Cornelius COR5916SPTD Service Manual

®

SANDWICH PREPARATION

UNDERCOUNTERS AND WORKTOPS

COR5916SPTD

Service Manual

Release Date: May, 2004

Publication Number: 630460271SER

Revision Date: NA

Revision: A

Visit the IMI Cornelius web site at www.cornelius.com

for all your Literature needs.

SERVICE MANUAL

The products, technical information, and instructions contained in this manual are subject

to change without notice. These instructions are not intended to cover all details or variations of the equipment, nor to provide for every possible contingency in the installation,

operation or maintenance of this equipment. This manual assumes that the person(s)

working on the equipment have been trained and are skilled in working with electrical,

plumbing, pneumatic, and mechanical equipment. It is assumed that appropriate safety

precautions are taken and that all local safety and construction requirements are being

met, in addition to the information contained in this manual.

To inquire about current revisions of this and other documentation or for assistance with

any Cornelius product contact:

www.cornelius.com

800-238-3600

Trademarks and copyrights:

Aurora, Cornelius, Decade, Hydro Boost, Sitco, Spirit, UF-1, Vanguard, Venture, Olympus,

and Vista are registered trademarks of IMI Cornelius Inc.

Optifill trademark is pending.

This document contains proprietary information and it may not be

reproduced in any way without permission from Cornelius.

Printed in U.S.A.

Copyright © 2004, All Rights Reserved, IMI Cornelius, Inc.

COR5916SPTD Service Manual

TABLE OF CONTENTS

English . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Features of the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Refrigeration System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Description of its components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

The Refrigeration Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Electrical Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Cleaning and Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Condensate Disposal System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Possible causes and solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Español . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Caracteristicas del equipo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Sistema de Refrigeracion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Explicación de los componentes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

El Ciclo de Refrigeracion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Diagrama eléctrico . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Limpieza y Mantenimiento Preventivo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Sistema de Recolección de Condensado . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Principales Problemas del Refrigerador . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Posibles causas y soluciones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

© 2004, IMI Cornelius Inc. - i - Publication Number: 630460271SER

COR5916SPTD Service Manual

Publication Number: 630460271SER - ii - © 2004, IMI Cornelius Inc.

FEATURES OF THE UNIT

1/6 size polypropylene pans

and 12” wide NSF approved

polyethylene cutting board

COR5916SPTD Service Manual

ENGLISH

Strong body with thick walls,

injected with CFC-free

polyurethane foam

Exterior cabinet made of

galvanized, pre-painted

steel, with baked polyester

paint

Reinforced, adjustable,

heavy-duty epoxy-coated

shelves

Aluminum interior lining

Heavy-duty R-134a

condensing unit with easy

access for maintenance

Stainless steel top, hood

and lid

Forced-air evaporator for

quick temperature pulldown

Heavy-duty casters for easy

transportation and added

mobility

Forced-air condenser made

of copper and aluminum,

resistant to rust and saline

environments

FIGURE 1

EFRIGERATION SYSTEM

R

Description of its components

Compressor:

The compressor is a factory-sealed unit located underneath (outside) the cooling cabinet. This pump is

activated by a motor which draws low-pressure vapor (refrigerant) from the evaporator. It then

compresses the gas and forces it into the condenser at a high pressure.

Starter relay:

The starter relay is attached on one side of the compressor box. The compressor motor has two

windings: one for starting and another for running. In order to provide for necessary additional torque

when the motor is first ignited, the starter relay connects the additional start-up windings. After the motor

reaches its correct operating speed, the relay opens the ignition windings and the motor carries on with

the operation windings.

Thermal protector:

This protector is a thermo-sensible device attached to one side of the compressor’s box. In any given

situation, if the compressor overheats or the voltage source varies drastically, the thermal protector

opens, turning off the compressor. After the compressor cools down to a normal and safe working

temperature, the thermal protector turns on the compressor.

