Page 1

OMS11

Outdoor Modem Switch

Installation and Operation Manual

TM133

Revision 1.1

Comtech EF Data • 2114 W 7th St. • Tempe, AZ 85281 • (480) 333-2200 • Fax: (480) 333-2540 • www.comtechefdata.com

Page 2

OMS11 1:1 Redundancy Switch Warranty Policy

Warranty Policy

WP

Comtech EF Data products are warranted against defects in material and workmanship for a period of two

years from the date of shipment. During the warranty period, Comtech EF Data will, at its option, repair or

replace products that prove to be defective.

For equipment under warranty, the owner is responsible for freight to Comtech E F Data and all related

customs, taxes, tariffs, insurance, etc. Comtech EF Data is responsible for the freight charges only for return

of the equipment from the factory to the ow ner. Comt ech EF Data will return the equipment by the same

method (i.e., Air, Express, Surface) as the equipment was sent to Comtech EF D ata.

All equipment returned for warranty repair must have a valid RMA number issued prior to return and be

marked clearly on the return p ack agin g. Comtech EF Data strongly recommends all equipment be returned

in its original packaging.

Comtech EF Data Corporation’s obligations under this warranty are limited to repair or replacement of failed

parts, and the return shipment to the buyer of the repaired or replaced parts.

Limitations of Warranty

The warranty does not apply to any part of a product that has been installed, altered, repaired, or misused in

any way that, in the opinion of Comtech EF Data Corporation, would affect the reliability or detracts from the

performance of any part of the product, or is damaged as the result of use in a way or with equipment that

had not been previously approved by Comtech EF Data Corporation.

The warranty does not apply to any product or parts thereof where the serial number or the serial number of

any of its parts has been altered, defaced, or removed.

The warranty does not cover damage or loss incurred in transportation of the product.

The warranty does not cover replacement or repair necessitated by loss or damage from any cause beyond

the control of Comtech EF Data Corporation.

The warranty does not cover any labor involved in the removal and or reinstallation of warranted equipment

or parts on site, or any labor required to diagnose the necessity for repair or replacement.

The warranty excludes any responsibility by Comtech EF Data Corpora t io n for incide ntal or con sequent i al

damages arising from the use of the equipment or products, or for any inability to use them either separate

from or in combination with any other equipment or products.

A fixed charge established for each product will be imposed for all equipment returned for warranty repair

where Comtech EF Data Corporation cannot identify the cause of the reported failure.

Exclusive Remedies

Comtech EF Data Corporation’s warranty, as stated is in lieu of all other warranties, expressed, implied, or

statutory, including those of merchantability and fitness for a particular purpose. The buyer shall pass on to

any purchaser, lessee, or other user of Comtech EF Data Corporation’s products, the aforementioned

warranty, and shall indemnify and hold harmless Comtech EF Data Corporation from any claims or liability of

such purchaser, lessee, or user based upon allegations that the buyer, its agents, or employees have made

additional warranties or representations as to product preference or use.

The remedies provided herein are the buyer’s sole and exclusive remedies. Comtech EF Data shall not be

liable for any direct, indirect, special, incidental, or consequential damages, whether based on contract, tort,

or any other legal theory.

TM133 – Rev. 1.1 iii

Page 3

Warranty Policy OMS11 1:1 Redundancy Switch

Warranty Repair Return Procedure

Before a warranty repair can be accomplished, a Repair Authorization must be received. It is at this time

that Comtech EF Data will authorize the product or part to be returned to the Comtech EF Data facility or if

field repair will be accomplished. The Repair Authorization may be requested in writing or by calling:

Comtech EF Data Corporation

2114 W 7

th

Street.

Tempe, Arizona 85281 (USA)

ATTN: Customer Support

Phone: (480) 333-2200

Fax: (480) 333-2540

Any product returned to Comtech EF Data for examination must be sent prepaid via the means of

transportation indicated as acceptable to Comtech EF Data. Return Authorization Number must be clearly

marked on the shipping label. Returned products or parts should be carefully packaged in the original

container, if possible, and unless otherwise indicated, shipped to the above address.

Non-Warranty Repair

When a product is returned for any reason, Customer and its shipping agency shall be responsible for all

damage resulting from improper packing and handling, and for loss in transit, not withstanding any defect or

nonconformity in the product. By returning a product, the owner grants Comtech EF Data permission to

open and disassemble the product as required for evaluation. In all cases, Comtech EF Data has sole

responsibility for determining the cause and nature of failure, and Comtech EF Data’s determination with

regard thereto shall be final.

iv TM133 – Rev. 1.1

Page 4

OMS11 1:1 Redundancy Switch Preface

Preface

P

This manual provides installation and operation information for the Radyne OMS11 1:1

Redundancy Switch. This is a technical document intended for use by engineers, technicians,

and operators responsible for the operation and maintenance of the OMS11.

Conventions

Whenever the information within this manual instructs the operator to press a pushbutton switch

or keypad key on the Front Panel, the pushbutton or key label will be shown in "less than" (<) and

"greater than" (>) brackets. For example, the Reset Alarms Pushbutton will be shown as

<RESET ALARMS>, while a command that calls for the entry of a ‘7’ followed by ‘ENTER’ Key

will be represented as <7,ENTER>.

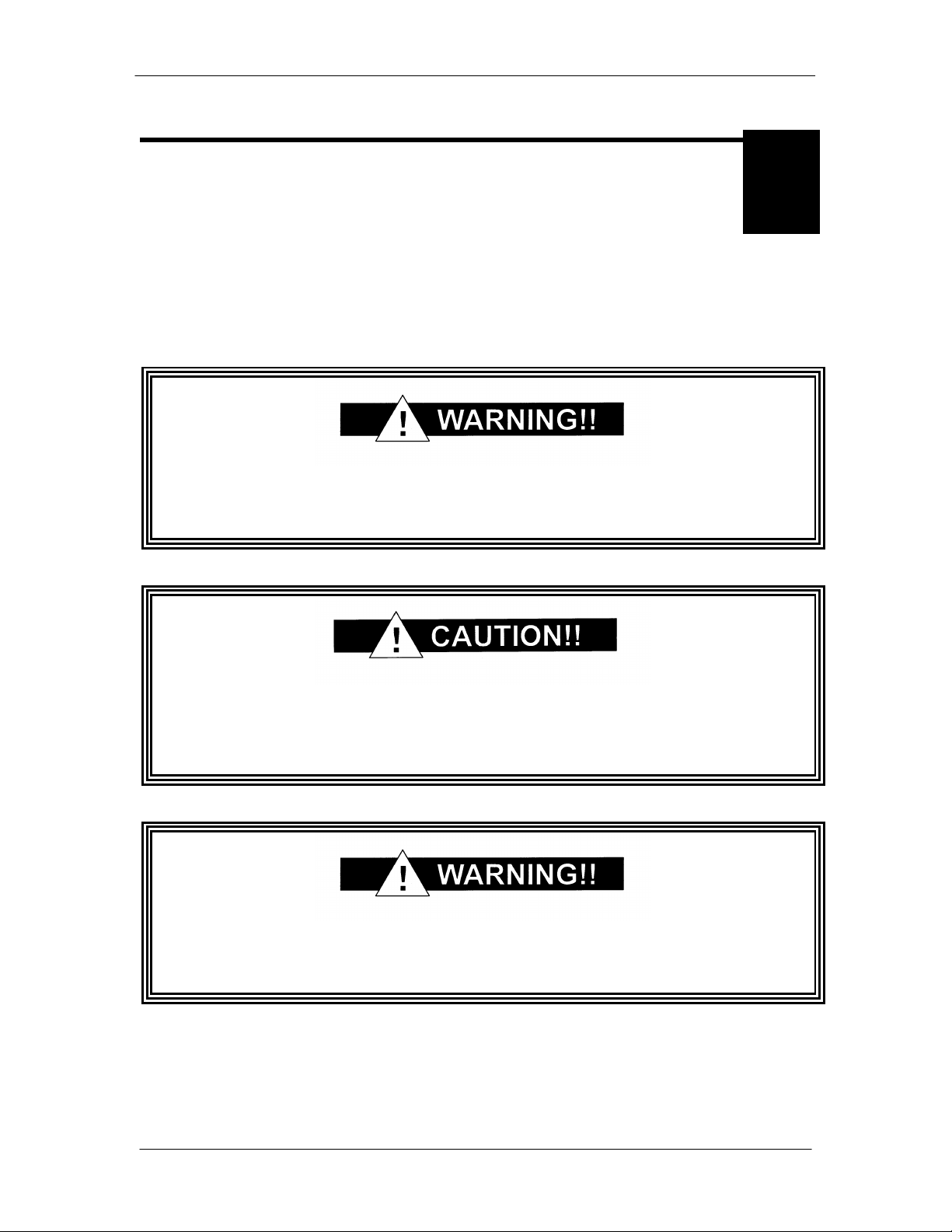

Cautions and Warnings

A caution icon indicates a hazardous situation that if not avoided, may result in minor or moderate

injury. Caution may also be used to indicate other unsafe practices or risks of property damage.

A warning icon indicates a potentially hazardous situation that if not avoided, could result in death

or serious injury.

TM133 – Rev. 1.1 v

Page 5

Preface OMS11 1:1 Redundancy Switch

Revision

Level

1.0

11-30-07

Initial Release

1.1

2-08-08

Updates. Added Fault Detection

A note icon identifies information for the proper operation of your equipment, including helpful

hints, shortcuts, or important reminders.

Trademarks

Product names mentioned in this manual may be trademarks or registered trademarks of their

respective companies and are hereb y acknowledged.

Copyright

2008, Comtech EF Data This manual is proprietary to Comtech EF Data and is intended for the

exclusive use of Comtech EF Data’s customers. No part of this document may in whole or in

part, be copied, reproduced, distributed, translated or reduced to any electronic or magnetic

storage medium without the express written consent of a duly authorized officer of Comtech EF

Data

Disclaimer

This manual has been thoroughly reviewed for accuracy. All statements, technical information,

and recommendations contained herein and in any guides or related documents are believed

reliable, but the accuracy and completeness thereof are not guaranteed or warranted, and they

are not intended to be, nor should they be understood t o be, represe nt at ions or war ranti es

concerning the products described. Comtech EF Data assumes no responsibility for use of any

circuitry other than the circuitry employed in Comtech EF Data systems and equipment.

