Page 1

www.cornelius.com

Installation Manual

ICE/BEVERAGE DISPENSER

Model: Enduro-200/250

IMPORTANT:

TO THE INSTALLER.

It is the responsibility of

the Installer to ensure that

the water supply to the

dispensing equipment is

provided with protection

against backflow by an air

gap as defined in

ANSI/ASME A112.1.2-1979;

or an approved vacuum

breaker or other such

method as proved effective

by test.

Water pipe connections

and fixtures directly

connected to a potable

water supply shall be

sized, installed, and

maintained according to

Federal, State, and Local

Codes.

Part No. 92181INS

March 24, 2004

Revised: March 2, 2006

Revision: D

THIS DOCUMENT CONTAINS IMPORTANT INFORMATION

This Manual must be read and understood before installing or operating this equipment

IMI CORNELIUS INC; 2006©

PRINTED IN U.S.A

Page 2

TABLE OF CONTENTS

SAFETY PRECAUTIONS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DESCRIPTION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION INSTRUCTIONS 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GATE RESTRICTOR PLATE ADJUSTMENT 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BLOWN FUSE OR CIRCUIT BREAKER. 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GATE DOES NOT OPEN. AGITATOR DOES NOT TURN. 13. . . . . . . . . . . . . . . . . .

GATE DOES NOT OPEN OR IS SLUGGISH. AGITATOR TURNS. 13. . . . . . . . . .

ICE DISPENSES CONTINUOUSLY. 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SLUSHY ICE. WATER IN HOPPER. 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BEVERAGES DO NOT DISPENSE. 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BEVERAGES TOO SWEET. 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BEVERAGE NOT SWEET ENOUGH. 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BEVERAGES NOT COLD (UNITS WITH BUILT-IN COLD PLATE). 14. . . . . . . . . . .

FLAVOR SYRUPS DO NOT DISPENSE. 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FLAVOR DISPENSES FOR MORE THAN 1 SEC. 14. . . . . . . . . . . . . . . . . . . . . . . . . .

FLAVOR DISPENSES MORE THAN .5 OZ. 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARRANTY 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

LIST OF FIGURES

FIGURE 1. DRIP TRAY DRAIN ASSEMBLY 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 2. GATE RESTRICTOR PLATE 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 3. MOUNTING TEMPLATE 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 4. FLOW DIAGRAM (”BC” UNIT WITH SIX BEVERAGE FAUCETS) 5.

FIGURE 5. FLOW DIAGRAM (”BC” UNIT WITH EIGHT BEVERAGE FAUCETS) 6

FIGURE 6. FLOW DIAGRAM (”BC” UNIT WITH TEN BEVERAGE FAUCETS) 7.

FIGURE 7. FLOW DIAGRAM (”B” UNIT WITH EIGHT BEVERAGE FAUCETS) 8

FIGURE 8. WIRING DIAGRAM (115 VOLT UNIT) 9. . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 9. SCHEMATIC (115 VOLT UNIT) 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 10. WIRING DIAGRAM (220–240 VOLT UNIT) 11. . . . . . . . . . . . . . . . . . . .

FIGURE 11. SCHEMATIC (220–240 VOLT UNIT) 12. . . . . . . . . . . . . . . . . . . . . . . . . .

i

92181INS

Page 3

SAFETY PRECAUTIONS

Always: Disconnect power to the dispenser before servicing or cleaning.

Never: Place hands inside of hopper or gate area without disconnecting power to the dispenser. Agitator rotation

occurs automatically when dispenser is energized!

This ice dispenser has been specifically designed to provide protection against personal injury and eliminates

contamination of ice.To insure continued protection and sanitation, observe the following:

ALWAYS: Be sure the removable lid is properly installed to prevent unauthorized access to the hopper interior

and possible contamination of the ice.

ALWAYS: Be sure the upper and lower front panels are securely fastened.

ALWAYS: Keep area around the dispenser clean of ice cubes.

CAUTION: Dispenser cannot be used with crushed or flaked ice.

Use of bagged ice which has frozen into large chunks can void warranty. The

dispenser agitator is not designed to be an ice crusher. Use of large chunks of

ice which ”jam up” inside the hopper will cause failure of the agitator motor and

damage to the hopper. If bagged ice is used, it must be carefully and completely

broken into small, cube–sized pieces before filling into the dispenser hopper.

DESCRIPTION

The ”ENDURO” series of ice dispensers solves your ice and beverage service needs in a sanitary, space saving,

economical way. Designed to be manually filled with ice from any remote ice making source, these dispensers will

dispense cubes (up to 1-1/4 in. in size), cubelets, and hard-chipped or cracked ice; and in addition, several flavors

of post–mix beverages. The “BC” units include beverage faucets and a cold plate and are designed to be supplied

direct from syrup tanks and a carbonator, with no additional cooling required.

