Page 1

CST-5005

p

C-Band Satellite Terminal

Installation and O

Part Number MN/CST5005.IOM Revision 1

eration Manual

Page 2

Comtech EFData is an ISO 9001

Registered Company.

CST-5005

C-Band Satellite Terminal

Installation and Operation Manual

Part Number MN/CST5005.IOM

Revision 1

July 23, 1996

Comtech EFData, 2114 West 7th Street, Tempe, Arizona 85281 USA, (480) 333-2200, FAX: (480) 333-2161.

Copyright © Comtech EFData, 2000. All rights reserved. Printed in the USA.

Page 3

Customer Support

Contact the Comtech EFData Customer Support Department for:

• Product support or training

• Information on upgrading or returning a product

• Reporting comments or suggestions concerning manuals

A Customer Support representative may be reached at:

Comtech EFData

Attention: Customer Support Department

2114 West 7th Street

Tempe, Arizona 85281 USA

(480) 333-2200 (Main Comtech EFData Number)

(480) 333-4357 (Customer Support Desk)

(480) 333-2161 FAX

or, E-Mail can be sent to the Customer Support Department at:

service@comtechefdata.com

Contact us via the web at www.comtechefdata.com.

1. To return a Comtech EFData product (in-warranty and out-of-warranty) for

repair or replacement:

2. Request a Return Material Authorization (RMA) number from the Comtech

EFData Customer Support Department.

3. Be prepared to supply the Customer Support representative with the model

number, serial number, and a description of the problem.

4. To ensure that the product is not damaged during shipping, pack the product in

its original shipping carton /p ack ag ing .

5. Ship the product back to Comtech EFData. (Shipping charges should be prepaid.)

For more information regarding the warranty policies, see Warranty Policy, p. ix.

ii Rev. 1

Page 4

Table of Contents

CHAPTER 1. INTRODUCTION........................................................................................1–1

1.1 Description.............................................................................................................................................................. 1–1

1.1.1 Applications...................................................................................................................................................... 1–4

1.1.2 Monitor and Control......................................................................................................................................... 1–4

1.1.3 Low Noise Amplifier (LNA)............................................................................................................................ 1–5

1.1.4 Outdoor Enclosure............................................................................................................................................ 1–5

1.2 Options.................................................................................................................................................................... 1–6

1.2.1 Configurations.................................................................................................................................................. 1–6

1.2.2 Equipment......................................................................................................................................................... 1–6

1.3 Specifications.......................................................................................................................................................... 1–7

CHAPTER 2. SINGLE THREAD SYSTEM INSTALLATION...........................................2–1

2.1 Unpacking............................................................................................................................................................... 2–1

2.2 Inspecting the Equipment...................................................................................................................................... 2–2

2.2.1 Included Parts................................................................................................................................................... 2–2

2.3 RFT Installation..................................................................................................................................................... 2–7

2.3.1 Tools Required .................................................................................................................................................2–8

2.3.2 Vertical Pole Installation .................................................................................................................................. 2–9

2.3.2.1 Round Pole................................................................................................................................................ 2–9

2.3.2.2 Square Pole................................................................................................................................................ 2–14

2.3.3 Spar Installation ................................................................................................................................................ 2–15

2.4 LNA Installation..................................................................................................................................................... 2–17

2.5 External Connections............................................................................................................................................. 2–19

2.5.1 TX/IF Input (J1)................................................................................................................................................ 2–20

2.5.2 TX/RF Output (J2)............................................................................................................................................ 2–20

2.5.3 RX/IF Output (J3)............................................................................................................................................. 2–21

2.5.4 RX/RF Input (J4).............................................................................................................................................. 2–21

2.5.5 Prime Power (J5).............................................................................................................................................. 2–22

2.5.6 Serial Remote Control (J6)............................................................................................................................... 2–23

2.5.7 GND ................................................................................................................................................................. 2–25

CHAPTER 3. REDUNDANT SYSTEM INSTALLATION..................................................3–1

3.1 Unpacking............................................................................................................................................................... 3–2

Rev. 1 iii

Page 5

Preface CST-5005

3.2 Inspecting the Equipment...................................................................................................................................... 3–2

3.2.1 Included Parts................................................................................................................................................... 3–3

3.3 RFT Installation..................................................................................................................................................... 3–7

3.3.1 Tools Required .................................................................................................................................................3–8

3.3.2 Vertical Pole Installation .................................................................................................................................. 3–9

3.3.2.1 Round Pole................................................................................................................................................ 3–9

3.3.2.2 Square Pole................................................................................................................................................ 3–16

3.3.3 Spar Installation ................................................................................................................................................ 3–16

3.3.4 1:1 Redundant Plate Installation....................................................................................................................... 3–19

3.4 RSU-503 Installation.............................................................................................................................................. 3–20

3.5 External Connections............................................................................................................................................. 3–20

CHAPTER 4 . OPERATION..............................................................................................4–1

4.1 System Operation................................................................................................................................................... 4–1

4.2 Remote Control...................................................................................................................................................... 4–1

CHAPTER 5. THEORY OF OPERATION........................................................................5–1

5.1 Monitor and Control.............................................................................................................................................. 5–1

5.1.1 EEPROM Memory........................................................................................................................................... 5–3

5.1.2 Remote Interface............................................................................................................................................... 5–3

5.1.2.1 Remote Interface Specification................................................................................................................. 5–4

5.1.3 Terminal Default Conditions ............................................................................................................................ 5–4

5.1.4 Theory of Operation ......................................................................................................................................... 5–4

5.1.5 M&C Board Connector Pinouts........................................................................................................................ 5–6

5.1.5.1 RS-232-C/485 Remote Control (J1).......................................................................................................... 5–6

5.1.5.2 Remote Relay Control, J2 DB15-Male......................................................................................................5–6

5.1.5.3 PS, Synthesizer, and D/C, P4 DB25-Male ................................................................................................ 5–7

5.1.5.4 U/C and HPA, J3 DB25-Female................................................................................................................ 5–8

5.1.6 Test Points and LEDs....................................................................................................................................... 5–9

5.2 High Stability Oscillator........................................................................................................................................ 5–9

5.2.1 Specifications.................................................................................................................................................... 5–10

5.3 IF Local Oscillator................................................................................................................................................. 5–11

5.3.1 Specifications.................................................................................................................................................... 5–11

5.4 Synthesizer.............................................................................................................................................................. 5–12

5.4.1 Specifications.................................................................................................................................................... 5–12

5.4.2 Theory of Operation ......................................................................................................................................... 5–12

5.5 Down Converter..................................................................................................................................................... 5–14

5.5.1 Specifications.................................................................................................................................................... 5–15

5.5.2 Theory of Operation ......................................................................................................................................... 5–15

5.6 Up Converter.......................................................................................................................................................... 5–16

5.6.1 Specifications.................................................................................................................................................... 5–17

5.6.2 Theory of Operation ......................................................................................................................................... 5–17

iv Rev. 1

Page 6

CST-5005 Preface

CHAPTER 6 . MAINTENANCE.........................................................................................6–1

6.1 Test Points and LEDs ............................................................................................................................................ 6–1

6.2 Fault Isolation......................................................................................................................................................... 6–2

APPENDIX A. REMOTE CONTROL OPERATION .........................................................A–1

A.1 General ................................................................................................................................................................... A–1

A.2 Message Structure................................................................................................................................................. A–2

A.2.1 Start Character................................................................................................................................................. A–2

A.2.2 Device Address................................................................................................................................................ A–3

A.2.3 Command/Response........................................................................................................................................ A–3

A.2.4 End Character.................................................................................................................................................. A–4

A.3 Configuration Commands/Responses.................................................................................................................. A–5

A.4 Status Commands/Responses............................................................................................................................... A–8

GLOSSARY .....................................................................................................................g–1

Rev. 1 v

Page 7

Preface CST-5005

Figures

Figure 1-1. CST-5005 Single Thread System............................................................................................................ 1–2

Figure 1-2. Redundant LNA Plate............................................................................................................................. 1–2

Figure 1-3. RSU-503................................................................................................................................................. 1–3

Figure 1-4. CST-5005 Block Diagram ......................................................................................................................1–3

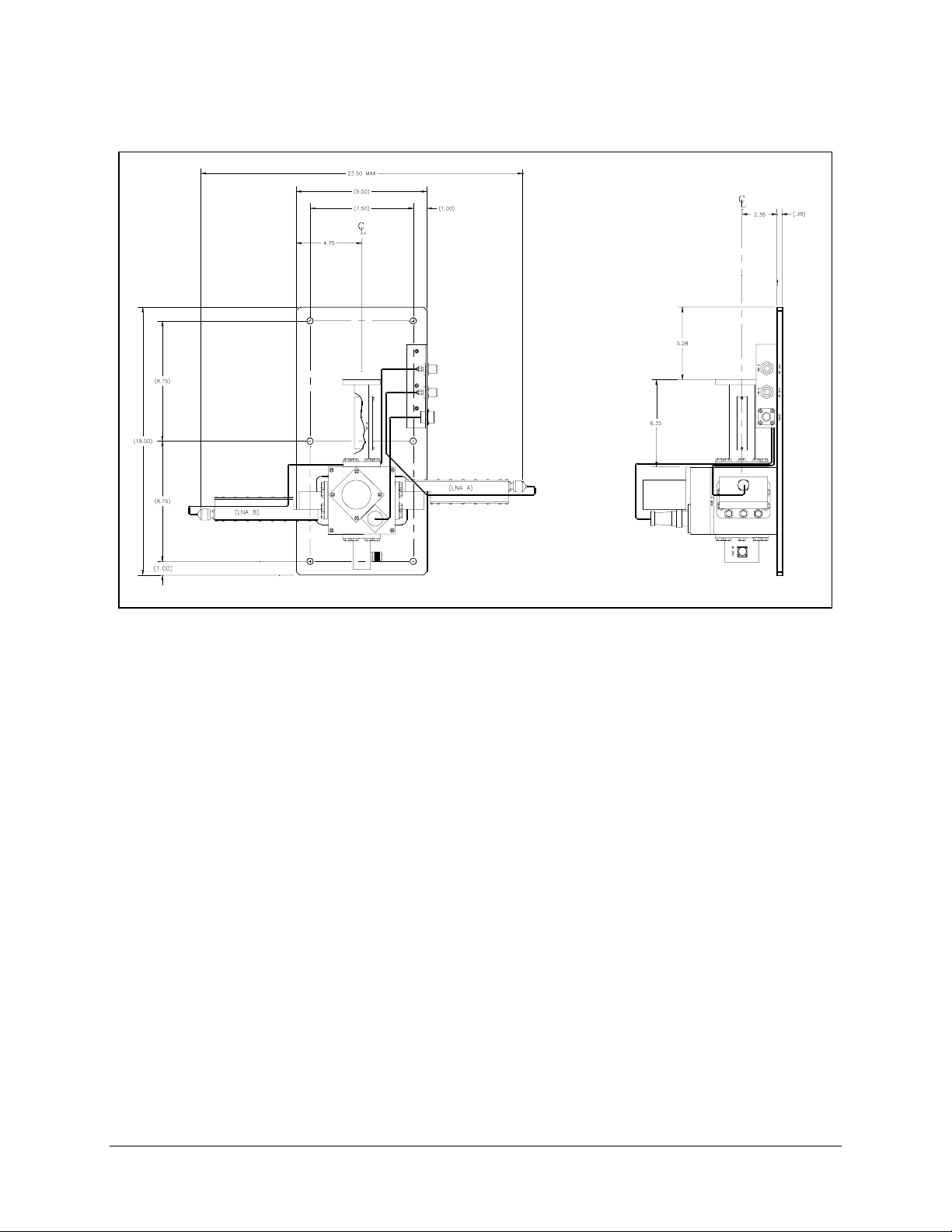

Figure 1-5. Dimensions for a Single Thread LNA.....................................................................................................1–11

Figure 1-6. Dimensions for 1:1 Redundant LNA Plate ............................................................................................. 1–12

Figure 2-1. RFT-505 External Connections............................................................................................................... 2–19

Figure 2-2. Serial Adapter Cables.............................................................................................................................. 2–25

Figure 5-1. M&C Board............................................................................................................................................ 5–2

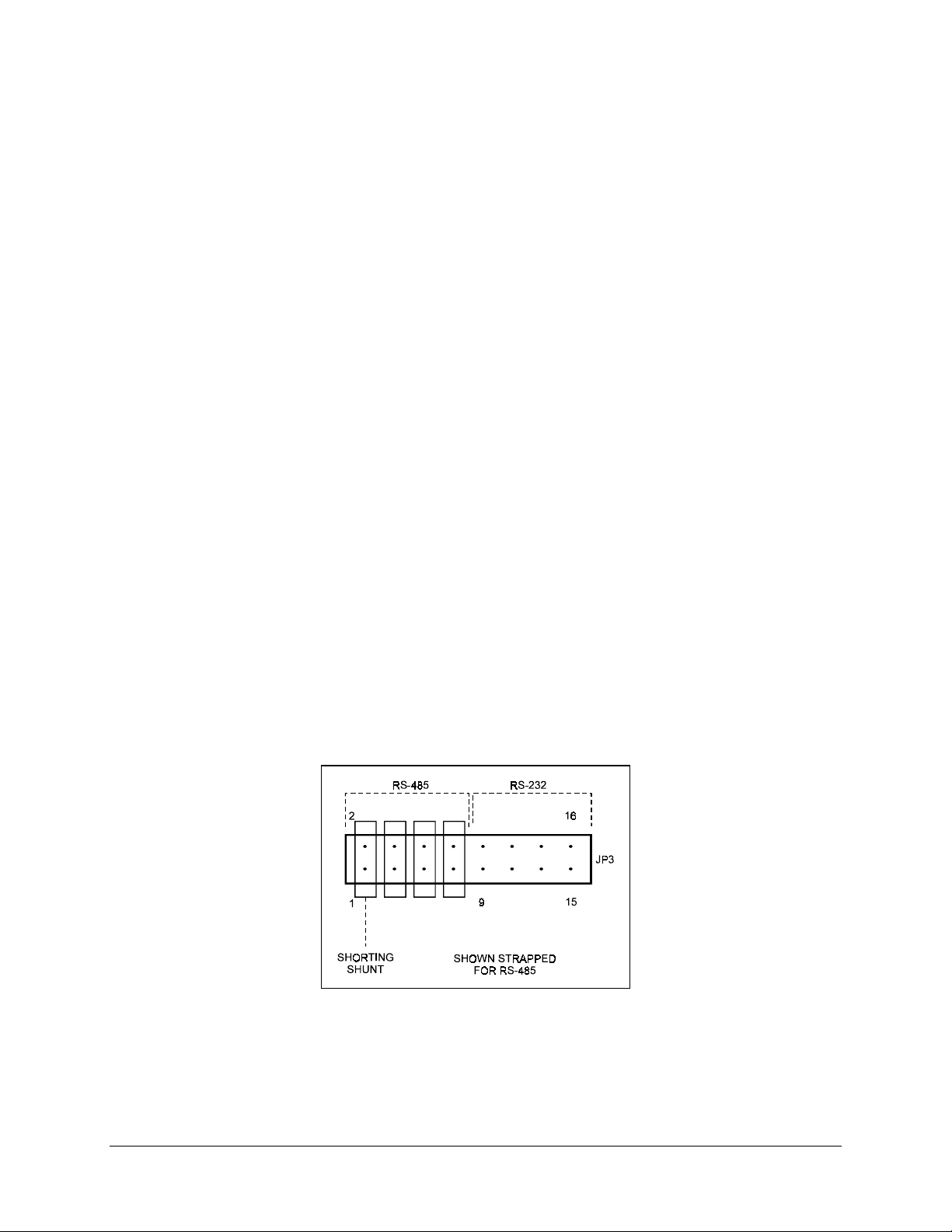

Figure 5-2. M&C Jumper Placement at JP3.............................................................................................................. 5–3

Figure 5-3. M&C Functional Block Diagram............................................................................................................ 5–5

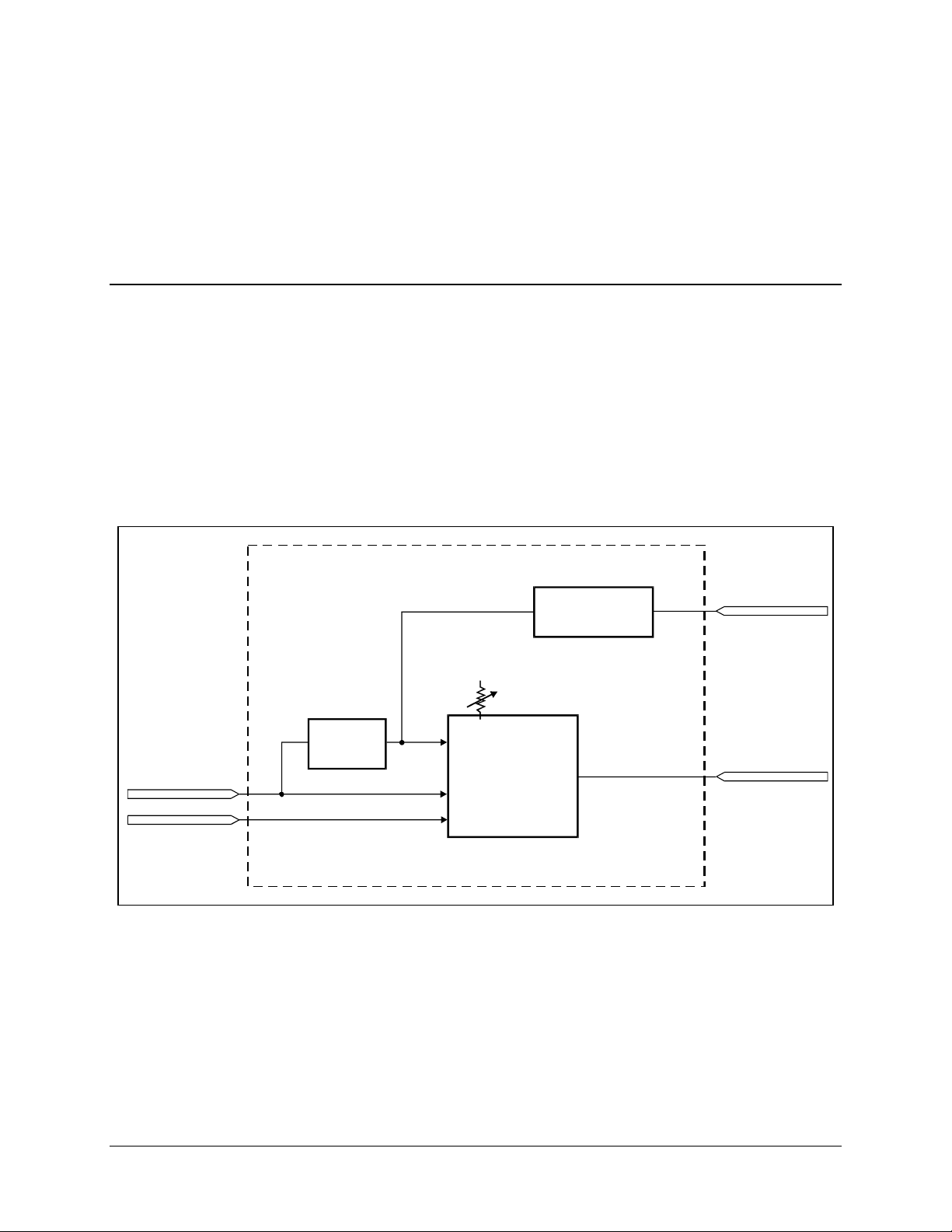

Figure 5-4. High Stability Oscillator Block Diagram................................................................................................ 5–9

