Page 1

IMI CORNELIUS REMCOR INC g 500 REGENCY DRIVE g GLENDALE HEIGHTS, IL 60139–2268

Telephone (800) 551–4423 Facsimile (800) 519–4423

Operator’s Manual

DURAFLEX ICE/BEVERAGE DISPENSER

Model: DF 250 BCP

IMPORTANT:

TO THE INSTALLER.

It is the responsibility of

the Installer to ensure that

the water supply to the

dispensing equipment is

provided with protection

against backflow by an air

gap as defined in

ANSI/ASME A112.1.2-1979;

or an approved vacuum

breaker or other such

method as proved effective

by test.

Water pipe connections

and fixtures directly

connected to a potable

water supply shall be

sized, installed, and

maintained according to

Federal, State, and Local

Codes.

Part No.620919540

Revised: July, 2001

Revision: A

Control Code: A

THIS DOCUMENT CONTAINS IMPORTANT INFORMATION

This Manual must be read and understood before installing or operating this equipment

IMI CORNELIUS INC; 2001

PRINTED IN U.S.A

Page 2

TABLE OF CONTENTS

START-UP AND OPERATING INSTRUCTIONS 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ICE PORTIONING SYSTEM OPERATION 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NORMAL OPERATION 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEAN MODE 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NORMAL ICE PORTION ADJUSTMENT 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EXTRA ICE PORTION ADJUSTMENT 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AGITATION REFILL TIME ADJUSTMENT 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MANUAL ICE DISPENSING OPERATION 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAILY (OR AS REQUIRED) 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WEEKLY (OR AS REQUIRED) 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MONTHLY 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING INSTRUCTIONS 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DISPENSER 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BEVERAGE SYSTEM 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING DISPENSING VALVES 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SANITIZING 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

BLOWN FUSE OR CIRCUIT BREAKER. 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SLUSHY ICE. WATER IN HOPPER 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BEVERAGES DO NOT DISPENSE. 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BEVERAGES TOO SWEET. 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BEVERAGES NOT SWEET ENOUGH. 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BEVERAGES NOT COLD (UNITS WITH BUILD-IN COLD PLATE). 11. . . . . . . . . .

NO ICE DISPENSED FROM ICE PORTION CONTROLLER 12. . . . . . . . . . . . . . . .

NO ICE DISPENSED FROM MANUAL ICE DISPENSE PUSHBUTTON

SWITCH 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ICE DISPENSING DURING AUTOMATIC AGITATION 13. . . . . . . . . . . . . . . . . . . . . .

PARTS LIST 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARRANTY 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LIST OF FIGURES

FIGURE 1. PARTS IDENTIFICATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 2. CUP SIZE LABEL 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 3. CABINET SECTION EXPLODED VIEW 15. . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 4. ELECTRICAL BOX ASSEMBLY 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 3

