Page 1

CLO-10

Link Optimizer

Installation and Operation Manual

For Firmware Version 1.2.1 or higher

(see New in this Release - Section 1.7)

Part Number MN/CLO-10.IOM

Revision 1

IMPORTANT NOTE: The information contained in this document supersedes all previously published

information regarding this product. Product specifications are subject to change without prior notice.

Page 2

Page 3

Errata A

Comtech EF Data Documentation Update

Subject:

Date:

Original Manual :

Part Number/Rev:

Agile Document ID:

Changes to Appendix A. REDUNDANT SYSTEM OPERATION

June 26, 2008

MN/CLO-10.IOM

Rev 1

ER-MN-CL

O-10_EA1

Agile CO Number:

CO4012

Change Specifics:

This information will be incorporated into the next revision.

Update Figures A-8 and A-9 in Appendix A. REDUNDANT SYSTEM OPERATION per redlines attached

on following pages.

Action: Replace pages A-9 through A-12 in manual with pages A-9 through A-12 provided in this Errata

to facilitate update.

AGILE DOC ID ER-MN-CLO- 10_EA1 THIS DOCUMENT IS NOT SUBJECT TO REVISION/UPDATE! AGILE CO4012

1

Page 4

AGILE DOC ID ER-MN-CLO- 10_EA1 THIS DOCUMENT IS NOT SUBJECT TO REVISION/UPDATE! AGILE CO4012

2

Page 5

AGILE DOC ID ER-MN-CLO- 10_EA1 THIS DOCUMENT IS NOT SUBJECT TO REVISION/UPDATE! AGILE CO4012

3

Page 6

This page is intentionally blank.

