Page 1

DM240XR

IMPORTANT NOTE: The information contained in this document supersedes all previously

published information regarding this product. This m anual is sub ject to c hange without prior no tice.

High-Speed Digital Modulator

Installation and Operation Manual

Part Number MN-DM240XR Revision 12

Page 2

Page 3

DM240XR

High-Speed Digital Modulator

Installation and Operation Manual

Part Number MN-DM240XR

Revision 12

Copyright © 2011 Comtech EF Data. All rights reserved. Printed in the US A.

Comtech EF Data, 2114 West 7th Street, Tempe, Arizona 85281 USA, 480.333.2200, FA X: 480.333.2161

Page 4

Page 5

Subject:

R

Errata A

Comtech EF Data Documentation Update

DM240X

High-Speed Digital Modulator

Installation and Operation Manual

Part Number MN-DM240XR

Appendix D: Update AutoEQ PIIC Interface Theory of Operation

Revision 12

Date:

Original Manual Part

Number/Rev:

Errata Number/

PLM Document ID:

PLM CO Number:

Comments:

Per PLM System

MN-DM240XR Rev 12

ER-MNDM240X.EA12

CO C-0022022

Replace Appendix D with these pages.

This information will be incorporated into the next revision of the

manual.

ER-MNDM240X.EA12 THIS DOCUMENT IS NOT SUBJECT TO REVISION/UPDATE

Page 6

Errata Page 2 of 2

This page is intentionally blank.

ER-MNDM240X.EA12 THIS DOCUMENT IS NOT SUBJECT TO REVISION/UPDATE

Page 7

Appendix D. AutoEQ™ Interface

D.1 Introduction

Appendix C outlines the operation and configuration of the AutoEQ™ PIIC Interface. The

AutoEQ™ Interface is used in conjunction with the DM240XR.

D.2 Applicable Documents

The following documents can be used for reference in aligning and troubleshooting the AutoEQ

system. Insure that the document revision is the same as the hardware revision of the assembly.

• AN208: DM240XR Firmware Upgrade Procedure

Operation Guide

MN-DM240XR– Revision 12 D–1

Page 8

DM240XR High-Speed Digital Modulator AutoEQ™ Interface Operation Guide

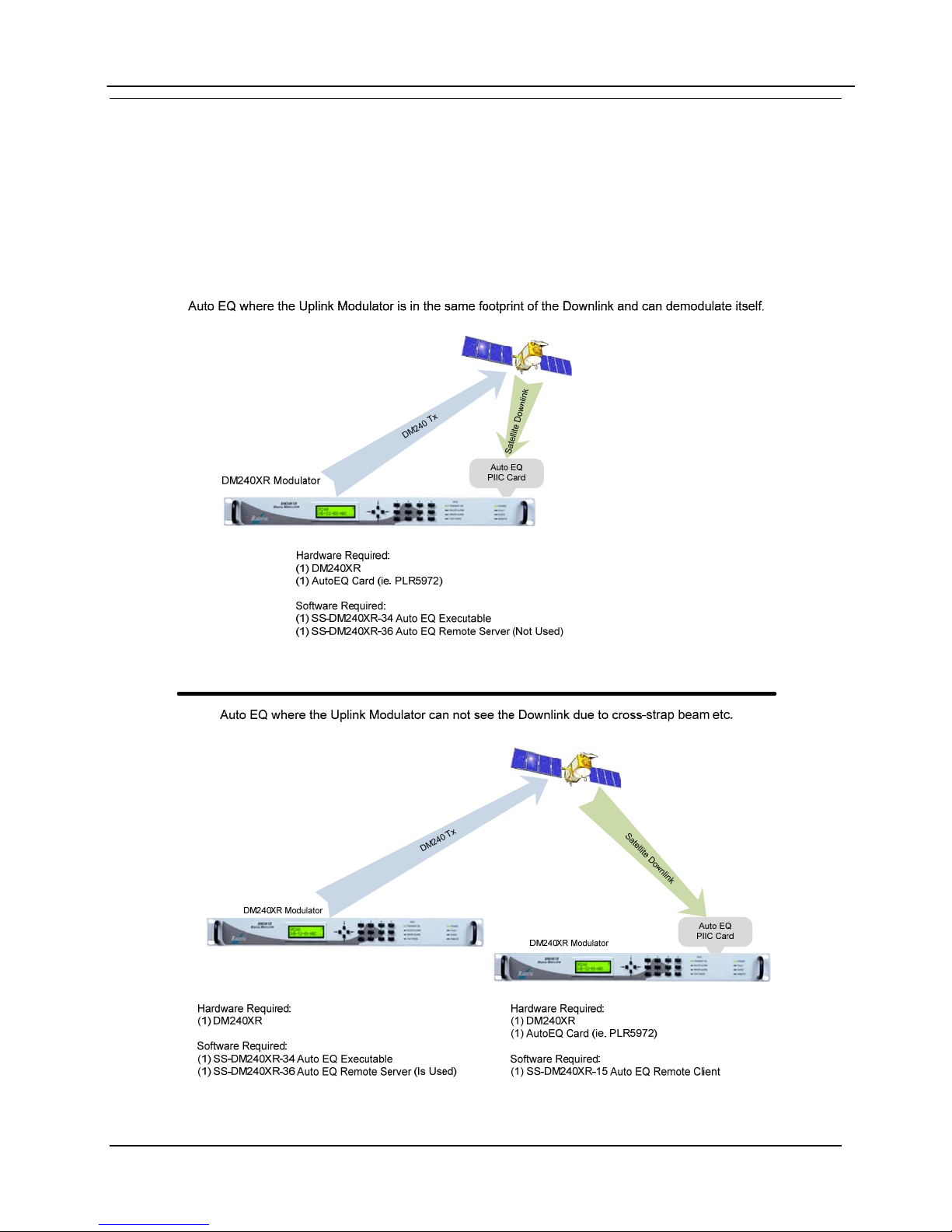

D.3 AutoEQ™ PIIC Interface Theory of Operation

AutoEQ™ PIIC Interface allows the ability to compensate for the overall system Group Delay

and Amplitude Equalization over the satellite by pre-distorting the Uplink Carrier, eliminating the

need for external Group Delay/Amplitude Equalizers. AutoEQ™ will automatically generate the

proprietary profile for the DM240XR to pre-distort the modulator, resulting in Amplitude and

Group Delay equalization over the Satellite Link.

Figure 1. Auto EQ PIIC Card Usage

MN-DM240XR– Revision 12 D–2

Page 9

DM240XR High-Speed Digital Modulator AutoEQ™ Interface Operation Guide

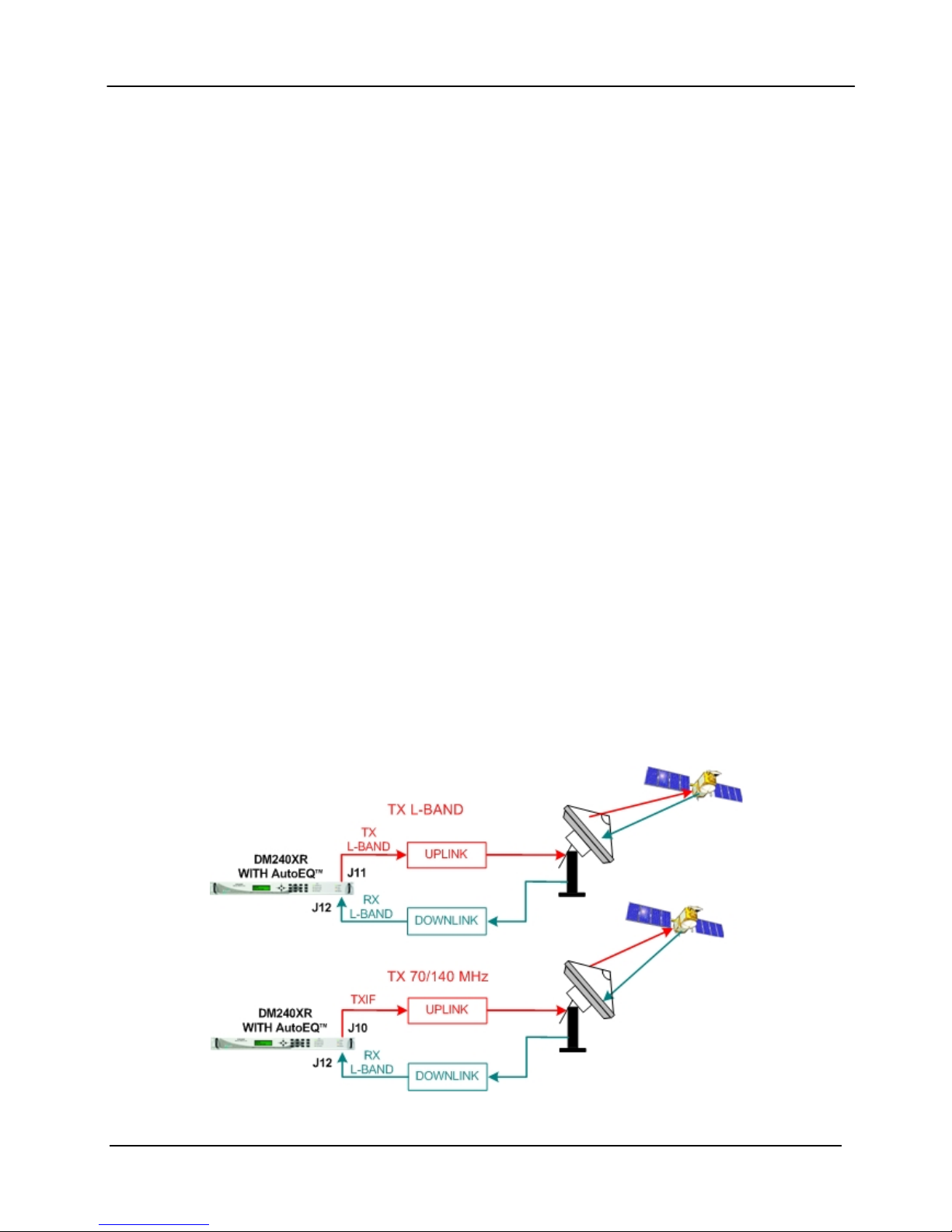

AutoEQ™ supports SCPC equalization of Group Delay and Amplitude over the satellite system.

When installed into the PIIC slot of the DM240XR (with Firmware Revision FO5377-J or

higher), the AutoEQ™ Calibration menu will be displayed allowing for selection and monitoring

of the AutoEQ™ functions. The AutoEQ™ will operate over the full transponder from a symbol

rate of 10.1 Msps to 45 Msps.

Note, the 45 Msps AutoEQ™ requires a different PIIC card (PLR5972) than the original PIIC

card (PLR5808) operating to 38 Msps. The new AutoEQ™ card supersedes and replaces the

original one and both are supported by revision N or later firmware.

When the AutoEQ™ Calibration mode is selected, the DM240XR will disable the existing

programmed modulated outbound signal, and replace it with the AutoEQ™ calibration signal at

the same Symbol Rate, Roll off, and Transmit frequency as programmed into the DM240XR.

This signal is transmitted to the satellite, and received (Satellite Loop-Back) by the DM240XR

AutoEQ™ input at the L-Band downlink frequency. The AutoEQ™ calibration mode will

demodulate the received signal, and automatically calculate the required pre-distortion parameters

for the Satellite Link.

This information is read by the DM240XR modulator where the new pre-distort values are

programmed into the outbound carrier, resulting with the required pre-distortion of the TX output.

Upon successful completion of the calibration cycles, the DM240XR will automatically return to

the programmed outbound signal (such as DVB-S2) with the proper pre-distortion for the satellite

loop per the selected symbol rate, roll off and transponder frequency. If any parameters are

changed affecting Symbol Rate or Roll off, AutoEQ™ must be re-calibrated to the new

parameters. At any time, AutoEQ™ can be enabled or disabled.

The DM240XR is capable of retaining 32 AutoEQ™ satellite loop pre-distortion values, which

can be useful for systems requiring relocation to different transponders or Satellites. Once the

applicable transponder is calibrated, the calibration information can be stored in memory for use

now or in the future. All storage locations can be renamed by the user to correspond with the

identification of the transponder, and recalled for operational use.

