Control Techniques Commander C200, Commander C300 Product Guide

Commander C200/C300

Step By Step Guide

Guide pas à pas Schritt-für-Schritt-Anleitung Guida dettagliata

Guía detallada

Frame sizes 5 to 9

Tailles 5 à 9

Baugrößen 5 bis 9

Taglie da 5 a 9

Tamaños 5 a 9

English

Introduction

The Commander C200 and C300 is a simple and flexible range of drives from 0.25 kW to 132 kW in 9 frame sizes and two input voltage ranges (200 V, and 400 V).

This Step-by Step guide provides simple step-by-step instructions on how to mount the drive, fuse and cable selection, wiring the drive-up, programming the drive and running the motor in analog input mode or keypad mode on frames 5 to 9.

Features of the drive

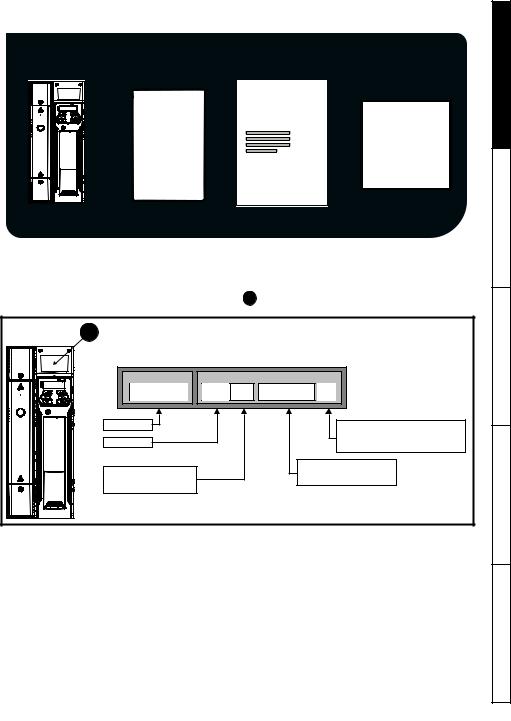

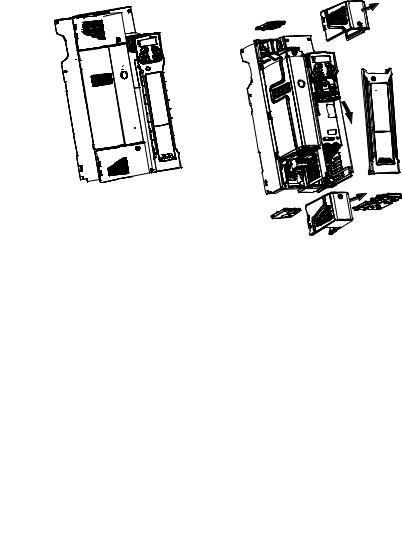

Figure 1-1 Feature diagram

128 |

129 |

10 |

|

|

6 |

|

|

|

|

|

12 |

|

|

|

|

12 |

|

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

L1 |

|

L2 |

L3 |

8 |

|

|

|

|

|

|||

|

|

|

PE |

+DC |

|

-DC |

|

|

|

|

5 |

|

|

|

9 |

|

|

|

|

|

|

|

1 |

7 |

|

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

6 |

|

7 8 |

9 |

|

|

|

|

|

3 |

|

|

|

||

|

|

|

77 |

|

|

41 42 |

2 |

|

|

|

|

|

|

|

3 |

|

|

13 |

|

|

|

|

|

6 |

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

13 |

|

|

5 |

|

|

|

|

|

5 |

|

|

U |

|

V |

W |

5 |

|

U V W |

|

|||||

|

|

|

|

+DC |

|

BRAKE |

|

|

|

|

5 |

|

|

|

|

|

4 |

|

|

8 |

|

10 |

|

|

|

|

|

|

|

||

|

|

11 |

|

|

|

|

11 |

Key |

|

|

|

|

|

|

|

1. Rating label |

|

|

2. Relay connections (Refer to Fig. 6-5) |

|

|||

3. Option module slot 1 |

4. Motor connections (Refer to Fig. 6-1 to Fig. 6-4) |

||||||

5. Ground connections (Refer to Fig. 6-1 to 6-4) |

6. AC supply connections (Refer to Fig. 6-1 to Fig. 6-4) |

||||||

7. Control connections (Refer to Fig. 6-5) |

8. DC bus + |

|

|

|

|

||

9. DC bus - |

|

|

10. Braking terminal |

|

|

|

|

11. Cable bracket to ground terminals |

12. Internal EMC filter screw* |

|

|||||

13.Safe Torque Off terminals (STO)** (Refer to Fig 6-5)