Figure 5-5. IF Local Oscillator Block Diagram......................................................................................................... 5–11

Figure 5-6. Synthesizer Block Diagram.....................................................................................................................5–13

Figure 5-7. Down Converter Block Diagram............................................................................................................ 5–14

Figure 5-8. 5W Up Converter Block Diagram...........................................................................................................5–16

Figure 6-1. RFT-505 Inside Front View.................................................................................................................... 6–3

Figure 6-2. RFT-505 Inside Rear View..................................................................................................................... 6–4

Tables

Table 1-1. CST-5005 System Specifications............................................................................................................. 1–7

Table 1-2. RFT-505 Specifications............................................................................................................................ 1–8

Table 1-3. LNA Specifications.................................................................................................................................. 1–10

Table 2-1. Front Panel Connectors............................................................................................. ............................... 2–19

Table 2-2. RFT Remote Control Connector, J6......................................................................................................... 2–24

Table 6-1. M&C LEDs.............................................................................................................................................. 6–1

vi Rev. 1

Page 8

CST-5005 Preface

Overview of Changes to Previous Edition

A summary of the changes made to Rev. 1 includes:

• Cosmetic (non-technical) changes (e.g., formatting, spelling)

• Corrected metric equivalents in Chapter 2

• Updated kits in Chapters 2 and 3

• Deleted Appendix B (refer to Comtech EFData Monitor and Control Software for

Comtech EFData Satellite Terminals User’s Guide)

• Updated VSWR, gain variation, and gain adjustment range specifications in Chapter 1

About this Manual

This manual provides installation and operation information for the CST-5005 C-band

satellite terminal. This is a technic al docum ent inte nded for earth st at ion eng ineer s,

technicians, and operators responsible for the operation and maintenance of the

CST-5005.

Related Documents

The following documents are referenced in this manual:

• Comtech EFData Specification SP/4450

• RSU-503 Redundancy Switch Unit Installation and Operation Manual

• KP-10 External Keypad Installation and Operation Manual

• Comtech EFData Monitor and Control Software for Comtech EFData Satellite

Terminals User’s Guide

Conventions and References

Cautions and Warnings

CAUTION indicates a hazardous situation that, if not avoided, may result in

minor or moderate injury. CAUTION may also be used to indicate other

CAUTION

Rev. 1 vii

unsafe practices or risks of property damage.

Page 9

Preface CST-5005

WARNING indicates a potentially hazardous situation that, if not avoided,

could result in death or serious injury.

WARNING

Metric Conversion

Metric conversion information is located on the inside back cover of this manual. This

information is provided to assist the operator in cross-referencing English to Metric

conversions.

Recommended Standard Designations

Recommended Standard (RS) Designations have been superseded by the new designation

of the Electronic Industries Association (EIA). References to the old designations are

shown only when depicting actual text displayed on the screen of the unit (RS-232, RS485, etc.). All other references in the manual will be shown with the EIA designations

(EIA-232, EIA-485, etc.) only.

Trademarks

Product names mentioned in this manual may be trademarks or registered trademarks of

their respective companies and are hereby acknowledged.

Reporting Comments or Suggestions Concerning this Manual

Comments and suggestions regarding the content and design of this manual will be

appreciated. To submit comments, please contact the Comtech EFData Customer Support

Department.

viii Rev. 1

Page 10

CST-5005 Preface

Warranty Policy

This Comtech EFData product is warranted against defects in material and workmanship

for a period of one year from the date of shipment. During the warranty period, Comtech

EFData will, at its option, repair or replace products that prove to be defective.

For equipment under warranty, the customer is responsible for freight to Comtech

EFData and all related custom, taxes, tariffs, insurance, etc. Comtech EFData is

responsible for the freight charges

the customer. Comtech EFData will return the equipment by the same method (i.e., Air,

Express, Surface) as the equipment was sent to Comtech EFData.

only

for return of the equipment from the factory to

Limitations of Warranty

The foregoing warranty shall not apply to defects resulting from improper installation or

maintenance, abuse, unauthorized modification, or operation outside of environmental

specifications for the product, or, for damages that occur due to improper repack ag ing of

equipment for return to Comtech EFData.

No other warranty is expressed or implied. Comtech EFData specifically disclaims the

implied warranties of merchantability and fitness for particular purpose.

Exclusive Remedies

The remedies provided herein are the buyer's sole and exclusive remedies. Comtech

EFData shall not be liable for any direct, indirect, special, incidental, or consequential

damages, whether based on contract, tort, or any other legal theory.

Disclaimer

Comtech EFData has reviewed this manual thoroughly in order that it will be an easy-touse guide to your equipment. All statements, technical information, and

recommendations in this manual and in any guides or related documents are believed

reliable, but the accuracy and completeness thereof are not guaranteed or warranted, and

they are not intended to be, nor should they be understood to be, representations or

warranties concerning the products described. Further, Comtech EFData reserves the

right to make changes in the specifications of the products described in this manual at any

time without notice and without obligation to notify any person of such changes.

If you have any questions regarding your equipment or the information in this manual,

please contact the Comtech EFData Customer Support Department.

Rev. 1 ix

Page 11

This chapter describes the CST-5005 C-band satellite terminal, referred to in this manual

as “the CST-5005.”

1.1 Description

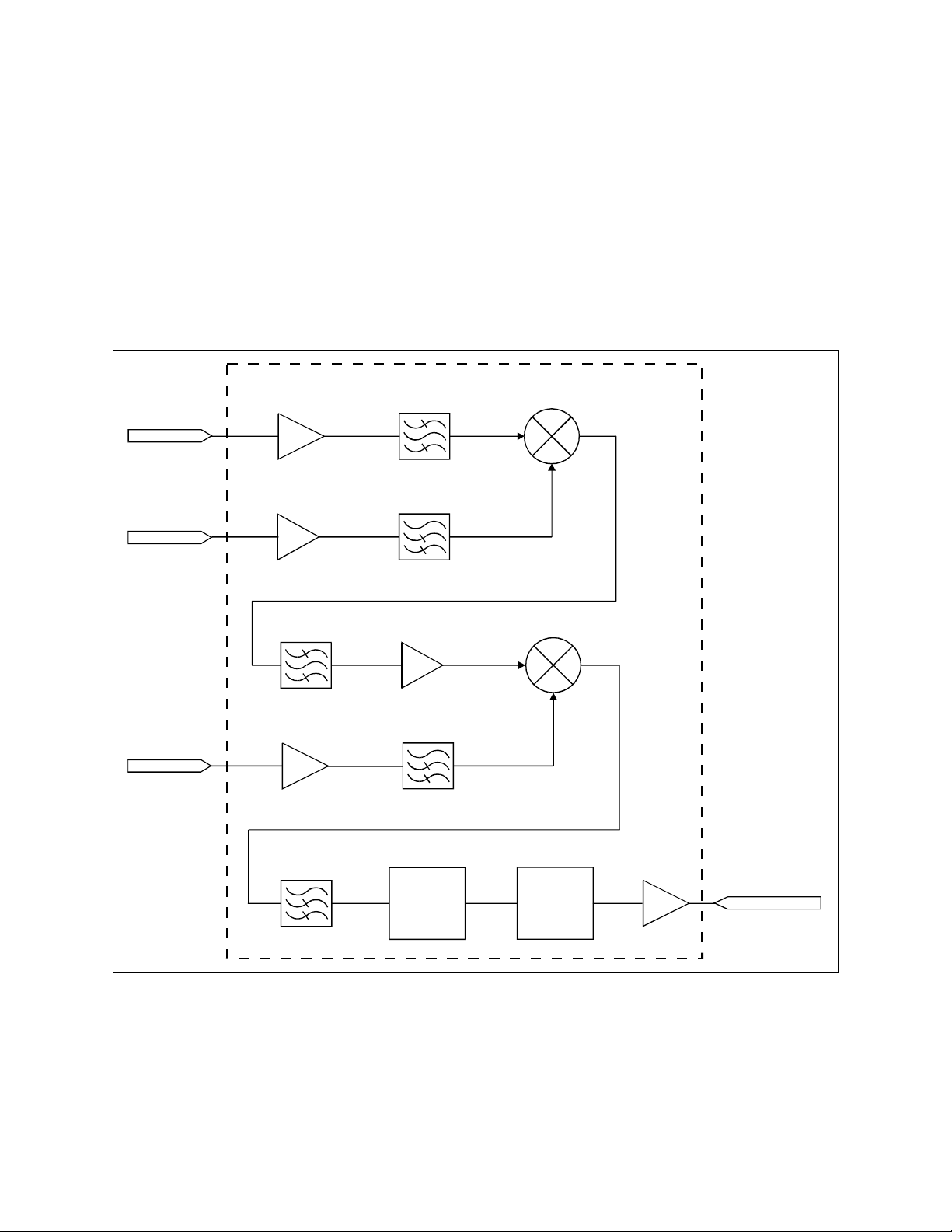

As a single thread system, the CST-5005 is comprised of the following assemblies

(Figure 1-1):

Chapter 1.

INTRODUCTION

1

• Outdoor enclosure assembly (RFT-505)

• Low Noise Amplifier (LNA)

As a redundant system, the CST-5005 is comprised of the following assemblies:

• Two outdoor enclosure assemblies (RFT-505s)

• Redundant LNA plate (Figure 1-2)

• RSU-503 (Figure 1-3)

For more information on the RSU-503, refer to the Comtech Comtech EFData RSU-503

Redundancy Switch Unit Installation and Operation Manual.

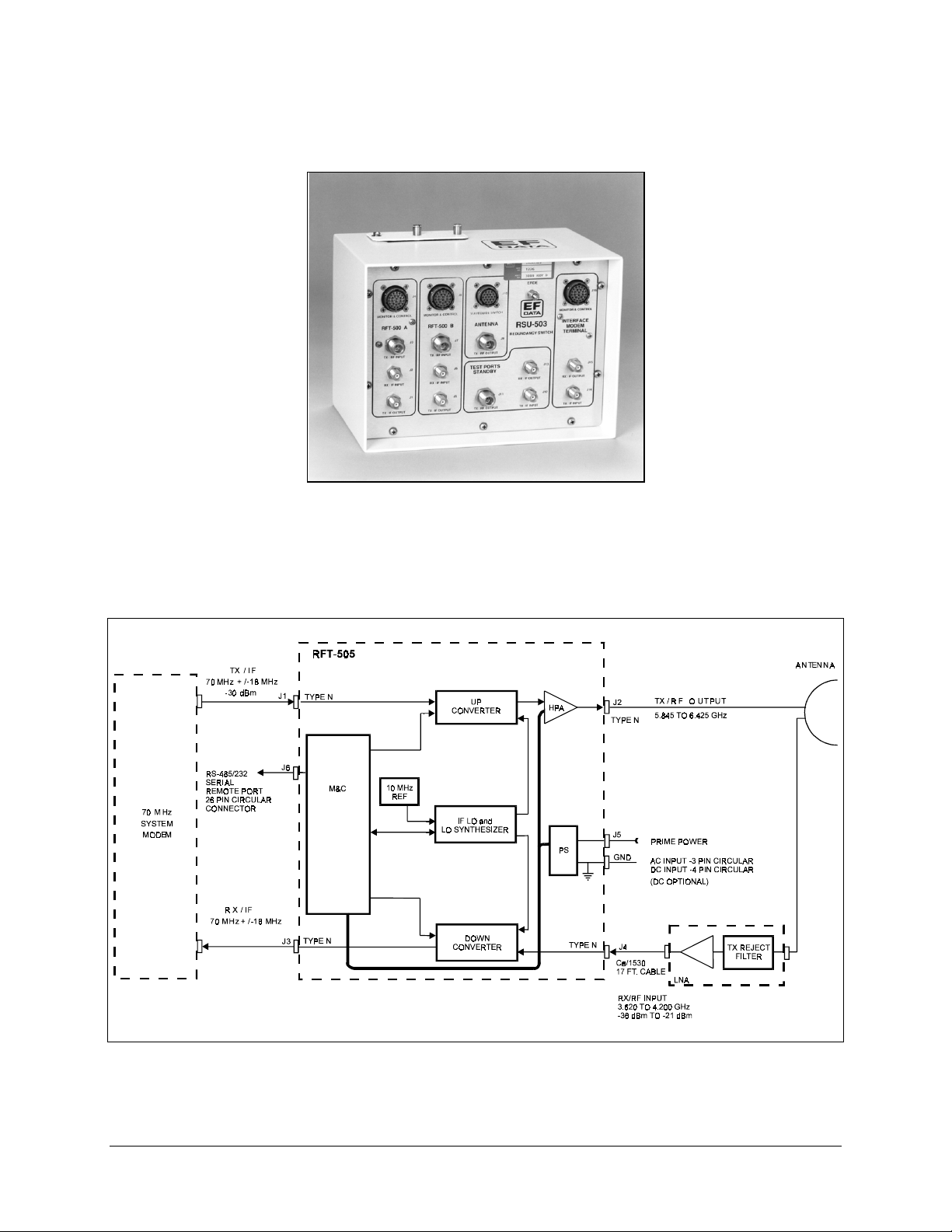

Refer to Figure 1-4 for a block diagram of the CST-5005.

The CST-5005 meets all requirements for operation on both private and regional

domestic C-band satellite networks.

Rev. 1 1–1

Page 12

Introduction CST-5005 C-Band Satellite Terminal

Figure 1-1. CST-5005 Single Thread System

Figure 1-2. Redundant LNA Plate

Note:

Pictured above are typical LNAs. Other LNAs are available, and can be ordered

from an Comtech EFData marketing representative.

1–2 Rev. 1

Page 13

CST-5005 C-Band Satellite Terminal Introduction

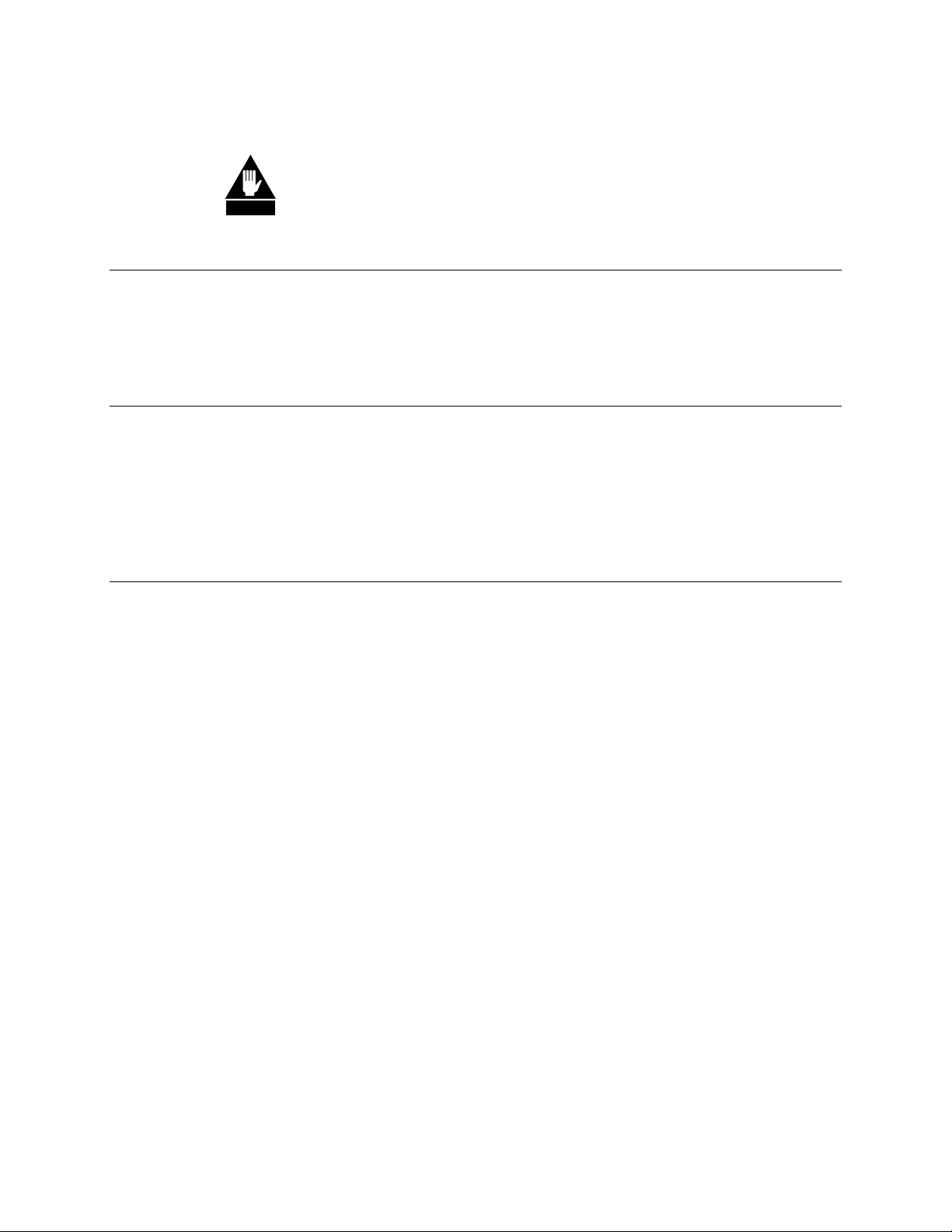

Figure 1-3. RSU-503

Figure 1-4. CST-5005 Block Diagram

Rev. 1 1–3

Page 14

Introduction CST-5005 C-Band Satellite Terminal

1.1.1 Applications

When used in conjunction with Comtech EFData modems, the CST-5005 is ideal for:

• Single digit carriers up to 2.048 Mbit/s

• Multiple carrier operation over a 36 MHz bandwidth

Because the CST-5005 has a 70 MHz IF, it can also be used for other analog and digital

applications.