Figure 2 AutoEQ™ Satellite Loopback

MN-DM240XR– Revision 12 D–3

Page 10

DM240XR High-Speed Digital Modulator AutoEQ™ Interface Operation Guide

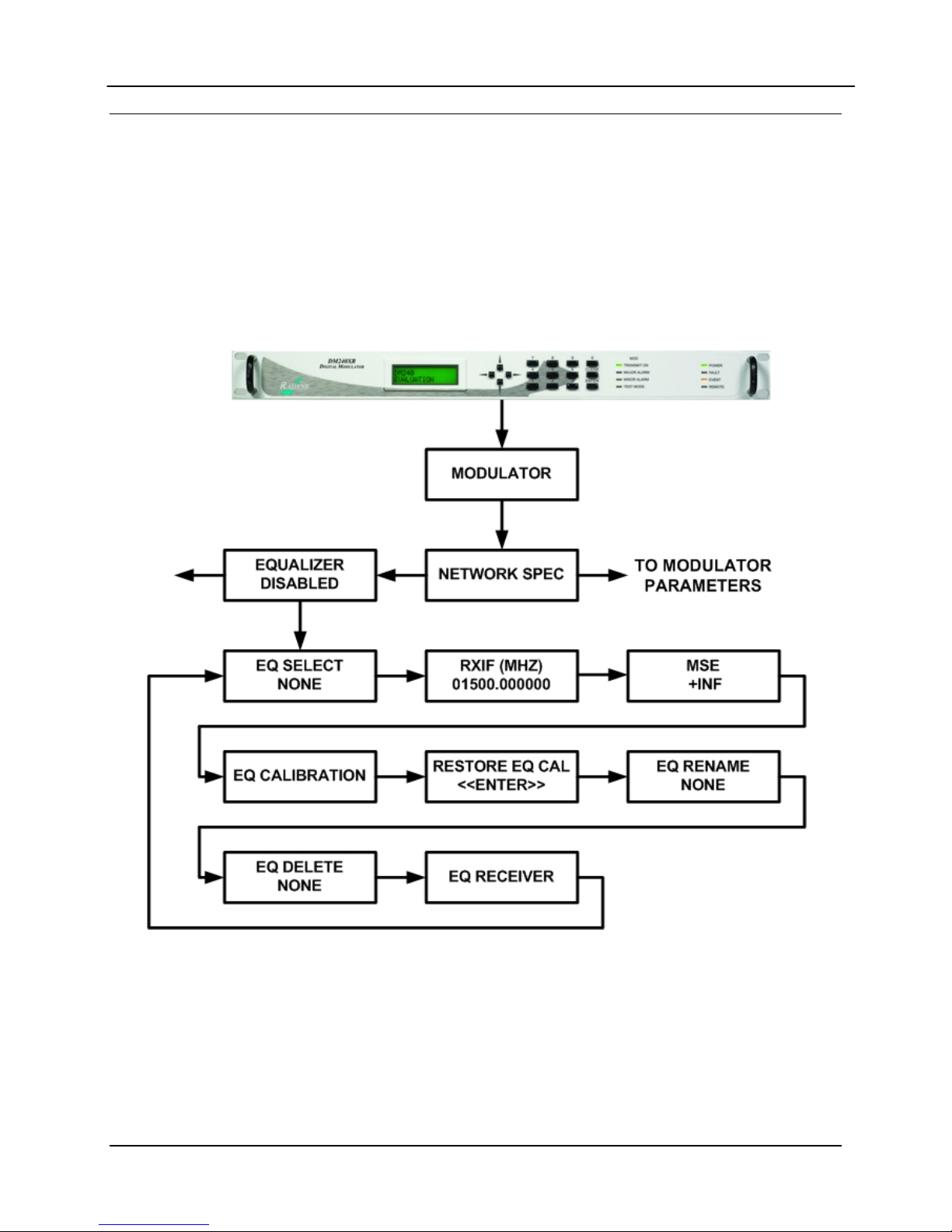

D.4 AutoEQ™ Menu Options and Parameters

These Menu options are only available when the DM240XR is configured for AutoEQ™

operation. Refer to Figure 3 for the AutoEQ™ portion of the DM240XR Menu Tree. The

DM240XR must have software Version FO5377-J or higher to operate the AutoEQ™ PIIC

Interface Card. These Menu options are also available on the Ethernet Web browser (J6), the

RS232 (J1) terminal port, and the Remote Port (J4) of the DM240XR. Refer to the DM240XR

Manual for all Modulator related options and Parameters.

Figure 3 AutoEQ™ Menu Tree

MN-DM240XR– Revision 12 D–4

Page 11

DM240XR High-Speed Digital Modulator AutoEQ™ Interface Operation Guide

EQ ENABLE: {Enable, Disable}

Allows the DM240XR Modulator to implement the AutoEQ™

coefficient values as specified by the EQ Select.

EQ SELECT: {None, User Specified Name}

Allows the DM240XR Modulator to select the stored AutoEQ™

coefficient file to be implemented. Up to 32 User Nameable

storage locations are available.

RXIF: {950 – 2050 MHz}

Sets the receive input center frequency for the AutoEQ™

Interface Card. This programmed frequency must be within +

25

kHz of the actual desired system downlink center frequency to

insure proper acquisition.

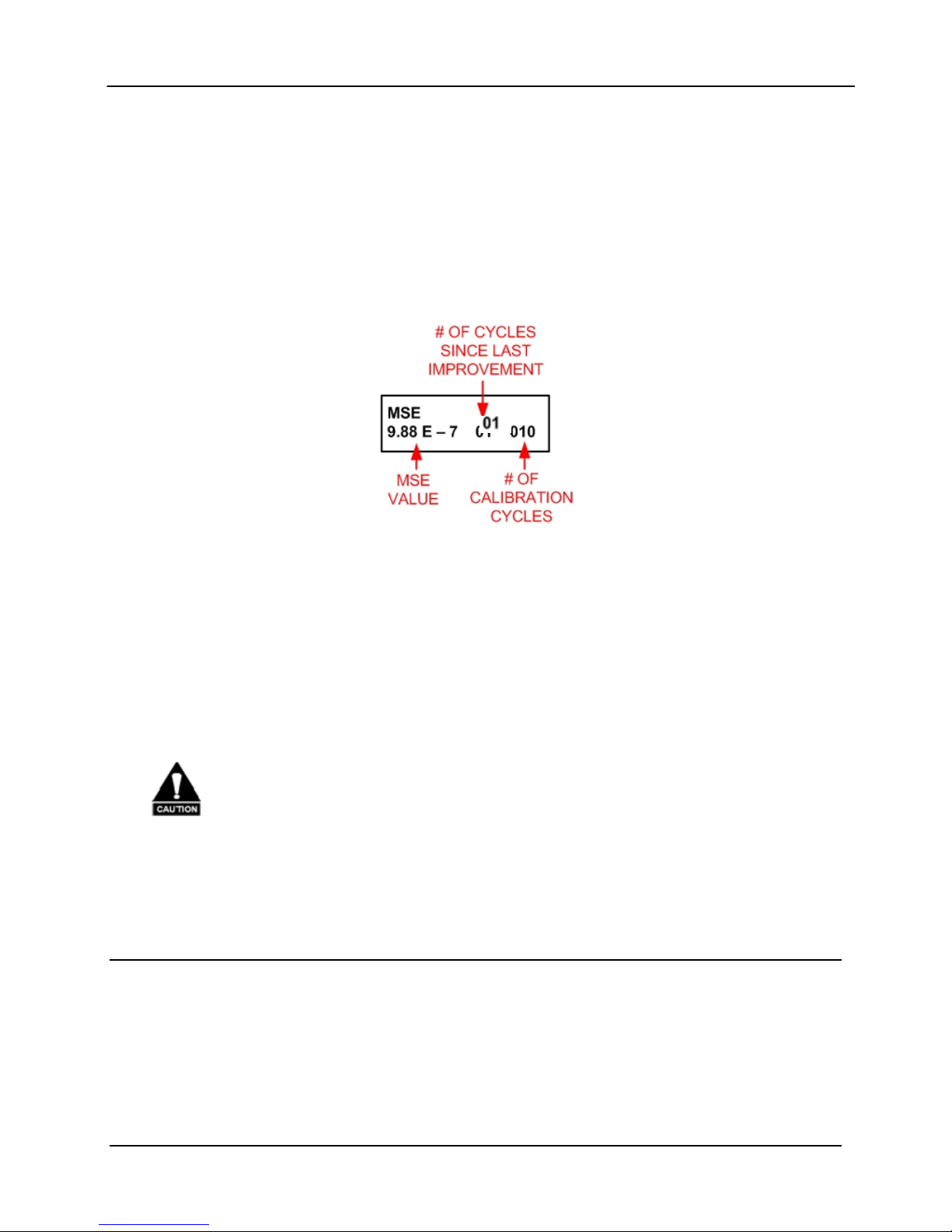

MSE: {Value}

Displays the Mean Squared Error (MSE) value of the equalizer.

A value of 1 E-5 or less indicates a successful calibration run

with acceptable coefficients for operation over the satellite.

EQ CAL: {Normal, Calibrating, Ref ACQ}

Allows the DM240XR Modulator to select the AutoEQ™

interface mode of operation.

Normal: When in this state, the AutoEQ™ is in monitoring

mode, with no Calibration or Reference Acquisition functions

being preformed.

Calibrating: When in this state, the AutoEQ™ will program the

DM240XR modulated output for the AutoEQ™ calibration

signal. The calibration output bandwidth is set by the symbol

rate currently programmed into the DM240XR Modulator.

During calibration, the AutoEQ™ will compute the coefficient

values required to successful equalize the group delay and

amplitude of the satellite link over the programmed symbol rate.

During this process, the MSE can be monitored reflecting the

calibration process. Upon successful completion of the

calibration, the EQ CAL will revert to the “Normal” state, and

the event log of the DM240XR will reflect “AutoEQ™ CAL

SUCCESSFUL”.

MN-DM240XR– Revision 12 D–5

Page 12

DM240XR High-Speed Digital Modulator AutoEQ™ Interface Operation Guide

(EQ CAL: Cont)

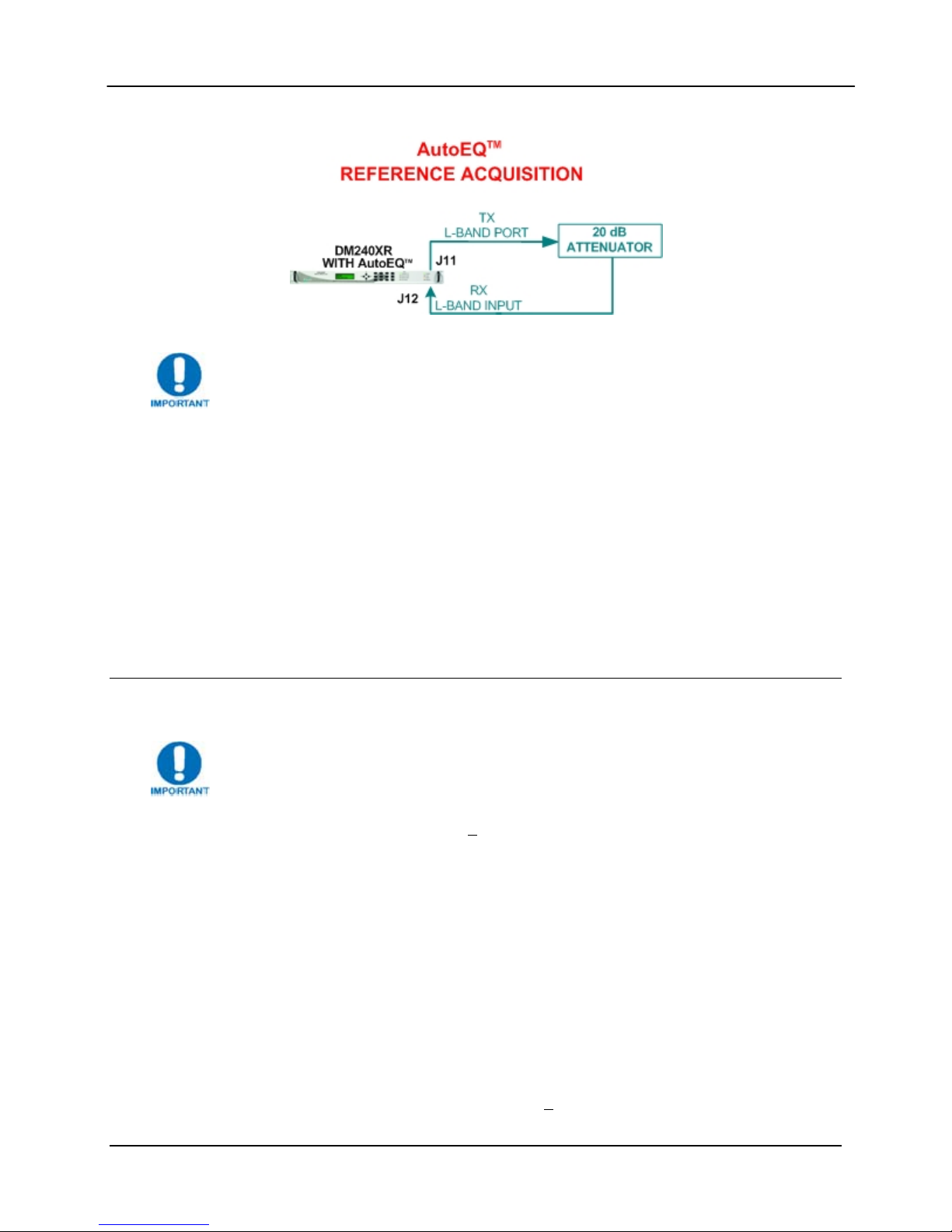

REF ACQ: Although default reference files are provided, the

operator may wish to acquire the best possible reference from

their modulator. A mechanism to accomplish this is allowed by

REF ACQ, this overwrites the stored default and replaces it with

a new reference. Prior to entering this state, the L-Band output

of the DM240XR (J11) must be connected to the AutoEQ™

RXRF Input (J12). The DM240XR Output power should be set

to -20 dBm, and a 20 dB in line attenuator should be used. The

Modulator output frequency should be set to set to the

corresponding AutoEQ™ RXRF Input Frequency. When

properly connected and in this state, the AutoEQ™ will program

the DM240XR modulated output for the AutoEQ™ calibration

signal. The calibration output bandwidth is set by the symbol

rate currently programmed into the DM240XR Modulator.