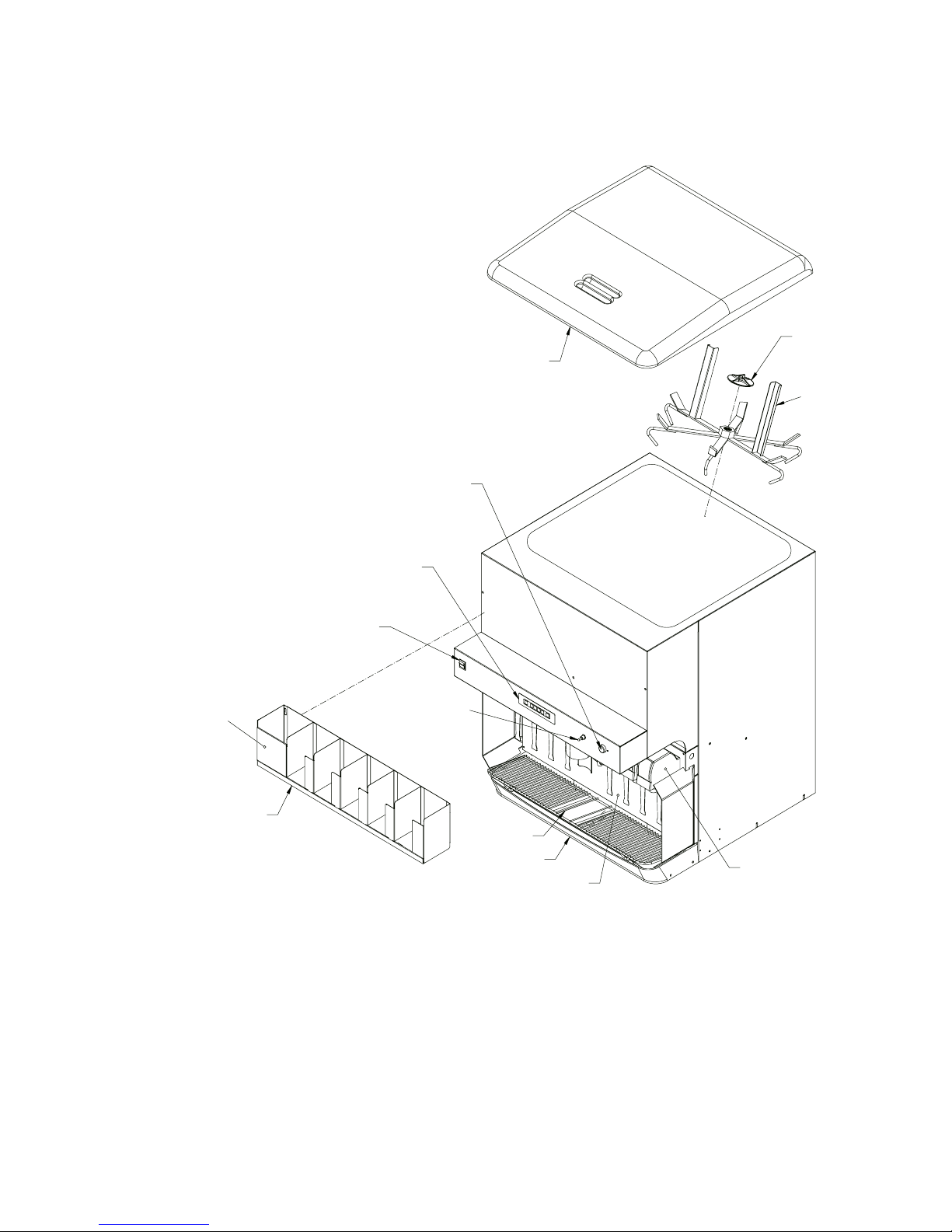

MANUAL ICE DISPENSE

RED PUSH BUTTON SWITCH

ICE PORTION

CONTROL MODULE

BEVERAGE FAUCET

ON/OFF SWITCH

RETAINER

ICE BIN COVER

ICE AGITATOR

REMOVABLE STRAW

HOLDER PANEL

LID/STRAW

HOLDER

MANUAL/AUTO ICE

TOGGLE SWITCH

CUP REST

DRIP TRAY

LOWER ACCESS

PANEL

FIGURE 1. PARTS IDENTIFICATION

BEVERAGE FAUCETS (8)

1

620919540

Page 4

THIS PAGE LEFT BLANK INTENTIONALLY

620919540

2

Page 5

START-UP AND OPERATING INSTRUCTIONS

Fill the hopper with ice and replace the lid. Allow 10 to 15 minutes for the cold plate to cool down. Repeat this

procedure whenever the dispenser has been standing overnight or other long periods without ice use. Start up the

beverage system and adjust faucets to the proper brix. Contact your local syrup distributor for complete

information on the beverage system.

To dispense ice, hold cup under ice chute and press the appropriate size button on the ice portion control located

above the ice chute. An extra ice portion may be obtained by pressing the increase key before pressing the

button.

For beverage dispensing, place a cup on the cup rest against the faucet lever of the desired flavor. Beverage will

be dispensed automatically filling the cup and shutting off. A delay feature is provided in the faucet controller to

“top-off” the drink after shut off.

CAUTION: Use caution to avoid spilling ice when filling dispenser. Clean up immediately

any spilled ice from filling or operating the unit. To prevent contamination of ice, the lid

must be installed at the unit at all times.

If the dispenser fails to dispense ice or beverage, see troubleshooting guide.