Furthermore, since Comtech EF Data is constantly improving its products, reserves the right to

make changes in the specifications of products, or in this manual at any time without notice and

without obligation to notify any person of such changes.

Record of Revisions

Date

Reason for Change

Comments or Suggestions Concerning this Manual

Comments or suggestions regarding the content and design of this manual are appreciated.

To submit comments, please contact the Comtech EF Data Corporation Customer Service

Department.

vi TM133 – Rev. 1.1

Page 6

OMS11 1:1 Redundancy Switch Preface

TM133 – Rev. 1.1 vii

Page 7

Page 8

OMS11 1:1 Redundancy Switch Table of Contents

1

Table of Contents

ToC

Section 1 - Introduction ............................................................................................................. 1-1

1.0 Description ............................................................................................................................. 1-1

1.1 Redundant Power Supplies ................................................................................................... 1-1

1.2 Front Panel Controls .............................................................................................................. 1-2

1.3 Power-Up Defaults ................................................................................................................. 1-2

Section 2 - Theory of Operation ................................................................................................ 2-1

2.0 Theory of Operation ............................................................................................................... 2-1

2.1 OMS11 Operation .................................................................................................................. 2-1

2.1.1 Operating Procedures ........................................................................................................ 2-2

2.1.2 Configuring the OMS11 ...................................................................................................... 2-2

2.1.3 Front Panel Controls ........................................................................................................... 2-2

2.1.4 Manual Mode ...................................................................................................................... 2-2

2.1.5 Auto Mode .......................................................................................................................... 2-2

2.1.6 Power-Up Defaults ............................................................................................................. 2-2

2.2 OMS11 Major Assemblies ..................................................................................................... 2-3

2.2.1 Main Switch Board .............................................................................................................. 2-3

2.2.2 Front Panel ......................................................................................................................... 2-3

2.2.3 Redundant Power Supplies ................................................................................................ 2-3

2.3 OMS11 General Operation .................................................................................................... 2-3

2.3.1 Signals ................................................................................................................................ 2-3

2.3.2 Backup ................................................................................................................................ 2-3

2.3.3 Fail-Safe ............................................................................................................................. 2-3

2.3.4 OMS11 Fault Relays .......................................................................................................... 2-4

2.4 Fault Detection ...................................................................................................................... 2-4

Section 3 - User Interfaces ........................................................................................................ 3-1

3.0 User Interfaces ...................................................................................................................... 3-1

3.1 Front Panel Interface ............................................................................................................. 3-1

TM133 – Rev. 1.1

Page 9

Introduction OMS11 1:1 Redundancy Switch

2

Section 4 - Installation ............................................................................................................... 4-1

4.0 Installation Requirements ...................................................................................................... 4-1

4.1 Unpacking .............................................................................................................................. 4-1

4.1.1 Test Data Sheet .................................................................................................................. 4-2

4.2 Site Considerations ............................................................................................................... 4-2

4.2.1 Power Sources ................................................................................................................... 4-2

4.3 System Setup & Connections ................................................................................................ 4-3

Section 5 - Connector Pinouts .................................................................................................. 5-1

5.0 OMS11 External Interface Connections ................................................................................ 5-1

5.1 LED Indicators ....................................................................................................................... 5-2

5.2 Power Input............................................................................................................................ 5-2

5.2.2 AC Power Input (J 6, J 10) ................................................................................................... 5-2

5.2.3 DC Power Input (J6, J10) (Optional) .................................................................................. 5-2

5.3 Ground Lug ............................................................................................................................ 5-3

5.4 Remote Monitor & Control (J8) .............................................................................................. 5-3

5.4.1 Terminal Mode (RS232) ..................................................................................................... 5-3

5.4.2 Modem Remote Communications (RLLP/RS485).............................................................. 5-4

5.4.3 Common Equipment Faults (J8) ......................................................................................... 5-4

5.4.3.1 Fault Detection ................................................................................................................ 5-5

5.5 Terrestrial Data Interface (J7) - RS422 Sync, Async Overhead, G.703 Balanced I/O Port .. 5-7

5.6 Modem A Data Interface (J1) - RS422 Sync, Async Overhead, G.703 Balanced I/O Port ... 5-9

5.7 Modem B Data Interface (J13) - RS422 Sync,Async Overhead,G.703 Balanced I/O Port . 5-11

5.8 Modem A Remote/Terminal/Fault Port on OMS11 (J2) ...................................................... 5-13

5.9 Modem A Remote/Terminal/Fault Port on OMS11 (J14) .................................................... 5-14

5.10 TX &RX Waveguide Switch Interface (J5 & J9) ................................................................ 5-14

5.11 Mating Connectors ............................................................................................................ 5-16

Section 6 - Maintenance and Troubleshooting ........................................................................ 6-1

6.0 Basic Troubleshootin g and Mai nte nanc e .............................................................................. 6-1

6.1 Basic User Checks ................................................................................................................ 6-1

6.1.1 Checking the Cabling and Connectors ............................................................................... 6-1

6.2 Major and Minor Faults .......................................................................................................... 6-1

TM133 – Rev. 1.1

Page 10

OMS11 1:1 Redundancy Switch Table of Contents

3

Section 7 - Technical Specifications ........................................................................................ 7-1

7.0 Introduction ............................................................................................................................ 7-1

7.1 General .................................................................................................................................. 7-1

7.2 Monitor and Control ............................................................................................................... 7-1

7.3 Terrestrial Interfaces .............................................................................................................. 7-1

7.4 Modem Data Cables .............................................................................................................. 7-1

7.5 Front Panel LED Indicators ................................................................................................... 7-1

7.6 Front Panel Controls .............................................................................................................. 7-2

7.7 Power and Environmental ..................................................................................................... 7-2

7.8 Physical ................................................................................................................................. 7-2

Appendix A - OMS11 DIP Switch Configuration ...................................................................... A-1

Appendix B - OMS11 Remote Comunications ......................................................................... B-1

B.0 Host Computer Remote Communications ............................................................................ B-1

B.0.1 Protocol Structure .............................................................................................................. B-1

B.0.2 Protocol Wrapper ............................................................................................................... B-1

B.0.3 Frame Description and Bus Handshaking ......................................................................... B-3

B.0.4 Global Response Operational Codes ................................................................................. B-5

B.0.5 Software Compatibility ....................................................................................................... B-5

B.0.6 RLLP Summary .................................................................................................................. B-6

B.1 Remote Port Packet Structure .............................................................................................. B-6

Appendix C - Interconnecting Cable Drawings ....................................................................... C-1

Glossary ..................................................................................................................................... G-1

TM133 – Rev. 1.1

Page 11

Introduction OMS11 1:1 Redundancy Switch

4

TM133 – Rev. 1.1

Page 12

OMS11 1:1 Redundancy Switch Introduction

1-1

Introduction

1

1.0 Description

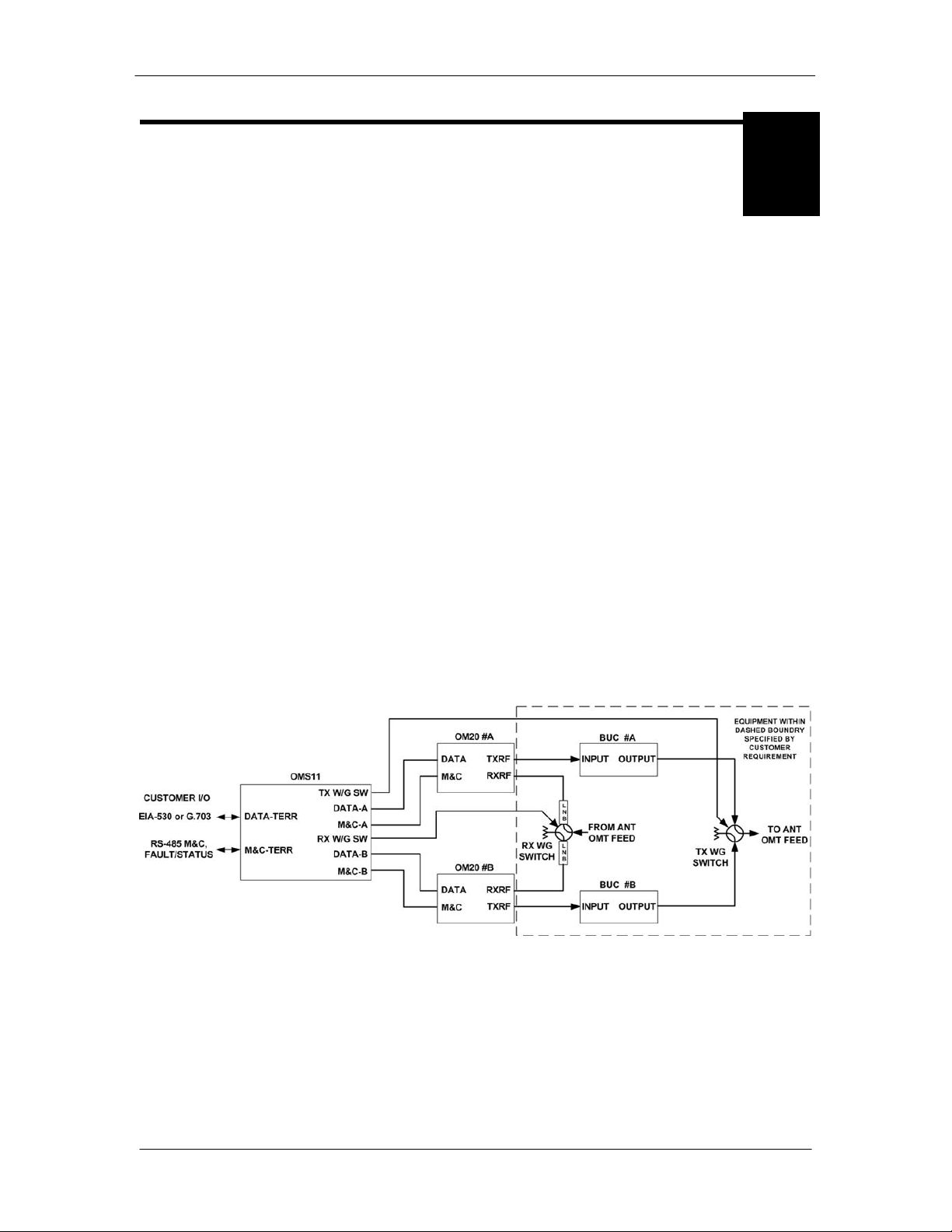

The Radyne OMS11 Outdoor Modem Switch provides redundancy protection for the OM20