SPECIFICATIONS

Model ED200 (ice only) ED250 (ice only)

B (Beverage Faucets) B (Beverage Faucets)

C (Cold Plate) C (Cold Plate)

Z (No drip tray) Z (No drip tray)

N (No Lid) N (No Lid)

F (Flavor) F (Flavor)

Ice storage 200 pounds 250 pounds

Maximum No. of

Beverage Faucets

Available

Cold Plate (Built–In) Yes, On BC Model Only Yes, On BC Model Only

10 10

Electrical 120/1/60, 3.5 Amps

220–240/1/50–60, 2.0 Amps

Dimensions 30 in. Wide X 30-11/16 in. Deep X 35-5/8

in. High

Z Model 30 in. Wide X 23-1/16 in. Deep X 35-5/8

in. High

1 92181INS

120/1/60, 3.5 Amps

220–240/1/50–60, 2.0 Amps

30 in. Wide X 30-11/16 in. Deep X 39-5/8

in. High

30 in. Wide X 23-1/16 in. Deep X 39-5/8

in. High

Page 4

INSTALLATION INSTRUCTIONS

1. Locate the dispenser indoors on a level counter top.

A. LEG OPTION

Note: Before installing legs, the plastic plugs must be removed.

Unpack the four (4) legs and install them into the threaded holes provided in the bottom of the unit. The

installer must provide flexibility in the product and utility supply lines to permit shifting the position of the

dispenser sufficiently to clean the area beneath it.

Rotate the line support bracket, located under base, to the down position and route all the lines above

the bracket.

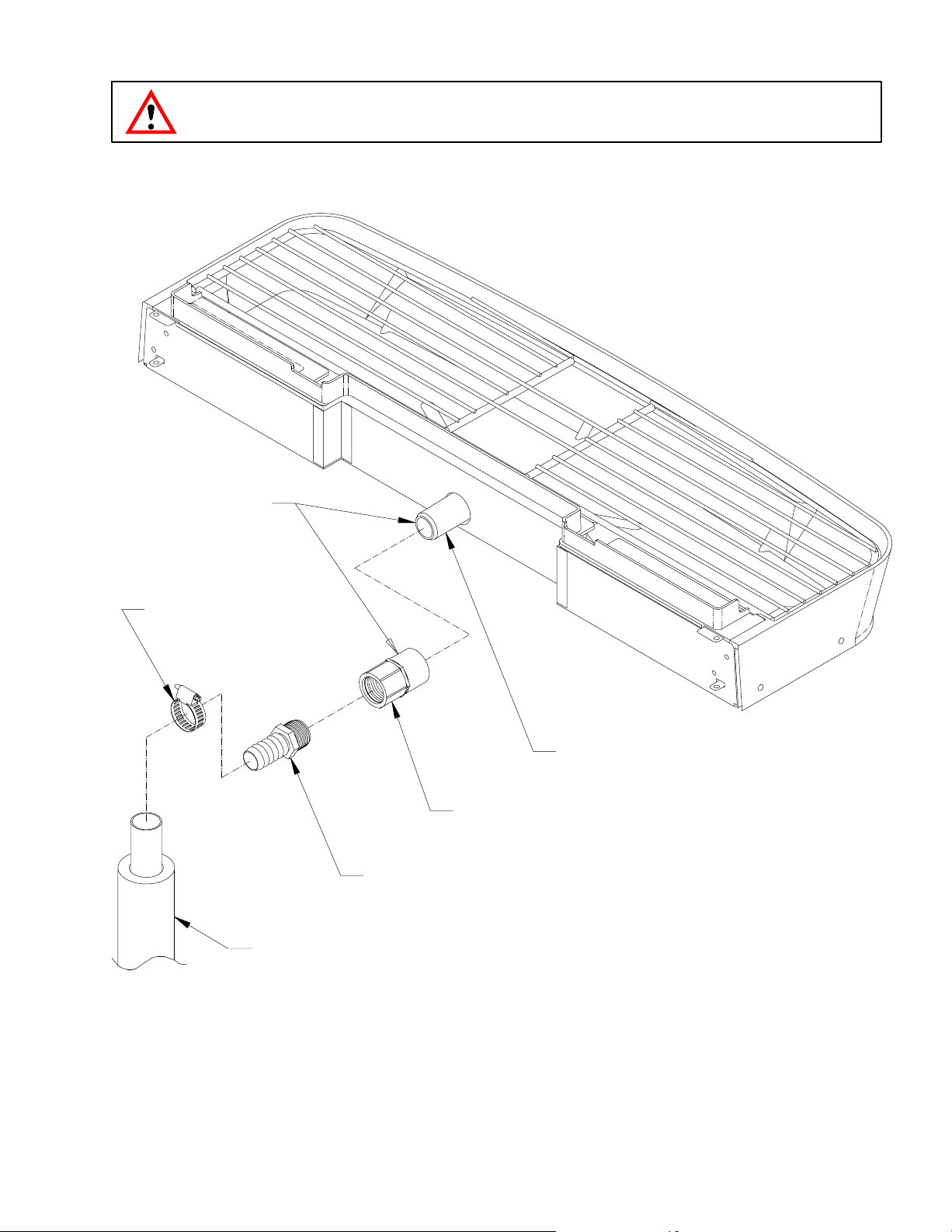

B. COUNTER MOUNTING

The ice dispenser must be sealed to the counter. The MOUNTING TEMPLATE (see Figure 3)

indicates where openings can be cut in the counter. Locate the desired position for the dispenser, then

mark the outline dimensions on the counter using the MOUNTING TEMPLATE. Cut openings in the

counter.

