Page 1

®

BOTTLE COOLERS

COR6519UBCSD

Service Manual

Release Date: May, 2004

Publication Number: 630460278SER

Revision Date: NA

Revision: A

Visit the IMI Cornelius web site at www.cornelius.com

for all your Literature needs.

Page 2

SERVICE MANUAL

The products, technical information, and instructions contained in this manual are subject

to change without notice. These instructions are not intended to cover all details or variations of the equipment, nor to provide for every possible contingency in the installation,

operation or maintenance of this equipment. This manual assumes that the person(s)

working on the equipment have been trained and are skilled in working with electrical,

plumbing, pneumatic, and mechanical equipment. It is assumed that appropriate safety

precautions are taken and that all local safety and construction requirements are being

met, in addition to the information contained in this manual.

To inquire about current revisions of this and other documentation or for assistance with

any Cornelius product contact:

www.cornelius.com

800-238-3600

Trademarks and copyrights:

Aurora, Cornelius, Decade, Hydro Boost, Sitco, Spirit, UF-1, Vanguard, Venture, Olympus,

and Vista are registered trademarks of IMI Cornelius Inc.

Optifill trademark is pending.

This document contains proprietary information and it may not be

reproduced in any way without permission from Cornelius.

Printed in U.S.A.

Copyright © 2004, All Rights Reserved, IMI Cornelius, Inc.

Page 3

COR6519UBCSD Service Manual

TABLE OF CONTENTS

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

English . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Features of the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Refrigeration System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Description of its components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

The Refrigeration Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Electrical Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Cleaning and Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Condensate Disposal System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Possible causes and solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Español . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Caracteristicas del equipo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Sistema de Refrigeracion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Explicación de los componentes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

El Ciclo de Refrigeracion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Diagrama eléctrico . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Limpieza y Mantenimiento Preventivo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Sistema de Recolección de Condensado . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Principales Problemas del Refrigerador . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Posibles causas y soluciones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

© 2004, IMI Cornelius Inc. - i - Publication Number: 630460278SER

Page 4

COR6519UBCSD Service Manual

Publication Number: 630460278SER - ii - © 2004, IMI Cornelius Inc.

Page 5

FEATURES OF THE UNIT

Sturdy, stainless steel top

Strong body with thick walls,

injected with CFC-free

polyurethane foam

Exterior cabinet and lining

made of galvanized, prepainted steel, with baked

polyester paint

Reinforced, heavy-duty,

adjustable dividers

Interior lining made of

acrylic-coated galvanized

steel for extra corrosion

resistance

Heavy-duty R-134a

condensing unit with easy

access for maintenance

COR6519UBCSD Service Manual

ENGLISH

Rubber pull handle for easy

sliding of lids

Forced-air evaporator for

quick temperature pulldown

Reinforced, 16 gauge

galvanized steel base

Forced-air condenser made

of copper and aluminum,

resistant to rust and saline

environments

FIGURE 1

R

EFRIGERATION SYSTEM

Description of its components

Compressor:

The compressor is a factory-sealed unit located underneath (outside) the cooling cabinet. This pump is

activated by a motor which draws low-pressure vapor (refrigerant) from the evaporator. It then

compresses the gas and forces it into the condenser at a high pressure.

Starter relay:

The starter relay is attached on one side of the compressor box. The compressor motor has two

windings: one for starting and another for running. In order to provide for necessary additional torque

when the motor is first ignited, the starter relay connects the additional start-up windings. After the motor

reaches its correct operating speed, the relay opens the ignition windings and the motor carries on with

the operation windings.

Thermal protector:

This protector is a thermo-sensible device attached to one side of the compressor’s box. In any given

situation, if the compressor overheats or the voltage source varies drastically, the thermal protector

opens, turning off the compressor. After the compressor cools down to a normal and safe working

temperature, the thermal protector turns on the compressor.

Condenser:

The condenser is located underneath (outside) the cooling cabinet in front of the compressor. It receives

hot, high-pressure refrigerant gas from the compressor and cools it down until it returns to liquid state.

© 2004, IMI Cornelius Inc. - 1 - Publication Number: 630460278SER

Page 6

COR6519UBCSD Service Manual

Condenser fan motor:

The condenser fan motor is located underneath the cooling cabinet. It is a ventilation device which forces

the ambient air to flow over the condenser in order to cool down the refrigerant flowing inside it. The fan

motor works only if the compressor is on.

Evaporator:

The evaporator is located inside the cooling cabinet. As the gas flows at a low pressure through the

evaporator, it absorbs heat through the copper coil from inside the cabinet.

Evaporator fan motor:

This device provides the required circulation of air through the cooling cabinet as well as over the surface

of the evaporator’s serpentine thermal exchange area. This fan motor runs continuously.

The evaporator and condenser serpentines have aluminum fins that help increase the surfaces for the

thermal exchange in an efficient way.