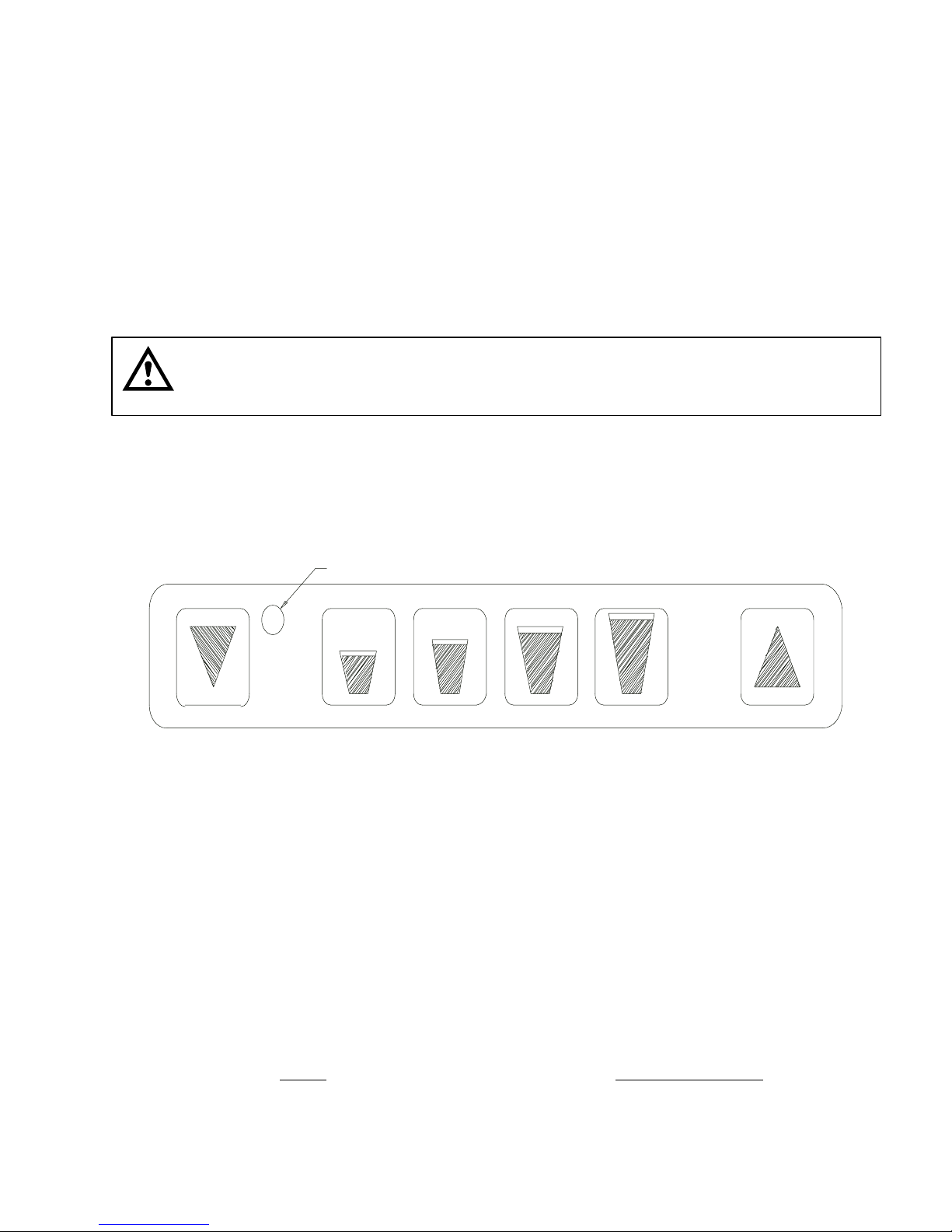

ICE PORTIONING SYSTEM OPERATION

INDICATOR LIGHT

DECREASE SMALL LARGEMEDIUM X-LARGE INCREASE

FIGURE 2. CUP SIZE LABEL

The ice portioning system consists of three main components:

1. Ice Portion Control

2. Ice Gate Mechanism

3. Solenoid Operated Air Valve

When a size button on the ice portion control is pressed, the control supplies a voltage to the air valve for a brief

period of time. The air cylinder attached to the ice gate will then open the ice gate for a short time allowing ice to

be dispensed from the ice chute.

The ice portion control has five modes to allow adjustment of the ice portions and for normal operation. They are

as follows: (Refer to Figure 2)

MODE

Normal operation Green

Cleaning mode Red/Amber flashing

Normal ice portion adjustment Amber

Extra ice portion adjustment Red

Agitation refill time adjustment Amber flashing

INDICATOR STATUS

3

620919540

Page 6

The control will return to Normal Operation Mode (green indicator) automatically if a button has not been operated

for a period of one minute whenever one of the three adjustment modes have been accessed.

NORMAL OPERATION

To dispense ice, hold a cup directly under the ice chute, then press the appropriate size button on the ice portion

control. To obtain a full cup of ice, press the increase button followed by the appropriate size button. The ice

portion control will not dispense ice and will display a flashing green indicator light if sufficient ice is not available

in the ice chute to dispense the selected size. The indicator light will return to solid green and ice dispensing will

resume after the ice chute has been filled.

The amount of ice dispensed for each size is changed in the Normal and Extra Ice Adjustment Modes. To access

the adjustment modes, press the decrease and increase button at the same time. The control will advance to the

next mode in the sequence as shown in the table on page 3 and the indicator light will change to identify which

mode is currently active.

CLEAN MODE

Access this mode to empty all the ice in the chute. To enter clean mode, press the decrease and increase buttons

at the same time. The indicator light will alternately display red and amber. To empty the ice chute, press any of

the size buttons. The ice gate will then open to allow the ice chute to empty. The ice gate will automatically close

after the ice has been emptied.

To return to normal operation, press the increase and decrease buttons at the same time; then press both buttons

three times in sequence. The indicator light will show amber, red, amber flashing, and finally green to indicate

normal operation.

NORMAL ICE PORTION ADJUSTMENT

From the Normal Operation Mode (green indicator), press both the decrease and increase buttons at the same

time twice. The amber indicator verifies that the normal portion adjustment mode has ben accessed.

To change the amount of ice dispensed, press and hold down the size button for the desired size to be changed.

While holding the size button, press the decrease or increase button to decrease/increase the ice portion size.

When the minimum ice portion adjustment has been reached, the indicator will flash at a slow rate; at the

maximum adjustment, the indicator will flash at a fast rate. After releasing the size button, the indicator light will

flash green for five seconds. During this time period a sample can be obtained to check the portion size by

pressing the size key. The indicator light will return to amber (normal portion adjustment mode) after the sample is

dispensed.

The indicator light will flash red after dispensing a sample, if an open circuit exists in the ice gate cylinder switch

wiring to the ice portion control or if an ice gate binding condition occurred during the sample. The indicator light

will display solid red briefly after a sample is dispensed if the ice gate cylinder switch was shorted.

To return to normal operation press the decrease and increase buttons at the same time, press twice.

EXTRA ICE PORTION ADJUSTMENT

The adjustment of Extra Ice Portion is accomplished in the same manner as ice portions, except the indicator light

displays red. To access this mode press both the decrease and increase buttons simultaneously three time from

the Normal Operation Mode (green indicator). The indicator will display red.

