Page 1

p

CRS-400

1:8 Redundancy Switch

Installation and O

eration Manual

Part Number

MN/CRS400.IOM Revision 0

Page 2

Page 3

Comtech EF Data Documentation Update

Subject:

Date:

Original Document

Part Number/Rev:

Errata

Part Number:

Change Specifics:

ELATED DOCUMENTS

R

Comtech EF Data SDM-2020 Satellite Modulator Installation and Operation Manual

Comtech EF Data SDM-2020 Satellite Demodulator Installation and Operation Manual

Comtech EF Data CRS-280L 1:N Redundancy Switch Installation and Operation Manual

Errata A

Changes to Related Documents

October 13, 2003

MN/CRS400.IOM Rev 0

MN/CRS400.EA0

This information will be incorporated into the next revision.

s:\tpubs\manuals\released_word\switches\crs400_rev0\errataa.doc

1

Page 4

Page 5

Comtech EF Data is an ISO 9001

Registered Company.

CRS-400

1:8 Redundancy Switch

Installation and Operation Manual

Part Number MN/CRS400.IOM

REVISION 0

August 31, 2001

Copyright © Comtech EF Data, 2001. All rights reserved. Printed in the USA.

Comtech EF Data, 2114 West 7th Street, Tempe, Arizona 85281 USA, (480) 333-2200, FAX: (480) 333-2161.

Page 6

USTOMER SUPPORT

C

Contact the Comtech EF Data Customer Support Department for:

Product support or training

Information on upgrading or returning a product

Reporting comments or suggestions concerning manuals

Contact Customer Support using any of the following methods:

Mail: Comtech EF Data

Email: service@comtechefdata.com

Customer Support Department

2114 West 7th Street

Tempe, Arizona 85281 USA

Phone: (480) 333-2200 (Main Comtech EF Data Number)

(480) 333-4357 (Customer Support Desk)

Fax: (480) 333-2161

Internet: www.comtechefdata.com

To return a Comtech EF Data product (in-warranty and out-of-warranty) for repair or

replacement:

Request a Return Material Authorization (RMA) number from the Comtech

EF Data Customer Support Department.

Be prepared to supply the Customer Support representative with the model

number, serial number, and a description of the problem.

To ensure that the product is not damaged during shipping, pack the product

in its original shipping carton/packaging.

Ship the product back to Comtech EF Data. (Shipping charges should be

prepaid.)

For more information regarding the warranty policies, see Warranty Policy, p. xii.

Page 7

Table of Contents

Customer Support.........................................................................................................................ii

About this Manual.....................................................................................................................viii

Related Documents..................................................................................................................viii

Conventions and References.....................................................................................................viii

Cautions and Warnings............................................................................................................viii

Metric Conversion ...................................................................................................................viii

Recommended Standard Designations ......................................................................................ix

Trademarks ................................................................................................................................ix

Reporting Comments or Suggestions Concerning this Manual.................................................ix

EMC Compliance.......................................................................................................................... x

EN55022 Compliance................................................................................................................. x

EN50082-1 Compliance..............................................................................................................x

Federal Communications Commission (FCC)........................................................................... x

Safety Compliance .......................................................................................................................xi

EN 60950...................................................................................................................................xi

Low Voltage Directive (LVD)...................................................................................................xi

Warranty Policy.......................................................................................................................... xii

Limitations of Warranty............................................................................................................xii

Exclusive Remedies..................................................................................................................xii

Disclaimer.................................................................................................................................xii

CHAPTER 1. INTRODUCTION .................................................................................... 1

1.1 Description............................................................................................................................... 1

1.2 Front And Rear Panels........................................................................................................... 5

1.3 Major Assemblies And Options............................................................................................. 6

1.4 Specifications (Preliminary)................................................................................................... 7

1.4.1 Data Redundancy And Controller...................................................................................... 8

1.4.2 CRS-280 IF Redundancy Switch Specifications ............................................................... 9

1.4.3 Outline Drawing............................................................................................................... 10

iii

Page 8

CRS-400 1:8 Redundancy Switch Revision 0

Preface MN/CRS400.IOM

CHAPTER 2. INSTALLATION AND INITIAL SETUP................................................ 11

2.1 Unpacking and Inspection....................................................................................................13

2.2 Front Panel............................................................................................................................ 13

2.3 Rear Panel.............................................................................................................................. 13

2.3.1 Data Connectors............................................................................................................... 14

2.4 Mounting Instructions.......................................................................................................... 14

2.4.1 Provide Airflow ............................................................................................................... 14

2.4.2 About Rack Support......................................................................................................... 15

2.5 Installation Details................................................................................................................ 15

2.6 Cables and Connectors......................................................................................................... 15

2.6.1 HSSI Cable Physical Requirements................................................................................. 15

2.6.2 TMI Data Connector (HSSI)............................................................................................ 16

2.6.3 System Alarms Connector ............................................................................................... 18

2.6.4 IF Switch Control Connector........................................................................................... 19

2.6.5 Remote Control Connector.............................................................................................. 20

2.6.6 Auxiliary Serial Connector / Pass-Through..................................................................... 21

2.7 TMI Modules......................................................................................................................... 22

2.7.1 HSSI Module ................................................................................................................... 22

2.8 RMI Modules......................................................................................................................... 24

2.8.1 HSSI Module ................................................................................................................... 24

2.9 Connecting the Cables.......................................................................................................... 26

2.9.1 HSSI Connection .............................................................................................................26

2.10 Configuring the Mods/Demods – Firmware Versions..................................................... 27

2.11 Applying Power to the Switch............................................................................................ 28

2.11.1 Single Power Supply Operation (Test).......................................................................... 28

2.12 Configuring the Switch....................................................................................................... 29

2.12.1 Activate Desired Traffic Mods/Demods........................................................................ 29

2.12.2 Verify Remote Communications to Each Active Mod/Demod.....................................29

2.13 Configuring the IF Carriers............................................................................................... 30

2.13.1 Configuring and Cabling for a Single Transponder....................................................... 30

2.13.2 Configuring and Cabling for Multiple Transponders, Using the CRS-280 Transponder

Switch ....................................................................................................................................... 31

iv

Page 9

CRS-400 1:8 Redundancy Switch Revision 0

Preface MN/CRS400.IOM

2.14 Configuring Automatic Operation Mode ......................................................................... 32

2.14.1 Set Auto Mode On......................................................................................................... 32

2.14.2 Backup Holdoff Operation............................................................................................. 32

2.14.3 125.................................................................................................................................. 33

2.14.4 Restore Holdoff Operation............................................................................................. 33

2.14.5 Alarm Masking .............................................................................................................. 33

CHAPTER 3. OPERATION........................................................................................35

3.1 Front Panel Display.............................................................................................................. 35

3.2 Front Panel Keys................................................................................................................... 37

3.3 LED Indicators...................................................................................................................... 38

3.4 Menu Trees............................................................................................................................39

3.5 Flash Upgrading.................................................................................................................... 42

3.5.2 Flash Upgrade Procedure................................................................................................. 42

3.5.3 Flash Upgrade Help ......................................................................................................... 42

APPENDIX A. FRONT PANEL OPERATION DETAILS ............................................ 43

A.1 OPENING SCREEN............................................................................................................ 43

A.2 SELECT................................................................................................................................ 43

A.3 CONFIG................................................................................................................................ 44

A.3.1 (CONFIG) MANUAL..................................................................................................... 44

A.3.2 (CONFIG) AUTO[OFF or ON]...................................................................................... 45

A.3.3 (CONFIG) ACTIVE ....................................................................................................... 45

A.3.4 (CONFIG) REMOTE CONTROL.................................................................................. 45

A.3.5 (CONFIG) OPTIONS..................................................................................................... 47

A.4 INFO (Information).............................................................................................................51

A.4.1 (INFO) SWITCH-ID....................................................................................................... 51

A.4.2 (INFO) SETUP ............................................................................................................... 51

A.4.3 (INFO) IF-SWITCH ....................................................................................................... 51

A.4.4 (INFO) REMCONT (Remote Control Info)...................................................................52

A.4.5 (INFO) MASKS (Alarm Mask Info) .............................................................................. 52

A.5 MONITOR............................................................................................................................ 53

A.5.1 (MONITOR) STATUS................................................................................................... 53

A.5.2 (MONITOR) SWITCH ALARMS ................................................................................. 53

A.5.3 (MONITOR) STORED EVENTS .................................................................................. 54

v

Page 10

CRS-400 1:8 Redundancy Switch Revision 0

Preface MN/CRS400.IOM

A.5.4 (MONITOR) COMM-STATE (Communications)......................................................... 54

A.6 STORE/LD (Store or Load Configuration)....................................................................... 55

A.6.1 (STORE/LD) STORE..................................................................................................... 55

A.6.2 (STORE/LD) LOAD....................................................................................................... 56

A.7 UTIL (Utility) ....................................................................................................................... 57

A.7.1 (UTILITY) CLOCK (Set Real-Time Clock) .................................................................. 57

A.7.2 (UTILITY) SWITCH-ID ................................................................................................ 57

A.7.3 (UTILITY) DISPLAY (Display Brightness)..................................................................58

A.7.4 (UTILITY) POLLING....................................................................................................58

APPENDIX B. REMOTE CONTROL.......................................................................... 59

B.1 Introduction..........................................................................................................................59

B.2 EIA-485 ................................................................................................................................. 59

B.3 EIA-232 ................................................................................................................................. 60

B.4 Basic Protocol ....................................................................................................................... 60

B.5 Packet Structure................................................................................................................... 61

B.5.1 Start Of Packet ................................................................................................................ 62

B.5.2 Address............................................................................................................................ 62

B.5.3 Instruction Code......................................................................................................... ..... 63

B.5.4 Instruction Code Qualifier............................................................................................... 63

B.5.5 Message Arguments........................................................................................................65

B.5.6 End Of Packet.................................................................................................................. 65

B.6 Remote Control Commands................................................................................................ 66

