Page 1

Multipoint-Low Voltage

Differential Signaling

(M-LVDS) Evaluation Module

User’s G uide

April 2004

High Performance Analog

SLLU039B

Page 2

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty. Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2004, Texas Instruments Incorporated

Page 3

EVM IMPORTANT NOTICE

Texas Instruments (TI) provides the enclosed product(s) under the following conditions:

This evaluation kit being sold by TI is intended for use for ENGINEERING DEVELOPMENT OR EV ALUATION

PURPOSES ONLY and is not considered by TI to be fit for commercial use. As such, the goods being provided

may not be complete in terms of required design-, marketing-, and/or manufacturing-related protective

considerations, including product safety measures typically found in the end product incorporating the goods.

As a prototype, this product does not fall within the scope of the European Union directive on electromagnetic

compatibility and therefore may not meet the technical requirements of the directive.

Should this evaluation kit not meet the specifications indicated in the EVM User’s Guide, the kit may be returned

within 30 days from the date of delivery for a full refund. THE FOREGOING WARRANTY IS THE EXCLUSIVE

WARRANTY MADE BY SELLER TO BUYER AND IS IN LIEU OF ALL OTHER W ARRANTIES, EXPRESSED,

IMPLIED, OR S TATUTORY, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY

PARTICULAR PURPOSE.

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user

indemnifies TI from all claims arising from the handling or use of the goods. Please be aware that the products

received may not be regulatory compliant or agency certified (FCC, UL, CE, etc.). Due to the open construction

of the product, it is the user’s responsibility to take any and all appropriate precautions with regard to electrostatic

discharge.

EXCEPT TO THE EXTENT OF THE INDEMNITY SET FORTH ABOVE, NEITHER PARTY SHALL BE LIABLE

TO THE OTHER FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

TI currently deals with a variety of customers for products, and therefore our arrangement with the user is not

exclusive.

TI assumes no liability for applications assistance, customer product design, software performance, or

infringement of patents or services described herein.

Please read the EVM User’s Guide and, specifically, the EVM Warnings and Restrictions notice in the EVM

User’s Guide prior to handling the product. This notice contains important safety information about temperatures

and voltages. For further safety concerns, please contact the TI application engineer.

Persons handling the product must have electronics training and observe good laboratory practice standards.

No license is granted under any patent right or other intellectual property right of TI covering or relating to any

machine, process, or combination in which such TI products or services might be or are used.

Mailing Address:

Texas Instruments

Post Office Box 655303

Dallas, Texas 75265

Copyright 2004, Texas Instruments Incorporated

Page 4

EVM WARNINGS AND RESTRICTIONS

It is important to operate this EVM within the supply voltage range of 3 V to 3.6 V.

Exceeding the specified supply range may cause unexpected operation and/or irreversible

damage to the EVM. If there are questions concerning the supply range, please contact a TI

field representative prior to connecting the input power.

Applying loads outside of the specified output range may result in unintended operation and/or

possible permanent damage to the EVM. Please consult the EVM User ’s Guide prior to

connecting any load to the EVM output. If there is uncertainty as to the load specification,

please contact a TI field representative.

During normal operation, some circuit components may have case temperatures greater than

125°C. The EVM is designed to operate properly with certain components above 125°C as

long as the input and output ranges are maintained. These components include but are not

limited to linear regulators, switching transistors, pass transistors, and current sense

resistors. These types of devices can be identified using the EVM schematic located in the

EVM User’s Guide. When placing measurement probes near these devices during operation,

please be aware that these devices may be very warm to the touch.

Mailing Address:

Texas Instruments

Post Office Box 655303

Dallas, Texas 75265

Copyright 2004, Texas Instruments Incorporated

Page 5

How to Use This Manual

This document contains the following chapters:

- Chapter 1—The M-LVDS Evaluation Module

- Chapter 2—Test Setup

- Chapter 3—Bill of Materials, Board Layout, and PCB Construction

- Appendix A—Schematic

Related Documentation From Texas Instruments and Others

- Introduction to M-LVDS (SLLA108)

- LVDS Designer’s Notes (SLLA014A).

- Reducing EMI With Low Voltage Differential Signaling (SLLA030B).

Preface

FCC Warning

- Interface Circuits for TIA/EIA−644 (LVDS) (SLLA038B).

- T ransmission at 200 Mpbs in VME Card Cage Using LVDM (SLLA088).

- LVDS Multidrop Connections (literature number SLLA054).

- SN65MLVD20x data sheets, Multipoint-LVDS Line Drivers and Receivers,

(SLLS573 and SLLS558)

- Electromagnetic Compatibility Printed Circuit Board and Electronic

Module Design, VEC workshop, Violette Engineering Corporation.

This equipment is intended for use in a laboratory test environment only. It

generates, uses, and can radiate radio frequency energy and has not been

tested for compliance with the limits of computing devices pursuant to subpart

J of part 15 of FCC rules, which are designed to provide reasonable protection

against radio frequency interference. Operation of this equipment in other

environments may cause interference with radio communications. In which

case the user , at his own expense, is required to take the necessary measures

to correct this interference.

Read This First

v

Page 6

vi

Page 7

Running Title—Attribute Reference

Contents

1 The M-LVDS Evaluation Module 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Overview 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 M-LVDS Standard TIA/EIA−899 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 M-LVDS EVM Kit Contents 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Configurations 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.1 Point-to-Point 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.2 Multidrop 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.3 Multipoint 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.4 EVM Operation With Separate Power Supplies 1-7. . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 Recommended Equipment 1-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Test Setup 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Typical Cable Test Configurations 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 Point-to-Point Simplex Transmission 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.2 Point-to-Point Parallel Terminated Simplex Transmission 2-3. . . . . . . . . . . . . . . . .