Small-to-medium size earth stations are easily constructed and commissioned with the

CST-5005.

When used with a high-gain antenna, the CST-5005 can also be used as the Radio

Frequency (RF) electronics of a central hub in point-to-multipoint applications, as well

as serve as the terminal for the end points of the network.

1.1.2 Monitor and Control

An on-board microcomputer monitors and controls all operational parameters and system

status of the CST-5005. This powerful M&C system enables the user to locally or

remotely control functions such as:

Output power

•

Transmit/receive channel frequencies

•

The system also reports terminal configuration status, as well as fault status of all

CST-5005 components.

The CST-5005 can be initially configured using a connection of a common

ASCII/RS-232-C terminal connected to the serial port.

A simple command set allows total configuration control and retrieval of status

information.

If the indoor unit is a more sophisticated station M&C computer, the serial port can be

set to RS-485 for bus operation.

For more information on the M&C board, refer to Chapter 5.

1–4 Rev. 1

Page 15

CST-5005 C-Band Satellite Terminal Introduction

1.1.3 Low Noise Amplifier (LNA)

The feed assembly consists of an LNA and a wave guide transmit reject filter.

The transmit reject filter provides receive system protection from transmit energy fed

back through the antenna feed system.

The LNA standard noise temperature is 65°K, with optional upgrades down to 33°K,

depending upon gain over temperature (G/T) requirements.

1.1.4 Outdoor Enclosure

The RFT-505 is a weatherproof enclosure housing the following:

Solid State Power Amplifier (SSPA)

•

Up and down converters

•

M&C microprocessor

•

Power supply and cables which interface with an antenna subsystem

•

In the transmit (uplink) direction, the RFT-505 accepts a 70 MHz IF signal, and transmits

it in the 5.845 to 6.425 GHz frequency band.

In the receive (downlink) direction, the terminal accepts an RF signal in the 3.620 to

4.200 GHz band, and converts the signal to 70 MHz IF output.

Power levels range from +8 dBm (for driving an external TWT) to 10W, depending upon

Equivalent Isotropically Radiated Power (EIRP) requirements.

The up and down converters are dual conversion, with individual synthesizers for

independent transmit and receive transponder selection.

The microprocessor provides:

• Online loop monitoring

• Dynamic control functions

• Configuration control

• Fault/status monitoring

• Serial computer/terminal interface

Rev. 1 1–5

Page 16

Introduction CST-5005 C-Band Satellite Terminal

1.2 Options

1.2.1 Configurations

The CST-5005 can be ordered with various configurations, including:

• Output power levels

• Input power (AC/DC)

• LNA gain

• Redundant LNA mounting plates

• Custom logos

Contact an Comtech EFData marketing representative for more information.

1.2.2 Equipment

The following item is available:

• KP-10 hand-held keypad. The KP-10 provides portable, external access for

controlling the RFT. For information, refer to the Comtech EFData KP-10

External Keypad Installation and Operation Manual.

Contact an Comtech EFData marketing representative for more information.

1–6 Rev. 1

Page 17

CST-5005 C-Band Satellite Terminal Introduction

1.3 Specifications

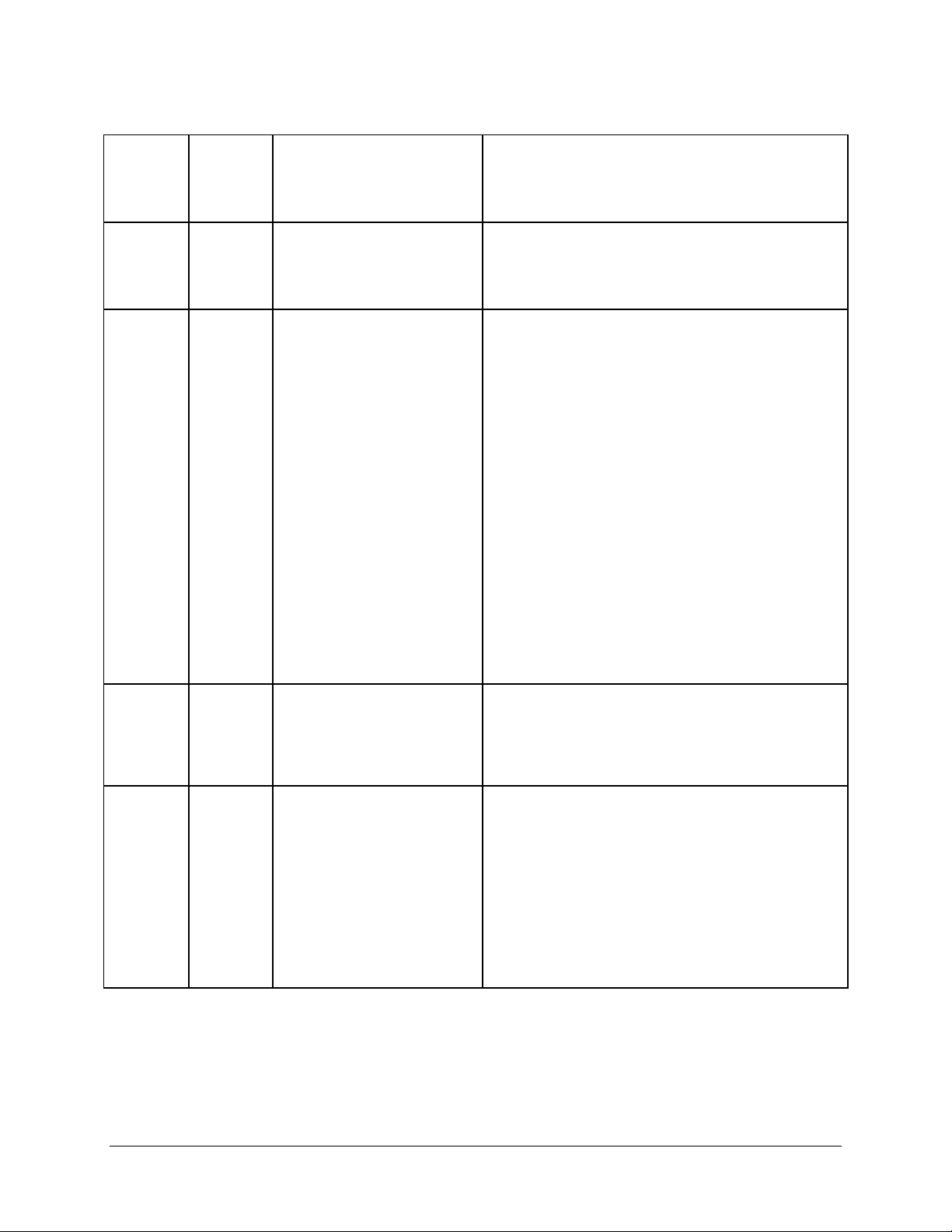

Table 1-1 lists the specifications for the CST-5005, Table 1-2 lists the specifications for

the RFT-505, and Table 1-3 lists the specifications for the LNA.

Notes:

1. For specifications on the RSU-503, refer to the Comtech EFData RSU-503

Redundancy Switch Unit Installation and Operation Manual.

2. For more information pertaining to CST-5005 specifications, refer to Comtech

EFData Specification SP/4450.

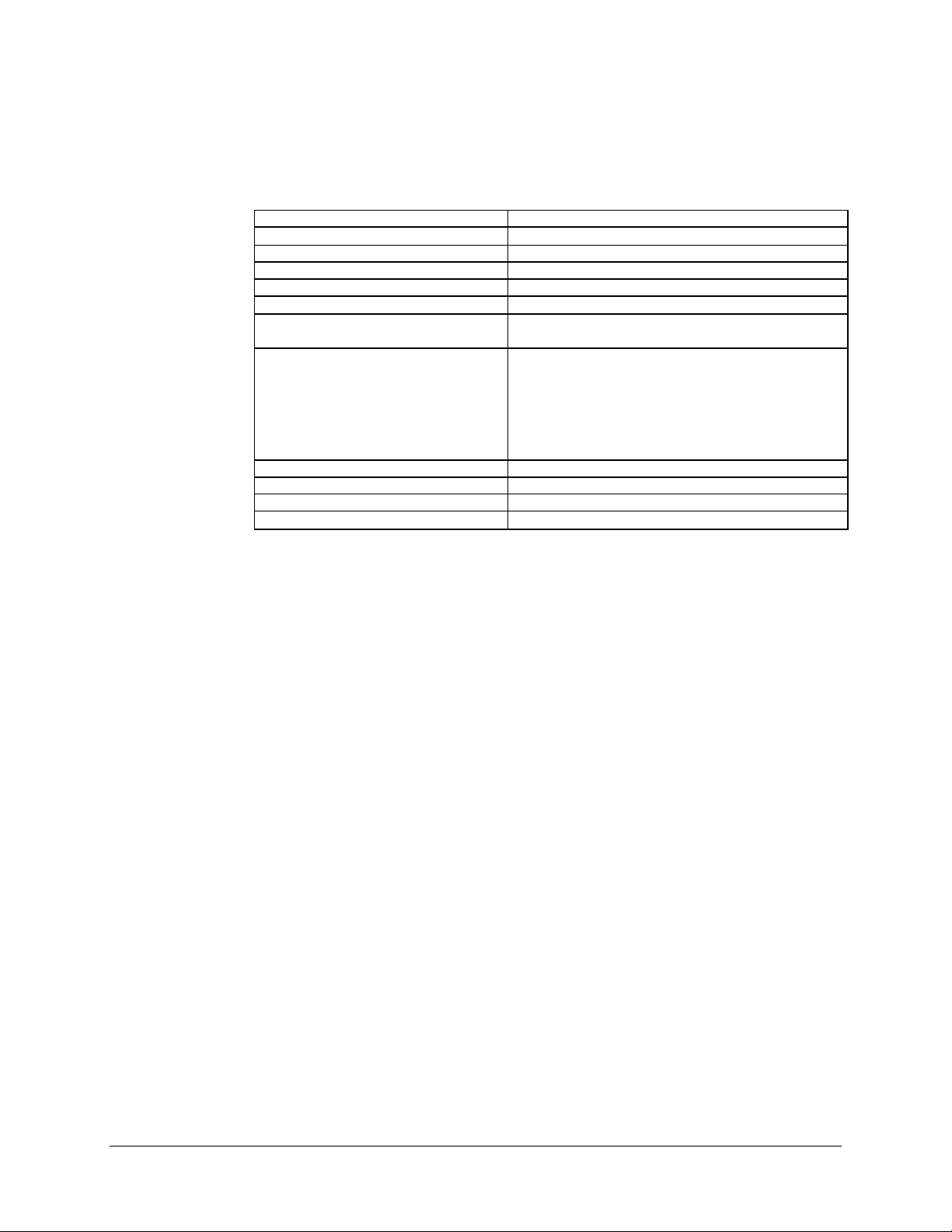

Table 1-1. CST-5005 System Specifications

Prime Power 95 to 230 VAC, 47 to 63 Hz, or 48 VDC

Power Consumption:

+8 dBm output

5W output

10W

Size 15.1” H x 10.5” W x 8.9” D

Weight 39 lbs (typical)

Sealing Weatherproof

Ground Attach #10 AWG ground lug

Environmental:

Temperature

Humidity

Altitude

70W

125W

175W

17.1” H x 10.5” W x 8.9” D (10W system)

-40 to +55

-50 to +80

0 to 100% RH

0 to 15,000 ft operational

0 to 50,000 ft storage

C operational

°

C storage

°

Rev. 1 1–7

Page 18

Introduction CST-5005 C-Band Satellite Terminal

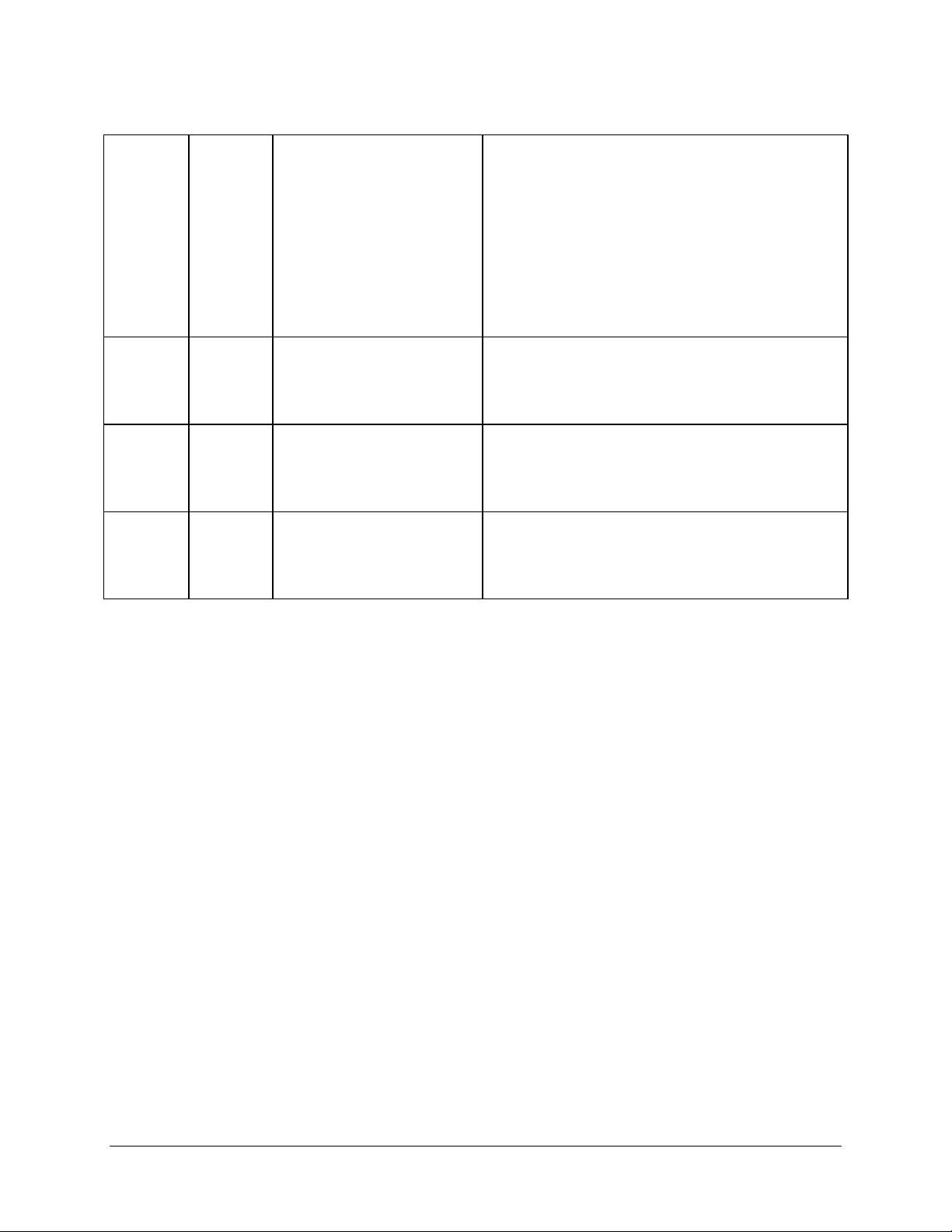

Table 1-2. RFT-505 Specifications

Transmit

Output Frequency (No inversion) 5.845 to 6.425 GHz

Input Frequency 70 MHz, ± 18 MHz (optional 140 MHz , ± 36 MHz)

Output Power:

at 1 dB compression +8 dBm

or 5W (+37 dBm)

or 10W (+40 dBm)

Third Order Intercept +18 dBm (for +8 dBm)

or +46 dBm (for 5W)

or +49 dBm (for 10W)

Nominal Small Signal Gain 26 dB (for +8 dBm)

or 68 dB (for 5W)

or +71 dBm (for 10W)

Gain Adjust Range (from nominal)

Gain Variation:

Over 36 MHz

Over 36 MHz, temperature, and aging

Noise Figure:

Maximum attenuation

Minimum attenuation

Group Delay, Total Variation in Passband 10 ns max

Synthesizer Step Size 125 kHz

Synthesizer Phase Noise -60 dBc/Hz at 100 Hz

Frequency Stability:

At shipment

Daily at 23

Annual at 23

C

°

C

°

Over temperature

After 30 minutes warm-up

Electrical adjustment

Isolation on Fault Shutdown -60 dBc

Spurious:

signal related

≤ 250 kHz carrier offset

> 250 kHz carrier offset

non-signal related

HPA Harmonics -50 dBc max

RF Output VSWR 1.35:1 at 50

RF Output Connector Type N female

IF Input VSWR 1.5:1 at 50

IF Input Connector Type N female

±

11 dB min

± 1 dB max

4

dB max variation

23 dB max

15 dB max

-70 dBc/Hz at 1 kHz

-80 dBc/Hz at 10 kHz

-90 dBc/Hz at 100 kHz

±

±

±

±

±

0.5 x 10

-8

1 x 10

-8

1 x 10

-7

1 x 10

1 x 10-8 (-40 to +55°C)