Capillary tube:

It consists of several feet of tubing having a small inside diameter. It is a device used to control the

amount of refrigerant that flows into the evaporator.

Drier:

The drier is located in between the condenser and the evaporator. It traps and removes moisture in the

refrigeration system while allowing oil and refrigerant to flow freely.

Accumulator:

The accumulator is located in between the evaporator and the compressor. It is a storage tank which

receives refrigerant liquid from the evaporator and prevents it from flowing into the compressor.

Temperature control:

The adjustable temperature control is responsible for detecting temperature changes inside the cooling

cabinet. It also starts the compressor motor whenever the cabinet rises above the desired temperature.

The temperature control consists of a switch which is mechanically activated by a diaphragm. This

diaphragm is connected to a thermo-sensible bulb (located inside the cabinet) through a small diameter

tube. All three components (the diaphragm, the thermo-sensible bulb, and the small diameter tube) are

filled with refrigerant gas which reacts to temperature changes.

When the cabinet temperature rises, the refrigerant in the bulb heats up and expands, expanding the

diaphragm. The diaphragm’s expanding closes the temperature control’s interrupting device and then

starts the compressor and condenser motors.

The drop in temperature inside the cooling compartment is caused by the refrigerant’s continuous

circulation through the system. When the temperature drops, the refrigerant inside the temperature

control’s bulb contracts, allowing the diaphragm to open the interrupting device, which consequently

shuts down the compressor and condenser motors.

Cooling cabinet:

This is the area where the goods are stored. It has been designed to allow for constant cold air circulation

to flow through the goods.

