Condec UVC1010 User Manual

UVC1000/UVC1010

Table Top & Rack-mountable Pneumatic

Vacuum Generator/Pressure Controller

Operation and Maintenance

Manual

Condec Sales Phone Number: (888) 295-8475

Condec Web Site: www.4condec.com

69481

Contents

About This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.0 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.0 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Input Air Pressure Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Pressure Measurement Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.0 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2 Test and Maintenance Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2.1 Test Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2.2 UVC1000/UVC1010 Cover - Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2.3 Pressure Limit Control (PN 58409) - Regulator Removal and Installation. . . . . . . . . . . . . . . . 5

3.2.4 Vacuum Monitor (PN 59230) and Pressure Limit Monitor (PN 59706) Gauges -

Removal and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2.5 Pressure and Vacuum Port Quick-Connect Fitting (PN 59997) -

Removal and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2.6 Input Port (PN 59761) - Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2.7 Input Port Filter (PN 54188) - Removal, Cleaning and Installation . . . . . . . . . . . . . . . . . . . . . 7

3.2.8 Vacuum Generator (PN 57960) - Removal, Cleaning and Installation . . . . . . . . . . . . . . . . . . 8

4.0 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

UVC1000/UVC1010 Warranty and Return Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

UVC1000/UVC1010 Return Material Authorization Form. . . . . . . . . . . . . . . . . . . . . . . . 11

Copyright © 2001 Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Specifications subject to change without notice.

