators and the dispensers by pulling up on the

ring attached to each relief valve, as shown in Figure 10.

Do not turn on the recirculation switches (Figure 7) until ice starts to form

on the evaporator coils.

Figure 2.

Publication Number: 621058457SER - 6 - © 2012, IMI Cornelius Inc.

Page 11

Figure 3.

Water

Fill Valve

Fill Valve

Top of

Drain

Pipe

Main Controller

Slave Controller

Indicator Light

Energize6 Service Manual

Figure 4.

Figure 5.

© 2012, IMI Cornelius Inc. - 7 - Publication Number: 621058457SER

Figure 6.

Page 12

Energize6 Service Manual

Compressor

Recirculation

Carbonator Tanks

(Not Used)

Recirculation

Carbonator Tanks

Master Controller

Slave Controller

Ta bl e 3 .

LED Warning Required Action

Green

ON Voltage OK None

OFF No Power Check/Reset Power

Blinks HIGH or LOW Voltage Check/Reset Power

Ye l l o w

ON CO

Red

ON

or

Blinks Slow

Blinks Fast Over Temp/Motion Controller Check/Reset Power

Red/Green

Red/Green

Blinks Main Controller Call Service

2 Pressure Low Check/Replace CO2 Supply

Time Out Carbonator

Water Supply Pressure Low

Reset Power, If it Remains On, Call

Service

Check/Replace Water Filter

Figure 7.

Publication Number: 621058457SER - 8 - © 2012, IMI Cornelius Inc.

Page 13

Figure 8.

CAUTION:

!

Agitator

Mounting

Bracket

Carbonator 2

Agitator

Mounting

Bracket

Carbonator 1

Relief Valve

Energize6 Service Manual

Figure 9.

The circulation pump runs even if there is no water in the soda circuit. Running the

Figure 10.

pumps dry damages the soda recirculation pump.

© 2012, IMI Cornelius Inc. - 9 - Publication Number: 621058457SER

Page 14

Energize6 Service Manual

ENDING OPERATION

To prevent loss or health hazard in the event of a leak, the CO2 supply and water

supply lines should be turned off when the system is not in use for a extended

period of time.

Publication Number: 621058457SER - 10 - © 2012, IMI Cornelius Inc.

Page 15

PREVENTIVE MAINTENANCE

!

WARNING:

Only trained and certified electrical, plumbing and refrigeration technicians should

service this unit.

ALL WIRING AND PLUMBING MUST CONFORM TO NATIONAL AND LOCAL

CODES. FAILURE TO COMPLY COULD RESULT IN SERIOUS INJURY, DEATH

OR EQUIPMENT DAMAGE.

CLEANING AND SANITIZING

Changing to a Different Flavor

DAILY

Energize6 Service Manual

• Clean and sanitize the syrup system, as described in “Cleaning and Sanitizing the Syrup System” on page 15.

Daily Inspection

WEEKLY

Cleaning and Sanitizing the Quick Disconnect Fittings

• Check CO2 and water supply.

• Visually check the beverage/syrup lines for

a service technician.

• Check overflow drain connection on the bottom of the unit and the floor

drain.

To clean and sanitize the BIB quick disconnect fittings, perform the procedure in

Ta bl e 4 .

leaks. If leaks are noted, call

© 2012, IMI Cornelius Inc. - 11 - Publication Number: 621058457SER

Page 16

Energize6 Service Manual

Ta bl e 4 .

Step Action

1 Remove all the quick disconnects from all the B-I-B containers.

2 Fill a 1-gallon bucket with mild detergent solution.

3

4 Using a plastic pail, prepare approximately five (5) gallons of sanitizing solution.

5 Rinse the B-I-B disconnects in the sanitizing solution.

6

Submerge all disconnects in the soap solution and then clean them using a

nylon bristle brush. (Do not use a wire brush). Rinse them with clean water.

Repeat Steps 1-5 for all BIB connectors on the rack. Discard the remaining

water from the bucket.

QUARTERLY

Beverage Tubing • Inspect beverage tubing for damage. Re-insulate and seal any uninsu-

lated or damaged tubing.

• Inspect python channels and seal any

• Inspect and clean the grills and condenser fins located on the remote

condenser

, if necessary.

open channel ends.

Water Filters

Syrup Supply

• Verify that water pressure is between 20 psi (1,4 bar) and 120 psi (8,3

bar). If the pressure is low, inspect the water filter cartridges to ensure

that they are able to supply adequate water pressure under normal sys

tem flow. Replace them if they are unable to provide the minimum pressure under load.

• If equipped with a water regulator, verify that it is set to 55 psi (3,8 bar).

Adjust the

setting as

needed.

The syrup supplies should be inspected and cleaned using the procedure in Table 5.

Ta bl e 5 .

Step Action

1

2 Disconnect and remove the syrup containers.

3 Clean the connectors with soap and warm water. Rinse them with plain water.

4 Return the syrup containers and reconnect them.

Inspect syrup lines for the proper flavor identification labels. Replace the labels

as needed.

-

Publication Number: 621058457SER - 12 - © 2012, IMI Cornelius Inc.

Page 17

CO2 Gas Supply

!

DANGER:

!

WARNING:

Energize6 Service Manual

CO2 displaces oxygen. Strict attention MUST be observed in the prevention of CO2

gas leaks in the entire CO

particularly in a small area, IMMEDIATELY ventilate the contaminated area before

attempting to repair the leak. Personnel exposed to high concentrations of CO

experience tremors which are followed rapidly by loss of consciousness and

DEATH.

The CO

Ta bl e 6 .

2 system should be inspected and adjusted according to the procedure in

Step Action

2 and soft drink system. If a CO2 gas leak is suspected,

2 gas

Ta bl e 6 .

ANNUALLY

Water Bath

1

2

3 Verify a proper pressure setting for the syrup pressure regulators.

4

5

The water bath should be inspected and cleaned at least once a year. Perform the

procedure in Table 7 to inspect the water bath.

Step Action

Verify a CO2 high pressure regulator setting of 100 psi (6,8 bar).

Adjust the high pressure regulator, if necessary to obtain the correct pressure

settings.

Adjust the syrup pressure regulators, if necessary to obtain the correct pressure settings.

Inspect the CO2 system for leaks, and repair as needed.

Ta bl e 7 .

1

2

3 If the water bath is clean, replace the unit cover.

If the water bath needs to be cleaned, perform the procedure in Table 8.

Disconnect power to the unit before servicing. Follow all lock out/tag out procedures

established by the user. Verify all power is off to the unit before performing any work.

Remove the cover using the procedure in “Removing the Unit Cover” on

page 14.

Use a flashlight or service light to inspect the water and ice for clarity, particles

and any algae growth.

Failure to comply could result in serious injury, death or damage

to the equipment.

© 2012, IMI Cornelius Inc. - 13 - Publication Number: 621058457SER

Page 18

Energize6 Service Manual

Ta bl e 8 .