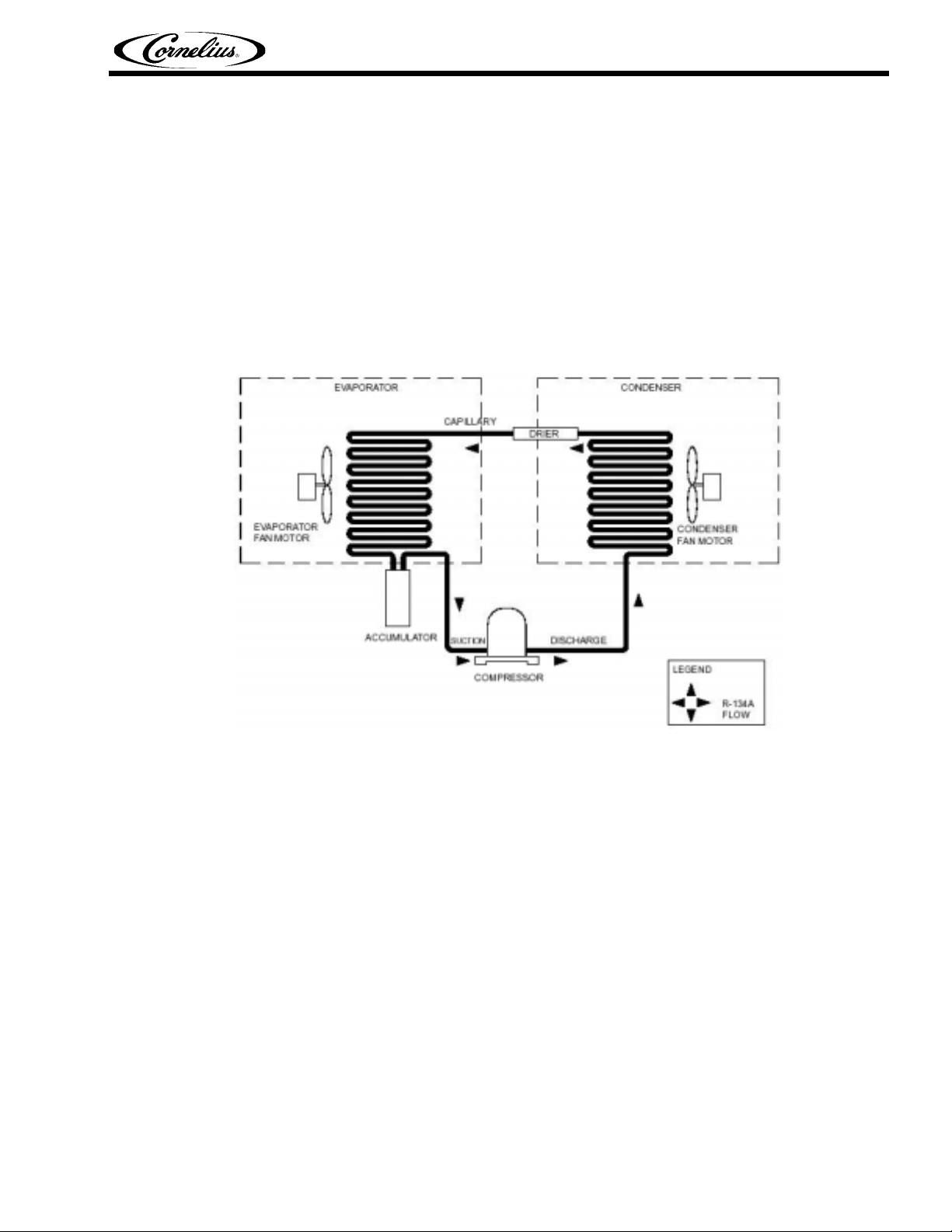

THE REFRIGERATION CYCLE

1. Depending on the increase in temperature inside the cooling compartment, the refrigerant gas

inside the temperature control's bulb heats up and expands, expanding the diaphragm. The

diaphragm's expansion closes the temperature control's interrupting device.

2. The temperature control's interrupting device turns on the compressor and condenser motors.

3. The compressor recirculates the refrigerant throughout the system by drawing the refrigerant gas

as low vapor pressure from the evaporator. Then it compresses the refrigerant and forces it into the

condenser.

Publication Number: 630460278SER - 2 - © 2004, IMI Cornelius Inc.

Page 7

COR6519UBCSD Service Manual

4. The condenser, with the help of its fan motor, removes the refrigerant's heat as it flows through the

condenser. The heat is then released to the outside environment. Consequently, the decrease in

temperature will change the refrigerant from a gaseous to a liquid state.

5. The capillary tube regulates the amount of refrigerant that is discharged into the evaporator.

6. The evaporator's serpentine allows the refrigerant to absorb and remove heat from the cooling

compartment.

7. The drop in temperature inside the cooling compartment is caused by the refrigerant's continuous

circulation through the system. This gas continuously absorbs the heat that exists inside the cooling

compartment and expels it to the outside environment. When the temperature drops, the refrigerant

inside the temperature control's bulb contracts, allowing the diaphragm to open the interrupting

device, which consequently shuts down the compressor and condenser motors.

FIGURE 2

© 2004, IMI Cornelius Inc. - 3 - Publication Number: 630460278SER

Page 8

COR6519UBCSD Service Manual

ELECTRICAL WIRING

FIGURE 3

Publication Number: 630460278SER - 4 - © 2004, IMI Cornelius Inc.

Page 9

CLEANING AND PREVENTIVE MAINTENANCE

Proper maintenance of your refrigerator is most important for efficient operation and economical

performance.

1. Disconnect the power source before cleaning, remove all products, and place them in another

cooler.

2. Clean the condenser at least once a month with a vacuum cleaner or brush. If the condenser coil

has accumulated dirt and grease (possible in heavy traffic areas or kitchen), use a strong cleaning

solution. If you find any oil in the condensing unit compartment, call a qualified service person

immediately.

COR6519UBCSD Service Manual

3. Keep the floor area around the fixture clean and orderly.

4. Check the door operation and door seal. Doors much close by themselves and seal on all sides.

5. Empty the drain pan located underneath the condensing unit at the rear and clean it as required.

Check it regularly for excessive water accumulation.

6. Replace any malfunctioning parts as soon as possible. Ask your dealer or service agency to order

the parts required.

7. It is most important that the interior of the fixture be cleaned on a periodic basis. Remove the

product load and all shelving.

8. Use only mild soap or detergent to wash the interior and exterior. Rinse with warm, clean water and

dry with a soft absorbent cloth.

CONDENSATE DISPOSAL SYSTEM

Refrigerators come equipped with an interior bottom floor drain that exits the cabinet at the motor

compartment side.

Beverage Coolers with Forced Air refrigeration system have a drain that collects the condensate from the

evaporator inside the baffle to a non-electric evaporating pan located in the bottom of the cabinet next to

the condensing unit. No additional plumbing installation is required. This pan should be checked

periodically for excessive accumulation of water.

An electric evaporator pan is available as an optional accessory. For additional information, please

contact our distributors.

FIGURE 4

© 2004, IMI Cornelius Inc. - 5 - Publication Number: 630460278SER

Page 10

COR6519UBCSD Service Manual

TROUBLESHOOTING

Possible causes and solutions

PROBLEM POSSIBLE CAUSE SOLUTION

COMPRESSOR WILL NOT

START

No voltage in the electrical

socket.

The electrical conductor or

wires may be cut.

Defective electrical

components such as:

thermostat, relay, thermal

protector, etc.

Thermostat in “off” position. Turn the thermostat’s knob to

Compressor motor has a

winding open or shorted.

Dirty condenser; lack of air

flow.

Low voltage. Use a voltage regulator if the

Compressor is stuck. Change the compressor.

Use a voltmeter to check the

voltage.

Use an ohmmeter to check for

continuity.

Replace defective components.

its maximum position and wait

to see if the compressor starts.