AGILE DOC ID ER-MN-CLO- 10_EA1 THIS DOCUMENT IS NOT SUBJECT TO REVISION/UPDATE! AGILE CO4012

4

Page 7

CLO-10 Link Optimizer Revision 1

Redundant System Operation MN/CLO-10.IOM

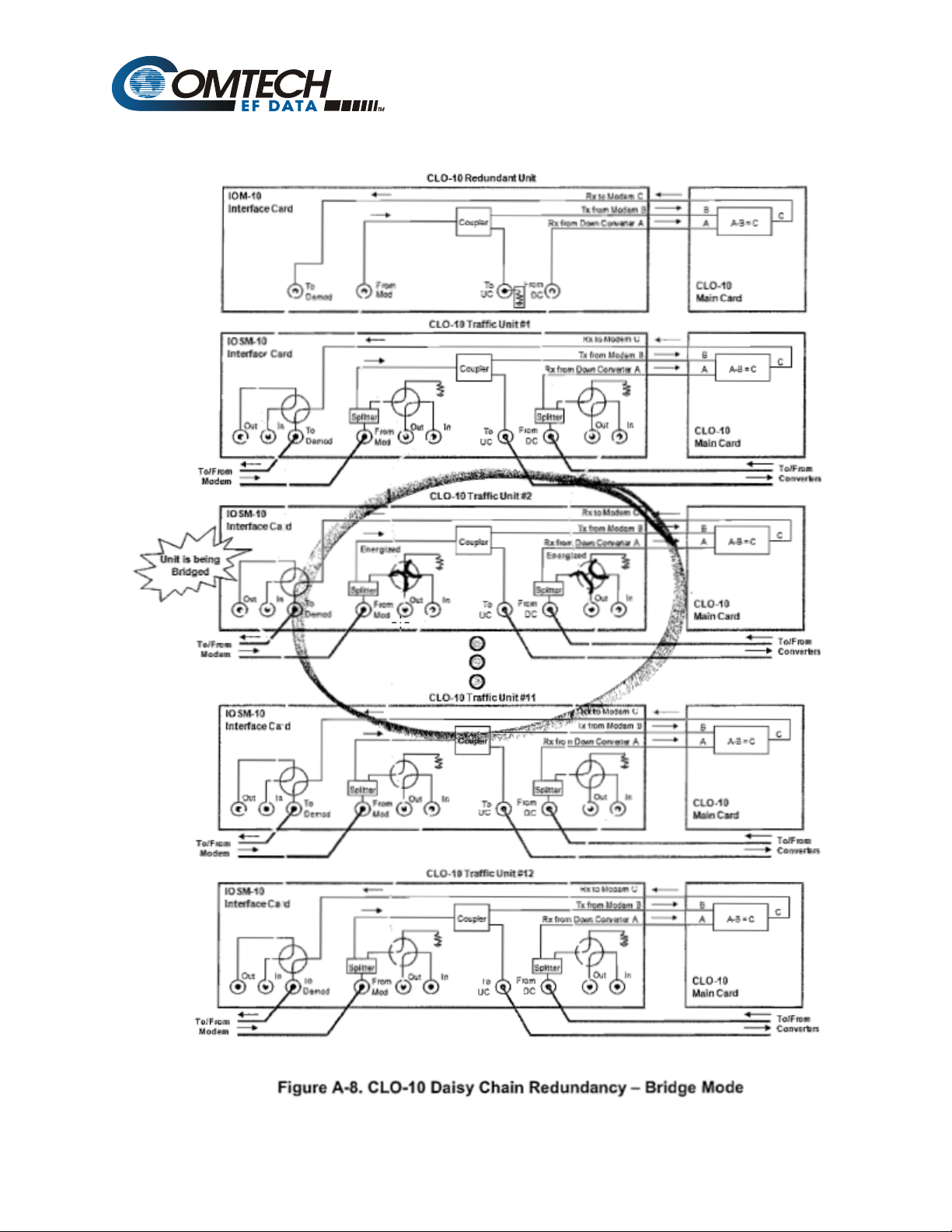

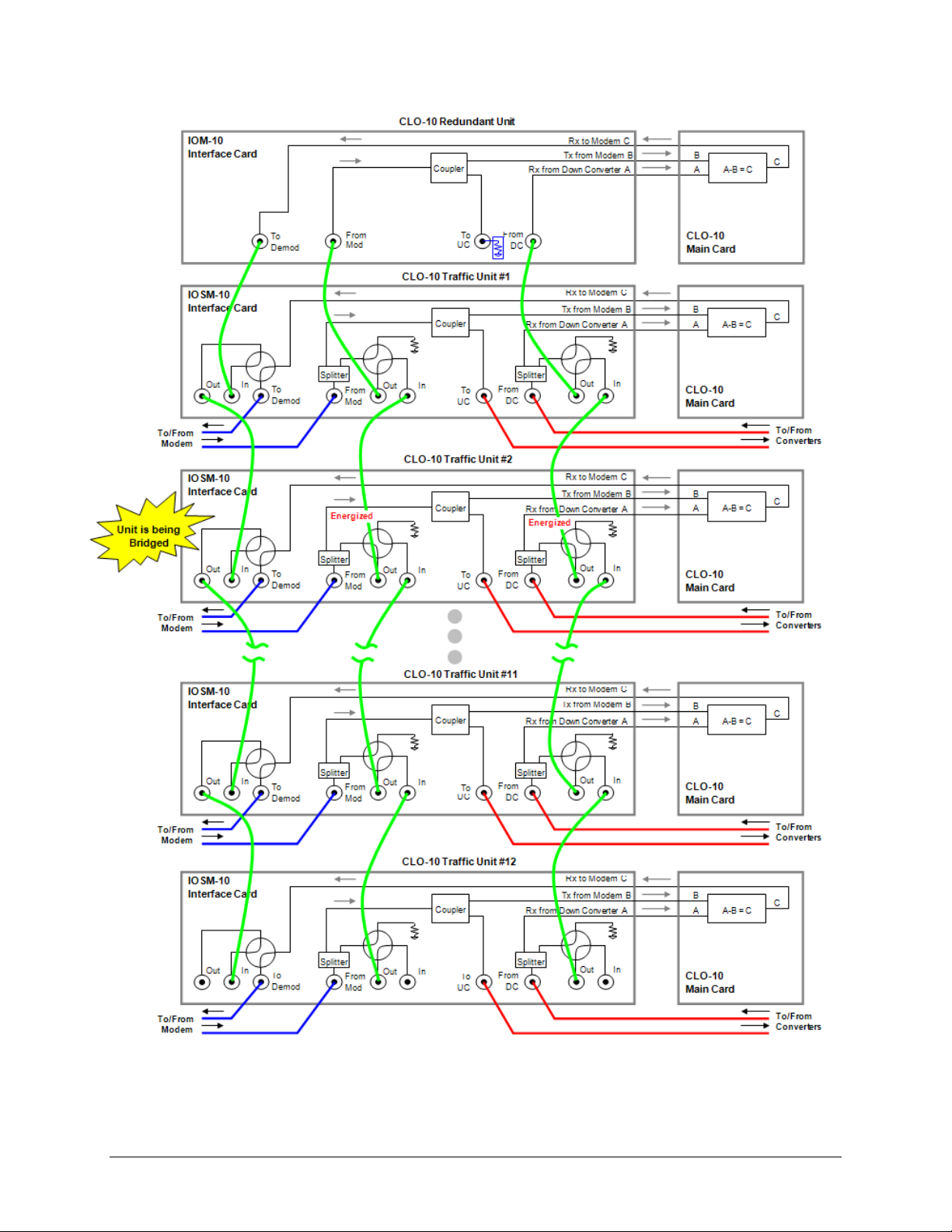

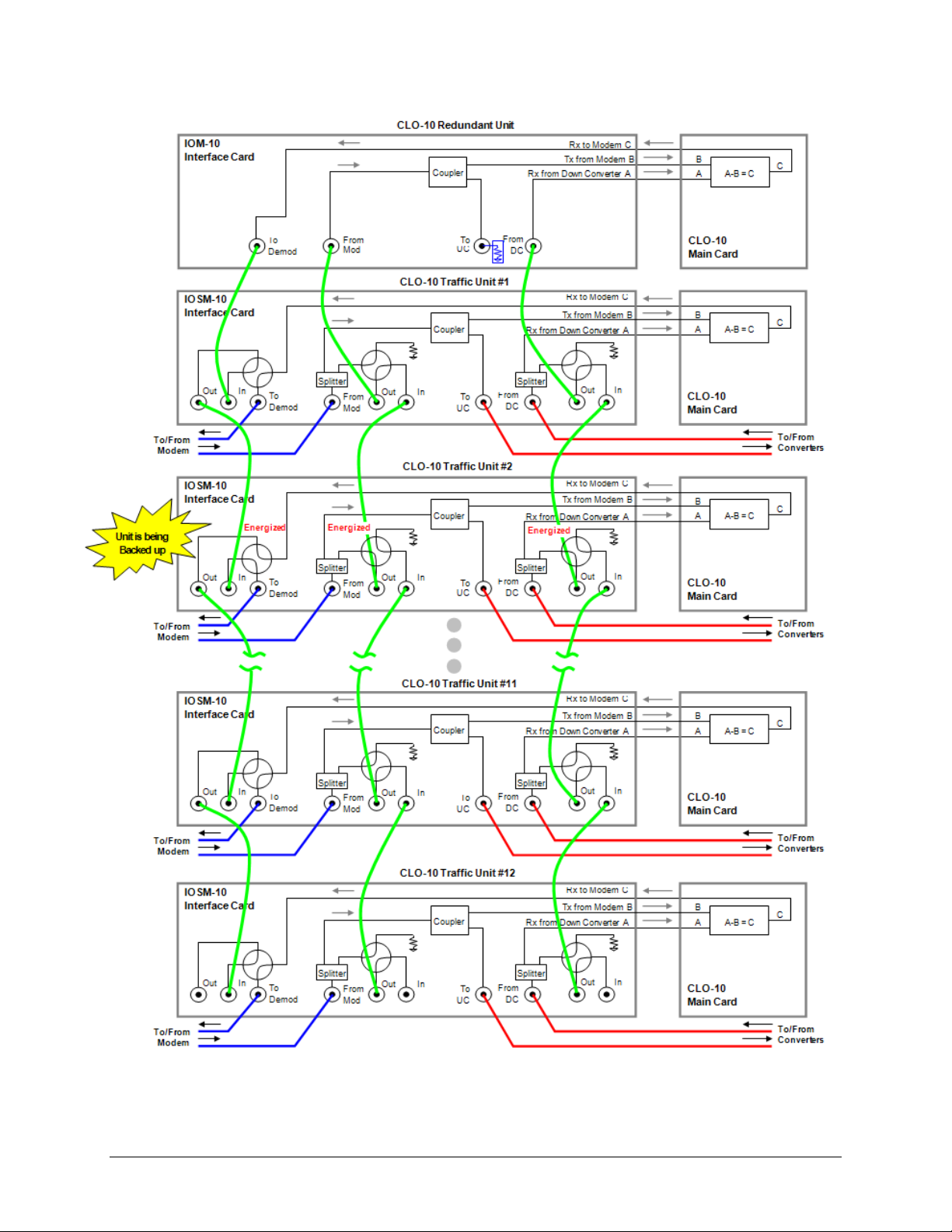

Figure A-8 shows the functional block diagram of Bridge Mode. In this example, Traffic Unit #2

is being bridged and, as the figure shows, the only energized “baseball” switches are on Traffic

Unit #2.

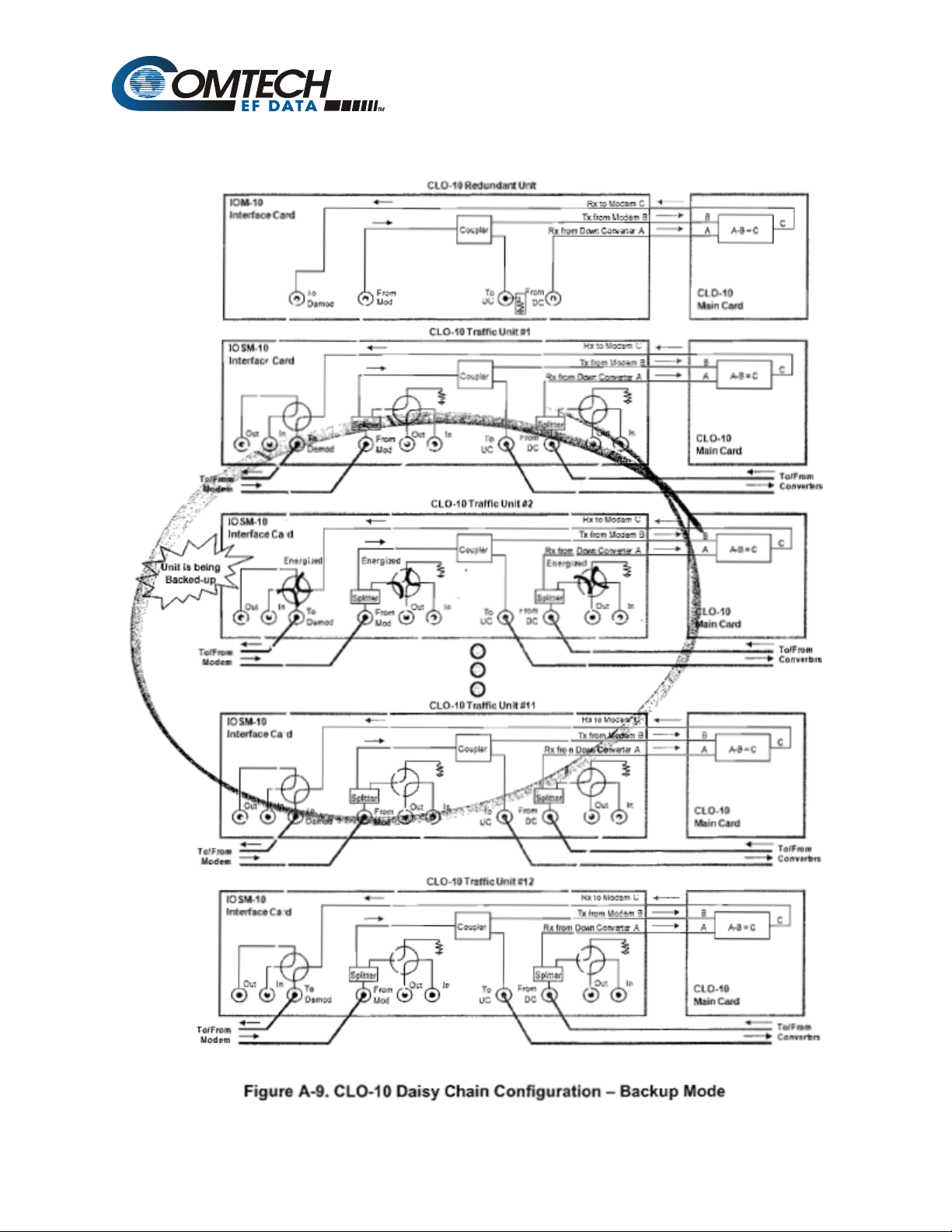

A.4.2 Backup Mode Operation

Backup Mode is similar to Bridge Mode, with an added function: In Backup Mode, the Redundant

Unit completely replaces the Traffic Unit. More specifically, the Redundant Unit will now be

online, and the failed Traffic Unit will go offline. The output IF signal directed to the demodulator

is subsequently taken from the Redundant Unit.

Figure A-9 shows the functional block diagram of Backup Mode. In this example, Traffic Unit #2

is being backed up and, as the figure shows, all of the “baseball” switches are energized on the

IOSM on Traffic Unit #2.

Backup Mode can be done manually or automatically. In automatic mode, the Redundant Unit

will monitor all of the Traffic Units continuously. When a fault is detected on any of these active

Traffic Units, the Redundant Unit will first bridge the faulted unit, then back it up. When a

faulted Traffic Unit needs to be replaced, its IOSM can be separated from the Traffic Unit

chassis, leaving the active online Redundant Unit HSB Daisy Chain intact through the IOSM

switch module. The chain can be extended without affecting the online unit’s operation.