Step Action

1 Turn off the electrical supply to the unit.

2 Turn off the water supply to the unit.

3

4 Drain the system by opening a dispense valve.

5 Empty the water bath by removing the overflow tube from the unit.

6

7

8 Fill the bath with a 200ppm chlorinated sanitizing solution.

9 Reconnect the electrical supply to the unit.

10 Turn on the agitator and allow it to run for 10 minutes.

11 Turn off the agitator.

12 Drain all of the sanitizing solution from the water bath.

13

14

15

16 Check the drain to make sure the overflow tube is not leaking.

17 Turn on the CO

18 Replace the cover on the unit.

Remove the cover using the procedure in “Removing the Unit Cover” on

page 14.

Thaw the ice bank. This can be accelerated by pouring warm water into the

water bath.

Carefully spray down the interior of the water bath, the ice coils and the product coils, if dirty.

Thoroughly rinse the bath, the ice coils and the product coils with the same

sprayer as used in Step 8.

Replace the overflow tube, being careful to lubricate the O-rings on the bottom

of the tube with water.

Turn the water supply on and refill the water bath up to the bottom of the overflow opening. See “Starting the Unit” on page 6.

2 supply to the unit.

SERVICE ACCESS

The following procedures describe how to service various subsystems and components of the Energize6 system.

Removing the Unit

Cover

To remove the top cover from the unit, perform the procedure in Table 9.

Ta bl e 9 .

Step Action

1

2 Lift the cover up, as shown in Figure 11, and store it in a safe place.

Publication Number: 621058457SER - 14 - © 2012, IMI Cornelius Inc.

Loosen the screw on the left end of the unit, shown in Figure 11.

Page 19

CLEANING AND SANITIZING THE SYRUP SYSTEM

Cover

Attaching

Screw

To effectively clean and sanitize the syrup lines, a two-step process must be used.

This two-step process includes: Cleaning the system with a cleaner solution, and

rinsing it with water, then sanitizing the system with sanitizer.

Materials required:

• 15 gallons of sanitizing solution (Kay-5 or equivalent - 200 ppm)

Energize6 Service Manual

Figure 11.

Cleaning/Sanitizing

the BIB Backroom

Package

Cleaning and Sanitizing the Quick Disconnect Fittings

• One gallon of mild detergent solution

• Sanitizing fittings or B-I-B end fittings

• One 1-gallon pail (minimum)

• One 5-gallon pail (minimum)

• One nylon brush

Weekly cleaning and sanitizing is recommended for the BIB system.

To clean and sanitize the BIB quick disconnect fittings, perform the procedure in Table

10.

Table 10.

Step Action

1 Remove all the quick disconnects from all the B-I-B containers.

2 Fill a 1-gallon bucket with mild detergent solution.

3

4 Using a plastic pail, prepare approximately five (5) gallons of sanitizing solution.

© 2012, IMI Cornelius Inc. - 15 - Publication Number: 621058457SER

Submerge all disconnects in the soap solution and then clean them using a

nylon bristle brush. (Do not use a wire brush). Rinse them with clean water.

Page 20

Energize6 Service Manual

Cleaning and Sanitizing Procedure

Table 10.

Step Action

5 Rinse the B-I-B disconnects in the sanitizing solution.

6

Repeat Steps 1-5 for all BIB connectors on the rack. Discard the remaining

water from the bucket.

To clean and sanitize the system, perform the procedure in Table 11.

Table 11.

Step Action

Thawing the Ice

Bank

1

2

3

4 Allow sanitizer to remain in the lines for fifteen (15) minutes.

5

6

In a 5-gallon container, mix 5 gallons of sanitizing/cleaning solution to manufacturer’s instructions.

Sanitizing fittings must be attached to each B-I-B disconnect. If these fittings

are not available, the fittings from empty B-I-B bags can be cut from the bags

and used for this purpose. These fittings open the disconnect so the sanitizing

solution can be drawn through the disconnect.

Place all the B-I-B disconnects into the pail of sanitizing solution. Open each

dispenser valve until the sanitizing solution is flowing from the valve.

Remove the nozzle and syrup diffuser from each valve (if equipped) and clean

them in a mild detergent solution. Rinse with clean water and reassemble the

nozzle and syrup diffuser to the valve.

Remove the sanitizing fittings from the B-I-B disconnects and connect the disconnects to the appropriate B-I-B container. Open the valves and let syrup flow

until all sanitizer has been flushed from the system and syrup is flowing freely.

If the unit becomes frozen, it must be carefully Thawed by trained personnel. To

Thaw the Energize6 unit, perform the procedure in Table 12.

Table 12.

Step Action

1 Turn off the electrical supply to the unit.

2 Turn off the water supply to the unit.

3

4 Drain the bath by removing the overflow tube from the unit.

5

6

7

8 Check the drain to make sure the overflow tube is not leaking.

Publication Number: 621058457SER - 16 - © 2012, IMI Cornelius Inc.

Remove the cover using the procedure in “Removing the Unit Cover” on

page 14.

Thaw the ice bank. This can be accelerated by pouring warm water into the

water bath.

Replace the overflow tube, being careful to lubricate the O-rings on the bottom

of the tube with water before inserting it into the drain.

Turn the water supply on and refill the water bath up to the bottom of the overflow opening.

Page 21

Table 12.

Step Action

9 Replace the cover on the unit.

10 Turn on the electrical supply to the unit.

Energize6 Service Manual

© 2012, IMI Cornelius Inc. - 17 - Publication Number: 621058457SER

Page 22

Energize6 Service Manual

!

WARNING:

!

WARNING:

CAUTION:

!

COMPONENT SERVICE

Only trained and certified electrical, plumbing and refrigeration technicians should

service this unit.

ALL WIRING AND PLUMBING MUST CONFORM TO NATIONAL AND LOCAL

CODES. FAILURE TO COMPLY COULD RESULT IN SERIOUS INJURY, DEATH

OR EQUIPMENT DAMAGE.

Disconnect power to the unit before servicing. Follow all lock out/tag out procedures

established by the user. Verify all power is off to the unit before performing any work.

Failure to comply could result in serious injury, death or damage

to the equipment.

All of the threaded plumbing connections in the system contain a plastic gasket to

ensure a proper seal when the connection is tightened. MAKE SURE TO REPLACE

THIS GASKET WHENEVER A CONNECTION IS OPENED FOR REPAIR.