Measure the ohmic resistance

of the main and auxiliary

windings using an ohmmeter.

Compare them with the correct

values.

Clean condenser and allow for

air circulation.

voltage is lower than 103 volts.

THE TEMPERATURE IS TOO

COLD

THE TEMPERATURE IS NOT

COLD ENOUGH

Thermostat knob is set at a

very cold position.

Thermostat does not

disconnect the condensing unit.

Thermostat capillary bulb is

loose or installed improperly.

Thermostat knob is set at a

very warm position.

Condenser is dirty; lack of air

flow.

The refrigerator has been

placed at an inadequate

location.

Set the thermostat knob to a

warmer position and check if

the compressor stops

according to the thermostat’s

operating range.

Check the insulation of the

thermostat. If the problem

persists, change the

thermostat.

Correctly fasten the thermostat

capillary bulb.

Set the thermostat knob to a

colder position.

Clean the condenser and allow

for air circulation.

The unit must not be near

stoves, walls that are exposed

to the sun, or places that lack

sufficient air flow.

Publication Number: 630460278SER - 6 - © 2004, IMI Cornelius Inc.

Page 11

COR6519UBCSD Service Manual

PROBLEM POSSIBLE CAUSE SOLUTION

THE TEMPERATURE IS NOT

COLD ENOUGH

The refrigerator has been used

improperly.

The refrigerator has been

overcharged with the

refrigerant gas.

The refrigerant gas is leaking. Find the location where the gas

The evaporator and/or

condenser fans aren’t working.

Low voltage. Use a voltage regulator if the

ELECTRICAL SHOCKS Wires or electrical components

are in direct contact with

metallic parts.

The shelves must never be

covered with any type of plastic

or other material that will block

the circulation of cold air within

the refrigerator.

Check to see if condensation or

ice crystals have formed on the

suction line. If so, charge with

the correct amount of gas.

is leaking in order to seal it or

replace the defective

component. Change the drier.

Perform a good vacuum and

recharge the unit.

Check the electrical

connections and make sure

that the fan blade isn’t stuck.

Replace the fan motor if it

doesn’t work.

voltage is lower than 103 volts.

Check for appropriate

insulation on the connections of

each electrical component.

NOISE The refrigerator is not properly

leveled.

The condenser is not fastened

correctly. Copper tubings are in

contact with metal.

The evaporator and/or

condenser fans are loose.

Compressor has an internal

noise.

EXTREME CONDENSATION

INSIDE THE REFRIGERATOR

Thermostat knob is set at a

very cold position.

The outside environment’s

relative humidity is very high

(over 75%).

Check if the noise goes away

after you level the refrigerator.

While the compressor is

working, check to see if metal

parts are in contact with one

another and/or if the screws

that fasten the condenser are

tightened.

Check if the fans are securely

fastened. Also, check if the fan

blades are loose, broken or

crooked. If so, change the

faulty blade.

If the noise persists after all

other measures have been

taken, it may be originating

from the compressor.

Set the thermostat knob to a

warmer position and check if

the compressor stops

according to the thermostat’s

operating range.

This type of occurrence is

caused by local climatic

conditions and not by the

refrigerated unit.

© 2004, IMI Cornelius Inc. - 7 - Publication Number: 630460278SER

Page 12

COR6519UBCSD Service Manual

PROBLEM POSSIBLE CAUSE SOLUTION

EXTREME CONDENSATION

INSIDE THE REFRIGERATOR

The refrigerator door won’t shut

completely.

The refrigerator has been

placed at an inadequate

location.

NO ILLUMINATION The light switch is in “off”

position.

False contact on the light

switch, the fluorescent tube, or

the ballast.

Light switch, ballast and/or

fluorescent tube are damaged.

Check the door and/or the

magnetic gasket. Adjust the

door hinges if needed; replace

the gasket if broken.

The unit must not be near

sources that produce too much

heat.

Press the light switch to the

“on” position.

Inspect all connections.

Replace the damaged

component.

Publication Number: 630460278SER - 8 - © 2004, IMI Cornelius Inc.

Page 13

CARACTERISTICAS DEL EQUIPO

Tapas, tope y tope para vasos

robustos, en acero inoxidable

Paredes gruesas y fuertes,

inyectadas con aislante de

poliuretano libre de CFC’s

Gabinete exterior de lámina

galvanizada, prepintada con

pintura de poliéster al horno

Divisores adjustables

“heavy-duty” reforzados

COR6519UBCSD Service Manual

ESPAÑOL

Tirador de goma para

facilitar el deslizamiento de

las tapas

Evaporador de aire forzado

para un rápido “pull-down”

Base reforzada con lámina

galvanizada calibre 16

Paredes interiores en acero

galvanizado con recubrimiento

acrílico para mayor resistencia

a la corrosión

Unidad condensadora “heavyduty” para R-134a de fácil

acceso para el servicio

SISTEMA DE REFRIGERACION

Explicación de los componentes

Compresor:

El compresor es una unidad herméticamente sellada localizada debajo (afuera) del compartimiento de

enfriamiento. El compresor es una bomba accionada por un motor, que extrae vapor de baja presión

(refrigerante) del serpentín del evaporador, lo comprime y lo fuerza dentro del condensador a alta

presión.