Outdoor Modem, BUC and LNB. The OMS11 offers redundancy support for OM20 user data,

Asynchronous data, RS485 and BUC/LNB Waveguide Switching control. The OMS11

redundancy system is based on a Chain switching system that switches the IF/RF primary path to

the IF/RF Backup path. Optional BUCs, LNBs, Waveguide Switches and Mounting hardware are

optional items that can be supplied with the system. Contact Radyne for supported hardware

options. Refer to Figure 1-1 for an illustration of the OMS11 1:1 Redundancy Switch Front Panel

and Figure 1-3 of an OMS11 Functional Block Diagram.

Operating in the Automatic Mode, the OMS11 immediately places a Backup Modem and IF/RF

Path online in the event of a Primary Modem/IF/RF path fails. The OMS11 chain switches the

modem, BUC and LNB. In the Manual Mode, the user may designate the selected Online

Primary Modem from either the Interactive Front Panel or a remote Terminal Interface. The

backup functions of the OMS11 may be performed manually via the front panel or the RS485,

RLLP remote protocol or the RS232 Terminal port.

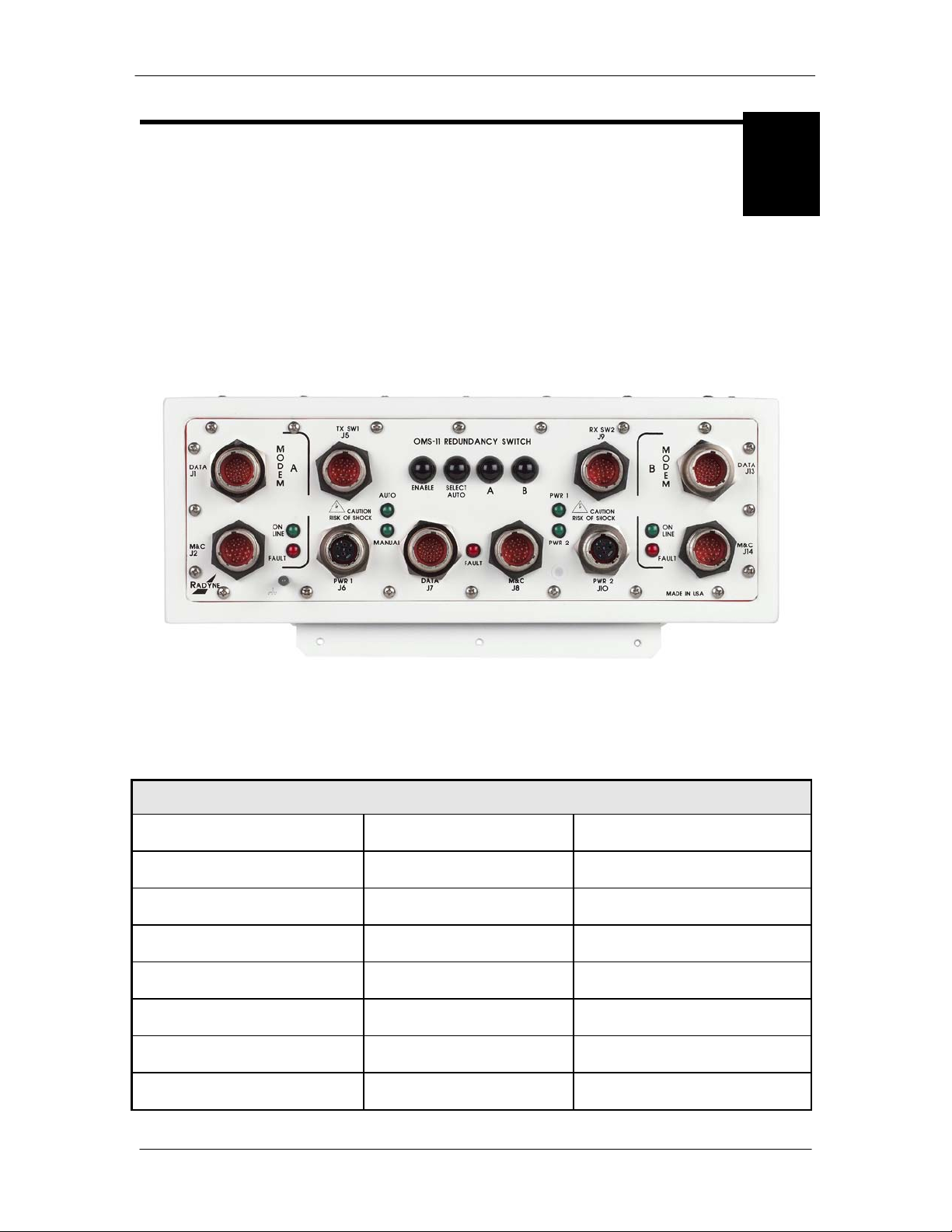

Figure 1-1 OMS11 1:1 Redundancy Switch Front Panel

1.1 Redundant Power Supplies

The OMS11 is equipped with two fully redundant internal power supplies. Each power supply is

independent of the other, including their source of AC or DC input source. The OMS11 remains

fully operational as long as either power supply is providing a source of power. The power

supplies are internal to the OMS11 Chassis.

TM133 – Rev. 1.1

Page 13

Introduction OMS11 1:1 Redundancy Switch

1-2

1.2 Front Panel Controls

The Front Panel of the OMS11 provides all of the necessary controls and LED indicators to

provide the operator with online status and backup status of the online and backup OM20

Modems.

1.3 Power-Up Defaults

During power-up, the OMS11 initializes itself to the last mode set by the Front Panel

Pushbuttons.

TM133 – Rev. 1.1

Page 14

OMS11 1:1 Redundancy Switch Introduction

1-3

TM133 – Rev. 1.1

Page 15

Page 16

OMS11 1:1 Redundancy Switch Theory of Operation

2-1

Theory of Operation

2

2.0 Theory of Operation

The Radyne OMS11 Outdoor Modem Switch provides redundancy protection for the OM20

Outdoor Modem, BUC and LNB. The OMS11 redundancy system is based on a Chain switching

system that switches the IF/RF primary path to the IF/RF Backup path. The Chain Switching

system can includes BUCs, LNBs, Waveguide, Waveguides Switches, mounting hardware and

connecting cables. BUCs, LNBs, Waveguide Switches and Mounting hardware are optional

items that can be supplied with the system. Refer to Figure 1-1 for an illustration of the OMS11

1:1 Redundancy Switch Front Panel and Figure 2-1 for the OMS11 Functional Block Diagram.

The BUC and LNB switch over fault detection system is primarily done by the OM20 Modem.

When the OM20 is configured to supply power to the BUC and LNB, the modem uses internal

detection circuitry to monitor current and voltage status of the BUC and LNB. User must properly

set up the BUC/LNB voltage and current threshold limits on the OM20. Refer to the OM20 user

manual for proper set.

In cases where the BUCs are powered by an external power supply, fault detection can be

detected by the OM20 only if the BUC includes Normally Closed contact closures. In order to

support BUC redundancy, the BUC must have Normally Closed Contact closures available for the

OMS11/OM20 to support redundancy.

2.1 OMS11 Operation

A block diagram of the signal flow is shown in Figure 2-1 below.

Figure 2-1 Functional Block Diagram

TM133 – Rev. 1.1

Page 17

Theory of Operation OMS11 1:1 Redundancy Switch

2-2

2.1.1 Operating Procedures

The OMS11 is designed to require minimal operator intervention and control during normal

operation. After initial setup, the unit should operate in a relatively ‘transparent’ manner,

providing trouble-free backup of the online Modems. The scope of this section is limited to

instruction on the various modes of control available to the operator. Refer to Section 3-1 for the

OMS11 Front Panel Controls and Indicators and Table 2-1 for a description of the Controls and

Indicators.

2.1.2 Configuring the OMS11

The redundancy switch must be properly configured prior to operation. Date interface type,

Remote communication type and remote baud rate must be set correctly to meet the users

needs. Configuring these options can only be done by removing the cover and accessing the dip

switches on the board. Appendix A of this manual gives specific information about the dip switch

settings for configuring the Terminal and Remote ports. If you need assistance with the settings,

contact Radyne customer service department.

2.1.3 Front Panel Controls (Refer to Figure 2-1)

The purpose of the ‘ENABLE’ pushbutton on the front panel is to reduce the risk of accidentally

changing the operating modes of the OMS11 by accidentally bumping any one of the front panel

pushbuttons. For any one of the front panel pushbuttons to function, the ‘ENABLE’ pushbutton

must be depressed simultaneously with the desired function pushbutton. Depress the ‘ENABLE’

pushbutton. This pushbutton must be depressed to allow the operator to proceed with any other

configurations. The ‘MANUAL’ LED should illuminate and the FAULT indicator may momentarily

flash. Under the MOD region of the front panel, depress ‘SELECT A’ to bring Modem ‘A’

modulator online. The green LED should illuminate. Under the DEMOD region of the front panel,

depress ‘SELECT A’ to bring modem ‘A’ demodulator online. The Green LED should illuminate.

The OMS11 should now be in backup mode with modem ‘A’ online.