2.1.3 Two-Node Multipoint Transmission 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Test Results 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Bill of Materials, Board Layout, and PCB Construction 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Bill of Materials 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Board Layout 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 PCB Construction 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A Schematic A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter Title—Attribute Reference

vii

Page 8

Running Title—Attribute Reference

Figures

1−1. M-LVDS Unit Interval Definition 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1−2. Expanded Graph of Receiver Dif ferential Input Voltage Showing Transition Region 1-4. . . .

1−3 Point-to-Point Simplex Circuit 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1−4 Parallel Termination Simplex Circuit 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1−5 Multidrop or Distributed Simplex Circuit 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1−6 Five-Node Multipoint Circuit 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1−7 Two-Node Multipoint Circuit 1-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1−8 EVM Configuration for Including a Ground Potential Difference Voltage Between Nodes 1-8

2−1 Point-to-Point Simplex Transmission 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−2 Point-to-Point Parallel Terminated Simplex Transmission 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . .

2−3 Two-Node Multipoint Transmission 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−4 Point-to-Point Parallel Simplex Typical Eye Pattern Data 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . .

2−5 Parallel Terminated Point-to-Point Parallel Simplex Typical Eye Pattern Data 2-6. . . . . . . . . .

2−6 Two-Node Multipoint Typical Eye Pattern Data 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−1 Assembly Drawing 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−2 Top Layer 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−3 Second Layer 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−4 Third Layer 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−5 Bottom Layer 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−6 Trace Configurations in Printed-Circuit Boards 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tables

1−1M−LVDS Devices Supported by the EVM 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1−2 Receiver Input V oltage Threshold Requirements 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−1 EVM Configuration Options 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−1 M-LVDS EVM Bill of Materials 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−2 EVM Layer Stack Up 3-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

Page 9

Chapter 1

The M-LVDS Evaluation Module

This document describes the multipoint low-voltage differential-signaling

(M-LVDS) evaluation module (EVM) used to aid designers in development and

analysis of this new signaling technology. The Texas Instruments

SN65MLVD200A, SN65MLVD201, SN65MLVD202A, SN65MLVD203,

SN65MLVD204A, SN65MLVD205A, SN65MLVD206, SN65MLVD207 series

are low-voltage differential line drivers and receivers complying with the

M-LVDS standard (TIA/EIA−899). The EVM kit contains the assembled

printed-circuit board and all of the released devices referred to in Table 1−1.

Using the EVM to evaluate these devices should provide insight into the design

of low-voltage differential circuits. The EVM board allows the designer to

connect an input to one or both of the drivers and configure a point-to-point,

multidrop, or multipoint data bus.

The EVM can be used to evaluate device parameters while acting as a guide

for high-frequency board layout. The board allows for the connection of a

100-Ω controlled impedance cable of varying lengths. This provides the

designer with a tool for evaluation and successful design of an end product.

Topic Page

1.1 Overview 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 M-LVDS Standard TIA/EIA−899 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 M-LVDS EVM Kit Contents 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Configurations 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 Recommended Equipment 1-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The M-LVDS Evaluation Module

1-1

Page 10

Overview

1.1 Overview

The EVM comes with all the production devices in Table 1−1. The

SN65MLVD201 and SN65ML VD207 are installed on the circuit board, and ca n

easily be replaced with the other devices supplied. The M-LVDS devices

evaluated with this EVM are in the SN75ALS180 and SN75176 footprint. Use

of these industry standard footprints allows the designer to easily configure the

parts into a simplex or half-duplex data bus. These are all TIA/EIA−899

M-LVDS standard compliant devices. While initially intended for half-duplex or

multipoint applications, M-LVDS devices are not precluded from being used

in a point-to-point or multidrop configuration. In these configurations there can

be a distinct advantage to the additional current drive provided by an M-LVDS

driver.