Rele de arranque:

El relé de arranque está montado en el costado de la caja del compresor. El motor del compresor tiene

dos devanados, un devanado de arranque y devanado de marcha. Para poder darle al motor fuerza

torsional adicional cuando primero arranca, el relé de arranque conecta el devanado de arranque

adicional. Después que el motor llega a la velocidad correcta el relay abre el devanado de arranque y el

motor continua con el devanado de marcha.

Condensador de aire

forzado en cobre y aluminio,

resistente a la oxidación y el

ambiente salino

FIGURE 5

Protector termico:

El protector térmico es un dispositivo termosensible montado en el costado de la caja del compresor. Si

el motor del compresor se pone demasiado caliente o toma una cantidad excesiva de corriente, el

protector térmico se abrirá, rompiendo los circuitos de arranque y de marcha del motor. Después que el

compresor se enfríe a una temperatura operacional segura, el protector térmico cerrará permitiendo que

el motor del compresor vuelva a arrancar.

© 2004, IMI Cornelius Inc. - 9 - Publication Number: 630460278SER

Page 14

COR6519UBCSD Service Manual

Condensador:

El serpentín del condensador está localizado debajo (afuera) del compartimiento de enfriamiento al

frente del compresor. El condensador desplaza calor del vapor de alta presión que se desprende del

compresor y lo condensa en líquido a alta presión.

Motor del ventilador del condensador:

El motor del ventilador del condensador, localizado debajo del compartimiento de enfriamiento, es un

dispositivo de ventilación forzada que usa aire ambiente para enfriar la superficie del serpentín del

condensador. El motor del ventilador está en marcha mientras que el compresor está en marcha.

Evaporador:

El serpentín del evaporador está localizado en el compartimiento de enfriamiento. Según pasa vapor a

baja presión a través del serpentín del evaporador, absorbe y desplaza calor del compartimiento.

Motor del ventilador del evaporador:

El motor del ventilador del evaporador es un dispositivo de ventilación forzada que circula aire a través

del compartimiento de enfriamiento y sobre la superficie de intercambio térmico del serpentín del

evaporador. El motor del ventilador del evaporador corre continuamente.

Observacion:

Los serpentines del Condensador y del Evaporador tienen aletas de aluminio para aumentar

eficazmente sus superficies de intercambio térmico.

Tubo capilar:

El tubo capilar está localizado en el conducto del refrigerante, entre los serpentines del condensador y

del evaporador. Este tubo de diámetro pequeño es usado como dispositivo de medición para controlar el

flujo de refrigerante líquido del serpentín del evaporador. Esto crea una baja presión que causa que el

refrigerante se vaporice y absorba calor según pasa a través del evaporador.

Filtro:

El filtro está localizado en el conducto del refrigerante entre el tubo capilar y el condensador. Atrapa y

desplaza humedad del sistema de refrigeración a la vez que permite que pase aceite y refrigerante a

través del sistema.

Acumulador:

El acumulador está localizado en el conducto del refrigerante, entre el serpentín del evaporador y el

compresor. El acumulador atrapa cualquier refrigerante líquido que no se vaporizó antes de llegar al

compresor.

Control de temperatura:

El control ajustable de temperatura es responsable por detectar cambios de temperatura en el

compartimiento de enfriamiento y arranca el motor del compresor cuando la temperatura del

compartimiento sube sobre una temperatura preestablecida.

El control de temperatura está compuesto de un interruptor de control que es accionado (abierto y

cerrado) por el movimiento mecánico del fuelle. El fuelle está conectado a un bulbo termosensible

(localizado en el compartimiento de enfriamiento) por un conducto (tubo) de refrigerante de pequeño

diámetro. El fuelle, el bulbo termosensible, y el conducto de refrigerante están llenos de refrigerante que

reaccionan a cambios de temperaturas.

Cuando la temperatura del compartimiento de enfriamiento sube, el refrigerante en el bulbo de detección

se expande forzando que el fuelle cierre el interruptor de control de temperatura. El interruptor de control

de temperatura ENCIENDE los motores del compresor y del condensador. Según el ciclo de

refrigeración enfría el compartimiento, el refrigerante en el bulbo de detección se contrae permitiendo

que el fuelle se relaje, accionando a su posición abierta, APAGANDO los motores del compresor y del

condensador.

Publication Number: 630460278SER - 10 - © 2004, IMI Cornelius Inc.