A–9

Page 8

CLO-10 Link Optimizer Revision 1

Redundant System Operation MN/CLO-10.IOM

Figure A-8. CLO-10 Daisy Chain Redundancy – Bridge Mode

A–10

Page 9

CLO-10 Link Optimizer Revision 1

Redundant System Operation MN/CLO-10.IOM

Figure A-9. CLO-10 Daisy Chain Configuration – Backup Mode

A–11

Page 10

CLO-10 Link Optimizer Revision 1

Redundant System Operation MN/CLO-10.IOM

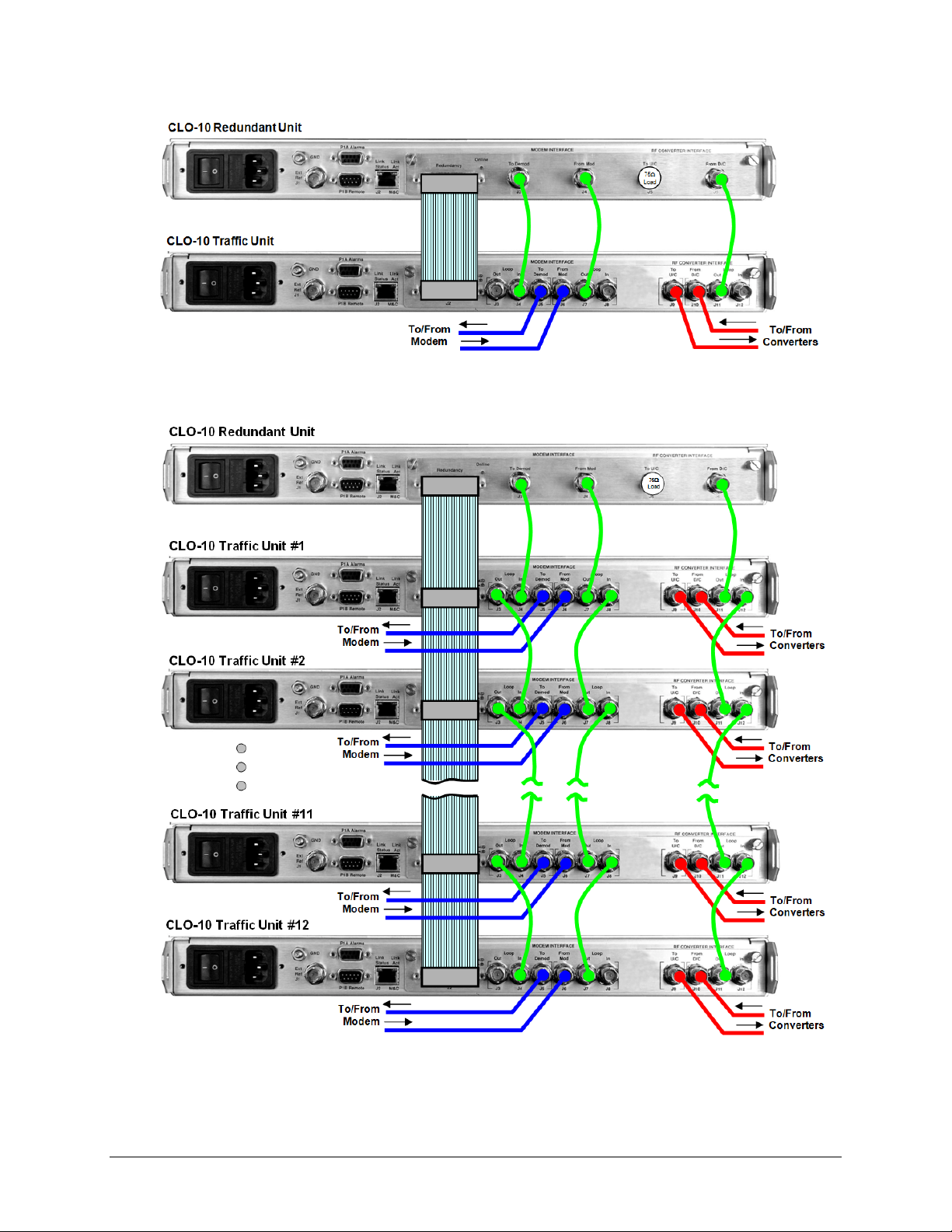

A.5 Cables and Connections

Once the CLO-10s and the accompanying equipment have been mounted, the user must properly

attach all required cabling. Referring to Figure A-10 and Figure A-11, interconnection between

all equipment in the Daisy Chain Redundancy System is accomplished as follows:

• Connect Redundancy and Traffic Unit(s) using the High Speed Bus Cable, fabricated and

supplied by CEFD. This cable connects to the DB-25F J2 Redundancy connector on each

unit, and consists of as few as (2X) DB-25M connectors (for the CEFD P/N

CA/RB0014-1-U2 1:1 Cable, shown in Figure A-10) to as many as (13X) connectors (for

the CEFD P/N CA/RB0014-12-U2 1:12 Cable, shown in Figure A-11). There will be only

as many DB-25M connectors as is required for the specific 1:N Redundancy system.

IMPORTANT

• Using CEFD-supplied BNC patch cable CA/BNC75OHM, first connect the inputs and

outputs between the Redundant Unit and Traffic Unit #1; then, connect the inputs and

outputs between each Traffic Unit subsequent in the redundancy chain.

The unit’s assignment number must match that of the numbered DB-25

connector on the High Speed Bus cable (CEFD P/N CA/RB0014-XX-U2).

• For the interfaces between the CLO-10, modem, and the up and down converters, use

standard off-the-shelf 75Ω BNC male-to-BNC male patch cables, supplied by the user.

As an alternative to using off-the-shelf patch cables, the user may purchase IF Cable

PL/0813-4 (75Ω BNC male-to-BNC male, 4’) from Comtech EF Data; this cable can be

ordered at the same time the order is placed for the CLO-10 Daisy Chain Redundancy

System.

A.5.1 75Ω Load in Redundant Unit

As shown in Figure A-10 and Figure A-11, a 75Ω load (CEFD P/N CN/CXLBNCTM01) must

be installed in the J5 (“To U/C”) port on the Redundant Unit’s IOM. This load is needed to

terminate the splitter on the IOM.

A–12

Page 11

CLO-10

Link Optimizer

Installation and Operation Manual

For Firmware Version 1.2.1 or higher

(see New in this Release - Section 1.7)

Part Number MN/CLO-10.IOM

Revision 1

June 18, 2008

Copyright © 2008 Comtech EF Data. All rights reserved. Printed in the USA.

Comtech EF Data, 2114 West 7th Street, Tempe, Arizona 85281 USA, 480.333.2200, FAX: 480.333.2161

Page 12

This page is intentionally blank.

Page 13

CLO-10 Link Optimizer Revision 1

Table of Contents MN/CLO-10.IOM

Table of Contents

TABLE OF CONTENTS ................................................................................................. III

TABLES ....................................................................................................................... VIII

FIGURES ....................................................................................................................... IX

PREFACE ...................................................................................................................... XI

Customer Support ........................................................................................................................ xi

About this Manual ...................................................................................................................... xii

Reporting Comments or Suggestions Concerning this Manual ................................................ xii

Conventions and References ...................................................................................................... xii

Cautions and Warnings ............................................................................................................. xii

Metric Conversion .................................................................................................................... xii

Recommended Standard Designations ..................................................................................... xii

Trademarks .............................................................................................................................. xiii

Electromagnetic Compatibility (EMC) Compliance .............................................................. xiii

EN55022 - 1997 Compliance ................................................................................................... xiii

EN50082-1 Compliance ........................................................................................................... xiii

Federal Communications Commission (FCC) ......................................................................... xiii

Safety Compliance ..................................................................................................................... xiv

EN 60950 ................................................................................................................................. xiv

Low Voltage Directive (LVD) ................................................................................................. xiv

Warranty Policy .......................................................................................................................... xv

Limitations of Warranty ............................................................................................................ xv

Exclusive Remedies ................................................................................................................. xvi

CHAPTER 1. INTRODUCTION ................................................................................ 1–1

1.1 Overview ........................................................................................................................ 1–1

1.2 Features .......................................................................................................................... 1–2

1.2.1 DoubleTalk™ Carrier-in-Carrier® .............................................................................. 1–2

1.2.2 Software – Flash Upgrading ....................................................................................... 1–2

1.2.3 Verification ................................................................................................................. 1–2

1.2.4 Remote Control ........................................................................................................... 1–3

iii

Page 14

CLO-10 Link Optimizer Revision 1

Table of Contents MN/CLO-10.IOM

1.3 Description of CLO-10 Features.................................................................................. 1–3

1.3.1 Front Panel .................................................................................................................. 1–3

1.3.2 Rear Panel ................................................................................................................... 1–3

1.4 Major Assemblies .......................................................................................................... 1–3

1.5 FAST Options and Hardware Options ....................................................................... 1–4

1.5.1 FAST System .............................................................................................................. 1–4

1.5.1.1 FAST Options ..................................................................................................... 1–4

1.5.1.2 FAST Implementation ........................................................................................ 1–4

1.5.2 Hardware Options ....................................................................................................... 1–5

1.6 Functional Description ................................................................................................. 1–5

1.6.1 What is DoubleTalk™Carrier-in-Carrier®? ................................................................ 1–5

1.6.2 Application Requirements .......................................................................................... 1–7

1.6.3 System Functionality .................................................................................................. 1–8

1.7 New in this Release........................................................................................................ 1–9

1.8 Summary of Specifications ......................................................................................... 1–10

1.8.1 System Specifications ............................................................................................... 1–10

1.8.2 Environmental and Physical Specifications .............................................................. 1–11

1.9 Dimensional Envelope ................................................................................................ 1–12

CHAPTER 2. INSTALLATION ................................................................................. 2–1

2.1 Unpacking and Inspection ............................................................................................ 2–1

2.2 Mounting ........................................................................................................................ 2–2

2.2.1 Optional Rear-Mounting Support Brackets ................................................................ 2–2

CHAPTER 3. REAR PANEL CONNECTORS ......................................................... 3–1

3.1 Connector Overview ..................................................................................................... 3–1

3.2 External Reference Connector, J1 (BNC-F) ............................................................... 3–2

3.3 Alarms Connector, P1A (DB-9F)................................................................................. 3–2

3.4 Remote Control Interface Connector, P1B (DB-9M) ................................................ 3–2

3.5 M&C 10/100 BaseT Ethernet Management Port (RJ-45) ......................................... 3–3

3.6 IOM/IOSM Connectors (BNC-F) ................................................................................ 3–4

3.7 IEC Line Input (AC Power) Connector ...................................................................... 3–5

iv

Page 15

CLO-10 Link Optimizer Revision 1

Table of Contents MN/CLO-10.IOM

3.8 DC Power Connector .................................................................................................... 3–5

3.9 Ground Connector ........................................................................................................ 3–6

CHAPTER 4. CABLES AND CONNECTIONS ........................................................ 4–1

4.1 Overview ........................................................................................................................ 4–1

4.2 External Cable Connections......................................................................................... 4–1

4.3 Redundancy Cable Connections .................................................................................. 4–1

CHAPTER 5. MODEM AND OPTIMIZER CONFIGURATION ................................. 5–1

5.1 Modem Configuration .................................................................................................. 5–1

5.1.1 Verify Link without Carrier-in-Carrier® .................................................................... 5–1

5.2 CLO-10 Configuration ................................................................................................. 5–1

5.2.1 CLO-10 Power ............................................................................................................ 5–1

5.2.2 Flash Updating ............................................................................................................ 5–2

5.2.2.1 Flash Update Help............................................................................................... 5–2

5.2.3 CLO-10 FTP Upload Procedure ................................................................................. 5–3

5.2.4 CLO-10 Tuning ........................................................................................................... 5–5

5.2.4.1 Initial Link Access Procedures ........................................................................... 5–5

5.2.4.2 Link Access Setup............................................................................................... 5–6

5.3 Other Useful Information............................................................................................. 5–6

CHAPTER 6. FRONT PANEL OPERATION ........................................................... 6–1

6.1 Introduction ................................................................................................................... 6–1

6.1.1 LED Indicators ............................................................................................................ 6–2

6.1.2 Keypad ........................................................................................................................ 6–3