APPENDIX C. CABLE DRAWINGS...........................................................................73

INDEX...........................................................................................................................77

vi

Page 11

CRS-400 1:8 Redundancy Switch Revision 0

Preface MN/CRS400.IOM

Figures

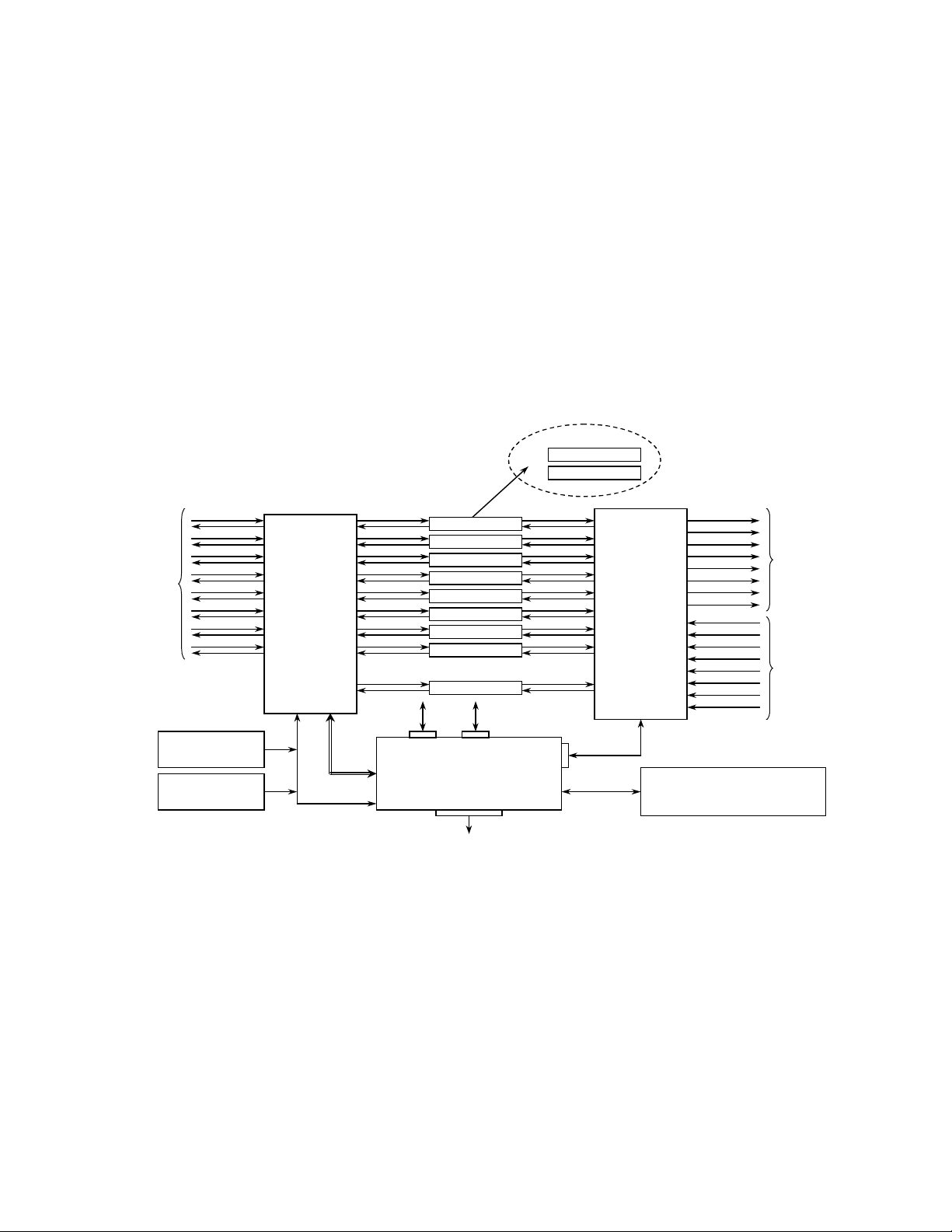

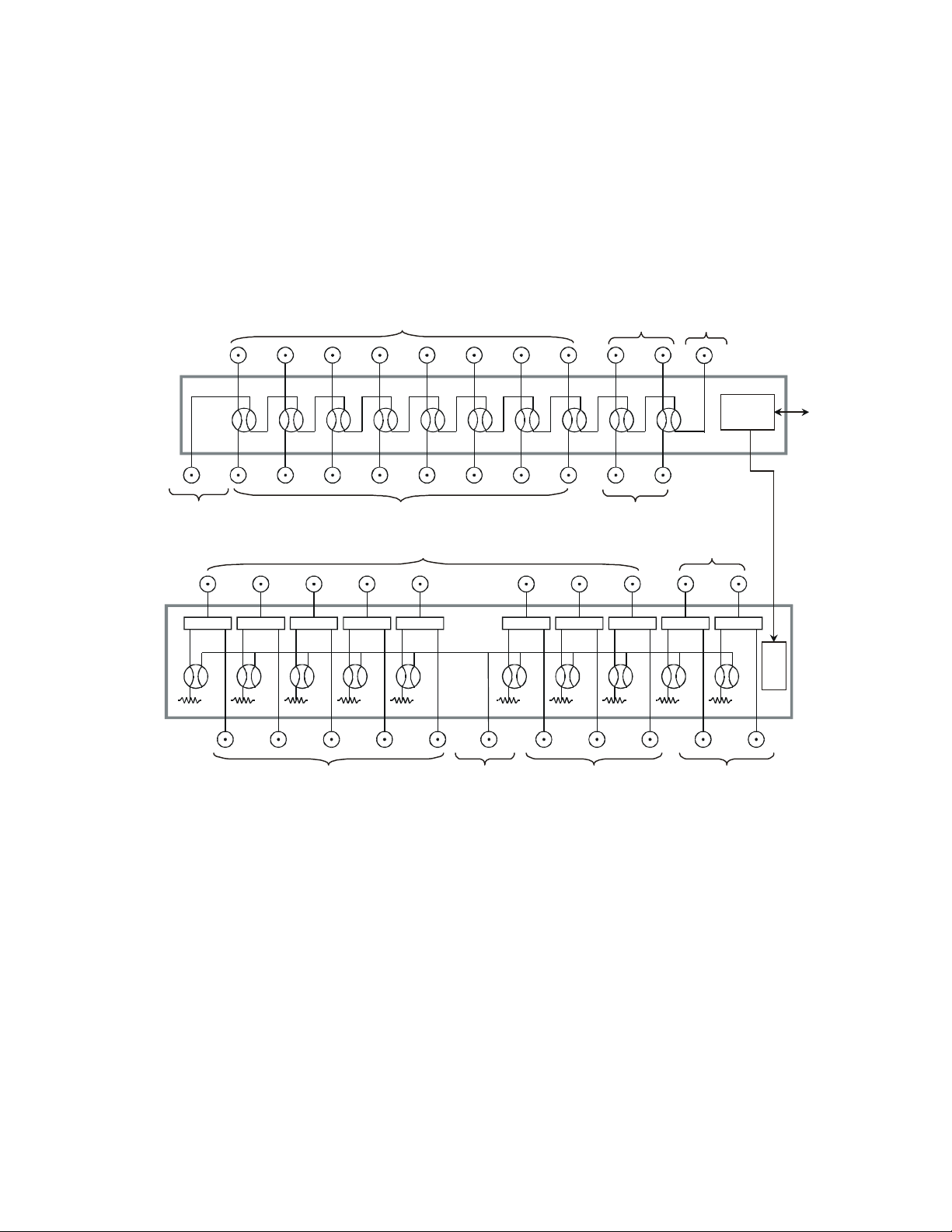

Figure 1-1 CRS-400 Block Diagram with Modems and CRS-280 IF Switch............................ 2

Figure 1-2 CRS-400 Data Switch Block Diagram (TMI #1 is Bridged).................................... 3

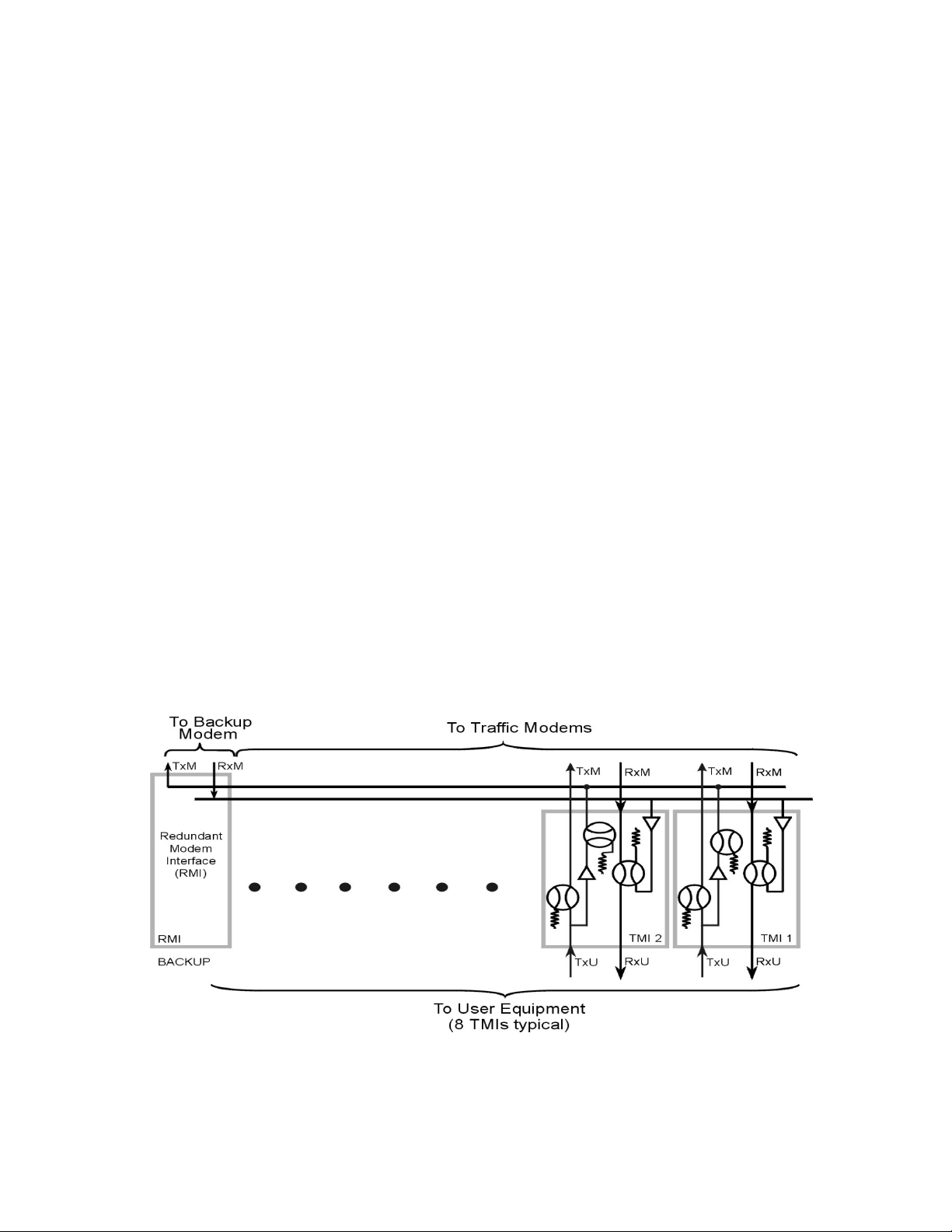

Figure 1-3 CRS-280 IF Switch Block Diagram (with TMI and RMI Modules) ........................ 4