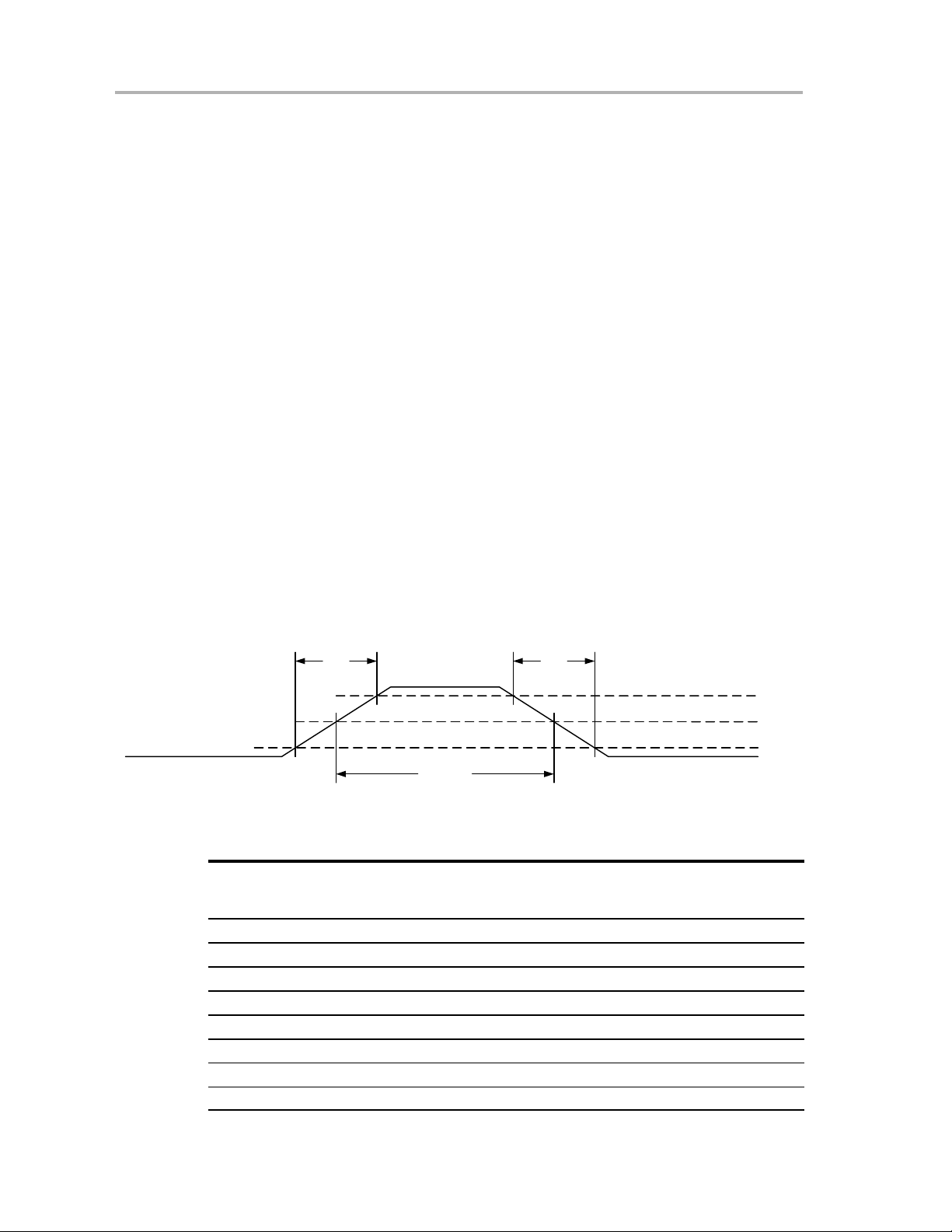

The M-LVDS devices shown in Table 1−1 all include output slew-rate limited

drivers, thus the need for different nominal signaling rates. The M-LVDS

standard recommends the transition time not exceed 0.5 of the unit interval

(UI). The definition of transition time (tr and tf) in M-LVDS is the 10% to 90%

levels shown in Figure 1−1. Using the maximum transition time for each of the

drivers and the 0.5(tUI) rule results in the signaling rates shown in Table 1−1.

This slew-rate control differentiates M-LVDS devices from LVDS

(TIA/EIA−644A) compliant devices. The slower transition times available with

M-LVDS help to reduce higher frequency components in the transmitted

signal. This reduces EMI and allows longer stubs on the main transmission

line. For this reason it is generally better to select a driver with a specified

signaling rate no greater than is required in the system.

Figure 1−1.M-LVDS Unit Interval Definition

t

r

UI

Table 1−1. M-LVDS Devices Supported by the EVM

Nominal

Signaling Rate

(Mbps)

100 SN75176 Type-1 SN65MLVD200AD Production

200 SN75176 Type-1 SN65MLVD201D Production

100 SN75ALS180 Type-1 SN65MLVD202AD Production

200 SN75ALS180 Type-1 SN65MLVD203D Production

100 SN75176 Type-2 SN65MLVD204AD Production

100 SN75ALS180 Type-2 SN65MLVD205AD Production

200 SN75176 Type-2 SN65MLVD206D Production

200 SN75ALS180 Type-2 SN65MLVD207D Production

Footprints

Receiver

Type

t

f

Part

Number

90%

50%

10%

Status

1-2

The M-LVDS Evaluation Module

Page 11

The EVM has been designed with the individual driver and receiver section

(SN75ALS180 footprint, U1) on one half of the board and the transceiver

section (SN75176 footprint, U2) on the other half (see Figure 3−1). The EVM

as delivered incorporates two 100-Ω termination resistors at each driver

output, receiver input, and transceiver I/O. These allow the user to evaluate

a single driver, receiver, or transceiver, while not having to deal with a

transmission line or additional I/Os.

Jumpers are included to allow the two sections of the EVM to either share the

same power and ground or be run off of independent supplies. Ground shifts

or common-mode offsets can be introduced by the removal of these jumpers

and using separate power supplies.

1.2 M-LVDS Standard TIA/EIA−899

The M-LVDS standard was created in response to a demand from the data

communications community for a general-purpose high-speed balanced

interface standard for multipoint applications. The TIA/EIA−644 standard

defines the LVDS electrical-layer characteristics used for transmitting

information in point-to-point and multidrop architectures. TIA/EIA−644 does

not address data transmission for multipoint architectures, therefore the need

for development of a new standard.

M-LVDS Standard TIA/EIA−899

The standard, Electrical Characteristics of Multipoint-Low-Voltage Differential

Signaling (M-LVDS) TIA/EIA−899, specifies low-voltage differential signaling

drivers and receivers for data interchange across half-duplex or multipoint

data bus structures. M-LVDS is capable of operating at signaling rates up to

500 Mbps. In other words, when the devices are used at the nominal signaling

rate, the rise and fall times will be within the specified values in the standard.