During reference calibration, the AutoEQ™ will obtain receive

lock and establish the baseline coefficients for internal reference.

References are captured for each modulator roll-off and

oversample rate. During this process, the MSE can be monitored

reflecting the Reference Acquisition process. Upon successful

completion of the Reference Acquisition, the REF ACQ will

revert to the “Normal” state, and the event log of the DM240XR

will reflect “REF ACQ SUCCESSFUL”.

RESTORE EQ CAL: {Filename}

Allows the selected Calibration coefficient file to be Restored.

EQ RENAME: {Filename}

Allows the Calibration coefficient file to be renamed using

Alpha-numeric characters.

EQ DELETE: {Filename}

Allows the selected Calibration coefficient file to be deleted.

EQ RECEIVER: {Local, Remote}

Allows selection of Local or Remote Equalization.

MN-DM240XR– Revision 12 D–6

Page 13

DM240XR High-Speed Digital Modulator AutoEQ™ Interface Operation Guide

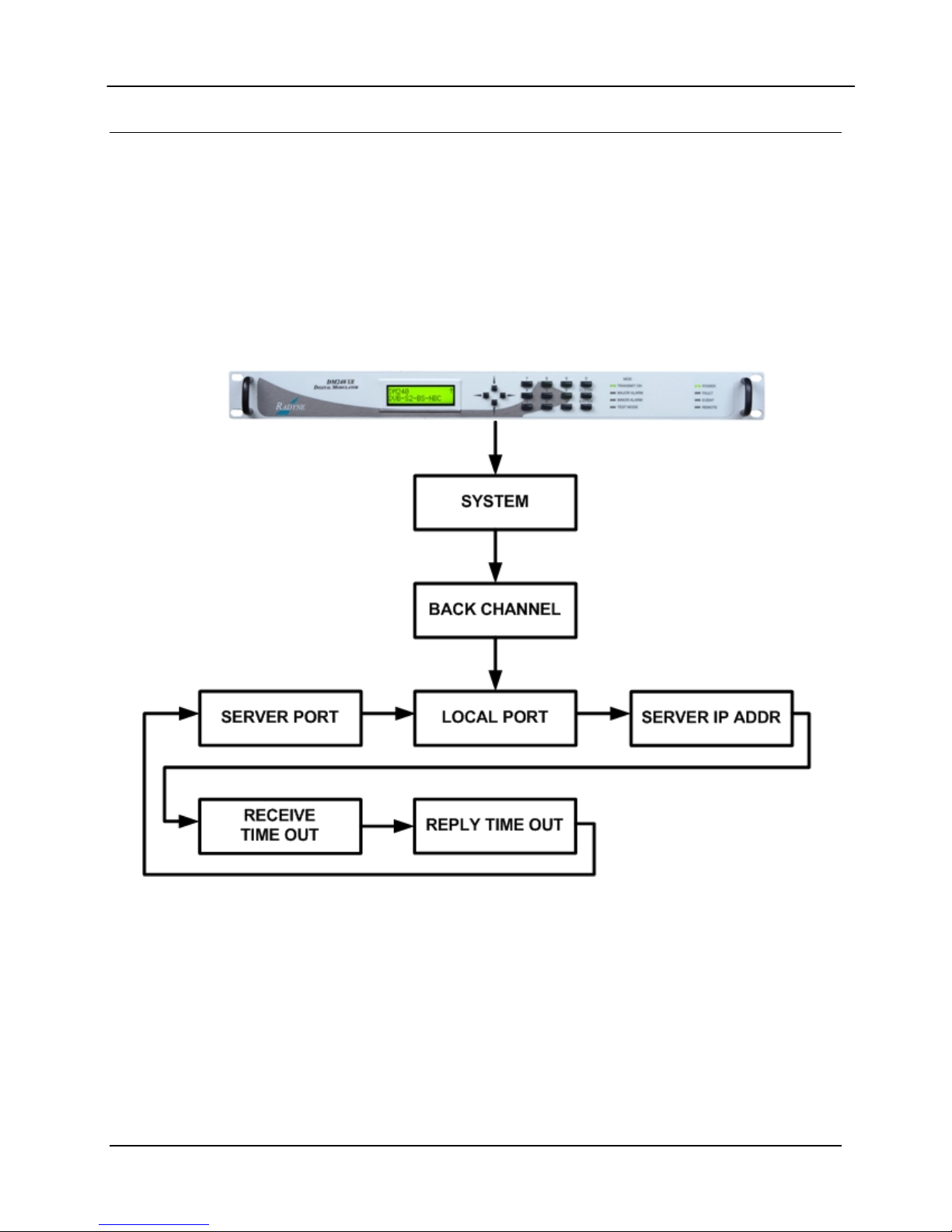

D.5 AutoEQ™ Back Channel Menu Options and Parameters

These Menu options are only available when the DM240XR is configured for AutoEQ™

operation. Refer to Figure 4 for the back channel portion of the DM240XR Menu Tree. The

DM240XR must have software Version FO5377-J or higher to operate the AutoEQ™ PIIC

Interface Card. These Menu options are also available on the Ethernet Web browser (J6), the

RS232 (J1) terminal port, and the Remote Port (J4) of the DM240XR. Refer to the DM240XR

Manual for all Modulator related options and Parameters.

Figure 4. AutoEQ™ Back Channel Menu Tree

MN-DM240XR– Revision 12 D–7

Page 14

DM240XR High-Speed Digital Modulator AutoEQ™ Interface Operation Guide

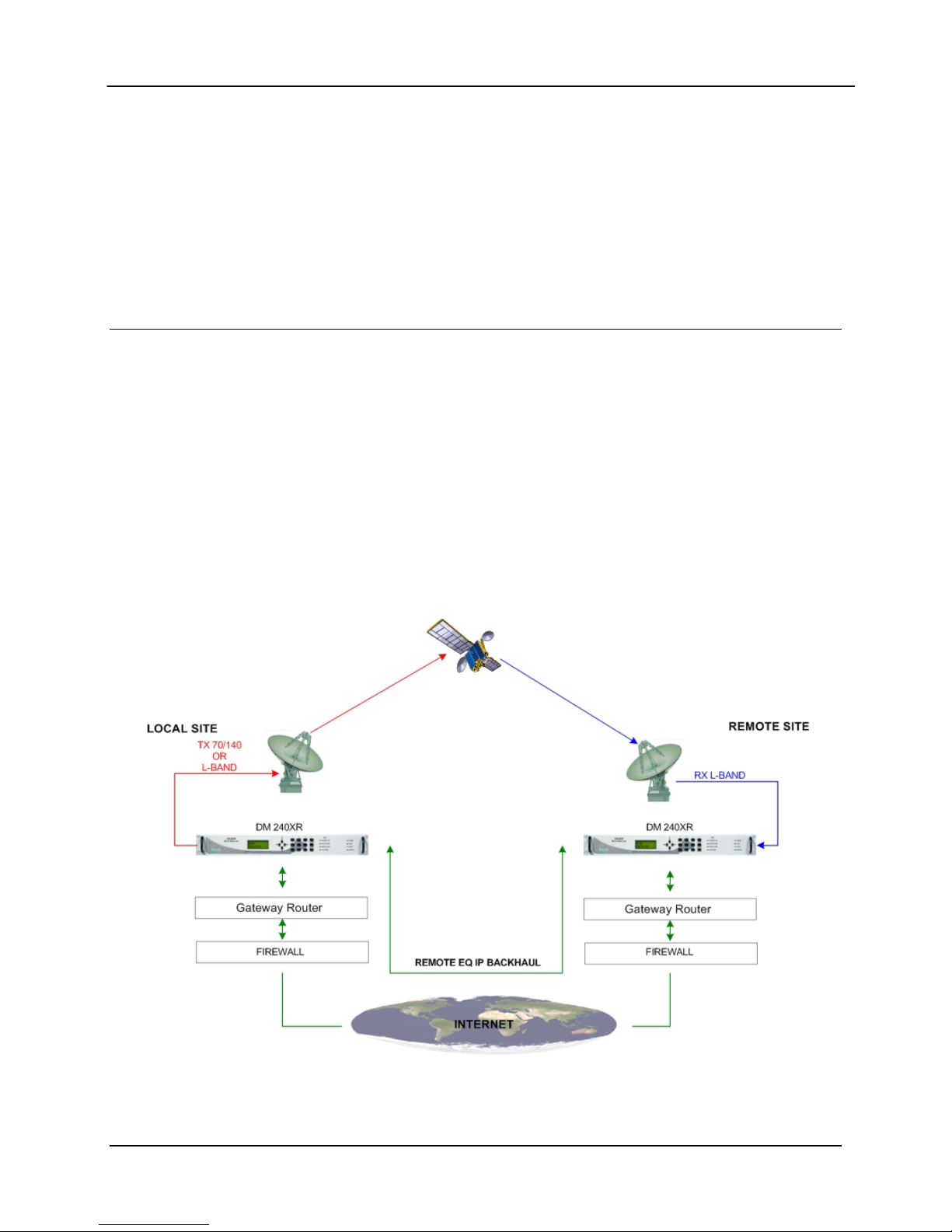

D.6 AutoEQ Backchannel Setup

Introduction

To support remote equalization with the AutoEQ system, the equalization data is

transported over TCP/IP using a backchannel protocol. Before setting up the

backchannel, perform the TCP/IP Ethernet setup as outlined in the TCP/IP Ethernet Setup

section of the user manual. This document is to be used only as a guideline for setting up

the backchannel menus. Contact the Network administrator for proper guidance and

support to ensure setup is successful.

Backchannel Configuration

Using the Front Panel display and arrow keys, scroll thru the System menu until the

Backchannel sub menu is displayed. Both the local unit (the Modulator) and the remote

unit (with the AutoEQ card installed) require the proper configuration with the correct

network settings.

Refer to Figure 4.

Note: The router/gateway/firewall system must be configured to allow these ports to

pass on each communication end. Contact your Network Administrator for allowable

port numbers and to open up the ports on the firewall if necessary.

Enter into the Backchannel menu and the following sub menus will appear, however the

order may vary.

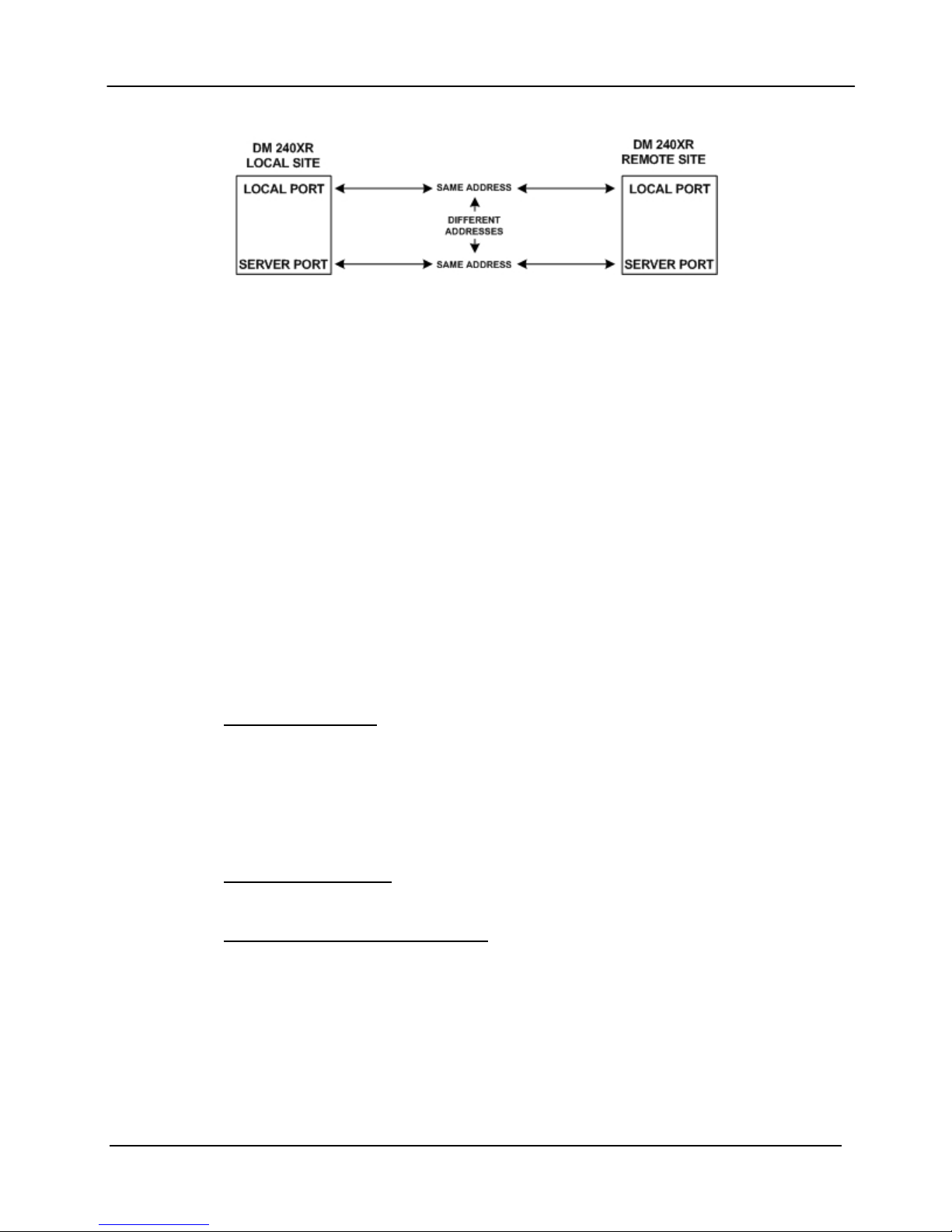

LOCAL PORT: {XXXX}

The local port number must be set to the same value at

both the local and remote sites.