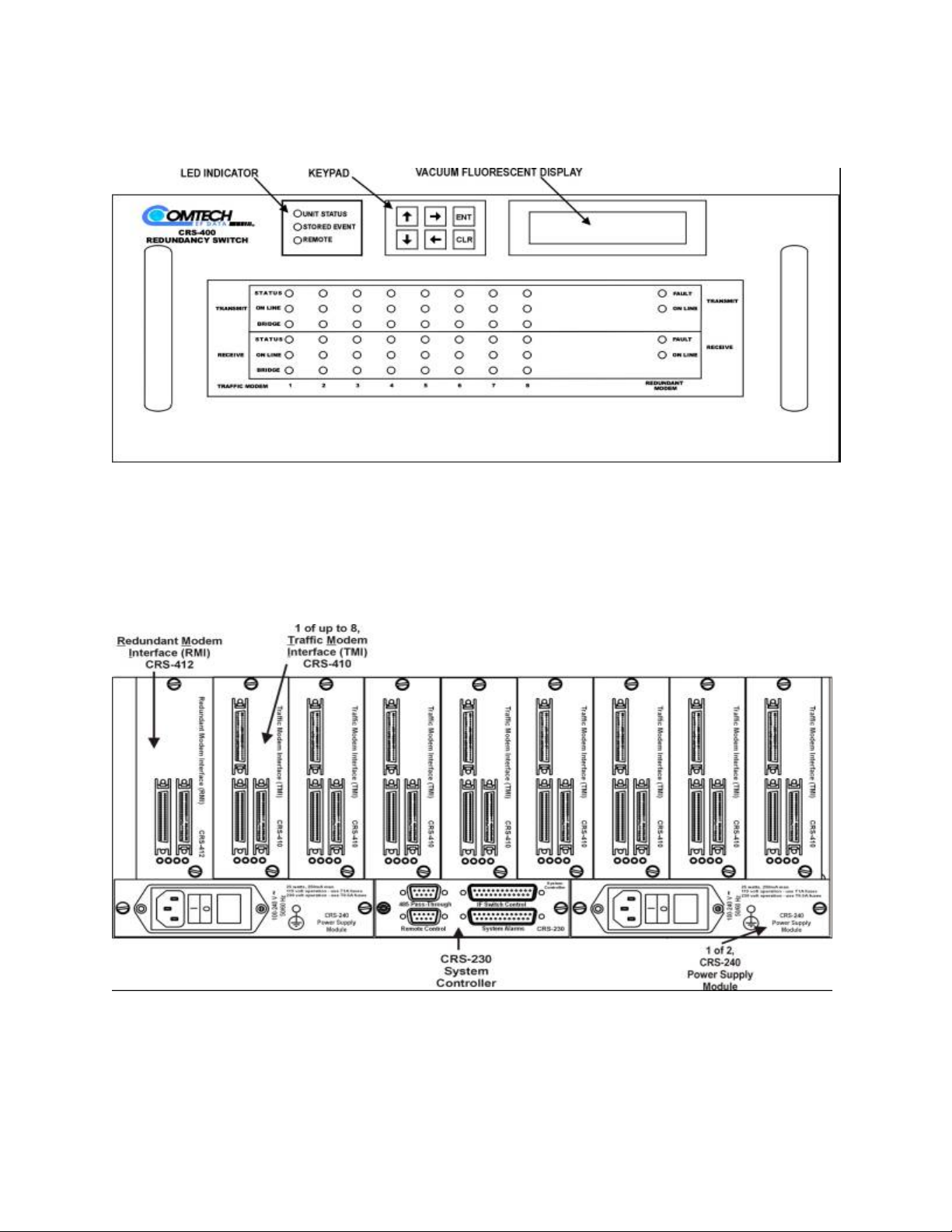

Figure 2-1 CRS-400 Front Panel .............................................................................................. 12

Figure 2-2 CRS-400 Rear Panel, with 8 HSSI TMI and 1 HSSI RMI ..................................... 12

Figure 2-3 SCSI-2 (ECL/HSSI) Connector, Pin Locations...................................................... 17

Figure 2-4 HSSI TMI Module .................................................................................................. 22

Figure 2-5 HSSI RMI Module..................................................................................................24

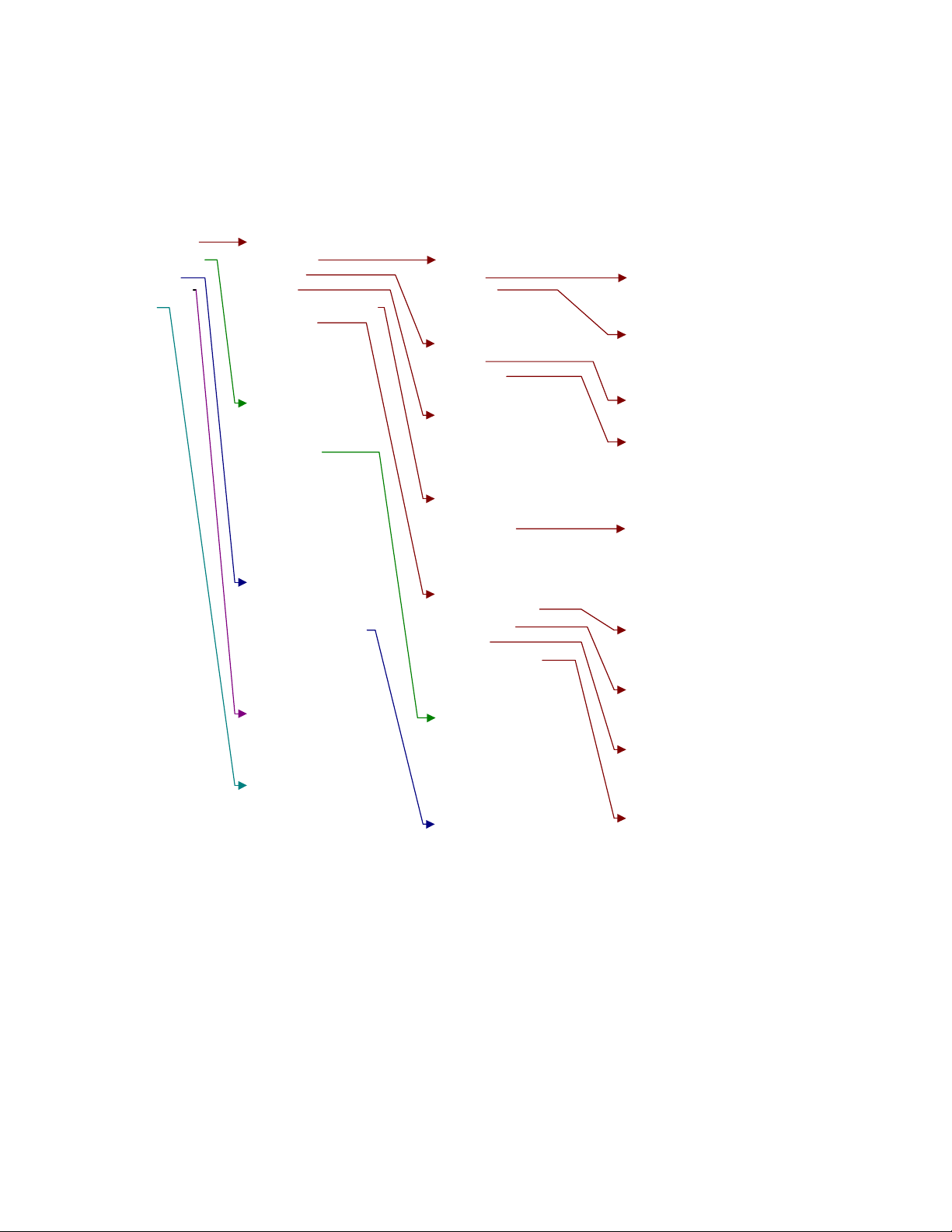

Figure 3-1 Principle Menus Tree for Independent Mode ......................................................... 40

Figure 3-2 Principle Menus Tree for Dependent Mode............................................................ 41

Figure C-1 PC 9-Pin Serial Port to CRS-400 EIA-232 Remote Control Port..........................73

Figure C-2 HSSI Data Cable..................................................................................................... 74

Tables

Table 2-1 HSSI Pinout (J5 / J6 / J7) 50-Pin Mini-D/SCSI-2 Male and Female.......................16

Table 2-2 Systems Alarm Connector Pinout, 25-Pin D Type Female...................................... 18

Table 2-3 IF Switch Control Connector, 25-Pin D Type Male................................................. 19

Table 2-4 Remote Control Connector, 9-Pin D Type Male...................................................... 20

Table 2-5 Auxiliary Serial Connector/Pass-Through, Cable # PL/9195-1...............................21

Table 2-6 HSSI TMI Jumper Selection (TA/CA)..................................................................... 23

Table 2-7 HSSI TMI Jumper Selection (RT/RD).....................................................................23

Table 2-8 HSSI RMI Jumper Selection.................................................................................... 25

Table 2-9 HSSI TMI Jumper Selection (RT/RD).....................................................................25

Table 2-10 CRS-400 to SDM-2020 Data Connection..............................................................26

Table 2-11 CRS-280 IF Switch Connections............................................................................ 31

Table 3-1 Switch LED Indicators ............................................................................................. 38

Table 3-2 Transmit and Receive Traffic Modem LED Indicators............................................ 38

Table C-1 CA/WR9189 Cable Assembly (Pinout, Male/Male, HSSI, Shielded)..................... 75

vii

Page 12

CRS-400 1:8 Redundancy Switch Revision 0

Preface MN/CRS400.IOM

BOUT THIS MANUAL

A

This manual provides installation and operation information for the Comtech EF Data

CRS-400 1:8 Redundancy Switch. This is a technical document intended for earth station

engineers, technicians, and operators responsible for the operation and maintenance of

the CRS-400 1:8 Redundancy Switch.

ELATED DOCUMENTS

R

Comtech EF Data SDM-2020 Satellite Modulator Installation and Operation Manual

Comtech EF Data SDM-2020 Satellite Demodulator Installation and Operation Manual

ONVENTIONS AND REFERENCES

C

AUTION S AND WARNINGS

C

Indicates information critical for proper equipment function.

IMPORTANT

Indicates a hazardous situation that, if not avoided, may result in minor or moderate

injury. CAUTION may also be used to indicate other unsafe practices or risks of

CAUTION

WARNING

ETRIC CONVERSION

M

property damage.

Indicates a potentially hazardous situation that, if not avoided, could result in

death or serious injury.

Metric conversion information is located on the inside back cover of this manual. This

information is provided to assist the operator in cross-referencing English to Metric

conversions.

viii

Page 13

CRS-400 1:8 Redundancy Switch Revision 0

Preface MN/CRS400.IOM

ECOMMENDED STANDARD DESIGNATIONS

R

Recommended Standard (RS) Designations have been superseded by the new designation

of the Electronic Industries Association (EIA). References to the old designations are

shown only when depicting actual text displayed on the screen of the unit (RS-232, RS485, etc.). All other references in the manual will be shown with the EIA designations

(EIA-232, EIA-485, etc.) only.

RADEMARKS

T

All product names mentioned in this manual may be trademarks or registered trademarks

of their respective companies and are hereby acknowledged.