SERVICE ACCESS

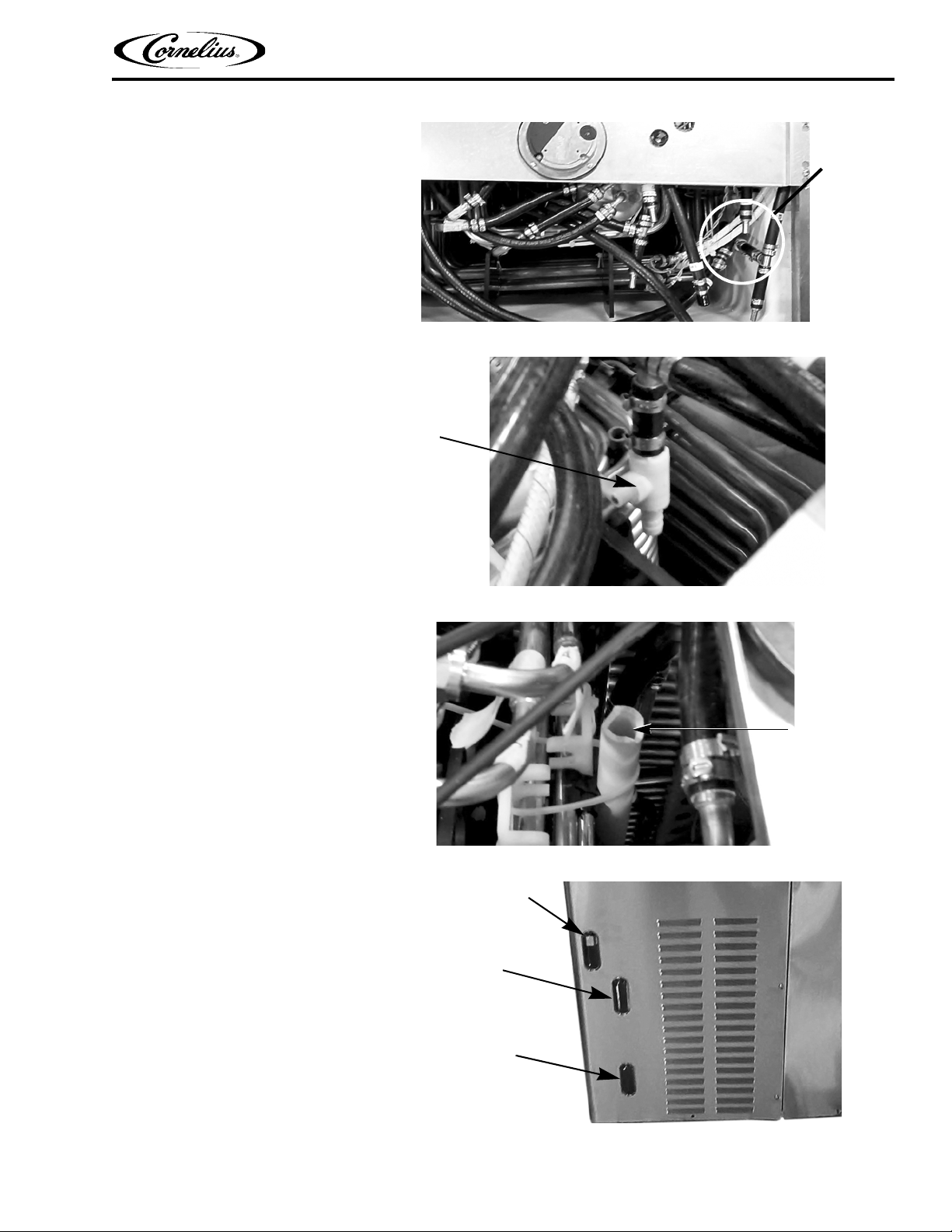

Main Service Panel

The following procedures describes how to access portions of the unit under the

main service panel.

To remove the main service panel, perform the procedure in Table 13.

Table 13.

Step Action this

1

2

3 Lift the service panel away from the base of the Energize6 unit.

Remove the cover using the procedure in "Removing the Unit Cover" on

page 14.

Using a Phillips screwdriver, remove the seven screws around the edges of

the service panel, shown in Figure 12 and Figure 13.

Publication Number: 621058457SER - 18 - © 2012, IMI Cornelius Inc.

Page 23

Figure 12.

Front

Panel

Screws

Access

Side

Panel

Screws

Access

Energize6 Service Manual

Figure 13.

REPLACING RECIRCULATING PUMP COMPONENTS

Replacing a Recirculating Pump

To remove and replace a recirculating pump, perform the procedure in Table 14.

Step Action

1 Determine which carbonator pump is malfunctioning.

2 Turn off the electrical supply to the unit.

3

4 Turn off the appropriate recirculating shutoff valves, shown in Figure 15.

© 2012, IMI Cornelius Inc. - 19 - Publication Number: 621058457SER

Remove the cover using the procedure in “Removing the Unit Cover” on

page 14.

Ta bl e 1 4 .

Page 24

Energize6 Service Manual

Circuit 1

Val ves

Circuit 2

Shutoff

Shut off

Valves

Ta bl e 1 4 .

Step Action

5 Peel back the insulation on the pump tubing, shown in Figure 16.

6 Remove the inlet and outlet plumbing from the pump, as shown in Figure 17.

7

8 Loosen the retaining collar, shown in Figure 18.

9 Remove the recirculating pump assembly by pulling it away from the motor.

10

11 Reinstall the insulation around the pump and over the pump tubing.

12

13

14

15 Open the appropriate recirculating shutoff valves, shown in Figure 15.

16 Turn on the CO

17 Turn on the electrical supply to the unit.

18 Turn on the water supply to the unit.

19 When the unit is refilled, replace the unit cover.

Carefully cut the tape holding the two halves of the insulation together

around the recirculating pump. (See Figure 17.) Save the insulation.

Install the new recirculating pump assembly onto the motor and tighten the

pump retaining collar.

Check and replace the gasket inside the fittings, shown in Figure 14, before

reconnecting the pump.

Reconnect the inlet and outlet plumbing to the pump, using teflon tape to

insure a proper seal.

Turn the water supply on and make sure the water bath level is up to the

notch in the overflow tube.

2 supply to the unit and check the system for leaks.

Figure 14.

Figure 15.

Publication Number: 621058457SER - 20 - © 2012, IMI Cornelius Inc.

Page 25

Figure 16.

Recirculating

Pump

Tubing

Insulation

Recirculating

Pump

Connections

Insulation

Recirculating

Pump

Retaining

Collar

Energize6 Service Manual

Figure 17.

Figure 18.

© 2012, IMI Cornelius Inc. - 21 - Publication Number: 621058457SER

Page 26

Energize6 Service Manual

Motor Ground

Motor Wiring to

Control Box

Motor

Mounting

Bolts

Replacing a Recirculating Pump

Motor

To remove and replace a recirculating pump motor, perform the procedure in Table 15.

Ta bl e 1 5 .

Step Action

1 Determine which recirculating pump motor is malfunctioning.

2 Turn off the electrical supply to the unit.

3

4

5

6 Remove the ground wire from the chassis, shown in Figure 19.

7 Remove the pump retaining collar, shown in Figure 18.

8 Remove the pump from the motor by pulling it away from the motor.

9

10 Install the new recirculating pump motor.

11

12

13 Turn on the CO2 supply to the unit and check the system for leaks.

14 Turn on the electrical supply to the unit.

15 Replace the unit cover.

Remove the cover using the procedure in “Removing the Unit Cover” on

page 14.