2.1.4 Manual Mode

To manually select which Modem is to be placed online, simultaneously depress the ‘ENABLE’

pushbutton and the appropriate Modem ‘SELECT’ pushbutton. When a Modem select ion is

made, the OMS11 enters Manual Mode to carry out the selection, and will not respond to either

modem’s Modem Fault signals until placed back into Auto Mode.

2.1.5 Auto Mode

To enable automatic backup in the event of a Modem failure, the OMS11 must be placed into the

Auto Mode. First, select which Modem that will be active by following the ‘Manual Mode’

procedure in the previous paragrap h. To enter the Auto Mode, simultaneously depress the

‘ENABLE’ pushbutton and the ‘SELECT AUTO’ pushbutton. The OMS11 will then enter into Auto

Mode with the last selections made in Manual Mode. In the Auto Mode, the decision to switch

from one Modem to another is made automatically by monitoring the Fault signals from each

modem.

2.1.6 Power-Up Defaults

During power-Up, the OMS11 initiali ze s its elf to the last mode set by the operator on the front

panel pushbuttons.

TM133 – Rev. 1.1

Page 18

OMS11 1:1 Redundancy Switch Theory of Operation

2-3

2.2 OMS11 Major Assemblies

The OMS11 Redundancy Control Unit contains the modules that control and monitor the

operation of the 1:1 Switch system. The 1:1 Switch is composed of the followin g major

assemblies and components:

Main Switch Board

Waveguide Switch Board

Front Panel

Dual (Redundant) Po wer Supplies

2.2.1 Main Switch Board

The Main Switch Board contains the OMS11 1:1 Switch Intelligenc e and Memory Circuitry and all

switching circuitry. The microprocessor controls and coordinates all of the major functions of the

Switch and performs all necessary calculations. The non-volatile system memory on the board

stores the switching parameter settings for each modem channel. Control and data signals are

routed to the appropriate devices in the system through various latches and transceivers that are

controlled by the microprocessor.

2.2.2 Front Panel

The Front Panel contains the LED Indicators and the pushbutton switches needed to control and

operate the OMS11. Refer to Figure 3.0 for a description of Front Panel Indicators.

2.2.3 Redundant Power Supplies

The 1:1 Switch comes equipped with two fully redundant internal power supplies (PS1 and PS2)

that supplies power to the switch and external switching components. Each supply is fully

independent of the other, including their source of AC/DC power and fusing. The Switch can

remain fully operational as long as it is supplied with a source of voltage from either power

supply.

2.3 OMS11 General Operation

2.3.1 Data Signals

Modem data signals are backed-up through a passive switching system. Signals that are

required to maintain the modem in off-line (hot-standby) are buffered by appropriate circuitry to

minimize loading on incoming signals.

2.3.2 Backup

If an online Modem fault is sensed, and the off-line Modem is in a non-faulted state, the OMS11

will switch to the Modem without the fault. The Fault Signal has a small debounce delay to

prevent false triggering. If the faulted Modem has its fault cleared, it stays off-line unless the

other MODEM has subsequently faulted.

2.3.3 Fail-Safe

If the OMS11 has a non-recoverable internal fault, the swit c h w il l revert back to Modem A, the

Switch Fault LED is illuminated, and the Switch Fault Relay switches to a faulted state.

TM133 – Rev. 1.1

Page 19

Theory of Operation OMS11 1:1 Redundancy Switch

2-4

If Power Supply 1 and Power Supply 2 simultaneously fail, the switching circuitry in the OMS11

reverts back to Modem A, and the Switch Fault Relay switches to a faulted state. Modem B does

not receive buffered signals in this condition.

2.3.4 OMS11 Fault Relays

The OMS11 M&C Connector (J8) has Form-C contacts available that indicate modem online and

OMS11 Fault status. Refer to section for additional information.

2.4 Fault Detection

The OMS11 & OM20 work simultaneously to determine the status of all the componen ts within

this system. The OMS11 & OM20 are capable of monitoring BUC and LNB redundancy system.

Faults detection is established by the OM20 and forwarded to the OMS11. Fault detection for a

redundant BUC system will be different based on whether the BUC Power is supplied by the

OM20 or if the BUC Power is supplied by an external power source. If the BUC power is supplied

externally, then the BUC must have Normally Closed Form C Fault contacts so the OMS11/OM20

can monitor the BUC fault status.

Fault detection with the OM20 supplying power to BUC:

• BUC Faults - OM20 uses internal fault detection circuitry to determine BUC status and

initiates a fault that is forwarded to the OMS11

• OM20 uses internal fault detection circuitry to determine LNB status and initiate fault

Fault detection with BUC power supplied externally:

• BUC must have Normally Closed Form C contacts in order for BUC fault detection to

work

• OM20 data cable CAR5902 or CAR5918 has an external connector that is used to

connect and monitor Form C Contacts from the BUC.

• OM20 uses internal fault detection circuitry to determine LNB status and initiate fault

TM133 – Rev. 1.1

Page 20

OMS11 1:1 Redundancy Switch Theory of Operation

2-5

TM133 – Rev. 1.1

Page 21

Page 22

OMS11 1:1 Redundancy Switch User Interfaces

3-1

applied

Power Available

Power 2

Indicates PS2 has power

applied

LED illuminates Green for

Power Available

Fault

Indicates a Switch Fault

has occurred

LED illuminates Red for Switch

Fault

Auto (LED)

Indicates OMS11 is in the

Auto Mode

LED illuminates Green for Auto

Mode

the Manual Mode

Manual Mode

SELECT AUTO (Pushbutton)

-------------------

Allows the operator to select

Automatic Mode of operation

ENABLE (Pushbutton)

-------------------

Enables Front Panel controls to

function

User Interfaces

3

3.0 User Interfaces

These are:

Front Panel Interface – Refer to Section 3.1.

Remote Interface – Refer to Appendix B.

Figure 3-1 OMS11 Front Panel

3.1 Front Panel Interface

Table 3-1. OMS11 Front Panel Controls and Indicators

Nomenclature Description Function

Power 1 Indicates PS1 has power

Manual (LED) Indicates the OMS11 is in

LED illuminates Green for

LED illuminates Green for

TM133 – Rev. 1.1

Page 23

User Interfaces OMS11 1:1 Redundancy Switch

3-2

SELECT Modem A

--------------------

Allows the operator to select

SELECT Modem B

--------------------

Allows the operator to select

Online LED

Indicates Modem A is

LED illuminates Green for Online

Fault LED

The OMS11 has received

LED illuminates Red for Fault

Online LED

Indicates Modem B is

LED illuminates Green for Online

Fault LED

The OMS11 has received

LED illuminates Red for Fault

(Pushbutton)

(Pushbutton)

Modem A

Modem B

Modem A Controls and Indicators

online

a fault from Modem A

Modem B Controls and Indicators

online

a fault from Modem B

TM133 – Rev. 1.1

Page 24

OMS11 1:1 Redundancy Switch User Interfaces

3-3

TM133 – Rev. 1.1

Page 25

Page 26

OMS11 1:1 Redundancy Switch Installation

4-1

Installation

4

4.0 Installation Requirements

The diagrams in this section display the OMS11 and OM20s mounted on the Antenna King Post

as shown in figure 4-1 an d 4-2. The cables supplied in the base system are based on this layout

utilizing the mounting kit supplied by Radyne.

There are no user-serviceable parts located inside the OMS11 Chassis.

There is a potential shock haz ard internally at the power supply module.

DO NOT open the OMS11 Chassis under any circumstance s.

Before initially applying power to the unit, it is a good idea to disconnect

the transmit output from the operating ground station equipment. This is

especially true if the curr ent OMS11 configuration settings are unknown,

where incorrect setting could disrupt existing communications traffic.

The OMS11 is shipped with protective covers over the connectors. The

protective covers are used to create a moisture tight seal. Protective

covers must remain on the unit if connector is not used.

4.1 Unpacking

The OMS11 was carefully packaged to avoid damage and should arrive complete with the

following items for proper installation:

TM133 – Rev. 1.1

Page 27

Installation OMS11 1:1 Redundancy Switch

4-2

OMS11 1:1 Redundancy Switch Unit

Two AC or DC Mating connectors (J6 & J10)

Data Mating Connector (J7)

M&C Mating Connector (J8)

OMS11/OM20 Interconnect Cables and Materials as required

1:1 Switch System Test Data Sheet

An Installation and Operation Manual

C-Band or Ku Band Waveguide Switches (Optional)

Antenna Mounting hardware (Optional)

BUCS and LNBS (Optional)

4.1.1 Test Data Sheet

Each OMS11 1:1 Redundancy Switch system is shipped with a Test Data Sheet. This report

contains information on the results of the Switch quality control testing. The report also includes

information pertaining to the system settings that were made at the factory. Radyne recommends

that the user save this report for future reference.

4.2 Site Considerations

Adequate site planning and preparation simplifies the installation process and results in a more

reliable system. The user should ensure that the site has adequate electrical power,

environmental controls and protection against sources of electrical radiation and interference.

4.2.1 Power Sources

The power sources should be properly grounded and as free as possible from electrical

interference. The OMS11 employs a dual redundant power supply configuration. Each power

connection on the OMS11 must be plugged into its own separate power circuit. Each circuit must

have its own independent circuit breaker.

Grounding is achieved automatically when the properly terminated power connector is inserted

into the power receptacle. This should be checked by testing that there is no voltage present

between the chassis of the Switch and the power line ground.

The protective ground must not be bypassed or defeated In any way.

Defeating the ground may result in operator Injury or damage to the

system.

TM133 – Rev. 1.1

Page 28

OMS11 1:1 Redundancy Switch Installation

4-3

PROPER GROUNDING PROTECTION: During installation and setup, the

user must ensure that the unit is properly grounded. The equipment

shall be connected to the protective earth connection through the end

use protective earth protection.

4.3 System Setup & Connections

1. Install OMS11/OM20 Mounting kit as shown in Figure 4-1 and Table 4-1. This displays

the optional Radyne unistrut mounting kit for antenna kingpost mounting.