6.1.3 Vacuum Fluorescent Display (VFD) .......................................................................... 6–4

6.2 CLO-10 Menu Structure .............................................................................................. 6–5

6.3 Main (Top-level Select) Menu ...................................................................................... 6–6

6.4 CONFIG (Configuration) ............................................................................................. 6–7

6.4.1 CONFIG: Remote ....................................................................................................... 6–8

CONFIG: Remote Æ Serial ........................................................................................ 6–8

CONFIG: Remote Æ Serial Æ Interface .................................................................... 6–8

CONFIG: Remote Æ Serial Æ Interface Æ RS485-2W or RS485-4W .................... 6–8

CONFIG: Remote Æ Serial Æ Baudrate ................................................................... 6–9

CONFIG: Remote Æ Ethernet .................................................................................... 6–9

v

Page 16

CLO-10 Link Optimizer Revision 1

Table of Contents MN/CLO-10.IOM

CONFIG: Remote Æ Ethernet Æ Gateway ............................................................... 6–9

CONFIG: Remote Æ Ethernet Æ Address ................................................................. 6–9

CONFIG: Remote Æ Ethernet Æ MAC ..................................................................... 6–9

6.4.2 CONFIG: BW (Bandwidth) ...................................................................................... 6–10

6.4.3 CONFIG: Uplink (Uplink Frequency) ...................................................................... 6–10

6.4.4 CONFIG: Downlink (Downlink Frequency) ............................................................ 6–10

6.4.5 CONFIG: Remod (Remodulation Parameters) ......................................................... 6–11

CONFIG: Remod ÆFrequency ................................................................................ 6–11

CONFIG: Remod Æ On/Off .................................................................................... 6–11

CONFIG: Remod Æ Attenuation ............................................................................. 6–11

6.4.6 CONFIG: CnC (Carrier-in-Carrier© Parameters) ..................................................... 6–12

CONFIG: CnC Æ SearchDelay ................................................................................ 6–12

CONFIG: CnC Æ FrequencyOffset ......................................................................... 6–12

6.4.7 CONFIG: Misc: (Miscellaneous Configurations) ..................................................... 6–12

CONFIG: Misc: Æ Mask .......................................................................................... 6–12

CONFIG: Misc: Æ Alarm Mask: Æ Unit ................................................................ 6–13

CONFIG: Misc: Æ Alarm Mask: Æ Unit Alarm Mask: Æ ERC ............................ 6–13

CONFIG: Misc: Æ Alarm Mask: Æ Unit Alarm Mask: Æ ACQ_FAIL ................. 6–13

CONFIG: Misc: Æ Alarm Mask: Æ Uplink ............................................................ 6–13

CONFIG: Misc: Æ Alarm Mask: Æ Downlink ....................................................... 6–13

CONFIG: Misc: Æ Reference (Reference Oscillator) .............................................. 6–14

CONFIG: Misc: Æ Redundancy .............................................................................. 6–14

6.5 Monitor ........................................................................................................................ 6–15

6.5.1 Monitor: Alarms (Live Alarms) ................................................................................ 6–15

Monitor: Alarms Æ (Live Alarms:) Unit (Unit Alarms) .......................................... 6–15

Monitor: Alarms Æ (Live Alarms:) Uplink (Uplink Alarms) .................................. 6–16

Monitor: Alarms Æ( Live Alarms:) Downlink (Downlink Alarms) ........................ 6–16

Monitor: Alarms Æ( Live Alarms:) Remod (Remod Alarms) ................................. 6–17

6.5.2 Monitor: Event Log (Stored Events) ......................................................................... 6–17

6.5.3 Monitor: CnC (Carrier-in-Carrier®) .......................................................................... 6–18

6.5.4 Monitor: Temp .......................................................................................................... 6–18

6.5.5 Monitor: RSL (Receive Signal Level) ...................................................................... 6–18

6.6 TEST ............................................................................................................................ 6–19

6.7 INFO (Information) .................................................................................................... 6–20

INFO: Remote (Remote Control Information) ......................................................... 6–20

INFO: Bw (Bandwidth Information) ........................................................................ 6–20

INFO: Uplink (Uplink Information) ......................................................................... 6–20

INFO: Downlink (Downlink Information) ............................................................... 6–21

INFO: Remod (Remodulation Information) ............................................................. 6–21

INFO: CnC (Carrier-in-Carrier® Information) ......................................................... 6–21

INFO: Ref (Frequency Reference) ............................................................................ 6–21

vi

Page 17

CLO-10 Link Optimizer Revision 1

Table of Contents MN/CLO-10.IOM

6.8 SAVE/LOAD ............................................................................................................... 6–22

Save/Load: Save (Save Configuration) ..................................................................... 6–22

Save/Load: Load (Load Configuration) .................................................................... 6–23

6.9 UTILITY ...................................................................................................................... 6–24

Utility: Clock (Real-time Clock) .............................................................................. 6–24

Utility: Ref (Reference Adjustment) ......................................................................... 6–24

Utility: ID (Circuit Identification) ............................................................................ 6–25

Utility: Display (Display Brightness) ....................................................................... 6–25

Utility: Firmware ...................................................................................................... 6–25

Utility: FAST (FAST Code Options) ........................................................................ 6–27

APPENDIX A. REDUNDANT SYSTEM OPERATION ............................................ A–1

A.1 Introduction .................................................................................................................. A–1

A.1.1 Overview ................................................................................................................ A–1

A.1.2 Redundancy System Operational Rules ................................................................. A–3

A.2 Installation .................................................................................................................... A–4

A.3 Description of Modules ................................................................................................ A–5

A.3.1.1 Overview: CLO-10 with Input/Output Module (IOM) ...................................... A–5

A.3.1.2 Overview: CLO-10 With Input/Output Switch Module (IOSM) ...................... A–6

A.3.2 Connector Pinouts .................................................................................................. A–6

A.3.2.1 IOM / IOSM Redundancy Connector, J2 (DB-25F) .......................................... A–6

A.3.2.2 IOM / IOSM BNC Connectors .......................................................................... A–7

A.4 Description of Operation ............................................................................................. A–8

A.4.1 Bridge Mode Operation ......................................................................................... A–8

A.4.2 Backup Mode Operation ........................................................................................ A–9

A.5 Cables and Connections ............................................................................................ A–12

A.5.1 75Ω Load in Redundant Unit ............................................................................... A–12

A.5.2 1:1 Redundancy Configuration Cabling .............................................................. A–13

A.5.3 1:N Redundancy Configuration Cabling ............................................................. A–14

A.5.4 Adding and Removing CLO-10s and/or Modules ............................................... A–15

A.6 Front Panel Operation ............................................................................................... A–17

A.6.1 Redundancy Menu Access ................................................................................... A–17

A.6.2 Traffic Unit Redundancy Configuration .............................................................. A–18

A.6.3 Redundant Unit Redundancy Configuration ........................................................ A–18

A.6.3.1 Redundancy Enable /Disable ........................................................................... A–19

A.6.3.2 Redundancy Holdoffs ...................................................................................... A–19

A.6.3.3 Active Unit Selection ....................................................................................... A–19

A.6.3.4 Establish the Operating Mode .......................................................................... A–20

A.6.3.4.1 Switch Auto Off/On .................................................................................. A–20

A.6.3.4.2 Redundancy Unit – Manual Select ............................................................ A–20

vii

Page 18

CLO-10 Link Optimizer Revision 1

Table of Contents MN/CLO-10.IOM

A.6.3.5 Set the Redundant Unit Address via the Main Menu ...................................... A–22

A.6.4 Set Operation Mode ............................................................................................. A–24

A.6.4.1.1 Set Holdoff Period ..................................................................................... A–24

A.6.4.1.2 Set Backup Holdoff Period ........................................................................ A–24

A.6.4.1.3 Set Restore Holdoff Period ........................................................................ A–25

A.7 Daisy Chain Remote Addressing .............................................................................. A–26

A.7.1 Introduction to Addressing .................................................................................. A–26

A.7.2 Switching Addresses ............................................................................................ A–26

A.7.3 Traffic Unit Addresses ......................................................................................... A–26

APPENDIX B. REMOTE CONTROL ........................................................................ B-1

B.1 Overview ........................................................................................................................ B-1

B.2 RS-485 ............................................................................................................................ B-1

B.3 RS-232 ............................................................................................................................ B-2

B.4 Basic Protocol ................................................................................................................ B-2

B.5 Packet Structure ............................................................................................................ B-2

B.5.1 Start of Packet ......................................................................................................... B-3

B.5.2 Address ................................................................................................................... B-3

B.5.3 Instruction Code ...................................................................................................... B-3

B.5.4 Instruction Code Qualifier ...................................................................................... B-4

B.5.5 Message Arguments ................................................................................................ B-5

B.5.6 End Of Packet ......................................................................................................... B-5

B.6 Remote Commands and Queries ................................................................................. B-6

B.6.1 Switch Remote Commands and Queries for the CLO-10 Link Optimizer ............. B-7

B.6.2 Remote Commands and Queries For the CLO-10 Link Optimizer ........................ B-9

B.6.3 Commands and Queries ........................................................................................ B-15

B.6.4 Bulk Commands and Queries ............................................................................... B-19

Tables

Table 3-1. External Connections ................................................................................................ 3–1

Table 3-2. Alarm Interface Connector Pin Assignments ............................................................ 3–2

Table 3-3. Remote Control Interface Connector Pin Assignments ............................................. 3–2

Table 3-4. M&C Interface Connector Pin Assignments ............................................................. 3–3

Table 3-5. CLO-10 IOM BNC Connectors Reference ............................................................... 3–4

Table A-1. IOM (CEFD P/N PL/12833-1) BNC Connectors Reference ................................... A–7

Table A-2. IOSM (CEFD P/N PL/12834-1) BNC Connectors Reference ................................ A–7

viii

Page 19

CLO-10 Link Optimizer Revision 1

Table of Contents MN/CLO-10.IOM

Figures

Figure 1-1. CLO-10 Link Optimizer ........................................................................................... 1–1

Figure 1-2. CLO-10 Front Panel ................................................................................................. 1–3