*Before removing the screw, refer to Chapter 4 in the Power Installation Guide.

**Commander C300 only

2 |

Commander C200/C300 Step By Step Guide |

|

Issue Number: 2 |

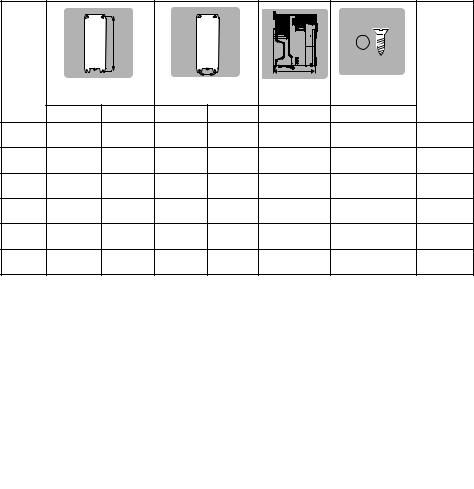

STEP 1: Check the contents of the box

Check you have all the components and your drive has not been damaged during transportation.

|

|

SAFETY |

|

|

KIT BOX* |

|

INFORMATION |

|

|

+ |

+ |

+ |

STEP BY STEP |

|

GUIDE |

||||

|

|

|

* With frame size 7, 8 and 9, surface mounting brackets are also supplied with the drive.

STEP 2: Check model and voltage

The model number can be found on the identification label |

1 on the top of the drive. Please check that the model |

||

and the drive voltage range is suitable for the installation. |

|

|

|

1 |

|

|

|

Derivative |

Electrical Specifications |

|

|

C300 - |

05 4 |

00270 |

A |

Product line: |

|

|

Drive Format : |

|

|

|

|

Frame size: |

|

|

A - AC in AC out |

|

|

E - AC in AC out (without internal choke) |

|

|

|

|

|

Voltage rating: |

|

Current Rating : |

|

|

|

|

|

2 - 200 V (200 - 240 ± 10 %) |

|

Heavy Duty current rating x10 |

|

4 - 400 V (380 - 480 ± 10 %) |

|

|

|

<![endif]>English

<![if ! IE]><![endif]>Français

<![if ! IE]><![endif]>Deutsch

<![if ! IE]><![endif]>Italiano

<![if ! IE]><![endif]>Español

Commander C200/C300 Step By Step Guide |

3 |

Issue Number: 2 |

|

STEP 3: Mount the drive

The drive should be mounted in an ambient temperature range of - 20 °C to 60 °C (- 4 °F to 140 °F).

Output current derating may be required at ambient temperatures >40 °C (104 °F). Refer to the relevant Power Installation Guide (section 5.1). For UL installations, the maximum ambient temperature permitted is 50 °C (122 °F) with any specified derating applied.

The drive can be screwed on a wall or Through-panel mounted (Refer to chapter 3 in the Power Installation Guide). Table 3-1 highlights the clearances.