Remove the main service panel, using the procedure in “Main Service

Panel” on page 18.

Unplug the connector from the carbonator pump motor, located in the control box.

TIP: Once all tie wraps have been removed, tie a length of string to the

connector before pulling it out of the control board. Then pull the wiring out

of the unit and untie the string. Use the string to fish the new wiring back

through the unit to the control box.

Using the proper size wrench, remove the pump mounting bolts, shown in Figure 20 and slide the motor out of the mounting bracket, shown in Figure 21.

Reconnect the electrical connection from the carbonator pump motor to

the control box.

Turn the water supply on and make sure the water bath is up to the notch in

the overflow tube.

Figure 19

Figure 20.

Publication Number: 621058457SER - 22 - © 2012, IMI Cornelius Inc.

Page 27

REPLACING CARBONATOR PUMP COMPONENTS

Motor

Bracket

Mounting

Energize6 Service Manual

Figure 21.

Replacing a Carbonator Pump

To remove and replace the recirculating pump, perform the procedure in Table 16.

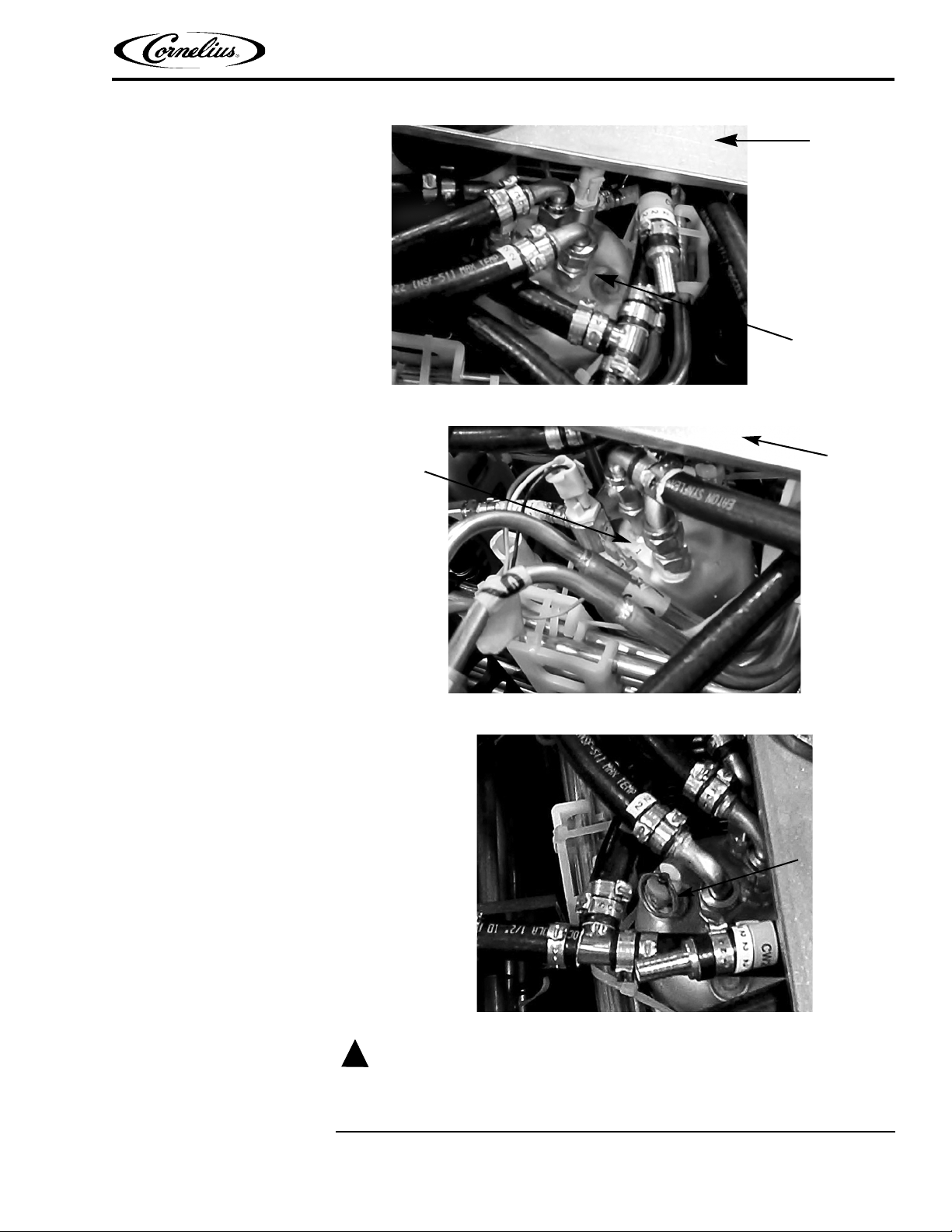

Ta bl e 1 6 .

Step Action

1 Determine which recirculating pump is malfunctioning.

2 Turn off the electrical supply to the unit.

3

4 Drain the system pressure by opening a dispense valve.

5 Turn off the recirculating shutoffs, shown in Figure 22.

6 Label and remove the pressure sensor wires, shown in Figure 24.

7 Remove the pressure sensors from the pump body.

8

9 Loosen the retaining collar, shown in Figure 25.

10 Remove the recirculating pump assembly by pulling it away from the motor.

11

12

13

14

15 Connect the pressure sensor wires to the appropriate sensor.

16

Remove the cover using the procedure in “Removing the Unit Cover” on

page 14.

Remove the high and low pressure plumbing connectors from the pump,

shown in Figure 23.

Install the new recirculating pump assembly onto the motor and tighten the

pump retaining collar.

Check and replace the gasket inside the fittings, shown in Figure 14 on

page 20, before reconnecting the inlet and outlet plumbing.

Reconnect the inlet and outlet plumbing to the pump, using teflon tape to

insure a proper seal.

Insert the pressure sensors into the new pump, using teflon tape to insure

a proper seal.

Turn the water supply on and make sure the water bath level is up to the

notch in the overflow tube.

© 2012, IMI Cornelius Inc. - 23 - Publication Number: 621058457SER

Page 28

Energize6 Service Manual

Carbonator

Shutoff

Val ve s

Low Pressure

Pump

Connection

Carbonator

High Pressure

Pump

Connection

Carbonator

Ta bl e 1 6 .

Step Action

17 Open the recirculating shutoffs, shown in Figure 22.

18 Turn on the CO

19 Turn on the electrical supply to the unit.

20 Replace the unit cover.

2 supply to the unit and check the system for leaks.

Figure 22.

Figure 23.

Publication Number: 621058457SER - 24 - © 2012, IMI Cornelius Inc.