Rotate the line support bracket, located under base, to the up position and route all the lines below the

bracket.

Apply a continuous bead of National Sanitation Foundation (NSF) listed silastic sealant (Dow 732 or

equal) approximately 1/4” inside of the unit outline dimensions and around all openings. Then, position

the unit on the counter within the outline dimensions. All excess sealant must be wiped away

immediately.

2. The beverage tubes, drain tube and power cord are routed through the large opening in the bottom of the

unit. See the MOUNTING TEMPLATE (see Figure 3), for locating the required clearance hole in the counter

for these utility lines.

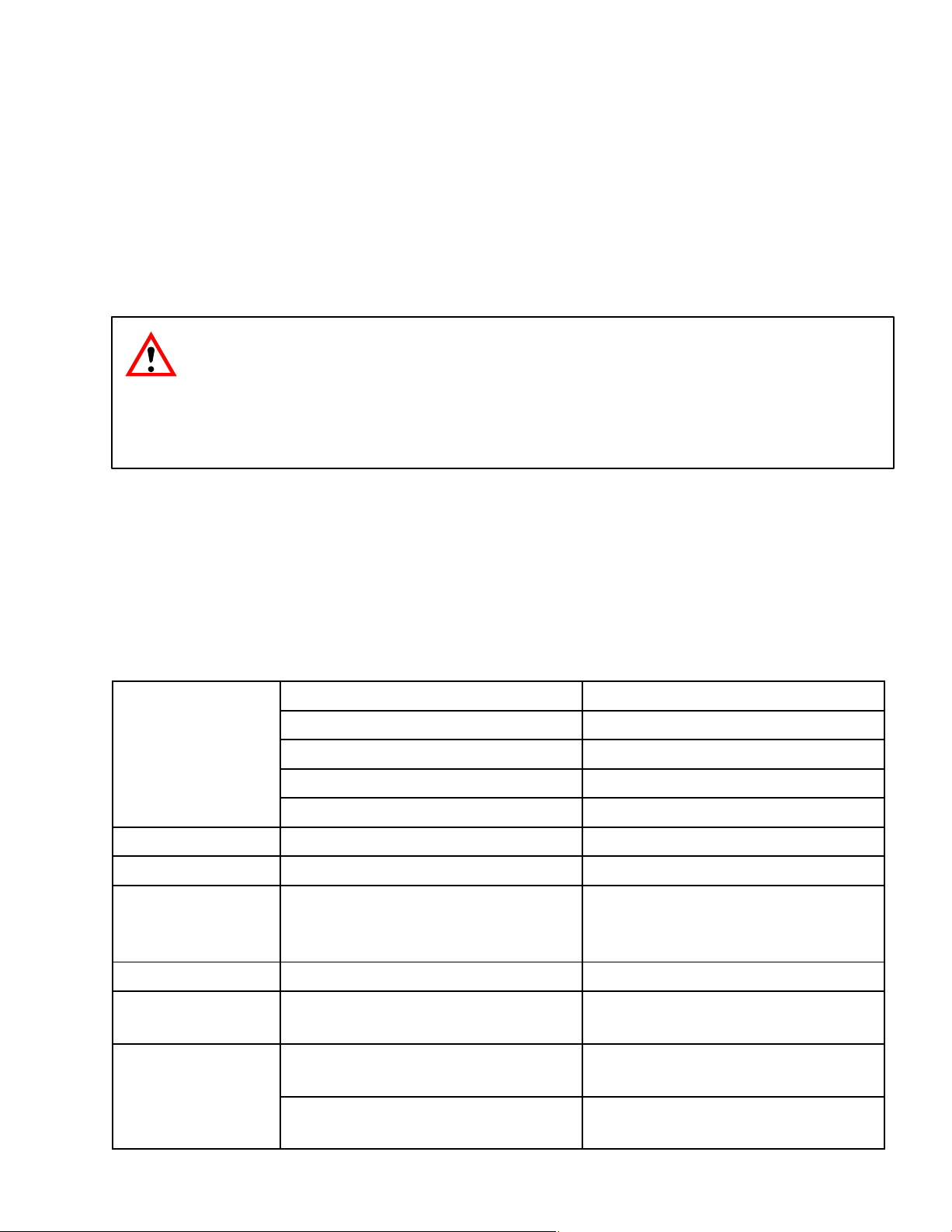

3. DRIP TRAY DRAIN ASSEMBLY (see Figure 1). Route the drain tube to an open drain with the end of the

tube above the “flood” level of the drain. Use the tubing, fittings, clamps, and insulation provided with the Dispenser to assemble the drain. The completed drain line must pitch continuously downward and contain no

“traps” or improper drainage will result.