SERVER PORT: {XXXX}

The server port number must be set to the same value at

both the local and remote sites.

Note: The local port and server port values must be different from the local and remote

sites.

SERVER IP ADDR: {XXX.XXX.XXX.XXX} Hexidecimal Address

{ddd.ddd.ddd.ddd} Decimal Address

On the local unit, this should have the value of the

remote unit’s IP address.

Note: If the remote IP address is not publicly accessible then its translated NAT

(Network Address Translation) needs to be applied.

RECEIVE TIMEOUT: {X.X MINUTES}

This value is factory set, and should only be adjusted as directed by your Network

administrator or Radyne Customer Service.

REPLY TIMEOUT: {XX secs}

This value is factory set, and should only be adjusted as directed by your Network

administrator or Radyne Customer Service.

MN-DM240XR– Revision 12 D–8

Page 15

DM240XR High-Speed Digital Modulator AutoEQ™ Interface Operation Guide

Figure 5. AutoEQ™ Backchannel Setup

Back Channel Test

The "BACK CHAN TEST" does the following:

1. Establishes a connection with the back channel server as defined under the

SYSTEM->BACK CHANNEL menu.

2. Issues a ping to the back channel server.

3. Sends a message to and validates the reply from the back channel server application

running on the back channel server.

4. If passes, no additional; events will appear in the event log.

5. If fails, logs one of the following events on the local side event log:

a. "BACK CHANNEL TEST: FAILED PING"

b. "BACK CHANNEL TEST: FAILED BACK CHAN SERVICE REQ"

c. "BACK CHANNEL TEST: REPLY FORMAT ERROR"

d. "BACK CHANNEL TEST: ERROR REPLY"

6. If fails, may log one of the following events on the server side event log:

a. "INVALID CHANNEL TEST SIZE"

b. "INVALID CHANNEL TEST PAYLOAD"

Ethernet Test

Verify Local Router:

On the local unit, using the Front Panel display and arrow keys, scroll thru the Monitor

menu and clear the Event Log.

Now scroll thru the Test menu and Ping Test the TCP/IP ROUTER. If the event LED on

the front panel does not light, communications between the modem and its router was

successful.

Verify Remote Router:

Perform the same test on the remote unit as detailed under Verify Local Router.

Verify Local to Remote Connection:

On the local unit, using the Front Panel display and arrow keys, scroll thru the Monitor

menu and clear the Event Log.

Now scroll thru the Test menu and Ping Test the BK CHAN SERVER. If the event LED

on the front panel does not light, communications between the local modem and the

remote modem was successful.

MN-DM240XR– Revision 12 D–9

Page 16

DM240XR High-Speed Digital Modulator AutoEQ™ Interface Operation Guide

D.7 AutoEQ™ Operation Procedure

The following sequence must be followed in order to perform the initial AutoEQ™ Calibration.

The sequence is identified into three (3) individual sections: 1) Reference Acquisition

Calibration (REF ACQ) - optional, 2) Equalizer Calibration (CALIBRATING), and 3) Equalizer

Modes (NORMAL). These three menu selections are selectable under EQ CAL.

All DM240XR Faults and Alarms must be cleared prior to any AutoEQ™

Calibration process. If Data is not present on the DM240XR Data interface

causing a data Alarm, Advanced ASI may be selected for the AutoEQ™

Calibration (Advanced ASI inserts Null Packets into the Data Stream).

D.8 Reference Acquisition Calibration (Optional Step)

This Section will establish the calibration reference for the AutoEQ™ Interface Card. This

optional step may be preformed prior to Equalizer Calibration. This step is optional as

default reference(s) are already loaded into the system. This operation will replace the

default reference(s) with the actual references measured during the calibration cycle. The

modulator must be programmed for an L-Band frequency and the AutoEQ

Frequency programmed to match.

™

RXIF

1. Install the AutoEQ™ PIIC Interface into one of the available PIIC Slots on the DM240XR.

2. Verify that the DM240XR revision is FO5377-K or greater.

3. Insure that there is a Flash Card installed in the Flash Card slot on the DM240XR.

4. Using the Front Panel menu, set the DM240XR Modulator Data Rate, Modulation type, Roll

off, and remaining Modulator parameters to the required system settings.

5. Using the Front Panel menu, scroll to “RXIF” located under the EQUALIZER menu and set

the AutoEQ “RXIF”.

For best results it is suggested that the RXIF frequency used to acquire the

reference be the actual frequency used to perform the equalization calibration.

6. Using the Front Panel menu, set the DM240XR Transmit Frequency (L-Band) to match the

programmed AutoEQ RXIF Frequency.

7. Using the Front Panel menu, set the DM240XR TX Output Power to -10 dBm.

8. Connect the DM240XR L-BAND Output (J11) through a 20 dB attenuator then to the AutoEQ

Interface RXRF Input (J12) using a suitable L-Band Cable.

MN-DM240XR– Revision 12 D–10

Page 17

DM240XR High-Speed Digital Modulator AutoEQ™ Interface Operation Guide

Figure 6. AutoEQ™ Ref Acq Set-up

For best results place the attenuator pad as close to the AutoEQ port (J12) as

possible.

9. Clear the events of the modulator by scrolling to <MONITOR> then down and over to <PRESS

CLEAR TO ERASE EVENTS> and press clear. Verify that the Event LED is now off.

10. Using the Front Panel menu, scroll to “EQ CALIBRATION” and set to “REF ACQ”

a. After a successful calibration the event log will display “REF ACQ SUCCESSFUL” upon

completion of this step. When the REF ACQ is complete, the “EQ CALIBRATION” will

revert to “NORMAL”.

11. Remove the interconnect cable installed in Step 8 above.

12. Verify through the event log that the system successfully calibrated the reference.

D.9 Equalizer Calibration

For best AutoEQ equalization calibration it is recommended that the amplifier be

run in its linear range and not saturated.

The AutoEQ™ RXRF Acquisition range is +

programmable. To insure proper operation, the actual center frequency of the carrier should be

accurately measured with this measured value programmed into the AutoEQ™. This can be

accomplished by generation a CW (Carrier Wave) frequency with the modulator, and measuring

the downlink L-Band frequency with an accurate frequency counter or spectrum analyzer.

1. Reprogram the DM240XR Modulator output frequency to the proper operating frequency of

the Uplink system (if it was reprogrammed for Section 4.1 above) and the output power to the

system operating level. Connect the DM240XR Modulator output to the Uplink system.

Enable the modulator and adjust all uplink parameters as required for proper uplink

operation.

25 kHz from the programmed frequency and is not

2. Measure the center frequency of the down converted modulated signal. Using the front panel

Menu, reprogram the AutoEQ™ to the center frequency of the down converted signal. The

AutoEQ™ programmed frequency must be within +

MN-DM240XR– Revision 12 D–11

25 kHz of the measured frequency in

Page 18

DM240XR High-Speed Digital Modulator AutoEQ™ Interface Operation Guide

order to assure proper acquisition of the downlink signal. Connect the AutoEQ™ Input (J12)

to the earth Station L-Band Downlink System. The desired downlink carrier should be

typically between the range of -45 to -20 dBm.

3. Clear the events of the modulator by scrolling to <MONITOR> then down and over to

<PRESS CLEAR TO ERASE EVENTS> and press clear. Verify that the Event LED is now

off.

4. Using the Front Panel menu, scroll to “EQ CAL” and set it to “CALIBRATING”. This will

start the AutoEQ™ Calibration for the Satellite Link.

a. After each data acquisition and processing cycle the MSE display will be updated. A normal

calibration cycle will take 60 to 90 seconds, and system typically performs two or three of

these cycles.

b. During this calibration, the MSE can be monitored showing the progress of the cycle. A

value of 1 E-5 or less will reflect a success full completion of this step. Additionally, event

light will come on, and the event log will display “EQ CAL SUCCESSFUL” upon

completion of this step. When the EQ CAL is complete, the “EQ CAL” will revert to

“NORMAL” and the AutoEQ file will be named “UNTITLED”.

The AutoEQ calibration must be saved or powering down of the system will lose

the calibration.

5. To change the name of the “UNTITLED” file, using the Front Panel menu, scroll to EQ

RENAME, Press ENTER, use the Up/DN Arrows on the Keyboard to change the name, and press

ENTER to save the new name for the file.

6. Using the Front Panel menu, scroll to “SAVE EQ CAL”, and press ENTER to save the file.

D.10 Equalizer Modes

The AutoEQ feature must be enabled on the DM240XR, and section 4.2 Equalizer Calibration

must be performed prior to this section.

Disable Mode

MN-DM240XR– Revision 12 D–12

Page 19

DM240XR High-Speed Digital Modulator AutoEQ™ Interface Operation Guide

To disable a programmed Equalizer Setting, use the Front Panel and scroll to “EQUALIZER”,

press the Enter” key, change the selection to “DISABLE”, and press the Enter key. This will

disable the Equalizer, and allow for normal operation of the DM240XR.

Enable Mode

To enable the equalizer, use the front panel and scroll to “EQ SELECT” and press the Enter key.

Using the Up/Dn keys, scroll to the desired saved equalizer file, and press the Enter key to select

the file. Scroll back to Equalizer, press the Enter key, and using the Up/Dn keys, scroll to

“ENABLE” and press the Enter key. This will enter the selected equalizer file parameters into

the DM240XR Modulator and initiate AutoEQ™ equalization.

D.11 AutoEQ™ Remote Operation

To operate the AutoEQ™ system in remote, perform the following setup steps.