Page 29

Figure 24.

Pressure

Sensors

Retaining

Collar

Energize6 Service Manual

Replacing a Carbonator Pump Motor

Figure 25.

To remove and replace a carbonator pump motor, perform the procedure in Table 17.

Ta bl e 1 7 .

Step Action

1 Turn off the electrical supply to the unit.

2 Remove the cover using the procedure in “Removing the Unit Cover” on page 14.

Unplug the connector from the control box, making sure to remove any tie

wraps holding the wiring in place.

3

4 Remove the ground wire from the chassis as shown in Figure 19 on page 22.

5 Remove the pump retaining collar, shown in Figure 25.

6 Remove the pump from the motor by pulling it away from the motor.

7 Install the new carbonator pump motor.

8 Replace the electrical connection from the recirculating pump to the control box.

9

TIP: Once all tie wraps have been removed, tie a length of string to the

connector before pulling it out of the control board. Then pull the wiring out

of the unit and untie the string. Use the string to fish the new wiring back

through the unit to the control box.

Turn the water supply on and make sure the water bath level is up to the

notch in the overflow tube.

© 2012, IMI Cornelius Inc. - 25 - Publication Number: 621058457SER

Page 30

Energize6 Service Manual

Agitator Motor

Mounting

Bracket

Tie Wrap

Replacing Carbonator Pump Pressure

Switch

es

Ta bl e 1 7 .

Step Action

10 Turn on the CO2 supply to the unit and check the system for leaks.

11 Turn on the electrical supply to the unit.

12 Replace the unit cover.

To replace the carbonator pressure switches, perform the procedure in Table 18.

Ta bl e 1 8 .

Step Action

1 Turn off the electrical supply to the unit.

2 Remove the cover using the procedure in “Removing the Unit Cover” on page 14.

3 Drain the system pressure by opening a dispense valve.

4 Turn off the carbonator shutoffs, shown in Figure 22.

5

6 Remove the malfunctioning pressure switch.

7

8 Connect the pressure switch wires to the appropriate switch.

9

10 Open the carbonator shutoffs, shown in Figure 22.

11 Turn on the CO

12 Turn on the electrical supply to the unit.

13 Replace the unit cover.

Label and remove the pressure switch wires on the sensor being replaced,

shown in Figure 24.

Insert the new pressure switch into the pump, using teflon tape to insure a

proper seal.

Turn the water supply on and make sure the water bath level is up to the

notch in the overflow tube.

2 supply to the unit and check the system for leaks.

REPLACING THE AGITATOR MOTOR

The agitator motor is mounted on the top of the unit, on a mounting bracket, shown

in Figure 26.

Figure 26.

To remove and replace the agitator motor, perform the procedure in Table 19.

Publication Number: 621058457SER - 26 - © 2012, IMI Cornelius Inc.

Page 31

Energize6 Service Manual

Bracket

Mounting

Screws

Impeller

Splash Guard

Slinger

Agitator

Motor

Ta bl e 1 9 .

Step Action

1 Turn off the electrical supply to the unit.

2 Remove the cover using the procedure in “Removing the Unit Cover” on page 14.

Unplug the two connectors from the control box, making sure to remove

any tie wraps holding the wiring in place.

3

4

5

6 Carefully slide the bracket and remove it.

7

8 Remove the slinger off the end of the motor shaft.

9

10 Remove the splash guard from the motor, shown in Figure 28.

11 Install the splash guard onto the new motor.

12

13

14 Install the agitator bracket assembly back onto the unit.

15 Replace the electrical connections from the agitator motor to the control box.

16 Turn on the electrical supply to the unit.

17 Replace the unit cover.

TIP: Once all tie wraps have been removed, tie a length of string to the

connector before pulling it out of the control board. Then pull the wiring out

of the unit and untie the string. Use the string to fish the new wiring back

through the unit to the control box.

Remove the tie wrap holding the pressure sensor wires to the agitator

motor bracket, shown in Figure 26.

Loosen the four screws (two on each side) holding the agitator bracket to

the unit, shown in Figure 27.

Place the bracket and pump assembly on a workbench or table and

unscrew the impeller blade from the shaft, shown in Figure 28.

Remove the four screws and nuts holding the agitator motor to the mounting bracket, shown in Figure 29.

Replace the slinger on the motor shaft and reinstall the impeller blade on

the end of the motor shaft.

Mount the motor assembly back onto the mounting bracket using the four

screws and nuts.

Figure 27.

© 2012, IMI Cornelius Inc. - 27 - Publication Number: 621058457SER

Figure 28.

Page 32

Energize6 Service Manual

Mounting

Screws

Mounting

Screws

REPLACING THE ELECTRONIC ICE PROBE

The electronic ice probe is located in the water bath near the center rear of the unit

To remove and replace the electronic ice probe, perform the procedure in Table 20.

Figure 29.

Ta bl e 2 0 .

Step Action

1 Turn off the electrical supply to the unit.

2 Remove the cover using the procedure in “Removing the Unit Cover” on page 14

3

4

5

6

7 Remove the tie wrap from the assembly.

8 Install a new tie wrap to retain the probe to the support clip.

9 Install the assembly back into the water bath.

10

11

12 Turn on the electrical supply to the unit.

13 When the unit is refilled, replace the unit cover.

Lower the water level of the water bath by removing the overflow tube from

the unit.

Thaw the ice bank. This can be accelerated by pouring warm water into the

water bath.

Unplug the connector from the control box, making sure to remove any tie

wraps holding the wiring in place.

TIP: Once all tie wraps have been removed, tie a length of string to the

connector before pulling it out of the control board. Then pull the wiring out

of the unit and untie the string. Use the string to fish the new wiring back

through the unit to the control box.

Unsnap the ice probe from the evaporator coil and lift the assembly up

and out of the water bath, shown in Figure 30 and Figure 31.

Replace the overflow tube, if removed, being careful to lubricate the Orings on the bottom of the tube with water before inserting it into the drain.

Reconnect the connector to the control box and replace the cable ties to

keep the wiring away from any hot areas of the unit.

Publication Number: 621058457SER - 28 - © 2012, IMI Cornelius Inc.

Page 33

Figure 30.

Ice Probe

Assembly

Energize6 Service Manual

REPLACING THE CARBONATORS

There are two carbonators in the Energize6 unit. To replace a carbonator, perform

the procedure in Table 21.

Step Action

1 Determine which carbonator is malfunctioning.

2 Turn off the electrical supply to the unit.

3 Turn off the water supply to the unit.

4 Turn off the CO

5 Remove the cover using the procedure in “Removing the Unit Cover” on page 14

6 Drain the bath by removing the overflow tube from the unit.

7

8 Drain the system pressure by opening a dispense valve.

9

10 Carefully slide the bracket out of the way.

11

Figure 31.

Ta bl e 2 1 .

2 supply to the unit.

Thaw the ice bank. This can be accelerated by pouring warm water into the

water bath.