The M-L VDS standard defines the transition time (tr and tf) to be 1 ns or slower

into a test load. Using this information combined with the requirement that the

transition time not exceed 0.5 of the unit interval (UI), gives a minimum unit

interval of 2 ns, leading to the 500 Mpbs maximum signaling rate.

The standard defines Type-1 and Type-2 receivers. Type-1 receivers include

no provisions for failsafe and have their differential input voltage thresholds

near zero volts. Type-2 receivers have their differential input voltage

thresholds of fset from zero volts to detect the absence of a voltage difference.

Type-1 receivers maximize the dif ferential noise margin and are intended for

the maximum signaling rate. Type-2 receivers are intended for control signals,

slower signaling rates, or where failsafe provisions are needed. The bus

voltage logic state definition can be seen in Table 1−2 and Figure 1−2.

The M-LVDS Evaluation Module

1-3

Page 12

M-LVDS EVM Kit Contents

Table 1−2. Receiver Input Voltage Threshold Requirements

Receiver Type Low High

Type-1 −2.4 V ≤ VID ≤ −0.05 V 0.05 V ≤ VID ≤ 2.4 V

Type-2 −2.4 V ≤ VID ≤ 0.05 V 0.15 V ≤ VID ≤ 2.4 V

Figure 1−2.Expanded Graph of Receiver Differential Input Voltage Showing Transition

Region

Type−1 and Type−2 Receiver Differential Input Thresholds

2.4

Type 1 Type 2

0.15

High

0.1

0.05

VID (V)

0

−0.05

Low

−2.4

1.3 M-LVDS EVM Kit Contents

High

Low

Transition Region

1-4

The M-LVDS EVM kit contains the following:

J M-LVDS EVM PWB with SN65MLVD201D and SN65MLVD207D

installed (6424409B)

J Additional devices SN65MLVD200A, SN65MLVD202A,

SN65MLVD203, SN65MLVD204A, SN65MLVD205A,

SN65MLVD206

J M-LVDS EVM kit documentation (user’s guide)

J SN65MLVD20x data sheets, Multipoint-LVDS Line Driver and

Receiver, (SLLS573 and SLLS558)

The M-LVDS Evaluation Module

Page 13

1.4 Configurations

The M-LVDS EVM board allows the user to construct various bus

configurations. The two devices on the EVM allow for point-to-point simplex,

parallel-terminated point-to-point simplex, and two-node multipoint operation.

All of these modes of operation can be configured through onboard jumpers,

external cabling, and different resistor combinations. The devices which are

delivered with the EVM change output operation but, configuration of jumpers

to setup the transmission type is independent of the devices installed

1.4.1 Point-to-Point

The point-to-point simplex configuration is shown in Figure 1−3. The setup

schematic for this option is shown in Figure 2−1. Although this is not the

intended mode of operation for M-LVDS, it works well for high noise or long

higher-loss transmission lines. Due to the increased drive current, a single

100-Ω termination resistor on the EVM will result in a differential bus voltage

(VOD) twice as large as a doubly terminated line. This practice is acceptable

as long as the combination of input voltage and common-mode voltage does

not exceed absolute maximum ratings of the line circuits.

Figure 1−3.Point-to-Point Simplex Circuit

Configurations

U1 U1

This configuration can also have a termination at the source and load (parallel

terminated), thereby, keeping normal M-LVDS signal levels as shown in Figure

1−4.

The schematic for this option is shown in Figure 2−2. Due to the increased

drive current, double termination can be used to improve transmission line

characteristics .

Figure 1−4.Parallel Termination Simplex Circuit

U1

T

U1

TT

The M-LVDS Evaluation Module

1-5

Page 14

Configurations

1.4.2 Multidrop

A multidrop configuration (see Figure 1−5) with two receiver nodes can be

simulated with the EVM. To get additional receiver nodes on the same bus

requires additional EVMs. M-LVDS controlled driver transition times and

higher signal levels help to accommodate the multiple stubs and additional

loads on the bus. This does not exempt good design practices, which would

keep stubs short to help prevent excessive signal reflections.

A bus line termination could be placed at both ends of the transmission line,

improving the signal quality by reducing return reflections to the driver. This

would allow the use of standard compliant TIA/EIA 644A receivers on the bus

in addition to M-LVDS receivers.

Figure 1−5.Multidrop or Distributed Simplex Circuit

T

1.4.3 Multipoint

The multipoint configuration is the primary application of the M-LVDS devices

and the associated standard. The M-LVDS standard allows for any

combination of drivers, receivers, or transceivers up to a total o f 32 o n the line.

Figure 1−6 shows a representation of a five-node multipoint configuration

using transceivers. Increased drive current, in addition to the wider commonmode input, allows M-LVDS parts to drive multiple receivers over longer line

lengths with up to 2 V of ground noise.

Figure 1−6.Five-Node Multipoint Circuit

T

A two-node multipoint setup (see Figure 1−7) can be configured with the EVM.

Additional EVMs are needed for more nodes. The test setup and schematic

for this configuration is shown in Figure 2−3.