2. Mount the units as shown per figure 4-2 below. Configure units.

Note: Customer configurations may vary.

3. Install BUCs, LNBs and waveguide hardware onto mounting kit as shown in Figure 4-4.

This displays the optional Radyne unistrut mounting kit for antenna kingpost mounting.

4. Attach the Power Cords to the OMS11 and OM20 units to be connected.

5. Power up the units to be connected. Their Green Power LEDs should illuminate.

If not, refer to the appropriate Installation and Operation manual for further action to be

taken.

TM133 – Rev. 1.1

Page 29

Installation OMS11 1:1 Redundancy Switch

4-4

1

FP5914-2

UNISTRUT 2 FEET

3

ZB356

PIPE BLOCK ELECTRO-PLATED FINISH

4

Z15ATC-04403

ALL THRD ROD 7/16-14 18.8 SS 3FT

5

Z15FNC3-044

NUT, 7/16-14, 18.8 S/S HEX

6

Z15LW3-044

LOCK WASHR 7/16 18.8 SS MEDIUM SPLT

7

Z15LW3-044

WASHER, 7/16, 18.8 S/S FLAT

8

Z15LW3-038

WASHER SPLIT LOCK 3/8 SS

9

Z15LW3-038

WASHER 3/8IN SS FLAT

10

Z15CSC3-0380125

BOLT HEXHD 3/8X1-1/4IN SS

11

ZN228WO

CHANNEL NUT 3/8-16 ELEC PLATE ZINC

Figure 4-1 Antenna Mounting Kit

Item Radyne P/N Description

2 FP/5914-4 UNISTRUT 4 FEET

Table 4-1 Antenna Mounting Kit

TM133 – Rev. 1.1

Page 30

OMS11 1:1 Redundancy Switch Installation

4-5

TM133 – Rev. 1.1

Figure 4-2 Antenna Mount Front View on King Post

NOTE: All connections are facing down

Page 31

Installation OMS11 1:1 Redundancy Switch

4-6

CAR5902

J13

--

J3

--

--

CAR5918**

J13

--

J3

--

--

CAR5903

J14

--

J2

--

--

CAR5904

J9

--

--

--

J

J

CAR5933

J3 Plug

Figure 4-3 Antenna Mount Bottom View

Cable

Connects

CAR5902* J1 J3 -- -- --

CAR5918** J1 J3 -- -- --

CAR5903 J2 J2 -- -- --

CAR5904 J5 -- -- J --

CAR5933 J3 Plug

* CAR5902 is for G703 Balanced Communications

** CAR5918 is for RS422 Serial Communications

OMS11

Location

Table 4-3 Cable Connections between OM20 and OMS11

Modem A

Location

Modem B

Location

TX

Waveguide

RX

Waveguide

BUC

A/B

J

TM133 – Rev. 1.1

Page 32

OMS11 1:1 Redundancy Switch Installation

4-7

Figure 4-4 BUC Mount Front View on King Post

NOTE: Reference only

TM133 – Rev. 1.1

Page 33

Installation OMS11 1:1 Redundancy Switch

4-8

TM133 – Rev. 1.1

Page 34

OMS11 1:1 Redundancy Switch Connector Pinouts

5-1

J1

DATA A

RS422 Data I/O / G.703 Balanced / Async

MODEM A

J2

M&C A

RS485 Monitor & Control

MODEM A

J6

PWR 1

Power

OMS11

J7

DATA

RS422 Data I/O / G.703 Balanced / Async

OMS11

J8

M&C

RS232/RS485 Monitor & Control

OMS11

J9

RX SW2

RX Waveguide I/O, 48V

OMS11

J10

PWR 2

Power

OMS11

J13

DATA B

RS422 Data I/O / G.703 Balanced / Async

MODEM B

J14

M&C B

RS485 Monitor & Control

MODEM B

Connector Pinouts

5

5.0 OMS11 External Interface Connections

All OMS11 external connections are interconnected to labeled connectors located on the front of

the unit. Any connection interfacing to the OMS11 must utilize the appropriate mating connector

(supplied). Refer to Table 5-1. OMS11 Connections and Figure 5-1. OMS11 Connection Ports

for the standard unit. Reference throughout this section will be identified as the OMS11.

Table 5-1. OMS11 Connections

Connector Label Description Location

J5 TX SW1 TX Waveguide I/O, 48V OMS11

Figure 5-1. OMS11 Connection Ports

TM133 – Rev. 1.1

Page 35

Connector Pinouts OMS11 1:1 Redundancy Switch

5-2

FAULT

Modem has a fault

MODEM A

AUTO

Auto Mode selected

OMS11

MANUAL

Manual Mode selected

OMS11

FAULT

OMS 11 has a fault

OMS11

PWR 1

Power 1 status

OMS11

PWR 2

Power 2 status

OMS11

ONLINE

Modem online

MODEM B

FAULT

Modem has a fault

MODEM B

5.1 LED Indicators

There are nine (9) Light Emitting Diodes (LED’S) on the front of the unit. LEDs identify status of

Modem A, Modem B and OMS11. LEDs for Modem A and Modem B include Modems Online

Status and Fault Status. LEDs for the OMS11 include Power 1 Status, Power 2 Status, OMS11

Fault status, Auto Mode and Manual Mode. When power is supplied to the unit and the power

supply is functioning normally, this LED will be Green. Refer to Table 5-2. LED’s for pin-out

descriptions.

Table 5-2. LED’s

Label Description Location

ONLINE Modem online MODEM A

5.2 Power Input

5.2.1 AC Power Input (J6, J10)

AC Inputs are located on connector J6 and J10 of the OMS11. The auto-ranging univer sa l power

supply input allows for the connection of AC power to the port between the range of 100 – 240

VAC and 50 – 60 Hz. Power consumption for the unit is 1.0A (OMS11) only. An external chassis

ground post is located on the OMS11. The ground post is a #10-32 threaded stud that is used for

external grounding and should not be used to ground the AC power Source on J6 and J10. The

mating power connector is a 4-pin socket MFG P/N (D38999/24FC4SN) connecter. The mating

connector supplied with the unit.

Refer to Table 5-3 AC Po w erfor the connector pinouts.

Table 5-3 AC Pow er

A Line (L1)

B Neutral (L2)

C Ground

5.2.2 DC Power Input (J6, J10) (Optional)

An Optional DC Power Input is available for the OMS11. DC Inputs are located on connector J6

AND J10 of the OMS11. The unit may be powered from a 44 – 56 VDC sour c e with maximum

power consumption is 1.5 amps. This port is a 4-pin plug MFG P/N (D38999/24FC4PN)

connector. The mating connector supplied with the unit. Refer to Table 5-4. DC Power for the

connector pinouts.

TM133 – Rev. 1.1

Page 36

OMS11 1:1 Redundancy Switch Connector Pinouts

5-3

Table 5-4. DC Power

A – VDC

B + VDC

C Ground

D N/C

5.3 Ground Lug

An external chassis ground post is located on the OMS11, which requires a #10-32 threaded

stud.

PROPER GROUNDING PROTECTION: During installation and setup, the

user must ensure that the unit is properly grounded. The equipment shall

be connected to the protective earth connection through the end use

protective earth protection.

5.4 Remote Monitor & Control (J8)

This port functions as the OMS11 Remote and Fault port utilizing an 18-Pin D38999/24FD18PN

Connector. The Remote Port located on J8 allows for control and monitoring of parameters and

functions via an RS-232 Serial Interface or RS-485 for RLLP Protocol. ‘Equipment remote setup

parameters can be configured via the main board or Terminal mode. Based on the user's

application, this may require the user to set the Remote Port, properly configuring the units for

Multidrop Address followed by setting the Remote Interface from RS232 to RS485.

The mating connector is supplied with the unit. Refer to Table 5-5 for the Remote/Terminal

connector pinouts.

The OMS11’s internal M&C system is connected to most of the circuitry on any board contained

in the chassis. These connections provide status on the condition of the circuitry and provide the

data required for the various measurements the OMS11 provides. The on-board M&C proc ess es

this information and generates status indications and alarms when necessary. Status information

is available via the Remote port and the Form-C fault connections available on this connector.

This summary information can be connected to external equipment or alarms. Refer to Table 5-3.

5.4.1 Terminal Mode (RS232)

The Terminal Mode has the advantage of providing full screen access to the switches

parameters, but requires a separate terminal or computer running a Terminal Program. No

external software is required other than VT-100 Terminal Emulation Sof tware (e.g. “Procomm”

for a computer when used as a terminal. The Control Port is normally used as an RS–232

TM133 – Rev. 1.1

Page 37

Connector Pinouts OMS11 1:1 Redundancy Switch

5-4

Connection to the terminal device. This is the standard configuration when shipped from factory.

Refer to Table 5-5for pinouts. Refer to Appendix A for configuring unit to RS232 Terminal.

The factory terminal setup is as follows:

Emulation Type: VT-100 (can be changed)

Baud Rate: 9600

Data Bits: 8

Parity: No Parity (Fixed)

Stop Bits: 1 Stop Bit

The factory terminal Baud Rate can be changed by accessing dip switches located on the main

board. Internal DIP switches are accessible only by removing the top cover. Refer to Appendix

A, Figure A2.

5.4.2 Modem Remote Communications (RLLP/RS485)

The RLLP Remote Port is located on J8 allows for control and monitoring of parameters and

functions via an RS-485. Control and status messages are conveyed between the modem and all

subsidiary modems and the host computer using packetized message blocks in accordance with

a proprietary communications specification. This communication is handled by the Radyne Link

Level Protocol (RLLP), which serves as a protocol ‘wrapper’ for the RM&C data. Complete

information on monitor and control software is contained in the following sections. Refer to Table

5-5 for pinout descriptions. Refer to Appendix A for configuring the unit to RS485 Remote.

Refer to Appendix B for the RLLP Protocol.