1. The TCP/IP Ethernet Setup described in the operator manual

2. The Backchannel Setup as described in Section 4.0

3. Select REMOTE under the EQ RECEIVER Submenu

4. Perform the Operations as described in Section 5.0 for equalization

Figure 7. Remote AutoEQ™ Site Equalization

MN-DM240XR– Revision 12 D–13

Page 20

DM240XR High-Speed Digital Modulator AutoEQ™ Interface Operation Guide

D.12 Additional Features

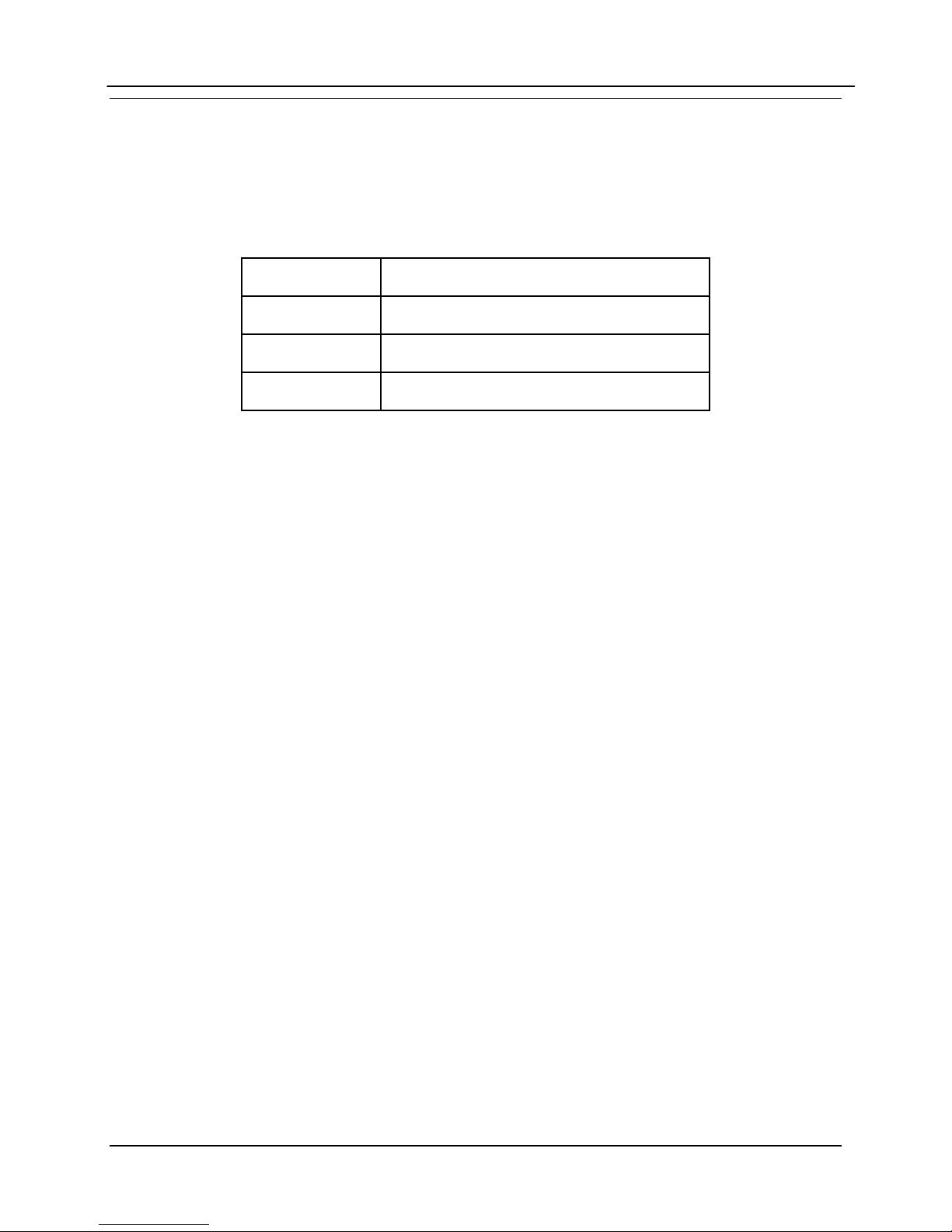

D.12.1 AutoEQ™ Status Indicator

The LED on the back of the AutoEQ™ interface card can provide additional status for the

operation of the AutoEQ™ system.

Short Blink Green Heartbeat, board ready for operation.

Solid Green AutoEQ™ test pattern lock.

Solid Yellow AutoEQ™ data being accessed.

Blink Red AutoEQ™ test pattern unlocked. Signal error.

D.12.2 LNB Power Connector

On the back of the AutoEQ™ interface card is the connector J13 that can be used to insert LNB

power to the J12 SMA connector to feed DC to the LNB.

Mating Connector: PP3-002A 5.5mm x 2.1mm x 9.5mm In-Line DC Power Plug.

(www.cui.com)

MN-DM240XR– Revision 12 D–14

Page 21

ER-DM240XR-EB12 THIS DOCUMENT IS NOT SUBJECT TO REVISION/UPDATE! PLM CO C-0023872 Page 1 of 2

Errata B

Comtech EF Data Documentation Update

Subject:

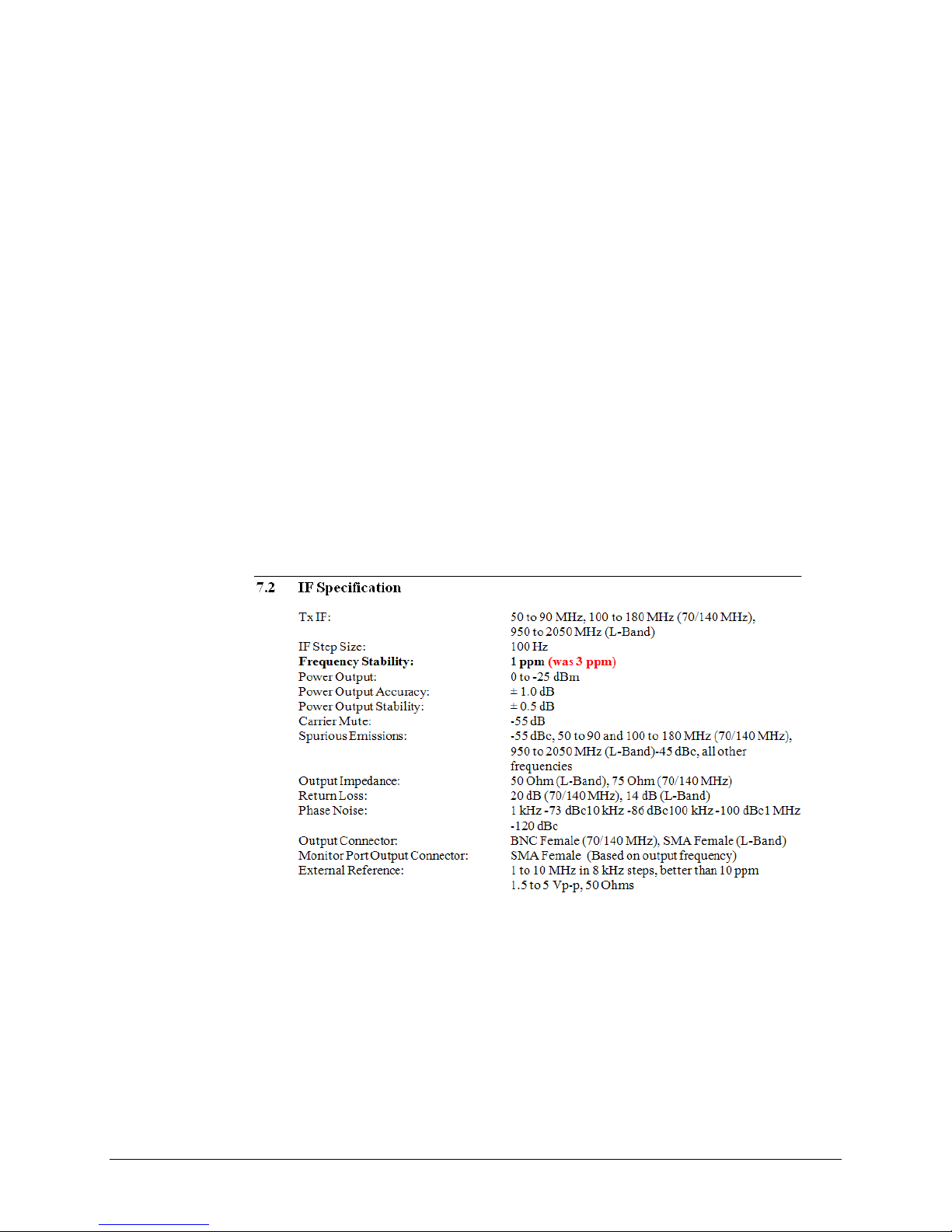

Revise Chapter 7. Technical Specifications – Update DM240XR IF Frequency

Specification

Date :

Per PLM System

Original Manual

Part Number/Rev:

MN-DM240XR Rev 12

Errata Number/

PLM Document

ID:

ER-DM240XR-EB12

PLM CO Number:

C-0023872

Comments:

The information provided in this erratum will be incorporated into the next

formal revision of the manual.

Revise Sect. 7.2 IF Specification / Frequency Stability (page 7-1):

Page 22

Errata C for MN-DM240XR Rev 12

/

p

Errata C

Comtech EF Data Documentation Update

Subject:

Revise Chapter 9. Rem ote Operations – Add Auto EQ data

Date :

Original Manual

Part Number/Rev:

Errata Number

PLM Document

PL M CO Number:

Comments: The informat ion

Per PLM System

MN-DM240XR Rev 12

ER-DM240XR-EC12

ID:

C-0024011

formal revision of the manual.

See attached pages for Chapter 9.

rovided in this erratum will be inc or por ated into the next

ER-DM240XR-EC12

Page 23

Errata C for MN-DM240XR Rev 12

Blank Page

ER-DM240XR-EC12

Page 24

DM240XR High-Speed Digital Modulator Remote Operations

e

m

d

Source

<1> Reserved TBD, Default = 0

<11> Reserved TBD

<1> Reserved TBD

<1> Major Alarm

Mask

Bit 0 = Spar

Bit 1 = Transmit Oversample PLL Lock

Bit 2 = FPGA Config Error

Bit 3 = IF Synthesizer PLL Lock

Bit 4 = External Reference PLL Lock

Bit 5 = Composite (SCT) PLL Lock

Bit 6 = Symbol PLL Lock

Bit 7 = Spare

0 = Mask, 1 = Allow

<1> Minor Alarm

Mask

Bit 0 = Terrestrial Ethernet data activity detect

Bit 1 = Loss Terrestrial Clock

Bit 2 = Loss Terrestrial Data

Bit 3 = FIFO Error

Bit 4 = Output Level

Bit 5 = Terrestrial Framing Error

Bit 6 = Terr Ethernet jitter buffer underflow

Bit 7 = Terr Ethernet jitter buffer overflow

0 = Mask, 1 = Allow

<1> Common Fault

Mask

Bit 0 = -12 V Alar

Bit 1 = +12 V Alarm

Bit 2 = +5 V Alarm

Bit 3 = Spare

Bit 4 = Spare

Bit 5 = Spare

Bit 6 = Spare

Bit 7 = Spare

0 = Mask, 1 = Allow

<1> Reserved TBD, Default = 0

<4> Symbol Rate Symbol Rate in Symbols Per Secon

<1> Terrestrial

Framing

<1> Roll Off 0 = 0.35, 25 = 0.25, 1 = 0.20

<1> Reserved TBD

<1> Output Clock

Source

<1> Network Spec 0 = DVB-S

MN-DM240XR– Revision 12 9–5

0 = 188 Byte, 1 = 204 Byte, 2 = No Framing

5 = COP3, 6 = ACM, 7 = Bridge

TE, 1 = SCT, 2 = None

9 = DirecTV

11 = DVB-S2 CCM

13 = Only DirecTV

15 = DVB-S2 ACM

Page 25

DM240XR High-Speed Digital Modulator Remote Operations

–

n

n

n

<1> BB Scrambler

0 = Normal, 1 = Bypass

Bypass

<1> Outer FEC

0 = Normal, 1 = Bypass

Bypass

<1> Test Pattern 0 = None, 1 = 2

<1> Last Rate

0 = Symbol Rate, 1 = Data Rate, 2 = Auto

Control

<1> Interleaver

0 = Bypass, 1 = Normal

Bypass

<1> PCR

0 = Off, 1= O

Restamping

<1> Multi-PIIC

Mode

1 = Manual,

2 = Redundancy

<1> Redundancy

Mode

0 = Force Prime,

1 = Force Backup,

2 = Manual Revert,

3 = Auto-Revert

<1> Prime PIIC Slot 1 – 3

15

1, 23 = 223-1

<1> Backup PIIC

1 – 3

Slot

<1> Pilot Symbols 0 = Off, 1= O

<1> Inner FEC

0 = Normal, 1 = Bypass

Bypass

<1> PL Scrambler

0 = Normal, 1 = Bypass

Bypass

<1> Reserved Set to 0

<1> Reserved Set to 1

<2> Reserved Set to 0

<4> Gold Code Seq

0 to 262142

Index

<1> Sat Framing 3=DVB-S, 5=DTV, 10=DVB-S2 Normal, 15=DVB-S2 Short

<1> Auto EQ

0=Off, 1=O

Enable

<9> Auto EQ Filter

Coef Name

8-character NULL terminated string, this is the filter’s name

as shown on the front panel (identical to the filter’s base

fil e name, th e ex tension is ass umed to be “ AE Q”)

<1> Reserved

<1> Reserved

MN-DM240XR– Revision 12 9–6

Status Bytes

Page 26

DM240XR High-Speed Digital Modulator Remote Operations

n

n

E

E

E

<1> Redundancy

Mode

0 = Force Prime,

1 = Force Backup,

2 = Manual Revert,

3 = Auto-Revert

<1> Prime PIIC Slot 1 – 3

<1> Backup PIIC

1 – 3

Slot

<1> P ilot Symbols 0 = Off, 1= O

<1> Inner FEC

0 = Normal, 1 = Bypass

Bypass

<1> PL Scrambler

0 = Normal, 1 = Bypass

Bypass

<1> Reserved Set to 0

<1> Reserved Set to 1

<2> Reserved Set to 0

<4> Gold Code Seq

0 to 262142

Index

<1> Sat Framing 3=DVB-S, 5=DTV, 10=DVB-S2 Normal, 15=DVB-S2 Short

<1> Auto EQ

0=Off, 1=O

Enable

<9> Auto EQ Filter

Coef Name

8-character NULL terminated string, this is the filter’s name

as shown on the front panel (identical to the filter’s base

fil e name, th e ex tension is ass umed to be “ AE Q”)

DM240XR Clock Source Selection Matrix

Interface T ype InClk Source OutClk Source

RS-422 Serial SCT or SCT

SCT Only

G.703 (E3, T3, STS-1) SCT E Only SCT , SCTE, or None

HSSI SCT or SCT

SCT Only

OC3 SCTE Only None

STM-1 SCTE Only None

ASI, Advanced ASI SCTE Only None

M2P Parallel SCT or SCT

SCT Only

DVB Parallel SCTE Only SCT Only

MN-DM240XR– Revision 12 9–19

Page 27

DM240XR High-Speed Digital Modulator Remote Operations

When changing Data Rate, Symbol Rate, Inner FEC Rate, Modulation Type,

or Terrestrial Framing using the Mod All Command, the Data Rate and

Symbol R ate p aramet er must be ra nge checked us ing the fo llo wi ng formu la s

to ensur e t hey d o no t exceed t he max l i mi t s :

Symbol Rate = (Data Rate * Over head)/(Code Rate * Modulation)

Data Rate = (Symbol Rate * Code Rate * Mod ulat ion)/Overhead

Maximum Symbol Rate 68 Msps.