Page 15

Compartimiento de enfriamiento:

El compartimiento de enfriamiento es el área del refrigerador donde se mantiene el producto para

entrega. Esta área está diseñada para permitir que circule un continuo flujo de aire a través del producto.

EL CICLO DE REFRIGERACION

1. Según sube la temperatura en el compartimiento de enfriamiento, el refrigerante en el bulbo del

control de tempretura se calienta y expande, expandiendo el fuelle. La expansión del fuelle cierra el

interruptor de control de temperatura.

2. El interruptor de control de temperatura ENCIENDE los motores del compresor y del condesador.

3. El compresor circula refrigerante a través del sistema extrayendo vapor refrigerante a baja presión

del serpentín del evaporador, comprimiéndolo y forzándolo en el serpentín del condensador.

4. El condensador, ayudado por el motor del ventilador del condensador, desplaza calor del

refrigerante según fluye a través del serpentín del condensador y lo libera al ambiente exterior. La

caída de la temperatura del refrigerante cambia el vapor a líquido.

5. El tubo capilar controla la cantidad de refrigerante liberado al serpentín del evaporador.

6. El serpentín del evaporador permite que el refrigerante absorba y desplace calor del

compartimiento de enfriamiento según fluye a través del serpentín.

7. La caída de temperatura en el compartimiento de enfriamiento es causada por la circulación

continua de refrigerante a través del sistema, desplazando calor del compartimiento de

enfriamiento y transportándolo al ambiente exterior. Cuando la temperatura baja, el refrigerante en

el bulbo del control de temperatura se contrae, permitiendo que el fuelle aba el interruptor de

control de temperatura, apagando los motores del compresor y del condensador.

COR6519UBCSD Service Manual

FIGURE 6

© 2004, IMI Cornelius Inc. - 11 - Publication Number: 630460278SER

Page 16

COR6519UBCSD Service Manual

DIAGRAMA ELÉCTRICO

FIGURE 7

Publication Number: 630460278SER - 12 - © 2004, IMI Cornelius Inc.

Page 17

LIMPIEZA Y MANTENIMIENTO PREVENTIVO

Un apropiado mantenimiento de su refrigerador es de muy alta importancia para un desempeño

económico y operación eficiente del mismo.

1. Desconecte la fuente de alimentación eléctrica del refrigerador antes de realizar la limpieza. Saque

los productos que contenga y colóquelos en otro refrigerador.

2. Limpie el condensador por lo menos una vez al mes utilizando una aspiradora o un cepillo de

cerdas suaves. Si el condensador ha acumulado sucio y grasa (lo cual es posible en áreas de

mucho tráfico o cocinas), utilice una solución limpiadora fuerte. Si encuentra rastros de aceite en el

compartimiento de la unidad condensadora, llame a un técnico de servicio calificado

inmediatamente.

COR6519UBCSD Service Manual

FIGURE 8

3. Mantenga el área alrededor del refrigerador limpia y ordenada.

4. Revise la correcta operación y sellado de las puertas. Las puertas deben cerrar por sí mismas y

sellar en todos los lados.

5. Vacíe la bandeja de drenaje localizada detrás de la unidad condensadora y límpiela según sea

requerido. Revísela regularmente para prevenir una acumulación excesiva de agua.

6. Reemplace cualquier pieza o parte defectuosa tan pronto sea posible. Diríjase a su distribuidor o

agencia de servicio para ordenar las piezas o partes requeridas.

7. Es de mucha importancia que el interior del refrigerador sea limpiado periódicamente. Remueva

todo el producto y las parrillas para realizar esta operación.

8. Utilice únicamente jabón o detergente suaves para lavar el interior y el exterior. Enjuague con agua

limpia y séquelo con un paño suave absorbente.

SISTEMA DE RECOLECCIÓN DE CONDENSADO

Algunos refrigeradores (enfriadores de botellas horizontales) vienen equipados con un drenaje interior

en el fondo que sale del gabinete del lado del compartimiento de la unidad condensadora.

Los refrigeradores con sistema de aire forzado tienen un drenaje que recoge la condensación producida

por el evaporador y la dirige a una bandeja localizada junto a la unidad condensadora. No es necesario

realizar ninguna instalación de plomería adicional. Esta bandeja debe ser revisada periódicamente para

prevenir una acumulación excesiva de agua.

Una bandeja evaporadora eléctrica está disponible como accesorio opcional. Para información adicional,

por favor contacte a nuestros distribuidores.