This requires the user to first properly setup the unit ensuring Multidrop Address are configured

as needed. The OMS11 has internal DIP switches that are accessible only by removing the top

cover. DIP switch S3 is used to configure remote baud rates and addressing. Refer to Appendix

A, Figure A2 for dip switch information. If you are having trouble with DIP switch settings, contact

Radyne Customer Service for any additional help.

5.4.3 Common Equipment Faults (J8)

Common equipment fault hardware is available on the OMS11. The OMS11 M&C Connector (J8)

has Form-C contacts available that indicate which modem is online and indicates OMS11 Fault

status. Refer to Table 5-5.

Table 5.5. Remote Monitor & Control / Faults (J8)

Pin No. Signal Name Signal Direction

A Receive Data RS-232 RXD-232 Input

B Transmit Data RS-232 TXD-232 Output

C Reserved --- --D Transmit Data RS-485 (+) TX-485-B Output

E Transmit Data RS-485 (-) TX-485-A Output

F Receive Data RS-485 (+) RX-485-B Input

G Receive Data RS-485 (-) RX-485-A Input

TM133 – Rev. 1.1

Page 38

OMS11 1:1 Redundancy Switch Connector Pinouts

5-5

H Ground GND ---

J Switch Fault – C SF-C --K Switch Fault – NC SF-NC --L Switch Fault – NO SF-NO ---

M No Connect --- --N No Connect --- ---

S DSR ---

R No Connect --- --U No Connect --- ---

P Modem A Online Relay – NC MO-NC --T Modem B Online Relay – NO MO-NO ---

5.4.3.1 Fault Detection

The OMS11 & OM20 work simultaneously to determine the status of all the components within

this system. The OMS11 & OM20 are capable of monitoring BUC and LNB redundancy system.

Faults detection is established by the OM20 and forwarded to the OMS11. Fault detection for a

redundant BUC system will be different based on whether the BUC Power is supplied by the

OM20 or if the BUC Power is supplied by an external power source. If the BUC power is supplied

externally, then the BUC must have Normally Closed Form C Fault contacts so the OMS11/OM20

can monitor the BUC fault status.

Figure 5-2 reflects the BUC fault detection connector which is required for BUC that are using

external Power supplies.

Figure 5-2 External BUC fault detection o n CAR5902 or CAR5918

TM133 – Rev. 1.1

Page 39

Connector Pinouts OMS11 1:1 Redundancy Switch

5-6

Fault detection with the OM20 supplying power to BUC:

• BUC Faults - OM20 uses internal fault detection circuitry to determine BUC status and

initiates a fault that is forwarded to the OMS11

• OM20 uses internal fault detection circuitry to determine LNB status and initiate fault

Fault detection with BUC power supplied externally:

• BUC must have Form C contacts in order for BUC fault detection to work

• OM20 data cable CAR5902 or CAR5918 has an external connector that is used to

connect and monitor Form C Contacts from the BUC.

• OM20 uses internal fault detection circuitry to determine LNB status and initiate fault

TM133 – Rev. 1.1

Page 40

OMS11 1:1 Redundancy Switch Connector Pinouts

5-7

5.5 Terrestrial Data Interface (J7) – RS422 S ynchronous Data,

Asynchronous Overhead Data, and G.703 Balanced Data I/O Port

This 37 Pin D38999/24FD35PN Connector contains the RS422 data connections, the RS485

Asynchronous Overhead data interface and the G.703 Balanced interface.

Refer to Table 5-6 for pin-outs. Refer to Table 5-7 for G.703 Balanced pin-outs.

Table 5.6. RS422 Synchronous Data I/O; Async Data Connector (J7)

J7

Pin No.

1 Shield--- --- 1

2 Send Data B (+) SD-B Input 14

3 Send Data A (-) SD-A Input 2

4 Send Timing A (-) ST-A Output 15

5 Receive Data RD-A Output 3

6 Receive Data B (+) RD-B Output 16

7 Request To Send A (-) RS-A Input 4

8 Receive Timing A (-) RT-A Output 17

9 Clear To Send A (-) CS-A Output 5

10

11 Data Mode A (-) DM-A Output 6

12 Request To Send B (+) RS-B Input 19

13 Signal Ground SGND --- 7

14 Data Terminal Ready A (-) TR-A Input 20

Signal Name Signal Direction EIA-530 25

Pin Connector

Reference

15 Receiver Ready A (-) RR-A Output 8

16

17 Receive Timing B (+) RT-B Output 9

18 Data Mode B (+) DM-B Output 22

19 Receiver Ready B (+) RR-B Output 10

20 Data Terminal Ready B (+) TR-B Input 23

21 Terminal Timing B (+) TT-B Input 11

22 Terminal Timing TT-A Input 14

23 Send Timing B (+) ST-B Output 12

24 No Connect --- --- 25

25 Clear To Send B (+) CS-B Output 13

TM133 – Rev. 1.1

Page 41

Connector Pinouts OMS11 1:1 Redundancy Switch

5-8

Table 5.6 cont. RS422 Synchronous Data I/O; Async Data Connector (J7)

J7

Async - Signal Name Signal Direction

Pin No.

26 Transmit Data B (Async) TXD_B Input N/C

27 Transmit Data A (Async) TXD_A Input N/C

30 Receive Data A (Async) RXD_A Output N/C

31 Receive Data B (Async) RXD_B Output N/C

Table 5.7. G.703 Balanced (J7)

J7

G703 Balance - Signal Name Signal Direction G.703

Pin No.

32 Send Data (-) SD-A Input 1

35 Receive Data A (-) RD-A Output 3

34 Ground GND --- 4

33 Send Data (+) SD-B Input 9

36 Receive Data B (+) RD-B Output 11

37

Balanced

15 Pin

Connector

Reference

29

28

TM133 – Rev. 1.1

Page 42

OMS11 1:1 Redundancy Switch Connector Pinouts

5-9

5.6 Modem A Data Interface (J1) – RS422 Synchronous Data,

Asynchronous Overhead Data, and G.703 Balanced Data I/O Port

This 37Pin D38999/24FD35PN Connector contains the RS422 data connections, RS485

Asynchronous Overhead data interface; G .7 03 Ba lanced interface, and the Open Collector

Modulator and Demodulator Faults. Refer to Table 5-8 for pin-outs. Refer to Table 5-9 for G.703

Balanced.

NOTE: Data cables between the Modem and OMS11 are different based on interface type:

G703 Balanced CAR5902

RS422 CAR5918

Table 5.8. RS422 Synchronous Data I/O; Async Data Connector (J1)

J1

Pin No.

1 Shield--- --- 1

2 Send Data B (+) SD-B Input 14

3 Send Data A (-) SD-A Input 2

4 Send Timing A (-) ST-A Output 15

5 Receive Data A (-) RD-A Output 3

6 Receive Data B (+) RD-B Output 16

7 Request To Send A (-) RS-A Input 4

8 Receive Timing A (-) RT-A Output 17

9 Clear To Send A (-) CS-A Output 5

10 Modulator Fault – Open Collector MF Output 18

11 Data Mode A (-) DM-A Output 6

12 Request To Send B (+) RS-B Input 19

13 Signal Ground SGND --- 7

14 Data Terminal Ready A (-) TR-A Input 20

RS422 - Signal Name Signal Direction EIA-530 Std.

Reference

25 Pin

15 Receiver Ready A (-) RR-A Output 8

16 Demodulator Fault DF Output 21

17 Receive Timing B (+) RT-B Output 9

18 Data Mode B (+) DM-B Output 22

19 Receiver Ready B (+) RR-B Output 10

20 Data Terminal Ready B (+) TR-B Input 23

21 Terminal Timing B (+) TT-B Input 11

22 Terminal Timing TT-A Input 14

23 Send Timing B (+) ST-B Output 12

24 No Connect --- --- 25

25 Clear To Send B (+) CS-B Output 13

TM133 – Rev. 1.1

Page 43

Connector Pinouts OMS11 1:1 Redundancy Switch

5-10

Table 5.8 cont. RS422 Synchronous Data I/O; Async Data Connector (J1)

J1

Async - Signal Name Signal Direction

Pin No.

26 Transmit Data B (Async) TXD_B Input N/C

27 Transmit Data A (Async) TXD_A Input N/C

28 No Connect --- --- N/C

30 Receive Data A (Async) RXD_A Output N/C

31 Receive Data B (Async) RXD_B Output N/C

Table 5.9 G.703 Balanced (J1)

J1

G703 Balance - Signal Name Signal Direction G.703

Pin No.

32 Send Data (-) SD-A Input 1

35 Receive Data A (-) RD-A Output 3

34 Ground GND --- 4

33 Send Data (+) SD-B Input 9

36 Receive Data B (+) RD-B Output 11

Balanced

15 Pin

Reference

37 No Connect --- --- 14

29 No Connect --- --- 15

TM133 – Rev. 1.1

Page 44

OMS11 1:1 Redundancy Switch Connector Pinouts

5-11

J13

5.7 Modem B Data Interface (J13) – RS422 Synchronous Data,

Asynchronous Overhead Data, and G.703 Balanced Data I/O Port

This 38 Pin D38999/24FD35PN Connector contains the RS422 data connections, RS485

Asynchronous Overhead data interface; G.703 Balanced interface, and the Open Collector

Modulator and Demodulator Faults. Refer to Table 5-10 for pin-outs. Refer to Table 5-11 for

G.703 pin-outs.

NOTE: Data cables between the Modem and OMS11 are different based on interface type:

G703 Balanced CAR5902

RS422 CAR5918

Table 5-10 RS422 Synchronous Data I/O; Async Data Connector (J13)

RS422 - Signal Name Signal Direction EIA-530 Std.

Pin No.