Figure 1-3. CLO-10 Rear Panel (CLO-10-1 shown) .................................................................. 1–3

Figure 1-4. Conventional FDMA Link ....................................................................................... 1–6

Figure 1-5. Link with Carrier-in-Carrier® ................................................................................... 1–6

Figure 1-6. Conceptual Block Diagram ...................................................................................... 1–8

Figure 1-7. CLO-10 Dimensional Envelope ............................................................................. 1–12

Figure 2-1. Typical CLO-10 Rack Installation (Side View) ....................................................... 2–3

Figure 2-2. Installation of the Optional Rear-Mounting Support Brackets ................................ 2–4

Figure 3-1. CLO-10 Rear Panel (CLO-10-1 Shown).................................................................. 3–1

Figure 4-1. CLO-10 External Cable Connections – Standalone Configuration ......................... 4–2

Figure 5-1. Flash Update via Internet ......................................................................................... 5–2

Figure 6-1. CLO-10 Front Panel ................................................................................................. 6–1

Figure 6-2. CLO-10 Menu Tree .................................................................................................. 6–5

Figure A-1. CLO-10 1:1 Daisy Chain Redundancy ................................................................... A–2

Figure A-2. CLO-10 1:N Daisy Chain Redundancy (1:12 shown) ........................................... A–2

Figure A-3. Typical Rack-mounted Redundancy Configuration ............................................... A–4

Figure A-4. IOM (CEFD P/N PL/12833-1) ............................................................................... A–5

Figure A-5. CLO-10 With IOM – Block Diagram .................................................................... A–5

Figure A-6. IOSM (CEFD P/N PL/12834-1) ............................................................................. A–6

Figure A-7. CLO-10 With IOSM – Block Diagram .................................................................. A–6

Figure A-8. CLO-10 Daisy Chain Redundancy – Bridge Mode ............................................. A–10

Figure A-9. CLO-10 Daisy Chain Configuration – Backup Mode .......................................... A–11

Figure A-10. CLO-10 1:1 Daisy Chain Redundancy Cabling ................................................. A–13

Figure A-11. CLO-10 1:N Daisy Chain Redundancy Cabling (1:12 shown) .......................... A–14

Figure A-15. Module Removal/Installation ............................................................................. A–15

Figure A-16. Operating Configuration .................................................................................... A–16

Figure A-12. Redundancy Menu Tree ..................................................................................... A–17

Figure A-13. Unit Bridging in AUTO-OFF (manual operating) Mode .................................. A–21

Figure A-14. Unit Backup in AUTO-ON (automatic operating) Mode .................................. A–21

Figure A-17. CLO-10 Daisy Chain Addressing Scheme Example: User Remote M&C RS-232 .... A–27

Figure A-18. CLO-10 Daisy Chain Addressing Scheme Example: User Remote M&C RS-485 .... A–27

Figure A-19. CLO-10 Base Addressing Scheme Example for Daisy Chained Multiple Redundant

Systems: User Remote M&C RS-485.............................................................................. A–28

ix

Page 20

CLO-10 Link Optimizer Revision 1

Table of Contents MN/CLO-10.IOM

This page is intentionally blank.

x

Page 21

Customer Support

Contact the Comtech EF Data Customer Support Department for:

• Product support or training

• Reporting comments or suggestions concerning manuals

• Information on upgrading or returning a product

A Customer Support representative may be reached at:

Comtech EF Data

Attention: Customer Support Department

2114 West 7th Street

Tempe, Arizona 85281 USA

480.333.2200 (Main Comtech EF Data Number)

480.333.4357 (Customer Support Desk)

480.333.2161 FAX

Preface

To return a Comtech EF Data product (in-warranty and out-of-warranty) for repair or

replacement:

• Contact the Comtech EF Data Customer Support Department. Be prepared to supply the

Customer Support representative with the model number, serial number, and a description

of the problem.

• Request a Return Material Authorization (RMA) number from the Comtech EF Data

Customer Support representative.

• Pack the product in its original shipping carton/packaging to ensure that the product is not

damaged during shipping.

• Ship the product back to Comtech EF Data. (Shipping charges should be prepaid.)

For Online Customer Support

An RMA number request can be requested electronically by contacting the Customer Support

Department through the online support page at www.comtechefdata.com/support.asp

• Click “Return Material Authorization Instructions” from the Service page for detailed

information on our return procedures.

• Click the “RMA Request form” hyperlink, then fill out the form completely before

sending.

• Send e-mail to the Customer Support Department at service@comtechefdata.com.

For information regarding this product’s warranty policy, refer to the Warranty Policy, p. xv.

:

:

xi

Page 22

CLO-10 Link Optimizer Revision 1

Preface MN/CLO-10.IOM

About this Manual

This manual provides installation and operation information for the Comtech EF Data CLO-10

Link Optimizer. This is a technical document intended for earth station engineers, technicians,

and operators responsible for the operation and maintenance of the CLO-10.

Comtech EF Data reserves the right to change specifications of products described in this

document at any time without notice and without obligation to notify any person of such changes.

Information in this document may differ from information published in other Comtech EF Data

documents. Refer to the company website or contact Customer Service for the latest released

product information.

Reporting Comments or Suggestions Concerning this Manual

Comments and suggestions regarding the content and design of this manual are appreciated. To

submit comments, please contact the Comtech EF Data Technical Publications department:

TechnicalPublications@comtechefdata.com

Conventions and References

Cautions and Warnings

IMPORTANT

CAUTION

WARNING

IMPORTANT or NOTE indicates a statement that is associated with the task

being performed or information critical for proper equipment function.

CAUTION indicates a hazardous situation that, if not avoided, may result in

minor or moderate injury. CAUTION may also be used to indicate other

unsafe practices or risks of property damage.

WARNING indicates a potentially hazardous situation that, if not avoided,

could result in death or serious injury.

Metric Conversion

Metric conversion information is located on the inside back cover of this manual. This information

is provided to assist the operator in cross-referencing non-Metric to Metric conversions.

Recommended Standard Designations

Recommended Standard (RS) Designations are interchangeable with the designation of the

Electronic Industries Association (EIA).

xii

Page 23

CLO-10 Link Optimizer Revision 1

Preface MN/CLO-10.IOM

Trademarks

Product names mentioned in this manual may be trademarks or registered trademarks of their

respective companies and are hereby acknowledged.

Electromagnetic Compatibility (EMC) Compliance

This is a Class A product. In a domestic environment, it may cause radio interference that

requires the user to take adequate protection measures.

EN55022 - 1997 Compliance

This equipment meets the radio disturbance characteristic specifications for information

technology equipment as defined in EN55022.

EN50082-1 Compliance

This equipment meets the electromagnetic compatibility/generic immunity standard as defined in

EN50082-1.

Federal Communications Commission (FCC)

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate ra dio freque ncy e nergy. If not installed and used in

accordance with the instruction manual, it may cause harmful interference to radio communications.

Operation of this equipment i n a residentia l area is likely to cause ha rmful interfere nce; in whic h case,

users are required to correct the interference at the ir own expe nse.

To ensure compliance, properly shielded cables for DATA I/O shall be used.

More specifically, these cables shall be shielded from end to end, ensuring a

continuous shield.

NOTE

xiii

Page 24

CLO-10 Link Optimizer Revision 1

Preface MN/CLO-10.IOM

Safety Compliance

EN 60950

Applicable testing is routinely performed as a condition of manufacturing on all units to ensure

compliance with safety requirements of EN60950.This equipment meets the Safety of

Information Technology Equipment specification as defined in EN60950.

Low Voltage Directive (LVD)

The following information is applicable for the European Low Voltage Directive (EN60950):

International Symbols:

NOTE

<HAR>

!

Symbol Definition Symbol Definition

~

For additional symbols, refer to Cautions and Warnings listed earlier in this Preface.

Applicable testing is routinely performed as a condition of manufacturing on all units

to ensure compliance with safety requirements of EN60950.

Type of power cord required for use in the European Community.

CAUTION: Double-pole/Neutral Fusing

ACHTUNG: Zweipolige bzw. Neutralleiter-Sicherung

Alternating Current

Fuse

Protective Earth /

Safety Ground

Chassis Ground

xiv

Page 25

CLO-10 Link Optimizer Revision 1

Preface MN/CLO-10.IOM

Warrant y Policy

Comtech EF Data products are warranted against defects in material and workmanship

for a period of two years from the date of shipment. During the warranty period,

Comtech EF Data will, at its option, repair or replace products that prove to be defective.

For equipment under warranty, the owner is responsible for freight to Comtech EF Data

and all related customs, taxes, tariffs, insurance, etc. Comtech EF Data is responsible for

the freight charges only for return of the equipment from the factory to the owner.

Comtech EF Data will return the equipment by the same method (i.e., Air, Express,

Surface) as the equipment was sent to Comtech EF Data.

All equipment returned for warranty repair must have a valid RMA number issued prior

to return and be marked clearly on the return packaging. Comtech EF Data strongly

recommends all equipment be returned in its original packaging.

Comtech EF Data Corporation’s obligations under this warranty are limited to repair or

replacement of failed parts, and the return shipment to the buyer of the repaired or

replaced parts.

Limitations of Warranty

The warranty does not apply to any part of a product that has been installed, altered,

repaired, or misused in any way that, in the opinion of Comtech EF Data Corporation,

would affect the reliability or detracts from the performance of any part of the product, or

is damaged as the result of use in a way or with equipment that had not been previously

approved by Comtech EF Data Corporation.

The warranty does not apply to any product or parts thereof where the serial number or the

serial number of any of its parts has been altered, defaced, or removed.

The warranty does not cover damage or loss incurred in transportation of the product.

The warranty does not cover replacement or repair necessitated by loss or damage from

any cause beyond the control of Comtech EF Data Corporation, such as lightning or other

natural and weather related events or wartime environments.

The warranty does not cover any labor involved in the removal and or reinstallation of

warranted equipment or parts on site, or any labor required to diagnose the necessity for

repair or replacement.