620919540

4

Page 7

AGITATION REFILL TIME ADJUSTMENT

To adjust the amount of ice chute refill agitation. begin by accessing the Extra Ice Portion Adjustment Mode (red

Indicator). Next, press and hold for the decrease and increase buttons for three seconds until the indicator flashes

amber. The indicator will flash up to four times, one flash corresponds to the minimum amount of refill agitation

and four flashes corresponds to the maximum amount of refill agitation. Change the amount of refill agitation by

pressing one of the four size buttons – the small button representing the minimum amount of refill agitation.

Increase the amount of refill agitation if the ice chute does not refill properly after dispensing ice.

To return to Normal Operation Mode, press the decrease and increase buttons at the same time.

MANUAL ICE DISPENSING OPERATION

A red pushbutton switch is provided on the upper front panel (see Figure 1) to manually dispense ice. This system

can be used for dispensing ice in portions other than cup-size or in the event of a malfunction with the ice portion

controller.

For manually dispensing ice, an auto/manual toggle switch is located adjacent to the ice portioning touch panel

(cup size selector) on the upper panel. The function of this switch is to bypass the gate solenoid valve (operated

by the portion controller) and to open the gate directly. Move the toggle switch to the “manual” position which

opens the gate immediately. Ice can now be dispensed by depressing and holding the red pushbutton switch for

the desired amount of ice. To return to the ice portioning mode of operation, move the toggle switch to the “auto”

position.

CAUTION: The gate closes immediately when the toggle switch is moved to the auto

position. Do not place fingers or foreign objects into the ice chute when operating the

toggle switch.

5

620919540

Page 8

THIS PAGE LEFT BLANK INTENTIONALLY

620919540

6

Page 9

MAINTENANCE

The following dispenser maintenance should be performed at the intervals indicated.

DAILY (or as required)

Remove foreign material from vending area drip tray to prevent drain blockage.

WEEKLY (or as required)

Clean vending area. Check for proper water drainage from the vending area drip tray.

MONTHLY

Clean and sanitize the hopper interior and beverage system if applicable (see CLEANING INSTRUCTIONS).

CLEANING INSTRUCTIONS

WARNING: Disconnect Power Before Cleaning! Do not use metal scrapers, sharp objects or

abrasives on the ice storage hopper, top cover, ice chute, and air cylinder access cover as

damage may result. Do not use solvents or other cleaning agents, as they may attack the

plastic material.

Soap solution - use a mixture of mild detergent and warm 100 degrees F potable water.

Sanitizing solution

solution to this ratio will create a solution of 200 PPM.

- use 1/2 ounce of household bleach in 1 gallon of potable water. Preparing the sanitizing

DISPENSER

1. CLEANING EXTERIOR SURFACES

Important: Perform the following daily.

A. Remove the cup rest from drip tray.

B. Wash the drip tray with soap solution. Rinse with clean water and allow solution to run down the drain.

C. Wash cup rest with soap solution and rinse in clean water. Install the cup rest into the drip tray.

D. Clean all exterior surfaces with soap solution and rinse in clean water.

2. CLEANING INTERIOR SURFACES

CAUTION: When pouring liquid into the hopper, do not exceed the rate of 1/2 gallon per

minute.

CAUTION: It will be necessary to have electrical power on to the unit in order to remove any

remaining ice from the storage hopper and ice chute. After the ice has been removed,

disconnect electrical power to the unit before proceeding with cleaning and sanitizing.

7

620919540

Page 10

A. Dispense all ice from the hopper and ice chute by switching the auto/manual toggle switch to the

“manual” position. The gate slide will then be held open to empty the ice chute. Depress the red

manual pushbutton switch to dispense all remaining ice from the hopper. Discard the ice. Return the

toggle switch to the “auto” position to close the gate slide.

B. IMPORTANT: Disconnect electrical power to the unit for the remainder of the cleaning and

sanitizing procedure.

C. Cold plate inspection before cleaning.

1. Remove splash panel.

2. Remove the plastic cold plate access cover to expose the cold plate.

3. Remove any remaining ice from the cold plate surface and discard.

4. Locate and remove any debris from the cold plate, drain trough and make certain that the drain

holes are not clogged.

5. Reinstall the cold platecover.

6. Reinstall the splash panel.

D. Remove the plastic lid, agitator retainer (turn counterclockwise to unscrew), and agitator from the ice

storage hopper.

E. Using a long handle nylon bristle brush, clean the interior of the hopper and cold plate with the soap

solution. The cold plate can be reached by going through the ice opening on the hopper bottom. Make

certain to reach the entire surface of the cold plate in cluding the corners. Thoroughly rinse the hopper

interior and cold plate with clean potable water.

F. Clean the agitator, agitator retainer, and lid with the soap solution. Thoroughly rinse with clean potable

water. Reassemble the agitator and retainer in the hopper. Make sure that the retainer is secured

tightly (turn clockwise to screw in place).

G. Clean and sanitize the ice chute as described below:

1. Remove the ice chute cover (snap-fit) by spreading the sides apart slightly to disengage the tabs in

the cover from the ice chute and sliding down to remove the cover. The ice chute (rear half) and

the ice gate are now exposed for cleaning.