NOTE: This equipment must be installed with adequate backflow protection to comply with federal, state,

and local codes.

4. Connect the beverage system product tubes as indicated in the applicable Flow Diagram. This work should

be done by a qualified Service Person. Any non-carbonated water tubing must be connected to the outlet of

the check valve.

Note: See applicable Flow Diagram (see Figure 4 through 7) or decal on lower front panel of the unit for

the location of syrup and water connections.

Note: Water pipe connections and fixtures directly connected to a potable water supply shall be sized,

installed and maintained according to Federal, State and Local Laws.

5. Clean the hopper interior (see Owner’s Manual P/N 92108 for cleaning instructions).

6. Connect the power cord to a 120 volt, 60 cycle, 3–wire grounded receptacle. For 220–240 volt units, a

3–wire power cord is provided. An adapter plug for the particular country will need to be provided by the

equipment Installer.

292181INS

Page 5

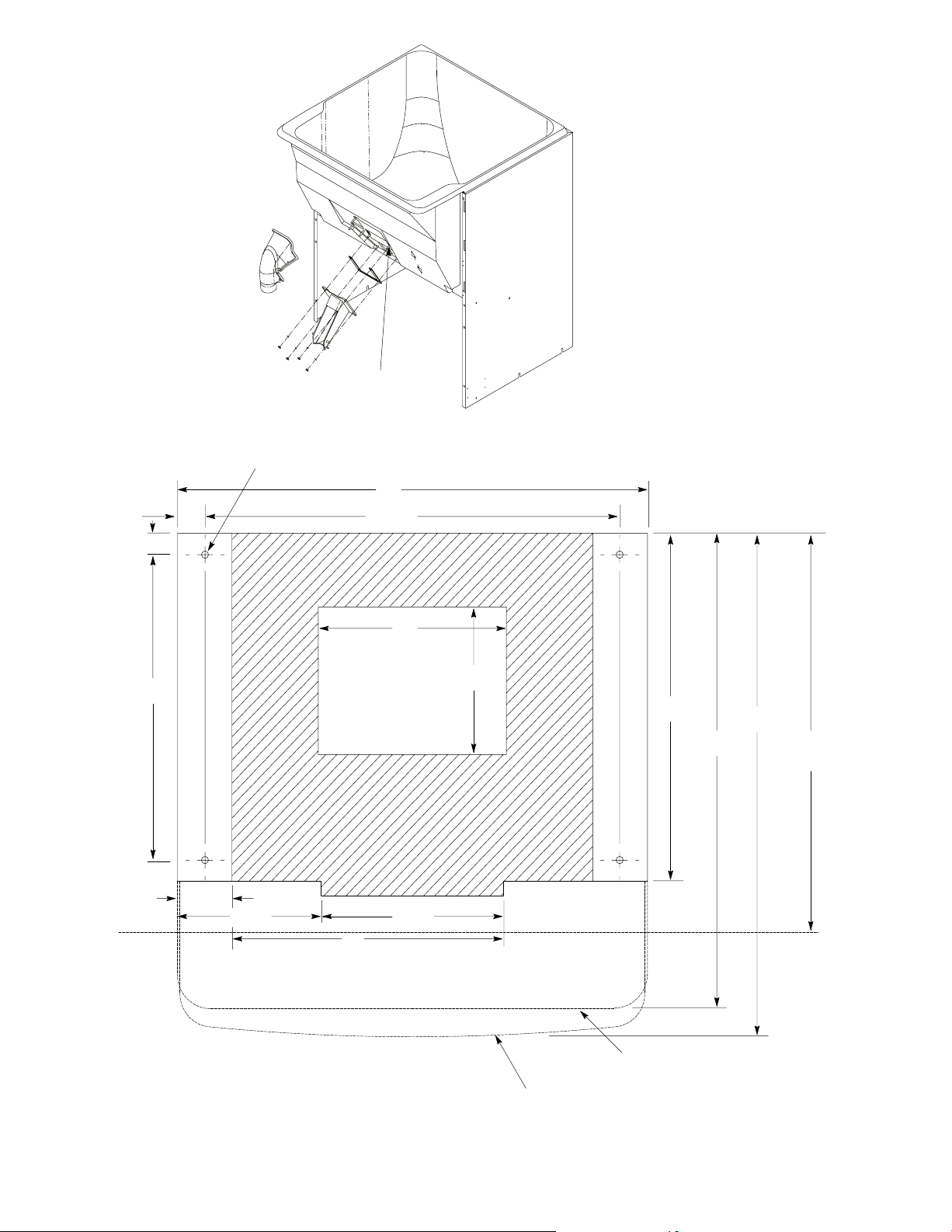

GATE RESTRICTOR PLATE ADJUSTMENT

CAUTION: Disconnect power to dispenser before installing, removing or adjusting

restrictor.