September 2001

About This Manual

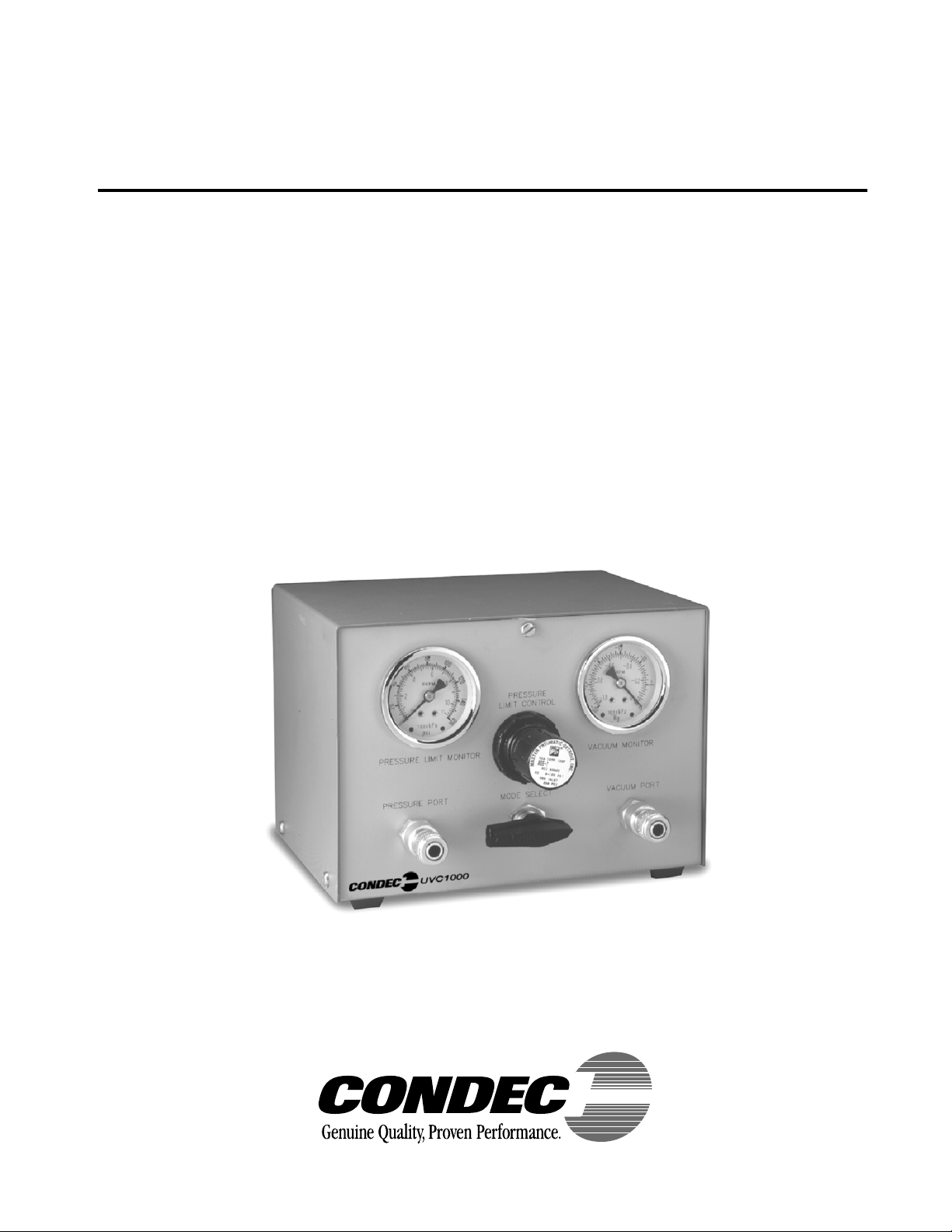

The UVC1000/UVC1010 is a rugged, compact

instrument manufactured by Condec, designed to

provide ease of operation, for the calibration of a wide

variety of pressure sensing and measuring devices.

Equipped to perform rapid on-site calibrations, these

instruments have proven to substantially reduce the

cost, system down-time and man-hours of labor

normally associated with these routine service

functions.

This instrument is an all-mechanical device that

provides up to 29 inches Hg vacuum in areas that are

off limits to vacuum pumps.The operator uses e xisting

shop air lines working with a built in vacuum

converter inside the unit. The unit has multiple ports,

including one for low pressure and one for vacuum.

Front panel gages tell the operator system pressure. A

pressure regulator will act as a pressure limiter so that

the operator can not over pressure a unit under test.

Adapter fittings are supplied for the customer to put

on their fill hose and test hose.

This manual has been written to give the user a simple

and clear explanation of how to operate, and

troubleshoot these instruments.

While a substantial effort has been

Warning

dangerous conditions could be produced through

negligent handling or operation of the

UVC1000/UVC1010.

These units are strictly for use with pneumatic

pressures. Erroneous readings and potential

damage could result from the introduction of

hydraulic fluids into the internal tubing lines.

expended to make this equipment

safe, simple and fool-proof to

operate, it is strongly

recommended that only personnel

formally trained in the use of

pneumatic pressure equipment be

permitted to operate it. Potentially

Authorized distributors and their

employees can view or download this

manual from the Condec distributor

site at

www.4condec.com

.

1.0 Introduction

The UVC1000/UVC1010 offers a combination of features, performance, versatility and reliability. Some of the

more outstanding features are listed below:

• Two models available: table top and 19" rackmount.

• Portable: These compact, self-contained systems are easily carried and operated by only one person. Total

weight is approximately 7 pounds.

• An internal input filter: Easily removed for inspection and cleaning.

• Simple Operation: All control regulator, gages, vacuum port and pressure port are accessible from the front

panel. The input port is located on the rear of unit. Accompan ying operator's manual pro vides clear , concise

instructions for system operation.

• Safe, Clean Operation: All pressure components are made of brass, aluminum or stainless steel and

proof-tested to at least 150% of maximum operating pressure.

Overpressure protection and clean line pressure must be provided by the customer. By virtue of this technique,

the UVC1000/UVC1010 and unit under test is fully protected from being inadvertently overpressurized.

