Condec MPV-10K Specifications

MPV-10k

Micro-metering Precision Valve

Applications

• Gas and uid applications

• High purity systems

• Medical and Bio-chemical gas analysis

• Natural gas systems

• Semi-conductor production

• Pollution analysis instrumentation

• Process plant instrumentation

• Solvent systems

• Chromatography

• Mass spectroscopy

• Research laboratory sampling

• Oxygen service

• Machine cutting tools

Please refer to price schedule for part numbers.

Ultimate control is at your fingertips with the MPV-10K

precision micro-metering valve.

The MPV-10K, a component of our pressure calibration standards, is also available as an independent, fine

micro-metering valve with positive shut off. This exclusive

device incorporates all stainless steel construction for

long lasting performance.

The versatile MPV-10K combines sophisticated performance with easy-to-use features. Adjustable stop with

soft seat prevents over-tightening. Each valve is customized with O-rings constructed from one of four materials

for specific operation. Fingertip adjustment up to 10,000

psi provides high-accuracy metering in a variety of gas

and fluid applications.

From process plant instrumentation to semiconductor

production, natural gas systems to oxygen service, the

MPV-10K is the ideal choice for precision micro-metering.

Standard Features

• Fine micro-metering valve with positive shut off

• Adjustable stop, soft seat. No over tightening

• Stainless steel

• Finger tip adjust - even at 10,000 psi

• Viton O-rings standard; other materials available by request

• Valve can be panel or bracket mounted

Options/Accessories

68859 ........Additional adjustment and maintenance manual

55277 ........Replacement Viton O-ring kit

Consult factory for additional O-ring materials:

• Buna-N

• Ethylene-propylene

• Silicone

• Neoprene

(Specifications on back)

CP-10

MPV-10k

Specications

PRESSURE RANGE:

Vacuum to 10,000 psi

PROOF PRESSURE:

15,000 psi

ORIFICE SIzE:

0.032

CV FACTOR:

0.007

MECHANICAL ROTATION:

10 turns, nominal

TORqUE:

Finger tip adjust

VOLUME:

0.5 cubic inch, nominal

SENSITIVITY:

0.0005 psi, minimum

CONSTRUCTION:

Body: 303 stainless steel

All other parts: 304 stainless steel

Knob: Black anodized aluminum

DESCRIPTION OF O-RING MATERIALS:

Viton (V): Standard supplied material. High temperature,

compatible with wide range of fluids and chemicals: Acids, oils,

fuels, solvents, gases, U.V. light, and ozone.

Buna-N (BN): For general applications, petroleum base lubricants, hydraulic oils, gasoline, fuels, alcohol, L.P. gases, water

and many other media. Order by request.

Ethylene - Propylene (EP): For hot water, steam, dilute acids,

alcohols, alkalis, ketones, phosphate, and brake fluids. Order

by request.

Silicone (S): Compatible with air, oxygen, ozone, and others.

For high temperature applications. Order by request.

Neoprene (C): For refrigeration gases (Freon

chlorine, ozone, sunlight exposure. F.D.A. approved for food

and beverages, odorless, tasteless and non toxic. Order by

request.

See literature sheet PN 65308

®

, ammonia), CO2,

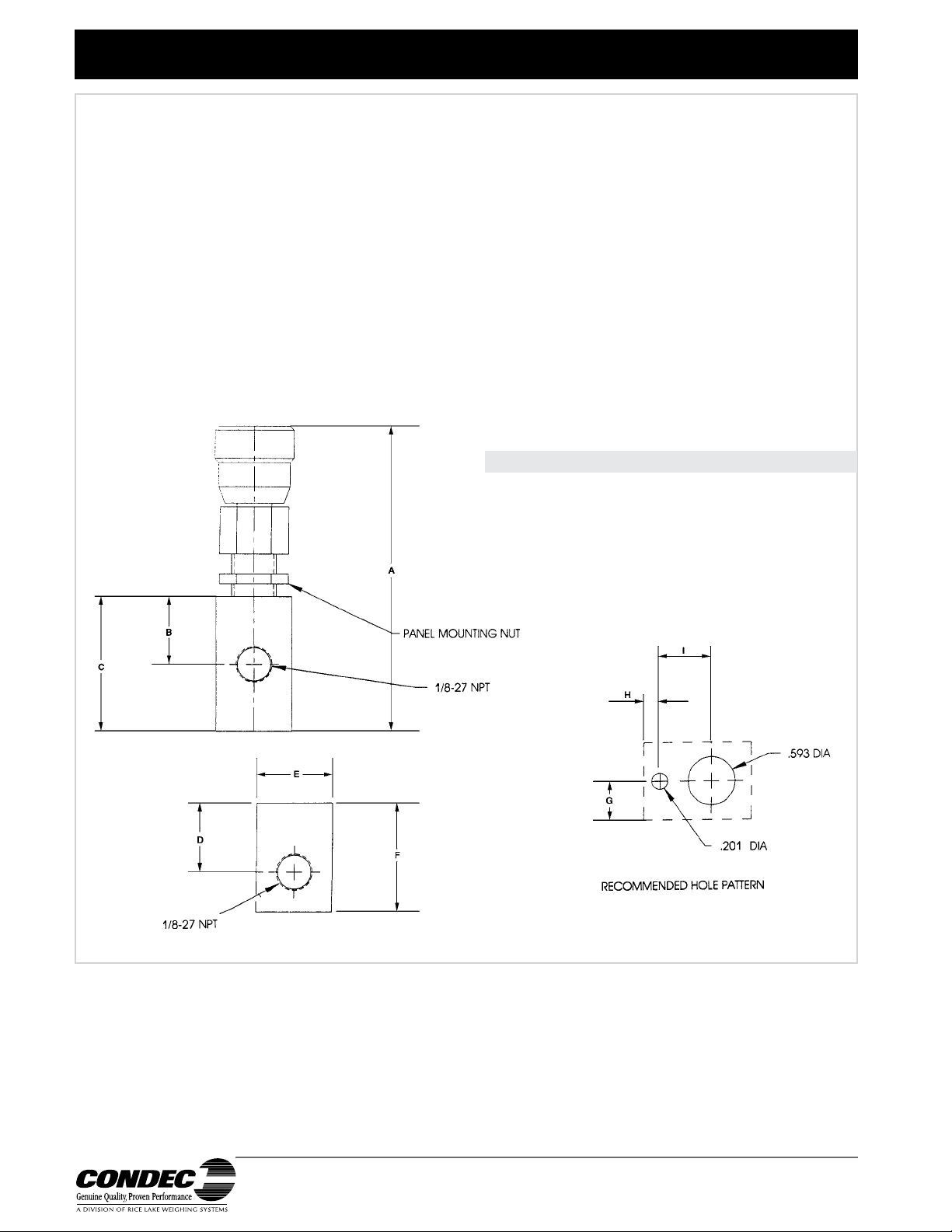

DIMENSIONS

A = 3.80 in. (96.52 mm) F = 1.35 in. (34.29 mm)

B = 0.853 in. (21.66 mm) G = 0.48 in. (12.19 mm)

C = 1.70 in. (43.18 mm) H = 0.20 in. (5.08 mm)

D = 0.85 in. (21.59 mm) I = 0.65 in. (16.51 mm)

E = 0.95 in. (24.13 mm)

Specifications subject to change without notice

© Condec 2012 Catalog PN 64749 1/12

Loading...

Loading...