Table 3-1 Recommended spacing

|

Spacing between drive |

Spacing between |

Spacing above |

Spacing below |

|

Frame size |

and enclosure / |

||||

drives |

drive |

drive |

|||

|

EMC filter |

||||

|

|

|

|

||

|

|

|

|

|

|

5 |

30 mm (1.18 in) |

0 mm (0.00 in) |

100 mm (4.0 in) |

100 mm (4.0 in) |

|

|

|

|

|

|

|

6 |

30 mm (1.18 in) |

0 mm (0.00 in) |

100 mm (4.0 in) |

100 mm (4.0 in) |

|

|

|

|

|

|

|

7 |

45 mm (1.77 in) |

30 mm (1.18 in) |

60 mm (2.37 in) |

100 mm (4.0 in) |

|

|

|

|

|

|

|

8 |

45 mm (1.77 in) |

30 mm (1.18 in) |

60 mm (2.37 in) |

100 mm (4.0 in) |

|

|

|

|

|

|

|

9 |

45 mm (1.77 in) |

60 mm (2.37 in) |

60 mm (2.37 in) |

100 mm (4.0 in) |

|

|

|

|

|

|

Frame |

|

|

|

|

|

|

Weight |

|

|

|

H |

|

W |

D |

Ø |

|

|

|

Mounting |

Overall |

Mounting |

Overall |

Overall |

Diameter |

|

|

5 |

375 mm |

391 mm |

106 mm |

143 mm |

200 mm |

6.5 mm (0.26 in) |

7.4 kg |

|

(14.76 in) |

(15.39 in) |

(4.17 in) |

(5.63 in) |

(7.87 in) |

(16.3 Ib) |

|||

|

|

|||||||

6 |

378 mm |

391 mm |

196 mm |

210 mm |

227 mm |

7.0 mm (0.28 in) |

14 kg |

|

(14.88 in) |

(15.39 in) |

(7.72 in) |

(8.27 in) |

(8.94 in) |

(30.9 Ib) |

|||

|

|

|||||||

7 |

538 mm |

557 mm |

220 mm |

270 mm |

280 mm |

9.0 mm (0.35 in) |

28 kg |

|

(21.18 in) |

(21.93 in) |

(8.66 in) |

(10.63 in) |

(11.02 in) |

(61.70 Ib) |

|||

|

|

|||||||

8 |

784 mm |

804 mm |

259 mm |

310 mm |

290 mm |

9.0 mm (0.35 in) |

52 kg |

|

(30.87 in) |

(31.65 in) |

(10.20 in) |

(12.21 in) |

(11.42 in) |

(114.6 Ib) |

|||

|

|

|||||||

9E |

1051 mm |

1069 mm |

259 mm |

310 mm |

290 mm |

9.0 mm (0.35 in) |

46 kg |

|

(41.38 in) |

(42.09 in) |

(10.20 in) |

(12.21 in) |

(11.42 in) |

(101.4 Ib) |

|||

|

|

|||||||

9A |

1090 mm |

1108 mm |

259 mm |

310 mm |

290 mm |

9.0 mm (0.35 in) |

66.5 kg |

|

(42.91 in) |

(43.62 in) |

(10.20 in) |

(12.21 in) |

(11.42 in) |

(146.6 Ib) |

|||

|

|

4 |

Commander C200/C300 Step By Step Guide |

|

Issue Number: 2 |

STEP 4: Select supply / motor cables and fuses

The supply/motor cables and fuses or MCB’s used should follow the ratings provided in the table below:

The voltage rating of fuses must be greater than or equal to the highest supply voltage of the system. Fuses: The AC supply to the drive must be installed with suitable protection against overload. Failure

to observe this requirement will cause risk of fire.