2. Remove the black plastic access cover for the air cylinder from the splash panel (2 thumbscrews).

3. Wash the ice chute cover, ice chute (rear half), ice gate, and air cylinder access cover with the

soap solution. Thoroughly rinse with clean potable water.

4. Using a mechanical spray bottle filled with sanitizing solution, spray these parts with sanitizer.

Allow to air dry.

5. Reassemble the ice chute cover and air cylinder access cover.

H. Using the mechanical spray bottle filled with sanitizing solution, spray the entire hopper interior, agitator

assembly, and hopper lid. Allow to air dry. Replace the lid on the unit.

620919540

8

Page 11

BEVERAGE SYSTEM

CLEANING

Soap solution - Use a mixture of mild detergent and warm 100 degrees F potable water.

Sanitizing solution

solution to this ratio will provide the required solution of 200 PPM.

Cleaning tank

potable water.

- Use 1/2 ounce of household bleach in 1 gallon of potable water. Preparing the sanitizing

- Fill clean, empty tank with a mixture of mild detergent and five (5) gallons of warm 120 degrees F

CLEANING DISPENSING VALVES

Refer to addendum supplied with the unit that is applicable to the manufacturer of the valves installed on the unit.

SANITIZING

IMPORTANT: Only trained and qualified persons should perform these cleaning and sanitizing

procedures.

Sanitize tank systems, Post-Mix and Pre-Mix

1. Remove all the quick disconnects from all the tanks. Fill a suitable pail or bucket with soap solution.

2. Submerge all disconnects (gas and liquid) in the soap solution and then clean them using a nylon bristle

brush. (Do not use a wire brush). Rinse with clean water.

3. Prepare sanitizing solution and using a mechanical spray bottle, spray the disconnects. Allow to air dry.

4. Using a clean, empty tank, prepare five (5) gallons of the sanitizing solution. Rinse the tank disconnects with

approximately 9 oz. of the

5. Prepare cleaning tank by filling clean five (5) gallon tank with a mixture of mild detergent and 120 degrees F

potable water.

6. Connect a gas disconnect to the tank and then apply one of the product tubes to the cleaning tank. Operate

the appropriate valve until liquid dispensed is free of any syrup.

7. Disconnect cleaning tank and hook up sanitizing tank to syrup line and CO

8. Energize beverage faucet until chlorine sanitizing solution is dispensed through the faucet. Flush at least two

(2) cups of liquid to insure that the sanitizing solution has filled the entire length of the syrup tubing.

9. Allow sanitizer to remain in lines for fifteen (15) minutes.

10. Repeat the step above, applying a different product tube each time until all tubes are filled with the sanitizing

solution.

11. For post-mix valves, remove the nozzle and syrup diffuser and clean them in a mild soap solution. Rinse

with clean water, then reinstall the nozzle and syrup diffuser on the valve.

12. For pre-mix valves, disconnect all product tubes from the tank of sanitizing solution and then open the valves

to allow the pressure to be relieved. Remove the valves from the dispenser, disassemble and wash

thoroughly in a mild soap solution.

sanitizing solution. Close the tank.

system.

2

9

620919540

Page 12

13. Rinse the parts in clean water, reassemble the valve and reconnect it to the dispenser.

14. Discard the tank of sanitizing solution and reconnect the product (syrup or pre-mix) tanks. Operate the

valves until all sanitizer has been flushed from the system and only product (syrup or pre-mix) is flowing.

Sanitize syrup lines, B-I-B Systems

1. Remove all the quick disconnects from all the B-I-B containers.

2. Fill a suitable pail or bucket with soap solution.

3. Submerge all disconnects (gas and liquid) in the soap solution and then clean them using a nylon bristle

brush. (Do not use a wire brush). Rinse with clean water.

4. Using a plastic pail, prepare approximately five (5) gallons of sanitizing solution.

5. Rinse the B-I-B disconnects in the sanitizing solution.

6. Sanitizing fittings must be attached to each B-I-B disconnect. If these fittings are not available, the fittings

from empty B-I-B bags can be cut from the bags and used. These fittings open the disconnect so the

sanitizing solution can be drawn through the disconnect.

7. Place all the B-I-B disconnects into the pail of sanitizing solution. Operate all the valves until the sanitizing

solution is flowing from the valve. Allow sanitizer to remain in lines for fifteen (15) minutes.

8. Remove the nozzle and syrup diffuser from each valve and clean them in a soap solution. Rinse with clean

water and reassemble the nozzle and syrup diffuser to the valve.

9. Remove the sanitizing fittings from the B-I-B disconnects and connect the disconnects to the appropriate

B-I-B container. Operate the valves until all sanitizer has been flushed from the system and syrup is flowing

freely.

620919540

10

Page 13

TROUBLESHOOTING

IMPORTANT: Only qualified personnel should service internal components or electrical wiring.

WARNING: If repairs are to be made to the beverage system, remove quick disconnects

from the applicable product tank, then relieve the system pressure before proceeding. If

repairs are to be made to the CO

system, stop dispensing, shut off the CO

2

relieve the system pressure before proceeding. If repairs are to be made to the ice dispensing

system, make sure electrical power is disconnected from the unit.

Trouble Probable Cause Remedy

NOTE: should your unit fail to operate properly, check that there is power to the unit and that the

hopper contains ice. If the unit does not dispense, check the following chart under the

appropriate symptoms(s) to aid in locating the defect.

supply, then

2

BLOWN FUSE OR CIRCUIT

BREAKER.