-8

1 x 10

-7

-35 dBc max

-50 dBc max

< -15 dBm/44 kHz max

Ω

Ω

1–8 Rev. 1

Page 19

CST-5005 C-Band Satellite Terminal Introduction

Receive

Input Frequency (No inversion) 3.620 to 4.2 GHz

Output Frequency 70 MHz, ± 18 MHz (optional 140 MHz , ± 36 MHz)

Output Power at 1 dB Comp +15 dBm

Gain Adjust Range (with LNA) 74 to 95 dB

Gain Variation (with LNA):

Over 36 MHz

Over 36 MHz, temperature, and aging

±

1.5 dB max

±

4 dB max

Noise Temperature (with LNA) LNA specification

Group Delay, Total Variation in Passband 10 ns max

Synthesizer Step Size 125 kHz

Synthesizer Phase Noise -60 dBc/Hz at 100 Hz

-70 dBc/Hz at 1 kHz

-80 dBc/Hz at 10 kHz

-90 dBc/Hz at 100 kHz

Frequency Stability:

At shipment

Daily at 23

Annual at 23

C

°

C

°

Over temperature

After 30 minutes warm-up

Electrical adjustment

±

±

±

±

±

0.5 x 10

-8

1 x 10

-8

1 x 10

-7

1 x 10

1 x 10-8 (-40 to +55°C)

-8

1 x 10

-7

Spurious In Band -60 dBc max

Image Rejection (all conversions) > 50 dB

Linearity Intermods < -35 dBc for two tones at -89 dBm at

+95 dB gain

RF Input VSWR (with LNA) 1.35:1 at 50

Ω

RF Input Connector Type N female

IF Output VSWR 1.5:1 at 50

Ω

IF Output Connector Type N female

Monitor and Control

Control Interface RS-232-C, RS-485

Control Functions SELECT PARITY

RF OUTPT LNA PWR

U/C FREQ LNA FLT

D/C FREQ CALIB. LNA

U/C ATTN REF ADJ

D/C ATTN XFLT ENABLE

PROGRAM RSW MODE

BAUD LOCK MODE

ADDRESS

Monitor Functions U/C TEMP

D/C TEMP

HPA TEMP

Fault Detect Functions 5V PWR HPA_FLT

D/C_FLT OSC_FLT

U/C_FLT SYN_LOCK_DET

2nd_SYN_LD XFE_FLT

RESET_FLT IFLO_LD

12V PWR UL_FLT

LNA_FLT DL_FLT

Rev. 1 1–9

Page 20

Introduction CST-5005 C-Band Satellite Terminal

Table 1-3. LNA Specifications

LNA Dimensions Refer to Figures 1-5 or 1-6

Frequency 3.620 to 4.200 GHz

Noise Temperature (with TRF) 65°K max (lower temperatures optional)

Gain 50 dB minimum, 54 dB nominal

Gain Flatness ± 1 dB/575 MHz

Gain vs. Temperature ± 3 dB max

1 dB Compression Point +12 dBm min

Third Order Intercept +22 dBm min

Group Delay:

Linear

Parabolic

Ripple

Input VSWR 1.25:1

Output VSWR 1.25:1

Input Connector CPR229G (hold pressure to .5PSIG)

Output Connector Type N

Spurious Below thermal noise/100 kHz

TRF Rejection 60 dB

± 0.01 ns/MHz max

0.001 ns/MHz

2

max

0.1 ns P-P

1–10 Rev. 1

Page 21

CST-5005 C-Band Satellite Terminal Introduction

Figure 1-5. Dimensions for a Single Thread LNA

Rev. 1 1–11

Page 22

Introduction CST-5005 C-Band Satellite Terminal

Figure 1-6. Dimensions for 1:1 Redundant LNA Plate

1–12 Rev. 1

Page 23

This chapter provides installation information for single thread systems, including:

For redundant systems, refer to Chapter 3.

2.1 Unpacking

Chapter 2.

SINGLE THREAD SYSTEM

INSTALLATION

2

• Unpacking and inspecting the parts

• Installing the RFT

• Installing the LNA

• External connections

The CST-5005 is packaged in preformed, reusable foam inside a cardboard carton.

Before unpacking the carton components, ensure that there is plenty of room around the

carton for workspace. A large table is recommended.

To remove the parts:

1. Cut the tape at the top of the carton where it is indicated OPEN THIS END.

2. Lift out the cardboard/foam spacer covering the unit.

3. Remove each part from the carton. Refer to Section 2.2.1 for a parts breakdown.

Because the RFT is heavy, assistance may be necessary to remove

the unit from the box.

CAUTION

Note:

Save the packing material for reshipment.

Rev. 1 2–1

Page 24

Single Thread System Installation CST-5005 C-Band Satellite Terminal

A

A

2.2 Inspecting the Equipment

1. Carefully check the equipment for damage incurred during shipment.

2. Carefully check the equipment against the packing list shipped with the

equipment to ensure that the shipment is complete. Refer to the following

paragraphs.

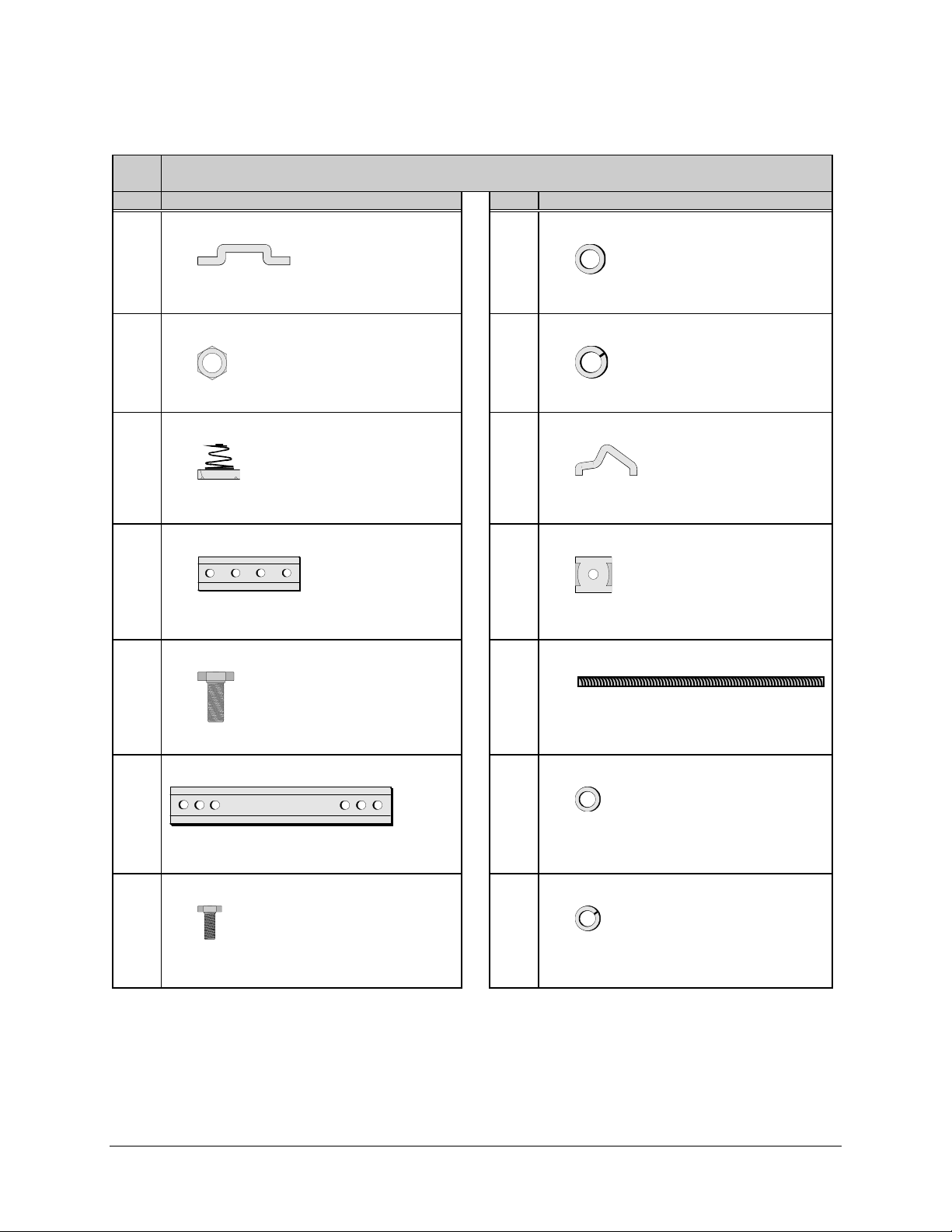

2.2.1 Included Parts

A typical single thread CST-5005 configuration contains the following components.

Notes:

1. Parts are not drawn to scale.

2. Because each system can be custom ordered, it is beyond the scope of this

manual to provide the unlimited configuration possibilities.

3. This chapter does not describe the installation procedures for amplifiers, high

performance LNAs, phase-locked LNBs, LNBs, and phase-locked block

converters.

Qty. Description Qty. Description

1 RFT outdoor unit. 1 Feed assembly.

T

U

O

F

R

N

G

O

O

N

N

L

L

E

D

Y

R

P

O

E

C

M

S

N

M

E

E

T

U

E

Q

S

E

O

R

F

N

N

I

F

R

Note:

Pictured is a typical LNA. Other LNAs

are available, and can be ordered from an

EFData marketing representative.

1 Envelope containing the test data sheet. 1 CST-5005 installation and operation manual.

1 Monitor and Control Software for EFData

Satellite Terminals User’s Guide.

2–2 Rev. 1

Page 25

CST-5005 C-Band Satellite Terminal Single Thread System Installation

1 LNA connector kit (EFData Part # KT/2721), which includes:

Qty. Description Qty. Descr iption

1 Gasket — thick.

1 Gasket — thin.

EFData Part # 32P1040.

10 1/4-20 x 5/8” bolt.

EFData Part # 03P1079.

10 1/4-20 nut.

EFData Part # HW/1/4HEXNUT.

EFData Part # 32D1002.

20 1/4” flat washer.

EFData Part # O4P1022.

10 1/4” split lockwasher.

EFData Part # HW/1/4-SPLIT.

Rev. 1 2–3

Page 26

Single Thread System Installation CST-5005 C-Band Satellite Terminal

1 Kit KT/3272-x (where x = 1 for AC power, and 2 for DC power), which includes:

Qty. Description Qty. Descr iption

1 Connector kit.

EFData Part # CN/STPG26M01.

Used to connect customer’s cable to the RFT

26-pin J6 (REMOTE). For remote control and

status monitoring (by using M&C system

monitor software).

2 17’ Heliax cable.

1

Note:

Either the AC or DC cable is

provided, depending upon the product

ordering code.

Assembly, 15’ AC prime power cable.

EFData Part # PL/2754.

Assembly, 15’ DC prime power cable.

EFData Part # PL/4157.

EFData Part # CA/1530.

Used for RF input and RF output.

2–4 Rev. 1

Page 27

CST-5005 C-Band Satellite Terminal Single Thread System Installation

Note:

If an RFT for a spar mount is ordered, EFData will provide a spar mount kit

(KT/4061). Otherwise, the universal installation kit (KT/3576) will be provided.

1 Kit KT/4061, which includes:

Qty. Description Qty. Descr iption

2 Spar support bracket.

EFData Part # FP/3175.

Used for spar mount only.

8 1/4-20 x 5/8” bolt.

EFData Part # HW/1/4-20X5/8BT.

Used to attach 8” or 14” unistruts to RFT.

8 1/4” flat washer.

4 5/16-18 x 1” bolt.

EFData Part # HW/5/16-18X1BLT.

Used to attach spar support bracket to 8”

unistrut.

4 5/16” split lockwasher.

EFData Part # HW/5/16-SPLIT.

Used to attach spar support bracket to 8”

unistrut.

4 5/16” flat washer.

EFData Part # HW/1/4-FLT.

Used to attach 8” unistruts to RFT.

8 1/4” split lockwasher.

EFData Part # HW/1/4-SPLIT.

Used to attach 8” unistruts to RFT.

2 Unistrut — 8” long.

EFData Part # FP/3481.

Attaches directly to RFT.

EFData Part # HW/5/16-FLT.

Used to attach spar support bracket to 8”

unistrut.

4 5/16-18 spring nut.

EFData Part # HW/5/16-18SPNUT.

Used to attach spar support bracket to 8”

unistrut.

Rev. 1 2–5

Page 28

Single Thread System Installation CST-5005 C-Band Satellite Terminal

1 Kit KT/3576, which includes:

Qty. Description Qty. Descr iption

2 Spar support bracket.

EFData Part # FP/3175.

Used for spar mount only.

4 Unistrut — 14” long.

12 5/16-18 x 1” bolt.

EFData Part # HW/5/16-18X1BLT.

24 5/16” split lockwasher.

EFData Part # FP/3595.

Used for round and square pole mount only.

2 Unistrut — 8” long.

EFData Part # FP/3481.

Attaches directly to RFT.

8 1/4-20 x 5/8” bolt.

EFData Part # HW/1/4-20X5/8BT.

Used to attach 8” or 14” unistruts to RFT.

8 1/4” flat washer.

EFData Part # HW/1/4-FLT.

Used to attach 8” or 14” unistruts to RFT.

8 1/4” split lockwasher.

EFData Part # HW/5/16-SPLIT.

24 5/16” flat washer.

EFData Part # HW/5/16-FLT.

12 5/16-18 hex nut.

EFData Part # HW/5/16-18HEXNT.

16 5/16-18 spring nut.

EFData Part # HW/5/16-18SPNUT.

8 Flat fitting plate, 5/16”.

EFData Part # HW/1/4-SPLIT.

Used to attach 8” unistruts to RFT.

8 Pipe block.

EFData Part # HW/BLK-PIPE2-8.

Used for round pole mount only.

2–6 Rev. 1

EFData Part # HW/FIT-PLT-5/16.

4 Threaded rod, 5/16-18 x 14”.

EFData Part # HW/RD5/16-18X14.

Used for round and square pole mount only.

Page 29

CST-5005 C-Band Satellite Terminal Single Thread System Installation

2.3 RFT Installation

At the customer’s discretion, the RFT can be installed anywhere on or near the antenna.

The supplied hardware allows the installer a wide range of installation alternatives,

including:

• Vertical pole (e.g., mast) (either square or round). This is the most typical

installation.

• Within the hub of a large antenna.

• Spar (i.e., square bar) on the antenna structure.

EFData recommends that the RFT be mounted vertically, with the connections facing the

ground.