© 2004, IMI Cornelius Inc. - 1 - Publication Number: 630460271SER

COR5916SPTD Service Manual

Condenser:

The condenser is located underneath (outside) the cooling cabinet in front of the compressor. It receives

hot, high-pressure refrigerant gas from the compressor and cools it down until it returns to liquid state.

Condenser fan motor:

The condenser fan motor is located underneath the cooling cabinet. It is a ventilation device which forces

the ambient air to flow over the condenser in order to cool down the refrigerant flowing inside it. The fan

motor works only if the compressor is on.

Evaporator:

The evaporator is located inside the cooling cabinet. As the gas flows at a low pressure through the

evaporator, it absorbs serpentine and removes the heat from inside the cabinet.

Evaporator fan motor:

This device provides the required circulation of air through the cooling cabinet as well as over the surface

of the evaporator’s serpentine thermal exchange area. This fan motor runs continuously.

The evaporator and condenser serpentines have aluminum fins that help increase the surfaces for the

thermal exchange in an efficient way.

Capillary tube:

It consists of several feet of tubing having a small inside diameter. It is a device used to control the

amount of refrigerant that flows into the evaporator.

Drier:

The drier is located in between the condenser and the evaporator. It traps and removes moisture in the

refrigeration system while allowing oil and refrigerant to flow freely.

Accumulator:

The accumulator is located in between the evaporator and the compressor. It is a storage tank which

receives refrigerant liquid from the evaporator and prevents it from flowing into the compressor.

Temperature control:

The adjustable temperature control is responsible for detecting temperature changes inside the cooling

cabinet. It also starts the compressor motor whenever the cabinet rises above the desired temperature.

The temperature control consists of a switch which is mechanically activated by a diaphragm. This

diaphragm is connected to a thermo-sensible bulb (located inside the cabinet) through a small diameter

tube. All three components (the diaphragm, the thermo-sensible bulb, and the small diameter tube) are

filled with refrigerant gas which reacts to temperature changes.

When the cabinet temperature rises, the refrigerant in the bulb heats up and expands, expanding the

diaphragm. The diaphragm’s expanding closes the temperature control’s interrupting device and then

starts the compressor and condenser motors.

The drop in temperature inside the cooling compartment is caused by the refrigerant’s continuous

circulation through the system. When the temperature drops, the refrigerant inside the temperature

control’s bulb contracts, allowing the diaphragm to open the interrupting device, which consequently

shuts down the compressor and condenser motors.

Cooling cabinet:

This is the area where the goods are stored. It has been designed to allow for constant cold air circulation

to flow through the goods.