To gain access to the carbonator tank, remove the agitator bracket from the

unit, as shown in “Replacing the Agitator Motor” on page 26.

Open the carbonator relief valves and depressurize the carbonators,

shown in Figure 32.

© 2012, IMI Cornelius Inc. - 29 - Publication Number: 621058457SER

Page 34

Energize6 Service Manual

Connector

Carbonator

Relief

Plumbing

Connections

Ground

Wire

Valve

O-Ring

Ta bl e 2 1 .

Step Action

12

13

Unplug the connector and remove the ground wire from the top of the carbonator, shown in Figure 32.

Label and remove the high and low pressure plumbing connectors from the

carbonator, shown in Figure 32.

14 Remove the carbonator from the unit by pulling it straight up out of its mount.

15

16

Remove the carbonator tank probe, shown in Figure 33, by unscrewing it

from the carbonator.

Place the probe into the new carbonator, making sure that the o-ring seal is

in place on the probe.

17 Slide the carbonator into the mount in the unit.

18

19

Check and replace the gasket inside the fittings, shown in Figure 14 on

page 20, before reconnecting the carbonator plumbing.

Reinstall the plumbing connectors to the carbonator, using teflon tape to

insure a proper seal.

20 Reconnect the connector and ground wire to the top of the carbonator.

21 Reinstall the agitator bracket.

22

23

24 Turn on the CO

Replace the overflow tube, being careful to lubricate the O-rings on the bottom of the tube with water before inserting it into the drain.

Turn the water supply on and make sure the water bath level is up to the

notch in the overflow tube. Check the drain for water leaks.

2 supply to the unit and check the system for leaks.

25 Turn on the electrical supply to the unit.

26 When the unit is refilled, replace the unit cover.

Figure 32.

Figure 33.

Publication Number: 621058457SER - 30 - © 2012, IMI Cornelius Inc.

Page 35

REPLACING THE CO2 PRESSURE SWITCHES

CO2

Pressure

Switches

There are two CO2 pressure switches in the Energize6 unit. One for Circuit 1 and

one for Circuit 2. If one of the pressure switches needs to be replaced, perform the

procedure in Table 22.

Step Action

1 Determine which pressure switch is malfunctioning.

2 Turn off the electrical supply to the unit.

3 Turn off the CO

4 Remove the cover using the procedure in “Removing the Unit Cover” on page 14.

5 Drain the system pressure by opening a dispense valve.

6 Vent the carbonators by opening the relief valves, shown in Figure 10 on page 9.

7 Label and disconnect the wiring from the pressure switch, shown in Figure 34.

8 Remove the pressure switch.

9 Install the new pressure switch, using teflon tape to insure a proper seal.

10

11 Turn on the CO

12 Turn on the electrical supply to the unit.

13 When the unit is refilled, replace the unit cover.

Replace the overflow tube, if removed, being careful to lubricate the Orings on the bottom of the tube with water before inserting it into the drain.

2 supply to the unit.

2 supply to the unit and check the system for leaks.

Energize6 Service Manual

Ta bl e 2 2 .

Figure 34.

REPLACING THE EXPANSION VALVE ASSEMBLIES

The Energize6 unit has one compressor and two cooling circuits. There are two

expansion valve assemblies to accommodate the two circuits, as shown in Figure

35. The expansion valves are located near the center of the unit, toward the rear. To

replace an expansion valve, perform the procedure in Table 23.

© 2012, IMI Cornelius Inc. - 31 - Publication Number: 621058457SER

Page 36

Energize6 Service Manual

Expansion

Valve Sensor

Bulbs

Expansion

Valves

(under Insulation)

Expansion

Val ves

Sensors

(w/Insulation

removed)

Figure 35.

Ta bl e 2 3 .

Step Action

1 Turn off the electrical supply to the unit.

2 Remove the cover using the procedure in “Removing the Unit Cover” on page 14

3 Reclaim the refrigerant from the system.

4 Carefully unwrap the insulation from around the sensor bulbs.

5

6 Replace the expansion valve and re-install the sensor bulb into the clamp.

7 Replace the insulation around the bulb sensor.

8

9 Evacuate the system.

10

Remove the expansion valve sensor bulb from the clamp holding it to the

refrigerant line, shown in Figure 36.

Replace the filter/dryer, located at the left rear of the unit, as shown in Figure 37.

Restore the proper refrigerant charge to the system and verify proper system operation.

Publication Number: 621058457SER - 32 - © 2012, IMI Cornelius Inc.

Figure 36.

Page 37

HIGH PRESSURE SWITCH REPLACEMENT

Filter/Dryer

Before replacing the high pressure switch, inspect the remote condenser for proper

air flow, any obstructions or a failed fan motor.

The high pressure switch, shown in Figure 38, is located at the left rear of the unit,

behind the access panel. The switch has a reset button. The reset button should be

pressed and the unit restarted before replacing the high pressure switch. If the

switch trips again, replace the switch by performing the procedure in Table 24.

Energize6 Service Manual

Figure 37.

Ta bl e 2 4 .

Step Action

1 Turn off the electrical supply to the unit.

2 Remove the access panel from the rear of the unit.

Unplug the electrical connections from the high pressure switch to the con-

3

4 Reclaim the refrigerant from the system.

5 Replace the high pressure switch.

6

7 Replace the filter/dryer, see Figure 37 on page 33.

8 Evacuate the system.

9

10 Replace the access panel.

trol box. and remove any tie wraps holding the wiring.

TIP: Tie a length of string to the connector before pulling it out of the control board. Then pull the wiring out of the unit and untie the string. Use the

string to fish the new wiring back through the unit to the control box.

Replace the electrical connection from the high pressure switch to the control box.

Restore the proper refrigerant charge to the system and verify proper system operation.

© 2012, IMI Cornelius Inc. - 33 - Publication Number: 621058457SER

Page 38

Energize6 Service Manual

Solenoid

Val ve

High

Pressure

Switch

Reset

Button

Electrical

Connections

REPLACING THE SOLENOID COIL

The solenoid valve, shown in Figure 38, is located at the left rear of the unit, behind

the access panel. To replace the solenoid coil, perform the procedure in Table 25.

Figure 38.

Ta bl e 2 5 .

Step Action

1 Turn off the electrical supply to the unit.

2 Remove the access panel from the rear of the unit.

3 Remove the electrical connections to the solenoid, shown in Figure 39.

4 Pull the solenoid off of the valve stem.

5

6 Reconnect the wiring to the solenoid.

7 Replace the access panel.

8 Turn on the electrical supply to the unit.

Replace the solenoid by pressing the new solenoid onto the valve stem, as

shown in Figure 40.

Figure 39.

Publication Number: 621058457SER - 34 - © 2012, IMI Cornelius Inc.