The restrictor plate may be adjusted up or down as shown in Figure 2 to reduce or increase the ice dispensing

rate, especially desirable when using glasses or other containers with small openings. Adjustment can be made

by sliding the restrictor plate up or down with nuts loosened, to obtain the desired ice dispensing rate.

SOLVENT BOND

HOSE CLAMP

1-IN. I.D. PLASTIC TUBING

DRIP TRAY DRAIN

FITTING

COUPLING

3/4 SOCKET X 3/4 FPT

BARB ADAPTER

1 BARB X 3/4 MPT

DRAIN LINE

(6 FT) WITH INSULATION

FIGURE 1. DRIP TRAY DRAIN ASSEMBLY

3 92181INS

Page 6

1 5/16

INSTALL PLATE ON

STUDS AS SHOWN

FIGURE 2. GATE RESTRICTOR PLATE

7/16 DIA.

30

26 7/161 13/16

12

Z Style

18 5/8

3 1/2

9 3/16 11 5/8

23

REMOVABLE SINK

RECOMMENDED COUNTER OPENING SIZE

9 X 12 FOR UTILITIES AND BEVERAGE

TUBING. OPENING CAN BE LOCATED

ANYWHERE WITHIN SHADED AREA.

9

21 1/4

TO FRONT OF DRIP

TRAY ON COUNTERTOP

TO FRONT TOP

OF DRIP TRAY

29

30 11/16

23 1/16

FIGURE 3. MOUNTING TEMPLATE

492181INS

Page 7

OPTIONAL

PRESSURE

REGULATOR

POTABLE

WATER

SUPPLY

FILTER

PRESSURE

REGULATORS

CO2

Cylinder

Non–Carb Water

CARBONATOR

REQUIRED

INSTALL FOR

NON–CARB AS

CHECK

VALV E

CO2

Carb Water

OPTIONAL FOR

OR ROOT BEER

DIET DRINK DRINKS

PSIG

5–15

S1S2

S3S6 S5 S4

15–50 PSIG

SYRUP TANKS

FLAVOR

F4

F2 F3

F1

TANKS

25–30 PSIG

FAUCETS

W1

S1

1

W2

W3

W2

S2

S3

2

3

S1

1234

FAUCETS VIEWED FROM THIS SIDE

W1

S3

S2

W4

INLET

COLDPLATE

CONNECTIONS

S4

S5

S6

W4

S4

4

W3

S5

5

COLD PLATE

S6

6

INCLUDED WITH UNIT

ITEMS INSIDE BROKEN LINE

FIGURE 4. FLOW DIAGRAM (UNIT WITH SIX FAUCETS)

5 92181INS

Page 8

POTABLE

WATER

SUPPLY

CO2

Cylinder

Non–Carb Water

OPTIONAL

PRESSURE

Carb Water

REGULATOR

CHECK

VALVE

FILTER

INSTALL FOR

CARBONATOR

Carb Water

REQUIRED

NON–CARB AS

CO2

OPTIONAL FOR

DIET DRINKS

OR ROOT BEER

PRESSURE

S1S2

S3

S5 S4

15–50 PSIG

SYRUP TANKS

S7 S6

S8

REGULATORS

FLAVOR TANKS

25–30 PSIG

F3F1 F2 F4

S1

1

FAUCETS

5–15

PSIG

W1

2

S2

W2

S6

S7

S1S2S3

S3

S4

3

4

S4

W1W2W3

W4

INLET

COLDPLATE

CONNECTIONS

S5

S8

W4

S5

S6

6

5

1234

FAUCETS VIEWED FROM THIS SIDE

FIGURE 5. FLOW DIAGRAM (UNIT WITH EIGHT FAUCETS)

W3

S7

7

COLD PLATE

S8

8

INCLUDED WITH UNIT

ITEMS INSIDE BROKEN LINE

692181INS

Page 9

OPTIONAL

PRESSURE

REGULATOR

POTABLE

WATER

SUPPLY

FILTER

REQUIRED

INSTALL FOR

NON–CARB AS

Carb Water

S1S2

PRESSURE

REGULATORS

CO2

Cylinder

Non–Carb Water

Carb Water

W1

CHECK

VALV E

CO2

S3S10 S9

S5 S4

S3S6 S5 S4

CARBONATOR

15–50 PSIG

SYRUP TANKS

W2

S8 S7 S6

5–15

PSIG

DIET DRINKS

OPTIONAL FOR

OR ROOT BEER

W4

W3

FLAVOR

TANKS

25–30 PSIG

S1

1

FAUCETS

S1

S3S2S4

S3

S4

S2

2

3

4

S5

5

S5

W1

W4

S6S7S8

INLET

CONNECTIONS

S9

S10

COLD PLATE

S6

S7

S8

S9

S10

8

7

6

9

10

W3COLDPLATE

W2

1234

FAUCETS VIEWED FROM THIS SIDE

FIGURE 6. FLOW DIAGRAM (UNIT WITH TEN FAUCETS)