Introduction

1

2

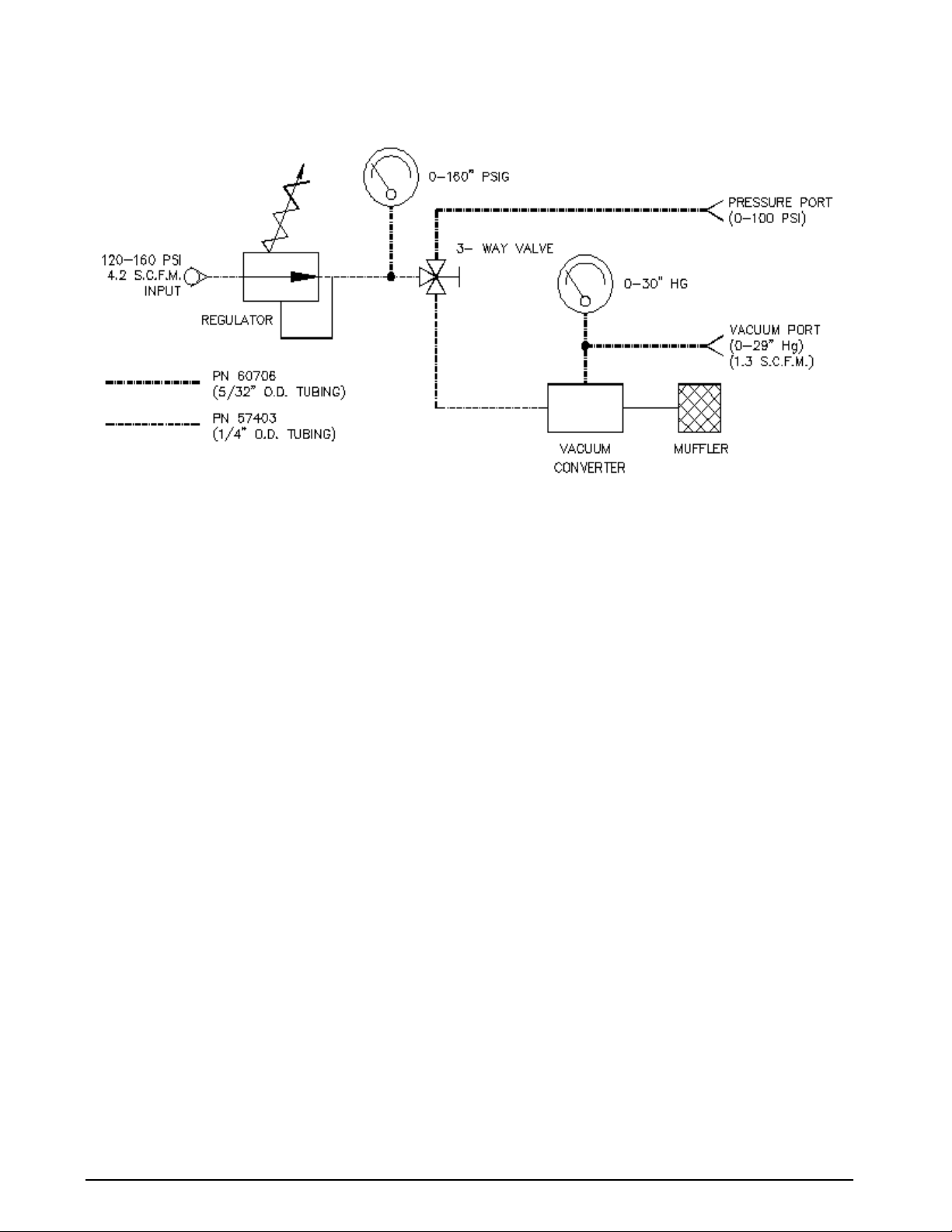

The following schematic provides an overview of the UVC1000/UVC1010’s function.

Figure 1-1. UVC1000/UVC1010 Flow Diagram

UVC1000/UVC1010 Operation and Maintenance Manual

Loading...

Loading...