© 2004, IMI Cornelius Inc. - 13 - Publication Number: 630460278SER

Page 18

COR6519UBCSD Service Manual

PRINCIPALES PROBLEMAS DEL REFRIGERADOR

Posibles causas y soluciones

PROBLEMA POSIBLE CAUSA SOLUCION

COMPRESOR NO ARRANCA NO HAY VOLTAJE EN LA

TOMA DE ALIMENTACION

CONDUCTO ELECTRICO O

ALAMBRES CORTADOS

FALLA EN LOS

COMPONENTES

ELECTRICOS TALES COMO:

TERMOSTATO, PROTECTOR

TERMICO

TERMOSTATO EN POSICION

"OFF"

BOBINAS DEL MOTOR DE

COMPRESOR CORTADAS O

QUEMADAS

VERIFIQUE CON UN

VOLTIMETRO

UTILIZANDO UN

OHMIMETRO, VERIFIQUE SI

EXISTE CONTINUIDAD EN EL

CONDUCTOR ELECTRICO O

ALAMBRE

REEMPLAZAR EL

COMPONENTE

DEFECTUOSO

FIJE LA POSICION DE LA

PERILLA DEL TERMOSTATO

EN FRIO MAXIMO Y

OBSERVE SI EL

COMPRESOR ARRANCA

MIDA LA RESISTENCIA

OHMICA DE LAS BOBINAS

PRINCIPAL Y AUXILIAR

UTILIZANDO UN

OHMIMETRO Y

COMPARELAS CON LOS

VALORES CORRECTOS

CONDENSADOR SUCIO,

FALTA CIRCULACION DE

AIRE

BAJO VOLTAJE PARA ELIMINAR EL

COMPRESOR TRANCADO REEMPLACE EL

DEMASIADO FRIO TERMOSTATO FIJADO EN

POSICION MUY FRIA

TERMOSTATO NO

DESCONECTA LA UNIDAD

CONDENSADORA

LIMPIE EL CONDENSADOR Y

PERMITA LA CIRCULACION

DE AIRE

PROBLEMA DE VOLTAJE

MENOR QUE 103 VOLTS, ES

RECOMENDABLE EL USO DE

UN REGULADOR DE

VOLTAJE

COMPRESOR

FIJE LA PERILLA DEL

TERMOSTATO A UNA

POSICION MAS CALIENTE Y

VERIFIQUE SI EL

COMPRESOR PARA

DENTRO DEL RANGO DE

OPERACION DEL

TERMOSTATO

VERIFIQUE LA FIJACION DEL

BULBO DEL TERMOSTATO,

SI EL PROBLEMA

CONTINUA, CAMBIE EL

TERMOSTATO

Publication Number: 630460278SER - 14 - © 2004, IMI Cornelius Inc.

Page 19

COR6519UBCSD Service Manual

PROBLEMA POSIBLE CAUSA SOLUCION

DEMASIADO FRIO BULBO DEL TERMOSTATO

DESPRENDIDO O MAL

FIJADO

POCO FRIO TERMOSTATO FIJADO EN

POSICION MUY CALIENTE

CONDENSADOR SUCIO,

FALTA DE CIRCULACION

DEL AIRE

EL REFRIGERADOR ESTA

MAL UBICADO

EL REFRIGERADOR ES MAL

UTILIZADO

REFRIGERADOR CON

SOBRECARGA DE GAS

FIJE CORRECTAMENTE EL

BULBO DEL TERMOSTATO

FIJE LA POSICION DEL

TERMOSTATO A UNA

POSICION MAS FRIA

LIMPIE EL CONDENSADOR Y

PERMITA LA CIRCULACION

DEL AIRE

EL REFRIGERADOR NO

DEBE DE ESTAR CERCA DE

COCINAS, PAREDES

EXPUESTAS AL SOL,

LUGARES SIN CIRCULACION

DE AIRE O MUY SOLEADOS

LAS PARRILLAS NO DEBEN

DE CUBRIRSE CON NINGUN

PLASTICO O MATERIAL QUE

OBSTRUYA LA

CIRCULACION DEL AIRE

DENTRO DEL

REFRIGERADOR

VERIFIQUE SI EXISTE

CONDENSACION O

FORMACION DE ESCARCHA

EN LA LINEA DE SUCCION.

SI EXISTE, CARGUE

CORRECTAMENTE

FALTA DE GAS

CARGUE CORRECTAMENTE

REFRIGERANTE

EXISTENCIA DE UNA FUGA

DE GAS REFRIGERANTE

VERIFIQUE EL PUNTO

DONDE SE ENCUENTRA LA

FUGA PARA ELIMINARLA O

REEMPLAZAR EL

COMPONENTE. CAMBIE EL

FILTRO DESHIDRATADOR,

EFECTUE VACIO Y

COLOQUE NUEVA CARGA

DE GAS

VENTILADOR DEL

EVAPORADOR O DE UNIDAD

CONDENSADORA NO

FUNCIONA

VERIFIQUE CONEXIONES

ELECTRICAS Y QUE EL

ASPA NO ESTE TRABADA.

