Condec MPV-10K User Manual

MPV-10K Micro-Metering Precision Valve

Patent No. 4.698.998

Part #57168: MPV-10K with Fluorocarbon “Viton” (standard)

Part #54803: MPV-10K with Nitrile Buna-N O-ring

Part #54906: MPV-10K with Ethylene-propylene

Part #57161: MPV-10K with Silicone

Part #57122: MPV-10K with Neoprene

SPECIAL FEATURES:

• MPV-10K features all stainless steel construction for use with corrosive gases and on

operating pressure from vacuum to 10,000 psi. It consists of one low torque, fine micrometering valve with positive shut-off, adjustable stop and soft seat. The valve allows the

operator a very fine fingertip pressure adjustment.

• Selecting the appropriate O-ring material may extend the wide range of gas applications.

OPERATION:

The pressure valve will begin to open when it is turned counter clockwise approximately

15 degrees. Full open position of the valves is achieved with a maximum of 3 1/2 turns

from the closed position. The valve has a fine adjustment sensitivity of .0005 psi. Very low

torque is required to turn the vernier... FINGERTIP ADJUSTMENT!!!!!

Micro-Metering Precision Valve

SPECIFICATIONS:

• Pressure Range: 0-10,000 psi and vacuum

• Proof Pressure: 15000 psi

• Orifice: .032

• CV: .007

• Mechanical Rotation: 10 turns (nom.)

• Torque: Fingertip adjust

• Volume: 1/2 cubic inch (Nom.)

• Adjustable sensitivity: .0005 psi

• Construction: 303 stainless steel body, black anodized aluminum knob. All other parts 304 series stainless,

O-rings fluorocarbon “Viton” STD, others available.

• Weight: 3.0 lbs.

• O-ring repair kits: Buna-N (part #58499); Ethylene-Propylene (part #58506);

Silicone (part #58509); Neoprene (part #58515); Fluorocarbon “Viton” (standard) (part #55277).

Note: Various O-ring materials may be installed in MPV-10K by special order, but may not be

rated for 10,000 psi

Toll Free: 888-295-8475 • International: 715-234-9171 • FAX: 715-234-6967

MPV-10K

© CONDEC 2001 • All rights reserved • Printed in the United States of America • Specifications subject to change without notice

WEB SITE: www.4condec.com

March 2001

67742

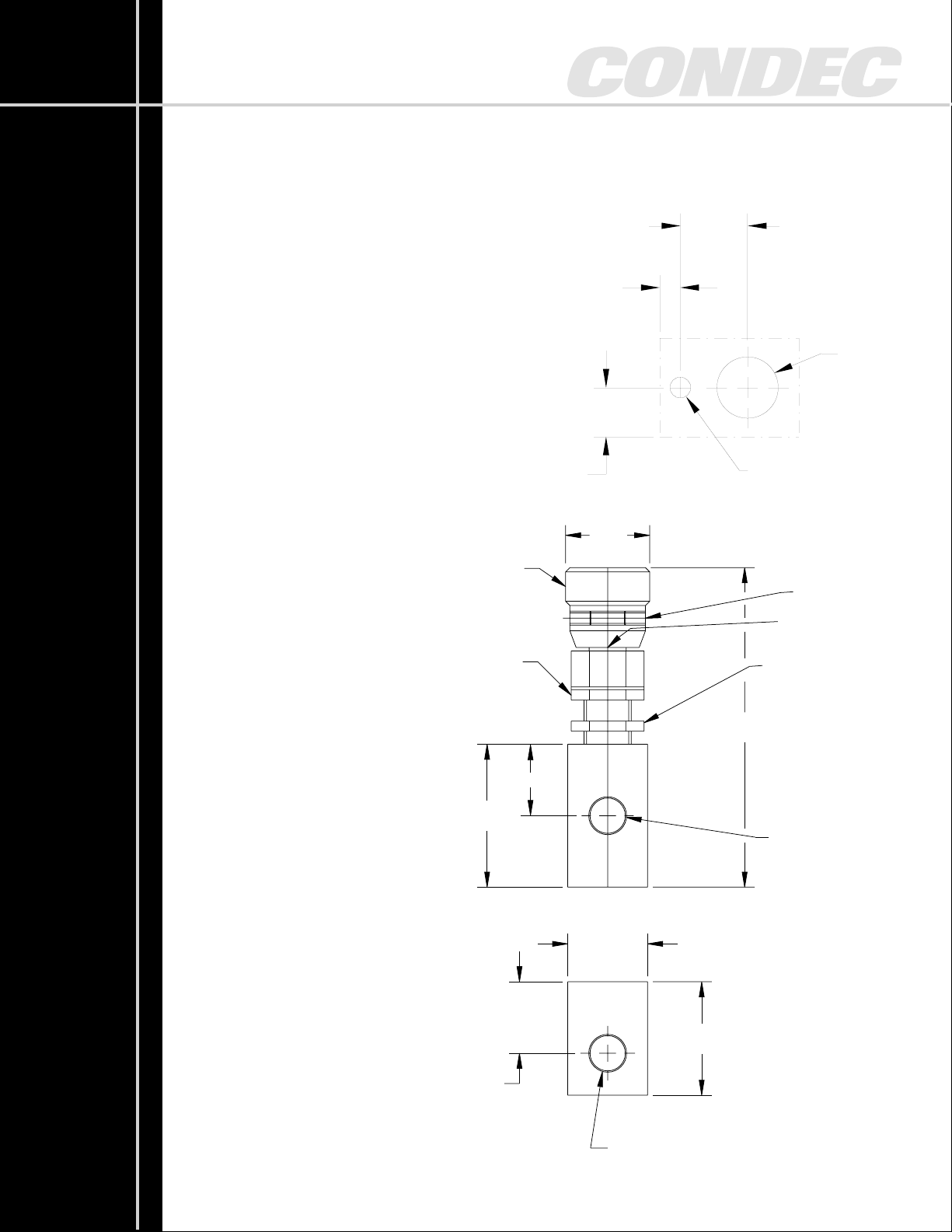

MPV-10K Micro-Metering Precision Valve

RECOMMENDED HOLE PATTERN

.48

.

20

.201 DIA

.650

.593 DIA

Patent No. 4.698.998

INSTALLATION:

The fine micro-metering valve is factory adjusted.

Panel or bracket mounting:

1. Turn the knob counter clockwise, remove

knob and stop washer.

2. Loosen #4 set screw, remove locknut

and panel mounting nut.

3. Install controller into recommended

hole pattern with two 8-32 x 3/8" lg. screw.

4. Install panel mounting nut, locknut

(all the way to the end), stop washer

and knob. Two dimples on valve stem

must line up with the two set screws

in knob.

Adjusting the stop:

Apply pressure to the valve

and turn knob clockwise

until flow of pressure stops

(make sure there is no leak

on down stream side), then

back up locknut all the

way to the knob and

lock it with #4 set screws.

KNOB

LOCKNUT

1.00

SETSCREW #6 (2)

STOP WASHER

PANEL MOUNTING NUT

3.80

.853

1.70

1/8-27 NPT

.95

1.35

© CONDEC 2001 • All rights reserved • Printed in the United States of America • Specifications subject to change without notice

.850

March 2001

1/8 -27 NPT

67742

Page 2

Loading...

Loading...