SLUSHY ICE. WATER IN

HOPPER

BEVERAGES DO NOT

DISPENSE.

BEVERAGES TOO SWEET.

A. Short circuit in wiring (115V

A. Replace defective wiring.

circuit).

B. Defective agitator motor. B. Replace agitator motor.

A. Blocked drain. A. Open–up/flush out drain.

B. Unit not level. B. Level unit.

C. Poor ice quality due to water

quality or ice maker problems.

C. Install water filter system. For

Icemaker problems, consult

icemaker manual.

D. Improper use of flaked ice. D. Replaced flaked ice with “cube

style ice (see page 2, Unit

Description).

A. No 24 volt power to faucets. A. Check that beverage switch is

“on”. Check 24V transformers.

B. No CO2 pressure. B. Check CO

regulator. Check CO

2

tank pressure.

A. Carbonator not working. A. Check carbonator.

B. No CO2 pressure in

carbonator.

B. Check CO2 regulator. Check CO

tank pressure.

C. Faucet brix requires adjusting. C. Brix Faucet.

2

2

BEVERAGES NOT SWEET

ENOUGH.

BEVERAGES NOT COLD

(UNITS WITH BUILD-IN COLD

PLATE).

NOTE: Contact your local syrup or beverage equipment distributor for additional information and

trouble shooting of beverage system.

A. Empty syrup tank. A. Refill syrup tank.

B. Faucet Brix requires adjusting. B. Brix Faucet.

A. Unit standing with no ice in

A. Refill hopper with ice.

hopper - no ice in cold plate

cabinet.

11

620919540

Page 14

Trouble RemedyProbable Cause

NO ICE DISPENSED FROM

ICE PORTION CONTROLLER

A. Insufficient ice supply in ice

A. Replenish ice supply as required.

bin.

B. Ice in ice bin bridged (stuck

B. Gently tap on ice to break it loose.

together).

C. No electrical power to

dispenser.

D. Insufficient or no CO

supply

2

C. Plug in dispenser power cord, or

check fuse or circuit breaker.

D. Restore CO2 supply to dispenser.

to dispenser.

E. Ice chute cover not properly

installed.

F. Defective ice chute interlock

E. Make sure that cover is “snapped”

into place.

F. Replace interlock switch.

switch.

G. Defective interlock relay. G. Replace relay.

H. Defective 24V transformer. H. Replace transformer.

I. Defective portion controller.

J. Defective ice gate cylinder.

K. Defective ice gate solenoid

I. Replace controller.

J. Replace cylinder.

K. Replace solenoid valve.

valve.

NO ICE DISPENSED FROM

MANUAL ICE DISPENSE

PUSHBUTTON SWITCH

L. Agitation relay wiring incorrect.

M. Defective agitation relay.

N. Defective agitator motor start

capacitor or start relay.

A. Manual/Auto toggle switch in

“Auto” position.

B. Insufficient or no CO2 supply

to dispenser.

C. Defective 24VAC transformer.

D. Defective manual override

solenoid valve.

E. Defective manual ice dispense

pushbutton switch.

F. Defective agitator motor or

start capacitor or start relay.

L. Red wire should be connected to

“+” terminal (#3) of relay coil.

M. Replace relay.

N. Replace defective component.

A. Move toggle switch to “Manual”

position.

B. Restore CO2 supply to dispenser.

C. Replace Transformer

D. Replace valve.

E. Replace switch.

F. Replace defective component.

G. Defective ice gate cylinder. G. Replace cylinder

620919540

12

Page 15

Trouble RemedyProbable Cause

ICE DISPENSING DURING

AUTOMATIC AGITATION

A. Manual/Auto toggle switch in

“manual” position.

B. Defective ice gate cylinder.

C. Defective ice gate solenoid

valve.

D. Defective portion controller.

A. Move toggle switch to “auto”

position.

B. Replace cylinder.

C. Replace valve.

D. Replace controller.

13

620919540

Page 16

THIS PAGE LEFT BLANK INTENTIONALLY

620919540

14

Page 17

PARTS LIST

90

56

94

40

77

92

79

43

46

50

67

49

62

1

53

26

11

3

40

72

15

40

37

70

9

51

72

42

45

2

52

77

57

75

61

59

88

76

71

88

148688

25

44

48

16

22

60

76

21

81

36

77

74

32

66

41

5

72

88

72

54

20

29

88

7

82

83

4

78

38

72

95

34

17

23

88

30

84

74

24

10

88

34

20

28

86

8

13

31

68

100

72

88

55

69

63

19

101

64

64

47

18

12

72

58

65

6

63

93

88

72

102

73

80

39

33

87

27

FIGURE 3. CABINET SECTION EXPLODED VIEW

15

620919540

Page 18

Item

No. Part No. Name

1 620031818 Ice Gate

2 620706001 Air Cylinder

3 620701208 Hex Nut, 5/8-18, S.S.