T

1-6

The M-LVDS Evaluation Module

Page 15

Figure 1−7.Two-Node Multipoint Circuit

Configurations

T

U1

1.4.4 EVM Operation With Separate Power Supplies

The EVM has been designed with independent power planes for the two

devices. The two devices can be powered with independent supplies or with

a single supply. Sending and receiving data between backplanes, racks, or

cabinets where separate power sources may exist can have offset ground

potentials between nodes. Jumpers W7, 8, 9, and 10 tie the two separate

power and ground planes together. If two separate supplies are used and

jumpers W7, 8, 9, and 10 are removed, care should be taken to ensure the

absolute maximum device ratings are not exceeded. Keep in mind that if

jumpers W7, 8, 9, and 10 are not removed when using separate power

supplies, a difference in potential between the supplies causes a current to

flow between supplies and through the jumpers.

T

U2

The EVM can be configured with three power supplies with isolated outputs

in such a way as to input a fixed offset between the grounds (see Figure 1−8).

This induces a ground potential difference voltage between U1 and U2. To

demonstrate this capability, the following steps should be followed.

- Adjust PS1 and PS3 to the supply voltage (3.3 V) and current limit to

50 mA.

- Set PS2 to 0 V

- Induce a ground offset by varying the output of PS2.

PS2 Output

The PS2 output should not exceed ± 2 V to remain within the device

ratings.

The M-LVDS Evaluation Module

1-7

Page 16

Recommended Equipment

Figure 1−8.EVM Configuration for Including a Ground Potential Difference Voltage

Between Nodes

+

PS1

−

J13 J14 J17 J18

+

W9

W7

W8

W10

PS2

−

+

PS3

−

Jumpers removed from

W7, W8, W9, W10

1.5 Recommended Equipment

- 3.3 Vdc at 0.5-A power supply or multiple power supplies (with both

devices powered and enabled the board draws about 35 mA).

- A 100-Ω transmission medium from the driver to the receiver, (twisted-pair

cable recommended, CAT5 cable for example).

- A function or pattern generator capable of supplying 3.3-V signals at the

desired signaling rate.

- A multiple-channel high-bandwidth oscilloscope, preferably above the

1-GHz range

- Differential or single ended oscilloscope probes.

1-8

The M-LVDS Evaluation Module

Page 17

Chapter 2

Test Setup

This chapter describes how to setup and use the M-LVDS EVM.

Topic Page

2.1 Typical Cable Test Configurations 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Test Results 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Setup

2-1

Page 18

Typical Cable Test Configurations

2.1 Typical Cable Test Configurations

Each of the following test configurations is a transmission line consisting of a

twisted-pair cable connected on the 2-pin connectors (P1, P2, or P3).

Table 2−1 shows the possible configurations.

In addition to the different transmission topologies, the EVM can also be

configured to run of f two or three separate power supplies, as described in the

previous section. This would allow the user to induce a ground shift or offset

between the two different drivers and receivers. This setup can be used with

any transmission line test.

Table 2−1. EVM Configuration Options

Configuration Jumpers In Resistors In Resistors Out Diagram

Point-to-point simplex transmission W1, 2, 7, 8, 9, 10 R4 R5, 6, 7 Figure 2−1

Point-to-point parallel terminated simplex

transmission

Two-node multipoint transmission W1, 2, 3, 4, 7, 8, 9, 10 R5, 16 R2, 4, 6, 7, 13 15 Figure 2−3

W1, 2, 7, 8, 9, 10 R4, 7 R5, 6 Figure 2−2

2.1.1 Point-to-Point Simplex Transmission

1) Connect a twisted-pair cable from P1 to P2.

2) Verify resistor R4 is installed.

3) Remove resistors R5, R6, and R7. This properly terminates the

transmission line at one end.

4) Enable the driver by connecting the jumper on W2 between pin 1 and

pin 2, or U1 pin 4 to VCC.

5) Enable the receiver by connecting the jumper on W1 between pin 2 and

pin 3, or U1 pin 3 to GND.

Figure 2−1.Point-to-Point Simplex Transmission

V

CC

Jumper

4

U1

10

W2

9

R7

100

P2

Twisted Pair Cable

R6

100

Signal Source

50-Ω

with

Output

50-

Ω

Cable

J2

TP2

Input Signal

5

R3

49.9

cable orΩ

50-

Active Voltage

Probe into one

Channel of Scope

Terminated in

High Impedance

2-2

50-Ω

Cable

Active Voltage

Probe

J1

TP1

Output Signal

R2

453

2

12

U1

11

3

V

CC

W1

Jumper

R4

100

P1

R5

100

Test Setup

Page 19

Typical Cable Test Configurations

2.1.2 Point-to-Point Parallel Terminated Simplex Transmission

1) Connect a twisted-pair cable from P1 to P2.

2) Verify resistor R4 and R7 are installed.

3) Remove resistors R5 and R6. This properly terminates the transmission

line at both ends.

4) Enable the driver by connecting the jumper on W2 between pin 1 and pin

2, or U1 pin 4 to VCC.

5) Enable the receiver by connecting the jumper on W1 between pin 2 and

pin 3, or U1 pin 3 to GND.

Figure 2−2.Point-to-Point Parallel Terminated Simplex Transmission

V

CC

Jumper

Input Signal

W2

50-Ω

Signal Source

with 50-Ω

Output

50- cable orΩ

Active Voltage

Probe into one

Channel of Scope

Terminated in

High Impedance

Cable

50-Ω

Cable

Active Voltage

Probe

J2

TP2

J1

TP1

Output Signal

R3

49.9

R2

453

2.1.3 Two-Node Multipoint Transmission

1) Connect a twisted-pair cable between P1, P2, and P3.