EPORTING COMMENTS OR SUGGESTIONS CONCERNING THIS MANUAL

R

Comments and suggestions regarding the content and design of this manual will be

appreciated. To submit comments, please contact the Comtech EF Data Customer

Support Department.

ix

Page 14

CRS-400 1:8 Redundancy Switch Revision 0

Preface MN/CRS400.IOM

EMC C

EN55022 C

EN50082-1 C

EDERAL COMMUNICATIONS COMMISSION

F

OMPLIANCE

This is a Class A product. In a domestic environment, it may cause radio interference that

requires the user to take adequate protection measures.

OMPLIANCE

This equipment meets the radio disturbance characteristic specifications for information

technology equipment as defined in EN55022.

OMPLIANCE

This equipment meets the electromagnetic compatibility/generic immunity standard as

defined in EN50082-1.

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment.

(FCC)

This equipment generates, uses, and can radiate radio frequency energy. If not installed

and used in accordance with the instruction manual, it may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference; in which case, users are required to correct the interference at their

own expense.

To ensure compliance, properly shielded cables for DATA I/O shall be used. More

Note:

specifically, these cables shall be shielded from end to end, ensuring a continuous shield.

x

Page 15

CRS-400 1:8 Redundancy Switch Revision 0

Preface MN/CRS400.IOM

AFETY COMPLIANCE

S

EN 60950

Applicable testing is routinely performed as a condition of manufacturing on all units to

ensure compliance with safety requirements of EN60950.

This equipment meets the Safety of Information Technology Equipment specification as

defined in EN60950.

OW VOLTAGE DIRECTIVE

L

The following information is applicable for the European Low Voltage Directive

(EN60950):

(LVD)

<HAR> Type of power cord required for use in the European Community.

CAUTION: Double-pole/Neutral Fusing.

!

ACHTUNG: Zweipolige bzw. Neutralleiter-Sicherung.

International Symbols:

Symbol Definition Symbol Definition

Alternating Current.

Fuse.

Protective Earth.

Chassis Ground.

For additional symbols, refer to “Cautions” listed earlier in this preface.

Note:

xi

Page 16

CRS-400 1:8 Redundancy Switch Revision 0

Preface MN/CRS400.IOM

ARRANTY POLICY

W

This Comtech EF Data product is warranted against defects in material and workmanship

for a period of two years from the date of shipment. During the warranty period, Comtech

EF Data will, at its option, repair or replace products that prove to be defective.

For equipment under warranty, the customer is responsible for freight to Comtech EF

Data and all related custom, taxes, tariffs, insurance, etc. Comtech EF Data is responsible

for the freight charges only for return of the equipment from the factory to the customer.

Comtech EF Data will return the equipment by the same method (i.e., Air, Express,

Surface) as the equipment was sent to Comtech EF Data.

IMITATIONS OF WARRANTY

L

The foregoing warranty shall not apply to defects resulting from improper installation or

maintenance, abuse, unauthorized modification, or operation outside of environmental

specifications for the product, or, for damages that occur due to improper repackaging of

equipment for return to Comtech EF Data.

No other warranty is expressed or implied. Comtech EF Data specifically disclaims the

implied warranties of merchantability and fitness for particular purpose.

XCLUSIVE REMEDIES

E

The remedies provided herein are the buyer's sole and exclusive remedies. Comtech EF

Data shall not be liable for any direct, indirect, special, incidental, or consequential

damages, whether based on contract, tort, or any other legal theory.

ISCLAIMER

D

Comtech EF Data has reviewed this manual thoroughly in order that it will be an easy-touse guide to your equipment. All statements, technical information, and

recommendations in this manual and in any guides or related documents are believed

reliable, but the accuracy and completeness thereof are not guaranteed or warranted, and

they are not intended to be, nor should they be understood to be, representations or

warranties concerning the products described. Further, Comtech EF Data reserves the

right to make changes in the specifications of the products described in this manual at any

time without notice and without obligation to notify any person of such changes.

If you have any questions regarding the equipment or the information in this manual,

please contact the Comtech EF Data Customer Support Department.

xii

Page 17

Chapter 1. Introduction

CRS-400

1:8 Redundancy

Switch

Optional CRS-280

IF Switch

1.1 D

ESCRIPTION

The Comtech EF Data CRS-400 1:8 Redundancy Switch is designed for use with the

Comtech EF Data SDM-2020 modulator and demodulator to provide fully automatic

protection of traffic circuits in case of equipment failure. It is intended for hub and other

redundancy applications and currently supports the HSSI interface type.

Connection to the traffic modulators/demodulators and the redundant

modulator/demodulator is simple – a Data cable, which carries all data signals and alarm

information, a 485 cable for remote control interfaces, and, in some cases, a fault cable.

This simplifies rack cabling, and reduces the number of potential failure points.

CAUTION

The Comtech EF Data CRS-400 switch is designed specifically as an accessory

product for the Comtech EF Data SDM-2020 modulator and demodulator and is

not designed to operate with any other manufacturer’s equipment.

1

Page 18

CRS-400 1:8 Redundancy Switch Revision 0

Introduction MN/CRS400.IOM

The CRS-400 is fully modular in construction. All replaceable modules insert into slots in

the rear. This includes the Controller, Power Supply Units (PSU), Traffic Modem

Interface (TMI) and the Redundant Modem Interface (RMI). Power consumption is

below 25 W for a fully populated switch, so no fan cooling is required.

The CRS-400 incorporates the following key reliability features:

Twin, independent, AC power supplies

Maintains normal traffic paths, error free, when AC power is removed

: Redundant Modulator/Demodulator traffic returns to normal traffic path if power is lost

Note

Modulator

Or

Demodulator

To

User

Equipment

1

2

3

4

5

6

7

IF

8

1

2

3

4

5

6

7

8

Front Panel Keyp ad ,

LCD and LE D Display

CRS-400

To

Up

Converters

From

Down

Converters

CRS-240

Power Supply

CRS-240

Power Supply

CRS-400.ppt

1

2

Traffic

3

Modem

Switches

4

(TMI)

5

6

7

Redundant

Modem

8

Switch

(RMI)

Redundant

1

2

3

4

5

&

6

7

8

Remote

Pass-Thru

Modem 1

Modem 2

Modem 3

Modem 4

Modem 5

Modem 6

Modem 7

Modem 8

Modem Re dund

Remote Contro l

To All Modems

CRS-230

Controller

System Alarms

1

2

3

4

5

6

7

8

Redundant

IF Switch

Control

CRS-280

Switch

(Optional)

Figure 1-1 CRS-400 Block Diagram with Modems and CRS-280 IF Switch

The function of the CRS-400 Redundancy Switch is depicted in Figure 1-1. User data enters and exits the switch at the left hand side of the diagram, while IF leaves and enters

from the right. The data and clock signals to and from a traffic modulator/demodulator

are routed through a TMI, via a set of relays. There are up to 8 TMIs in the switch,

labeled 1 through 8 in the figure. The relays in the TMI are arranged so that the

unpowered state connects the data signals directly through to the traffic

modulator/demodulator. If the power supplies to the system are lost, or if a TMI carrying

traffic is removed, traffic is not interrupted. In normal circumstances, when the redundant

modulator/demodulator is not in service, no data is carried through the CRS-400

backplane – all data is routed through the TMI.

2

Page 19

CRS-400 1:8 Redundancy Switch Revision 0

Introduction MN/CRS400.IOM

There are several other key operational features of the CRS-400 architecture:

“Bridging” a traffic modulator/demodulator clock and data: A copy of the data and

clock signals feeding a particular modulator/demodulator is selectively routed to the

redundant modulator/demodulator.

“Bridging” a traffic modulator/demodulator IF: RMI Rx IF is tuned to receive any

selected carrier.

Live traffic may be checked on the redundant demodulator when the traffic

demodulator is placed in “bridge” mode.

There are two ways to set up the CRS-400 for IF operation. The first method does not

require an optional IF switch and is used when all modulators/demodulators within a

group are connected to the same up/down converter.

The second method is used when operation with more than one up/down converter is

required. In this case, adding the CRS-280 IF Switch permits connections to as many

converters as traffic modulators/demodulators.

The data switch and IF switch are shown in Figure 1-2 and Figure 1-3, respectively. Data

enters the TMI modules (CH1 - CH8) at the bottom of Figure 1-2. The Tx data entering

each channel is routed through the TMI and sent out to the traffic modulators/demodulators. The Tx data and clock are also buffered by an amplifier to make them

available for bridging and routing through the RMI.

Figure 1-2 CRS-400 Data Switch Block Diagram (TMI #1 is Bridged)

3

Page 20

CRS-400 1:8 Redundancy Switch Revision 0

g

Introduction MN/CRS400.IOM

Figure 1-3 depicts the separate Tx and Rx sections of the optional IF switch. Either in the

non-energized state of the relays, or when the switch is not powered, the IF traffic is

routed straight through on the primary units. Traffic enters the Tx section of the switch

from the bottom of the switch and leaves from the top. In the Rx section of the switch,

traffic flows in the opposite direction. There is a loss of 3 dB in the demodulator path

because of the receive splitter.

To Up Converters

UC1 UC2 UC3 UC4 UC5 UC6 UC 7 UC8 UC9 UC10

Tx2Tx1 Tx3 Tx4 Tx5 Tx6 Tx7 Tx8 Tx9 Tx10TxBU

From Redundant

Modulator

DC1 DC2 DC3 DC4 DC5 DC6 DC7 DC8 DC9 DC10

Splitter Splitter Splitter Splitter Splitter Splitter Splitter Splitter Splitter Splitter

Rx1 Rx2 Rx3 Rx4 Rx5 Rx6 Rx7 Rx8 Rx9 Rx10RxBU

CRS-400.ppt

To Demodulators 1 Through 5

From Modulators 1 Through 8

From Down Converters Not Used

Demodulator

Switch

Demodulator

Not Used

Not Used

Test Point

Modulator Switch

Controller

Interface

Drivers

h 8To Redundant

Not UsedTo Demodulators 6 Throu

Figure 1-3 CRS-280 IF Switch Block Diagram (with TMI and RMI Modules)

All of the modulators/demodulators are connected to the CRS-400 via a single, 9-pin,

EIA-485, multi-drop cable and the HSSI cable. The EIA-485 link permits the CRS-400 to

determine and store a modulator/demodulator’s configuration, and to send a chosen

configuration to the redundant modulator/demodulator.

4

Page 21

CRS-400 1:8 Redundancy Switch Revision 0

Introduction MN/CRS400.IOM

1.2 F

RONT AND REAR PANELS

The front panel contains the Vacuum Fluorescent Display (VFD), keypad, and several

LED indicators. Enter data via the keypad, and messages are displayed on the VFD.

Behind the front panel, there is an audio alarm that can be controlled to respond to

various faults.

External cables are attached to connectors on the rear panel of the CRS-400’s plug-in

modules.

The connectors are listed below for reference.

Data connector to each Mod/Demod

User Data Interface connector for each traffic Mod/Demod to the outside world

System Alarms connector

Remote Control connector

Auxiliary EIA-485 connector, (Pass-Through)

Diagrams of the front and back panels are shown in Chapter 2.