Page 39

REPLACING THE SOLENOID VALVE BODY

Solenoid

The solenoid valve, shown in Figure 38, is located at the left rear of the unit, behind the

access panel. To replace the solenoid valve body, perform the procedure in Table 26.

Energize6 Service Manual

Figure 40.

Step Action

1 Turn off the electrical supply to the unit.

2 Remove the access panel from the rear of the unit.

3 Remove the solenoid coil from the valve body.

4 Reclaim the refrigerant from the system.

5 Replace the solenoid valve body.

6

7 Replace the filter/dryer, see Figure 37 on page 33.

8 Evacuate the system.

9

10 Replace the access panel.

REPLACING THE HEAD MASTER

The head master is located at the top of the compressor, near the left side of the

unit. To replace the head master, perform the procedure in Table 27.

Step Action

Ta bl e 2 6 .

Replace the solenoid coil by pressing the it onto the valve stem, as shown

in Figure 40.

Restore the proper refrigerant charge to the system and verify proper system operation.

Ta bl e 2 7 .

1 Turn off the electrical supply to the unit.

2 Remove the access panel from the left side of the unit.

3 Drain the bath by removing the overflow tube from the unit.

4

5 Reclaim the refrigerant from the system.

© 2012, IMI Cornelius Inc. - 35 - Publication Number: 621058457SER

Thaw the ice bank. This can be accelerated by pouring warm water into the

water bath.

Page 40

Energize6 Service Manual

Head

Master

Compressor

Ta bl e 2 7 .

Step Action

6 Replace the head master, shown in Figure 41.

7 Replace the filter/dryer, shown in Figure 37 on page 33.

8 Evacuate the system.

9

10 Replace the access panel.

Restore the proper refrigerant charge (shown on the unit nameplate) to the

system and verify proper system operation.

REPLACING THE MESH STRAINER

There is a mesh strainer in each of the output lines from the carbonated water

pumps. Occasionally, one of these strainers may become clogged and require

replacement. To replace the mesh strainer, perform the procedure in Table 28.

Figure 41.

Ta bl e 2 8 .

Step Action

1 Turn off the electrical supply to the unit.

2 Turn off the water supply to the unit.

3 Remove the cover using the procedure in “Removing the Unit Cover” on page 14

4 Drain the system pressure by opening a dispense valve.

5 Vent the carbonators by opening the relief valves, shown in Figure 10 on page 9.

6 Turn off the recirculation shutoffs, shown in Figure 22 on page 24.

7

8 Remove the mesh strainer from the check valve, shown in Figure 42.

9 Install a new mesh strainer, using teflon tape to insure a proper seal.

10

11

12

Remove the high pressure plumbing connector from the pump, shown in

Figure 23 on page 24.

Check and replace the gasket inside the fitting, shown in Figure 14 on

page 20, before reconnecting the outlet plumbing.

Reconnect the outlet plumbing to the pump, using teflon tape to insure a

proper seal.

Replace the overflow tube, being careful to lubricate the O-rings on the bottom of the tube with water before inserting it into the drain.

Publication Number: 621058457SER - 36 - © 2012, IMI Cornelius Inc.

Page 41

Ta bl e 2 8 .

Mesh

Strainer

Check

Valve

Relief

Valve

Step Action

Energize6 Service Manual

13

14 Turn on the electrical supply to the unit.

15 When the unit is refilled, replace the unit cover.

REPLACING THE CHECK VALVE

There is a check valve in back of the mesh strainers in each of the output lines from

the recirculating water pumps. To replace the check valve, perform the procedure in

Ta bl e 2 9 .

Turn the water supply on and make sure the water bath level is up to the

notch in the overflow tube.

Figure 42.

Ta bl e 2 9 .

Step Action

1 Turn off the electrical supply to the unit.

2 Turn off the water supply to the unit.

3 Remove the cover using the procedure in “Removing the Unit Cover” on page 14

4 Drain the system pressure by opening a dispense valve.

5

6 Turn off the recirculation shutoffs, shown in Figure 22 on page 24.

7

8 Remove the check valve, shown in Figure 42.

9 Install a new check valve, using teflon tape to insure a proper seal.

10

11

12 Turn on the electrical supply to the unit.

13 When the unit is refilled, replace the unit cover.

Vent the carbonators by opening the relief valves, shown in Figure 10 on

page 9.

Remove the high pressure plumbing connector from the pump, shown in

Figure 23 on page 24.

Reinstall the plumbing connector to the pump, using teflon tape to insure a

proper seal.

NOTE: Make sure to replace the gasket inside the fitting, when reconnecting the plumbing.

Turn the water supply on and make sure the water bath level is up to the

notch in the overflow tube.

© 2012, IMI Cornelius Inc. - 37 - Publication Number: 621058457SER

Page 42

Energize6 Service Manual

REPLACING THE CONTROLLER BOARDS

The controller boards are located on the front, left side of the unit, under the access

panel. To remove and replace a controller board, perform the procedure in Table 30.

Step Action

1 Turn off the electrical supply to the unit.

2 Remove the cover using the procedure in “Removing the Unit Cover” on page 14

3 Remove the service panel using the procedure in “Service Access” on page 14

4 Remove the cover from the malfunctioning control board, shown in Figure 43.

5 Unplug the connectors from the control board.

6 Install the new control board.

7 Reconnect all the connectors to the control board.

8 Replace the cover on the control board.

9 Turn on the electrical supply to the unit.

10 Replace the unit cover.

Ta bl e 3 0 .

Figure 43.

Publication Number: 621058457SER - 38 - © 2012, IMI Cornelius Inc.

Page 43

Energize6 Service Manual

TROUBLESHOOTING

Before looking for problems with the dispensing equipment, first check the following:

1. Is the power connected to the unit?

2. Is the power switch turned on?

3. Is the water connected to the unit?

4. Is the water filter clogged?

5. Are the beverage containers empty?

6. Is the CO

Seq Symptom Potential Failure Mode Potential Diagnosis Check

1 Warm Drinks System Not Running No Power or Low / High Voltage Check LED - (Green Blinking)

2 Warm Drinks Compressor - Running Insufficient System Capacity

3 Warm Drinks Compressor - Running Low on Charge

4 Warm Drinks Compressor - Not Running Power Switch Off Check Switch Position

5 Warm Drinks Compressor - Not Running Low Water Level

6 Warm Drinks Compressor - Not Running

7 Warm Drinks Compressor - Not Running Condenser Fan Motor Failure

8 Warm Drinks Compressor - Not Running Compressor internal cut out

9 Warm Drinks Compressor - Not Running Compressor Failure

10 Warm Drinks Compressor - Not Running Main Controller Fail Check LED - (R&G Blinking)

1 Warm Drinks Agitator Motor - Not Running Controller Failure

2 Warm Drinks Agitator Motor - Not Running Agitator Motor Failure Replace the motor

2 supply empty?

Condenser Dirty or Partially

Blocked

# of Drinks Served/Hr and python

losses. Python and insulation wet?