4 29541R Plate, Motor Mounting

5 29694 Agitator Ass’y

6 29555 Cover, Rear Wrapper

7 629086701 Splash Panel Ass’y (Insulated)

8 620028702 Extension Ass’y, Drip T ray

9 28708 Lid and Straw Holder

10 29547 Wrapper

11 31934 On/Off Switch (Beverage Faucets)

12 620407447 Panel/Cold Plate/Faucet Ass’y

13 53011 Elbow, Cold Plate Drain

14 31960 Toggle Switch, Auto/Manual

15 32839 Portion Control, Ice

16 50767 Bushing

17 10145 Pin, Drip Tray Mounting

18 15090 Baffle

19 620041018 Baffle

20 52084 Splash Guard

21 30794 Agitator Motor Heater 120 Volt

22 30894 Switch, Red, Pushbutton

23 620031807 Upper Support, Electrical Box

24 620031812 Mounting Bracket, E l e c t r i c a l B o x

25 33387 Agitator Motor 120 Volt

26 620031814 Box Control, Portion Ext.

27 53268 Insulated Cold Plate Cover

28 620041016 Bracket, Ice Chute Stabilizer

29 620031804 Cover, Electrical Box

30 620307702 Electrical Box Ass’y

31 620041017 Stabilizer Wire, Ice Chute

32 29542 Bracket, Motor Mounting

33 53255 Cover, Access (Cold Plate)

34 71010 Washer, Captivating No. 8

35 620041020 Mounting Bracket, Portion Controller

36 620308301 Connector , Power Inlet

37 620505903 Gate Gasket

38 620046001 Cover Access, Air Cylinder, Black

39 620019701 Hinge Gusset

40 620702505 Bushing, Air Cylinder

41 70188 Thumbscrew, No. 8-32

42 70122 Screw, No. 4 By 3/8-In. Long

43 620705901 Screw, No. 4 Type B By 3/8-In. Long

44 53199 Shaft Seal, Agitator Motor

45 32953 Ice Chute Interlock Switch

46 31981 Actuator Interlock Switch

47 51908 Hole Plug

48 71025 Strap, 3/8-16 Threaded (Agitator Motor

49 620505901 Ice Chute

50 620505902 Cover, Ice Chute

51 70075 Nut, 6-32, Keps

52 15132 Bracket, Agitator Motor Strap

53 620701202 Hex Nut, 1/4-28

54 53211 Drip Tray , Insulated, Gray

55 53018 Lid, Dispenser, Gray

56 620506008 Hopper Ass’y, Insulated

57 620506006 Fitting, 90 Elbow, 1/8NPT By 1/4 Tube

Mounting)

620919540

16

Page 19

Item

No. Part No. Name

58 52967 Plug, Plastic (.312 Hole)

59 620028283 Retainer , Corner Cushion

60 620041402 Merchandiser, Stainless Steel

61 620506018 Cushion, Corner

62 70016 Hex Nut, No. 10-32, S.S.

63 50459 Bushing, 1.00 Dia.

64 50475 Bushing, .875 Dia.

65 70242 Screw, No. 10-32 By 3/8-In. Long

66 70015 Hex Nut, No. 10-32, Keps

67 70056 Flatwasher, .219 I.D. x .500 O.D.

68 50335 Armaflex Tubing, 1 3/8 O.D. By

69 50822 Nylon Mounting Tie

70 620513506 Drip Shield Cylinder

71 50130 Armaflex Tubing, 5/8 I.D. By 3/8 Wall

72 70171 Screw, No. 8-32 By 3/8-In. Long

73 70178 Screw, No. 8-32 By 1/2-In. Long

74 70204 Sheet Metal Screw, No. 8 By 1/2-In.

75 50705 Nylon Mounting Tie

76 71033 Screw, Hex Hd, 3/8-16 By 3/4-In. Long

77 70068 Washer, 3/8 I.D.

*78 91997 Label, Plumbing Manifold, RT to LT

79 71061 Washer, .480 I.D. x 1.1 O.D. x

80 70320 Pop Rivet, 1/8 Dia. (.063-.125-In. Grip

81 70341 Spring, Agitator Motor Heater

82 71006 Screw, No. 8-32 By 2 1/8-In. Long

83 70478R Clip, Push-on

84 70555 Screw, No. 8-32 By 2 5/16-In. Long

*85 70798 Tool, Beverage Valve, LEV or FFV

86 620701601 Sheet Metal Screw, No. 10 By 1/2-In.

87 70456 Pop Rivet, 3/16 Dia.

88 70959 Hex Nutsert, No. 8-32

89 620516201 Air Cylinder Splash Shield (Not Shown)

90 15087 Retainer, Agitator

91 620516202 Back Air Cylinder Splash Shield (Not

92 71059 Wing Nut, 3/8-16

93 92334 Label Inlet, 8-FL., LT to R T

92345 Label Inlet, 8-FL., RT to L T

94 71028 Shoulder Screw, 1/4-20

95 71094 Cup Rest

*96 51288 Adapter, 1-In. Barb By 3/4 MPT (For

*97 50952 Adapter, 3/4 Soc By 3/4 FPT (For Drip

*98 70750 Hose Clamp (For Drip Tray Drain)

*99 620702201 Brush, Cold Plate Cleaning

100 92050 Decal, Cabinet, L.S.

101 92051 Decal, Cabinet, Back

102 92050 Decal, Cabinet, R.S.

x .049 Thk.