The warranty excludes any responsibility by Comtech EF Data Corporation for incidental or

consequential damages arising from the use of the equipment or products, or for any inability

to use them either separate from or in combination with any other equipment or products.

xv

Page 26

CLO-10 Link Optimizer Revision 1

Preface MN/CLO-10.IOM

A fixed charge established for each product will be imposed for all equipment returned

for warranty repair where Comtech EF Data Corporation cannot identify the cause of the

reported failure.

Exclusive Remedies

Comtech EF Data Corporation’s warranty, as stated is in lieu of all other warranties,

expressed, implied, or statutory, including those of merchantability and fitness for a

particular purpose. The buyer shall pass on to any purchaser, lessee, or other user of

Comtech EF Data Corporation’s products, the aforementioned warranty, and shall

indemnify and hold harmless Comtech EF Data Corporation from any claims or liability

of such purchaser, lessee, or user based upon allegations that the buyer, its agents, or

employees have made additional warranties or representations as to product preference or

use.

The remedies provided herein are the buyer’s sole and exclusive remedies. Comtech EF

Data shall not be liable for any direct, indirect, special, incidental, or consequential

damages, whether based on contract, tort, or any other legal theory.

xvi

Page 27

1.1 Overview

The CLO-10 is Comtech EF Data’s Link Optimizer incorporating DoubleTalk™ Carrier-in-Carrier®

technology. The CLO-10 allows transmit (Tx) and receive (Rx) carriers in a full-duplex link to use

the same transponder segment via advanced signal processing techniques. The result is a reductio n

in bandwidth required for the duplex link by as much as 50%.

The CLO-10 operates on the 70/140 MHz IF band, which facilitates retrofitting into existing

systems. The unit is installed in the IF path between the modem and the up/down converters. The

CLO-10 does not require prior knowledge of the signals to be processed (i.e., modulation type,

FEC, etc) other than the bandwidth and center frequency of the desired signal.

Figure 1-1 shows the CLO-10 Link Optimizer. The Link Optimizer can be configured for two

versions – the standard CLO-10-1 (shown), and the CLO-10-2, which features the optional

redundancy hardware upgrade.

Chapter 1. INTRODUCTION

Figure 1-1. CLO-10 Link Optimizer

For the purpose of brevity, the Link Optimizer is referred to throughout this manual as the CLO-10.

With the exception of redundancy operations, all content in this manual is applicable to both the CLO10-1 and CLO-10-2 models; the CLO-10-2’s added functionality is explained in detail in

A. REDUNDANT SYSTEM OPERATION.

Appendix

1–1

Page 28

CLO-10 Link Optimizer Revision 1

Introduction MN/CLO-10.IOM

1.2 Features

The CLO-10 includes the following features:

• DoubleTalk™ Carrier-in-Carrier® allowing Tx and Rx carriers of a full-duplex link to

use the same transponder segment

• 50- 90 and 100-180 MHz frequency range

• Signal Bandwidth up to 10MHz (bandwidth typically refers to usable bandwidth of signal

of interest)

• 10/100 BaseT Ethernet (Telnet), RS-232 or RS-485 for M&C remote control

• Fully Accessible System Topology (FAST)

• Optional User-configurable Redundancy — 1:1 up to 1:12 (CLO-10-2 unit only)

• Future / planned upgrade: HTTP, SNMP Remote Management

1.2.1 DoubleTalk™ Carrier-in-Carrier®

Designed for bandwidth compression, DoubleTalk™ Carrier-in-Carrier® (CnC) uses a patented

technology that allows full duplex satellite links to transmit concurrently in the same segment of

transponder bandwidth.

CnC is complementary to all advances in modem technology, including advanced FEC and

modulations techniques. As these technologies approach theoretical limits of power and

bandwidth efficiencies, CnC utilizes advanced signal processing techniques to achieve a new

dimension in bandwidth efficiency.

CnC can be successfully deployed in bandwidth-limited as well as power-limited scenarios.

Combining CnC with advanced FEC techniques such as Turbo Product Codes (TPC) or Low

Density Parity Check Codes (LDPC) [also used by DVB-S2] can recover enough power that can

then be traded for bandwidth.

Refer to

in-Carrier

Chapter 1.6 Functional Description for detailed information on DoubleTalk™ Carrier-

®

.

1.2.2 Software – Flash U pgrading

The internal software is both powerful and flexible, permitting storage and retrieval of up to 10

different unit configurations. The CLO-10 uses ‘flash memory’ technology internally, and new

firmware can be uploaded to the unit from an external PC. This simplifies software upgrading,

and updates can now be sent via the Internet, e-mail, or on disk. The upgrade can be performed

without opening the unit by simply connecting the modem to the Ethernet port of a computer.

1.2.3 Verification

The CLO-10 includes test modes for rapid verification of the correct functioning of the unit.

Test modes that exercises various signal paths within the CLO-10, as well as carrier test modes,

allow an operator to quickly perform simple diagnostics without having to remove/connect

cables from the unit.

1–2

Page 29

CLO-10 Link Optimizer Revision 1

Introduction MN/CLO-10.IOM

1.2.4 Remote Control

The operator may configure and monitor the modem from the front panel, or through the remote

M&C port. M&C is via RS-232, RS-485 (2/4 wire) or 10/100 BaseT Ethernet.

1.3 Description of CLO-10 Features

1.3.1 Front Panel

The CLO-10 is constructed as a 1RU-high, rack-mounting chassis that can be freestanding if desired.

It is provided with rack handles at the front for easy removal from and placement into a rack.

Figure 1-2 sho ws t he C L O-1 0 f ro nt p an el . The front panel features a Vacuum Fluorescent Display

(VFD), six-button keypad, and eight LED indicators. The user enters data via the keypad, and

messages are displayed on the VFD. The LEDs indicate, in a summary fashion, the status of the unit.

See

Chapter 6. Front Panel Operation for detailed information pertaining to this functionality.

Figure 1-2. CLO-10 Front Panel

1.3.2 Rear Panel

Figure 1-3 shows the rear panel of the standard CLO-10-1 chassis configuration. Refer to

Chapter 3. REAR PANEL CONNECTORS for detailed information about these connectors and

their functionality.

Figure 1-3. CLO-10 Rear Panel (CLO-10-1 shown)

1.4 Major Assemblies

Unit Part No. Description

CLO-10-1 PL/12833-1 Input Output Module (IOM)

CLO-10-2 PL/12834-1 Input Output Switch Module (IOSM) – 1:N

1–3

Page 30

CLO-10 Link Optimizer Revision 1

Introduction MN/CLO-10.IOM

1.5 F A ST Options and Hardware Options

The CLO-10 incorporates several optional features. These include redundancy and cancellation

bandwidth. In order to permit a lower initial cost, the unit may be purchased with only the desired

features enabled. The base configuration is 1.024 MHz of bandwidth, and standalone (no

redundancy) operation.

Bandwidth

Options

1.024 MHz Capable of suppressing signals with 1.024MHz bandwidth Base Unit

2.046 MHz Capable of suppressing signals with 2.048 MHz of bandwidth FAST

4.096 MHz Capable of suppressing signals with 4.096 MHz of bandwidth FAST

8.192 MHz Capable of suppressing signals with 8.192 MHz of bandwidth FAST

10 MHz Capable of suppressing signals with up to 10 MHz of bandwidth FAST

1:N

Redundancy

Each traffic unit requires installation of IOSM

Description and Comments

Installation

Method

(CLO-10-1)

HARDWARE

(CLO-10-2)

1.5.1 F A ST Sy stem

Comtech EF Data provides FAST (Fully Accessible System Topology) as an enhancement

feature available in CEFD products, enabling on-location upgrade of the most operating feature

sets - in the rack - without removing a unit from the setup.

When service requirements change, the operator can upgrade the topology of the product to meet

those requirements within minutes after confirmation by Comtech EF Data. This accelerated

upgrade can be accomplished only because of FAST’s extensive use of programmable devices

incorporating Comtech EF Data-proprietary signal processing techniques. These techniques allow

the use of a unique access code to enable configuration of the available hardware. The access

code can be purchased at any time from Comtech EF Data. Once obtained, the access co de is

loaded into the unit via the front panel user interface keypad or the rear remote port.

With the exclusive FAST technology, operators have maximum flexibility for enabling functions

as they are required. FAST allows an operator to order a modem precisely tailored for the initial

application.

1.5.1.1 FAST Options

FAST permits the purchase and installation of options through special authorization codes entered

remotely, or via the front panel user interface keypad where immediate implementation of the

different options is facilitated. All FAST options are available through the basic platform unit.

1.5.1.2 FA ST Implementation

FAST is factory-implemented in the modem at the time of order. Options for basic modems can

be ordered and installed either at the factory or in the field. The operator can select Bandwidth

options that can be activated easily in the field.

1–4

Page 31

CLO-10 Link Optimizer Revision 1

Introduction MN/CLO-10.IOM

1.5.2 Hardware Options

Redundancy is the only available hardware option for the CLO-10. See Appendix A.

REDUNDANT SYSTEM OPERATION for more information.

If the user wishes to add redundancy to an existing single-thread system, the ex isting standalone

setup may be converted by purchasing and installing an IOSM interface in place of the original

IOM interface. More specifically, the CLO-10 design ated as the system’s Redundant Unit must be

equipped with an IOM, while each CLO-10 within the redundant system desig nated as a Traffic

Unit will require the IOSM interface.

1.6 Functional Description

1.6.1 What is DoubleTalk™Carrier-in-Carrier®?

The CLO-10 utilizes Carri er-in-Carri er® (CnC): Comtech EF Data’s implementation of Ap plied

Signal Technology, Inc.’s patented (United States #6,859,641) DoubleTalk™ signal processing

algorithm technology, which allows both the forward and reverse carriers of a full duplex lin k to

share the same segment of transponder bandwidth..

CnC allows satellite users to achieve spectral efficiency (i.e., bps/Hz) that cannot be achieved with

traditional links. For example, CnC u sed with a pair of 16-QAM carriers achieves the bandwidth

efficiency of 256-QAM (8bps/Hz when using uncoded operation as a baseline for both modulation

types) with the power efficiency that is closer to that of 16-QAM. This allows CnC to not only

provide significant operating expenditure (OPEX) savings, but also reduce capital expenditure

(CAPEX) by allowing a smaller BUC/HPA and/or antenna.