Maximum Data Rate 238 Mbps with high-speed interface card.

Overhead 204/188 for 188 byte

204/204 for 204 byte

204/187 for none

Modulation QPSK = 2, 16QAM = 4, BPSK = 1, 8PSK = 3

Code Rate 1/4, 1/3, 2/5, 3/5, 1/2, 2/3, 3/4, 5/6, 6/7, 7/8, 8/9, 9/10

MN-DM240XR– Revision 12 9–20

Page 28

Errata B for M N-DM240XR Rev 12 Rev ise DM24 0XR IF Frequen cy S tabi lity Spe cifi cati on

ER-DM240XR-EB12 THIS DOCUMENT IS NOT SUBJECT TO REVISION/UPDATE! PLM CO C-0023872 Page 2 of 2

This page is intentionally blank.

Page 29

Table of Contents

TABLE OF CONTENTS .............................................................................................................. III

CHAPTER 1. INTRODUCTION ................................................................................... 1–1

1.1 Description ................................................................................................................................... 1–1

CHAPTER 2. INSTALLATION .................................................................................... 2–1

2.1 Installation Requirements .......................................................................................................... 2–1

2.2 Unpacking .................................................................................................................................... 2–2

2.3 Removal and Assembly ............................................................................................................... 2–2

2.4 Mounting Considerations ........................................................................................................... 2–2

2.5 Modulator Checkout ................................................................................................................... 2–3

2.5.1 Initial Power-Up .................................................................................................................... 2–3

CHAPTER 3. THEORY OF OPERATION ................................................................... 3–1

3.1 Theory of Operation ................................................................................................................... 3–1

3.2 DVB-S Operation ........................................................................................................................ 3–1

3.3 DVB-S2-BS-NBC Operation ...................................................................................................... 3–2

CHAPTER 4. USER INTERFACES ............................................................................. 4–1

4.1 User Interfaces ............................................................................................................................ 4–1

4.2 Front Panel User Interface ......................................................................................................... 4–1

4.2.1 Front Panel LCD Display ...................................................................................................... 4–2

4.2.2 Front Panel LED Indicators .................................................................................................. 4–2

4.2.3 Front Panel Keypad ............................................................................................................... 4–2

4.2.4 Parameter Setup .................................................................................................................... 4–3

4.3 Front Panel Control Screen Menus ........................................................................................... 4–5

4.3.1 Main Menus .......................................................................................................................... 4–5

4.3.2 Modulator Menu Options and Parameters ............................................................................ 4–6

4.3.3 Interface Menu Opt ions and Parameters ............................................................................... 4–9

4.3.3.1 Plug-In Interface Card (PIIC) ......................................................................................... 4–10

4.3.3.2 Ethernet Interface (J1) ..................................................................................................... 4–12

4.3.4 RF Switch Menu Options and Parameters .......................................................................... 4–20

4.3.5 Monitor Menu Options and Parameters .............................................................................. 4–20

4.3.6 Alarms Menu Optio ns and Parameters ............................................................................... 4–20

iii

Page 30

Table of Contents Revision 12

DM240XR High-Speed Digital Modulator MN-DM240XR

4.3.7 System Menu Options and Parameters ............................................................................... 4–22

4.3.8 Test Menu Option s and Parameters .................................................................................... 4–30

4.4 Remote Port User Interface ..................................................................................................... 4–30

4.4.1 Protocol Structure ............................................................................................................... 4–31

4.4.2 Protocol Wrapper ................................................................................................................ 4–31

4.4.3 Frame Description and Bus Handshaking ........................................................................... 4–34

4.4.4 Global Response Operational Codes ................................................................................... 4–34

4.4.5 Collision Avoidance ............................................................................................................ 4–36

4.4.6 Software Compatibility ....................................................................................................... 4–37

4.4.7 RLLP Summary .................................................................................................................. 4–38

4.4.8 DM240XR Opcode Command Set ..................................................................................... 4–38

4.5 Ethernet Port User Interface ................................................................................................... 4–39

4.6 Simple Network Management Protocol (SNMP) ................................................................... 4–39

4.7 The Management Information Base (MIB) ............................................................................ 4–39

4.7.1 Directory {internet 1} 1.3.6.1.1 ........................................................................................ 4–39

4.7.2 Mgmt {internet 2} 1.3.6.1.2 ............................................................................................. 4–39

4.7.3 Experimental {internet 3} 1.3.6.1.3 ................................................................................... 4–39

4.7.4 Private {internet 4} 1.3.6.1.4 ............................................................................................ 4–40

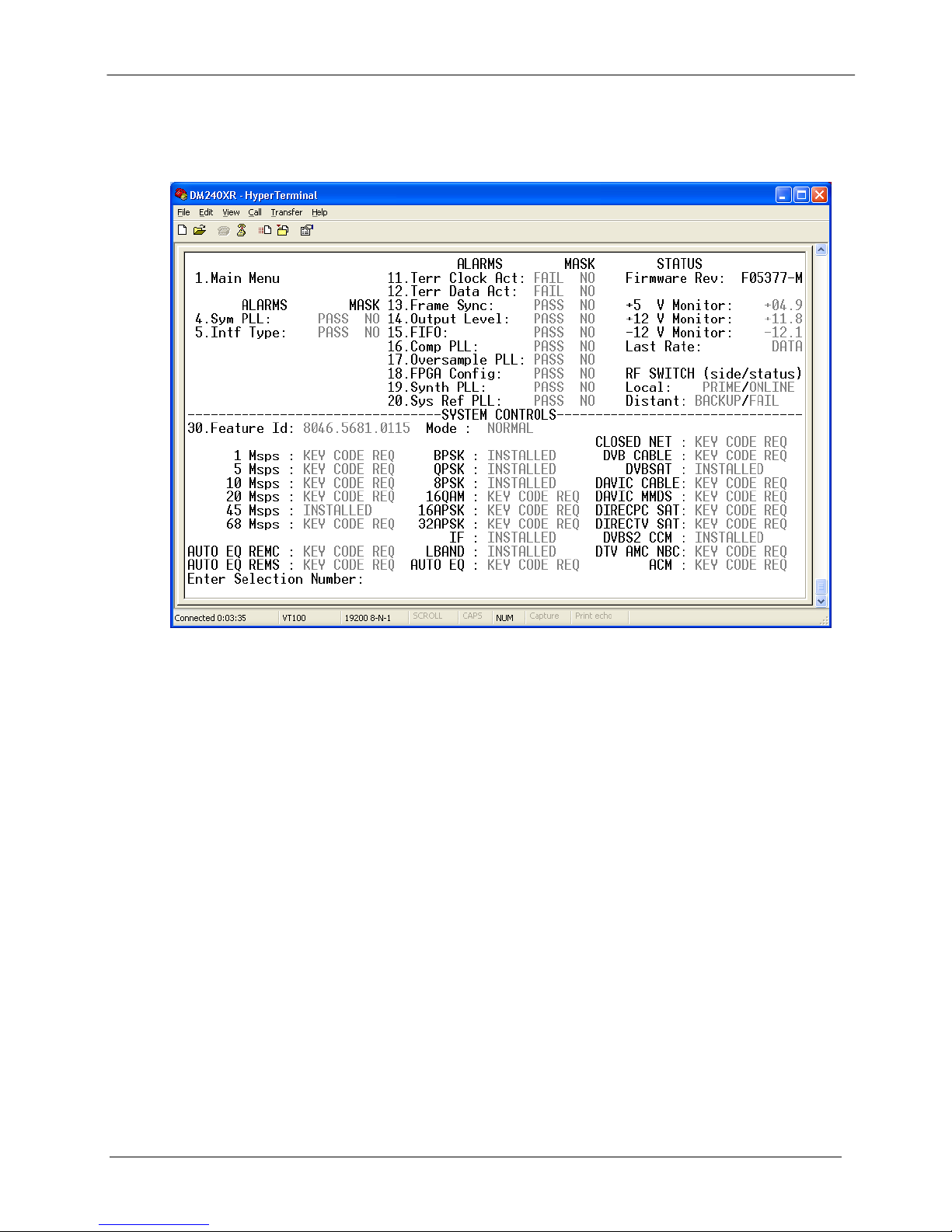

4.8 Terminal Port User Interface ................................................................................................... 4–41

4.8.1 Connecting the Terminal ..................................................................................................... 4–42

4.8.2 Terminal Screens ................................................................................................................ 4–42

CHAPTER 5. REAR PANEL INTERFACES ............................................................... 5–1

5.1 DM240XR Connections .............................................................................................................. 5–1

5.2 AC Power ..................................................................................................................................... 5–3

5.3 Compact Flash Interface (J5) ..................................................................................................... 5–3

5.3.1 Feature Upgrade .................................................................................................................... 5–3

5.3.2 Firmware Update .................................................................................................................. 5–3

5.3.3 Custom Configuration ........................................................................................................... 5–4

5.4 Ethernet Interface (J6) ............................................................................................................... 5–4

5.5 External Reference (Input) ........................................................................................................ 5–4

5.6 Remote Port (I/O) ....................................................................................................................... 5–4

5.7 Terminal Port (I/O) ................................................................

..................................................... 5–5

5.8 Alarm Port ................................................................................................................................... 5–5

5.9 IF Output Port (J10 & J11) ........................................................................................................ 5–6

5.9.1 Output Monitor Port (J9) ....................................................................................................... 5–6

iv

Page 31

Table of Contents Revision 12

DM240XR High-Speed Digital Modulator MN-DM240XR

5.10 RF Redundancy Switch Control (J2) ........................................................................................ 5–6

5.11 Built in ASI/Advanced ASI Interface (J7) ................................................................................ 5–6

5.12 Plug-In Interface Cards (PIICs) ................................................................................................ 5–7

5.12.1 ASI PIIC ................................................................................................................................ 5–7

5.12.1.1 ASI (Asynchrono us Serial Interface) ................................................................................ 5–7

5.12.1.2 AASI (Advanced Asy nchronous Serial Interface) ............................................................ 5–7

5.12.2 ASI Monitor .......................................................................................................................... 5–8

5.12.3 Parallel RS-422 Interface ...................................................................................................... 5–8

5.12.3.1 M2P (Parallel, RS-422) ..................................................................................................... 5–8

5.12.3.2 DVB (Parallel, RS-422) .................................................................................................... 5–9

5.12.4 Parallel LVDS Interface ...................................................................................................... 5–10

5.12.5 HSSI Interface ..................................................................................................................... 5–10

5.12.6 Ethernet 100/1000 Base-T Interface ................................................................................... 5–11

5.12.7 EIA-530 /RS-422 Serial Interface ....................................................................................... 5–11

5.12.8 G.703 Interface (Contact factory for avai lability) ............................................................... 5–12

CHAPTER 6. MAINTENANCE AND TROUBLESHOOTING ...................................... 6–1

6.1 Periodic Maintenance ................................................................................................................. 6–1

CHAPTER 7. TECHNICAL SPECIFICATIONS ........................................................... 7–1

7.1 Introduction ................................................................................................................................. 7–1

7.2 IF Specification ............................................................................................................................ 7–1

7.3 Baseband Specification ............................................................................................................... 7–2

7.3.1 DVB-S ................................................................................................................................... 7–2

7.3.2 DVB-S2-CCM (CCM - Normative) .................................................................................... 7–2

7.3.3 DVB-S2-ACM (Normative Features with Single Transports streams) ................................ 7–3

7.4 Interface Types Available (PIIC) ............................................................................................... 7–4

7.5 Monitor and Control ................................................................................................................... 7–4