5

Page 22

CRS-400 1:8 Redundancy Switch Revision 0

Introduction MN/CRS400.IOM

1.3 M

AJOR ASSEMBLIES AND OPTIONS

Part Number Description Model # Comments Install Option

Main Unit Chassis,

Motherboard and Display

AS/9163 Traffic Modem Interface, HSSI CRS-410 Option User

AS/9165 Redundant Modem Interface, HSSI CRS-412 Option User

AS/0377 System Controller CRS-230

AS/0376 Power Supply: 100–250 VAC CRS-240 With Main Unit User

FP/CV9167 Blank Panel Option User

PL/WR9212-1 485 Multi-drop cable With Main Unit User

AS/8976-2 I/F Switch: 50 Ohm

(Not Available)

AS/8976-1 I/F Switch: 75 Ohm CRS-280-1 Option User

PL/WR9195-6 HSSI – 6 foot cable Option With

PL/0946-1 IF BNC to BNC 50 Ohm,

4 foot cable

Main Unit Factory

CRS-280-2 Option User

User

Main Unit

Spare User

PL/0946-2 IF BNC to BNC 50 Ohm,

8 foot cable

PL/0813-4 IF BNC to BNC 75 Ohm,

4 foot cable

PL/0813-8 IF BNC to BNC 75 Ohm,

8 foot cable

Option With

Main Unit

Spare User

Option With

Main Unit

User

User

6

Page 23

CRS-400 1:8 Redundancy Switch Revision 0

Introduction MN/CRS400.IOM

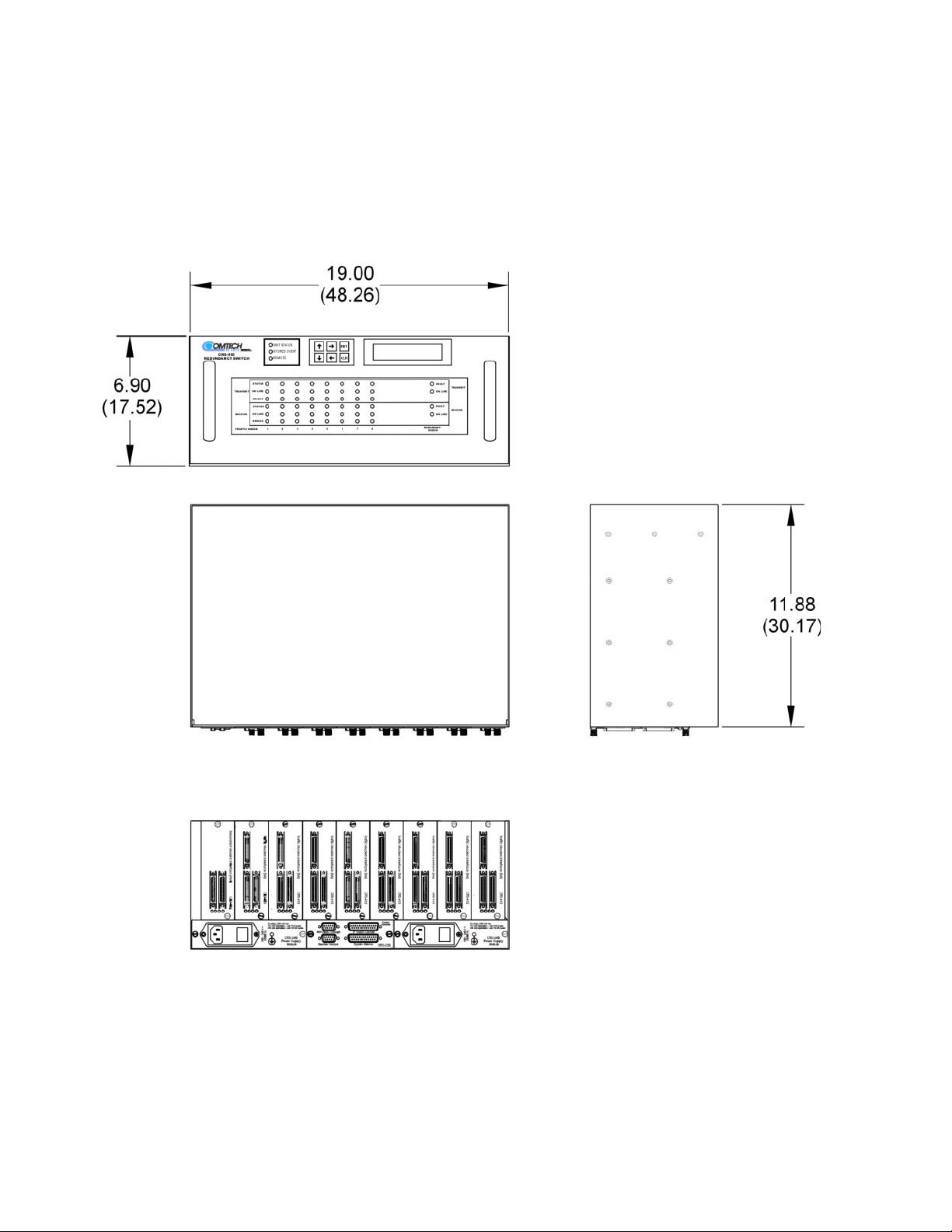

1.4 S

PECIFICATIONS (PRELIMINARY

Characteristic Requirement

AC Prime Power Two independent inputs,

Size/Weight

Data Switch/Control Unit

IF Switch Unit

Environmental

Temperature

Humidity

)

90 to 264 VAC; 50/60 Hz;

at 25 Watts

4U 19 in. by 20.1 in. deep, Rack Mount

(4U 48.26 cm W by 51.054 cm D)

< 20 pounds (< 9.07 kg)

4U 19 in. by ~4.5 in. deep, Rack Mount

(4U 48.26 cm W by 11.43 cm D)

< 10 pounds (<4.54 kg)

0 to +40°C Operating

-50 to +100°C Storage

95% at +40°C, Non-condensing

EMC And Safety EN 55022 Class B emissions

EN 50082-1 immunity

EN 60950 Safety

FCC Part 15 Class B

7

Page 24

CRS-400 1:8 Redundancy Switch Revision 0

Introduction MN/CRS400.IOM

1.4.1 D

Characteristic Requirement

Number of Prime

Mods/Demods

Number of Backup

Mods/Demods

Operating Mode - Data

Switch

Operating Mode - IF Switch Dependent or Independent

Mod/Demod

Priority/Programmable

Switching Hold Off Time 2 to 99 Seconds

Switching Manual or Auto

Default on Power Loss Redundant Modulator/Demodulator traffic returns to the normal

Operating Modes Fully Automatic

ATA REDUNDANCY AND CONTROLLER

1 to 8

1

Dependent or Independent

1 Bridge Mode

traffic path.

Manual, force backup to replace selected traffic channel

Manual, force backup to parallel traffic channel, Bridge

Remove selected traffic channel from control, Active or Not Active

User interface/Connector

(8 Data/TMI Channels)

Configuration Control Remote:

Tx Offline Activity Bridged unit receives a copy of the clock and data from one of the

HSSI to 70 Mbit/s SCSI-2 female

75 Ohm, Supporting : BNC-Female

EIA-485/232-C, programmable

Both switch and mod/demod communications

Manual:

Menu driven from switch front panel

Both switch and mods/demods

traffic channels. User designates the traffic channel.

8

Page 25

CRS-400 1:8 Redundancy Switch Revision 0

Introduction MN/CRS400.IOM

1.4.2 CRS-280 IF R

Characteristic Requirement

Tx/Rx Operating Frequency 50 to 180 MHz

Return Loss 18 dB return loss into 75Ω (50Ω optional)

Tx to Tx Channel Isolation > 50 dB

Rx to Rx Channel Isolation > 50 dB

Tx to Rx Channel Isolation > 60 dB

Number of Uplinks 1 to 8 traffic mods/demods

Transmit IF Loss < 1.5 dB over operating frequency

Receive IF Loss < 5 dB over operating frequency

Tx / Rx Connectors BNC female

L-Band IF Switch

Number of Downlinks 1 to 8 traffic units

Powering of IF Switch From the CRS-400 chassis for 70 / 140 MHz or L-Band

EDUNDANCY SWITCH SPECIFICATIONS

Switch

9

Page 26

CRS-400 1:8 Redundancy Switch Revision 0

Introduction MN/CRS400.IOM

1.4.3 O

UTLINE DRAWING

Dimensions are shown in both inches and (centimeters).

10

Page 27

Chapter 2. Installation and Initial Setup

Unpacking and Inspection

Front Panel

Rear Panel

Mounting Instructions

Installation Details

Cables and Connectors

TMI Modules

RMI Modules

Connecting the Cables

Configuring the Mods/Demods – Firm ware Vers ions

Applying Power to the Switch

Configuring the Switch

Configuring the IF Carriers

Configuring Automatic Operation Mode

13

13

13

14

15

15

22

24

26

27

28

29

30

32

: The term “modulator/demodulator” will be abbreviated to “mod/demod” throughout the

Note

remainder of this chapter.

11

Page 28

CRS-400 1:8 Redundancy Switch Revision 0

Installation and Setup MN/CRS400.IOM

Figure 2-1 CRS-400 Front Panel

Figure 2-2 CRS-400 Rear Panel, with 8 HSSI TMI and 1 HSSI RMI

12

Page 29

CRS-400 1:8 Redundancy Switch Revision 0

Installation and Setup MN/CRS400.IOM

2.1 U

2.2 F

NPACKING AND INSPECTION

1

Inspect shipping containers for damage.

If shipping containers are damaged, keep them until the contents of the shipment have

been carefully inspected and checked for normal operation.

2

Remove the packing list from the outside of the shipping carton.

3

Open the carton and remove the contents.

4

Check the contents against the packing list to verify completeness of the shipment.

5

If damage is evident, contact the carrier and Comtech EF Data immediately and submit a

damage report.

6

Be sure to keep all shipping materials for the carrier's inspection.

If the unit needs to be returned to Comtech EF Data, please use the original shipping

container.

RONT PANEL

Figure 2-1 is an illustration of the front panel. The CRS-400 is constructed as a 4U high

rack-mounting chassis that can be freestanding, if desired. It is provided with rackhandles at the front for easy removal from and placement into a rack.

2.3 R

EAR PANEL

The connectors on the rear panel (see Figure 2-2) of the CRS-400 include:

Data connectors

Data connector to each Mod/Demod

User Data Interface connector for each traffic Mod/Demod to the outside world

Redundant Modem Interface (RMI) connectors

System Alarms connector

Remote Control connector

Auxiliary (Pass-Through) EIA-485 connector, 19200 baud with 7-E-2 (7 Data bits,

Even parity, and 2 Stop bits protocol only)

IF Switch Control connector

Power Supply connectors

13

Page 30

CRS-400 1:8 Redundancy Switch Revision 0

Installation and Setup MN/CRS400.IOM

2.3.1 D

The Data connectors on the TMI plug-ins lead to/from the mods/demods, and lead

to/from the outside world (User Data).