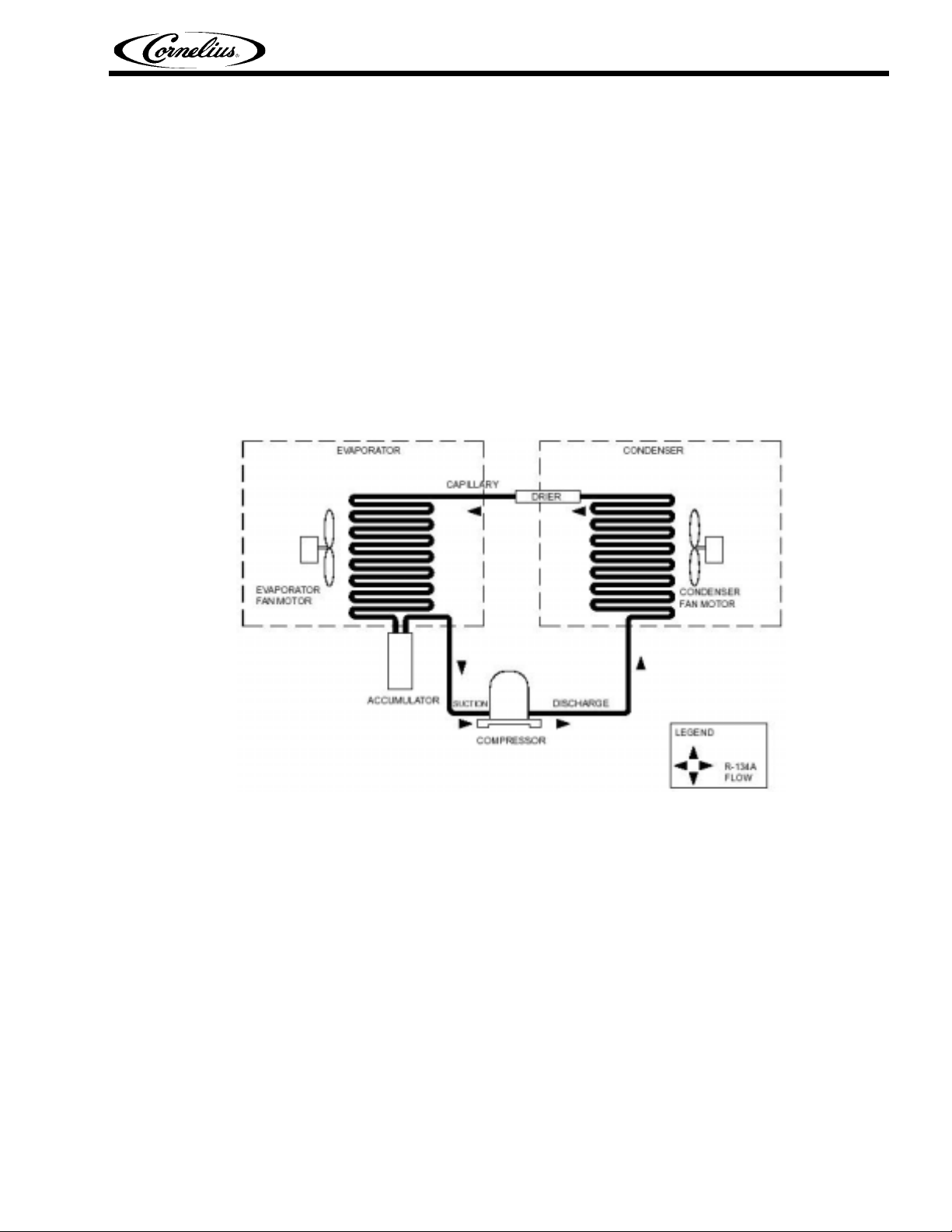

THE REFRIGERATION CYCLE

1. Depending on the increase in temperature inside the cooling compartment, the refrigerant gas

inside the temperature control's bulb heats up and expands, expanding the diaphragm. The

diaphragm's expansion closes the temperature control's interrupting device.

2. The temperature control's interrupting device turns on the compressor and condenser motors.

Publication Number: 630460271SER - 2 - © 2004, IMI Cornelius Inc.

COR5916SPTD Service Manual

3. The compressor recirculates the refrigerant throughout the system by drawing the refrigerant gas

as low vapor pressure from the evaporator. Then it compresses the refrigerant and forces it into the

condenser.

4. The condenser, with the help of its fan motor, removes the refrigerant's heat as it flows through the

condenser. The heat is then released to the outside environment. Consequently, the decrease in

temperature will change the refrigerant from a gaseous to a liquid state.

5. The capillary tube regulates the amount of refrigerant that is discharged into the evaporator.

6. The evaporator's serpentine allows the refrigerant to absorb and remove heat from the cooling

compartment.

7. The drop in temperature inside the cooling compartment is caused by the refrigerant's continuous

circulation through the system. This gas continuously absorbs the heat that exists inside the cooling

compartment and expels it to the outside environment. When the temperature drops, the refrigerant

inside the temperature control's bulb contracts, allowing the diaphragm to open the interrupting

device, which consequently shuts down the compressor and condenser motors.

FIGURE 2

© 2004, IMI Cornelius Inc. - 3 - Publication Number: 630460271SER

Loading...

Loading...