7 92181INS

Page 10

REGULATORS

15–50 PSIG

2

CO TANK

SYRUP

TANKS

S7 S8

FLAVOR

TANKS

F4F3F2F1

30 PSIG

CO2

OPTIONAL

PRESSURE

REGULATOR

60–100 PSIG

CHECK

VALVE

POTABLE

WATER

SUPPLY

APPROPRIATE WATER MANIFOLD OUTLE T.

CARBONATOR FILTER

REGULATOR FOR

DIET OR

ROOT BEER

5–15

PSIG

1

S1 S2 S3 S4 S5 S6

2

1

FAUCETS

3

4

5

6

7

8

S5

S4

S3

S2

S1

2

3

4

5

1234

S6

6

7

WATER *

S7

CARB

WATER

CW

CW

REMOTE

SYSTEM

REFRIGERATION

S8

WATER

MANIFOLD

8

ITEMS OUTSIDE BROKEN LINES ARE

NOT INCLUDED WITH UNIT. * – FOR NON–CARBONATED DRINK(S)/PLUG

FAUCETS VIEWED FROM FRONT OF UNIT

FIGURE 7. FLOW DIAGRAM (”B” UNIT WITH EIGHT BEVERAGE FAUCETS)

892181INS

Page 11

Q.C. CONNECTOR

GATE

SOLENOID

(106VDC)

CAP

R

E

D

AGITATOR

MOTOR

Y

E

L

TO HINGE

MOTOR

HEATER

BLK

GRN

N

L

WIRING DIAGRAM

SERVICE INFORMATION

DISPENSE

SWITCH

DANGER!

ELECTRIC SHOCK HAZARD. DISCONNECT

POWER BEFORE SERVICING UNIT.

2

1

BLUE

ICE LEVEL SIGNAL

OPTION

TO 24V

TRANSFORMER

BLUE

LIGHTT’STAT

TO BEVERAGE VALVES

KEY SWITCH

YELLOW

9 92181INS

W

B

B

B

H

L

L

L

A

I

U

U

C

T

E

E

E

K

BLACK

WHITE

OPTIONAL

LIGHT SOCKET

620904701 REV.D

B

L

U

E

B

L

U

E

B

L

A

C

K

R

Y

E

E

D

L

L

O

W

OPTIONAL

LIGHT

STARTER

W

G

R

E

E

N

R

B

B

B

B

G

E

H

L

L

L

L

R

D

I

A

A

A

A

E

T

C

C

C

C

E

E

K

K

K

K

N

WHITE

BLACK

Y

E

L

L

W

H

I

T

E

O

W

NC

NC

R

E

D

NO

NO

G

R

E

E

N

COM

L2

AGITATION

TIMER

COM

L1

R

E

D

BLACK

G

R

E

E

N

WHITE

J10

J9

B

L

U

E

BLACK

WHITE

BLACK

OPTIONAL

LIGHT BALLAST

WHITE

WHITE

WHITE

BLACK

BLACK

BLACK

BLACK

BEVERAGE

TRANSFORMER

(OPTIONAL)

W

H

I

T

E

BEVERAGE

TRANSFORMER

(OPTIONAL)

W

H

B

L

A

C

K

I

T

E

BLACK

WHITE

B

L

A

C

K

OPTIONAL

LIGHT SOCKET

FIGURE 8. WIRING DIAGRAM (115 VOLT UNIT)

Page 12

G

L

N

VEND SWITCH

L1

MOTOR HEATER

N.O.

C

N.C.

TIMER

RECTIFIER

O/L

CAPACITOR

L2

AGITATOR MOTOR

R

S

START CAPACITOR

3

2

MOTOR

START

RELAY

4

BALLAST

OPTIONAL FLAVOR VLVS

VLV

SOLENOIDS

PCB

BOARD

OPTIONAL

BEVERAGE

VALVES

KEYPAD

GATE

SOLENOID

LIGHT

STARTER

BEVERAGE TRANSFORMER

OPTIONAL

OPTIONAL LOW ICE LEVEL LIGHT

T’STAT

OPTIONAL

BEVERAGE

VALVES

BEVERAGE PANEL

FIGURE 9. SCHEMATIC (115 VOLT UNIT)

1092181INS

Page 13

WIRING DIAGRAM

SERVICE INFORMATION

11 92181INS

Q.C. CONNECTOR

GATE

SOLENOID

GRN/YEL

MOTOR START

CAPACITOR

BLACK

WHITE

AGITATOR

MOTOR

OPTIONAL

LIGHT

SOCKET

B

L

A

C

K

B

B

L

L

U

K

E

TO HINGE

GUSSET

BLACK

RED

OPTIONAL

LIGHT

STARTER

ELECTRIC SHOCK HAZARD. DISCONNECT

POWER BEFORE SERVICING UNIT.