7.6 Environmental ............................................................................................................................. 7–4

7.7 Physical ........................................................................................................................................ 7–5

7.8 Options ......................................................................................................................................... 7–5

7.9 DVB-S Series Configuration

7.9.1 DVB-S2 Series Configuration .............................................................................................. 7–5

7.10 Data Rates (DVB-S) .................................................................................................................... 7–5

7.10.1 Data Rates (DVB-S2)............................................................................................................ 7–7

CHAPTER 8. SNMP .................................................................................................... 8–1

...................................................................................................... 7–5

v

Page 32

Table of Contents Revision 12

DM240XR High-Speed Digital Modulator MN-DM240XR

CHAPTER 9. REMOTE OPERATIONS ....................................................................... 9–1

9.1 DM240XR Opcode Command Set ............................................................................................ 9–1

9.2 Modulator Command Set ........................................................................................................... 9–1

9.3 Detailed Command Descriptions ............................................................................................... 9–3

CHAPTER 10. WEB BROWSER ................................................................................. 10–1

10.1 Web Browser User Interface .................................................................................................... 10–1

10.2 Configuring Your PC ............................................................................................................... 10–2

10.2.1 LED Indicators .................................................................................................................... 10–3

10.3 GUI Screen Menus .................................................................................................................... 10–4

10.3.1 Introduction Menu .............................................................................................................. 10–5

10.3.1.1 Login Screen ................................................................................................................... 10–6

10.3.2 Password Setup ................................................................................................................... 10–7

10.3.3 IP and Application Administration ..................................................................................... 10–9

10.3.4 Monitor and Control Menu ............................................................................................... 10–14

10.3.4.1 Transmit Menu .............................................................................................................. 10–14

10.3.4.2 Interface Menu .............................................................................................................. 10–16

10.3.4.3 RFSWITCH Menu ........................................................................................................ 10–17

10.3.4.4 Monitor Menu ............................................................................................................... 10–17

10.3.4.5 Alarms Menu ................................................................................................................ 10–19

10.3.4.6 System Menu ................................................................................................................ 10–20

10.3.4.7 Test Menu ..................................................................................................................... 10–22

APPENDIX A. FRONT PANEL UPGRADE PROCEDURE ......................................... A–1

A.1 Introduction ................................................................................................................................ A–1

A.2 Required Equipment ................................................................................................................. A–1

A.3 Upgrade Procedure .................................................................................................................... A–1

A.4 Demonstrati on Procedure ......................................................................................................... A–3

A.4.1 Running in Demonstration Mode ......................................................................................... A–5

A.4.2 Canceling Demonstration Mode .......................................................................................... A–6

APPENDIX B. TCP/IP ETHERNET SETUP ................................................................. B–1

B.1 Introduction ................................................................................................................................ B–1

B.2 TCP/IP Network Configuration ............................................................................................... B–1

B.3 Network Configuration Summary ................................................................

............................ B–3

B.4 Ethernet Test .............................................................................................................................. B–3

vi

Page 33

Table of Contents Revision 12

DM240XR High-Speed Digital Modulator MN-DM240XR

B.4.1 Connecting the Modem Ethernet Cable to a Network Link ................................................. B–3

B.4.2 Connecting the Modem Ethernet Cable Directly to a Computer (without a Network) ........ B–4

B.4.3 Testing the Ethernet connection using the Ping Program (Optional) ................................... B–6

APPENDIX C. WEB BROWSER QUICK SETUP GUIDE ............................................ C–1

C.1 Introduction ................................................................................................................................ C–1

C.2 Web Users Configuration .......................................................................................................... C–2

C.2.1 Change Web User Name ...................................................................................................... C–3

C.2.2 Change Authentication Password ........................................................................................ C–3

C.2.3 Change Access Rights .......................................................................................................... C–4

C.3 Modem Web Site ........................................................................................................................ C–4

C.4 Web Page Appearance ............................................................................................................... C–5

APPENDIX D. AUTOEQ™ INTERFACE OPERATION GUID E .................................. D–1

D.1 Introduction ................................................................................................................................ D–1

D.2 Applicable Documents ............................................................................................................... D–1

D.3 AutoEQ™ PIIC Int erf ace Theory of Operation ..................................................................... D–1

D.4 AutoEQ

D.5 AutoEQ

™

Menu Options and Parameters ............................................................................... D–3

™

Back Channel Menu Options and Parameters ...................................................... D–6

D.6 AutoEQ Backchannel Setup ...................................................................................................... D–7

D.7 AutoEQ™ Operation Procedure .............................................................................................. D–9

D.8 Reference Acquisition Calibration (Optional Step) ................................................................ D–9

D.9 Equalizer Calibration .............................................................................................................. D–11

D.10 Equalizer Modes ....................................................................................................................... D–12

D.11 AutoEQ™ Remote Operation ................................................................................................. D–13

D.12 Additional Features ................................................................................................................. D–14

D.12.1 AutoEQ™ Status Indicator ................................................................................................ D–14

D.12.2 LNB Power Connector ....................................................................................................... D–14

vii

Page 34

Table of Contents Revision 12

DM240XR High-Speed Digital Modulator MN-DM240XR

Notes:

viii

Page 35

PREFACE

About this Manual

This manual describes the installation and operation for the Radyne DM240XR. This is a

technical document intended for earth station engineers, technicians, and operators responsible

for the operation and maintenance of the DM204XR.

Reporting Comments or Suggestions Concer ning this Manual

Comments and suggestions regarding the content and design of this manual are appreciated. To

submit comments, please contact the Comt ech E F Data Technical Publications department :

TechnicalPublications@comtechefdata.com

Conventions and Referenc es

Related Documents

The following documents are referenced in thi s m anual:

• EN300-421 and EN301-210 ETSI

• ETSI EN302-307

• INTELSAT Earth Station Standards IESS-308, -309, -310, and -315

• EUTELSAT SMS

Metric Conversion

Metric conversion information is located on the inside back cover of this manual. This information is

provided to assist the operator in cross-referencing non-Metric to Metric conversions.

Cautions and Warnings

i

Page 36

DM240XR Revision 12

CAUTION

CAUTION indicates a hazardous situation that, if not avoided, may result in

may also be used to indicate other

WARNING

indicates a potentially hazardous situation that, if not avoided,

IMPORTANT

Preface MN-DM240XR

IMPORTANT or NOTE indicates a statement associate d with the task

being performed or information critical for proper equipment function.

minor or moderate injury. CAUTION

unsafe practices or risks of property damage.

WARNING

could result in death or serious injury.

Examples of

Multi-Hazard Formats

Trademarks

Product names mentioned in this manual may be trademarks or registered trademarks of their

respective companies and are hereby acknowle dged.

ii

Page 37

DM240XR Revision 12

!

NOTE

Preface MN-DM240XR

Safety Compliance

EN 60950

Applicable testing is routinely performed as a condition of manufacturing on all units to ensure

compliance with safety requirements of EN60950.This equipment meets the Safety of Information

Technology Equipment specification as defined in EN60950.

Low Voltage Directive (LVD)

The following information is applicable for the E uropean Low Voltage Directive (EN60950):

<HAR> Type of power cord required for use in the European Community.

CAUTION: Double-pole/Neutral Fusing

ACHTUNG: Zweipolige bzw. Neutralleiter-Sicherung

International Symbols:

Symbol Definition Symbol Definition

~

Alternating Current

For additional symbols, refer to Cautions and Warnings, listed

earlier in this Preface.

Fuse

Protective Earth /

Safety Ground

Chassis Ground

iii

Page 38

DM240XR Revision 12

Preface MN-DM240XR

Warranty Policy

Comtech EF Data products are warranted against defects in material and

workmanship for a period of two years from the date of shipment. During the

warranty period, Comtech EF Data will, at its option, repair or replace products

that prove to be defective. Repairs are warr anted for t he remainder of the origi nal

two year warranty, or a 90 day extended warranty, whichever is longer.

For equipment under warr anty, the owner is responsibl e for freight t o Comtech EF

Data and all related custom s, taxes, tariffs, insurance, etc. Comtech EF Da ta is

responsible for the freight c har ge s on ly f or return of the equipment from the factory

to the owner. Comtech EF Data will return the equipment by the same method

(i.e., Air, Express, Surface) as the equipment was sent to Comtech EF Data.

All equipment returned for warranty repair must have a valid RM A number i ssued

prior to return and be marked clearly on the return packaging. Comt ech EF Data

strongly recommends all equipment be returned in its original packaging.

Comtech EF Data Corporation’s obligations under this warranty are limited to

repair or replacement of failed parts, and the r eturn shipment to the buyer of the

repaired or replaced parts.

Limitations of Warranty

The warranty does not apply to any part of a product that has been installed,

altered, repaired, or misused in any way tha t, in the opinion of Comt ech EF Data

Corporation, would affect the reliability or d etracts from the performance of any

part of the product, or is damaged as the result of use in a w ay or with eq uip ment

that had not been previously approved by Comtech EF Data Corporation.

The warranty does not apply to any product or parts thereof where the serial number

or the serial number of any of its parts has be en altered, defaced, or removed.

The warranty does not cover damage or loss incurred in transportation of the

product.

The warranty does not cover replacement or repair necessitated by loss or

damage from any cause beyond the control of Comtech EF Data Corporation,

such as lightning or other natural and weather related events or wartime

environments.

The warranty does not cover any labor involved in the removal and or

reinstallation of warranted equipment or parts on site, or any labor required to

diagnose the necessity for repair or replacement.

iv

Page 39

DM240XR Revision 12

Preface MN-DM240XR

The warranty excludes any responsibility by Comtech EF Data Corporation for

incidental or consequential damages arising from the use of the equipment or

products, or for any inability to use them either separate from or in combination with

any other equipment or products.

A fixed charge established for each product will be imposed for all equipment

returned for warranty repair where Comtech EF Data C orporation cannot identify

the cause of the reported failure.

Exclusive Remedies

Comtech EF Data Corporation’s warranty, as stated is in lieu of all other

warranties, expressed, implied, or statutory, including those of merchantability

and fitness for a particular purpose. The buyer shall pass on t o any purchaser,

lessee, or other user of Comtech EF Data Corporation’s products, the

aforementioned warranty, and shall indemnify and hold harmless Comtech EF

Data Corporation from any claims or liability of such purchaser, lessee, or user

based upon allegations that the buyer, its agents, or employees have made

additional warranties or representations as to product preference or use.

The remedies provided herein are the buyer’s sole and exclusive remedies.

Comtech EF Data shall not be liable for any direct, indirect, special, incidental, or

consequential damages, whether based on contract, tort, or any other legal

theory.

v

Page 40

DM240XR Revision 12

Preface MN-DM240XR

Customer Support

Contact the Comtech EF Data Customer S upport Department for:

• Product support or training

• Rep ort i ng comments or suggestions concerning manuals

• Information on upgrading or returning a product

A Customer Support representative may be reached at:

Comtech EF Data

Attention: Customer Support Department

2114 West 7th Street

Tempe, Arizona 85281 USA

480.333.2200 (Main Comtech EF Data number)

480.333.4357 (Customer Support Desk)

480.333.2161 FAX

To return a Comtech EF Data product (in-warranty and out-of-warranty) for repair or replacement:

• Contact the Comtech EF Data Customer Support Department. Be prepared to supply

the Customer Support representative with the model number, serial number, and a

description of the problem.

• Request a Return Material Authorization (RMA) number from the Comtech EF Data

Customer Support representative.

• Pack the product in its original shipping carton/packaging to ensure that the product is

not damaged during shipping.

• Ship the product back to Comtech EF Data. (Shipping charges should be prepaid.)

Online Customer Support

An RMA number request can be requested electronically by contacting the Customer Support

Department through the online support page at www.comtechefdata.com/support.asp:

• Click on the “Service” hyperlink, then read the “Return Material Authorization” section

for detailed instructions on our return proced ures.

• Click on the “RMA Request Form” hyperlink, then fill out the form completely before

sending.

• Send e-mail to the Customer Support Department at service@comtechefdata.com.

For information regarding this product’s warranty policy, refer to the Warranty Policy, p. xxii.

vi

Page 41

This chapter provides an overview of the DM240XR High-Speed Digital Modulator. The

DM240XR will be referred to in this manual as “the DM240XR”, “the modulator”, or “the unit”.

1.1 Description

The New Standard in Digital Modulator Performance

Radyne’s DM240XR family of High-Speed Modulators is the ideal choice to meet the exacting

standards of High Data-Rate Video, Internet and Fiber Restoral Satellite Applications. The

DM240XR offers various options that comply to the international standards, supporting both

DVB-S and DVB-S2 specifications. With a variety of frequency options and Plug-In Data

Interfaces (PIIC), it provides greater flexibility for changing and upgrading the unit the required

application.

The DVB-S Network specification complies with both EN300-421 and EN301-210 ETSI

specifications. The DM240XR suppor ts FEC rates of BPSK, QPSK, 8PSK and 16QAM

applications with symbol rates up to 68 Msps.