The User Data female connector can be treated as an extension of the traffic

mod/demod’s Data connector. The RMI has no User Data connector, since it will only

replace one of the traffic mods/demods. The pinout for both connectors is provided in the

next chapter.

Open Collector TTL (OC-TTL) signals for mod/demod faults are used to initiate

switching in the CRS-400 switch. The conductors are either in the data cable or in a

separate cable, depending upon the type of data interface.

Note

2.4 M

ATA CONNECTORS

: It is the user’s responsibility to provide the appropriate User Data cable to connect

between the outside user equipment and the TMI.

Reliable Data cables are available from Comtech EF Data to connect between the TMI

(or RMI) and the Mod (or Demod).

OUNTING INSTRUCTIONS

The CRS-400 is constructed as a 4U high rack-mounting chassis. Rack-handles at the

front of the unit facilitate removal from and placement into a rack.

Mount the switch in the rack using the mounting holes on the front panel.

For the CRS-400 to operate correctly, identical types of Mod/Demod models must be

used for all traffic Mods/Demods, and for the redundant Mod/Demod.

2.4.1 P

Typically, the CRS-400 is mounted in a rack along with all the Mods/Demods with which

it is to operate, so it is important to ensure that there is adequate clearance for ventilation.

Since the switch itself is relatively passive, no additional clearance is needed between it

and the nearest Mod/Demod.

In rack systems where there is high heat dissipation, provide forced-air cooling by

installing top- or bottom-mounted fans or blowers.

DO NOT MIX MODELS OF MODS/DEMODS CONNECTED TO THE SWITCH

WARNING

ROVIDE AIRFLOW

14

Page 31

CRS-400 1:8 Redundancy Switch Revision 0

Installation and Setup MN/CRS400.IOM

o

C.

CAUTION

Do not allow the internal rack temperature to exceed 50

2.4.2 A

Mount the switch using front panel screws only. Do not install rack slides to the side of

the CRS-400 chassis. Contact the factory if there are questions about rack supports.

2.5 I

Cable connections for the switch are wired on a channel by channel basis as indicated in

Figure 1-1 of Chapter 1, a block diagram of the CRS-400. Further detail for the data

switch and IF switch is provided in Chapter 1, Figure 1-2 and Figure 1-3. The subsequent

tables provide the detail cable connections between the CRS-400 and the mods/demods

and other interfaces.

In Paragraph 2.13 a separate connection table is presented for connections made to the

optional IF switch.

2.6 C

Please use the following information to verify that you have the correct cables and

connectors available prior to installing the unit.

BOUT RACK SUPPORT

NSTALLATION DETAILS

ABLE S AN D CONNECTORS

IMPORTANT

2.6.1 HSSI C

The HSSI cables required between each Mod/Demod and its plug-in card (TMI or RMI)

should be of shielded, twisted-pair construction with the grounded shield bonded to the

back shell. All 50 pins should be wired to the same pin number at either connector (pinto-pin), with a male connector at both ends. The Data and Clock must be on twisted-pair

cable.

Appropriate HSSI cables lengths are available from Comtech EF Data, so please consult

the factory for ordering information. Please note that these cables are an extra-cost item.

Comtech EF Data can supply IF cables or IF splitters/combiners with the

CRS 280 Redundancy Switch as an option.

ABLE PHYSICAL REQUIREMENTS

15

Page 32

CRS-400 1:8 Redundancy Switch Revision 0

Installation and Setup MN/CRS400.IOM

2.6.2 TMI D

ATA CONNECTOR

(HSSI)

Table 2-1 describes the pinout for the HSSI connector. User equipment connects to the

CRS-400 at J5. Make the connections from the CRS-400 to the mod/demod using J6 and

J7 for the modulator and demodulator, respectively. Two connectors, J6 and J7, are

provided to eliminate the need for a Y-cable between the mod/demod and the switch

when the modulator and demodulator are housed in separate chassis. Use only J6 when

connecting a combined modulator and demodulator (modem) to the switch.

Table 2-1 HSSI Pinout (J5 / J6 / J7) 50-Pin Mini-D/SCSI-2 Male and Female

HSSI/EIA-613 Interface Connector Pinout -- J6 / J7 To modem J5 To User

Signal Function HSSI

Signal

Signal Ground SG 102 1, 26 Mod/Demod 1, 26

Receive Timing RT 115 2, 27 from DCE Demodulator 2, 27

DCE Available CA 107 3, 28 from DCE Mod/Demod 3, 28

Receive Data RD 104 4, 29 from DCE Demodulator 4, 29

Loopback Circuit C LC undefined 5, 30 from DCE Mod/Demod unused

EIA-613

Circuit

Pin # (+, -) Circuit

Direction

Comment Pin # (+, -)

Send Timing ST 114 6, 31 from DCE Modulator 6, 31

Signal Ground SG 102 7, 32 Mod/Demod 7, 32

DTE Available TA 108/2 8, 33 to DCE Mod/Demod 8, 33

Terminal Timing TT 113 9, 34 to DCE Modulator 9, 34

Loopback Circuit A LA 143 10, 35 to DCE Mod/Demod unused

Send Data SD 103 11, 36 to DCE Modulator 11, 36

Loopback Circuit B LB 144 12, 37 to DCE Mod/Demod unused

Signal Ground SG 102 13, 38 Mod/Demod 13, 38

TX PSYNC

TX DVALID

Reserved (to DCE) 16, 41 unused unused

Reserved (to DCE) 17, 42 unused unused

Reserved (to DCE) 18, 43 unused unused

Signal Ground SG 102 19, 44 Mod/Demod 19, 44

Carrier Detect (lock)

(Notes 1 and 2)

(Note 1)

TPSYNC undefined 14, 39 to DCE Modulator unused

(Note 1)

TDVALID undefined 15, 40 to DCE Modulator unused

CD undefined 20 from DCE Demodulator 20

16

Page 33

CRS-400 1:8 Redundancy Switch Revision 0

Installation and Setup MN/CRS400.IOM

HSSI/EIA-613 Interface Connector Pinout -- J6 / J7 To modem J5 To User

Signal Function HSSI

Signal

Demod Fault

(Notes 1 and 3)

Mod Fault

(Notes 1 and 3)

DF undefined 45 from DCE Demodulator unused

MF undefined 21 from DCE Modulator unused

EIA-613

Circuit

Pin # (+, -) Circuit

Direction

Comment Pin # (+, -)

Reserved (to DTE) 46 unused unused

RX PSYNC

RX DVALID

(Note 1)

RPSYNC undefined 22, 47 from DCE Demodulator unused

(Note 1)

RDVALID undefined 23, 48 from DCE Demodulator unused

Test Mode TM 142 24, 49 from DCE Mod/Demod unused

Signal Ground SG 102 25, 50 Mod/Demod 25, 50

:

Notes

1) Noted signal function names are non-HSSI defined signals. On Cisco routers there is no

connection to those pins. Refer to the Comtech EF Data web site for an Application Note

describing the use of the SDM-2020 with Cisco routers.

2) TTL - output.

3) TTL – open collector output.

The HSSI interface uses the type of SCSI-2 connector shown in Figure 2-3.

Figure 2-3 SCSI-2 (ECL/HSSI) Conn ec tor , Pin Loca ti ons

17

Page 34

CRS-400 1:8 Redundancy Switch Revision 0

Installation and Setup MN/CRS400.IOM

2.6.3 S

Located on the System Controller card, the System Alarms connector provides access to

Form-C relay contacts that indicate the fault status of the switch and the summary faults.

If any of the attached mods/demods has any fault active, the corresponding Tx or Rx

summary relay will energize, forcing the normally open pin to connect to (and the

normally closed pin to disconnect from) the common pin.

Another pin provides a ground connection when the audio alarm is sounded so that the

user may add additional audible alarms.

There are also relay contacts to indicate which, if any, of the traffic mods/demods is

currently being backed up. To determine which mod/demod is being backed up (see the

connector pinout, Table 2-2), decode the BCD relay outputs.

YSTEM ALARMS CONNECTOR

Table 2-2 Systems Alarm Connector Pinout, 25-Pin D Type Female

Pin Description

13 Unused Rela y – NC Contac t

25 Unused Rela y – NO Contac t

12 Mod/demod Summary Rx Traffic Fault – NC Contact

24 Mod/demod Summary Rx Traffic Fault – NO Contact

11 Mod/demod Summary Tx Traffic Fault – NC Contact

23 Mod/demod Summary Tx Traffic Fault – NO Contact

10 Mod/demod Summary Unit Fault – NC Contact

22 Mod/demod Summary Unit Fault – NO Contact

9 Switch Unit Fault – NC Contact

21 Switch Unit Fault – NO Contact

8 Common contact for pins 9-12 and 21-24

20 Audio Indicator (Gnd = Audio on Float = Audio off)

7 Ground

19 Not Connected

6 BU Mod Replaces Traffic Mod “N”, Bit 1 of 3 – NO Contact

18 BU Mod Replaces Traffic Mod “N”, Bit 2 of 3 – NO Contact

5 BU Mod Replaces Traffic Mod “N”, Bit 3 of 3 – NO Contact

17 Unused Rela y – NO Contac t

4 BU Demod Replaces Traffic Demod “N”, Bit 1 of 3 – NO Contact

18

Page 35

CRS-400 1:8 Redundancy Switch Revision 0

Installation and Setup MN/CRS400.IOM

Pin Description

16 BU Demod Replaces Traffic Demod “N”, Bit 2 of 3 – NO Contact

3 BU Demod Replaces Traffic Demod “N”, Bit 3 of 3 – NO Contact

15 Unused Rela y – NO Contac t

2 Unused Relay – NO Contact

14 Unused Rela y – NO Contac t

1 Common contact for pins 3-6 and 15-18

* Note

: Mod/demod Select 0-3 represent the binary address of the Mod/Demod.

2.6.4 IF S

The IF Switch Control connector should be cabled directly to the corresponding

connector on the CRS-280 IF Switch, if used. This supplies power to the CRS-280, along

with the logic interface to drive the currently selected traffic mod/demod, and to decide

whether the system is in bridged or back-up mode. The CRS-280 must perform the same

bridging and backing up functions to the transmit and receive IF signals to match what

the CRS-400 does to the terrestrial data signals. Table 2-3 provides the pinout

information.

WITCH CONTROL CONNECTOR

Table 2-3 IF Switch Control Connector, 25-Pin D Type Male

Pin # Condition

16

Enable

5 Clock

17 Serial Data

4 Mod_Backup

8 Demod_Backup

3 Rev_Bit0, (for PCA hardware revision control)

18 Rev_Bit1

6 Rev_Bit2

19 Rev_Bit3

7 Product_ID_Bit0, (for IF switch identification)

20 Product_ID_Bit1

21 IF Switch Present

19

Page 36

CRS-400 1:8 Redundancy Switch Revision 0

Installation and Setup MN/CRS400.IOM

Pin # Condition

10, 22 +5V input

12, 24 +12V input

11, 13 Ground

1, 2, 9, 14, 15 No Connection

2.6.5 R

The Remote Control connector provides access to the remote control ports of the switch,

both EIA-232 and EIA-485. Table 2-4 provides the pinout information.