T’STAT

1

FLAVOR SOLENOIDS

WHT

BLK

LIGHT

2

BLUE

ICE LEVEL SIGNAL

OPTION

TO 24V

TRANSFORMER

BLUE

BEVERAGE

TRANSFORMER

(OPTIONAL)

W

H

I

T

E

FILTER

ASY

LT BLUE

KEY SWITCH

YELLOW

N

L

BLACK

B

L

A

C

K

BROWN

BROWN

BROWN

BROWN

POWER

SWITCH

TO BEVERAGE VALVES

BEVERAGE

TRANSFORMER

(OPTIONAL)

W

H

I

T

E

OPTIONAL

LIGHT

SOCKET

BLACK

WHITE

B

L

A

C

K

TO

BEVERAGE

PANEL

E

N

L

MOTOR

HEATER

BLK

DISPENSE

SWITCH

(220–240 VAC)

1234

PCB BOARD

KEYPAD

ESD

(WATER–5)

DANGER!

BLK

YEL

BLU

RED

BRN

WHT

1

2

3

4

FLAVOR OPTION

B

R

B

B

B

Y

G

G

E

L

L

L

R

R

E

D

U

A

U

L

N

N

E

C

E

L

/

/

K

O

Y

Y

E

E

W

L

L

W

H

I

T

E

B

G

G

G

R

N

/

Y

E

L

R

L

B

B

L

L

R

R

E

T

R

L

N

A

A

N

D

A

O

C

C

/

/

C

B

W

K

K

Y

Y

L

N

K

E

E

U

L

L

E

BLACK

3

2

G

R

N

/

Y

E

L

MOTOR

START

RELAY

WHITE

L1

BLACK

BLACK

L

O

A

D

BLACK

LT BLUE

J10

J9

B

L

U

E

LT BLUE

BROWN

WHITE

G

R

G

N

R

G

/

N

R

G

Y

/

N

R

E

Y

/

N

L

E

Y

/

L

E

Y

L

E

L

4

W

H

I

T

E

GRN

NC

NC

NO

NO

R

E

D

N

POWER LINE

FILTER

L

BROWN

COM

L2

AGITATION

TIMER

COM

R

E

D

LT BLUE

WHITE

LAMP

LINE

B

L

A

C

K

BROWN

OPTIONAL

LIGHT

BALLAST

BLACK

BROWN

WHITE

WHITE

FIGURE 10. WIRING DIAGRAM (220–240 VOLT UNIT)

Page 14

L

G N

EMI FILTER

LINE

FILTER

POWER SWITCH

VEND SWITCH

L1

N.O.

N.C.

TIMER

RECTIFIER

MOTOR HEATER

O/L

C

GATE

SOLENOID

L2

AGITATOR MOTOR

R

S

START CAPACITOR

3

2

MOTOR

START

RELAY

4

OPTIONAL

BALLAST

OPTIONAL

BEV. TRANSFORMER

OPTIONAL LIGHT

OPTIONAL STARTER

OPTIONAL BEV. TRANSFORMER

OPTIONAL FLAVOR VLVS

VLV

SOLENOIDS

BEV. FAUCETS

BEVERAGE PANEL

FIGURE 11. SCHEMATIC (220–240 VOLT UNIT)

PCB

BOARD

KEYPAD

1292181INS

Page 15

TROUBLESHOOTING

IMPORTANT: Only qualified personnel should service internal components or electrical wiring.

WARNING: If repairs are to be made to a product system, remove quick disconnects from

the applicable product tank, then relieve the system pressure before proceeding. If repairs

are to be made to the CO

system, stop dispensing, shut off the CO

2

system pressure before proceeding. If repairs are to be made to the refrigeration system, make sure

electrical power is disconnected from the unit.

Should your unit fail to operate properly, check that there is power to the unit and that the hopper contains ice. If the unit does not dispense, check the following chart under the appropriate symptoms to aid

in locating the defect.

supply, then relieve the

2

Trouble

Probable Cause

BLOWN FUSE OR CIRCUIT BREAKER. A. Short circuit in wiring.

B. Defective gate solenoid.

C.Defective agitator motor.

GATE DOES NOT OPEN. AGITATOR DOES NOT

A. No power.

TURN.

B. Bent depressor plate (does not actuate switch).

C.Defective dispensing switch.

GATE DOES NOT OPEN OR IS SLUGGISH.

A. Defective gate solenoid.

AGITATOR TURNS.