Rev. 1 2–7

Page 30

Single Thread System Installation CST-5005 C-Band Satellite Terminal

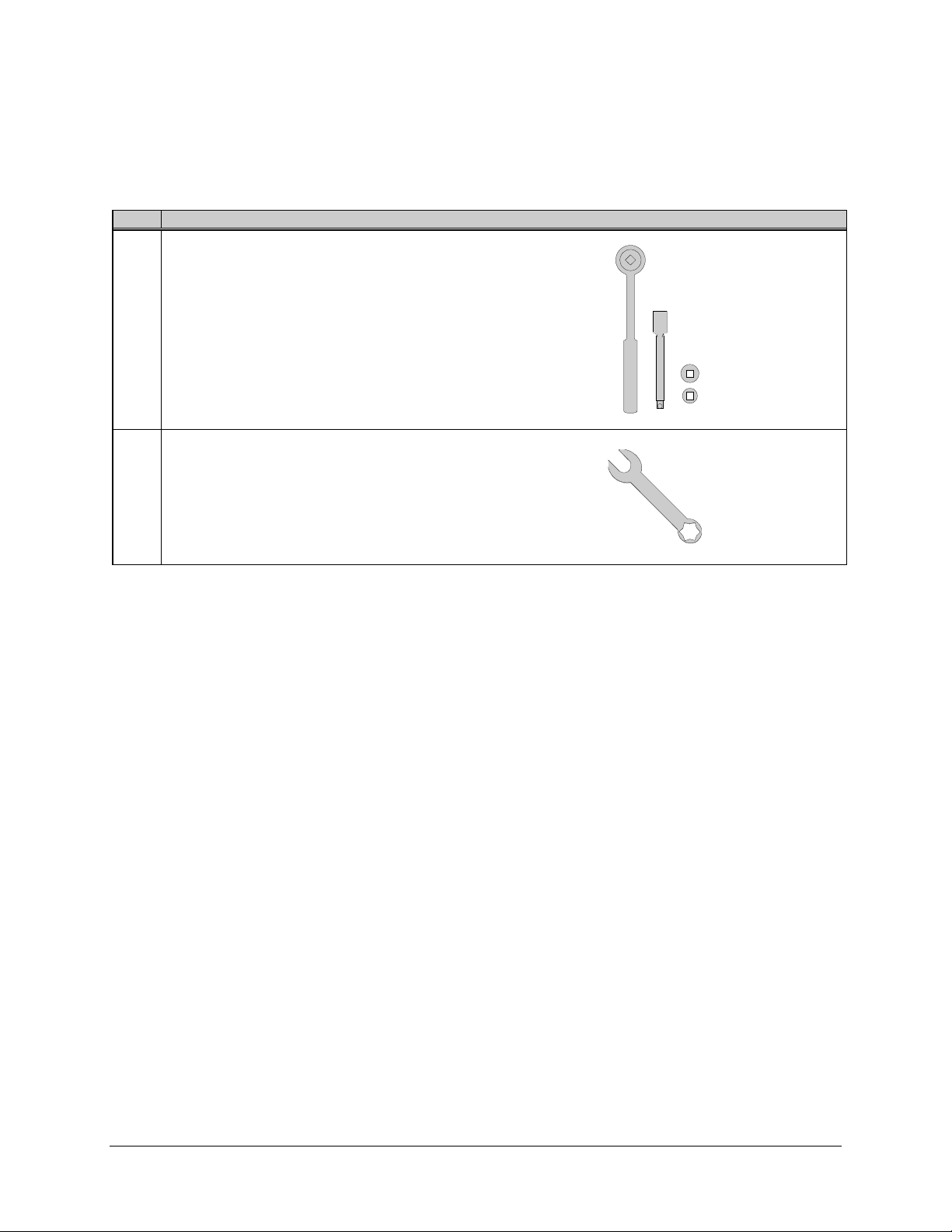

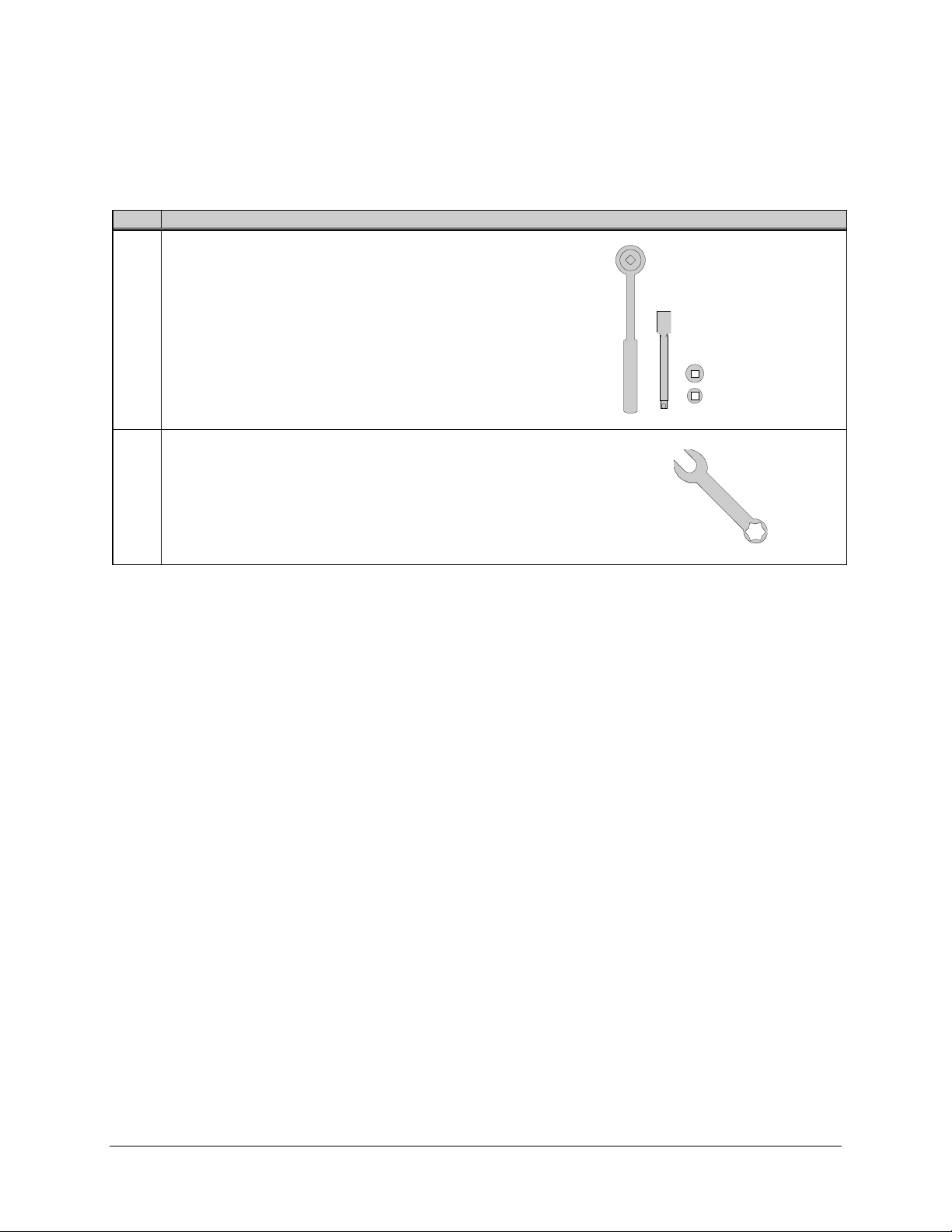

2.3.1 Tools Required

Qty. Description

1

3/8” drive ratchet.

1

3” x 3/8” drive extension.

1

7/16” x 3/8” drive socket. (Metric equivalent: 12mm, 6 pt.)

1

1/2” x 3/8” drive socket. (Metric equivalent: 13mm , 6 pt.)

1 1/2” combination wrench. (Metric equivalent: 13mm combination

wrench with a 6 pt. box end.)

2–8 Rev. 1

Page 31

CST-5005 C-Band Satellite Terminal Single Thread System Installation

2.3.2 Vertical Pole Installation

2.3.2.1 Round Pole

Note:

The following process is for a typical installation. Custom systems may be

ordered, and are beyond the scope of this manual.

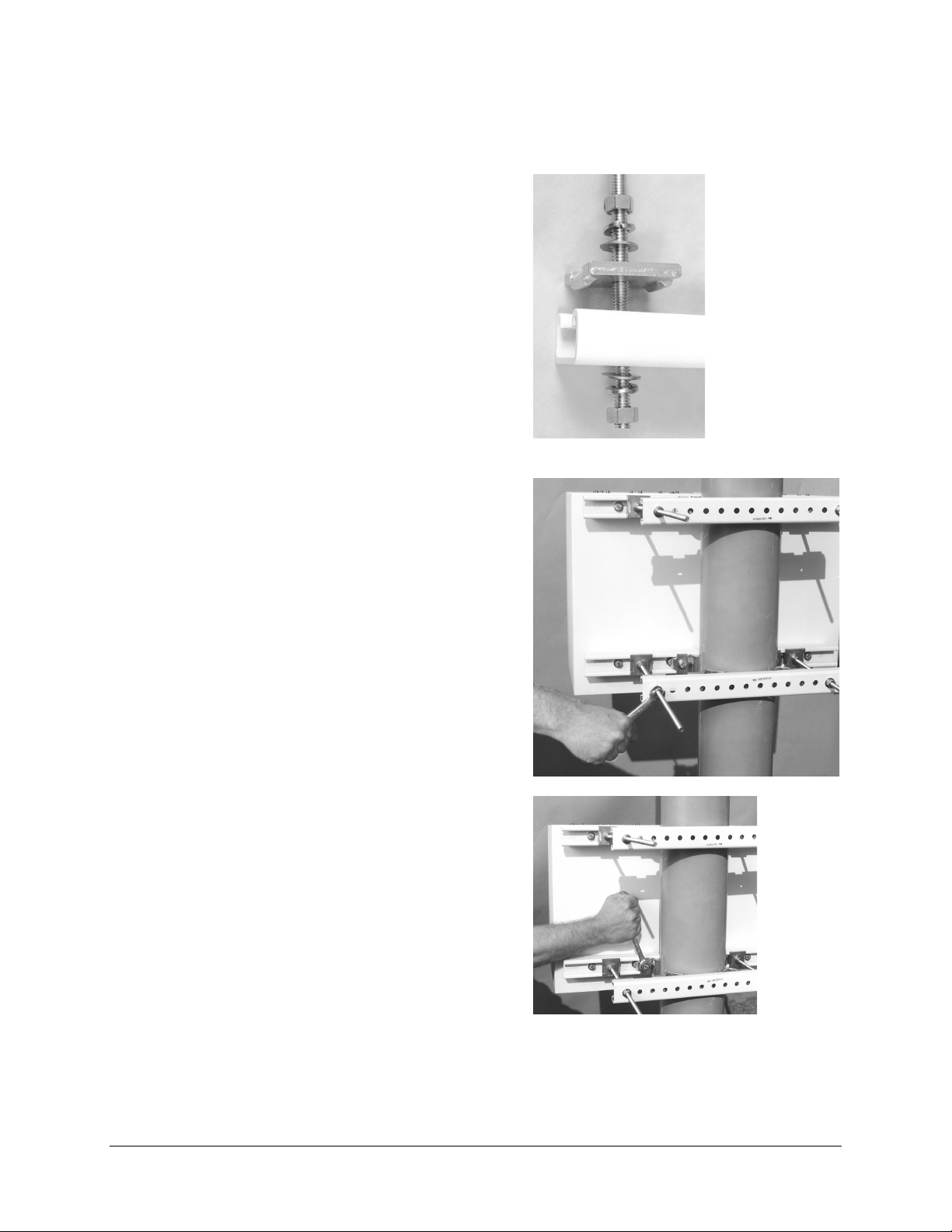

To install the RFT to a round vertical pole:

1. Set the unit on its side, with the mounting holes facing up.

2. Install the two 14” unistruts as follows:

a. Position a 14” unistrut (with

the open side facing up)

over one set of the mounting

holes on the RFT.

b. Using four 1/4-20 bolts,

1/4” split lockwashers, and

1/4” flat washers, attach the

14” unistrut to the RFT.

Tighten the bolts firmly.

c. Repeat Steps 2.a. and 2.b.

for the second 14” unistrut.

Rev. 1 2–9

Page 32

Single Thread System Installation CST-5005 C-Band Satellite Terminal

3. Install the pipe blocks as follows:

a. Install two spring nuts in each of four 14” unistruts (the two just mounted on

the RFT, and two additional).

Be sure to position the spring nuts in the unistruts wide enough apart so that

when the pipe blocks are installed, they will clear the pole when the unit is

lifted into place for installation.

b. Install each spring nut as follows:

(1) Place the spring nut in the unistrut channel, spring side down, with its

wide side parallel with the unistrut channel.

(2) Press down on the spring nut to compress the spring, and rotate the nut

90° (i.e., perpendicular to the unistrut).

(3) Release pressure on the spring nut.

(4) Repeat Steps 3.b.(1) through 3.b.(3) for each spring nut.

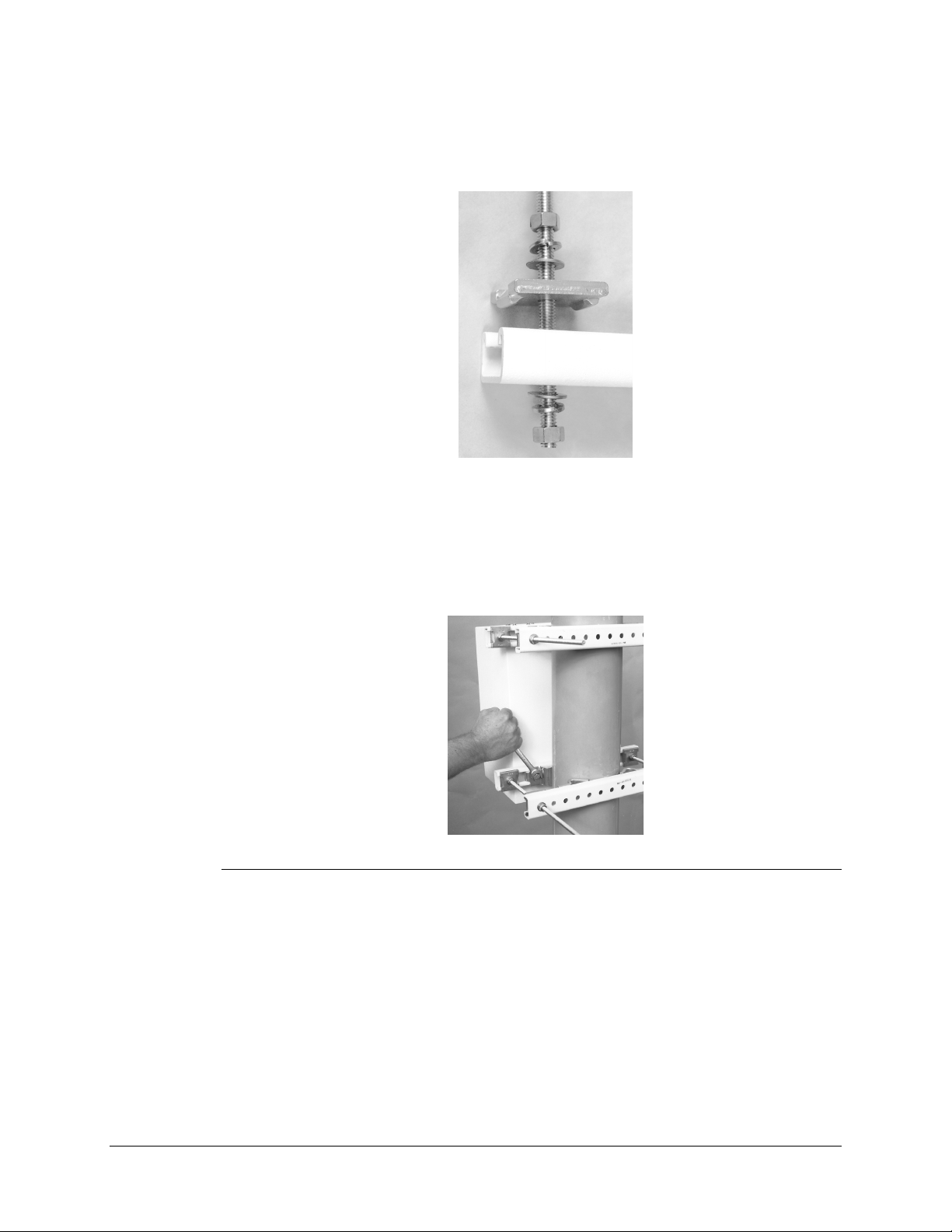

c. Using four 5/16-18 bolts, 5/16” split

lockwashers, and 5/16” flat washers,

loosely secure the pipe blocks to the

spring nuts.

Ensure the pipe blocks are installed

with the long angle facing inward,

toward the pipe, as illustrated.

DO NOT tighten the pipe block bolts

until after mounting the RFT on the

vertical pole. (See Step 5.e.)

2–10 Rev. 1

Page 33

CST-5005 C-Band Satellite Terminal Single Thread System Installation

4. Install the threaded rods as follows:

a. Install two spring nuts in both 14”

unistruts mounted on the RFT.

Note:

Ensure the spring nuts are

positioned over the outer holes in the

14” unistruts, as illustrated.

b. To install each spring nut:

(1) Place the spring nut in the

unistrut channel, spring side

down, with its wide side parallel

with the unistrut channel.

(2) Press down on the spring nut to

compress the spring, and rotate

the nut 90° (i.e., perpendicular to

the unistrut).

(3) Release pressure on the spring nut.

(4) Repeat Steps 4.b.(1) through 4.b.(3) for each spring nut.

c. Thread a 5/16-18 nut approximately 1-1/2” onto each threaded rod. (This

will ensure that the threaded rods will extend beyond the spring nuts when

installed.)

d. Place a 5/16” split lockwasher, 5/16” flat washer, and flat fitting plate over

each threaded rod.

Rev. 1 2–11

Page 34

Single Thread System Installation CST-5005 C-Band Satellite Terminal

e. One threaded rod at a time, hold the

washers and plate in place on the rod,

and screw the rod into a spring nut, as

illustrated.

Notes:

1. Be sure to position the flanges

of the flat fitting plates in the

grooves of the unistruts.

2. Before tightening the nuts on

the threaded rods, ensure that

the end of each rod is screwed

in until it is flush with the

backside of the unistruts. This

ensures the rods are threaded

completely through the spring

nuts.

Tighten each nut firmly.

f. Thread a 5/16-18 nut about 2” onto the

end of each threaded rod.

g. Slip a 5/16” split lockwasher, 5/16” flat

washer, and flat fitting plate (in that

order) onto each threaded rod.

2–12 Rev. 1

Page 35

CST-5005 C-Band Satellite Terminal Single Thread System Installation

5. Mount the RFT as follows:

a. Lift the RFT into position on the vertical pole.

b. Slip a 14” unistrut over each of pair of threaded rods (upper and lower).

Note:

Install the 14” unistruts with the open face toward the pole as

illustrated below.

Rev. 1 2–13

Page 36

Single Thread System Installation CST-5005 C-Band Satellite Terminal

c. Install a 5/16” flat washer, 5/16” split lockwasher, and 5/16-18 nut on each

threaded rod.

d. Position the RFT as desired, and tighten the 5/16-18 nuts installed in

Step 5.c.

e. Slide the pipe blocks inward until they contact the vertical pole, then firmly

tighten the 5/16-18 bolts.

2.3.2.2 Square Pole

For square vertical pole installation, follow the steps in Section 2.3.2.1, with the

following exceptions:

• Do not perform Step 3.

• Do not perform Step 5.e.

2–14 Rev. 1

Page 37

CST-5005 C-Band Satellite Terminal Single Thread System Installation

2.3.3 Spar Installation

Note:

The following process is for a typical installation. Custom systems may be

ordered, and are beyond the scope of this manual.

To install the RFT to a spar:

1. Set the unit on its side, with the mounting holes facing up.

2. Install the 8” unistruts as follows:

a. Position an 8” unistrut (with the open

side facing up) over one set of the

mounting holes on the RFT.

b. Using four 1/4-20 bolts, 1/4” split

lockwashers, and 1/4” flat washers,

attach an 8” unistrut to the RFT.

Tighten the bolts firmly.

c. Repeat Steps 2.a. and 2.b. for the

second 8” unistrut.

Rev. 1 2–15

Page 38

Single Thread System Installation CST-5005 C-Band Satellite Terminal

3. Mount the RFT as follows:

a. Position a spring nut between the

inner and outer bolts on both sides

of each 8” unistrut, as illustrated.

b. Install each spring nut as follows:

(1) Place the spring nut in the

unistrut channel, spring side

down, with its wide side

parallel with the unistrut

channel.

(2) Press down on the spring nut

to compress the spring, and

rotate the nut 90° (i.e.,

perpendicular to the unistrut).

(3) Release pressure on the

spring nut.

(4) Repeat Steps 3.b.(1) through

3.b.(3) for each spring nut.

c. Lift the RFT into position.

d. Using four 5/16-18 bolts, 5/16”

split lockwashers, and 5/16” flat

washers, bolt the two spar support

brackets in place.

Tighten the bolts firmly.

2–16 Rev. 1

Page 39

CST-5005 C-Band Satellite Terminal Single Thread System Installation

2.4 LNA Installation

Refer to Section 2.2.1 for included parts.