3/8-Wall

Long

3+1+1+3

.063 Thk

Range)

Long

Shown)

Drip Tray Drain)

Tray Drain)

NOTES: *NOT SHOWN

17

620919540

Page 20

21

25

10

16

26

18

11

14

13

21

10

15

17

20

21

4

7

8

27

5

25

24

21

12

9

19

22

FIGURE 4. ELECTRICAL BOX ASSEMBLY

Item

No. Part No. Name

1 620031802 Electrical Box

2 32714 Diode Ass’y, T ransient Voltage

3 449999999 Transformer, 24 V olt

4 31107 Terminal Board

5 33162 Start Relay, Agitator Motor

6 620307501 Agitation Relay

7 620031810 Strap Capacitor

8 33160R Start Capacitor, Agitator Motor

9 620701206 Mounting Nut, Filter/Regulator

10 620031811 Mounting Bracket, Solenoid Valve

11 620701204 Air Filter/Regulator Ass’y

12 620702504 Tee, 1/8-MPT x 1/8-FPT x 1/8-FPT

13 620702501 Tee, 1/8-FPT x 1/8-FPT x 1/8-FPT

14 620702503 Gage Pressure

15 620404301 Nipple, 1/8-NPT By 1 1/2-In. Long

16 620404303 Manual Override Solenoid Valve

17 620702102 Pneumatic Gate Solenoid Valve

18 620701207 Nipple, Close 1/8-NPT Hex

19 70663 Fitting, 1/4-Barb x 1/8-MPT

20 620506006 Elbow, 1/8-MPT x 1/4-Tube

21 620512101 Tube, .250 O.D. x .0425 Wall

22 50299 Tubing, Non-Coke, .265 I.D.

*23 30995 Power Cord Ass’y

24 70661 Fitting, 1/8-FPT x 1/4-MPT

25 620404302 Elbow, 1/4-MPT x 1/4-Tube

26 620702506 Nipple/Orifice (.052) 1/8-NPT

27 31206 Interlock Relay

3

6

3

1

NOTES: *NOT SHOWN

620919540

18

Page 21

WARRANTY

IMI Cornelius Inc. warrants that all equipment and parts are free from defects in material and workmanship

under normal use and service. For a copy of the warranty applicable to your Cornelius, Remcor or Wilshire

product, in your country, please write, fax or telephone the IMI Cornelius office nearest you. Please provide the

equipment model number, serial number and the date of purchase.

IMI Cornelius Offices

AUSTRALIA D P.O. 210, D RIVERWOOD, D NSW 2210, AUSTRALIA D (61) 2 533 3122 D FAX (61) 2 534 2166

D AM LANGEN FELDE 32 D A-1222 D VIENNA, AUSTRIA D (43) 1 233 520 D FAX (43) 1-2335-2930

AUSTRIA

D BOSKAPELLEI 122 D B-2930 BRAASCHAAT, BELGIUM D (32) 3 664 0552 D FAX (32) 3 665 2307

BELGIUM

D RUA ITAOCARA 97 D TOMAS COELHO D RIO DE JANEIRO, BRAZIL D (55) 21 591 7150 D FAX (55) 21 593 1829

BRAZIL

ENGLAND

D TYTHING ROAD ALCESTER D WARWICKSHIRE, B49 6 EU, ENGLAND D (44) 789 763 101 D FAX (44) 789 763 644

D 71 ROUTE DE ST. DENIS D F-95170 DEUIL LA BARRE D PARIS, FRANCE D (33) 1 34 28 6200 D FAX (33) 1 34 28 6201

FRANCE

GERMANY

GREECE

HONG

ITALY

NEW

SINGAPORE

SPAIN

USA

D CARL LEVERKUS STRASSE 15 D D-4018 LANGENFELD, GERMANY D (49) 2173 7930 D FAX (49) 2173 77 438

D 488 MESSOGION AVENUE D AGIA PARASKEVI D 153 42 D ATHENS, GREECE D (30) 1 600 1073 D FAX (30) 1 601 2491

KONG D 1104 TAIKOTSUI CENTRE D 11-15 KOK CHEUNG ST D TAIKOKTSUE, HONG KONG D (852) 789 9882 D FAX (852) 391 6222

D VIA PELLIZZARI 11 D 1-20059 D VIMARCATE, ITALY D (39) 39 608 0817 D FAX (39) 39 608 0814

ZEALAND D 20 LANSFORD CRES. D P.O. BOX 19-044 AVONDALE D AUCKLAND 7, NEW ZEALAND D (64) 9 8200 357 D FAX (64) 9 8200 361

D 16 TUAS STREET D SINGAPORE 2263 D (65) 862 5542 D FAX (65) 862 5604

D POLIGONO INDUSTRAIL D RIERA DEL FONOLLAR D E-08830 SANT BOI DE LLOBREGAT D BARCELONA, SPAIN D (34) 3 640 2839 D FAX (34) 3 654 3379

D ONE CORNELIUS PLACE D ANOKA, MI NNESOTA D (612) 421-6120 D FAX (612) 422-3255

LD004

4/21/98

62091954019

Page 22

IMI CORNELIUS INC.

Corporate Headquarters:

Anoka, Minnesota 55303-6234

One Cornelius Place

(763) 421-6120

(800) 238-3600

Loading...

Loading...