WARNING

|

Maximum |

Fuses |

|

|

Cables |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

continuous |

IEC Class |

UL |

IEC60364-5-52 |

UL 508C |

||||

Model |

input |

Class CC, |

|||||||

|

current |

gG or gR |

J, or T* |

|

mm² |

AWG |

|||

|

A |

A |

A |

Input |

|

Output |

Input |

|

Output |

|

|

|

|

|

|

|

|

|

|

05200250 |

31 |

40 |

40 |

|

10 |

|

8 |

||

06200330 |

48.8 |

63 |

60 |

|

16 |

|

4 |

||

|

|

|

|

|

|

|

|

||

06200440 |

56.6 |

63 |

70 |

|

25 |

|

3 |

||

|

|

|

|

|

|

|

|

||

05400270 |

29 |

40 |

35 |

|

6 |

|

8 |

||

05400300 |

29 |

40 |

35 |

|

6 |

|

8 |

||

|

|

|

|

|

|

|

|

||

06400350 |

36 |

63** |

40 |

|

10 |

|

6 |

||

|

|

|

|

|

|

|

|

||

06400420 |

46 |

63** |

50 |

|

16 |

|

4 |

||

|

|

|

|

|

|

|

|

||

06400470 |

60 |

63** |

70 |

|

25 |

|

3 |

||

07200610 |

67 |

80 |

80 |

|

35 |

|

2 |

||

07200750 |

84 |

100 |

100 |

|

35 |

|

1 |

||

|

|

|

|

|

|

|

|

||

07200830 |

105 |

125 |

125 |

|

70 |

|

1/0 |

||

|

|

|

|

|

|

|

|

||

08201160 |

137 |

200** |

200*** |

|

95 |

|

3/0 |

||

|

|

|

|

|

|

|

|||

08201320 |

166 |

200** |

225*** |

2 x 70 |

|

2 x 1 |

|||

|

|

|

|

|

|

|

|

||

09201760 |

205 |

250** |

250*** |

2 x 70 (B1) |

|

2 x 95 (B2) |

2 x 2/0 |

||

|

|

|

|

|

|

|

|

||

09202190 |

260 |

315** |

300*** |

2 x 95 (B1) |

|

2 x 120 (B2) |

2 x 4/0 |

||

|

|

|

|

|

|

|

|

|

|

07400660 |

74 |

100 |

80 |

|

35 |

|

1 |

||

07400770 |

88 |

100 |

100 |

|

50 |

|

2 |

||

|

|

|

|

|

|

|

|

||

07401000 |

105 |

125 |

125 |

|

70 |

|

1/0 |

||

|

|

|

|

|

|

|

|||

08401340 |

155 |

250** |

225*** |

2 x 50 |

|

2 x 1 |

|||

|

|

|

|

|

|

||||

08401570 |

177 |

250** |

225*** |

2 x 70 |

2 x 1/0 |

||||

|

|

|

|

|

|

|

|

|

|

09402000 |

232 |

315** |

300*** |

2 x 70 (B1) |

|

2 x 95 (B2) |

2 x 3/0 |

|

2 x 2/0 |

09402240 |

267 |

315** |

350*** |

2 x 95 (B1) |

|

2 x 120 (B2) |

2 x |

4/0 |

|

|

|

|

|

|

|

|

|

|

|

*These fuses are fast acting.

**These fuses are class gR.

***These fuses are class HSJ.

NOTE |

The product is UL listed for use on a circuit up to 100 kA maximum supply symmetrical fault current, |

|

when protected by fuses. |

||

|

||

NOTE |

IEC cable sizes assume Copper conductor, PVC insulation, Installation method B2 and ambient |

|

temperature of 40 °C (104 °F). UL cable sizes assume Copper conductor with insulation rated at 75 °C |

||

|

||

|

(167 °F). |

<![endif]>English

<![if ! IE]><![endif]>Français

<![if ! IE]><![endif]>Deutsch

<![if ! IE]><![endif]>Italiano

<![if ! IE]><![endif]>Español

Commander C200/C300 Step By Step Guide |

5 |

Issue Number: 2 |

|

Table 4-1 Protective ground cable ratings

Input phase conductor size |

Minimum ground conductor size |

|

|

|

|

≤ 10 mm² |

Either 10 mm² or two conductors of the same cross-sectional area as the input |

|

phase conductor |

||

|

||

|

|

|

> 10 mm² and ≤ 16 mm² |

The same cross-sectional area as the input phase conductor |

|

|

|

|

> 16 mm² and ≤ 35 mm² |

16 mm² |

|

|

|

|

> 35 mm² |

Half of the cross-sectional area of the input phase conductor |

|

|

|

STEP 5: Remove the terminal cover and finger guard breakouts

1.Using a flat bladed screwdriver, turn the terminal cover locking clip anti-clockwise by approximately 30°.

2.Slide the terminal cover down.

3.Remove terminal cover in direction shown.

1

2

3

6 |

Commander C200/C300 Step By Step Guide |

|

Issue Number: 2 |

Loading...

Loading...