B. Excessive pressure against gate slide.

C.Defective Rectifier.

ICE DISPENSES CONTINUOUSLY.

A. Stuck or bent depressor plate (does not release

switch).

B. Defective dispensing switch.

C.Improper switch installation.

SLUSHY ICE. WATER IN HOPPER.

A. Blocked drain.

B. Unit not level.

C.Poor ice quality due to water quality or icemaker

problems.

D.Improper use of flaked ice.

BEVERAGES DO NOT DISPENSE.

BEVERAGES TOO SWEET.

A. No 24 volt power to faucets.

B. No CO

pressure.

2

A. Carbonator not working.

B. No CO

pressure in carbonator.

2

C.Faucet brix requires adjusting.

13 92181INS

Page 16

Trouble Probable Cause

BEVERAGE NOT SWEET ENOUGH.

A. Empty syrup tank.

B. Faucet brix requires adjusting.

BEVERAGES NOT COLD (UNITS WITH BUILT-IN

COLD PLATE).

A. Unit standing with no ice in hopper or no ice in cold

plate cabinet.

FLAVOR SYRUPS DO NOT DISPENSE. A.No 24 volt power to PC board.

B. No CO2 pressure.

C.Empty syrup tank.

D.Kinked tubing.

E. Clogged inner nozzle.

F. Defective PC board.

G.Defective harness from keypad.

H.Defective Flow control.

I. Defective solenoid harness.

J. Defective keypad.

FLAVOR DISPENSES FOR MORE THAN 1 SEC. A. Dip switch settings on control board incorrect.

B. PC board defective.

C.Defective flow control.

FLAVOR DISPENSES MORE THAN .5 OZ. A. Dip switch settings on control board incorrect.

B. Flow control incorrectly set.

C.PC board defective.

D.Defective flow control.

Contact your local syrup or beverage equipment distributor for additional information and troubleshooting of beverage system.

1492181INS

Page 17

WARRANTY

IMI Cornelius Inc. warrants that all equipment and parts are free from defects in material and

workmanship under normal use and service. For a copy of the warranty applicable to your Cornelius

product, in your country, please write, fax or telephone the IMI Cornelius office nearest you. Please

provide the equipment model number and the date of purchase.

IMI Cornelius Offices

AUSTRALIA D P. O. 210, D RIVERWOOD, D NSW 2210, AUSTRALIA D (61) 2 533 3122 D FAX (61) 2 534 2166

D AM LANGEN FELDE 32 D A-1222 D VIENNA, AUSTRIA D (43) 1 233 520 D FAX (43) 1-2335-2930

AUSTRIA

D BOSKAPELLEI 122 D B-2930 BRAASCHAAT, B ELGIUM D (32) 3 664 0552 D FAX (32) 3 665 2307

BELGIUM

D RUA ITAOCARA 97 D TOMAS COELHO D RIO DE JANEIRO, BRAZIL D (55) 21 591 7150 D FAX (55) 21 593 1829

BRAZIL

D TYTHING ROAD ALCESTER D WARWICKSHIRE, B49 6 EU, ENGLAND D (44) 789 763 101 D FAX (44) 789 763 644

ENGLAND

D 71 ROUTE DE ST. DENIS D F-95170 DEUIL LA BARRE D PAR IS, FRANCE D (33) 1 34 28 6200 D FAX (33) 1 34 28 6201

FRANCE

GERMANY

GREECE

HONG

ITALY

NEW

SINGAPORE

SPAIN

USA

D CARL LEVERKUS STRASSE 15 D D-4018 LANGENFELD, WEST GERMANY D (49) 2173 7930 D FAX (49) 2173 77 438

D 488 MESSOGION AVENUE D AGIA PAR ASK EV I D 153 42 D ATHENS, GREECE D (30) 1 600 1073 D FAX (30) 1 601 2491

KONG D 1104 TAIKOTSUI CENTRE D 11-15 KOK CHEUNG ST D TAIKOKTSUE, HONG KONG D (852) 789 9882 D FAX (852) 391 6222

D VIA PELLIZZARI 11 D 1-20059 D VIMARCATE, ITALY D (39) 39 608 0817 D FAX (39) 39 608 0814

ZEALAND D 20 LANSFORD CRES. D P. O . BOX 19-044 AVONDALE D AUCKLAND 7, NEW ZEALAND D (64) 9 8200 357 D FAX (64) 9 8200 361

D 16 TUAS STREET D SINGAPORE 2263 D (65) 862 5542 D FAX (65) 862 5604

D POLIGONO INDUSTRAIL D RIERA DEL FONOLLAR D E-08830 SANT BOI DE LLOBREGAT D BARCELONA, SPAIN D (34) 3 640 2839 D FAX (34) 3 654 3379

D ONE CORNELIUS PLACE D ANOKA, MINNESOTA D (763) 421-6120 D FAX (763) 422-3255

15 92181INS

Loading...

Loading...