A CLO-10 at each end of the link suppresses the uplink carrier (at the near end) and allows the

distant end carrier to be received by the (near end) demodulator. The CLO-10 operates on the

standard IF band of 50-90 MHz and 100-180 MHz and allows users to upgrade existing sy stems

while preserving their initial investment in modems and up/down converters. By placing the CLO10 in the signal path between the modem and the up/down converters, up to 50% savings in

bandwidth can be immediately realized.

Figure 1-4 illustrates a conventional, full duplex satellite link where two carriers are placed in non-

overlapping channels.

Figure 1-5 shows operation of the same link but utilizing the CLO-10 on both ends of the link. The

two carriers now overlap and occupy half the bandwidth of the scenario in Figure 1-4.

The transponder downlinks the composite signal containing both carriers on the same band to the

CLO-10 which then translates the signal to near baseband where it can be filtered (decimated) and

then processed as a complex envelope signal. The CLO-10 next suppresses the version of the near end

carrier on the downlink side and then remodulates the desired carrier to the modem for dem odulati on.

The CLO-10 operates on the IF signal between the modem and the up/down converters and is

waveform agnostic. This means that no prior knowledge of th e underly ing modulation , FEC, or any

other waveform specific parameter is required in order to perform the signal suppression op eration.

The only caveat to this is that the waveform must be “sufficiently random”.

1–5

Page 32

CLO-10 Link Optimizer Revision 1

Introduction MN/CLO-10.IOM

Upconverter Downconverter

Upconverter Downconverter

CDM-600 Satellite Modem

CDM-600 Satellite Modem

Figure 1-4. Conventional FDMA Link

Figure 1-5. Link with Carrier-in-Carrier

1–6

®

Page 33

CLO-10 Link Optimizer Revision 1

Introduction MN/CLO-10.IOM

Because acquiring the delay and frequency offset of the interfering carrier is fundamentally a

correlation operation, anything deterministic in the interfering carrier (within the correlation

window of the algorithm) will potentially produce false correlation peaks, and result in incorrect

delays and/or frequency. Normally, this is not a problem, since energy dispersal techniques are

utilized in the vast majority of commercial and military modems; however, this is something the

user must keep in mind when troubleshooting a system that utilizes the DoubleTalk™ Carrier-inCarrier

®

technique for signal suppression.

One possible way to mitigate false peaks is to narrow the correlation window. For example, if you

know the delay to be around 240ms, set the minimum search delay to 230ms and the maximum

search delay to 250ms.

A typical CnC system does require a 3dB increase within the band (for symmetric links). This i s

usually compensated for by using a more powerful FEC like TPC or LDPC, by use of a larger

antenna, or carefully managing the link budget. Many links operate with excessive margins which

can be allocated to CnC without having to resort to changing out the equipment.

1.6.2 Application Requirement s

The following conditions are necessary in order to operate Carrier-in-Carrier®:

• Link must be full duplex

• A CLO-10 must be used at each end of the link

• The transponder is operated as Loopback. That is, each end of the link must be able to see

a copy of its own signal in the return (downlink) path from the satellite. The looped back

signal is then subtracted which leaves the signal from the distant end of the link. CnC

cannot be used in spot beam systems.

• The transponder is “bent-pipe”, meaning no on-board processing, demodulation, or

regeneration can be employed. Demodulating/remodulating does not preserve the linear

combination of the forward and return signals and the resulting reconstituted waveform

prevents recovery of the original const ituent si gnals.

1–7

Page 34

CLO-10 Link Optimizer Revision 1

Introduction MN/CLO-10.IOM

1.6.3 System Functionality

Carrier-in-Carrier® achieves its cancellation performance due to its ability to automatically adapt

to dynamic system impairments.

Figure 1-6 shows a simplified conceptual block diagram of CnC processing. The two ends of the

link are denoted 'A' and 'B', and the uplink and downlink are shown. As depicted here, a variety

of dynamic system impairments must b e considered for CnC application. Their effects must be

minimized in order to realize sufficient cancellation of the user’s own uplink signal. The

cancellation process adds a small amount of degradation to the existing link (tenths of a dB)

under various signal conditions.

Figure 1-6. Conceptual Block Diagram

This performance is achieved through advanced signal processing algorithms that provide superior

cancellation while tracking and compensating for the following comm on link impair ments:

• Time varying delay. In addition to the static delays of the electronics and the round-trip

delay associated with propagation to the satellite and back, there is a time-varying

component due to movement of the satellite. CnC tracks and compensates for this

variation.

• Frequency offset and drift. Common sources are satellite Doppler shift, up/down

converter frequency uncertainties, and other drift associated with the electronics in the

1–8

Page 35

CLO-10 Link Optimizer Revision 1

Introduction MN/CLO-10.IOM

modem and the CLO-10 itself. The CLO-10 tracks and compensates for this frequency

offset and drift.

• Atmospheric effects. Fading and scintillation can affect amplitude, phase, and spectral

composition of the signal and the degree to which it correlates with the original signal.

CnC tracks and compensates for these atmospheric related impairments.

• Link Asymmetries. Various asymmetries in the forward and return link can produce

differences in the relative power of the two received signal components. These can be

both deterministic (static) or random (and time varying). An example of the former would

be the differences resulting from antenna size/gain variations between the two ends of the

link. An example of the latter would be transient power differences due to different levels

of atmospheric fading in the uplinks. CnC compensates for the impairments, but these

differences drain CnC’s cancellation ability.

1.7 New in this Release

Version 1.2.1 firmware adds the following new features:

• 1:N Redundancy

1–9

Page 36

CLO-10 Link Optimizer Revision 1

Introduction MN/CLO-10.IOM

1.8 Summary of Specifications

1.8.1 System Specifications

Characteristic Requirement

Eb/No Degradation <0.5dB for QPSK at 1E-6BER and 0dB C/I (desired carrier to interferer)

Delay/Doppler range 0 to 330 ms, +/-32kHz

Latency <10ms

Cancellation Bandwidth Up to 10MHz

Input Frequency 50MHz - 90MHz, 100MHz -180MHz, 1kHz steps

Input level, Uplink 0 to –40dBm Reference Carrier

+10dBc Maximum Composite

Input level, Downlink -105dbm + 10*log(BW)

BW is input signal processing bandwidth, usually set to the symbol bandwidth

of the desired or signal of interest

Maximum 35 dB above minimum

94 – 10log(BW) dBc maximum composite

+20 dBm absolute maximum composite

Output Frequency 50MHz - 90MHz, 100MHz-180MHz, 1kHz steps

Uplink output level Tx Input level –1 +/-0.5dB

Uplink output spurs, stability, spectrum Set by uplink modem

Output level to modem (RX OUT port)

Reflash FTP Ethernet (rear panel)

Frequency Reference:

Internal Reference

External Ref

(BNC Female*)

Input/Output impedance

Form C Unit Fault

1:N Redundancy (optional) Daisy Chain via High Speed Bus (HSB) cable

Agency Approval

M&C/ Remote Port Telnet (10/100 Base-T Ethernet with HTTP, SNMP at a later release)

Eb/No Degradation <0.5dB for QPSK at 1E-6BER and 0dB C/I (desired carrier to interferer)

-20 to –30dBm for C/I of ±10dB

Selectable

10 MHz for data and IF, stability ±1.5 ppm

None (off), 1, 2, 5, or 10MHz for IF, internally phase locked. Input is

50 / 75 Ω compatible with 0.5 to 4.0 V pp sine or square wave. Requires high

stability source.

75 Ω, 17 Return Loss

Safety, conducted and radiated emissions (Class B) and Immunity sufficient for

CE certification

1–10

Page 37

CLO-10 Link Optimizer Revision 1

Introduction MN/CLO-10.IOM

1.8.2 Environmental and Physical Specifications

Characteristic Requirement

Operating Temp 0 to 50ºC (32 to 122ºF)

Humidity 95% maximum, non-condensing

Power Supply Input

Power Consumption < 70W

Weight 10lbs (4.5 kg) maximum

Dimensional Envelope, 1RU

Rack Slides

AC Receptacle Retainer to prevent plug from disconnecting due to vibration

Keypad and Display

100 - 240AC 50/60Hz (standard)

48 VDC (optional)

1.75H x 19.0W x 18.65D inch

(4.4H x 48W x 46.8D cm) approximate

Not recommended — use rack shelf or rack mounting kit KT/6228-2

(see Chapter 2. INSTALLATION).

Per CEFD “style”. See Figure1-2 and Chapter 6. FRONT PANEL

OPERATION.

1–11

Page 38

CLO-10 Link Optimizer Revision 1

Introduction MN/CLO-10.IOM

1.9 Dimensional Envelope

Figure 1-7 shows the dimensional envelope for the CLO-10 Link Optimizer.

Figure 1-7. CLO-10 Dimensional Envelope

1–12

Page 39

Chapter 2. INSTALLATION

2.1 Unpacking and Inspection

The CLO-10 Link Optimizer and its Installation and Operation Manual are packaged and shipped in

a pre-formed, reusable cardboard carton containing foam spacing for maximum shipping protection.

Do not use any cutting tool that will extend more than 1” into the container

CAUTION

IMPORTANT

Unpack and inspect the CLO-10 as follows:

and cause damage to the unit.

Be sure to keep all shipping materials for the carrier's inspection.

Step Procedure

Inspect shipping containers for damage. If shipping containers are

1

2 Remove the packing list from the outside of the shipping carton.

3

4

5

6

7 Refer to the following sections for further installation instructions.

damaged, keep them until the contents of the shipment have been

carefully inspected and checked for normal operation.

Open the carton by cutting the tape at the top of the carton (indicated by

OPEN THIS END).

Remove the cardboard/foam space covering the CLO-10. Remove the

CLO-10, manual and power cord from the carton.

Check the contents against the packing list to verify completeness of the

shipment.

Inspect the equipment for any possible damage incurred during shipment. If

damage is evident, contact the carrier and Comtech EF Data immediately

and submit a damage report.