EMOTE CONTROL CONNECTOR

Table 2-4 Remote Control Connector, 9-Pin D Type Male

Pin Description

1 Ground

9 EIA-485 Transmit Data B

8 EIA-485 Transmit Data A

5 EIA-485 Receive Data B

4 EIA-485 Receive Data A

2 EIA-232 Transmit Data

3 EIA-232 Receive Data

6 Not connected

7 Not connected

20

Page 37

CRS-400 1:8 Redundancy Switch Revision 0

Installation and Setup MN/CRS400.IOM

2.6.6 A

This connector is used for switch remote control of each SDM-2020 modulator or

demodulator. This remote communication is fixed at a rate 19200 Baud with 7-E-2

character format. Ensure that each mod/demod is set for EIA-485 4-wire communications

and the matching protocol and baud rate.

The pinout for EIA-485 communication at the switch is the same as the remote control on

the SDM-2020 modems. Table 2-5 provides the pinout information.

UXILIARY SERIAL CONNECTOR

Table 2-5 Auxiliary Serial Connector/Pass-Through, Cable # PL/9195-1

CRS-400

9-Pin D

Male Description VO

9 EIA-485 Receive Data B I

8 EIA-485 Receive Data A I

5 EIA-485 Transmit Data B O

4 EIA-485 Transmit Data A O

ASS-THROUGH

/ P

1 Ground

2 Not connected

3 Not connected

6 Not connected

7 Not connected

21

Page 38

CRS-400 1:8 Redundancy Switch Revision 0

Installation and Setup MN/CRS400.IOM

2.7 TMI M

The following paragraphs describe settings for any of the individual TMI modules that

require jumper or other installation settings on the module.

2.7.1 HSSI M

An outline drawing of the HSSI interface is shown in Figure 2-4. The jumper settings are

explained in Table 2-6 and Table 2-7.

Recommended Setting: CA looped to TA at J5.

J5 User DataInterface

J7 De mod

J6 Mod / Modem

Terrestrial Modem Interface (TMI)

ODULES

ODULE

J2

J1

12

J2

78

12

J1

78

J10 J9

J3

On Line

On Line

Bridged

Bridged

CRS-400.

HSSI TMI

12

J3

78

Jumpers Shown In

Default Position

Figure 2-4 HSSI TMI Module

22

Page 39

CRS-400 1:8 Redundancy Switch Revision 0

Installation and Setup MN/CRS400.IOM

Table 2-6 HSSI TMI Jumper Selection (TA/CA)

TA/CA Selection J1 Jumpers J2 Jumpers J3 Jumpers

Default: CA Looped to TA at J5 5 - 6

Modulator Only or Mod/Demod.

J5-TA to Modulator,

CA From Modulator to J5.

Demodulator Only.

CA from Demod to J5

(TA ignored)

Table 2-7 HSSI TMI Jumper Selection (RT/RD)

RT/RD Selection J9 Jumpers J10 Jumpers

Default: RT/RD from Demod 5 - 6

RT/RD from Modem

(Full Duplex at J6)

7 - 8

1 - 2

3 - 4

1 - 2

3 - 4

7 - 8

1 - 2

3 - 4

1 - 2

3 - 4

5 - 6

7 - 8

1-2

3-4

1 - 2

3 - 4

None 5 - 6

7 - 8

5 - 6

7 - 8

1 - 2

3 - 4

23

Page 40

CRS-400 1:8 Redundancy Switch Revision 0

Installation and Setup MN/CRS400.IOM

2.8 RMI M

The following paragraphs describe settings for any of the individual RMI modules that

require jumper or other installation settings on the module.

2.8.1 HSSI M

Figure 2-5 shows the RMI module, Table 2-8 and Table 2-9 describe the jumper settings

on the module.

ODULES

ODULE

Figure 2-5 HSSI RMI Module

24

Page 41

CRS-400 1:8 Redundancy Switch Revision 0

Installation and Setup MN/CRS400.IOM

Table 2-8 HSSI RMI Jumper Selection

TA/CA Selection J1 Jumpers

Default: Modulator Only or Mod/Demod.

CA From Modulator to J6.

Demodulator Only.

CA from Demod to J7 (TA ignored)

1 - 2

3 - 4

5 - 6

7 - 8

Table 2-9 HSSI TMI Jumper Selection (RT/RD)

RT/RD Selection J9 Jumpers J10 Jumpers

Default: RT/RD from Demod 5 - 6

7 - 8

RT/RD from Modem

(Full Duplex at J6)

1 - 2

3 - 4

5 - 6

7 - 8

1 - 2

3 - 4

25

Page 42

CRS-400 1:8 Redundancy Switch Revision 0

Installation and Setup MN/CRS400.IOM

2.9 C

ONNECTING THE CABLES

WARNING

All Mods/Demods must be the same model and contain the same software revision so

that the Redundant Mod/Demod can properly mimic all traffic Mods/Demods.

2.9.1 HSSI C

1

Connect HSSI data cables between each traffic Mod/Demod and TMI card.

2

Connect a HSSI data cable between the redundant Mod/Demod and the RMI card.

3

Replace any unused cards with blank panels .

4

Connect the multidrop cable (PL/WR9212-1) from the Pass-Through connector to each

SDM-2020 remote port.

5

Do not connect the IF ports at this time.

6

Apply power to the Mods/Dem ods only.

Table 2-10 lists connections made between the CRS-400 and SDM-2020 units.

Ensure that all power to the equipment is off.

ONNECTION

Table 2-10 CRS-400 to SDM-2020 Data Connection

From To

Switch Connectors

TMI J5 (User)

J6

J7

RMI J6

J7

Controller Remote (User)

Remote Pass-Through

IF Sw Control

System Alarms (User)

SDM-2020

Mod Only Demod Only Mod + Demod

-

J3

-

J3

-

-

J1

-

-

-

-

J3

-

J3

-

J1

-

-

-

J3, Mod

J3 Demod

J3, Mod

J3, Demod

-

J1

-

-

Future

26

Page 43

CRS-400 1:8 Redundancy Switch Revision 0

Installation and Setup MN/CRS400.IOM

2.10 C

IMPORTANT

1

Note:

ONFIGURING THE MODS/DEMODS

For correct operation of the CRS-400, the Mods/Demods must have

the following Firmware versions installed:

Feature CRS-400 SDM-2020

HSSI M&C Firmware

75 Ohm Data Ver xxx

Backplane xxx

If the Mods/Demods do not meet this requirement, please contact the factory.

Configure these parameters for the SDM-2020 Mod/Demod remote control interfaces:

EIA-485: 4-wire

Rate: 19200 Baud

Format: 7 Data Bits, Even Parity, 2 Stop Bits ( 7-E-2 )

These values are the default settings for the SDM-2020

Utility/System menu, REMOTE BAUD RATE/PARITY settings.

Minimum Revision

Mod

Ver 8.1.6

M&C Firmware

newer than

April 2001

IRMWARE VERSIONS

– F

SDM-2020

Demod

M&C Firmware

Ver 22.2.1

M&C Firmware

newer than

April 2001

Future Future

Mod

Remote Address: Positions 1 through 8, set Addresses 1 through 8,

with the Redundant Modulator at Address 9

Demod

Remote Address: Positions 1 through 8, set Addresses 11 through 18,

with the Redundant Demodulator at Address 19

The switch is now ready for the next procedure, Applying Power to the Switch.

27

Page 44

CRS-400 1:8 Redundancy Switch Revision 0

Installation and Setup MN/CRS400.IOM

2.11 A

Note:

With the terrestrial cabling complete and the Mods/Demods powered on, but the IF ports

still unconnected, applying power to the CRS-400 is the next procedure. The auto-sensing

AC power supplies do not require any adjustments.

1

2

The switch should show a green Unit Status.

The IEC line input connector for each Power Supply Module contains the ON/OFF

switch for that module. It is also fitted with two fuses, one each for line and neutral

connections (or L1, L2, where appropriate). These are contained within the body of the

connector, behind a small plastic flap.

For 115/230 volt AC operation, use T1A fuses, (slow-blow) 20mm fuses.

WARNING

PPLYING POWER TO THE SWITCH

Each CRS-400 is shipped with two power supplies, and it is recommended that both be

used for maximum reliability.

Plug in the supplied line cords.

Turn on the switches on the rear panel.

For continued operator safety, always replace the fuses with the correct type and

rating.

2.11.1 S

If only one power supply module is used, mask the fault for the unused power supply as

follows:

1

2

The switch is now ready for the next procedure, Configuring the Switch.

INGLE POWER SUPPLY OPERATION (TEST

Go to the CONFIG, OPTIONS, MASKS, SW-ALARMS menu.

Select the unused power supply.

)

28

Page 45

CRS-400 1:8 Redundancy Switch Revision 0

Installation and Setup MN/CRS400.IOM

2.12 C

The unit was shipped with the following default configuration:

No units (mods/demods) are active.

The switch was set to Manual operating mode. (This Manual setting causes the Stored

The TMI modules have internal jumpers to be configured. Use the front panel keypad and

display to configure the switch as described in the following paragraphs.

2.12.1 A

IMPORTANT

1

2

ONFIGURING THE SWITCH

Event LED to blink.)

CTIVATE DESIRED TRAFFIC MODS/DEMODS

Ensure that the redundant mod/demod installation is complete prior to activating any

traffic mods/demods, because an active unit is going to be polled regularly by the

switch.

Go to the CONFIG, ACTIVE menu.

Activate all desired traffic Mods/Demods.

After ENTER is pressed, the Switch Status LED briefly turns red. The switch then polls each

of the activated Mods/Demods, and programs the bridged Mod/Demod configuration into the

redundant Mod/Demod.

2.12.2 V

The LEDs are arranged in columns corresponding to each modulator and demodulator,

and should accurately reflect the status of each.

1

2

3

4

Once the programming is completed successfully, the red LED turns green.

: The Demod takes several seconds to configure. If the LED remains red, check the

Note

communication status using the (MONITOR: COMM-STATE) menu.

ERIFY REMOTE COMMUNICATIONS TO EACH ACTIVE MOD/DEMOD

Verify that the Status LED for each modulator and demodulator shows a green light,

indicating no faults.

Verify that the Online LED is lit

Verify that the Online LED is not lit

CRS-280 IF switch).

Verify that the Bridge LED is lit for only one traffic Mod/Demod.

for all connected TMIs.

for the redundant Mod/Demod (for systems not using the

29

Page 46

CRS-400 1:8 Redundancy Switch Revision 0

Installation and Setup MN/CRS400.IOM

Notes:

The switch is now ready for the next procedure, Configuring the IF Carriers.