The DVB-S2 Network specification compli es with the next generation DVB open standard

supported by ETSI EN302-307. At the core of this standard is a powerful Bose-ChaudhuriHocquenghem BCH encoder and concatenated Low-Density Parity Check (LDPC). The DVB-S2

FEC rates supported are BPSK, QPSK, 8PSK and 16APSK with symbol rates up to 45Msps.

Chapter 1. INTRODUCTION

The powerful new onboard Monitor and Control (M&C) processor has the unique capability to

download firmware and enhance features from a field-changeable Flash Card. Offering

unprecedented flexibility, this feature represents a new level of Radyne outstanding Customer

Support. Additionally, features are added to the installed equipment base with extreme ease,

allowing the equipment to expand with changes in service while lowering initial installation

budgets.The Modulator offers a frequency-agile IF Output from 50 to 90, 100 to 180 MHz

(70/140), or 950 to 2050 MHz (L-Band) in 100 Hz steps. Variable data rates from 1 Mbps to 238

Mbps can be set in 1 bps steps.

The DM240XR, AutoEQ™ option supports SCPC equalization of Group Delay and Amplitude.

Installing the AutoEQ™ PIIC Interface allows the ability to compensate for the overall system

Group Delay and Amplitude Flatness over the satellite by pre-distorting the Uplink Carrier,

MN-DM240XR– Revision 12 1–1

Figure 1-1 DM240XR

Page 42

DM240XR High-Speed Digital Modulator Introduction

eliminating the need for external Group Delay/Amplitude Equalizers. AutoEQ™ will

automatically generate the proprietary profile for the DM240XR to pre-distort the modulator,

resulting in Amplitude and Group Delay equalization over the Satellite Link. The AutoEQ

TM

will

operate over the full transponder from a symbol rate of 10.1 Msps to 45 Msps.

Additional features include the choice of remotely interfacing through one of three onboard

connections: 10/100 Base-T Ethernet, RS-485, RS-232 or Web Browser. The familiar Radyne

Front Panel (Figure 1-1) offers push-button control of all features and a backlit LCD display.

Menus are specifically designed for ease of use and quick online operation as well as changes in

all modulator configurations.

The DM240XR supports optional 1:1 Redundancy for data, IF or both offering superior system

reliability based on customer needs and applications.

Redundancy Options support include:

• RCS11: 1 RU Chassis that supports redundancy for both IF (70/140MHz or L-band) and

supports various data interfaces.

• RRS11: 1RU Chassis supports redundancy for either 70/140 MHz or L-ba nd. In c l ude s

easy access to monitor ports for online and offline monitoring via the front panel. Power

and control logic is supplied by a rear panel connector on the DM240XR.

• STS11: Small package design that supports redundancy for either 70/140 MHz or L-

band. Includes easy access to monitor ports for online and offline monitoring via the

front panel. Power and control logic is supplied by a rear panel connector on the

DM240XR

• Data Redundancy: The DM240XR PIIC int er f aces allows for data redundancy when dual

interfaces are installed. The modulator can satisfy the user's applications when the

system requires monitoring of the redundant data paths. Simply configure the redundant

interface and the modulator will monitor the integrity of the data paths and switch in the

event data is corrupted on either path.

MN-DM240XR– Revision 12 1–2

Page 43

WARNING

WARNING

Chapter 2. Installation

This section provides unpacking and installation instructions, and a description of external

connections and backward alarm information.

2.1 Installation Requirements

The DM240 can be installed within any standard 19-inch equipment cabinet or rack, and requires

1 RU mounting space (1.75 inches) vertically and 17 inches of depth. Including cabling, a

minimum of 20-inches of rack depth is required. The rear panel of the DM240XR

have power enter from the left and IF cabling enter from the right when viewed from the rear of

the unit. Data and control cabling can enter from either side although they are closer to the

center. The unit can be placed on a table or suitable surface if required.

is designed to

PROPER GROUNDING PROTECTION: During installation and setup, the

user must ensure that the unit is properly grounded. The equipment shall

be connected to the protective earth connection through the end use

protective earth protection.

In addition, the IF input and output coax cable shielding must be properly

terminated to the chassis/unit ground.

There are no user-serviceable parts or configuration settings located

inside the DM240 Chassis. There is a potential shock hazard internally at

the power supply module. DO NOT open the DM240 Chassis under any

circumstances.

MN-DM240XR– Revision 12 2–1

Page 44

DM240XR High-Speed Digital Modulator Installation

CAUTION

Before initially applying power to the unit, it is a good idea to disconnect

the transmit output from the operating ground station equipment. This is

especially true if the current DM240XR configuration settings are

unknown, where incorrect settings could disrupt existing

communications traffic.

2.2 Unpacking

The DM240XR Modulator was carefully packaged to avoid damage and should arrive complete

with the following items for proper installation:

DM240XR Unit.

Compact Flash Card. Must be installed.

Power Cord, 6-foot with applicable AC connector.

Installation and Operation Manual.

2.3 Removal and Assembly

Carefully unpack the unit and ensure that all of the above items are in the carton. If the Prime AC

power available at the installation site requires a different power cord/AC connector, then

arrangements to receive the proper device will be necessary before proceeding with the

installation.

The DM240XR modulator is shipped fully assembled. It does not require removal of the covers

for any purpose in installation. The only repl aceable assembly in the unit is the data interface and

is not intended to be accomplished in the field. Should the power cable AC connector be of the

wrong type for the installation, either the cable or the power connector end should be replaced.

The power supply itself is designed for universal application using from 100 to 240 VAC, 50 to

60 Hz, < 40 W.

2.4 Mounting Considerations

When mounted in an equipment rack, adequate ventilation must be provided. The ambient

temperature in the rack should be between 10° and 35° C, and held constant for best equipment

operation. The air available to the rack should be clean and relatively dry. The DM240XR units

may be stacked one on top of the other up to a maximum of 10 consecutive units before providing

a 1 RU space for airflow.

Do not mount the DM240XR in an unprotected outdoor location where there is direct contact

with rain, snow, wind or sun. The DM240XR is designed for indoor applications only.

The only tools required for rack mounting the DM240XR is a set of four rack mounting screws

and an appropriate screwdriver. Rack mount brackets are an integral part of the cast front bezel

of the unit and are not removable.

MN-DM240XR– Revision 12 2–2

Page 45

DM240XR High-Speed Digital Modulator Installation

CAUTION

Shielded cables with the shield terminated to the conductive backshells are required in order to

meet EMC directives. Cables with insul ation flammability ratings of 94 VO or better are required

in order to meet low voltage directives.

2.5 Modulator Chec kout

The following descriptions assume that the DM240XR is installed in a suitable location with

prime AC power and supporting equipment available.

2.5.1 Initial Power-Up

Before initial power up of the DM240XR, it is a good idea to disconnect

the transmit output from the operating ground station equipment. This is

especially true if the current modulator configuration settings are

unknown, where incorrect setting could disrupt existing communications

traffic. New units from the factory are normally shipped in a default

configuration which includes setting the transmit carrier off.

Turn the unit ‘ON’ by placing the rear panel switch (above the power entry connector) to the

‘ON’ position. Upon initial and subsequent power-ups, the DM240XR microprocessor will test

itself and several of its components before beginning its main Monitor/Control program. These

power-up diagnostics show no results if successful. If a failure is detected, the Fault LED is

illuminated.

The initial field checkout of the DM240XR can be accomplished from the front panel, Terminal

Port, Remote Port, or Ethernet Port.

MN-DM240XR– Revision 12 2–3

Page 46

DM240XR High-Speed Digital Modulator Installation

Notes:

MN-DM240XR– Revision 12 2–4

Page 47

Chapter 3. Theory of Operation

3.1 Theory of Operation

The advanced hardware/software archi tecture of the DM240XR allows a single piece of hardware

to be configured for a variety of different applications. Several of these hardware/software

platforms are listed in the next sections. C ustom applications are available.

The basic operation of each platform is simil ar . A digital terrestrial interface supplies the

modulator with a data stream. The data stream is synchronized if the incoming stream is framed.

The data is scrambled, and FEC is added. The data is then convolutionally encoded, punctured,

then constellation mapped. The resulting I&Q Symbols are digitally filtered. The data is then

converted into an analog waveform and is vector modulated onto an RF Carrier produced from

the Transmit IF Synthesizer Circuitry.

Since the baseband processing is complet ely digital, many different variations of signal

processing can be performed. Therefore, the DM240XR is one of the most flexible digital

modulators available today.

3.2 DVB-S Operation

The DVB-S version of the DM240XR complies with both EN300-421 and EN301-210 ETSI

Specifications.

A block diagram of the signal flow is shown in Figure 3-1 below.

MN-DM240XR– Revision 12 3–1

Page 48

DM240XR High-Speed Digital Modulator Theory of Operation

Terrestrial

Interface

PRBS

Generator

Terrestrial

Buffer

CRC-8

Encoder

Slicer

BCH

Encoder

LDPC

Encoder

Bit

Interleaver

BB

Filter

PL

Framing

DVB

Sync

PLL

IQ

Modulator

Tx Clock

Symbol Clock

Stream

Adaptation

Mapping IF Out

Tx Data

SCT

SCTE

DDS

Figure 3-1. Functional Block Diagram

3.3 DVB-S2-BS-NBC Operation

The DVB-S2-BS-NBC version of the DM240XR complies with the ETSI EN 302 307 V1.1.1

(2004-01) specification for non-backward compatible broadcast services.

A block diagram of the signal flow is shown in Figure 3-2 below.

Figure 3-2. Functional Block Diagram

MN-DM240XR– Revision 12 3–2

Page 49

Chapter 4. User Interfaces

4.1 User Interfaces

There are four user interfaces available for the DM240XR family of products. These are:

Front Panel

Remote Port

Ethernet Port

Terminal

4.2 Front Panel User Interface

The front panel of the DM240XR allows for complete control and monitor of all DM240XR

parameters and functions via a keypad, LCD di splay and status LEDs.

The front panel layout is shown in Figure 4−1, showing the location and labeling of the front

panel. The front panel is divided into three functional areas: the LCD display, the Keypad and

the LED Indicators, each described below in Table 4-1.

1 2 3 4

Figure 4-1. DM240XR Front Panel

MN-DM240XR– Revision 12 4–1

Table 4-1.

Page 50

DM240XR High-Speed Digital Modulator User Interfaces

Displays DM240XR Operating

parameters and Configuration data.

Controls the up, down, right and left

Display window (see Figure x-x).

Allows entry of numeric data and Clear

and Enter function keys.

See Table 4-2 for a description of these

LED Indicators.

LED

Color

Function

Transmit On

Green

Indicates the DM240 XRTransmitter is turned on.

Major Alarm

Red

Indicates that the transmit direction has failed, losing traffic.

Minor Alarm

Yellow

Indicates a transmit warning condition exists.

Test Mode

Yellow

Indicates the modulator is involved in a current test mode

activity.

Power

Green

Indicates the DM240XR unit is currently powered up.

Fault

Red

Indicates a common fault exists such as power out of spec.

Event

Yellow

Indicates that events have been logged into the event buffer.

Remote

Green

Indicates that the unit is set to respond to the remote control

Item Number Description Function

1 LCD Front Panel Display

2 Cursor Control Arrows

3 Numeric Keypad

4 Operational Function LEDs

4.2.1 Front Panel LCD Display

The front panel display is a 2 line by 16-character LCD display. The display is lighted an d the

brightness can be set to increase when the front panel is currently in use. The LCD display

automatically dims after a period of inactivity. The display has two distinct areas showing

current information. The upper area shows the current parameter being monitored, such as

‘Frequency’ or ‘Data Rate’. The lower line shows the current value of that parameter. The LCD

display is a single entry window into the large matrix of parameters that can be monitored and set

from the front panel.

4.2.2 Front Panel LED Indicators

Eight LEDs on the DM240 front panel (Refer to Table 4-2) indicate the status of the DM240’s

operation. The LED colors maintain a consistent meaning. Green signifies that the indication is

appropriate for normal operation, Yellow means that there is a condition not proper for normal

operation, and Red indicates a fault condition that will result in lost communications.

motion of the cursor in the LCD

4.2.3 Front Panel Keypad

The front panel keypad consists of two areas: a 10-key numeric entry with 2 additional keys for

the ‘Enter’ and ‘Clear’ function. The second area is a set of ‘Arrow’ or ‘Cursor’ keys (

(

→), (←), used to navigate the parameter currently being monitored or controlled. Table 4-3

describes the key functions available at the front panel.

Table 4-2.

or terminal input.

↑), (↓),

MN-DM240XR– Revision 12 4–2

Page 51

DM240XR High-Speed Digital Modulator User Interfaces

↑ ↓ ← →

←

→

4.2.4 Parameter Setup

The four arrow keys (↑), (↓), (→), (←), to the right of the LCD display are used to navigate the