To install a single LNA to an antenna:

1. Remove the protective cover from the antenna mount location (if installed).

2. Remove the plastic cover from the antenna end (RF IN) of the LNA.

3. Remove the plastic cover from the RF OUT end of the LNA.

After removing the protective cover(s), ensure that no foreign

material or moisture enters the antenna waveguide or LNA.

CAUTION

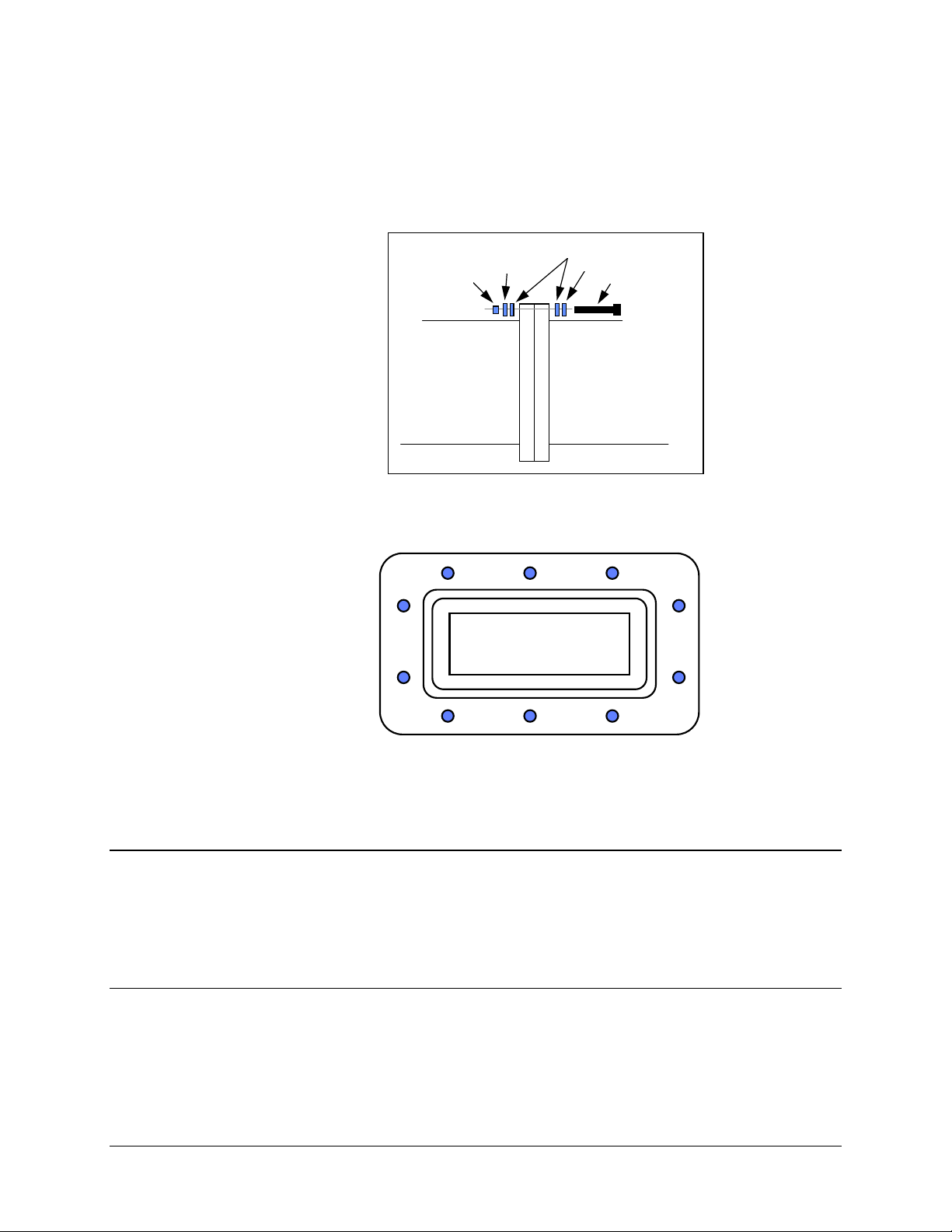

4. Install the appropriate gasket on the antenna end of the LNA:

a. If the LNA has a groove, and the antenna flange does not, the thin gasket

should be used.

b. If both the LNA and antenna flanges have grooves, the thick gasket should

be used.

5. Position the LNA in place on the antenna, and install the 1/4-20 bolts, washers,

and nuts. Do not tighten at this time.

FLAT WASHER

SPLIT WASHER

BOLT

LNA

ANTENNA

NUT

SPLIT

WASHER

Rev. 1 2–17

Page 40

Single Thread System Installation CST-5005 C-Band Satellite Terminal

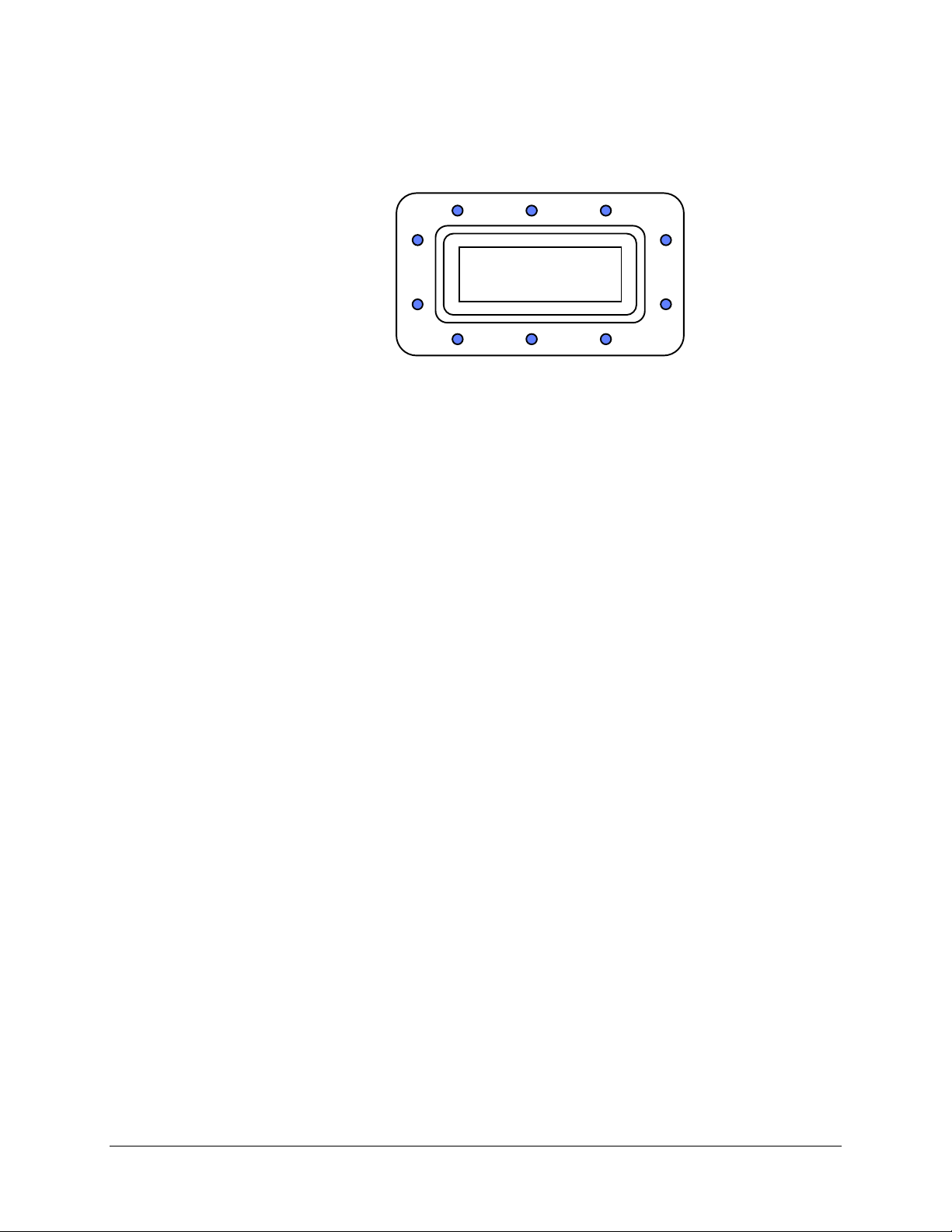

6. After all the bolts, washers, and nuts have been installed, tighten them according

to the following illustrated sequence.

5

7

4

1

2

3

10

89

6

2–18 Rev. 1

Page 41

CST-5005 C-Band Satellite Terminal Single Thread System Installation

2.5 External Connections

Connections between the RFT and other equipment are made through six connectors.

These connectors are listed in Table 2-1, and their locations are shown in Figure 2-1.

The use of each connector is described in the following paragraphs.

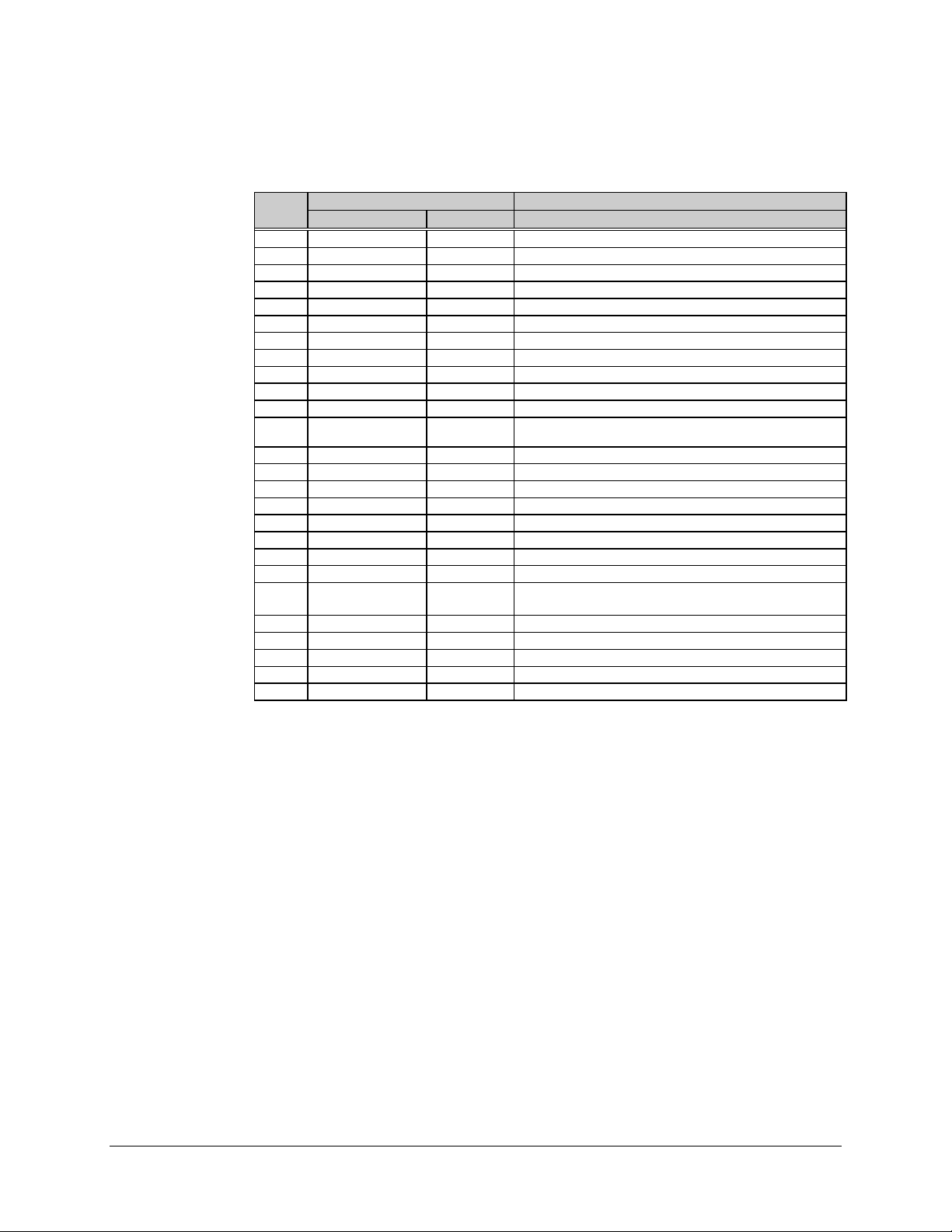

Table 2-1. Front Panel Connectors

Name Ref. Design. Connector Type Function

TX/IF IN J1 Type N TX IF INPUT (70 MHz)

TX/RF OUT J2 Type N 5.845 to 6.425 GHz Out

RX/IF OUT J3 Type N RX IF OUT (70 MHz)

RX/RF IN J4 Type N 3.620 to 4.200 GHz Input

PRIME PWR J5 Standard Prime Power Input

REMOTE J6 26-pin CIR Remote Interface

GND ERDE GND #10-32 Stud Chassis Ground

Figure 2-1. RFT-505 External Connections

Rev. 1 2–19

Page 42

Single Thread System Installation CST-5005 C-Band Satellite Terminal

2.5.1 TX/IF Input (J1)

The TX/IF input is from the indoor unit, and utilizes a type N connector.

The input impedance is 50

140 MHz,

± 36 MHz).

The typical power level is from -43 to -19 dBm, depending on the configuration and

application.

2.5.2 TX/RF Output (J2)

The TX/RF output has an output impedance of 50

The output frequency range is from 5.845 to 6.425 GHz. The output power level ranges

from +8 dBm to 10W (+40 dBm), depending on the power option ordered.

, and the frequency is 70 MHz, ± 18 MHz (optional

Ω

, and utilizes a type N connector

Ω

.

2–20 Rev. 1

Page 43

CST-5005 C-Band Satellite Terminal Single Thread System Installation

2.5.3 RX/IF Output (J3)

The RX/IF output goes to the indoor unit, and utilizes a type N connector.

The output impedance is 50

140 MHz,

± 36 MHz).

The 1 dB output compression point is +15 dBm minimum.

Nominal output power operation is +9 dBm (-6 dB from 1 dB compression) to -27 dBm,

depending on system gain requirements.

The down converter has 24 to 45 dB of gain, and is adjustable by the customer from 0 to

21 dB of attenuation.

The typical system gain includes a 50 dB LNA, making the total system gain 74 to

95 dB.

Note:

A 60 dB LNA is only used when there are extremely long cables from the LNA to

the down converter.

2.5.4 RX/RF Input (J4)

The RX/RF input comes from the LNA, and utilizes a type N connector.

The input impedance is 50

, and the frequency is 70 MHz, ± 18 MHz (optional

Ω

and the input frequency range is from 3.620 to 4.200 GHz.

Ω,

The input signal level ranges between -53 dBm and -30 dBm, depending on LNA and

antenna gain.

The input level should be set to give the required signal level at J3, the RX/IF Output

(refer to Section 2.5.3).

Rev. 1 2–21

Page 44

Single Thread System Installation CST-5005 C-Band Satellite Terminal

2.5.5 Prime Power (J5)

The AC power is supplied to the terminal by a 3-pin power connector.

Normal input voltage is 90 to 260 VAC, 47 to 63 Hz. Maximum power consumption is as

follows:

Maximum

Power Output

+8 dBm 70W

5W (+37 dBm) 125W

10W (+40 dBm) 175W

The AC pinout is as follows:

Pin # Name Function Wire Color

AHI Line Brown

B LO Neutral Blue

C GND Ground Green/Yellow

Power Consumption

A circular 4-pin power connector is used for the DC (48 VDC) option.

The DC pinout is as follows:

Pin # Name

A + INPUT

B CHASSIS GROUND

C - INPUT

DN/C

2–22 Rev. 1

Page 45

CST-5005 C-Band Satellite Terminal Single Thread System Installation

2.5.6 Serial Remote Control (J6)

The remote connector on the RFT is used to interface the M&C functions to a remote

location. This interface can be either RS-232-C or RS-485.

When using an RS-485 interface, the transmit and receive signals are able to

accommodate either type of remote equipment pinouts. As long as the polarities of the

remote equipment TX and RX signals are correct, this remote interface will be

completely compatible.

Refer to Table 2-2 for a list of pinouts for the J6 connector.

For standard RS-232-C or RS-485 applications, an adapter cable must be used to connect

the 26-pin connector (J6) to a standard 9-pin D.