Refrigerant Pressures. Check ice

bank form. Ice up to the last winding?

Check Water level. Ice bank probe

must be located below water level

Power to / from refrigerant High

Pressure Switch (check reset)

Start compressor and look if the fan

motor starts as well.

Power to compressor? Check voltage to each leg (120V to ground)

Check start relay and start capacitor

No Power to agitator motor (power

and signal cable connected?)

1 Warm Drinks

2 Warm Drinks

3 Warm Drinks

4 Warm Drinks

No Carb

1

Water

No Carb

2

Water

No Carb

3

Water

© 2012, IMI Cornelius Inc. - 39 - Publication Number: 621058457SER

Recirculation Pump Motor Not Running

Recirculation Pump Motor Not Running

Recirculation Pump Motor Not Running

Recirculation Pump Motor Not Running

Carbonator Pump Motor Running

Carbonator Pump Motor Running

Carbonator Pump Motor - Not

Running

Recirculation Motor Switch Off Power Switch

Motion Controller Failure Power to pump motor

Pump failure or Blocked Power to pump motor

Pump Motor Failure Replace motor

Blocked Filter Screen

Water inlet pressure switch fail

closed

Out of CO2

Pump falls into the 20min max run

time. Power reset required.

Check LED (Yellow) Check CO2

Supply

Page 44

Energize6 Service Manual

Seq Symptom Potential Failure Mode Potential Diagnosis Check

4

5

6

7

8

9

10

11

No Carb

Water

No Carb

Water

No Carb

Water

No Carb

Water

No Carb

Water

No Carb

Water

No Carb

Water

No Carb

Water

Carbonator Pump Motor - Not

Running

Carbonator Pump Motor - Not

Running

Carbonator Pump Motor - Not

Running

Carbonator Pump Motor - Not

Running

Carbonator Pump Motor - Not

Running

Carbonator Pump Motor - Not

Running

Carbonator Pump Motor - Not

Running

Carbonator Pump Motor - Not

Running

Low CO2 Psi Switch fails closed

Low Water Pressure

Water inlet pressure switch fail

open

Short circuit the switch and check if

yellow LED is off

Check LED (Red blnks) check

water pressure

Check water pressure at gauge or

replace switch

Carbonator Level Sensor Shorted Check wiring or replace the probe

Fill Time Out Check LED (Red) - Reset Power

Main Controller Failure Check LED - (R&G Blinking)

Pump Motor Failure Replace motor

Still Water Solenoid fails closed

Check if valve does open or replace

solenoid

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

Low Carbonation

Low Carbonation

Low Carbonation

Low Carbonation

Low Carbonation

Low Carbonation

Low Carbonation

Low Carbonation

Low Carbonation

Low Carbonation

Agitator

pump

Agitator

pump

Agitator

pump

Agitator

pump

Agitator

pump

Carbonator Pump Motor Running

Carbonator Pump Motor Running

Carbonator Pump Motor Running

Carbonator Pump Motor Running

Carbonator Pump Motor short cycling

Carbonator Pump Motor short cycling

onator Pump Motor -

Carb

short cycling

Carbonator Pump Motor short cycling

Low CO2 Pressure Regulator Setting / Bottle empty

Air in carbonator Bleed Carbonator

Water Temp too high Ice Bank and Water Temp too high

Still Water Solenoid fails open

Low Water pressure

Level control probe and connections

Check if solenoid is closing if still

water is being dispensed

Check red indicator (flashing once

per second)

Check probe location and connections

Unplug probe connector on main

Defective probe

control board, pump should run

continuously

Defective pressure switch on inlet Jumper to test

Unplug corresponding recirculation

Carbonator Pump Motor short cycling

Defective thermistor

control thermistor from correspond-

ing main board. Short cycling stops

if defective

Carbonator Pump Motor short cycling

Defective carbonator pump or

motor

Check pump and motor

Continuously runs hi or lo Water bath temp sensor Test sensor

Continuously runs hi or lo Connections at main controller Check connections

Continuously runs hi or lo Bad agitator motor Check motor

Continuously runs hi or lo Low water level/probe out of water Check probe position

Continuously runs hi or lo Bad main control board Check and replace board

1 Freeze up Compressor running

Publication Number: 621058457SER - 40 - © 2012, IMI Cornelius Inc.

Ice bank probe in wrong bend/

wrong location

Check ice probe position and cor-

rect

Page 45

Energize6 Service Manual

Seq Symptom Potential Failure Mode Potential Diagnosis Check

2 Freeze up Compressor running Ice bank probe not connected

3 Freeze up Compressor running Ice bank probe interrupted Check cable resistance end to end

4 Freeze up Compressor running Controller relay defect Exchange main controller

5 Freeze up Compressor running Agitator motor off Check agitator motor

Irregular Ice

1

2

3

Bank

Irregular Ice

Bank

Irregular Ice

Bank

Ice bank buiding unequally Agitator motor bad Check agitator motor

Ice bank buiding unequally

Water bath overflow tube not

seated

Ice bank buiding unequally TXV sensing bulb mounting bad

Check cable connector on controller side

Check water bath level

Check TXV sensing bulb mounting

(2)

1

2

3

1

2

3

4

5

Water bath

overflows

Water bath

overflows

Water bath

overflows

No recirculation

No recirculation

No recirculation

No recirculation

No recirculation

Water bath continues to overfill

Water bath continues to overfill

Water bath continues to overfill

Recirculation pump not running

Recirculation pump not running

Recirculation pump not running

Recirculation pump not running

Recirculation pump not running

Water bath fill valve not shut off

completely

Stainless steel cooling coil(s) ruptured

Leaking crimped water line connection

Check water bath fill valve

Check coils and replace if necessary

Check crimped water line connections

Defective pump motor Check and replace motor

Defective motor control board Check and replace control board

Motor control board shut down on

error

Loose or defective wire connection

Troubleshoot error

Check and tighten connections

Low voltage Check and verify voltages

© 2012, IMI Cornelius Inc. - 41 - Publication Number: 621058457SER

Page 46

Energize6 Service Manual

FLOW CHARTS AND CIRCUIT DIAGRAMS

PLUMBING DIAGRAM

Publication Number: 621058457SER - 42 - © 2012, IMI Cornelius Inc.

Page 47

Energize6 Service Manual

© 2012, IMI Cornelius Inc. - 43 - Publication Number: 621058457SER

Page 48

Energize6 Service Manual

Publication Number: 621058457SER - 44 - © 2012, IMI Cornelius Inc.

Page 49

WIRING DIAGRAM

Energize6 Service Manual

© 2012, IMI Cornelius Inc. - 45 - Publication Number: 621058457SER

Page 50

Energize6 Service Manual

Publication Number: 621058457SER - 46 - © 2012, IMI Cornelius Inc.

Page 51

Page 52

IMI Cornelius Inc.

www.cornelius.com

Loading...

Loading...