1 Shield--- --- 1

2 Send Data B (+) SD-B Input 14

3 Send Data A (-) SD-A Input 2

4 Send Timing A (-) ST-A Output 15

25 Pin

Reference

5 Receive Data RD-A Output 3

6 Receive Data B (+) RD-B Output 16

7 Request To Send A (-) RS-A Input 4

8 Receive Timing A (-) RT-A Output 17

9 Clear To Send A (-) CS-A Output 5

10 Modulator Fault – Open Collector MF Output 18

11 Data Mode A (-) DM-A Output 6

12 Request To Send B (+) RS-B Input 19

13 Signal Ground SGND --- 7

14 Data Terminal Ready A (-) TR-A Input 20

15 Receiver Ready A (-) RR-A Output 8

16 Demodulator Fault DF Output 21

17 Receive Timing B (+) RT-B Output 9

18 Data Mode B (+) DM-B Output 22

19 Receiver Ready B (+) RR-B Output 10

20 Data Terminal Ready B (+) TR-B Input 23

21 Terminal Timing B (+) TT-B Input 11

22 Terminal Timing TT-A Input 14

23 Send Timing B (+) ST-B Output 12

24 No Connect --- --- 25

25 Clear To Send B (+) CS-B Output 13

TM133 – Rev. 1.1

Page 45

Connector Pinouts OMS11 1:1 Redundancy Switch

5-12

3

Table 5-10 cont. RS422 Synchronous Data I/O; Async Data Connector (J13)

J13

Async - Signal Name Signal Direction

Pin No.

26 Transmit Data B (Async) TXD_B Input N/C

27 Transmit Data A (Async) TXD_A Input N/C

28 No Connect --- --- N/C

30 Receive Data A (Async) RXD_A Output N/C

31 Receive Data B (Async) RXD_B Output N/C

Table 5-11 G.703 Balanced (J13)

J1

G703 Balance - Signal Name Signal Direction G.703 Bal

Pin No.

32 Send Data (-) SD-A Input 1

35 Receive Data A (-) RD-A Output 3

34 Ground GND --- 4

33 Send Data (+) SD-B Input 9

15 Pin

Connector

Reference

36 Receive Data B (+) RD-B Output 11

37 No Connect --- --- 14

29 No Connect --- --- 15

TM133 – Rev. 1.1

Page 46

OMS11 1:1 Redundancy Switch Connector Pinouts

5-13

5.8 Modem A Remote/Terminal/Fault Port on OMS11 (J2)

This port provides Fault status and RS485 Communications to the OMS11 from the OM20

(Modem A). This port utilizes an 18-Pin D38999/24FD18PN Connector. Refer to Table 5-12 for

the pinout information. .

Table 5-12 Remote/Terminal/Fault Connector (J2)

Pin No. Signal Name Signal Direction

A Receive Data RS-232 RX-232 ---

B Transmit Data RS-232 TX-232 ---

C No Connect --- --D Transmit Data RS-485 (+) TX-485-B Output

E Transmit Data RS-485 (-) TX-485-A Output

F Receive Data RS-485 (+) RX-485-B Input

G Receive Data RS-485 (-) RX-485-A Input

H Ground GND ---

J Mod Fault – Common MF-C --K Mod Fault – NC MF-NC --L Mod Fault – NO MF-NO ---

M Demod Fault - Common DF-C --N Demod Fault – NO DF-NO ---

S Demod Fault – NC DF-NC ---

R Ground GND --U No Connect --- ---

P No Connect --- --T No Connect --- ---

TM133 – Rev. 1.1

Page 47

Connector Pinouts OMS11 1:1 Redundancy Switch

5-14

5.9 Modem B Remote/Terminal/Fault Port on the OMS11 (J14)

This port provides Fault status and RS485 Communications to the OMS11 from the OM20

(Modem B). This port utilizes an 18-Pin D38999/24FD18PN Connector. Refer to Table 5-13 for

the pinout information.

Table 5-13 Remote/Terminal/Fault Connector (J14)

Pin No. Signal Name Signal Direction

A Receive Data RS-232 RX-232 --B Transmit Data RS-232 TX-232 ---

C No Connect --- --D Transmit Data RS-485 (+) TX-485-B Output

E Transmit Data RS-485 (-) TX-485-A Output

F Receive Data RS-485 (+) RX-485-B Input

G Receive Data RS-485 (-) RX-485-A Input

H Ground GND ---

J Mod Fault – Common MF-C --K Mod Fault – NC MF-NC --L Mod Fault – NO MF-NO ---

M Demod Fault - Common DF-C --N Demod Fault – NO DF-NO ---

S Demod Fault – NC DF-NC ---

R Ground GND --U No Connect --- ---

P No Connect --- --T No Connect --- ---

5.10 TX & RX Waveguide Switch Interface (J5 & J9)

These ports provide 48Volts for switching the RX and TX Waveguide switches. For TX

waveguide switching, connect the CAR5904 cable between the J5 of the OMS11 to the TX

waveguide Switch. For RX waveguide switching, connect the CAR5904 cable between the J9 of

the OMS11. The chart below identifies the J5 & J9 pinouts on the OMS11 and the mating

connector pinout for a Sector Microwave Switch. Connector information and pinout descriptions

are identified below. Refer to Table 5-14 and Figure 5-3. CAR5904 is supplied by Radyne when

waveguide switching hardware is supplied by Radyne.

TM133 – Rev. 1.1

Page 48

OMS11 1:1 Redundancy Switch Connector Pinouts

5-15

Table 5-154 CAR5904 OMS11 TO SECTOR MICROWAVE W/G SWITCH

CONNECTOR

OMS11 J5 / J9

SECTOR MICROWAVE SWITCH

TX / RX W/G SW

MFGR

AMPHENOL

SOUR

HOUSING

AL07F15-18P

MS3116F12-10S

DESCRIPTION

CONTACTS

10-251415-205

INC.

STRAIN RELIEF

M85049-38S15N

INC.

CABLE INFO

MFG: NATIONAL

CABLE

P/N: NQP-1928SJ

WIRING LIST

SIGNAL

CONN # PIN #

CONN # PIN #

N/C

N/C

N/C

Pos 2 Volts

C

C

Pos 1, Ind 1

D

D

Pos 1 Common

E

E

Pos 2, Ind 1,

F

F

Pos 1, Ind 2

G

G

Ind 2, Com

H

H

Pos 2, Ind 2

J

J

N/C

K

N/C

N/C

L

N/C

N/C

M

N/C

N/C

N

N/C

N/C

N/C

N/C

R

N/C

N/C

U

N/C

N/C

P

N/C

Pos 1 Volts

T

A

JAM NUT RECPT CONN. W/ST.RELF.

Common B B

TM133 – Rev. 1.1

S

Page 49

Connector Pinouts OMS11 1:1 Redundancy Switch

5-16

J1 & J13

Data

CN/26FD35SN

JD3899/26FD35SN

J1 & J13

Data / Stress Relief

CN/M85049/38-15

M85049/3/-15A

J2 & J14

Faults

CN/26FD18SN

JD38999/26FD18SN

J2 & J14

Faults / Stress Relief

CN/M85049/38-15

M85049/38-15A

J5 & J9

TX/RX WG SW

CN/26FD18SN

JD38999/26FD18SN

J5 & J9

TX/RX WG SW / Stress Relief

CN/M85049/38 -15

M85049/38-15A

J6 & J10

Power / DC

CN/26FC4PN

D38999/26FC4PN

J6 & J10

Power / DC / Stress Relief

CN/M85049/38-13

M85049/38-13A

J6 & J10

Power / AC

CN/26FC4SN

D38999/26FC4SN

J6 & J10

Power / AC / Stress Relief

CN/M85049/38-13

M85049/38-13A

J7

Data

CN/26FD35SN

JD3899/26FD35SN

J7

Data / Stress Relief

CN/M85049/38-15

M85049/3/-15A

J8

Faults

CN/26FD18SN

JD38999/26FD18SN

J8

Faults / Stress Relief

CN/M85049/38-15

M85049/38-15A

Figure 5-3. Pinout for Sector Microwave Switch

5.11 Mating Connectors

The chart below identifies Radyne and Manufacturer part numbers for the mating connectors to

the OMS11. Refer to Table 5-15 for connector part numbers.

Table 5-15 Mating Connectors

Connector Description Radyne P/N MFG P/N Amphenol

TM133 – Rev. 1.1

Page 50

OMS11 1:1 Redundancy Switch Connector Pinouts

5-17

TM133 – Rev. 1.1

Page 51

Page 52

OMS11 1:1 Redundancy Switch Maintenance and Troubleshooting

Maintenance and Troubleshooting

6

6.0 Basic Troubleshooting and Maintenance

This section provides information on the basic troubleshooting and repair procedures for the

OMS11 1:1 Switch that may be performed on-site by qualified personnel. Only minor repairs will

be discussed. For serious failures, the user should not attempt to repair the unit without first

contacting the Radyne Customer Service Department at 602-437-9620 for further information and

instructions.

6.1 Basic User Checks

Upon the detection of an operational failure, the source of the failure must be determined. Basic

user checks include checking the various cables and connectors.

6.1.1 Checking the Cabling and Connectors

Problems that appear difficult to solve can often be traced to a loose or defective cable or

connector. The user should first verify the following:

• All cables within the system have no broken or loose connections. Cables that are

suspect should be replaced.

• All jacks on the units have no bent or broken pins.

• Both AC Power Cords are properly plugged into the rear of the OMS11.

6.2 Major and Minor Faults

Major faults are failure conditions or combinations of conditions that result in loss of service on

one or more channels. Minor faults are failure conditions that do not result in loss of service.

Possible Major Fault conditions are:

A Read-Only Memory (ROM) failure in the Switch;

A Random Access Memory (RAM) failure in the Switch;

A loss of Carrier Detect on a Demodulator Channel where this attribute is monitored;

A loss of Terrestrial Input Clock on a Channel where this attribute is monitored;

A failure of two monitored Modulators;

A failure of two monitored Demodulators;

A failure of both OMS11 power supplies.

Possible Minor Fault conditions are as follows:

A failure of one of the Switch’s two redundant power supplies;

A failure of one Demodulator that is being monitored (i.e., a Demodulator that has not

been locked out);

A failure of one Modulator that is being monitored;

A reference clock slip.