REEMPLACE EL

COMPONENTE CUANDO EL

MOTOR ESTE QUEMADO

BAJO VOLTAJE PARA ELIMINAR EL

PROBLEMA DE VOL-TAJE

MENOR QUE 103 VOLTS. ES

RECO-MENDADO EL USO DE

UN REGULADOR DE

VOLTAJE

© 2004, IMI Cornelius Inc. - 15 - Publication Number: 630460278SER

Page 20

COR6519UBCSD Service Manual

PROBLEMA POSIBLE CAUSA SOLUCION

CHOQUE ELECTRICO ALAMBRES O DISPOSITIVOS

ELECTRICOS EN CONTACTO

CON PARTES METALICAS

COMPRESOR CON PASO DE

CORRIENTE A LA CARCAZA

RUIDO MALA NIVELACION DEL

REFRIGERADOR

CONDENSADOR MAL

FIJADO. TUBERIAS EN

CONTACTO CON METAL

VERIFIQUE SI HAY FALLA EN

EL AISLA-MIENTO DE UN

COMPONENTE ELECTRICO

QUE ESTE EN CONTACTO

CON PARTES METALICAS.

AISLE CORRECTAMENTE.

VERIFIQUE CONTINUIDAD

CONECTANDO LOS

TERMINALES DE UNA

LAMPARA DE PRUEBA

ENTRE EL BORDE COMUN Y

EL TERMINAL DE TIERRA

DEL COMPRESOR. SI LA

LAMPARA ENCIENDE,

REEMPLACE EL

COMPRESOR

VERIFIQUE SI EL RUIDO SE

ELIMINA CUANDO EL

REFRIGERADOR ESTA

NIVELADO

TENIENDO EL COMPRESOR

FUNCIONANDO. VERIFIQUE

SI PARTES METALICAS

ESTAN EN CONTACTO Y/O

QUE LOS TORNILLOS DE

SUJECCION DEL

CONDENSSADOR ESTEN

DEBIDAMENTE APRETADOS

CONDENSACION EXTREMA

EN EL REFRIGERADOR

ABANICO DEL

EVAPORADOR O DE UNIDAD

CONDENSADORA FLOJO

COMPRESOR CON RUIDO

INTERNO

TERMOSTATO FIJADO EN

POSICION DEMASIADO FRIA

HUMEDAD REALTIVA DEL

AIRE ES MUY ALTA (ARRIBA

DEL 75%)

VERIFIQUE SI LOS

ABANICOS ESTAN BIEN

FIJADOS. VERIFIQUE SI EL

ASPA DEL ABANISCO ESTA

FLOJA, QUEBRADA O

TORCIDA CREANDO UNA

EXCESIVA VIBRACION.

CAMBIE EL ASPA.

SI DESPUES DE ANALIZAR

TODOS LOS ASPECTOS

PREVIAMENTE DESCRITOS,

EL RUIDO PERSISTE, SU

ORIGEN PUEDE ESTAR EN

EL COMPRESOR

FIJE LA PERILLA DEL

TERMOSTATO EN UNA

POSICION MAS CALIENTE.

VERIFQUE QUE EL

COMPRESOR PARE

DENTRO DEL RANGO DE

OPERACION DEL

TERMOSTATO

ESTA CLASE DE DAÑO ES

CAUSADO POR LAS

CONDICIONES

CLIMATOLOGICAS LOCALES

Y NO POR EL

REFRIGERADOR

Publication Number: 630460278SER - 16 - © 2004, IMI Cornelius Inc.

Page 21

COR6519UBCSD Service Manual

PROBLEMA POSIBLE CAUSA SOLUCION

CONDENSACION EXTREMA

EN EL REFRIGERADOR

PUERTA DEL

REFRIGERADOR NO SELLA

VERIFIQUE SI LA PUERTA

ESTA MAL AJUSTADA O SI

EL EMPAQUE ESTA ROTO.

AJUSTE LA PUERTA O

REEMPLACE EL EMPAQUE

EL REFRIGERADOR ESTA

MAL UBICADO

EL REFRIGERADOR NO

DEBE DE ESTAR UBICADO

CERCA DE FUENTES DE

CALOR

LAMPARA NO ENCIENDE SWITCH EN POSICION "OFF" COLOQUE EL SWITCH EN

POSICION "ON"

FALSO CONTACTO EN EL

REVISE CONEXIONES

SWITCH, CONECTORES DEL

TUBO FLUORESCENTE O

BALASTRO

SWITCH , BALASTRO Y/O

TUBO FLOURESCENTE

REEMPLACE COMPONENTE

DEFECTUOSO

DEFESTUOSO

© 2004, IMI Cornelius Inc. - 17 - Publication Number: 630460278SER

Page 22

COR6519UBCSD Service Manual

Publication Number: 630460278SER - 18 - © 2004, IMI Cornelius Inc.

Loading...

Loading...