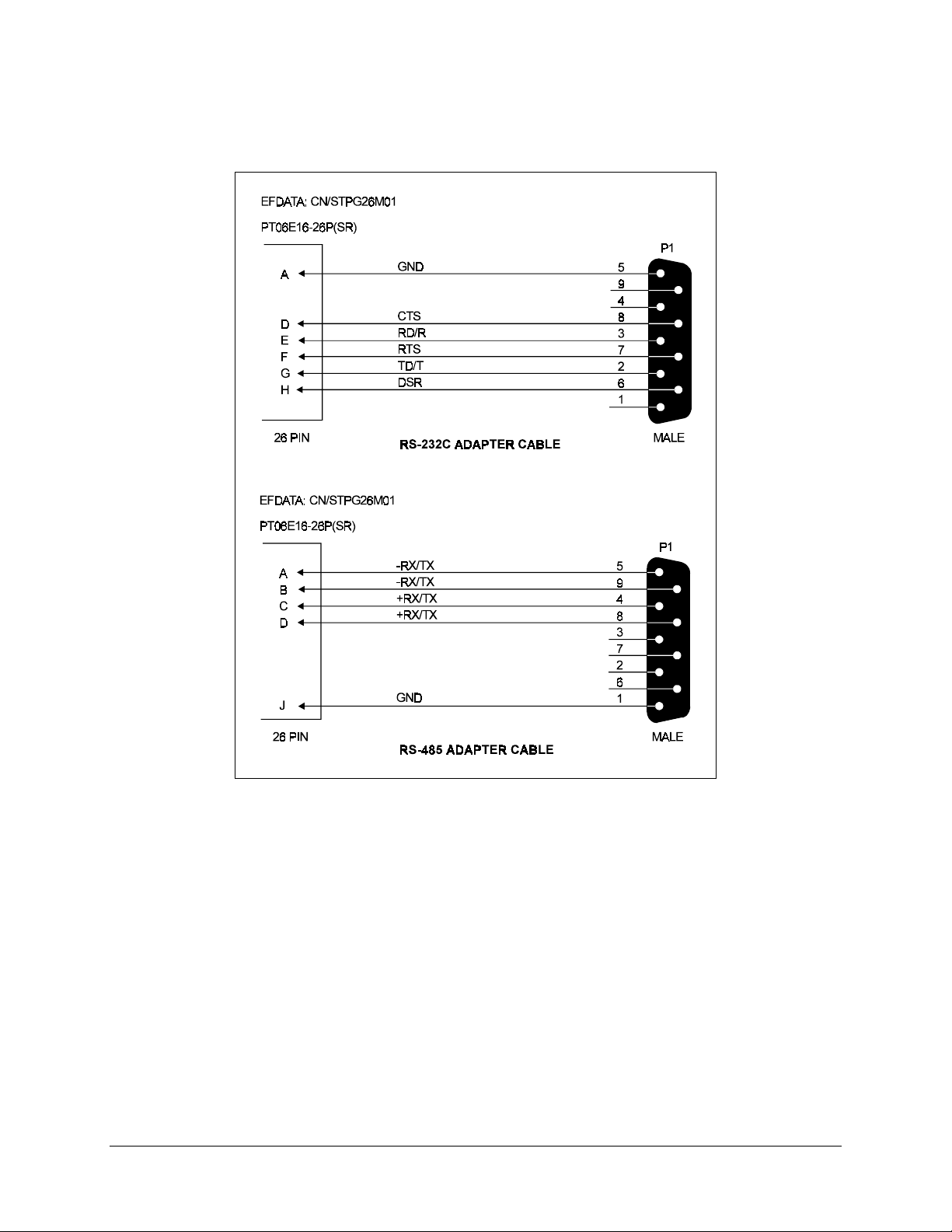

Refer to Figure 2-2 for an illustration of the adapter cable with its pinouts.

Rev. 1 2–23

Page 46

Single Thread System Installation CST-5005 C-Band Satellite Terminal

Table 2-2. RFT Remote Control Connector, J6

Pin # Name Description

RS-232-C RS-485

A GND -RX/TX RX/TX Data

B -RX/TX RX/TX Data

C +RX/TX RX/TX Data

D CTS +RX/TX Clear to send

E RD/RX Receive data

F RTS Ready to send

G TD/TX Transmit Data

H DSR Data Set Ready

J GND Ground (green)

K LNA_PWR Output, 10V for powering LNA

L EXT_PWR Output voltage, 11V, to power RSU-503 and KP-10

M EXT TWT FLT Input, logic 0 or 5V, 5V = FLT, 0V = normal

N EXT IN_1 Input, logic 0 or 5V, spare

P SPARE N/C

R GND Ground (green)

S GND Ground, Signal

T SPARE N/C

U UL_NC Uplink fault relay, connects to uplink COM with fault

V UL_COM Uplink fault relay, COMMON

W UL_NO Uplink fault relay, opens with fault

X DL_NC Downlink fault relay, connects to downlink COM

with fault

Y DL_COM Downlink fault relay, COMMON

Z DL_NO Downlink fault relay, opens with fault

a LNA PWR RTN Return for LNA Power

b EXT IN_2 Input, 0 to 5V Logic

c SPARE N/C

(see Note 1)

(see Note 1)

(see Note 2)

(see Note 3)

(see Note 3)

(see Note 2)

Notes:

1. In RS-232-C mode, CTS is tied to RTS (and vice versa).

2. LNA can be powered from these pins instead of up through the RF cable.

3. 5V is a floating level.

2–24 Rev. 1

Page 47

CST-5005 C-Band Satellite Terminal Single Thread System Installation

Figure 2-2. Serial Adapter Cables

2.5.7 GND

A #10-32 stud is available on the rear for the purpose of connecting a common chassis

ground between all of the equipment.

Rev. 1 2–25

Page 48

Single Thread System Installation CST-5005 C-Band Satellite Terminal

This page is intentionally left blank.

2–26 Rev. 1

Page 49

Chapter 3.

REDUNDANT SYSTEM

INSTALLATION

3

This chapter provides installation information for redundant systems, including:

• Unpacking and inspecting the parts

• Installing the RFTs

• Installing the 1:1 redundant plate

• External connections

For RSU-503 installation information, refer to the EFData RSU-503 Redundancy Switch

Unit Installation and Operation Manual.

For single thread systems, refer to Chapter 2.

If the RFTs are to be mounted individually, refer to Chapter 2 for installation

information.

Rev. 1 3–1

Page 50

Redundant System Installation CST-5005 C-Band Satellite Terminal

3.1 Unpacking

The CST-5005 redundant system is shipped in two cartons (one RFT each) and one crate.

To remove the parts:

1. Cut the tape at the top of each carton where it is indicated OPEN THIS END.

2. Lift out the cardboard/foam spacer covering the units.

3. Remove the parts from the cartons. Refer to Section 3.2.1 for a parts breakdown.

Because the RFTs are heavy, assistance may be necessary to remove

the units from the boxes.

CAUTION

4. Remove the screws from the lid of the wooden crate, and remove the lid.

5. Unbolt the redundant LNA plate and remove it from the crate.

6. Remove the remainder of the parts from the crate. Refer to Section 3.2.1 for a

parts breakdown.

Note:

Save the packing material for reshipment.

3.2 Inspecting the Equipment

1. Carefully check the equipment for damage incurred during shipment.

2. Carefully check the equipment against the packing list shipped with the

equipment to ensure that the shipment is complete. Refer to the following

paragraphs.

3–2 Rev. 1

Page 51

CST-5005 C-Band Satellite Terminal Redundant System Installation

3.2.1 Included Parts

A typical redundant CST-5005 configuration contains the following components.

Notes:

1. Parts are not drawn to scale.

2. Because each system can be custom ordered, it is beyond the scope of this

manual to provide the unlimited configuration possibilities.

3. This chapter does not describe the installation procedures for amplifiers, high

performance LNAs, phase-locked LNBs, LNBs, or phase-locked block

converters.

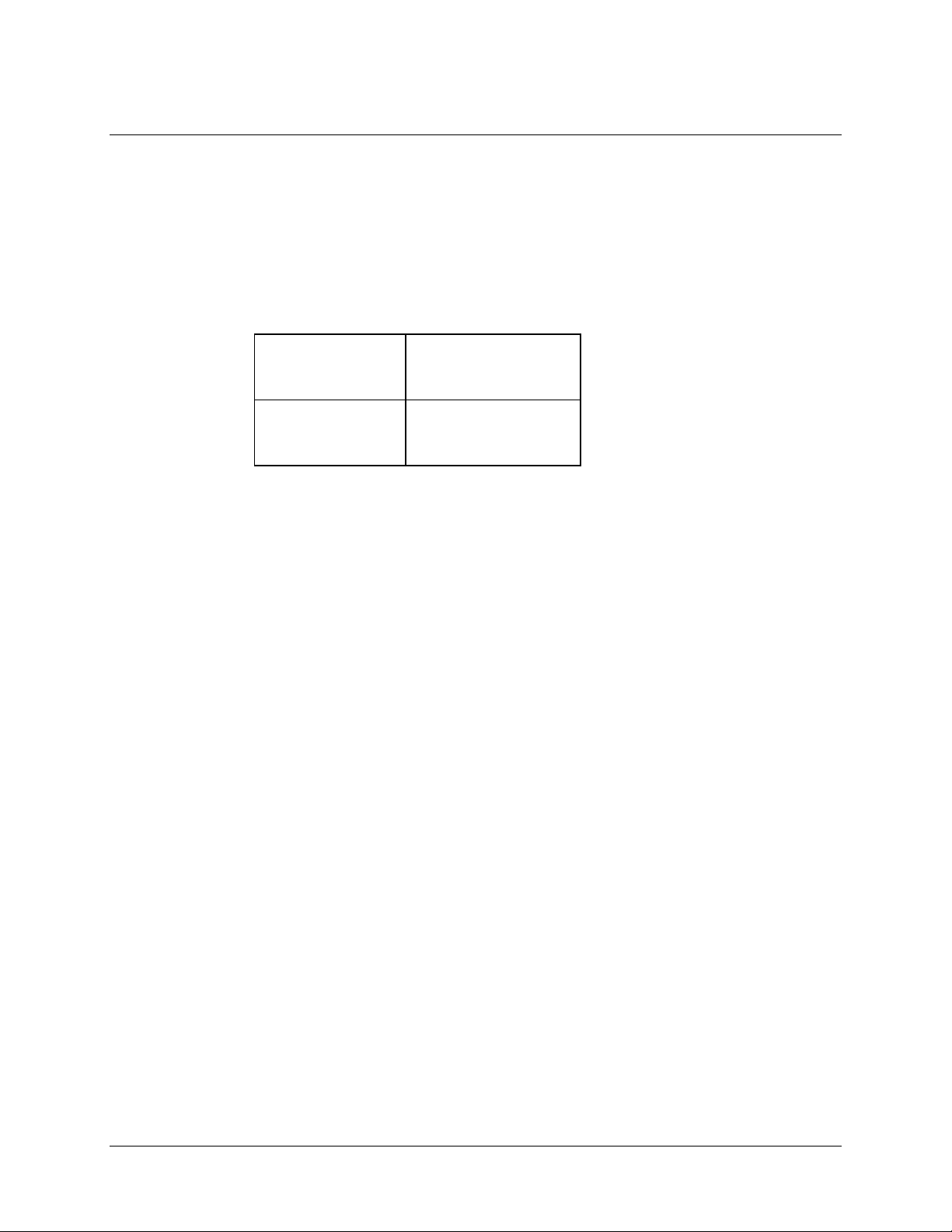

Qty. Description Qty. Description

2 RFT outdoor unit. 1 Redundant LNA plate.

Note:

Pictured is a typical LNA plate. Other

LNA plates are available, and can be ordered

from an EFData marketing representative.

1 RSU-503. 1 CST-5005 installation and operation manual.

1 Envelope containing the test data sheet. 1 RSU-503 installation and operation manual.

1 Monitor and Control Software for EFData

Satellite Terminals User’s Guide.

Rev. 1 3–3

Page 52

Redundant System Installation CST-5005 C-Band Satellite Terminal

1 LNA connector kit (EFData Part # KT/2721), which includes:

Qty. Description Qty. Description

1 Gasket — thick.

1 Gasket — thin.

EFData Part # 32P1040.

10 1/4-20 x 5/8” bolt.

EFData Part # 03P1079.

10 1/4” split lockwasher.

EFData Part # HW/1/4-SPLIT.

EFData Part # 32D1002.

20 1/4” flat washer.

EFData Part # O4P1022.

10 1/4-20 nut.

EFData Part # HW/1/4HEXNUT.

3–4 Rev. 1

Page 53

CST-5005 C-Band Satellite Terminal Redundant System Installation

1 Kit KT/3107-x (where x = 5 for AC power, and 6 for DC power), which includes:

Qty. Description Qty. Description

3 Connector kit.

EFData Part # CN/STPG26M01.

Used to connect customer’s cable to the RFT

26-pin J6 (REMOTE). For remote control and

status monitoring (by using M&C system

monitor software).

3 17’ Heliax cable.

2

Note:

Either the AC or DC cable is provided,

depending upon the product ordering code.

Assembly, 15’ AC prime power cable.

EFData Part # PL/2754.

Assembly, 15’ DC prime power cable.

EFData Part # PL/4157.

2 4’ M&C Redundancy Assy.

EFData Part # CA/1530.

Used for RF input and RF output.

4

TNC to N, 50Ω, 4’ cable.

EFData Part # PL/5143.

IF Tx and Rx cables from RFT to RSU.

2 Cable, N-Male, LDF4-50A, 3’, Heliax C -band.

EFData Part # CA/3230-1.

Used for CST-5000 terminal system only.

EFData Part # PL/3003.

Used for communications from RFTs A and B

to RSU.

1 17’ Cable, RSU-503 to redundant LNA plate.

EFData Part # PL/3006.

Communications from RSU to redundant LNA

plate.

Rev. 1 3–5

Page 54

Redundant System Installation CST-5005 C-Band Satellite Terminal

2 Kit KT/3576, which includes:

Qty. Description Qty. Description

5 Spar support bracket.

58 5/16” flat washer.

EFData Part # FP/3175.

Used for spar mount only.

30 5/16-18 hex nut.

EFData Part # HW/5/16-18HEXNT.

38 5/16-18 spring nut.

EFData Part # HW/5/16-18SPNUT.

4 Unitstrut — 8” long.

EFData Part # FP/3481.

Attaches directly to RFTs.

28 5/16-18 x 1” bolt.

EFData Part # HW/5/16-18X1BLT.

2 Unistrut, modified, 20” long.

EFData Part # HW/5/16-FLT.

58 5/16” split lockwasher.

EFData Part # HW/5/16-SPLIT.

20 Pipe block.

EFData Part # HW/BLK-PIPE2-8.

Used for round pole mount only.

20 Flat fitting plate, 5/16”.

EFData Part # HW/FIT-PLT-5/16.

10 Threaded rod, 5/16-18 x 14”.

EFData Part # HW/RD5/16-18X14.

Used for round and square pole mount only.

19 1/4” flat washer.

EFData Part #FP/3482.

Used for round and square pole mount only.

19 1/4-20 x 5/8” bolt.

EFData Part # HW/1/4-20X5/8BT.

Used to attach short unistruts to RFTs.

3–6 Rev. 1

EFData Part # HW/1/4-FLT.

Used to attach short unistruts to RFT.

19 1/4” split lockwasher.

EFData Part # HW/1/4-SPLIT.

Used to attach short unistruts to RFT.

Page 55

CST-5005 C-Band Satellite Terminal Redundant System Installation

3.3 RFT Installation

At the customer’s discretion, the RFTs can be installed anywhere on or near the antenna.

The supplied hardware allows the installer a wide range of installation alternatives,

including:

• Vertical pole (e.g., mast) (either square or round). This is the most typical

installation.

• Within the hub of a large antenna.

• Spar (i.e., rectangular bar) on the antenna structure.

EFData recommends that the RFTs be mounted vertically, with the air inlets facing the

ground.

Rev. 1 3–7

Page 56

Redundant System Installation CST-5005 C-Band Satellite Terminal

3.3.1 Tools Required

Qty. Description

1

3/8” drive ratchet.

1

3” x 3/8” drive extension.

1

7/16” x 3/8” drive socket. (Metric equivalent: 12mm, 6 pt.)

1

1/2” x 3/8” drive socket. (Metric equivalent: 13mm , 6 pt.)

1 1/2” combination wrench. (Metric equivalent: 13mm combination

wrench with a 6 pt. box end.)

3–8 Rev. 1

Page 57

CST-5005 C-Band Satellite Terminal Redundant System Installation

3.3.2 Vertical Pole Installation

3.3.2.1 Round Pole

The following process is for a typical installation. Custom systems may be ordered, and

are beyond the scope of this manual.

To install the RFTs to a round vertical pole:

1. Set the units on their sides, with the mounting holes facing up.

2. Install the 8” unistruts as follows:

a. Position an 8” unistrut (with

the open side facing up) over

one set of the mounting holes

on the RFT.

b. Using four 1/4-20 bolts, 1/4”

split lockwashers, and 1/4” flat

washers, attach an 8” unistrut

to the RFT.

Tighten the bolts firmly.

c. Repeat Steps 2.a. and 2.b. for

each of the remaining 8”

unistruts (for a total of four).

Rev. 1 3–9

Page 58

Redundant System Installation CST-5005 C-Band Satellite Terminal

3. Install the 20” unistruts as follows:

Note:

The placement of the pipe blocks may interfere with the inner or center

unistrut attaching bolts. Be sure to determine the pipe block placement locations

before bolting the 20” unistruts in place. It may be necessary to eliminate the

center or inner 20” unistrut mounting spring nuts and bolts.

a. Insert a spring nut between

the unistrut mounting bolts

on both RFTs, as illustrated.

b. To install each spring nut:

(1) Place the spring nut in

the unistrut channel,

spring side down, with

its wide side parallel

with the unistrut

channel.

(2) Press down on the

spring nut to compress

the spring, and rotate

the nut 90° (i.e.,

perpendicular to the

unistrut).

(3) Release pressure on the spring nut.

(4) Repeat Steps 3.b.(1) through 3.b.(3) for each spring nut.

3–10 Rev. 1

Page 59

CST-5005 C-Band Satellite Terminal Redundant System Installation

c. With the RFTs side-by side,

position a 20” unistrut

(open side facing up) in

place over one pair of 8”

unistruts.

Ensure the long unistrut is

centered over the RFTs.

d. Using two or three 5/16-18

bolts, 5/16” split

lockwashers, and 5/16” flat

washers, attach the 20”

unistrut to the 8” unistruts.

Tighten the bolts firmly.

e. Attach the second 20” unistrut to the second set of 8” unistruts by repeating

Steps 3.a. through 3.d.

4. Install the pipe blocks as follows:

a. Install two spring nuts in each of the two 20” long unistruts and two 14” long

unistruts (centered in the unistruts, and wide enough apart so the pipe blocks

will clear the pole when the unit is installed).

b. Install each spring nut as follows:

(1) Place the spring nut in the unistrut channel, spring side down, with its

wide side parallel with the unistrut channel.

(2) Press down on the spring nut to compress the spring, and rotate the nut

90° (i.e., perpendicular to the unistrut).

Rev. 1 3–11

Page 60

Redundant System Installation CST-5005 C-Band Satellite Terminal

(3) Release pressure on the spring nut.

(4) Repeat Steps 4.b.(1) through 4.b.(3) for each spring nut.

c. Using eight 5/16-18 bolts, 5/16” split lockwashers, and 5/16” flat washers,

loosely secure the pipe blocks to the spring nuts.

Ensure the pipe blocks are installed with the long angle face inward, toward

the pipe, as illustrated.

DO NOT tighten the pipe block bolts until after mounting the RFTs on the

vertical pole. (See Step 6.e.)