TM133 – Rev. 1.1 6-1

Page 53

Maintenance and Troubleshooting OMS11 1:1 Redundancy Switch

6-2 TM061 – Rev. 2.0

Page 54

OMS11 1:1 Redundancy Switch Technical Specifications

Technical Specifications

7

7.0 Introduction

This section defines the technical performance parameters and specifications for the OMS11 1:1

Redundancy Switch.

7.1 General

Modes of Operation: Auto, Manual, Remote

Configurations: Modem (Chain Switch)

Modem Switch Time: 50 msec Maximum

7.2 Monitor and Control

Operating parameters can be monitored and controlled via the RS232 Terminal port or the

RS485 RLLP control channel. The following modem parameters may be controlled and/or

monitored:

Parameters Monitored: Mode, Modem, Power Supply Status, Internal Switch

Settings, Software Revision, Auto/Manual, Select A,

Select B

Parameters Controlled: Modem, Auto/Manual, Select A, Select B

7.3 Terrestrial Interfaces

RS422 & G703 Balanced

RS422 & G703 Unbalanced (Optional)

7.4 Modem Data Cables

CAR5902 G703 Balanced

CAR5918 RS422

7.5 Front Panel LED Indicators

Unit: Power Supply 1

Power Supply 2

Switch Fault

Auto

Manual

Modem: Online A

Online B

Fault A

Fault B

TM133 – Rev. 1.1 7-1

Page 55

Technical Specifications OMS11 1:1 Redundancy Switch

7.6 Front Panel Controls

Enable

Select Auto

Modem Select A

Modem Select B

7.7 Power and Environmental

Prime Power: 100 to 240VAC, 50/60 Hz, 40W typ, 200W Max

44 - 56VDC, 40W typical, 200W Max during switchover

Operating Temperature: -40 to 50°C, 95% Humidity, Noncondensing

Storage Temperature: -50 to 70°C, 99% Humidity, Noncondensing

7.8 Physical

OMS11 Chassis Size: 11.4” L x 15.4” W x 5.7” H

(28.9 cm x 39.1 cm x 14.48 cm)

12 Pounds (5.4 Kg)

7-2 TM133 – Rev. 1.0

Page 56

OMS11 1:1 Redundancy Switch Technical Specifications

TM133 – Rev. 1.1 7-3

Page 57

Page 58

OMS11 1:1 Redundancy Switch Appendix A

OMS11 DIP Switch Configuration

A

The OMS11 has four internal DIP switches that ar e accessible only by removing the top cover .

These DIP switches S2, S3, S4 & S5 are used to configure Interface options, data rates and

remote baud rates . An upgrade or cha nge from an existing interface or configuration to another

may require a change to o ne or more of the DIP switch settings . If you are having trouble with

DIP switch settings, contact Radyne Customer Service for any additional help.

Figure A-1 Illustrates the DIP switch positions for the OM20.

Figure A-2 Illustrates the unit Addressing for and Baud Rate switch positions for remote M&C.

Figure A-1. DIP Switch Positions for the OM20

Figure A2. DIP Switch showing Address and Baud Rate

Table A-1 identifies the various S3 dip switch positions. Pins 1 - 6 are utilized for M&C unit

addressing when using m ultiple s witches. Pins 7 & 8 are utilize d for baud rate f or the term inal or

remote M&C. Address settings are also accessible through the Remote Port (J-20) with the

switch in Terminal Mode. An empty space in Table A-1: represents the (off) position.

TM133 – Rev. 1.1 A-1

Page 59

Appendix A OMS11 1:1 Redundancy Switch

9600

4800

ON

2400

ON

ADDRESS

32

33

ON

36

ON

37

ON ON

38

ON

ON

40 ON

41

ON

ON

42

ON ON

43

ON

ON ON

44

ON

ON

45

ON ON

ON

47

ON

ON

ON

ON

48

ON

49

ON ON

52

ON ON

53

ON ON ON

54

ON

ON ON

55

ON

ON

ON ON

56 ON

ON

57

ON

ON

ON

59

ON

ON ON

ON

60

ON

ON

ON

61

ON ON

ON

ON

62

ON

ON

ON

ON

64 ON

65

ON

ON

66

ON ON

67

ON

ON ON

68

ON

ON

69

ON ON

ON

72 ON ON

73

ON

ON ON

74

ON ON ON

76

ON

ON ON

77

ON ON

ON ON

78

ON

ON

ON ON

79

ON

ON

ON

ON ON

80

ON

ON

81

ON ON

ON

82

ON

ON

ON

83

ON

ON

ON

ON

86

ON

ON ON

ON

87

ON

ON

ON ON

ON

88 ON

ON

ON

90

ON ON

ON

ON

91

ON

ON ON

ON

ON

92

ON

ON

ON

ON

93

ON ON

ON

ON

ON

94

ON

ON

ON

ON

ON

SOFT

ON

ON

ON

ON

ON

ON

BAUD RATE

Table A-1. Baud Rate Switch Positions

SW-1 SW-2 SW-3 SW-4 SW-5 SW-6

SW-7 SW-8

34 ON

35 ON ON

39 ON ON ON

46 ON ON ON

50 ON ON

51 ON ON ON

58 ON ON ON

63 ON ON ON ON ON

70 ON ON ON

71 ON ON ON ON

75 ON ON ON ON

84 ON ON ON

85 ON ON ON ON

89 ON ON ON ON

A-2 TM133 – Rev. 1.1

Page 60

OMS11 1:1 Redundancy Switch Appendix A

When Jumpers are set for SOFT, this allows user to set the Baud and Unit

Addresses remotely via the terminal port.

Figure A3 Illustrates how to configure the Dip Switches for RS232 Data on an OMS11.

Figure A3. DIP Switch on the RS232 Driver

Figure A4 Illustrates how to configure the Dip Switches for G.703 Unbalanced data on an OMS11

with Universal Data Interface.

Figure A4. DIP Switch on the G.703 Driver

TM133 – Rev. 1.1 A-3

Page 61

Appendix A OMS11 1:1 Redundancy Switch

Figure A5. JP1 on AS/3436-6

Figure A5 illustrates the standard jumper block for configuring unit to RS485 Remote or RS232

Terminal mode. Unit is configured to RS232 Terminal when shipped from the factory as per the

picture above.

The diagram above indicates an RS232 configuration. Installing the jumper, connecting the pins

will configure the unit for RS485.

A-4 TM133 – Rev. 1.1

Page 62

OMS11 1:1 Redundancy Switch Appendix A

TM133 – Rev. 1.1 A-5

Page 63

Page 64

OMS11 1:1 Redundancy Switch Appendix B

OMS11 Rem ot e Comm unications

B

B.0 Host Computer Remote Communications

Control and status messages are conveyed between the OMS11 and the host computer using

packetized message blocks in accordance with a proprietary communications specification. This

communication is handled by the Radyne Link Level Protocol (RLLP), which serves as a protocol

‘wrapper’ for the RM&C data.

Complete information on monitor and control software is contained in the Radyne RLLP

Protocol Reference Guide.

For RS485 Remote communication, install CA/3733 gender changer into

the remote port. Gender changes port from RS232 to RS485

B.0.1 Protocol Structure

The Communications Specification (COMMSPEC) defines the interaction of computer resident

Monitor and Control software used in satellite earth station equipment such as Modems,

redundancy switches, multiplexers, and other ancillary support gear. Communication is bidirectional, and is normally established on one or more full-duplex 9600-baud multi-drop control

buses that conform to EIA Standard RS-485.

Each piece of earth station equipment on a control bus has a unique physical address, which is

assigned during station setup/configuration or prior to shipment. Valid decimal addresses on one

control bus range from 032 through 255 for a total of up to 224 devices per bus. Address 255 of

each control bus is usually reserved for the M&C computer.

B.0.2 Protocol Wrapper

The Radyne COMMSPEC is byte-oriented, with the Least Significant Bit (LSB) issued first. Each

data byte is conveyed as mark/space information with two marks comprising the stop data. When

the last byte of data is transmitted, a hold comprises one steady mark (the last stop bit). To begin

or resume data transfer, a space (00h) substitutes this mark. This handling scheme is controlled

by the hardware and is transparent to the user. A pictorial representation of the data and its

surrounding overhead may be shown as follows:

S1 S2 B

B1 B2 B3 B4 B5 B6 B7 S1 S2, etc.

0

TM133 – Rev. 1.1 B-1

Page 65

Appendix B OMS11 1:1 Redundancy Switch

The stop bits, S1 and S2, are each a mark. Data flow remains in a hold mode until S2 is replaced

by a space. If S2 is followed by a space, it is considered a start bit for the data byte and not part

of the actual data (B

- B 7).

0

The COMMSPEC developed for use with the Radyne Link Level Protocol (RLLP) organizes the

actual monitor and control data within a shell, or ‘protocol wrapper’, which surrounds the data.

The format and structure of the COMMSPEC message exchanges are described herein. Decimal

numbers have no suffix; hexadecimal numbers end with a lower case h suffix and binary values

have a lower case b suffix. Thus, 22 = 16h = 000010110b. The principal elements of a data

frame, in order of occurrence, are summarized as follows:

<SYN> - the message format header character, or ASCII sync character, that defines the

beginning of a message. The <SYN> character value is always 16h.

<DATA COUNT> - the 2 Byte Data Count is the number of bytes in the <DATA> field, ranging

from 0 through 509.

<SOURCE ID> - the Source Identifier defines the multi-drop address origin. Note that all nodes

on a given control bus has an unique address that must be defined.

<DESTINATION ID> - the Destination Identifier serves as a pointer to the multi-drop destination

device that indicates where the message is to be sent.

<FRAME SEQUENCE NUMBER> -the FSN is a tag with a value from O through 255 that is sent

with each message. It assures sequential information framing and correct equipment

acknowledgment and data transfers.

<OPCODE> - the 2 Byte Operation Code field contains a number that identifies the message type

associated with the data that follows it. Equipment under MCS control recognizes this byte via

firmware identification and subsequently steers the DATA accordingly to perform a specific

function or series of functions. Acknowledgment and error codes are returned in this field. 1 Byte

for the DMD5000 protocol and 2 Bytes for the DMD15 protocol.