2.13 C

Next, configure the IF carriers for all the Mods/Demods. There are two configuration

methods: single transponder and multiple transponders.

For a single transponder, all the Mods/Demods are connected to the same up/down

converter.

For multiple transponders, the Mods/Demods may be grouped and connected in various

combinations to multiple up/down converters. The CRS-280 IF Switch is required for

multiple transponder operation.

Proceed with the transponder configuration method applicable to your system.

Use the INFO and MONITOR menus to view the status of the mods/demods, in addition

to viewing the LEDs.

Use MONITOR: COMM-STATE to verify the devices that are responding via remote

control.

ONFIGURING THE

IF C

ARRIERS

2.13.1 C

2.13.1.1 T

1

2

3

IMPORTANT

2.13.1.2 R

1

2

When a traffic Modulator is taken offline, its Transmit IF shuts down automatically and

is replaced by the redundant Modulator IF.

ONFIGURING AND CABLING FOR A SINGLE TRANSPONDER

RANSMIT SIDE

Configure each Modulator’s transmit settings to the proper data rate, IF frequency and output

power level.

Combine the carriers (with user-supplied BNC cables) into a single power combiner.

Feed the output of the combiner to the up converter.

Ensure that the impedance for the Mods/Demods’ cables and combiner are the

same to prevent problems resulting from a mismatch.

ECEIVE SIDE

Attach the output of the down converter (with user-supplied BNC cables) to a single splitter.

Feed the output of the splitter into the Receive IF ports of the Demodulators.

30

Page 47

CRS-400 1:8 Redundancy Switch Revision 0

Installation and Setup MN/CRS400.IOM

2.13.2 C

U

The CRS-280 provides complete isolation of the IF signals. The redundant Mod/Demod

IF signals are routed to the traffic Mod/Demod IF path when the RMI is online.

Once connected, the CRS-400 automatically senses the presence of the CRS-280. The

CRS-400, upon switching, leaves the offline modulator with its RF on, and the CRS-280

switch relays isolate any undesired signals.

1

2

3

The same IF connections are used between the CRS-280 and all modems as shown in

Table 2-11.

ONFIGURING AND CABLING FOR MULTIPLE TRANSPONDERS

SING THE

Connect the CRS-280 to the CRS-400 with a 25-pin control cable.

Refer to Table 2-11 for a complete listing of the CRS-280 IF connections.

Connect the Transmit and Receive IF of each Mod/Demod to the CRS-280 with the correct IF

cables.

From CRS-280 To Other To Modulator

Tx BU - Tx IF, Ch Bu Rx1 Rx IF, Ch1

CRS-280 T

Table 2-11 CRS-280 IF Switch Connections

RANSPONDER SWITCH

From CRS-280 To Demodulator

,

Tx1 - Tx IF, Ch1 Rx2 Rx IF, Ch1

Tx2 - Tx IF, Ch2 Rx3 Rx IF, Ch2

Tx3 - Tx IF, Ch3 Rx4 Rx IF, Ch3

Tx4 - Tx IF, Ch4 Rx5 Rx IF, Ch4

Tx5 - Tx IF, Ch5 RxBu Rx IF, Ch Bu

Tx6 - Tx IF, Ch6 Rx6 Rx IF, Ch5

Tx7 - Tx IF, Ch7 Rx7 Rx IF, Ch6

Tx8 - Tx IF, Ch8 Rx8 Rx IF, Ch7

Tx9 (Not Used) - - Rx9 (Not Used) -

Tx10 (Not Used) - - Rx10 (Not Used) -

Switch Control

CRS-230

IF Switch Control

- - -

Once the applicable transponder configuration and cabling has been completed, the

switch is ready for the next procedure, Configuring Automatic Operation Mode.

31

Page 48

CRS-400 1:8 Redundancy Switch Revision 0

Installation and Setup MN/CRS400.IOM

2.14 C

After the IF cabling is finished, the system should be completely operational; however, it

is still operating in Manual mode. While in Manual mode, the switch does not

automatically react to any traffic Mod/Demod failures it detects.

Comtech EF Data recommends that an unattended system be set to operate in Auto mode.

2.14.1 S

When Auto mode is enabled, the first active Mod/Demod that fails is first bridged by the

redundant Mod/Demod, then backed up. To enable Auto mode:

1

2

Additional configuration settings are useful for fine-tuning the switch’s Auto mode.

These settings, Backup Holdoff, Restore Holdoff, Alarm Mask, and Restore Time are

described next.

2.14.2 B

ONFIGURING AUTOMATIC OPERATION MODE

ET AUTO MODE ON

Go to the CONFIG, AUTO menu and turn on Auto mode.

Verify that the Stored Event LED stops blinking.

ACKUP HOLDOFF OPERATION

When in Auto mode, additional delays may be introduced to the backup procedure by

setting the number of seconds for a “backup holdoff”. The default backup holdoff period

is five seconds (a minimum of 2 seconds is allowed).

If a traffic modulator or demodulator fails, the switch waits for the backup holdoff time to

determine two things: 1) does the traffic Mod/Demod remain faulted, and 2) is the

redundant Mod/Demod not exhibiting the same fault? If the answer is yes to both

questions for the entire backup holdoff time, then the switch places the traffic onto the

redundant Mod/Demod.

The switch performs the actual backup as follows: First, the faulty unit is bridged.

Second, the faulty unit is backed up. Holdoff times prevent unwarranted backups due to

an intermittent fault, or due to a transmit fault detected by both demods, which cannot be

resolved by switching.

2.14.2.1 S

1

2

ET THE BACKUP HOLDOFF PERIOD

Go to the CONFIG, OPTIONS, HOLDOFFS menu.

Change the BACKUP HOLDOFF to any number in the range of 2 to 99 seconds.

32

Page 49

CRS-400 1:8 Redundancy Switch Revision 0

Installation and Setup MN/CRS400.IOM

2.14.3 125

2.14.4 R

The “Restore Holdoff” setting, which is also programmable from 2 to 99 seconds,

determines the switch’s ability to automatically put a backed up traffic Mod/Demod

online again if its fault goes away. Normally, a failed Mod/Demod that was taken offline

will remain offline indefinitely (unless the Auto-Restore feature is enabled). If the fault

goes away, traffic will be returned to the unit (in Auto mode) if another traffic

Mod/Demod fails. The switch places the originally failed Mod/Demod back online if its

fault has been clear for the full programmed Restore Holdoff time. The redundant

Mod/Demod can then be used to backup a newly failed Mod/Demod.

The switch has no prioritization scheme, so that multiple traffic Mod/Demod failures are

treated on a “first come, first serve” basis only. If the redundant unit is set to bridge the

highest priority circuit, switching time will be minimized in the event of a failure. If two

faults occur simultaneously, and are both sustained for the holdoff time, the lower

number circuit will be backed up.

2.14.4.1 S

1

2

ESTORE HOLDOFF OPERATION

ET THE RESTORE HOLDOFF PERIOD

Go to the CONFIG, OPTIONS, HOLDOFFS menu.

Change the RESTORE HOLDOFF to any number in the range of 2 to 99 seconds.

2.14.5 A

Another way to adjust the switch’s reaction in Auto mode is to mask Mod/Demod faults.

The user may disable modulator, demodulator, or both fault types so that the switch does

not react to them. This masking prevents the switch from taking automatic action and

prevents the logging of the faults in the stored events list.

Note

2.14.5.1 S

1

2

Note

Once the switch has been installed and setup has been completed, regular operation may

begin. Please refer to Chapter 3, Operation, for more information.

LARM MASKING

: These masks are global to all the Mods/Demods attached to the switch.

ET THE ALARM MASKS

Go to CONFIG, OPTIONS, MASKS, MODEM-ALARMS.

Set the mask parameters as desired.

: Please read the manual for the SDM-2020 also. Details of the modulator and

demodulator equipment operation are not covered in the CRS-400 manual.

33

Page 50

CRS-400 1:8 Redundancy Switch Revision 0

Installation and Setup MN/CRS400.IOM

34

Page 51

Chapter 3. Operation

Front Panel Display

Front Panel Keys

LED Indicators

Menu Trees

Flash Upgrading

3.1 F

RONT PANEL DISPLAY

Users can fully control and monitor the CRS-400 from the front panel using the display

and keypad. The display has two lines each of 24 characters:

COMTECH CRS-400 SWITCH

SN 123456789 VER 1.01

35

37

38

39

42

On most menu screens, users see a flashing, solid-block cursor. This indicates the

currently selected item, digit, or field:

CONFIG: MANUAL AUTO[OFF]

ACTIVE REMCONT OPTIONS

35

Page 52

CRS-400 1:8 Redundancy Switch Revision 0

Remote Control MN/CRS400.IOM

Where this solid block cursor would obscure the item being edited (for example, a

numeric field) the cursor will automatically change to an underline cursor.

ACTIVE MODEMS: (ENTER)

1 2 3 – 5 6 - 8

To prevent the display from becoming burnt by a constant image, the unit employs a

screen saver feature. After one hour, the screen saver activates. The top line of the display

shows the Switch ID (which can be entered by the user), and the bottom line shows the

current status of the switch followed by the message “Press any key....”.

------------------------

Press any key-----------

The message moves across the screen constantly. Press any key to restore the previous

screen.

36

Page 53

CRS-400 1:8 Redundancy Switch Revision 0

Remote Control MN/CRS400.IOM

3.2 F

RONT PANEL KEYS

The keypad contains six individual key switches mounted

behind a sealed membrane overlay. The keys have a positive

“click” action for tactile feedback. These six switches are

identified as follows:

UP

ARROW

DOWN

ARROW

RIGHT

ARROW

LEFT

ARROW

ENTER

CLEAR

Ï

Ð

Î

Í

ENT

CLR

Edits the value at the current cursor position, if appropriate. Increments the

value of a numeric field.

Edits the value at the current cursor position, if appropriate. Decrements the

value of a numeric field.

Moves the cursor to the right, when it is displayed.

Moves the cursor to the left, when it is displayed.

Accepts an edited entry. Most menus prompt users to press this key by

displaying the text (PRESS ENTER), (ENTER) or (ENT). Press ENT to

accept the entry and display the previous menu.

Exits the current operation and dis p lays the previous menu without

accepting any configuration changes.

IMPORTANT

The keypad has an auto-repeat feature. If a key is held down for more than 1 second,

the key action will repeat, automatically, at the rate of 15 keystrokes per second. This

is particularly useful when edit in g num er ic fields .

37

Page 54

CRS-400 1:8 Redundancy Switch Revision 0

Remote Control MN/CRS400.IOM

3.3 LED I

NDICATORS

Table 3-1 describes the three LEDs at the top left of the front panel. These LEDs reflect

the condition of the switch itself.

Table 3-1 Switch LED Indicators

LED Color Condition

Unit

Status

Stored

Event

Remote

Red A Switch Fault exists Example: PSU fault or COMMS failure

Green No Switch Faults

Off No Stored Events, Auto S witc hi ng On

Orange

Orange

Flashing

Off

Orange