2–1

Page 40

CLO-10 Link Optimizer Revision 1

s

Installation MN/CLO-10.IOM

2.2 Mounting

Figure 2-1 provides a “cut-away” side view of a typical CLO-10 rack configurati on, com bining use o f

CLO-10s and – as furnished by Comtech EF Data or others – modems, up converters, and down

converters. Mount all equipment in the rack(s) as required for efficient arrangement and operation.

(Note: For depiction of the CLO-10 in optional redundancy configuration, refer to Appendix A.

REDUNDANCY SYSTEM OPERATION for details and illustrations pertaining to this setup.)

If the CLO-10 is to be mounted in a rack, ensure that there is adequate clearance for ventilation,

particularly at the sides. In rack systems where there is high heat dissipation, forced air cooling

must be provided by top or bottom mounted fans or blowers. Under no circumstance should the

highest internal rack temperature be allowed to exceed 50°C (122°F).

Because a cooling fan is installed in the right-hand side of the unit, the CLO-10

CAN NOT have rack slides mounted to the side of the chassis. Comtech EF

Data therefore recommends that an alternate method of support, such as rack

IMPORTANT

helves, is employed within the rack. If there is any doubt, please consult the

Comtech EF Data Customer Support department.

2.2.1 Optional Rear-Mounting Support Brackets

Install optional rear-mounting support brackets using mounting kit KT/6228-2 or KT/6228-3:

Quantity

KT/6228-2 KT/6228-3

2 2 HW/10-32SHLDR Screw, #10 Shoulder

4 4 HW/10-32FLT Washer, #10 Flat

2 2 HW/10-32SPLIT Washer, #10 Split

2 2 HW/10-32HEXNUT Nut, #10 Hex

2 ─ FP/6138-1 Bracket, 4”, Rear Support

─ 2 FP/6138-3 Bracket, 10”, Rear Support

4 4 HW/10-32x1/2RK Bolt, #10 Rack Bracket

The tools required for this installation are a medium Phillips™ screwdriver and a 5/32-inch SAE

Allen™ Wrench. The kit is installed as illustrated in Figure 2-2 via the following procedure:

Step Procedure

Secure the #10 shoulder screws to the unit chassis through the rear right and left

1

2

side mounting slots, using the #10 flat washers, #10 split washers, and #10 hex

nuts as shown.

Install the rear support brackets onto the equipment rack threaded rear

mounting rails, using the #10 rack bracket bolts.

Part Number Description

3

Mount the unit into the equipment rack, ensuring that the shoulders of the #10

shoulder screws properly engage into the rear support bracket slots.

2–2

Page 41

CLO-10 Link Optimizer Revision 1

Installation MN/CLO-10.IOM

Figure 2-1. Typical CLO-10 Rack Installation (Side View)

2–3

Page 42

CLO-10 Link Optimizer Revision 1

Installation MN/CLO-10.IOM

Support Bracket

#10 Bracket Bolt

#10 Shoulder Screw

#10 Flat Washer

#10 Flat Washer

#10 Split Washer

Equipment Rack

Rear Mounting Rail

#10 Hex Nut

Back of unit

Figure 2-2. Installation of the Optional Rear-Mounting Support Brackets

2–4

Page 43

Chapter 3. REAR PANEL

3.1 Connector Overview

The connectors located on the CLO-10 rear panel (Figure 3-1) provide all necessary external

connections between the modem and other equipment.

Table 3-1 summarizes these connections and identifies the chapter sections providing more

detailed information.

Figure 3-1. CLO-10 Rear Panel (CLO-10-1 Shown)

CONNECTORS

Name Sect Connector Type Function

Ext Ref

Alarms

Remote

M&C

To Demod

IOM / IOSM

Interface

(AC Plug)

(DC Connector – not shown)

GND

From Mod Input from Uplink Modulator

To U/C Output to Upconverter

From D/C Input from Downconverter

Table 3-1. External Connections

3.2

BNC (female) External 1,5, 10 MHz Reference input

3.3

9-Pin Type ‘D’ (female) Form C Unit Alarm

3.4

9-Pin Type ‘D’ (male) Serial Remote Control Interface

3.5

RJ-45 10/100 Ethernet M&C

Output to Demod

3.6 BNC (female)

3.7

IEC Modem Power

3.8

Terminal Block Modem Power

3.9

#10-32 Stud Grounding

3–1

Page 44

CLO-10 Link Optimizer Revision 1

Rear Panel Connectors MN/CLO-10.IOM

3.2 External Reference Connector, J1 (BNC-F)

The J1 External Reference Input is used to supply a master

reference to entire chassis. Use of an external reference is not

required. The input/output signal supplied here by the user is used for

phase-locking the internal 10MHz reference oscillator, and can be 1,

2, 5, or 10 MHz. The impedance is matched for 50/75Ω, and requires

a level in the range 0.5V-4.0Vpp square or sine wave.

3.3 Alarms Connector, P1A (DB-9F)

The P1A Alarms connector is a Type 'D' 9-pin female connector (DB-9F), providing

the user with access to the Form-C relay contacts that indicate the fault status of the

unit. P1A is typically connected to an external fault monitoring system, often found in

satellite earth stations.

Table 3-2. Alarm Interface Connector Pin Assignments

Pin # Signal Function Name

8 Unit is faulted NO

3 Unit is not faulted NC

7 Unit Alarm common COM

1,2,4,5,6,9 NOT USED --

3.4 Remote Control Interface Connector, P1B (DB-9M)

The P1B Remote Control connector is a Type ‘D’ 9-pin male connector (DB-9M), providing

the user with access to both EIA-232 and EIA-485 remote control ports of the modem.

Table 3-3. Remote Control Interface Connector Pin Assignments

Pin # Description Direction

1 Ground

2 EIA-232 Transmit Data Out

3 EIA-232 Receive Data In

4 Reserved—NO CONNECT

5 Ground

EIA-485 Receive Data B *

6

EIA-485 Receive Data A *

7

8 EIA-485 Transmit Data B Out

9 EIA-485 Transmit Data A Out

*NOTE: Use for 2-wire EIA-485 operation.

In

In

3–2

Page 45

CLO-10 Link Optimizer Revision 1

Rear Panel Connectors MN/CLO-10.IOM

3.5 M&C 10/100 BaseT Ethernet Management Port (RJ-45)

This is a standard RJ-45 female connector used for management via Telnet, HTTP (future), and

SNMP (future). It is also used for upgrading CLO-10 firmware. This receptacle uses a UTP

cable to connect to an Ethernet hub, router, switch, PC, etc.

Table 3-4. M&C Interface Connector Pin Assignments

Pin # Description Direction

1 Tx+ Out

2 TX- Out

3 Rx+ In

4 N/A

5 N/A

6 Rx- In

3–3

Page 46

CLO-10 Link Optimizer Revision 1

Rear Panel Connectors MN/CLO-10.IOM

3.6 IOM/IOSM Connectors (BNC-F)

The CLO-10 may be used in Standalone configuration with either the Input/Output Module (IOM) or

Input/Output Switch Module (IOSM) installed. Table 3-5 defines use of the BNC connectors (in

Standalone and in Daisy Chain Redundancy configurations) for both modules.

Note that the J2 DB-25F Redundancy connector is not used in a Standalone configuration. For detailed

information pertaining to the IOM/IOSM connectors used in Daisy Chain Redundancy configuration,

refer to Appendix A. REDUNDANCY SYSTEM OPERATION.

Table 3-5. CLO-10 IOM BNC Connectors Reference

BNC

Connector

To Demod J3 J5

From Mod J4 J6

To U/C J5 J9

From D/C J6 J10

Ref. Des.

IOM IOSM

Description / Function Direction

Output to Demod – signal from the downconverter

with the near-end carrier suppressed.

Input from near-end Modulator – used as

reference copy for cancellation processing.

Output to Upconverter – same signal as J4/J6

with up to 5 dB ±0.2 dB loss.

Composite signal from Downconverter – far-end

carrier signal summed with the near-end carrier.

Out

In

Out

In

3–4

Page 47

CLO-10 Link Optimizer Revision 1

Rear Panel Connectors MN/CLO-10.IOM

3.7 IEC Line Input (AC Power) Connector

The IEC line input connector contains the ON/OFF switch for the unit. It is also

fitted with two fuses, one each for line and neutral connections (or L1, L2, where

appropriate). These are contained within the body of the connector, behind a

small plastic flap.

A standard, detachable, non-locking, 3-prong power cord (IEC plug) supplies the

Alternating Current (AC) power to the CLO-10. Observe the following:

AC Power Specifications

Input Power 75W maximum, less than 65W typical

Input Voltage 100 - 240 volts AC, +6/-10% - autosensing

(total absolute max. range is 90 to 254 VAC)

Connector Type IEC

Fuse Protection

• For 230 volt AC operation, use T2.5A, (slow-blow)

20mm fuses.

• For 115 volt AC operation, use T5.0A, (slow-blow)

20mm fuses.

IMPORTANT

3.8 DC Power Connector

A standard 3-screw terminal block supplies the Direct Current (DC)

power to the CLO-10. Observe the following:

Input Power 200W maximum, less than 50W typical

Input Voltage 36 to 72 VDC; 6.25 amps

Connector Type Terminal Block

Fuse Protection

IMPORTANT

For continued operator safety, always replace the fuses

with the correct type and rating.

DC Power Specifications

3.15A Slow-blow

20mm type fuses

For continued operator safety, always replace the fuses with

the correct type and rating.

3–5

Page 48

CLO-10 Link Optimizer Revision 1

Rear Panel Connectors MN/CLO-10.IOM

3.9 Ground Connector

A #10-32 stud is used for connecting a common chassis ground among equipment.

Note: The AC power connector provides the safety ground.

3–6

Page 49

CABLES AND CONNECTIONS

T

4.1 Overview

Leave the CLO-10, up and down converters, and modem powered OFF

IMPORTAN

Once the CLO-10(s) and accompanying modem(s) have been mounted, the user must properly

attach all required cabling. These interfaces between the CLO-10, modem, and the up and down