2) Verify resistor R5 and R16 are installed.

3) Remove resistors R4, R6, R7, and R15. This properly terminates the

transmission line at both ends.

4

9

5

U1

10

2

12

U1

11

3

V

CC

W1

Jumper

R7

100

R4

100

P2

Twisted Pair Cable

P1

R6

100

R5

100

4) Enabling the driver in a two-node multipoint configuration will be a slightly

more challenging task. The user can either jumper enable a single driver

and send all of the data on the bus through a single driver, or sync the

driver enable to the data and send data from each driver. Enable a single

driver by connecting the jumper on W4 between pin 1 and pin 2 which

connects U2 pin 3 to VCC, or by connecting the jumper on W2 between pin

1 and pin 2 which connects U1 pin 4 to VCC.

5) Enable the receivers by connecting the jumpers on W1 and W3 between

pin 2 and pin 3, or U1 pin 3 to GND and U2 pin 2 to GND.

Test Setup

2-3

Page 20

Typical Cable Test Configurations

Figure 2−3.Two-Node Multipoint Transmission

Input Signal

V

CC

W2

Jumper

Signal Source

with 50-Ω

Output

50- cable orΩ

Active Voltage

Probe into one

Channel of Scope

Terminated in

High Impedance

50- cable orΩ

Active Voltage

Probe into one

Channel of Scope

Terminated in

High Impedance

50-Ω

Cable

50-Ω

Cable

Active Voltage

Probe

50-Ω

Cable

Active Voltage

Probe

J2

TP2

J1

TP1

Output Signal

Input Signal

J8

TP4

J7

TP3

Output Signal

R2

453

R13

453

R3

49.9

R14

49.9

4

5

9

U1

10

R7

100

P2

R6

100

Twisted Pair Cable

3

U2

U1

12

11

V

CC

W1

3

Jumper

R4

100

V

6

7

CC

W4

Jumper

R15

100

P1

P3

R5

100

R16

100

2

4

1

V

CC

2

W3

Jumper

2-4

Test Setup

Page 21

2.2 Test Results

Test Results

The test configurations described in Section 2.1 were used to simulate pointto-point simplex, parallel-terminated point-to-point simplex, and two-node

multipoint. The test results are shown in the following figures. A Tektronix

HFS9003 was used to generate input signals, and a Tektronix TDS784D was

used to collect the output data.

The EVM was populated with a SN65MLVD207D and SN65MLVD201D for U1

and U2 respectively. The eye patterns were measured with the source

(Tektronix HFS9003) generating 2

length of the transmission line is approximately 21 inches (53 cm), and adds

to the propagation delay in the device. This can be seen in the figures below

as a time delay from input to output

Figure 2−4 shows the point-to-point simplex transmission eye patterns. Trace

1 is the driver input signal applied to J2. The output signal is shown below

measured on both J1 (Figure 2−4 left picture), and TP1 (Figure 2−4 right

picture). The receiver output in both figures shows the offset zero crossing,

which is due to the Type-2 receiver incorporated into the SN65MLVD207

device. The reduced offset from a Type-1 receiver can be seen in Figure 2−6,

receiver number 2 output.

Measuring the output signal on J1 with a 50-Ω cable terminated into 50-Ω at

the scope will attenuate the signal due to the 453-Ω resistor in series with the

receiver output. The resistor is installed as a current limit for termination into

a 50-Ω load. As can be seen in the traces below the magnitude of trace 2 on

the left is one-tenth of trace 2 on the right. Measuring the signal with a

high-impedance probe on TP1 requires replacing R2, the 453-Ω resistor, with

a short to reduce signal roll-off. Measuring the output on TP1 allows the user

to see absolute signal levels out of the device.

15

−1 PRBS NRZ data. In all cases, the

Figure 2−4.Point-to-Point Parallel Simplex Typical Eye Pattern Data

Driver

Input

Receiver

Output

Differential

Bus

Voltage

50-Ohm Output Termination

Receiver Output Scaled 10:1

The eye patterns in Figure 2−5 are parallel-terminated point-to-point simplex

data where trace 1 is the input signal applied to J2, and trace 2 is the output

High Impedance Output Termination, R2 Shorted

Test Setup

2-5

Page 22

Test Results

signal on TP1, R2 is shorted. Type-2 behavior is again observed on the

SN65MLVD207 receiver output.

Trace three shows the differential voltage on the bus. Note that the bus voltages are nominal M-LVDS levels of 1.1 VPP due to the lower load seen by the

current driver.

Figure 2−5.Parallel Terminated Point-to-Point Parallel Simplex Typical Eye Pattern Data

Driver

Input

Receiver

Output

Differential

Bus

Voltage

Figure 2−6 represents the two-node multipoint transmission eye patterns

where trace 1 is the input signal applied to J2, and traces 2 and 3 are the output

signals seen at TP1 and TP3 respectively with R2 and R13 shorted. The offset

zero-crossing shows the difference between Type−2 (Receiver #1 Output) and

Type−1 (Receiver #2 Output).

Figure 2−6.Two-Node Multipoint Typical Eye Pattern Data

Driver

Input

Receiver #1

Output

Receiver #2

Output

2-6

Test Setup

Page 23

Chapter 3

Bill of Materials, Board Layout, and PCB

Construction

This chapter contains the bill of materials, board layout of the M-LVDS, and

describes the printed-circuit board.