5. Install the threaded rods as follows:

a. Install two spring nuts in both

20” unistruts mounted on the

RFTs.

b. Install each spring nut as

follows:

(1) Place the spring nut in

the unistrut channel,

spring side down, with

its wide side parallel

with the unistrut

channel.

3–12 Rev. 1

Page 61

CST-5005 C-Band Satellite Terminal Redundant System Installation

(2) Press down on the spring

nut to compress the

spring, and rotate the nut

90° (i.e., perpendicular

to the unistrut).

(3) Release pressure on the spring nut.

(4) Repeat Steps 5.b.(1) through 5.b.(3) for each spring nut.

c. Thread a 5/16-18 nut

approximately 1-1/2” onto

each threaded rod. (This will

ensure that the threaded rods

will extend beyond the spring

nuts when installed.)

d. Place a 5/16” split

lockwasher, 5/16” flat

washer, and flat fitting plate

over each threaded rod.

Rev. 1 3–13

Page 62

Redundant System Installation CST-5005 C-Band Satellite Terminal

e. One threaded rod at a time,

hold the washers and plate in

place on the threaded rod and

screw it into a spring nut, as

illustrated.

Notes:

1. Be sure to position

the flanges of the flat

fitting plates in the

grooves of the

unistruts.

2. Before tightening the

nuts on the threaded

rods, ensure that the

end of each rod is

screwed in until it

contacts the unistrut.

This ensures the rods

are threaded

completely through

the spring nuts.

Tighten each nut firmly.

f. Thread a 5/16-18 nut about 2”

onto the end of each threaded

rod.

g. Slip a 5/16” split lockwasher,

5/16” flat washer, and flat

fitting plate (in that order)

onto each threaded rod.

3–14 Rev. 1

Page 63

CST-5005 C-Band Satellite Terminal Redundant System Installation

6. Mount the RFTs as follows:

a. Lift the RFT into position on

the vertical pole.

b. Slip a 14” unistrut over each

of pair of threaded rods

(upper and lower).

Note:

Install the 14” unistruts

with the open face toward the

pole, as illustrated.

c. Install a 5/16” flat washer,

5/16” split lockwasher, and

5/16-18 nut on each threaded

rod.

d. Position the RFT, as desired,

and tighten the 5/16-18 nuts

installed in Step 6.c.

e. Slide the pipe blocks in until

they contact the vertical pole.

Then, firmly tighten the

5/16-18 bolts.

Rev. 1 3–15

Page 64

Redundant System Installation CST-5005 C-Band Satellite Terminal

3.3.2.2 Square Pole

For square vertical pole installation, follow the steps in Section 3.3.2.1, with the

following exceptions:

• Do not perform Step 4.

• Do not perform Step 6.e.

3.3.3 Spar Installation

Note:

The following process is for a typical installation. Custom kits may be ordered and

are beyond the scope of this manual.

To install the RFTs to a spar:

1. Set the units on their side, with the mounting holes facing up.

2. Install the 8” unistruts as follows:

a. Position an 8” unistrut (with the open

side facing up) over one set of the

mounting holes on an RFT.

b. Using four 1/4-20 bolts, 1/4” split

lockwashers, and 1/4” flat washers,

attach an 8” unistrut to the RFT.

Tighten the bolts firmly.

c. Repeat Steps 2.a. and 2.b. for the

remaining 8” unistruts (for a total of

four).

3–16 Rev. 1

Page 65

CST-5005 C-Band Satellite Terminal Redundant System Installation

3. Install the 20” unistruts as follows:

a. Position a spring nut between the 1/4-20 bolts in each 8” unistrut, as

illustrated below:

b. Install each spring nut as follows:

(1) Place the spring nut in the unistrut channel, spring side down, with its

wide side parallel with the unistrut channel.

(2) Press down on the spring nut to compress the spring, and rotate the nut

90° (i.e., perpendicular to the unistrut).

(3) Release pressure on the spring nut.

(4) Repeat Steps 3.b.(1) through 3.b.(3) for each spring nut.

c. With the RFTs side by side, position a 20” unistrut in place over one pair of

8” unistruts (open side up).

Rev. 1 3–17

Page 66

Redundant System Installation CST-5005 C-Band Satellite Terminal

d. Using four 5/16-18 bolts, 5/16” split lockwashers, and 5/16” flat washers,

bolt the 20” unistrut to the 8” unistruts.

e. Tighten the bolts firmly.

f. Repeat Steps 3.c. through 3.e. for the second 20” unistrut.

4. Mount the RFTs as follows:

a. Lift the RFTs into position.

b. Using four 5/16-18 bolts, 5/16”

split lockwashers, and 5/16” flat

washers, bolt the two spar support

brackets in place.

Tighten the bolts firmly.

3–18 Rev. 1

Page 67

CST-5005 C-Band Satellite Terminal Redundant System Installation

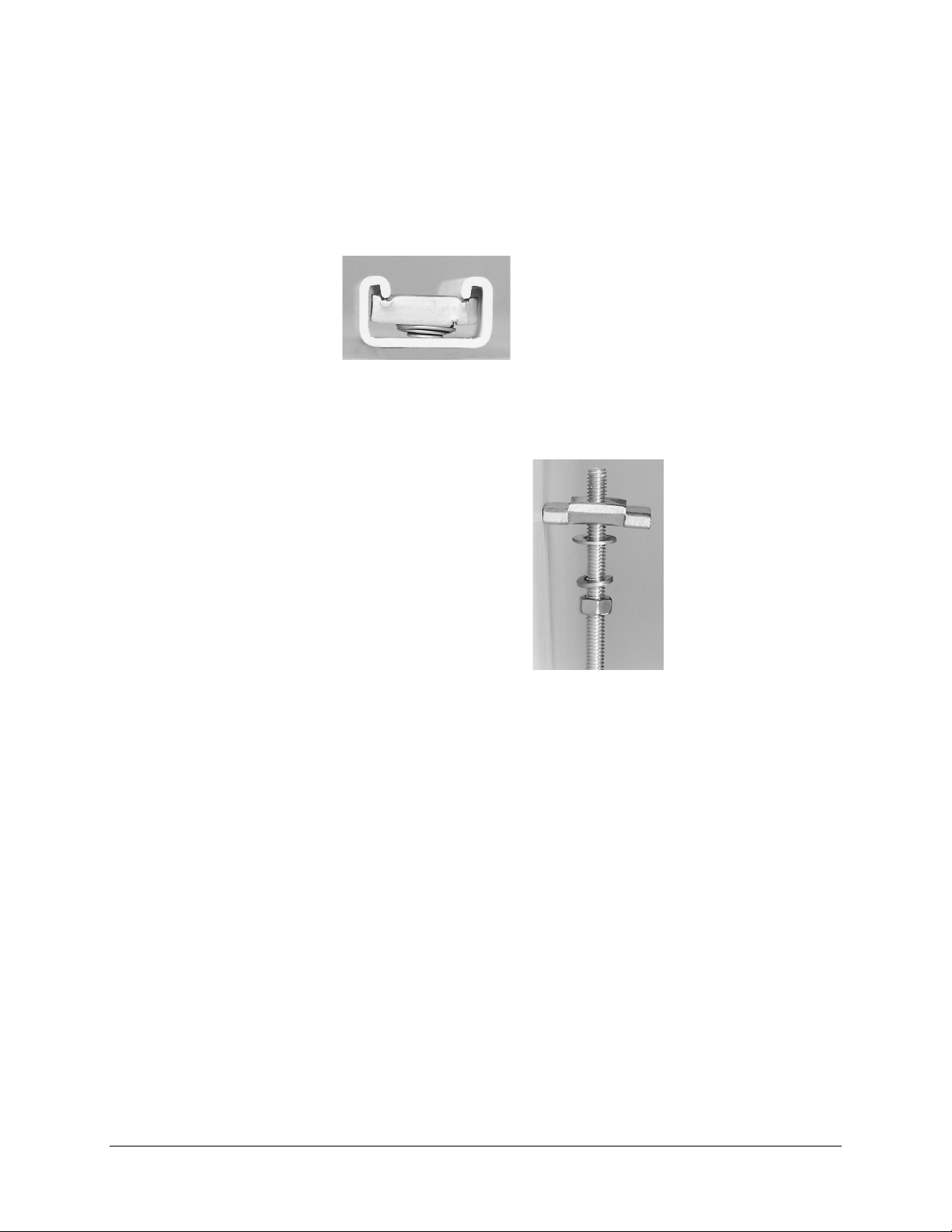

3.3.4 1:1 Redundant Plate Installation

A typical 1:1 redundant plate is shown below. Refer to Section 3.2.1 for included parts.

To install the 1:1 redundant plate:

1. Mount the 1:1 redundant plate to the antenna.

Note:

The type of mounting is determined by the brand of antenna on which the

equipment will be installed.

2. Remove the plastic cover from the RF IN connector of the redundant plate.

After removing the protective cover, ensure that no foreign material

or moisture enters the 1:1 redundant plate’s waveguide.

CAUTION

3. Install the appropriate gasket on the RF IN connector of the redundant plate:

a. If the LNA has a groove, and the antenna flange does not, the thin gasket

should be used.

b. If both the LNA and the antenna flange have grooves, the thick gasket should

be used.

Rev. 1 3–19

Page 68

Redundant System Installation CST-5005 C-Band Satellite Terminal

4. Position the antenna waveguide in place on the RF IN connector, and install the

1/4-20 bolts, 1/4” split lockwashers, 1/4” flat washers, and 1/4-20 nuts.

Do not tighten the bolts at this time.

FLAT WASHER

SPLIT WASHER

BOLT

LNA

ANTENNA

NUT

SPLIT

WASHER

5. After all the bolts, washers, and nuts have been installed, tighten them according

to the following illustrated sequence.

5

7

1

3

10

89

4

2

6

6. Remove the plastic covers from all the connectors, and attach the appropriate

cables.

3.4 RSU-503 Installation

Refer to the EFData RSU-503 Redundancy Switch Unit Installation and Operation

Manual.

3.5 External Connections

Refer to Section 2.5 for external connections information.

3–20 Rev. 1

Page 69

This chapter provides operation information for the RFT-505.

4.1 System Operation

There are two methods of operating the RFT-505:

• Connect a PC running DOS to the RS-232-C/485 remote control port, and run

the M&C system monitor software. This software is DOS-based and provides an

interface to the remote commands.

For more information on the M&C system monitor program, refer to the Monitor

and Control Software for EFData Satellite Terminals User’s Guide.

Chapter 4 .

OPERATION

4

• Connect the optional KP-10 hand-held keypad. For more information, refer to

the KP-10 External Keypad Installation and Operation Manual.

4.2 Remote Control

Refer to Appendix A.

Rev. 1 4–1

Page 70

Operation CST-5005 C-Band Satellite Terminal

This page is intentionally left blank.

4–2 Rev. 1

Page 71

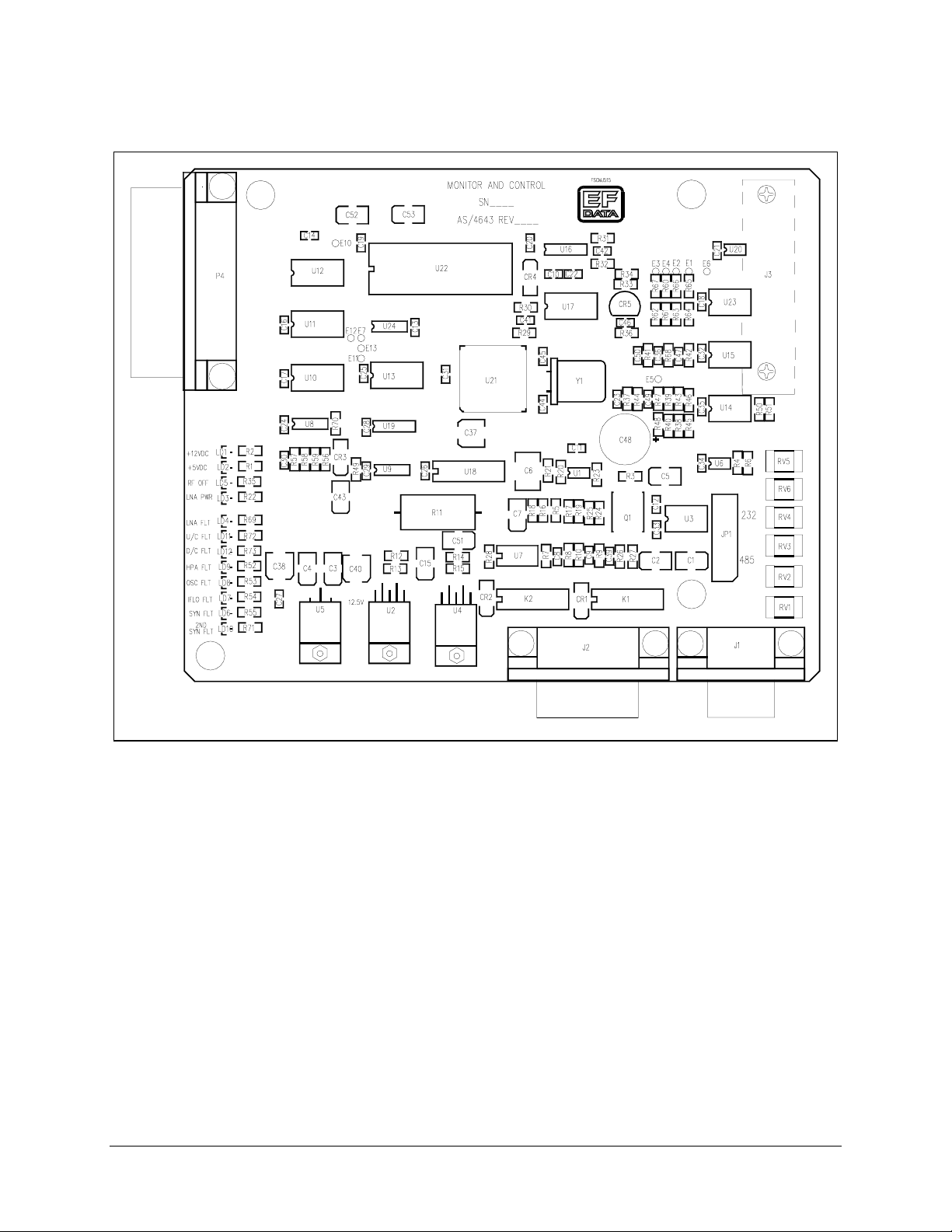

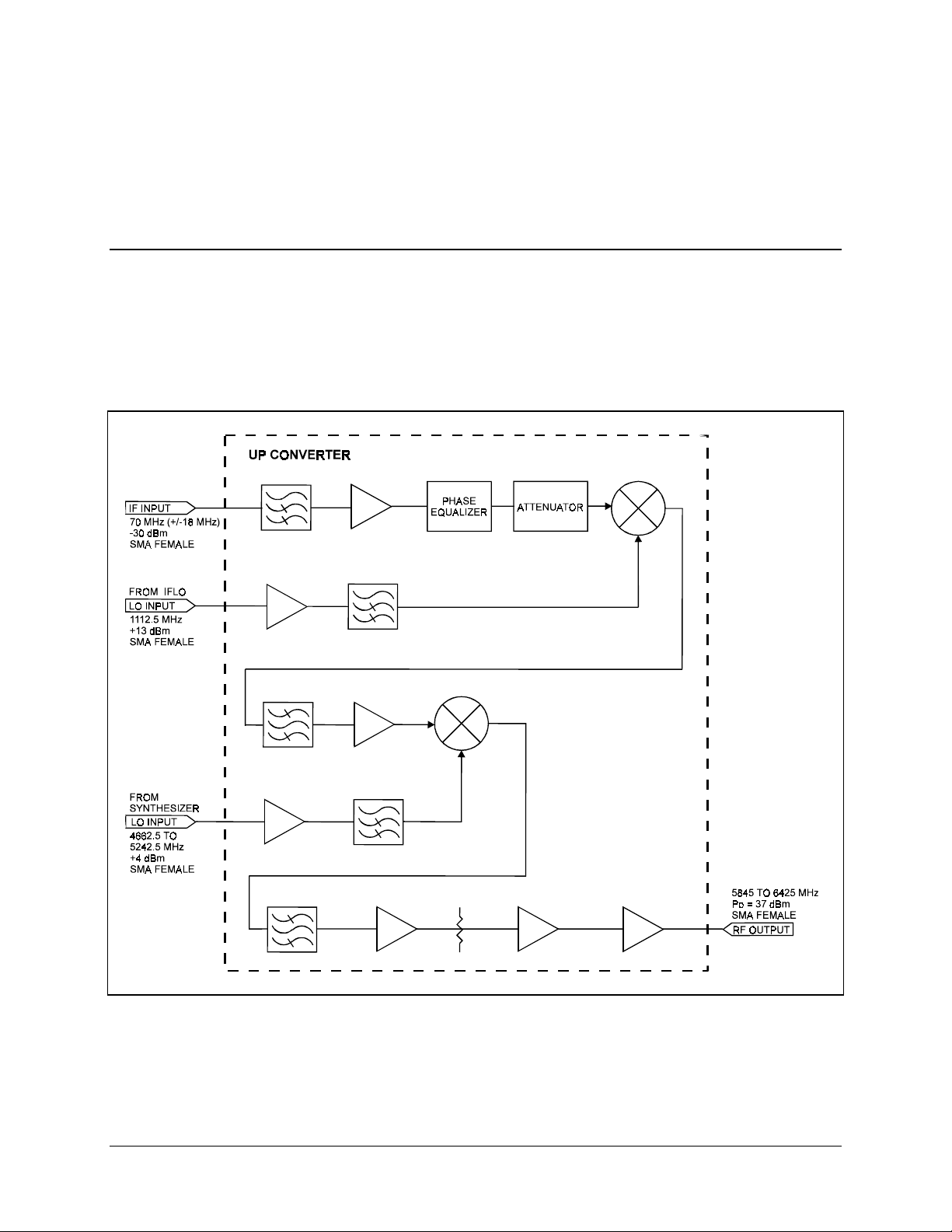

THEORY OF OPERATION