Topic Page

2.1 Bill of Materials 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Board Layout 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 PCB Construction 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bill of Materials, Board Layout, and PCB Construction

3-1

Page 24

Bill of Materials

3.1 Bill of Materials

Table 3−1.M-LVDS EVM Bill of Materials

Item

Qty.

No.

1 2 C1, C2 Capacitor, SMT1206, 50 V, 10%,

2 4 C5, C6, C9,

3 4 C3, C4, C7, C8 Capacitor, SMT1210, 10 V, 10%,

4 2 J11, J13, J15,

5 2 J12, J14, J16,

6 4 J1 − J 10 Connector Allied 713−4339 J3 − J6, J9, J10

7 4 TP1 − TP4 Header (make from 4−103239−0) AMP 4−103239−0x2

8 3 P1 − P3 Header (make from 4−103239−0) AMP 4−103239−0x2

9 4 W7 − W10 Header (make from 4−103239−0) AMP 4−103239−0x2

10 4 W1 − W4 Header (make from 4−103239−0) AMP 4−103239−0x3

11 1 U1 IC, SMT, 14P, High speed 50-Ω

12 1 U2 IC, SMT, 8P High speed 50-Ω

Reference

Designation

C10

J17

J18

Description MFG Part # Not Installed

0.01 µF

Capacitor, SMT1206, 16 V, 10%,

1 µF

10 µF

Banana jack, red Allied ST−351A J11, J15

Banana jack, black Allied ST−351B J12, J16

line driver/receiver

line driver/receiver

AVX 12101C103JATMA

AVX 1206YC105KAT

AVX 1210ZG106ZAT2A

TI

TI

†

SN65MLVD202AD

SN65MLVD205AD

SN65MLVD203D

SN65MLVD207D

†

SN65MLVD200AD

SN65MLVD204AD

SN65MLVD201D

SN65MLVD206D

13 2 R1, R3, R12,

14 2 R2, R13 Resistor, SMT, 1/4 W, 1%, 453 Ω Dale CRCW12104530F

15 6 R8 − R11, R17,

16 6 R4 − R7, R15,

17 4 1/2” nylon, hex, standoff Keystone 1902C

18 4 Phillips, pan head, screw H703−ND

19 8 Jumper, shorting

†

Only one will be installed.

R14

R18

R16

3-2

Resistor, SMT, 1/4 W, 1%, 49.9 Ω Dale CRCW121049R9F R1, R12

Resistor, SMT, 1/4 W, 1%, 0.0 Ω Dale CRCW12100000F R8 − R11, R17,

Resistor, SMT, 1/4 W, 1%, 100 Ω Dale CRCW12101000F

Bill of Materials, Board Layout, and PCB Construction

R18

Page 25

3.2 Board Layout

Figure 3−1.Assembly Drawing

Board Layout

J8 J7

R12

W4

TP4

J15

W3 W2

VCC01

GND01

VCC01

R14

J16

GND01

R18 R17

J10 J9

Figure 3−2.Top Layer

J18

TP3

J17

VCC01GND01 GND VCC

GND01

VCC01

W10

GND

VCC

J14

W8

R13

MADE

U2

R15

P3 P2

R16

IN

U.S.A.

TEXAS INSTRUMENTS

A/W NO. # 6424409B

PWA. EVM.

SN65MLVD

SERIAL NO.

VCC01

GND01

W7

W9

VCC

GND

J6

J13

R3

R7

R6

R11

J5

TP2

U1

R10

J2

W1

TP1

VCC

GND

R2

R4

P1

R5

R8

R9

J4

J1

R1

J11

VCC

J12

GND

J3

The top layer of the EVM contains the controlled impedance and matched

length traces.

Bill of Materials, Board Layout, and PCB Construction

3-3

Page 26

Board Layout

The second layer of the EVM has the separate ground planes. These are the

reference planes for the controlled impedance traces on the top layer.

Figure 3−3.Second Layer

Figure 3−4.Third Layer

The third layer of the EVM has the power planes. These are matched to the

ground planes to reduce radiated emission and crosstalk, while increasing

distributed capacitance.

3-4

Bill of Materials, Board Layout, and PCB Construction

Page 27

The bottom layer of the EVM contains bulk and decoupling capacitors to be

placed close to the power and ground pins on the device.

Figure 3−5.Bottom Layer

Board Layout

VCC01

C5 C4

GND01

C2

C9

C8 C7

C10

C1

C6

VCC

C3

GND

Bill of Materials, Board Layout, and PCB Construction

3-5

Page 28

PCB Construction

3.3 PCB Construction

Information in this section was obtained from the following source:

- Electromagnetic Compatibility Printed Circuit Board and Electronic

Characteristic impedance is the ratio of voltage to current in a transmission line

wave traveling in one direction. This characteristic impedance is the value that

is matched with our termination resistors so as to reduce reflections. This

reduction in reflections improves signal to noise ratio on the line and reduces

EMI caused by common mode voltages and spikes.

Two typical approaches are used for controlled impedance in printed-circuit

board construction, microstrip and stripline. Microstrip construction is shown

in Figure 3−6. The characteristic impedance of a microstrip trace on a

printed-circuit board is approximated by:

Module Design, VEC workshop, Violette Engineering Corporation.

Z

+

O

Ǹ

60

0.475år ) 0.67

ln

4h

0.67(0.8 W ) t)

(1)

where εr is the permeability of the board material, h is the distance between

the ground plane and the signal trace, W is the trace width, and t is the

thickness of the trace. The differential impedance for a two microstrip traces

can be approximated as follows with S being the distance between two

microstrip traces:

Z

DIFF

+ 2 Z

O

ǒ

1 * 0.48e

*0.96sńh

Ǔ

(2)

Stripline construction is also shown in Figure 3−6, the signal lines should be

centered between the ground planes. The characteristic impedance of a

stripline trace in a printed-circuit board is approximated by:

60

Z

+

O

ln

Ǹ

år

0.67p(0.8 W ) t)

4h

(3)

where εr is the permeability of the board material, h is the distance between

the ground plane and the signal trace, W is the trace width, and t is the

thickness of the trace. The differential impedance for a two stripline traces can

be approximated as follows with S being the distance between two stripline

traces:

3-6

Z

+ 2 Z

DIFF

Note: For edge-coupled striplines, the term 0.374 may be replaced with 0.748 for lines which

are closely coupled (S < 12 mils, or 0,3 mm).

O

ǒ

1 * 0.374e

*2.9sńh

Ǔ

(4)

Bill of Materials, Board Layout, and PCB Construction

Page 29

Figure 3−6.Trace Configurations in Printed-Circuit Boards

W

t

PCB Construction

Board

Material

MICROSTRIP

Stripline construction is the preferred configuration for differential signaling.

This configuration reduces radiated emissions from circuit board traces due

to better control of the lines of flux. The additional ground plane also allows for

better control of impedance on the traces.

It can be seen from the functions and physical construction parameters that

careful consideration must be given to these parameters for a robust board

design. For instance it is not uncommon for εr to vary 10% across one board,

affecting skew. This is a good reason to keep differential lines close. Other

factors to keep in mind when doing a printed-circuit layout for transmission

lines are as follows:

1) Differences in electrical length translate into skew.

h

W

WS

t

STRIPLINE

2) Careful attention to dimensions, length and spacing help to insure isolation between differential pairs.

3) Where possible use ideal interconnects, point-to-point with no loads or

branches. This keeps the impedance more uniform from end to end and

reduce reflections on the line.

4) Discontinuities on the line, vias, pads, test points will:

J Reduce characteristic impedance

J Increase the prop delay, and rise-time degradation

J Increase signal transition time

5) Prioritize signals and avoid turns in critical signals. Turns can cause impedance discontinuities.

6) Within a pair of traces, the distance between the traces should be minimized to maintain common-mode rejection of the receivers. Differential

transmission works best when both lines of the pair are kept as identical

as possible.

Bill of Materials, Board Layout, and PCB Construction

3-7

Page 30

PCB Construction

Table 3−2 shows the layer stack up of the EVM with the defined trace widths

for the controlled impedance etch runs using microstrip construction.

Table 3−2.EVM Layer Stack Up

Material

Type:

FR 406

PREPREG 0.025

CORE 0.004

PREPREG 0.025

Layer

Layer

Type

Thickness

(mils)

No.

1 Signal 0.0006 0.5 oz (start) 0.027 0.230 100 0.0420 50

2 Plane 0.0012 1

3 Plane 0.0012 1

4 Signal 0.0006 0.5 oz (start) 0.027 0.230 100 0.0420 50

Copper

Weight

Differential Model Single-Ended Model

Line

Width

(mils)

Spacing

(mils)

Impedance

(Ω)

Line

Width

(mils)

Impedance

(Ω)

3-8

Bill of Materials, Board Layout, and PCB Construction

Page 31

This Appendix contains the EVM schematic.

Appendix A

Schematic

Schematic

A-1

Page 32

D

C

B

Vcc

A

R eceiver Output

R eceiver Enable

Driver Enable

Driver Input

GND

R eceiver Output

R eceiver Enable

Driver Enable

Driver Input

VCC VCC01

C7

C10

10uF

1.0uF

J1

J2

J7

J8

J13 J17J14 J18

* These parts are for board test purposes only and not installed in the final product.

1 2 3 4 56

R1*

49.9

V cc01

R12*

49.9

54321

VCC

R2

453

TP1

R3

TP2

49.9

VCC01

R13

453

TP3

R14

TP4

49.9

C8

10uFC91uF

W1 W2

W3

Vcc

C1

0.01uF

U1

1

NC

2

R

3

RE

4

DE

5

D

5

GND

7

GND

SN 65M LV D 202, 203, 205, OR 207

W4

U2

1

R

2

RE

3

DE

D4GND

SN65M LVD200, 201, 204 OR 206

VCC VCC01

C3

10uFC61.0uF

14

Vcc

13

Vcc

12

A

11

B

10

Z

9

Y

8

NC

C2

0.01uF

8

Vcc

7

B

6

A

5

J11* J15*J12* J16 *

V cc01

OPTIONAL

R4

100

R7

100

R15

100

C4

10uFC51uF

R8*

0.0

R5

P1

100

R9*

0.0

J5*

R10*

0.0

R6

P2

100

R11*

0.0

R17*

0.0

R16

P3

100

R18*

0.0

Driver Output -

J6*

Driver Output +

J9*

Transceiver I/O

J10*

Transceiver I/O

VCC

VCC01

Title

M-LV DS EV M SC H EM A TIC

Number RevisionSize

B

Date: 27-Feb-2002 Sheet of

File: C :\Userdata\Protel_database\LV D M 200_EV M .ddbDraw n By:

6424409

J3*

J4*

W8W7

R eceiver Inp ut +

R eciever Input -

6

D

C

B

W10W9

A

Loren Demers

Loading...

Loading...